Page 1

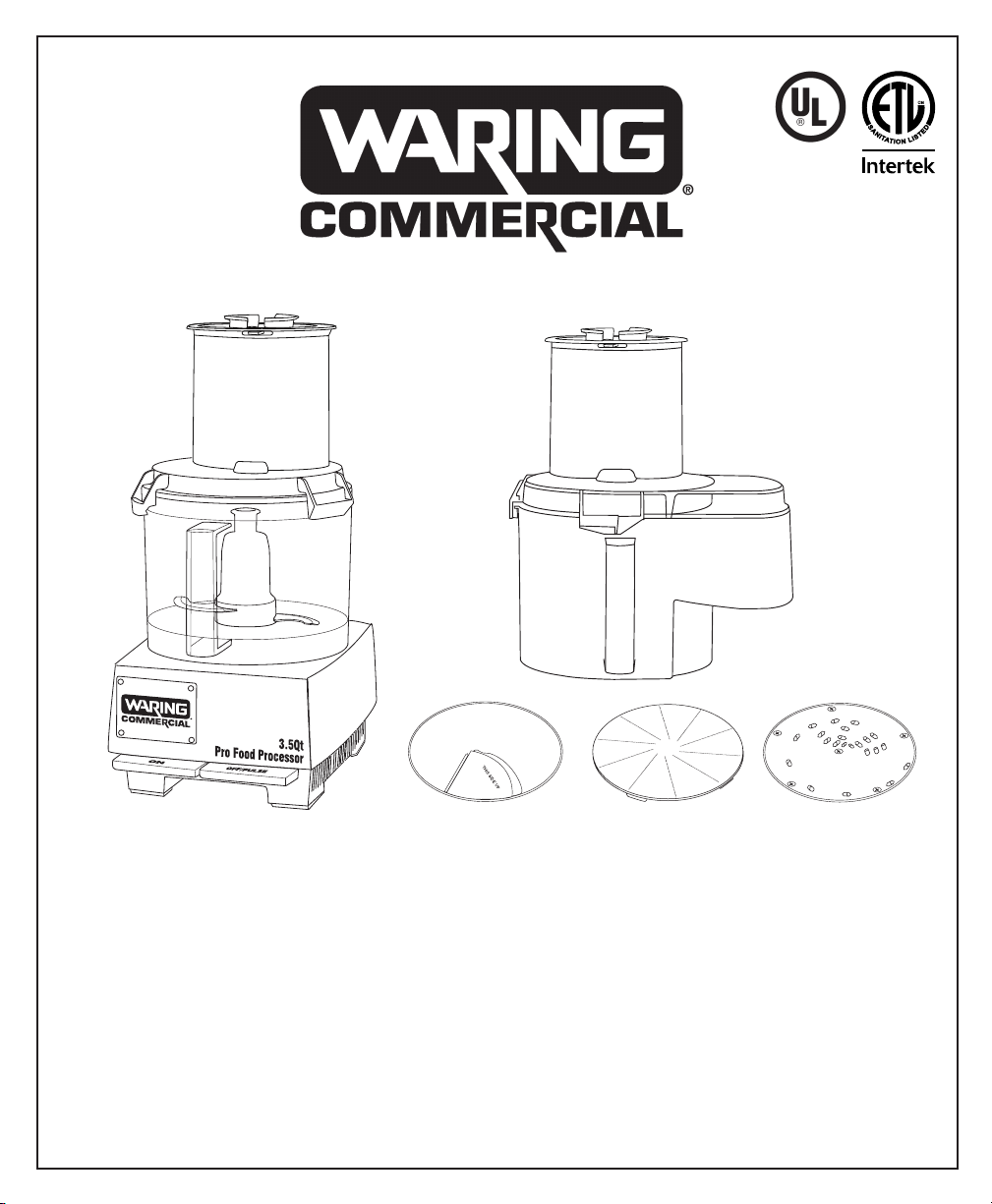

Operation Manual for Waring

WFP14SC Food Processor

Manuel d’utilisation du robot de cuisine WFP14SC

Manual de instrucciones del robot de cocina WFP14SC

Page 2

2

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should always be followed, including these:

1. Read all instructions.

2. Blades are sharp. Handle carefully.

3. Your Waring® food processor is a piece of kitchen equipment and, as with all other kitchen

equipment, extreme care must be used when operating it. Although training requirements

are minimal, only responsible and prudent individuals should be allowed to operate this

food processor. It should not be used by or near children or individuals with certain disabilities.

4. To avoid injury, never place cutting blade or disc on base without first having put the bowl

properly in place.

5. Keep hands as well as spatulas and other utensils away from moving blades or discs while

processing food to prevent the possibility of severe personal injury or damage to the food

processor. A plastic scraper may be used, but must be used only when the food processor is

not running.

6. To protect against risk of electrical shock, do not put base in water or other liquids.

7. Unplug from outlet when not in use, before putting on or taking off parts, before removing

food from work bowl, and before cleaning. To unplug, grasp plug and pull from electrical outlet.

Never pull cord.

8. Avoid contact with moving parts. Never feed food by hand when slicing or grating. Always use

food pusher.

9. Make sure motor has completely stopped before removing the cover.

10. Do not operate any appliance with a damaged cord or plug, or after appliance has been dropped

or damaged in any manner. Return appliance to the nearest authorized Waring service facility for

examination, repair or adjustment.

11. The use of attachments not recommended or sold by Waring may cause fire, electric shock

or injury.

12. Do not use outdoors.

13. Do not let cord hang over edge of table or counter, or touch hot surfaces.

14. Do not attempt to defeat the cover interlock mechanism.

15. Be certain cover is securely locked in place before operating appliance.

16. If the machine malfunctions for any reason, discard any food being processed at that time.

17. This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

18. Children should be supervised to ensure that they do not play with the appliance.

SAVE THESE INSTRUCTIONS

APPROVED FOR COMMERCIAL USE

Page 3

3

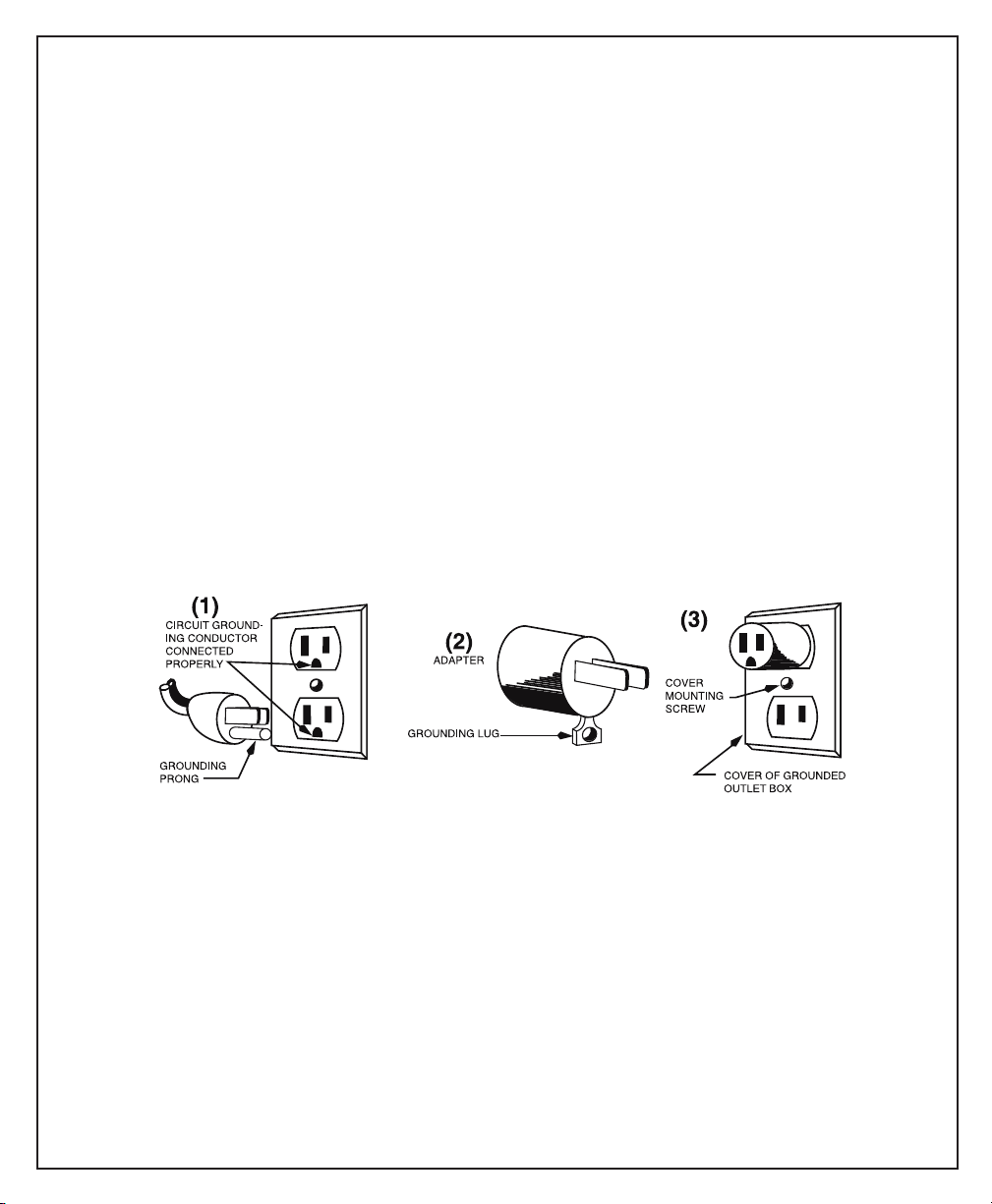

GROUNDING INSTRUCTIONS

For your protection, this appliance is equipped with a 3-conductor cordset.

120 volt units are supplied with a molded 3-prong grounding-type plug (NEMA5-15P), and should be

used in combination with a properly connected grounding-type outlet as shown in Figure 1.

If a grounding-type outlet is not available, an adapter, shown in Figure 2, may be obtained to

enable a 2-slot wall outlet to be used with a 3-prong plug.

As shown in Figure 3, the adapter must be grounded by attaching its grounding lug under the

screw of the outlet cover plate.

CAUTION: Before using an adapter, it must be determined that the outlet cover plate screw is

properly grounded. If in doubt, consult a licensed electrician. Never use an adapter unless you are

sure it is properly grounded.

NOTE: USE OF AN ADAPTER IS NOT PERMITTED IN CANADA. 220–240 volt “GS Safety

Approved” units are supplied with a molded European grounding-type plug (CEE 7/7).

The WFP14SC food processor features a seal system unlike any food processor in the industry. Now,

you can process larger volumes of liquid and don’t have to worry about removing the S-blade while

pouring. Waring Commercial has once again revolutionized food processing. This feature, along with

the continuous feed chute capabilities, makes the Waring Commercial WFP14SC food processor the

most versatile food processor in the industry.

Page 4

4

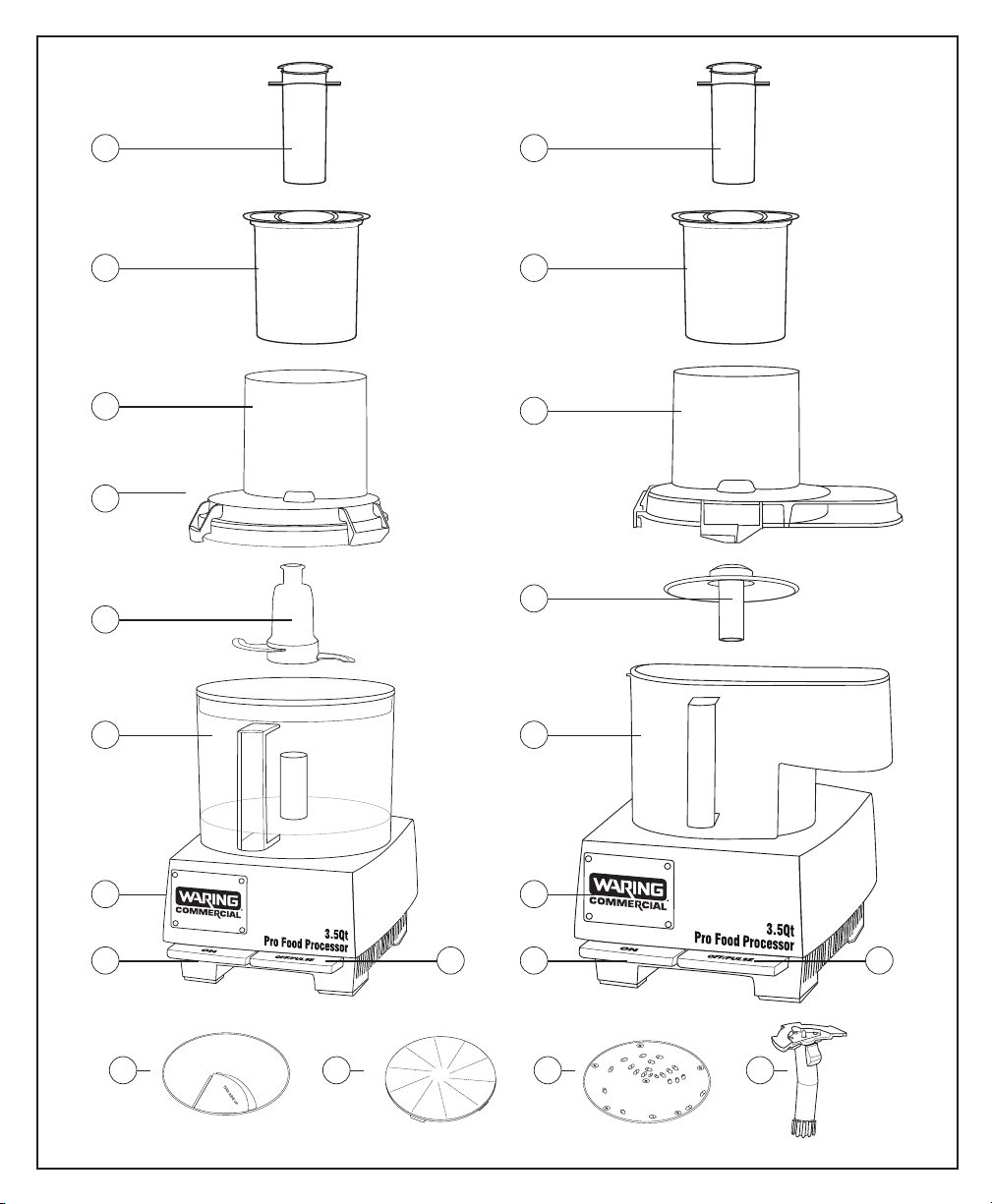

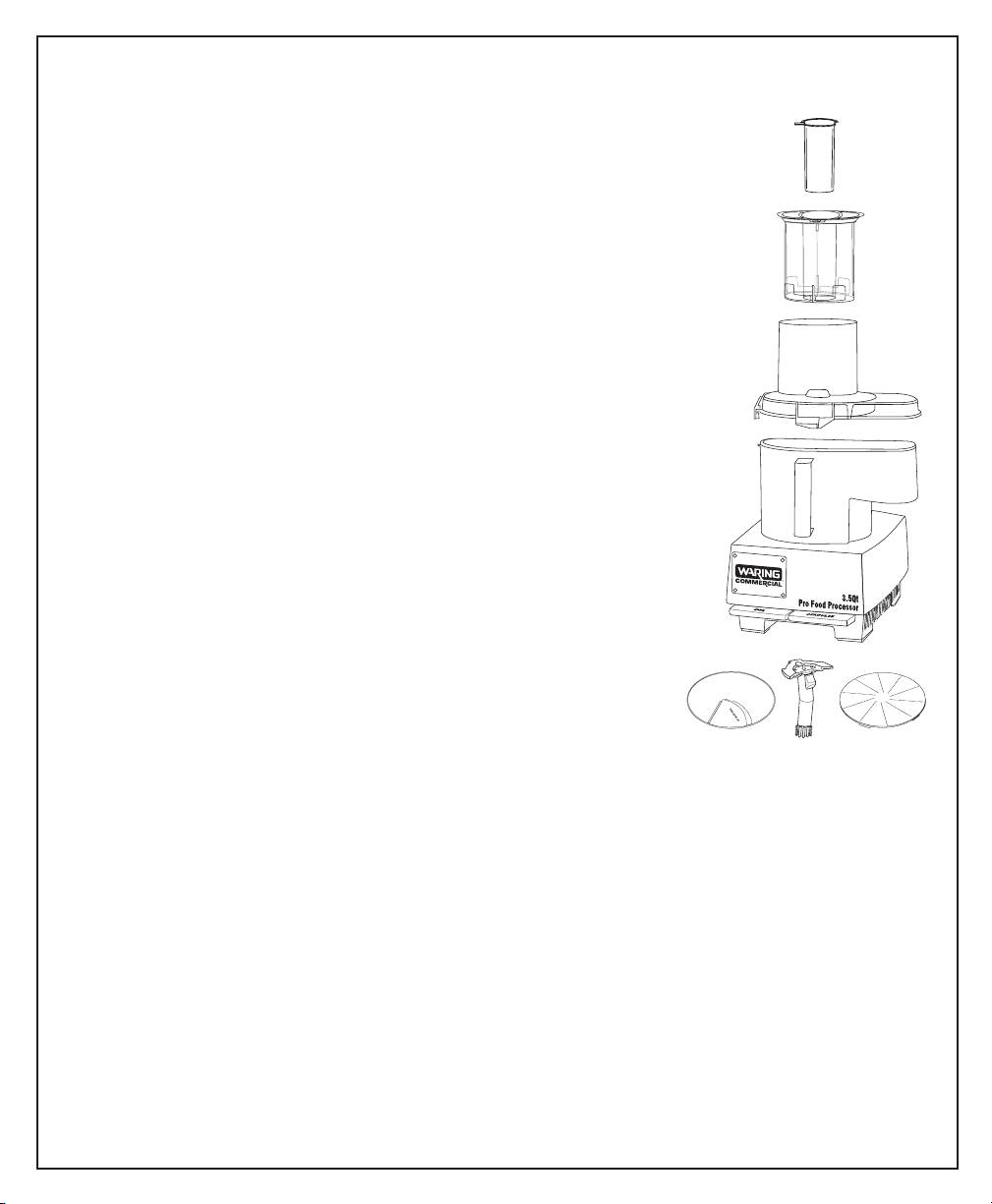

THE PARTS

The Waring WFP14SC food processor consists of the following standard parts and

accessories (see diagram on next page):

1. Motor base with vertical heavy-duty shaft

2. Two control levers

a. ON

b. OFF/PULSE

3. Safety interlock (not shown)

Prevents machine from operating until cover is in place

4. Clear work bowl with dry capacity of 3.5 quarts

5. Clear work bowl cover with new seal system for use with larger liquid volumes.

a. Large oval-shaped feed tube for maximum use of cutting surface

b. Large pusher with full-size and reduced-size feed options

c. Small pusher used within the large pusher for smaller vegetables, pepperoni, etc.

Note: This combination pusher allows use of the entire feed tube for large foods and

provides controlled processing for small-diameter foods such as carrots, celery

and pepperoni.

6. Sealed S-blade (cutter blade) to chop, grind, purée and mix: locks in place for liquid processing

and easy pouring.

7. 4 mm, 5⁄32" slicing disc

8. 2 mm, 5/64" grating disc

9. 4 mm, 5⁄32” shredding disc

10. Detachable stem for use with processing discs

Note that all of the WFP14SC accessory discs have a unique offset removable

stem. The design of this stem increases the cutting/processing efficiency of these

accessories.

11. Continuous feed chute with handle

12. Continuous feed chute clear cover

13. Slinger for continuous feed chute

Page 5

5

2a 2b

1

6

4

5

5a

5b

5c

7 8 9

2a 2b

1

13

11

12

5b

5c

10

Page 6

6

ASSEMBLY OF BATCH BOWL PARTS

WFP14SC

We will use the terms bowl, work bowl and batch bowl interchangeably throughout this instruction

book. They mean the same thing.

• Clean and sanitize the motor base, and wash, rinse, and sanitize the bowl, cover, food pusher, food

pusher insert and processing tools prior to initial use.

• Place the base on a counter or table near an outlet. Position it so you look at the front of the unit and

can see the control levers. Be certain that the cord is unplugged and the OFF lever has been pressed.

Do not plug in the cord until the processor is completely assembled.

• Pick up the transparent work bowl, holding it in both hands with the handle toward you.

• Place the bowl on the base, fitting its central tube over the motor shaft on the base and placing its

handle slightly to the left of front-center (at about a 7 o’clock position).

• Press the bowl down so the lower rim fits around the circular platform. Turn the bowl counterclock-

wise as far as it will go. It will lock into position with the tabs on the sides of the platform.

Read this if assembling the batch bowl parts to use S-blade (cutter blade).

• Pick up the metal blade, noting the diagram on the top of the plastic center. It matches the shape of

the motor shaft.

• Place the S-blade over the tip of the motor shaft, lining up the inside of the hub with the shaft.

Press it down firmly, rotating the center hub until the blade assembly is fully seated. It should

easily drop into place. Push firmly to lock and seal S-blade hub in place. Be sure it is pushed down

as far as it will go. If it is not all the way down, it may become damaged and any liquid may leak.

Push only on the center section (plastic part); never touch the cutting blade as it is extremely sharp.

• Check to be sure the blade is all the way down by turning it back and forth while lightly pushing it

down. If properly installed and fully seated, the lower blade will be positioned just above the inside

bottom of the bowl.

• If processing food with the S-blade, now is the time to add the food or liquid to the work bowl.

• Always process dry food first, then add wet food.

• Do not fill liquid past “Max liquid fill” level. If too much liquid is used, it will overflow. In this case,

stop operation, remove liquid to below “Max liquid fill” line and continue processing.

Read this if assembling batch bowl parts to use accessory discs in batch bowl.

• Do not put any food in the bowl before placing the accessory disc onto the shaft.

• Select the appropriate accessory disc: shredding disc, grating disc or slicing disc.

• Hold the disc with the cutting side facing your hand. Be careful not to scrape your

hand on the sharp edges. Notice the bottom of the disc has a plastic receptacle

for the detachable stem. Holding the stem with your thumb on the release switch,

place the center and right-most two tabs in the two open slots on the bottom of

the disc and rotate clockwise. Refer to diagram.

• Once the stem is installed in the proper disc, carefully guide the center disc hub

over the metal shaft so the double flats on the shaft line up with the disc stem. Put

the disc on top of the shaft and rotate until it drops down and into place. Be sure it is pushed down

as far as it will go. Push on the outside rim only; never touch the cutting blades. It should easily drop

into place, but if not, then gently rock it back and forth until you feel the disc drop into place.

Note: Do not put any food in the bowl before placing the accessory disc onto the shaft.

(batch bowl assembly continues)

L

O

C

K

U

N

L

O

C

K

Page 7

7

(batch bowl assembly continued)

• Place the cover on the bowl, with the feed tube on the right, slightly toward the front. The locking

tabs on the cover should be at the left of the locking tabs on the rim of the work bowl.

• Rotate the cover counterclockwise to lock it into place. When the cover is rotated into place, the

safety interlock tab on the back rim of the cover will lock with the interlock mechanism.

NOTE: The cover must be in place correctly, with the cover’s safety interlock tab firmly engaged, for

the food processor to operate. This is an important safety feature.

NEVER ATTEMPT TO START THE FOOD

PROCESSOR WITHOUT THE COVER LOCKED

INTO POSITION.

Two pushers for feed tube

Pick up the large food pusher and the small food pusher.

The large pusher is for processing larger vegetables. The smaller

pusher nests in the larger pusher and can be used for smaller

vegetables, guiding long thin vegetables for more precise cuts,

or for jobs like slicing pepperoni.

Large pusher

Insert the small food pusher into the large food pusher opening.

When it is fully inserted, rotate the small pusher counterclockwise to

lock it into place. Now you are ready to insert the large pusher

into the feed tube opening.

Small pusher

To use the small pusher, rotate it counterclockwise to disengage

the locking feature. Now you can lift the small pusher up and

out of the large pusher. When using the small pusher, the large

pusher becomes the feed tube for the small pusher.

Page 8

8

DISASSEMBLY OF BATCH BOWL PARTS

WFP14SC

ALWAYS UNPLUG THE CORD BEFORE DISASSEMBLING.

• Turn the bowl cover clockwise until the safety interlock tab on the cover is disengaged and the lock-

ing tabs are clear of the tabs on the bowl. In this position you can lift the cover off the bowl.

• Remove the large food pusher from the feed tube. Remove the small pusher from the large pusher.

Disassembly when removing the S-blade

• Remove the work bowl from the unit by rotating clockwise (left) to disengage the tabs on the bottom

of the bowl platform from the work bowl. When the bowl handle is on the left (about 7 o’clock

position), you can gently lift the bowl straight up and out.

It is recommended that you remove the bowl from the motor base before you

remove the S-blade.

• To remove the blade, keep a slight downward pressure on the top of the center hub of the blade

while removing the bowl from the motor base. This will form a seal to prevent food particles from

spilling into the center tube of the bowl and onto the motor base or the work surface. REMOVE

ALL FOOD AND LIQUID BEFORE REMOVING S-BLADE, OR BOWL WILL LEAK.

Then remove the S-blade from the bowl by pulling upward to unlock the seal. Handle the S-blade

with caution; the blades are extremely sharp.

Disassembly when removing an accessory disc

• Do not remove the work bowl until the accessory disc is removed.

• To remove an accessory disc, place your fingers on the outer edge of two opposite sides of the disc

and lift. The disc should remove cleanly. To remove the detachable stem, hold the disc in one hand

with the stem facing away from your hand. Be careful not to scrape your hand on any sharp edges;

depress the release switch with your thumb and rotate counterclockwise.

• Remove the work bowl from the unit by rotating clockwise to disengage the tabs on the bottom

of the bowl platform from the work bowl. When the bowl handle is on the left (about 7 o’clock

position), you can gently lift the bowl straight up and out.

Page 9

99

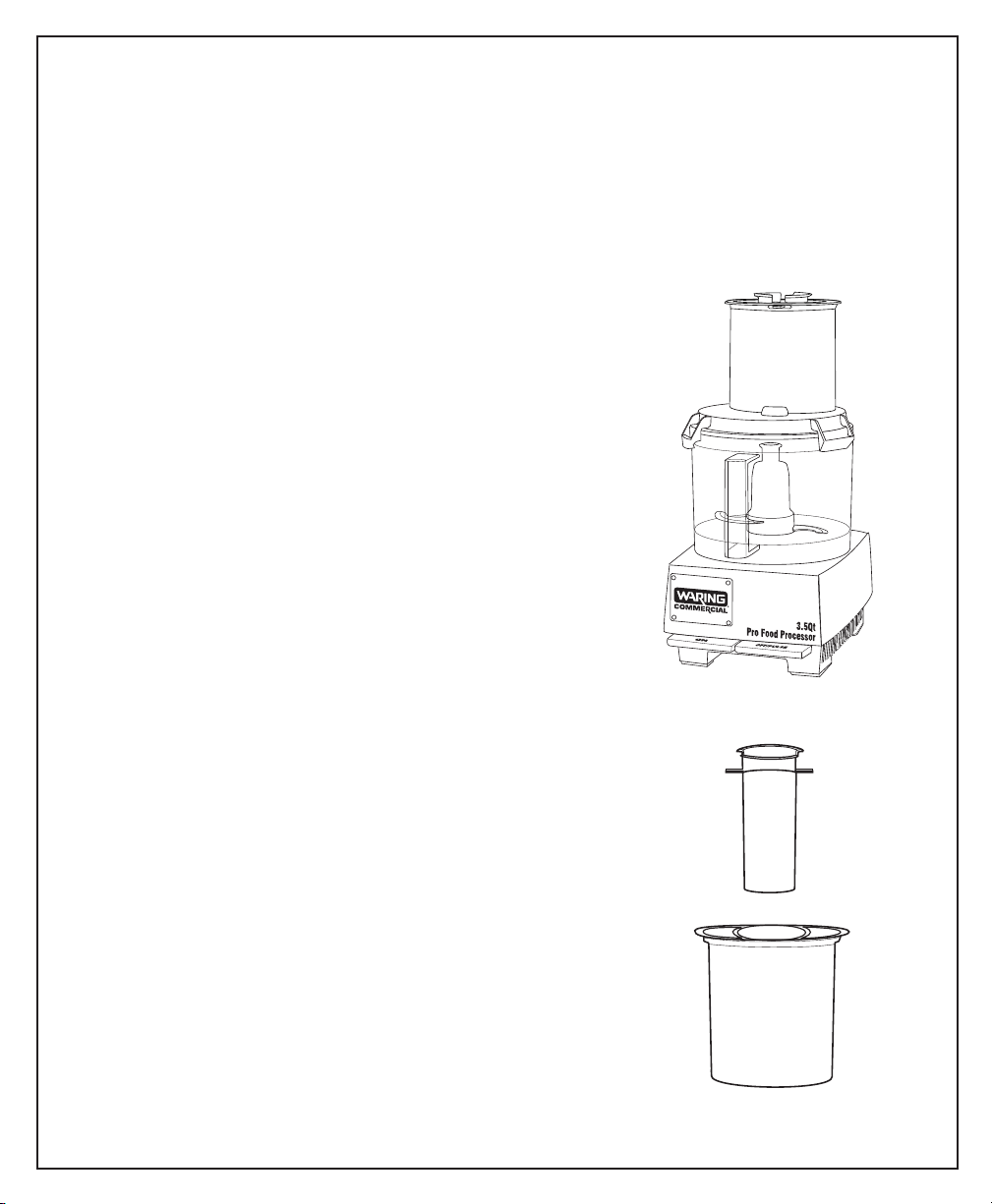

ASSEMBLY OF CONTINUOUS FEED CHUTE PARTS

• Clean and sanitize the motor base, and wash, rinse, and sanitize the

continuous feed chute, cover, slinger disc, food pusher, food pusher

insert and processing tools prior to initial use.

• Place the base on a counter or table near a 3-prong electrical outlet.

Position it so that you are looking at the front of the unit and can see

the control levers. Be certain that the cord is unplugged and the OFF

lever has been pressed. Do not plug in the cord until the processor is

completely assembled.

• Pick up the continuous feed chute, holding it in both hands with the

chute pointing in the 4 o’clock position and the handle at 7 o’clock

position. Place the chute on the base, fitting its center opening over the

motor shaft.

• Press the chute down so the round lower rim of the chute fits around

the circular platform. Rotate counterclockwise until it clicks into place

and engages the rear interlock.

• Place the slinger (or ejector disc) in the bowl, sliding it over the metal

motor shaft until it reaches the bottom of the chute.

• Select the appropriate accessory disc. Follow directions on page 7 to

attach stem to disc.

• After selecting the appropriate disc and attaching the disc stem, pick

up the disc by holding the disc firmly between both hands. Be careful

not to grab the blades or scrape your hands on the slicing/shredding/

grating nodules.

• Carefully guide the disc stem over the metal shaft so the double flats

on the shaft line up with the matching shape of the disc stem. The disc

should easily drop into place, but if not, gently rotate until you feel it

drop into place. Be sure it is pushed down as far as it will go. Push on the outside rim only; never

touch the cutting blades. Do not put any food in the chute before placing the accessory disc

onto the shaft.

• Place the cover on top of the chute with cover locking tab at left of locking tab on chute. Press down

and rotate the cover until it latches to the tab on the continuous feed chute. This will prevent the lid

from rising up during processing.

• The interlock tab on the cover will slide into the interlock slot on the cover and engage the magnetic

safety interlock switch. The interlock switch prevents operation of the machine unless the cover is in

the proper position. With this switch engaged, the food processor will operate if the power is on and

the controls are turned to ON or PULSE.

NEVER ATTEMPT TO START THE FOOD PROCESSOR WITHOUT THE CHUTE AND

COVER LOCKED INTO POSITION.

Page 10

10

Two Pushers for Feed Tube

Pick up the large food pusher and the small food pusher. The large pusher is for processing larger vegetables. The smaller pusher nests in the larger pusher and can be used for smaller vegetables, guiding

long thin vegetables for more precise cuts and for jobs like slicing pepperoni.

DISASSEMBLY OF CONTINUOUS FEED CHUTE PARTS

ALWAYS UNPLUG THE CORD BEFORE DISASSEMBLING.

• Turn the cover clockwise until the safety interlock tab on the cover is disengaged from the safety

interlock switch on the chute, and the tabs are clear of the tabs on the cover.

• When the chute is in the 4 o’clock position, you can lift the cover off the chute. Remember to rotate

the cover lock to the open position before removing the cover.

• Remove the large food pusher from the feed tube. Remove the small pusher from the large pusher.

• To remove an accessory disc from the continuous feed chute, place two fingers under each side of

the disc and lift it straight up. Be careful not to touch the blades, as they are extremely sharp. Follow

directions on page 9 to remove stem from disc.

• Remove the continuous feed chute from the motor base. If the chute is pointing in the 4-o’clock

position, just lift it up. If not, rotate clockwise (left) to disengage the tabs on the bottom of the chute

platform (motor base) from the slots on the bottom of the continuous feed chute.

Page 11

11

OPERATING THE CONTROLS

• Plug the machine into an electrical outlet. The outlet must be120V, 60Hz.

• There are two control levers located on the base of the machine. They are on the front and they give

you fingertip control of processing. They are large enough to find easily in case of emergency.

The two controls are: ON

PULSE/OFF

How they work: ON: Press the lever down to start the motor.

PULSE/OFF: To turn the motor off, press the lever down

and release.

To pulse the motor, press the PULSE/OFF lever down, then

release. The motor will run as long as you hold the lever down; it stops when

you release the lever. Try it a few times.

How to Use

Continuous use

For continuous processing, use the ON lever, which is located on the left.

Pulsing

The pulsing function is intended for use with the S-blade in the work bowl.

• For rapid on-off operation, called pulsing, use the PULSE/OFF lever located on the right. The

motor runs as long as you hold the lever down; it stops when you release the lever.

• You control pulsing. You control the duration of each pulse by the amount of time you hold the

lever down. You control the frequency of pulses by the rate at which you press the lever. The interval

between pulses must be long enough to allow everything in the work bowl to fall to the bottom.

• Pulsing gives you precise control over chopping, mincing, blending and mixing. You can process food

to any texture or consistency you want, from coarse to fine.

• Pulsing is also useful in processing hard foods. Pulse the food a few times to break up into smaller

parts. Then proceed with continuous use after the pieces are broken up and easier to process.

• Always use the PULSE/OFF lever for pulsing. Never move the bowl (or chute) and cover assembly

on or off to control pulses. It is less efficient and could damage the machine.

Turning off

Always turn the machine off with the PULSE/OFF lever and wait until the blade or disc comes to a

complete stop before removing the pusher assembly. The motor stops within seconds after the machine

is turned off.

Page 12

12

FOOD PREPARATION

• Prepare all food items to be processed by washing and peeling as required. Remove pits, stones, and

large seeds.

• Cut vegetables, meats, cheeses, etc. into sizes that will fit into your choice of small feed tube or large

feed tube for processing with accessory discs, or into sizes as required by your processing task.

• Preparation for slicing: Produce that is long and cylindrical such as carrots, cucumbers and celery

should be cut flat at both ends. This will provide a consistent slice for all food processed.

FOOD PUSHER SELECTION

S-blade usage

The feed tube can be used for adding ingredients while the food processor is running. However it is

recommended that the food pushers be left in place whenever possible to prevent splashing and avoid

unwanted additions to the work bowl.

Small pusher

This pusher with smaller chute is typically used when inserting vegetables vertically for smaller cuts. It

should be used when slicing foods such as carrots, celery, pepperoni, etc., when a consistent, flat result

is desired.

This pusher is also used when a shorter grate or slice is desired as opposed to a longer grate or slice

using the larger feed tube and pusher.

Large pusher

This pusher with larger chute is typically used when inserting vegetables horizontally for longer cuts.

This pusher is used when a longer grate or slice is desired. It is also used when processing large

volumes of food or bulky food items such as potatoes or onions.

RESETTING THERMAL PROTECTION

The WFP14SC Food Processor is equipped with an automatic reset switch to protect the motor from

overheating.

If your food processor stops running under heavy use, turn the power switch off and unplug the power

cord. Empty the work bowl of all its contents and discard food. Allow approximately 5 minutes for the

motor to cool down.

Reassemble unit, plug the power cord back into the outlet and run first with the bowl empty. Put food

into the bowl and continue processing.

If your food processor does not function properly following this procedure, discontinue use and

contact a Certified Waring Customer Service Center.

Page 13

13

BATCH BOWL MAXIMUM CAPACITY CHART

Do not exceed the capacities listed in the table below when processing in the batch bowl:

FOODS CAPACITY

Chopped and Puréed Fruit and Vegetables 475 g (1.1 lbs)

Chopped or Puréed Meat, Poultry, Fish or Seafood 1 kg (2¼ lbs)

Sliced Fruit, Cheese or Vegetables 1.5 kg (3.5 lbs)

USE INSTRUCTIONS FOR S-BLADE

IN THE BATCH BOWL

1. Cut food into 2.5cm pieces.

2. Insert the metal S-blade and put the pieces of food into the work bowl. Attach the lid and the

pusher assembly; press the pusher assembly down to lock it into place. Press and release the

PULSE/OFF lever two or three times. Each time the blade stops, let the pieces drop

to the bottom of the bowl before pulsing again.

3. Using the pulse/chopping technique, you can get an even chop without the danger of over-

processing. Check the texture frequently by looking through the cover of the work bowl. If you

want a finer chop, press and release the PULSE/OFF lever until you achieve the desired texture.

Onions and other foods with a high water content will quickly end up as a purée unless examined

through the work bowl after each pulse to make sure they are not overprocessed.

• For better results, ensure all the pieces you add to the bowl are about the same size.

Ensure the amount you process is no larger than recommended.

• When processing liquid, do not exceed 10 cups or fill past “Max liquid fill” line.

REMOVING PROCESSED FOOD FROM THE BATCH BOWL

1. Turn the machine off and wait for the blade to stop moving before removing the lid and pusher.

2. If the blade holds the bowl locked when the motor stops, move the handle of the bowl rapidly

back and forth – first clockwise, then counterclockwise.

3. If using a disc, remove before tilting the bowl, using a spatula to scrape off any food sticking to it.

If using S-blade, it will stay locked in the bowl when you tilt to pour. Use spatula to scrape food

out of bowl. NEVER USE FINGERS TO REMOVE FOOD WHILE BLADE IS IN BOWL.

Page 14

14

CHOPPING HARD FOODS IN THE BATCH BOWL

To chop hard foods like garlic, remove the small pusher, press the ON lever and drop the food through

the small feed tube while the machine is running. Small foods like garlic can be dropped in whole.

This method of processing minces garlic, shallots and onions. Larger foods like meat and hard cheese

should be cut into 1-inch (25.4 mm) cubes to ensure an even chop. Press the PULSE/OFF lever for 1

to 2 seconds, 3 times. Then press the ON lever and process for a maximum of 30 seconds for desired

consistency.

Never try to process cheese that is too hard to cut with a knife. You may damage the blade

or the machine.

SLICING OPERATION

Round fruits and vegetables

Before processing onions, apples and other large, round fruits and vegetables, trim them with a knife.

Cut the bottom end flat to make the food lie stable on the disc. Place the food in the feed tube, flat

side down. Position it as far left as possible to prevent it from tilting when being processed. Choose

fruits that are firm and not too ripe. Always remove large hard stones and pips/seeds from fruits before

processing. Seeds from citrus fruits need not be removed. You may remove the rind before slicing or

leave the rind on.

Whole peppers are an exception

Remove the stem and cut the stem end flat. Remove the core and scoop out the seeds. Leave the end

opposite the stem whole, to keep the structure stiff. This ensures round, even slices.

Large fruits like pineapple and melon

Cut them in half and remove the seeds or core. If necessary, cut the halves into smaller pieces to fit the

feed tube. Remember to cut the ends flat.

Cabbage and iceberg lettuce

Turn the head on its side and slice off the top and bottom, leaving a center section about 3 inches deep.

Remove the core and cut the center section in wedges to fit the feed tube. Remove the core from the

bottom piece and cut it and the top piece into wedges to fit the feed tube.

If the fruit or vegetable doesn’t fit

Try inserting it from the bottom of the feed tube. The opening there is slightly larger.

Pack the feed tube for desired results

For long slices, cut the food in feed-tube widths and pack the pieces horizontally. For small round

slices from carrots, zucchini and other long vegetables, cut them in feed-tube heights and pack them

tightly upright. Food should fit snugly, but not so tight that it prevents the pusher from moving. When

slicing food, always use the pusher. Never put your fingers or a spatula into the feed tube.

Never push down hard on the pusher. Use light pressure for soft fruits and vegetables like bananas,

mushrooms, strawberries and tomatoes, and for all cheese. Use medium pressure for most foods like

apples, celery, citrus fruit and potatoes. Use firm pressure for really hard vegetables like carrots.

Page 15

15

Small round fruits and vegetables

For large berries, radishes and mushrooms, trim the opposite ends flat with a knife. Insert the food

through the feed tube, standing each piece on a flat end. You can fill the tube to about 1 inch (25.4

mm) from the top. The bottom layer gives you perfect slices for garnish. If you want all the slices to be

perfect, it’s best to process one layer at a time.

Long fruits and vegetables

Trim food like bananas, celery and zucchini by cutting them into pieces a little shorter than the feed

tube. Cut both ends flat. (Use a ruler as a guide, or the pusher assembly with the pusher pulled out as

far as it will go.) Fill the feed tube with the pieces, standing them vertically and adding enough pieces

so they are solidly packed and cannot tilt sideways as they are sliced.

Small amounts of food

Use the small feed tube and the small pusher. Remove the small pusher from the pusher assembly.

Slide the pusher assembly over the feed tube and press the sleeve down to lock it into place. Cut the

food in lengths a little shorter than the feed tube. If you are slicing one or two long, thin vegetables

like carrots, push them against the left. If you are slicing a few vegetables that are wide at one end and

narrow at the other (carrots, celery or scallions) cut them in half and pack in pairs, one wide end up,

one narrow end up.

French-cut green beans

Trim fresh green beans to feed-tube widths. Blanch them for 60 seconds in boiling salted water.

Plunge them immediately into cold water to stop the cooking. When they are cold to the touch, drain

and dry them. Stack them in the feed tube horizontally to about 1 inch (25.4 mm) from the top. Use

the slicing disc. Be sure the small pusher is locked. Apply light pressure to the pusher and press the

PULSE/OFF lever until beans are sliced. To make long, horizontal slices of raw zucchini or carrots,

use the same procedure.

Matchsticks or julienne strips

Process the food twice – double slice it. Insert any large fruit or vegetable – potatoes, turnips,

zucchini, apples – in the feed tube horizontally. Apply pressure to the pusher while pressing the

PULSE/OFF lever until the food is sliced. You will get long slices. Remove the slices from the work

bowl and reassemble them. Reinsert them in the feed tube, wedging them in tightly. Slice them again.

You will obtain long julienne strips.

SLICING MEAT AND POULTRY

Cooked meat and poultry

The food must be very cold. If possible, use a chunk of food just large enough to fit the feed tube. To

make julienne strips of ham, bologna or luncheon meat, stack slices of them. Then roll or fold them

double and stand them upright in the feed tube, wedging in as many rolls as possible. This technique

works better with square or rectangular pieces than with round ones.

Page 16

16

Uncooked meat and poultry

Cut the food into pieces to fit the feed tube. Boned, skinned chicken breasts will usually fit when cut in

half crosswise. Wrap the pieces in plastic wrap and put them in the freezer. They are ready to slice

when they pass this “knife test”: they are easily pierced with the tip of a sharp knife although semifrozen and hard to the touch. Stand them in the feed tube, cut side down, and slice them against the

grain, using firm pressure on the pusher. Or lay them flat in the feed tube, as many as will fit, and slice

with the grain, using firm pressure.

Frankfurters, salami and other sausages

If the sausage is soft, freeze it until hard to the touch but easily pierced with the tip of a sharp knife.

Hard sausages need not be frozen. If the sausage is thin enough to fit in the small feed tube, use that

tube. Otherwise, cut the sausage into pieces to fit the large feed tube completely. Stand the pieces

vertically, packing them in tightly so they cannot tilt sideways.

SLICING CHEESE

Firm cheese like Swiss and Cheddar

Cut the cheese into pieces to fit the feed tube. Put it in the freezer until it is semi-frozen – hard to the

touch but easily pierced with the tip of a sharp knife. Stand the pieces in the feed tube and apply light

pressure to the pusher.

IMPORTANT: Never try to slice soft cheese. Slice only hard cheese such as Parmesan. Do not use

block sizes larger than 3.5" x .750" x 4.0" (89 mm x 19 mm x 101 mm). Always use well-chilled cheese

when slicing. It is recommended to place cheese in refrigerator for at least 1 hour before slicing. Do

not slice mozzarella in this unit. Damage to the unit may occur.

GRATING OPERATION

Prepare all food items to be processed by washing and peeling as required. Remove pits, stones, and

large seeds. Be sure the food will fit into the proper feed chute.

Select which feed tube to use. Horizontal placement of carrots will result in a long grated product,

while using the smaller chute and inserting the food vertically will give you a short grated product.

Never try to grate soft cheese. Grate only hard cheese such as Parmesan. Do not use block sizes larger

than 3.5" x .750" x 4.0" (89 mm x 19 mm x 101 mm). Always use well-chilled cheese when grating. It is

recommended to place cheese in refrigerator for at least 1 hour before grating. Do not grate mozzarella

in this unit. Damage to the unit may occur.

For grating cheese, it is recommended that a slight pulsating pressure be applied with the pusher,

alternating push/no push until the cheese block is completely grated. Cheese grating puts more strain

on the food processor motor than other tasks and may cause overheating if too much pressure is

applied in a continuous manner.

You can typically expect to grate 10 pounds (4.5 kg) of cheese in about 5 minutes. It is

recommended that you plan your food preparation in a manner that will allow for five minutes

of grating, followed by five minutes of food preparation while the machine rests.

When grated food reaches nearly full capacity of the bowl, remove all grated food from the bowl.

Page 17

17

SHREDDING OPERATION

• Prepare all food items to be processed by washing and peeling as required. Remove pits, stones,

and large seeds. Be sure the food will fit into the proper feed chute.

• Select which feed tube to use. Horizontal placement of foods such as carrots and zucchini will result

in a longer shredded product. Using the smaller chute and small pusher with food inserted vertically

will yield a shorter shredded product.

• Never try to shred soft cheese. Use only hard cheese. Mozzarella may be shredded only when well

chilled. Pre-cut mozzarella must be 0.75” thick by 3.5” wide and 4” high for the WFP11S, and 1”

thick by 3.5” wide and 4” high for the WFP14S. Place mozzarella in a freezer for 1 hour prior to

shredding. Only use pulse button when shredding cheese.

• When shredded food reaches nearly full capacity of the bowl, remove all shredded food from

the bowl.

Page 18

18

TROUBLESHOOTING

This section describes potential problems and the correct solutions for them. Problems that cannot

be solved with the guidelines listed below should be referred to one of your local distributors for

assistance. A listing of authorized service agencies is supplied with each Waring food processor.

Unit does not start when assembled correctly

• Pull the plug and try plugging into another outlet.

• Press ON lever to ON.

• Make sure the bowl is properly positioned on the motor base, that the bowl or chute cover is

attached properly, and that the safety interlock tab on the cover has properly engaged the safety

interlock switch.

Unit stops running during processing

• The unit may have overheated. Refer to Resetting Thermal Protection section (page 13).

• Turn unit off and unplug.

• Remove bowl attachment.

• Remove food being processed from inside the bowl and discard.

• Allow unit to cool for 5 minutes.

• Reassemble unit, and run first with the bowl empty, then put food into the bowl and try again.

Unit will not come up to full speed

• Bowl is overloaded – remove food being processed and reload using smaller quantities.

If unit does not operate after you have followed the above

• Check outlet to be sure there is current.

• Check to be sure circuit breaker is on.

• Check to be sure the fuse is not blown if there are fuses on this circuit.

• Contact your local distributor.

If unit starts to spark or smoke

• Turn unit off, unplug it, and call local factory-authorized service agency.

If food processor makes grinding noise

• Turn unit off, unplug, disassemble, check bowl and blade to see if they have been rubbing together.

• If bowl and blade are rubbing, call your local distributor.

Page 19

19

CLEANING

Clean the food processor and accessories prior to initial use and after each use. Do not use harsh

abrasive-type cleaners on any part of the food processor. Wash the motor shaft with a small brush.

Wash, rinse, sanitize and dry the bowl, covers, continuous feed chute, small food pusher, large food

pusher, accessory discs, and S-blade prior to initial use and after use, unless they will be used again

immediately. These items are all dishwasher safe and may be cleaned and rinsed in the dishwasher

instead of manually in the sink.

Wash and rinse all of the above items after each use.

The bowl cover has a black seal around its outer rim that is easily removable for cleaning and should

be cleaned periodically. There are three small holes on the outer lip of the top of the cover for pushing

the seal out. Use a small, dull object like a toothpick or paper clip, to push the seal downward and out

of the groove. DO NOT USE ANYTHING SHARP THAT CAN CUT THE SEAL. Hand wash

with warm soapy water, rinse, and dry. To reassemble, insert the clean and dry seal back in to groove

with your fingers, with the round edge at the top and the slotted edge at the bottom, facing in. Make

sure the seal is fully inserted and in proper position. Note picture below.

Note: The flap of the cover seal must be downward and the opening must face to center of cover.

A stiff bristle brush will help to knock food particles out of the crevices of the discs and blades before

washing. Handle very carefully as the blades are sharp.

For manual cleaning, it is recommended that you use washing solutions based on non-sudsing

detergents, and chlorine-based sanitizing solutions that have a minimum chlorine concentration

of 100 PPM. The following washing, rinsing, and sanitizing solutions, or their equivalents, may

be used:

SOLUTION PRODUCT DILUTION IN WATER TEMPERATURE

Washing *Ajax® Sanitizer ¼ oz. per Hot 115°F (46°C)

Cleaner Powder 2½ gallons

Rinsing Plain Water Warm 95°F (35°C)

Sanitizing **Clorox® 1 tablespoon per Cold 50°F (10°–21°C)

Institutional gallon

*Ajax® is a registered trademark owned by the Colgate-Palmolive Company.

**Clorox® is a registered trademark owned by the Clorox Company.

Page 20

20

To clean and sanitize the motor base

Clean and sanitize the motor base prior to initial use and after each use. Unplug the unit, then

wipe down the exterior surfaces of the motor base with cloth or sponge dampened with a soluble

detergent. Next, wipe down with rinse water. Prevent liquid from running into the motor base by

wringing out all excess moisture from cloth or sponge before using it.

NEVER IMMERSE THE MOTOR BASE IN WATER OR ANY OTHER LIQUID.

Allow the unit to air-dry before using again.

Never use harsh abrasive-type cleaners on any part of the commercial food processor.

LIMITED WARRANTY

LIMITED FIVE YEAR MOTOR WARRANTY

LIMITED TWO YEAR PARTS AND LABOR WARRANTY

Waring Commercial warrants that this product’s motor shall be free from defects in material and

workmanship for a period of five years from the date of purchase when used with foodstuffs,

nonabrasive liquids (other than detergents) and nonabrasive semi-liquids, providing it has not

been subject to loads in excess of indicated rating. All other components are warranted for a period

of two years from date of purchase.

Under this warranty, the Waring Commercial division will repair or replace any part which, upon our

examination, is defective in materials and workmanship, provided the product is delivered prepaid to

the Waring Service Center, 314 Ella T. Grasso Ave., Torrington, CT 06790, or any factory-approved

service center.

This warranty does not: a) apply to any product that has become worn, defective, damaged or

broken due to use or due to repairs or servicing by other than the Waring Service Center or a factoryapproved service center or due to abuse, misuse, overloading or tampering; b) cover incidental or consequential damages of any kind.

This warranty is applicable only to appliances used in the United States or Canada; this supersedes all

other express product warranty or guaranty statements. For Waring products sold outside of the U.S.

and Canada, the warranty is the responsibility of the local importer or distributor. This warranty may

vary according to local regulations.

This warranty is void if appliance is used on Direct Current (DC current).

Page 21

21

MEDIDAS DE SEGURIDAD IMPORTANTES

Siempre que use aparatos eléctricos, debe tomar precauciones básicas de seguridad, entre las cuales las

siguientes:

1. Lea todas las instrucciones.

2. Las cuchillas son muy filosas. Manipúlelas con sumo cuidado.

3. Como todo electrodoméstico, su robot de cocina Waring® debe usarse con mucha precaución.

Aunque no se necesita mucha preparación para operar este aparato, sólo debería ser usado por

personas responsables y cuidadosas. No debería ser usado por o cerca de niños o personas con

alguna discapacidad.

4. Para reducir el riesgo de heridas, asegúrese que el bol esté debidamente ensamblado antes de

instalar la cuchilla o el disco.

5. Para reducir el riesgo de herida seria o de daño al aparato, mantenga las manos y los utensilios

alejados de la cuchilla o del disco durante el funcionamiento. Se podrá usar una espátula de goma,

siempre en cuando el aparato esté apagado.

6. Para reducir el riesgo de electrocución, no coloque el bloque-motor en agua u otro líquido.

7. Desconecte el aparato cuando no esté en uso, antes de instalar o de remover piezas, antes de

vaciar el bol y antes de limpiarlo. Para desconectar el aparato, coja el cable por la clavija. Nunca

jale el cable

8. Evite el contacto con las piezas móviles. Nunca introduzca la mano en la boca de llenado. Siempre

utilice el empujador.

9. Espere hasta que el motor se haya detenido completamente antes de remover la tapa.

10. No opere este aparato si el cordón o la clavija estuviesen dañados, después de que hubiese

funcionado mal o que se hubiese caído o si estuviese dañado. Regrese el aparato a un centro

de servicio autorizado para su revisión, reparación o ajuste.

11. El uso de accesorios no recomendados o vendidos por el fabricante presenta un riesgo de

incendio, electrocución o herida.

12. No lo utilice en exteriores.

13. No permita que el cordón cuelgue del borde de la encimera o de la mesa, ni que haga contacto

con superficies calientes.

14. No intente forzar el mecanismo de bloqueo de seguridad de la tapa.

15. Asegúrese que la tapa esté debidamente cerrada antes de encender el aparato.

16. En caso de mal funcionamiento durante el uso, tire el contenido del bol a la basura.

17. Los niños o las personas que carezcan de los conocimientos o la experiencia necesarios para

manipular el aparato, o aquellas cuyas capacidades físicas, sensoriales o mentales estén limitadas,

no deben utilizar el aparato sin la supervisión o la dirección de una persona responsable por su

seguridad.

18. Asegúrese que los niños no jueguen con este aparato.

GUARDE ESTAS INSTRUCCIONES

Page 22

22

INSTRUCCIONES DE PUESTA A TIERRA

Para su protección, este aparato está equipado con un cable eléctrico con conductor de tierra.

Los aparatos de 120V están equipados con clavija de tierra de tipo NEMA5-15P, la cual debe ser

conectada a un tomacorriente debidamente puesto a tierra (Fig. 1).

Si un tomacorriente puesto a tierra no está disponible, se podrá usar un adaptador para conectar el

aparato a un tomacorriente polarizado (Fig. 2).

El adaptador debe ser puesto a tierra mediante un tornillo de metal que conecte la lengüeta del

adaptador a la placa del tomacorriente (Fig. 3).

PRECAUCIÓN: Antes de conectar el adaptador, asegúrese que el tomacorriente esté puesto a tierra.

Si no está seguro, comuníquese con un electricista. Nunca use un adaptador sin estar seguro de que el

tomacorriente esté puesto a tierra.

NOTA: Está prohibido usar un adaptador en el Canadá. Los aparatos de 220–240V, homologados por

GS, están equipados con un enchufe europeo CEE 7/7.

El robot multifunción WFP14SC cuenta con un sello hermético único que permite procesar un gran

volumen de líquido y vaciar el bol sin remover la cuchilla. Una vez más, Waring Commercial está

revolucionando el mundo de la preparación culinaria. Gracias a esta característica y a su bol para

procesado continuo, el WFP14SC de Waring Commercial es el robot de cocina más versátil

del mercado.

TOMACORRIENTE

PUESTO A TIERRA

POLO DE TIERRA

ADAPTADOR

LENGÜETA DE

PUESTA A TIERRA

TORNILLO

DE METAL

CAJA ELÉCTRICA

PUESTA A TIERRA

Page 23

23

PIEZAS

El robot de cocina de WFP14SC incluye las piezas y accesorios siguientes (ver el diagrama a

continuación):

1. Sólido bloque-motor con resistente árbol motor

2. Dos botones de control

a. ON (encendido continuo)

b. OFF/PULSE (apagado/pulso)

3. Mecanismo de bloqueo de seguridad (no enseñado)

Impide que el aparato se ponga en marcha a menos que la tapa esté debidamente cerrada

4. Bol transparente con capacidad de 3.5 litros

5. Tapa transparente hermética

a. Boca de llenado ovalada y ancha, para reducir el tiempo de preparación

b. Empujador grande, ideal para los alimentos grandes

c. Empujador pequeño, ideal para los alimentos finos (zanahorias, apio, salchicha, etc.)

Nota: El empujador pequeño encaja en el empujador grande. Este sistema de empujadores

2-en-1 permite procesar una gran variedad de alimentos.

6. Cuchilla sellada que evita los derrames y permanece en posición al vaciar el bol. Ideal para picar,

moler, licuar o mezclar.

7. Disco rebanador de 4 mm

8. Disco rallador de 2 mm

9. Disco triturador de 4 mm

10. Adaptador amovible

Nota: los discos proveídos con el modelo WFP14SC deben usarse con el adaptador

amovible. Éste ha sido especialmente diseñado para aumentar su eficacia.

11. Bol para procesado continuo con asa

12. Tapa del bol para procesado continuo

13. Disco eyector

Page 24

24

2a 2b

1

6

4

5

5a

5b

5c

7 8 9

2a 2b

1

13

11

12

5b

5c

10

Page 25

25

ENSAMBLADO DEL BOL

WFP14SC

• Antes de usar el aparato por primera vez: Limpie y desinfecte el bloque-motor. Lave, enjuague y

desinfecte el bol, la tapa, los empujadores y los accesorios.

• Coloque el aparato sobre una mesa o una encimera, cerca de un tomacorriente. Posiciónelo de

manera que esté fácilmente accesible. Asegúrese que el aparato esté desconectado y apagado (OFF).

No enchufe el aparato hasta haber terminado de ensamblar todas las piezas.

• Sostenga el bol con ambas manos, de manera que el asa apunte hacia su cuerpo.

• Haga coincidir el árbol motor con el cilindro en el centro del bol e instale el bol sobre la base. El asa

se encontrará ligeramente a mano izquierda.

• Presione el bol hasta que encaje con la plataforma circular del bloque-motor. Gírelo en sentido

antihorario para sujetarlo. El bol se bloqueará cuando las anclas en el lado de la plataforma encajen

con el mismo.

Instalación de la cuchilla

• Sostenga la cuchilla por el eje de plástico. Note la forma del eje. Éste ha sido diseñado para adaptarse

al árbol motor.

• Haga coincidir el eje de la cuchilla con el árbol motor.

Presione hacia abajo mientras gira la cuchilla. No debería encontrar resistencia. Presione con firmeza

para sellar la cuchilla. Compruebe que esté bien asentada. En el caso contrario, podría dañarse y

líquido podría derramarse. Los filos de la cuchilla son muy afilados. Nunca los toque. Siempre

sostenga la cuchilla por la parte de plástico.

• Asegúrese que la cuchilla esté bien asentada, volteándola de un lado a otro. La cuchilla debería

encontrarse prácticamente en el fondo del bol.

• Si usted desea utilizar el aparato con la cuchilla, puede agregar los ingredientes ahora.

• Procese los ingredientes secos, y luego los ingredientes líquidos.

• No pase la línea “MAX”. Esto podría provocar un derrame. Si esto ocurriera, apague el aparato y

vacíe parcialmente el bol.

Instalación de los discos

• No llene la boca de llenado antes de haber instalado el disco.

• Elija el disco deseado.

• Sostenga el disco con el lado cortante hacia la palma de su mano, Teniendo

cuidado de no cortarse. Conecte el disco al adaptador. Oprima el botón de

liberación del adaptador, instale éste en el centro del disco y gire en sentido

horario. Véase el dibujo a continuación.

• Una vez el disco conectado al adaptador, haga coincidir el adaptador con el árbol

motor, de manera que las hendiduras en el adaptador coincidan con los resaltos en el árbol, y empuje para sujetarlo. Ponga el disco sobre el adaptador y gire hasta que encaje.

Compruebe que esté bien asentado. Apriete los bordes del disco únicamente. Nunca toque los filos.

No debería encontrar resistencia. En el caso contrario, gire ligeramente el disco hasta que encaje.

Nota: No llene la boca de llenado antes de haber instalado el disco.

B

L

O

Q

U

E

A

R

A

F

L

O

J

A

R

(Continúa en la página siguiente)

Page 26

26

• Coloque la tapa encima del bol, con la boca de llenado apuntando ligeramente hacia la derecha. Las

anclas de la tapa deberían encontrarse a la izquierda de las anclas ubicadas en la parte delantera del

bol.

• Gire la tapa en sentido antihorario para sujetarla. Una vez encajadas, las anclas desactivarán el sistema

de seguridad magnético y se podrá encender el aparato.

NOTA: • El aparato no se pondrá en marcha a menos que la tapa esté

debidamente cerrada. Este mecanismo de seguridad es muy importante.

NUNCA INTENTE ENCENDER EL APARATO SI LA

TAPA NO ESTÁ DEBIDAMENTE CERRADA.

Juego de empujadores 2-en-1

El juego de empujadores incluye dos empujadores: un empujador

grande que encaja en la boca de llenado y un empujador pequeño

que encaja en el empujador grande. Elija el empujador deseado.

Utilice el empujador grande para cortar las verduras grandes. Utilice

el empujador pequeño para cortar las verduras pequeñas o finas, o

para tareas precisas, como cortar salchicha en rodajas.

Empujador grande

Introduzca el empujador pequeño en el centro del empujador grande.

Gire entonces el empujador pequeño en sentido horario para sujetarlo.

Introduzca el empujador grande en la boca de llenado.

Empujador pequeño

Gire el empujador pequeño en sentido anti horario para aflojarlo.

Retírelo del empujador grande. Introduzca los alimentos en el centro

del empujador grande y empújelos con el empujador pequeño.

(Continuación)

Page 27

27

DESENSAMBLADO DEL BOL

WFP14SC

SIEMPRE DESENCHUFE EL APARATO ANTES DE DESENSAMBLARLO.

• Gire la tapa en sentido horario hasta desencajar las anclas. Retire la tapa.

• Retire el empujador grande de la boca de llenado. Retire el empujador pequeño del empujador

grande.

Remoción de la cuchilla:

• Gire el bol en sentido horario para liberar las anclas. El asa debe encontrarse a mano izquierda para

poder alzar el bol.

Le aconsejamos que remueva el bol del bloque-motor antes de sacar la cuchilla.

• Apriete la cuchilla mientras alza el bol. Esto impedirá que los alimentos se derramen hacia el

bloque-motor. IMPORTANTE: VACÍE EL BOL ANTES DE REMOVER LA CUCHILLA.

Para remover la cuchilla del bol, simplemente álcela. Los filos de la cuchilla son muy afilados.

Manipúlela con sumo cuidado.

Remoción de los discos:

• Remueva el disco antes de retirar el bol de la base.

• Sostenga el disco por los costados, entre dos dedos, y álcelo. Debería salir fácilmente. Para remover

el adaptador amovible, sostenga el disco en una mano, teniendo cuidado de no cortarse. Oprima el

botón de liberación del adaptador ubicado sobre éste y gire en sentido antihorario.

• Gire el bol en sentido horario para liberar las anclas. El asa debe encontrarse a mano izquierda para

poder alzar el bol.

Page 28

28

ENSAMBLADO DEL BOL PARA PROCESADO

CONTINUO

• Antes de usar el aparato por primera vez: Limpie y desinfecte el

bloque-motor. Lave, enjuague y desinfecte el bol, la tapa, el disco

eyector, los empujadores y los accesorios.

• Coloque el aparato sobre una mesa o una encimera, cerca de un

tomacorriente. Posiciónelo de manera que esté fácilmente accesible.

Asegúrese que el aparato esté desconectado y apagado (OFF). No

enchufe el aparato hasta haber terminado de ensamblar todas las piezas.

• Sostenga el bol con ambas manos. El conducto de salida debería

encontrarse a 110 grados y el asa a 160 grados a la derecha. Haga

coincidir el árbol motor con el cilindro ubicado en el centro del bol.

• Presione el bol hasta que encaje con la plataforma circular del

bloque-motor. Gire en sentido antihorario hasta que encaje.

• Introduzca el disco eyector sobre el árbol motor. Debería

prácticamente tocar el fondo del bol.

• Elija el disco deseado. Conecte el disco al adaptador, según se

describió en la sección “Instalación de los discos”.

• Sostenga el disco que desea usar con ambas manos. Tenga cuidado

de no tocar los filos del disco.

• Haga coincidir el eje del disco con el árbol del motor, de manera que

las hendiduras en el eje coincidan con los resaltos en el árbol. No

debería encontrar resistencia. En el caso contrario, gire ligeramente el

disco hasta que encaje. Compruebe que esté bien asentado. Apriete los

bordes del disco únicamente. Nunca toque los filos. No llene la boca

de llenado antes de haber instalado el disco.

• Coloque la tapa sobre el bol para procesado continuo. Las anclas de la

tapa deberían encontrarse a la izquierda de las anclas en el bol. Presione la tapa y gírela hasta que se

bloquee. Esto evitará que se alce durante el procesado.

• Las anclas del bol coincidirán con las anclas del bloque-motor, lo que activará el sistema de seguridad

magnético. Este importante mecanismo de seguridad impide que el aparato se ponga en marcha a

menos que la tapa esté debidamente cerrada. Una vez cerrada la tapa, se podrá encender el aparato,

oprimiendo el botón ON o PULSE/OFF.

NUNCA INTENTE ENCENDER EL APARATO SI LA TAPA NO ESTÁ DEBIDAMENTE

CERRADA.

Page 29

29

Juego de empujadores 2-en-1

El juego de empujadores incluye dos empujadores: un empujador grande que encaja en la boca de

llenado y un empujador pequeño que encaja en el empujador grande. Elija el empujador deseado.

Utilice el empujador grande para cortar las verduras grandes. Utilice el empujador pequeño para cortar

las verduras pequeñas o finas, o para tareas precisas, como cortar salchicha en rodajas.

DESENSAMBLADO DEL BOL PARA PROCESADO

CONTINUO

SIEMPRE DESENCHUFE EL APARATO ANTES DE DESENSAMBLARLO.

• Gire la tapa en sentido horario hasta desencajar las anclas.

• Cuando la boca de salida se encuentre a mano derecha, casi en el centro, alce la tapa. No se olvide de

abrir el cierre de la tapa antes de retirarla.

• Retire el empujador grande de la boca de llenado. Retire el empujador pequeño del empujador

grande.

• Para retirar el disco, ponga dos dedos debajo de cada lado y álcelo. Los filos del disco son muy

afilados. Tenga cuidado de no tocarlos. Retire el adaptador según se describió en la sección

“Remoción de los discos”.

• Retire el bol del bloque-motor. Si la boca de salida está en el centro a mano derecha, sólo

necesitará alzarlo. Si no fuera el caso, gírelo en sentido horario para liberar las anclas en la plataforma

del bloque-motor.

Page 30

30

FUNCIONAMIENTO DEL APARATO

Enchufe el cable en un tomacorriente de 120V (60 Hz).

• El aparato cuenta con dos botones de control, los cuales son convenientemente posicionados, fáciles

de usar y suficientemente grandes como para encontrarse fácilmente en caso de emergencia.

Los dos controles son: ON (encendido continuo)

PULSE/OFF (pulso/apagado)

Modo de funcionamiento: ON: Oprima este botón para encender el aparato.

PULSE/OFF: Oprima este botón una vez para apagar el aparato.

Oprímalo repetidamente para usar la función de pulso. El motor permanecerá

encendido hasta que suelte el botón. Pruébelo varias veces.

MODO DE EMPLEO

Encendido continuo

Oprima el botón ON.

Función de pulso

La función de pulso solamente debe usarse con la cuchilla, no con los discos.

• Para usar la función de pulso, oprima repetidamente el botón PULSE/OFF. El motor permanecerá

encendido hasta que suelte el botón.

• La función de pulso le ofrece más control, ya que le permite controlar con precisión la cantidad y la

duración de cada pulso. Permita que los alimentos bajen al fondo del bol entre dos pulsos.

• La función de pulso es muy conveniente para controlar la consistencia de los alimentos. Permite

obtener exactamente los resultados deseados.

• También es conveniente para picar alimentos duros. Utilice la función de pulso para quebrar los

alimentos, luego termine de picarlos con la función de encendido continuo.

• Siempre utilice el botón PULSE/OFF para activar la función de pulso. Nunca intente controlar las

pulsaciones moviendo el bol o la tapa. Esto podría dañar el aparato.

Para apagar el aparato:

Siempre oprima el botón PULSE/OFF y espere hasta que la cuchilla o el disco esté completamente

inmóvil antes de abrir la tapa. Esto demorará tan sólo segundos.

Page 31

31

PREPARACIÓN DE LOS ALIMENTOS

• Lave todos los alimentos antes de procesarlos. Pele las frutas/verduras si fuera necesario. Quite las

pepas, pepitas y semillas grandes.

• Corte los alimentos, por ejemplo las verduras, la carne o el queso, al tamaño deseado. Si desea utilizar

los discos, los pedazos deberían caber en la boca de llenado.

• Preparación para rebanar: Corte ambos lados de los alimentos largos como las zanahorias, los pepinos

o el apio. Esto mejoraré la consistencia de las rodajas.

SELECCIÓN DEL EMPUJADOR

Nota – Cuando use la cuchilla:

Aunque puede introducir alimentos en la boca de llenado durante el funcionamiento, es preferible dejar

el empujador grande en la boca de llenado para evitar salpicaduras.

Empujador pequeño

El empujador pequeño sirve para empujar los alimentos introducidos verticalmente en el centro del

empujador grande. Permite obtener pedazos más cortos. Se usa típicamente para cortar en rodajas

zanahorias, apio, salchicha seca y otros alimentos largos y finos.

Es ideal para rallar en pedazos cortos y cortar en rodajas pequeñas.

Empujador grande

El empujador grande sirve para empujar alimentos introducidos horizontalmente en la boca de llenado.

Permite obtener pedazos más largos.

Se usa típicamente para rallar en pedazos largos, cortar en rodajas largas y procesar alimentos enteros,

como papas o cebollas.

DISPOSITIVO DE PROTECCIÓN DEL MOTOR

Este aparato está dotado de un dispositivo de protección térmica que apaga automáticamente el motor

en caso de recalentamiento.

Si esto ocurriera, apague y desenchufe el aparato. Vacíe el bol y tire los alimentos procesados. Permita

que el motor enfríe durante 5 minutos.

Vuelva a conectar el aparato y hágalo funcionar, vacío, durante algunos segundos. Luego, llene el bol y

continúe.

Si el aparato no funcionara debidamente después seguir estos pasos, deje de usarlo y comuníquese con

un centro de servicio autorizado.

Page 32

32

CAPACIDADES MÁXIMAS

No exceda las cantidades máximas indicadas en la tabla a continuación:

ALIMENTOS CAPACIDAD

Frutas/verduras picadas o puré de frutas/verduras 475 g

Carne, pescado o marisco picado o molido 1 kg

Frutas, vegetales o queso cortados en rodajas 1.5 kg

UTILIZACIÓN DE LA CUCHILLA

1. Corte los alimentos en pedazos de 2.5 cm.

2. Instale la cuchilla y llene el bol. Cierre la tapa y cerciórese que los empujadores estén debidamente

puestos. Oprima y luego afloje el botón PULSE/OFF dos o tres veces. Permita que los alimentos

bajen al fondo del bol entre dos pulsos.

3. Utilizar la función de pulso evita sobreprocesar los alimentos. Inspeccione la textura de los

alimentos a menudo. Siga pulsando hasta obtener la consistencia deseada. Ciertos alimentos, como

la cebolla, suelen licuarse muy rápidamente. Averigüe su textura después de cada pulso.

• Para obtener resultados uniformes, utilice pedazos del mismo tamaño.

No procese cantidades de alimentos más altas que las recomendadas.

• Cuando procese líquidos, no pase la línea “MAX”.

CÓMO VACIAR EL BOL

1. Apague el aparato y espere hasta que la cuchilla esté completamente inmóvil antes de retirar

la tapa.

2. Retire el bol de la base. Si está bloqueado, sosténgalo por el asa y gírelo rápidamente de la derecha

a la izquierda.

3. Si está usando un disco, retírelo antes de vaciar el bol. Si está usando la cuchilla, puede dejarla

en el bol para vaciarlo. Utilice una espátula para vaciar el bol. NUNCA INTRODUZCA LOS

DEDOS EN EL BOL CUANDO LA CUCHILLA AÚN ESTÁ ADENTRO DE ÉSTE.

Page 33

33

USOS ESPECIALES DE LA CUCHILLA

Para picar alimentos duros como el ajo, encienda el aparato e eche los alimentos por la abertura en el

centro del empujador grande. Los alimentos pequeños como el ajo pueden introducirse enteros. Este

método es ideal para picar ajo, chalote y cebolla. Para moler carne o queso, utilice pedazos de 2.5 cm.

Oprima el botón PULSE/OFF durante 1–2 segundos, 3 veces seguidas. Después, oprima el botón ON

y procese durante 30 segundos adicionales.

Si el queso es demasiado duro como para cortarse con cuchillo, no intente picarlo. Esto podría dañar la

cuchilla o el aparato.

USOS DEL DISCO REBANADOR

Frutas y vegetales redondos (cebollas, manzanas, etc.)

Preparación: Corte la parte inferior de la fruta/verdura para que repose bien recto sobre el disco.

Introduzca la fruta/verdura en la boca de llenado, en lado cortado primero, y lo más posible hacia la

izquierda para que no mueva durante el procesado. Elije frutas maduras, pero firmes. Siempre retire las

colas, pepas, huesos y semillas. No es necesario quitar las pepas de los cítricos. Tampoco es necesario

pelarlos.

Para cortar pimientos en rodajas:

Córtelo del lado de la cola. Quite el corazón y las semillas con una cuchara. No corte el otro lado del

pimiento. Esto producirá rodajas más redondas y uniformes.

Frutas grandes (piña, melón, etc.)

Corte la fruta por la mitad y retire el corazón o las pepas. Corte cada mitad en pedazos más pequeños

si fuera necesario. Corte la parte de arriba y la parte de abajo.

Col, lechuga y otras verduras con corazón duro

Corte la parte de arriba y la de abajo, y luego córtela verticalmente por la mitad. Quite el corazón y

corte la verdura en pedazos más pequeños si fuera necesario, siempre verticalmente.

Si los pedazos nos caben en la boca de llenado:

introdúzcalos por la parte de abajo, la cual es ligeramente más ancha.

Posicione los alimentos según el resultado deseado:

horizontalmente para obtener rodajas largas, o verticalmente para obtener rodajas cortas. Apretuje los

alimentos en la boca de llenado, pero no la sobrecargue. Siempre use los empujadores para empujar los

alimentos. Nunca introduzca los dedos ni algún utensilio en la boca de llenado.

Nunca empuje el empujador con mucha fuerza. Emplee presión leve para empujar el queso y los

alimentos suaves (bananos, champiñones, fresas, tomates). Emplee presión moderada para empujar los

alimentos firmes (manzanas, apio, cítricos, papas). Emplee presión firme para empujar los alimentos

duros (zanahorias).

Page 34

34

Pequeñas frutas y hortalizas redondas (fresas, rábanos, champiñones, etc.)

Corte las frutas/hortalizas por ambos lados. Introdúzcalas en la boca de llenado, un lado cortando hacia

abajo. La boca de llenado podrá llenarse hasta 2.5 cm de la cumbre. Las primeras rodajas son perfectas

para servir de aderezo. Si desea que todas las rodajas tengan exactamente el mismo espesor, procese una

capa de frutas/hortalizas a la vez.

Frutas y vegetales largos (bananos, apio, calabacines, etc.)

Córtelos en pedazos más pequeños si fuera necesario. Córtelos por ambos lados. Mida los pedazos

con una regla o con el empujador antes de introducirlos en la boca de llenado. Posicione los pedazos

verticalmente en la boca de llenado, de manera que no se puedan mover durante el procesado.

Pequeñas cantidades

Introduzca los alimentos en el centro del empujador grande y empújelos con el empujador pequeño.

Retire el empujador pequeño del empujador grande. Introduzca el empujador grande en la boca de

llenado y sujételo. Corte los alimentos en pedazos más pequeños si fuera necesario. Si los alimentos

son largos y finos (por ejemplo zanahorias), colóquelos lo más posible a la izquierda para que no se

muevan. Si los alimentos son más ancho de un lado que de otro, córtelos por la mitad y júntelos en

pares de manera que cada lado tenga aproximadamente el mismo diámetro.

Habichuelas estilo francés

Corte las habichuelas por ambos lados para que quepan horizontalmente en la boca de llenado.

Escáldelas en agua hervida salada durante 60 segundos, y luego póngalas inmediatamente en agua

helada para detener la cocción. Una vez frías, escúrralas y séquelas. Dispóngalas horizontalmente en la

boca de llenado, llenando ésta hasta 2.5 cm de la cumbre. Utilice el disco rebanador. Asegúrese que el

empujador pequeño esté asegurado. Utilice el modo PULSE/OFF para cortar las habichuelas en lonjas

finas. Utilice el mismo método para cortar las zanahorias y los calabacines crudos en rodajas largas y

oblicuas.

Juliana de frutas o de vegetales

Preparar una Juliana consiste en cortar las frutas o los vegetales dos veces, para obtener tiras largas

y muy delgadas. Introduzca las frutas o los vegetales (papas, nabos, calabacines, manzanas, etc.)

horizontalmente en la boca de llenado. Utilice el modo PULSE/OFF para cortarlos en rodajas.

Obtendrá así rodajas largas. Retire las rodajas del bol. Introdúzcalas verticalmente en la boca de

llenado. Córtelas otra vez. Obtendrá tiras largas y delgadas.

CARNE Y AVES

Carne/aves cocinados

La carne debe estar muy fría. Corte la carne en pedazos más pequeños si fuera necesario. Para

preparar Juliana de jamón o Bolonia, enrolle varias lonchas juntas para formar rollos. Coloque cuantos

más rollos posible verticalmente en la boca de llenado. Para obtener resultados óptimos, utilice lonchas

cuadradas o rectangulares.

Page 35

35

Carne/aves crudos

Córtelos en pedazos suficientemente pequeños como para caber en la boca de llenado. Generalmente,

las pechugas deberán cortarse longitudinalmente por la mitad. Utilice pechugas deshuesadas y sin piel.

Envuelva los pedazos en una película de plástico y póngalos en el congelador. Una vez semi-congelada

(está dura al tacto, pero se puede perforar fácilmente con la punta de un cuchillo afilado), está lista.

Coloque los pedazos horizontalmente o verticalmente en la boca de llenado, según los resultados

deseados.

Salchichas, salami, etc.

Congele las salchichas tiernas hasta que estén duras al tacto pero que se puedan perforar fácilmente

con la punta de un cuchilla afilado. No es necesario congelar las salchichas duras. Introduzca las

salchichas una por una en el centro del empujador grande. Corte las salchichas grandes en pedazos

suficientemente pequeños como para caber en la boca de llenado. Disponga los pedazos verticalmente

en la boca de llenado, de manera que no se muevan durante el procesado.

QUESO

Quesos duros como el queso suizo y el queso Cheddar.

Corte el queso en pedazos suficientemente pequeños como para caber en la boca de llenado. Congélelo

hasta que esté duro al tacto pero que se pueda perforar fácilmente con la punta de un cuchilla afilado.

Llene la boca de llenado y procese, empujando suavemente.

IMPORTANTE: Nunca intente cortar queso suave en rodajas. Solamente procese queso duro, como

el queso Parmesano. No utilice pedazos de más de 9 x 2 x 10 cm. El queso debería estar muy frío. Le

aconsejamos que refrigere el queso durante 1 hora antes de rebanarlo. No intente rebanar mozzarella.

Esto podría dañar el aparato.

USO DEL DISCO RALLADOR

Lave todos los alimentos antes de procesarlos. Pele las frutas/verduras si fuera necesario. Quite las

pepas, pepitas y semillas grandes. Corte los alimentos en pedazos más pequeños si fuera necesario.

Coloque los alimentos en la boca de llenado deseada, horizontalmente para obtener pedazos largos

o verticalmente para obtener pedazos cortos.

Nunca intente rallar queso suave. Solamente ralle queso duro, como el queso Parmesano. No utilice

pedazos de más de 9 x 2 x 10 cm. El queso debería estar muy frío. Le aconsejamos que refrigere el

queso durante 1 hora antes de rallarlo. No intente rallar mozzarella. Esto podría dañar el aparato.

Para evitar que el motor sobrecaliente, se aconseja empujar, y luego aflojar el empujar sucesivamente,

hasta que el queso esté rallado. Rallar queso cansa más el motor que otras tareas. Por eso es preferible

no ejercer presión continua.

Este robot puede rallar hasta 4.5 kg de queso en menos de 5 minutos. Permita que el aparato descanse

durante 5 minutos después de 5 minutos de funcionamiento continuo.

Vacíe el bol antes de que el queso alcance la capacidad máxima.

Page 36

36

USO DEL DISCO TRITURADOR

• Lave todos los alimentos antes de procesarlos. Pele las frutas/verduras si fuera necesario. Quite las

pepas, pepitas y semillas grandes. Corte los alimentos en pedazos más pequeños si fuera necesario.

Coloque los alimentos en la boca de llenado deseada, horizontalmente para obtener pedazos largos,

o verticalmente para obtener pedazos cortos.

• Nunca intente triturar queso suave. Solamente use queso duro. Puede triturar mozzarella, pero debe

estar muy fría. No utilice pedazos de más de 2 x 9 x 10 cm con el modelo WFP11S o 2,5 x 9 x 10 cm

con el modelo WFP14S. Refrigere la mozzarella durante 1 hora antes de triturarla. Utilice la función

de pulso para triturar queso.

• Vacíe el bol antes de que el queso alcance la capacidad máxima.

Page 37

37

RESOLUCIÓN DE PROBLEMAS

Esta sección describe los problemas más comunes. Si esta lista no soluciona su problema, por favor

comuníquese con su distribuidor local. Consulte la lista de los centros de servicio autorizados, proveída

con el aparato.

El aparato no se enciende

• Desconecte el aparato y enchúfelo en otro tomacorriente.

• Oprima el botón ON .

• Asegúrese que el bol esté debidamente instalado, que la tapa esté bien cerrada y que las anclas estén

encajadas.

El aparato se apaga durante el uso

• Puede que el motor haya sobrecalentado. Véase la sección “Dispositivo de protección del motor”.

• Apague y desconecte el aparato.

• Retire el bol del bloque-motor.

• Vacíe el bol.

• Permita que el aparato enfríe durante 5 minutos.

• Vuelva a instalar el bol, cierre la tapa y haga funcionar el aparato, vacío, durante unos segundos antes

de volver a llenar el bol.

El aparato no alcanza la velocidad máxima

• Vacíe el bol e intente procesar menos alimentos a la vez.

Si el aparato aún no funciona correctamente:

• Averigüe que el tomacorriente está funcionando.

• Averigüe que el cortacircuito está encendido.

• Averigüe que el fusible no está quemado.

• Comuníquese con el distribuidor local.

El aparato produce chispas o humo

• Apague y desconecte el aparato. Comuníquese con un centro de servicio autorizado.

El aparato rechina

• Apague y desconecte el aparato. Averigüe que la cuchilla no está tocando el bol.

• Si la cuchilla está tocando el bol, comuníquese con el distribuidor local.

Page 38

38

LIMPIEZA

Limpie el aparato y todos los accesorios antes del primer uso y después de cada uso. No utilice

detergentes abrasivos en ninguna parte del aparato. Restriegue el árbol motor con un cepillo pequeño.

Lave, enjuague, desinfecte y seque el bol, el bol para procesado continuo, las tapas, los empujadores,

los discos y la cuchilla antes del primer uso y después de cada uso, al menos que los vuelva a utilizar

inmediatamente. Todos los accesorios son aptos para lavavajillas.

Seque todos los accesorios antes de ensamblarlos otra vez.

El sello hermético de la tapa es removible y debe limpiarse regularmente. Notará tres pequeños orifi-

cios en el borde de la tapa. Para retirar el sello, simplemente introduzca un objeto fino como un palillo

o un clip en los orificios y empuje el sello fuera de la ranura. NO UTILICE OBJETOS AFILADOS.

ESTO PODRÍA LASTIMAR EL SELLO. Lave el sello en agua jabonosa tibia, y luego enjuáguelo y

séquelo. Una vez seco, inserte el borde redondeado del sello en la ranura, apretando todo alrededor con

los dedos. Asegúrese que el sello esté bien puesto. Véase el dibujo a continuación.

Nota: La solapa del sello debe apuntar hacia abajo y dentro.

Restriegue la cuchilla y los discos con un cepillo duro antes de lavarlos. Manipule los discos y la

cuchilla con sumo cuidado. Sus filos son muy afilados.

Para lavar los accesorios a mano, le recomendamos que utilice soluciones limpiadoras a base de

detergente sin espuma y soluciones desinfectantes con una concentración mínima de cloro de 100 ppm.

Se podrán usar las soluciones siguientes o sus equivalentes:

SOLUCIÓN PRODUCTO PROPORCIÓN DE DILUCIÓN TEMPERATURA

Para limpiar *Ajax

®

en polvo 2 cucharadas Caliente 46 °C (115 °F )

por 9.5 litros de agua

Para enjuagar Agua Tibia 35 °C (95 °F )

Para sanear **Cloro ordinario o Clorox® 1 cucharada Fría 10 °C (50 °F)

por 4 litros de agua

*Ajax® es una marca registrada de Colgate-Palmolive Company.

**Clorox® es una marca registrada de Clorox Company.

Page 39

39

Limpieza del bloque-motor

Limpie y sanee el bloque-motor antes del primer uso y después de cada uso. Desconecte el aparato y

limpie la base con una esponja o un paño ligeramente humedecido con detergente líquido. Después,

enjuague la base con una esponja o un paño ligeramente humedecido con agua. Estruje bien la esponja

o el paño para evitar que agua penetre adentro del aparato.

NUNCA SUMERJA EL BLOQUE-MOTOR EN AGUA U OTRO LÍQUIDO

Permita que la base seque antes de usar el aparato.

Nunca utilice detergentes abrasivos en ninguna parte del aparato.

GARANTÍA LIMITADA

GARANTÍA LIMITADA DE CINCO AÑOS (MOTOR)

GARANTÍA LIMITADA DE DOS AÑOS (MATERIAL Y FABRICACIÓN)

Waring Commercial garantiza el motor de este aparato contra todo defecto de materiales o

fabricación durante cinco años a partir de la fecha de compra, siempre en cuando el aparato haya

sido usado con alimentos, líquidos no abrasivos (a excepción de detergentes) y semi-líquidos no

abrasivos, y que no haya sido sujeta a cargas que excedan su máxima capacidad. Todas las otras piezas

del aparato están garantizadas durante un periodo de dos años a partir de la fecha de compra.

Bajo esta garantía, Waring Commercial reparará o reemplazará toda pieza que, tras estar inspeccionada

por nuestro servicio posventa, demuestre defectos de materiales o fabricación, siempre que el producto

se regrese a un centro de servicio autorizado o se entregue con franqueo pagado a: 314 Ella T. Grasso

Ave., Torrington, CT 06790.

Esta garantía: a) no se aplica a ningún producto desgastado, defectuoso, dañado o roto debido a uso,

reparaciones/servicio realizados por personas no autorizadas, o abuso, mal uso, sobrecarga o daños

intencionales; b) no cubre daños incidentales o consecuentes de ningún tipo.

Esta garantía es válida solamente para los aparatos comprados en los Estados Unidos y el Canadá y

reemplaza todas las demás declaraciones expresas de garantía. La garantía de los productos Waring