Page 1

MANUAL

CARL WALTHER. WORKS FOR SPORTS-AND HUNTING WEAPONS. ULM DONAU . GERMANY

Page 2

The

Police Pistol Models PP and PPK hove, by virtue of their unique construc-

tion, proved themselves to be the World’s safest and most dependable handguns.

The absolute faith in these two products induced specialists both at home and abroad to

demand

a pistol of a similarly recognized and approved construction which would retain

principle of a

light

and at

powerful

Cal. 9 mm

9 mm

ounces with all

stantaneous readiness, and easy handling

of

appropriate considerations was

which combines a phantastically low

advantages of a modern handgun

and which allows the

new

Model P

of only a

over

absolute safety, in-

of a considerably

Cal.

more potent cartridge. This pistol stands without rival.

All

component parts are

They are

by means of

most

date production methods involving the use of modern machinery under strictest

vision. As in the

very best materials are used in the production of

The pages of this little brochure will give

description of the various

of any other of the

Model P

most detailed and therefore very useful

relating to the pistol Model P 38.

products, only

Page 3

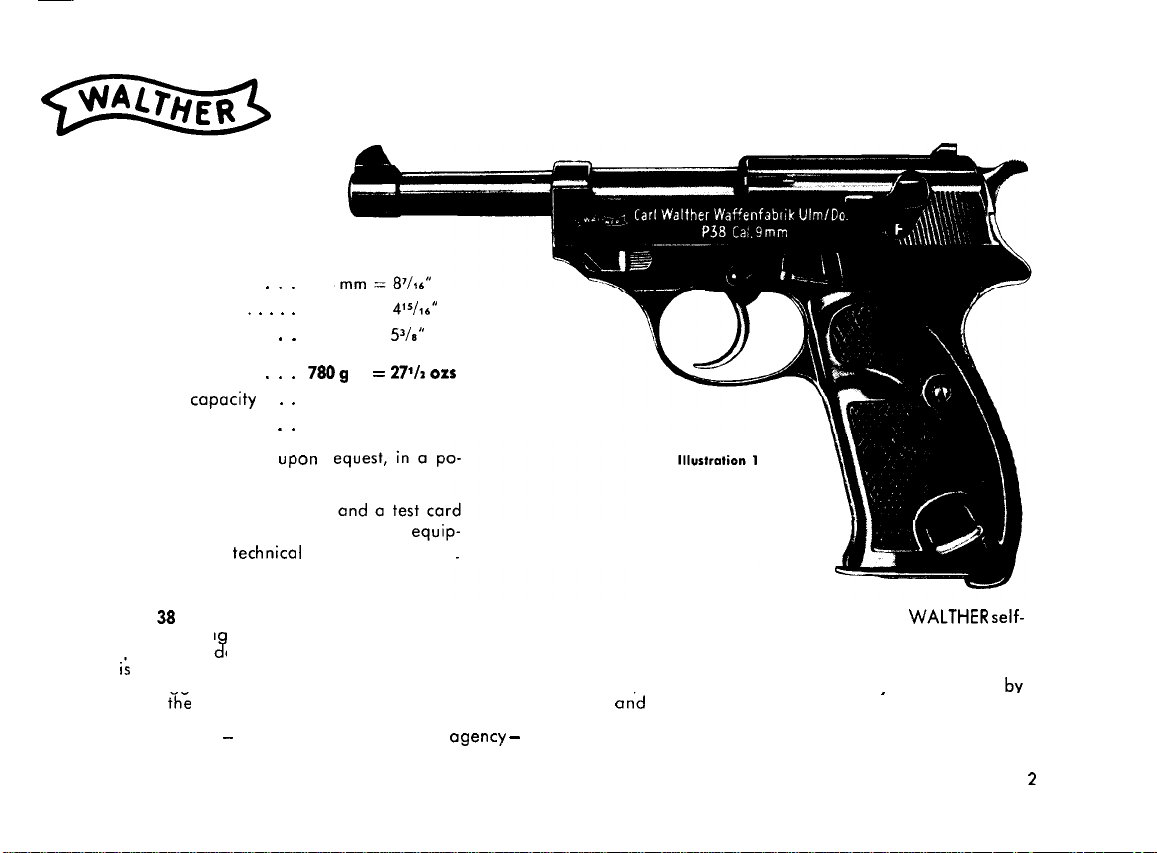

General Data:

Auto Pistol Model P 38 Cal. 9 mm Parabellum

Overall Length

Length of Barrel

Height of Pistol

Total Weight

Magazine capacity .

Standard Finish

The pistol can be supplied, Up

lished and blued finish.

A spare magazine, a cleaning

are supplied with every pistol.

ment also includes a

delivered in a stout carton.

The pistol P

loading pistols havin an external hammer, and the constant readiness of a revolver makes the enormous odvantages of

these weaoons obun

The P 38

to a tension triaaer and which has a distinctive pressure point. The P 38, like the models PP and PPK, may be fired by

merely pulling

Cartridges with faulty primer cops can be fired by pulling the trigger repeatedly.

A bulge in the borrel

mounted in on open and unencumbered manner. The pistol is thus alwoys ready for instant use.

has an external hammer. The combination of o perfect action design, mode evident in the

o double-actidn, locked-breech, semi-automatic pistol. It is fitted with on external hammer which is connected

trigger. It may, moreover, readily be co’rried loaded

214

125 mm =

136 mm =

8 Cartridges

set block (matted).

r

rod,

The complete equip-

description and is

antlv manifest.

caused by some irregular agency

uncocked.

will not impede the functioning of the P 38, since the barrel is

Page 4

An entirely new method has been adopted in the construction of the safety device’of the P 38.

As may be well known, there is always a certain amount

of danger inherent in any loaded and cocked firearm,

even though the latter may be rendered ‘safe’ by means

of the safety lever. Any sudden mechonicol

fracture of on

component con cause on accidental

or a

discharge.

In the P 38, this basic evil has been remedied: the rotary

safely

the cocked stage.

causes the hammer to become uncocked,

does not make the action mechanism safe in

application of the safety catch

and that without any danger to the user. When the safety catch is moved to the ‘Safe’ position, the firing pin becomes

first. Immediately following this, the action mechanism is

automatically

and the hammer drops harmlessly

and the pistol is completely uncocked.

Un-cocking of the hammer by means of applying the

fety catch, preceded by the locking of the firing pin and

the connection with the tension trigger, make the P

truly ideal service pistol.

Since the pistol is thus always uncocked but nevertheless

always ready for immediate use, the hammer spring is

therefore not subject to fatigue and weakening.

The P 38 can be dismantled within a few seconds and

without using any tools. Component parts

drop out.

Any unnecessary operating of the trigger mechanism

should be duly avoided, and the hammer should not be

allowed to drop while the

is empty. In any instance of ‘dry’ shooting practice, a dummy cartridge

should be introduced into the chamber first.

It is an essential rule for every shooter that despite the

fully guaranteed safety of the weapon, the pistol should

always be held so that the muzzle points downwards while

the

is not being actually used.

a

3

Page 5

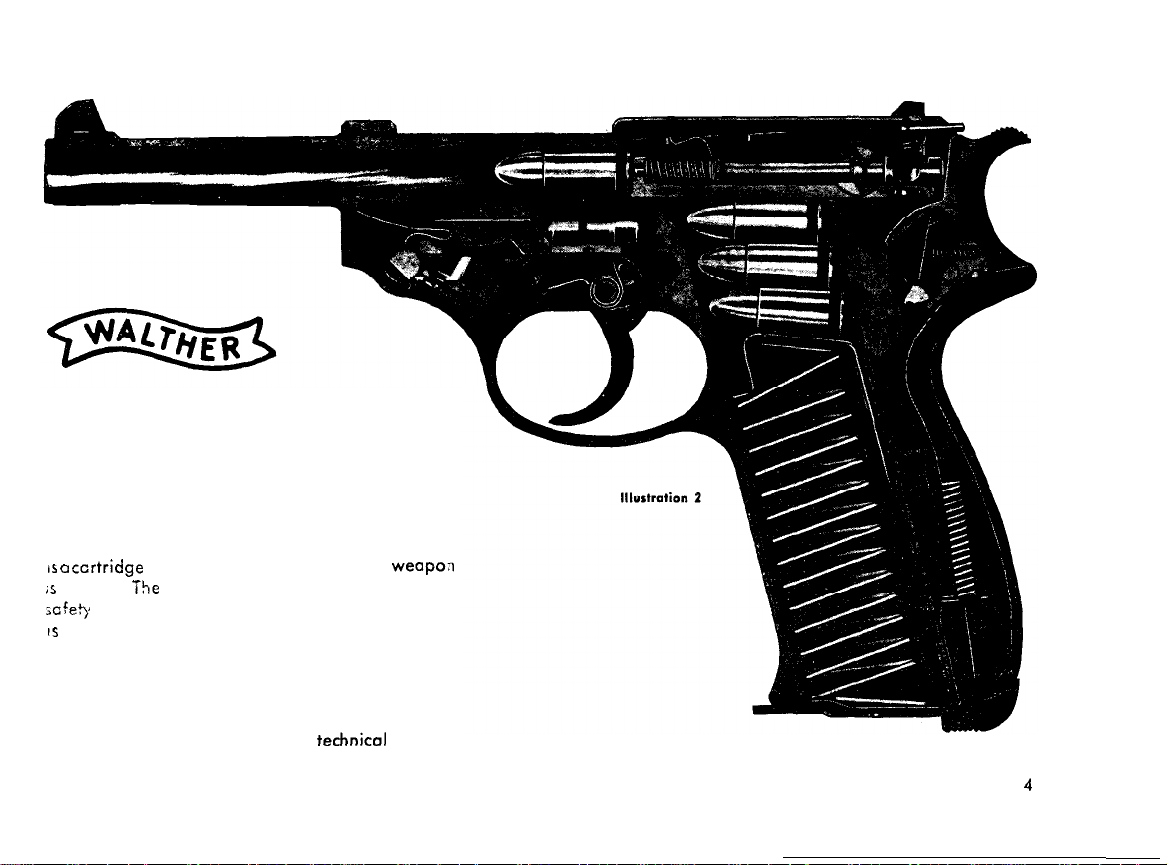

P 38 Auto Pistol

Cal. 9mm Parabellum

in

longitudinal section

In this Illustration, the signal pin immediately above

the hammer is clearly visible. It indicates that there

ccrtridge in the chamber. i. e., that the

loaded. The signal pin remains visible when the

nevertheless ready for action. Illustration 4 shows

how the pistol is fired by merely pulling the trigger

(in ‘Double-action’ shooting).

A list of the individuol component parts moy be

found on pages 17 and 18 of this

tion.

descrip-

Page 6

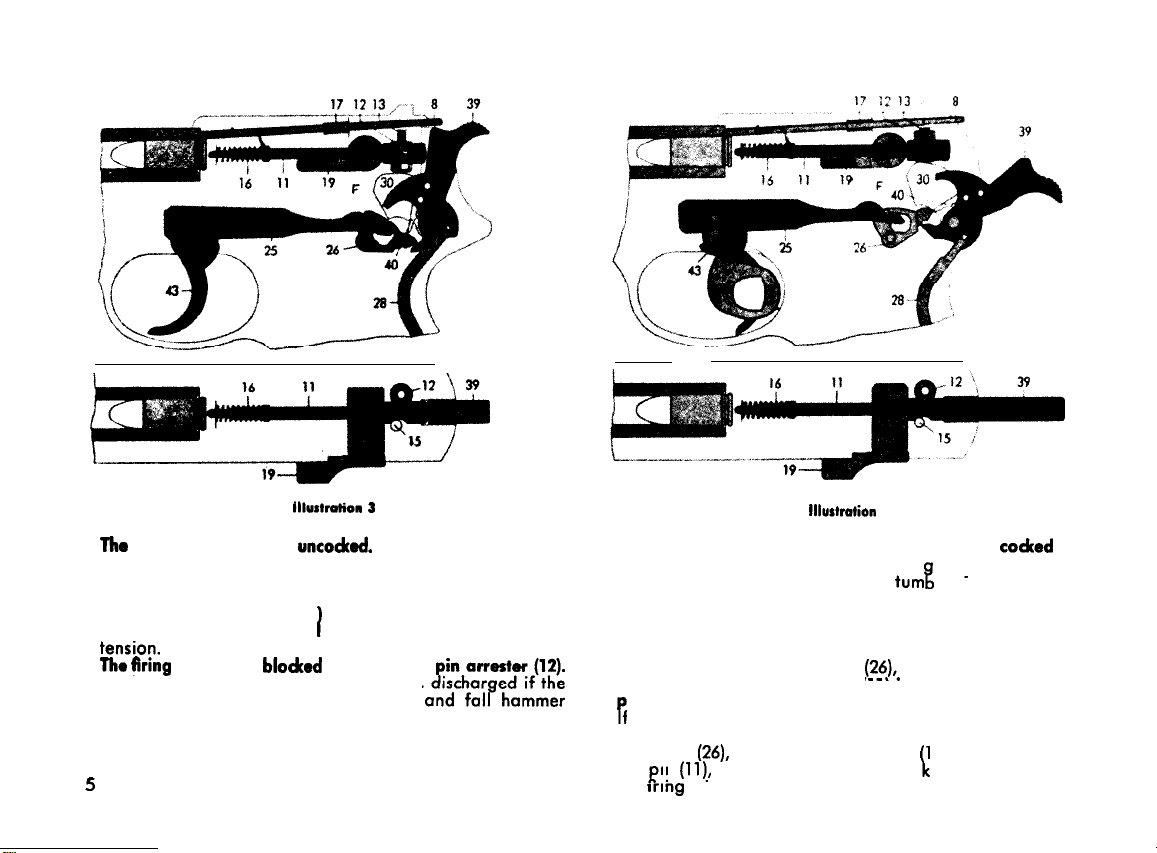

Graphic Description

4

pistol is loaded and

The pistol is thus ready for instont use (‘Double-Action’).

Automatic Safety

The pistol, though uncocked and loaded, moy thus be

fired. The safety lever (19

weopon is, OS shown in II ustration

The live round in the chamber cannot be

pistol should occidentally be dropped

first on the floor. The signal pin (8) can both be felt and

seen, and indicates that there is a cartridge in the

&amber (Illustration 3).

pin (11) is

The safety lever is ‘off.

is in the ‘Fire’ position. The

3, entirely free from

by the firing

The pistol is loaded, safety lever ‘off’, and

‘pulling through’ (Double-Action

here in the moment in which the

released by the sear).

Operating the Trigger

The trig er (43) has been pulled back until the tumbler

edge (40 of the hammer (39) barely rests on the sear

edge of the tensioning piece

tion 4.

f the trigger (43) is now pulled back a little further, the

sear (40) of the hammer slides off the edge of the cocking piece

ing

the

3

Until then, the firing pin (11)

in

arrester 92).

in

the firing pin arrester 12) releases the fir-

and the hammer (39) stri

pm (11).

trig er motion, shown

ler IS about to be

as shown in Illustra-

IS

blocked by the firing

by

Page 7

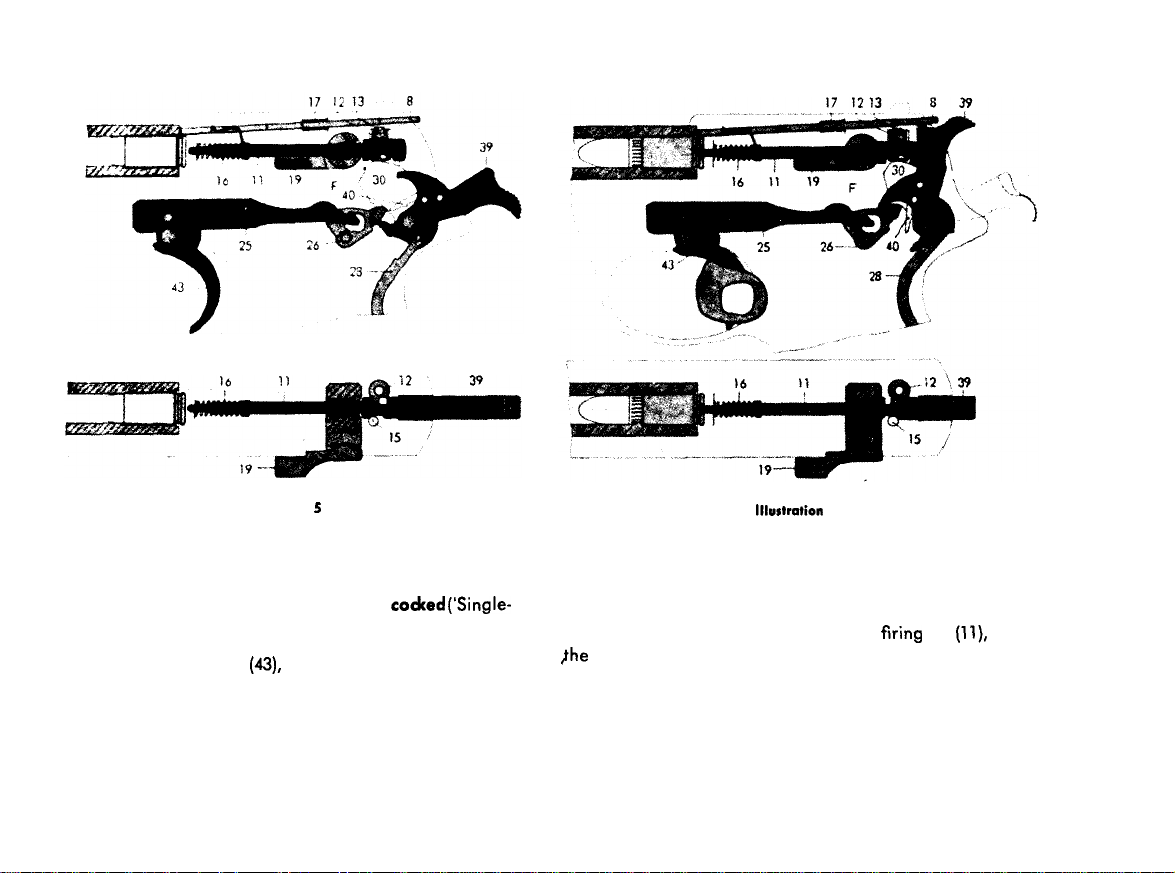

Illustration

6

Pistol loaded and cocked, safety lever ‘Off

Operating the trigger when the hammer is

Action’).

Upon pulling the trigger

the cocked hammer (39) is

releosed from its rearward position by the lifting motion

of the cocking piece (26) and strikes the unlocked firing

pin (11).

Pistol at the moment of firing

Process of firing

The hammer (39) strikes the unlocked

pin

ond

indenting the primer cap, thus igniting the powder charge

and thereby causing the resultant pressure gases to drive

the bullet out of the cartridge case.

6

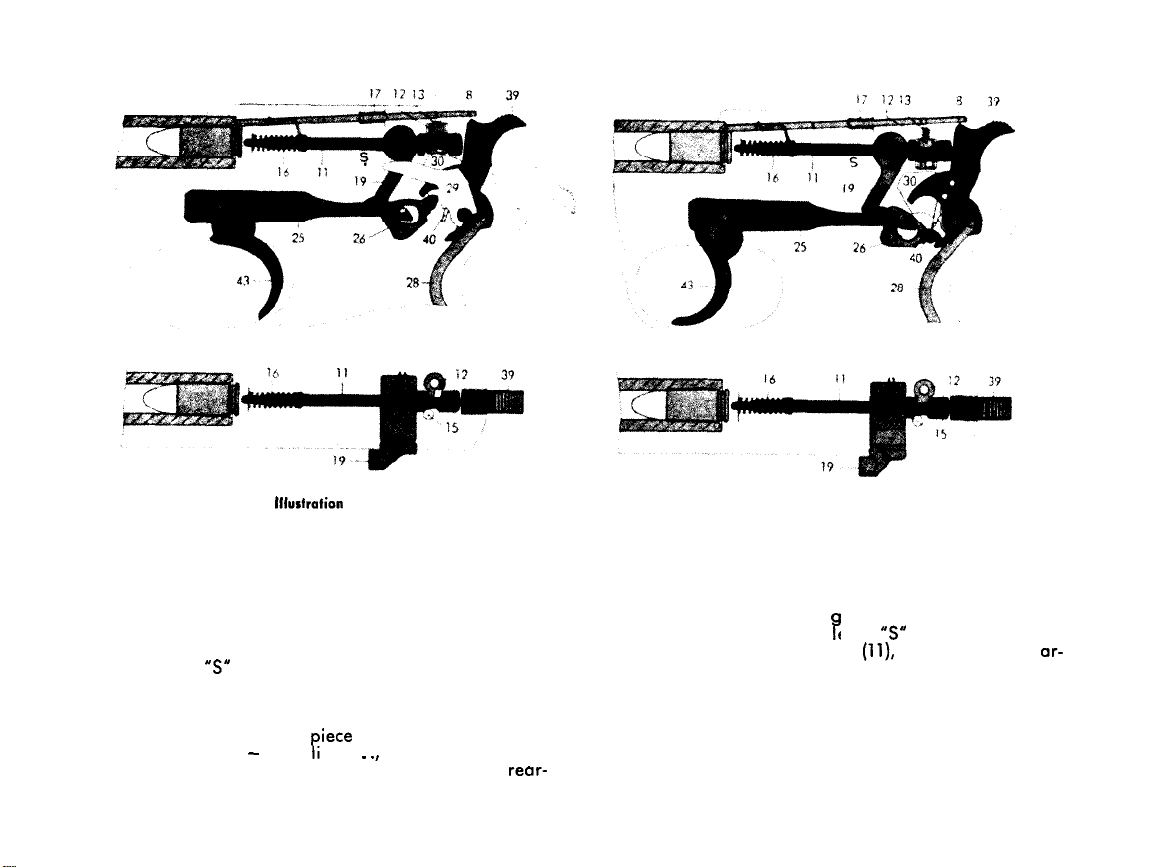

Page 8

7

illustration 8

Pistol loaded, safety lever ‘Off

Operating the safety lever when the hammer is cocked.

The hammer (39) has been drawn back, and the arm is

thus ready. The protruding signal pin (8) indicates that

there is a cartridge in the chamber.

If for some reason it is not intended to fire the round, the

safety lever (19) should in such case be moved downwards

until the letter

becomes clearly exposed. This application of the safety lever (19) causes the firing pin (11) to

be blocked (see arrows). Moreover, during the last third

of the lever travel the hammer (39) becomes disengaged

by the lifting of the cocking

(See also: page 10,

‘Hand ing’ . and Illustration 14.)

(26) and drops forward.

The trigger moves backwards and remains in the rear-

most limit of its travel.

Pistol loaded, safety lever ‘Off

Operating the safety lever when the hammer is uncodced.

The firing pin (11) remains blocked by the automatic safety

effect of the firing pin arrester (12) when the hammer is in

an uncocked state. By movin

wards, thereby exposing the etter

lock is applied to the firing pin

the safety lever (19) down-

fully, an additional

as shown by the or-

rows in Illustration 8. The trigger remains in its normal

forward position.

Page 9

Directions for the Use and Handling of the Pistol P 38

Illustration 9

loading

Hold the pistol with the right hand and render it safe by

turning the safety lever downwords to the fullest extent

of its travel, thus fully exposing the letter

the mogozine

left thumb. The eft index

from the grip, as shown in the above Illustration 9.

releasin the ma azine catch with the

b

wtt

draws the magazine

Remove

10

Filling the magazine

Hold the magazine with the left hand and push the cartridges

depressing the feeder platform wtt the cartridge rim. The

magazine holds 8 cartridges. When emptying the mogo-

zine, push the cartridges

finally expelled by the upwor

spring. The 7 holes in the side of the magazine serve to

facilitate chedcing the contents of the magazine.

Any forceful jamming-in or tearing-out during either of

these two respective operations would cause damo

the magazine and consequently lead to functiona

orders of the pistol.

base first

under the ma

ozine lips by carefully

forward until they are

thrust of the magazine

e to

8

Page 10

11

12

Introducing the first cartridge into the chamber

After inserting the full

ma

azine into the pistol grip, hold

the pistol with the right 3,and. The pistol must still be

‘safe’. Next, grip the slide by the ribbed rear end with the

left hand and pull fully backwards

then let go. This

operation causes the first cartridge to slip into the chamber. The hammer, however, does not become cocked by

this process, as the safety lever is still ap

mer of the P

therefore cannot be co

lied and the ham-

ed either by hand

or else be pulling the trigger through. To make the pistol

ready for immediate use, push the safety lever upwards to

cover the letter

completely and the letter

(‘Fire’)

becomes visible. The weapon will still remain uncocked,

since the firing pin is still blocked. The pistol is nevertheless ready for firing.

9

‘Single-Action’ shooting

In tar

et shooting, it is recommended to cock the hammer

with

e right thumb as shown in Illustration 12. With a

little practice, this operation should become fairly

eas

It offers the advantage of having only a comparafive y

slight amount of resistance (trigger pressure) to overcome.

in its turn increases the accuracy in shooting quite

considerably.

Page 11

Illustration 13

14

‘Double-Action’ shooting

Firing fhe first shot by means of the ‘single-action’ method

is, of course, chiefly enacted in practice and competition

shooting at targets, while ‘double-action’ shooting occurs

mainly under active service conditions. In the latter event,

the hammer is cocked by simply pulling the trigger through

its entire length of travel for the first shot.

Should for reasons of faulty ammunition the pistol fail to

fire in such exceptional cases, the trigger should be pulled

again. A second impact of the firing pin on the primer cap

will as a rule cause even a defective round to detonate.

Operating the safety lever

Hold the weapon with the right hand, and place the right

index finger along the side of the trigger guard. The right

thumb grips the hammer, while the left thumb pushes the

safety lever downwards. The hammer can now slowly

return to its resting position, as shown in illustration

Care should be taken that the muzzle of the pistol paints

downwards.

Page 12

Illustration

Illustration 16

The emptied magazine

When the last round in the magazine has been fired, the

slide stays open. If shooting is to be continued, remove

the empty magazine and insert the next full magazine.

Pull the slide

lightly and then let it glide forwards.

This process will cause the first round to be introduced

into the chamber.

This cartridge may also be fed into the chamber without

using the left hand: by simply depressing the catch lever

with the right thumb. If it is not intended to continue

shooting, apply the safety lever (see page 10, Illustration 14).

11

Unlooding

If the pistol P 38 is to be unloaded after a live round has

been lodged in the chamber, put the safety lever into the

Safe’ position (see page 10, Illustration

withdraw the

magazine, and remove the cartridges from the latter. Now

pull the slide fully back (as shown in Illustration 16). The

cartridge will be extracted from the chamber by this operation and drop out.

Page 13

Illustration 17 lllustmtion

18

Dismantling

insert an empty magazine. Hold the pistol with the right

hand and move the safety lever to ‘Safe’ (see page 10,

Illustration 14). Next, pull the slide back until it stays open,

and remove the magozine. Then turn the barrel catch lever

downwards with the left thumb until it engages with an

audible ‘click’.

If an empty magazine is not available, the retracted slide

may be made to stay open by pushing the catch lever upwards.

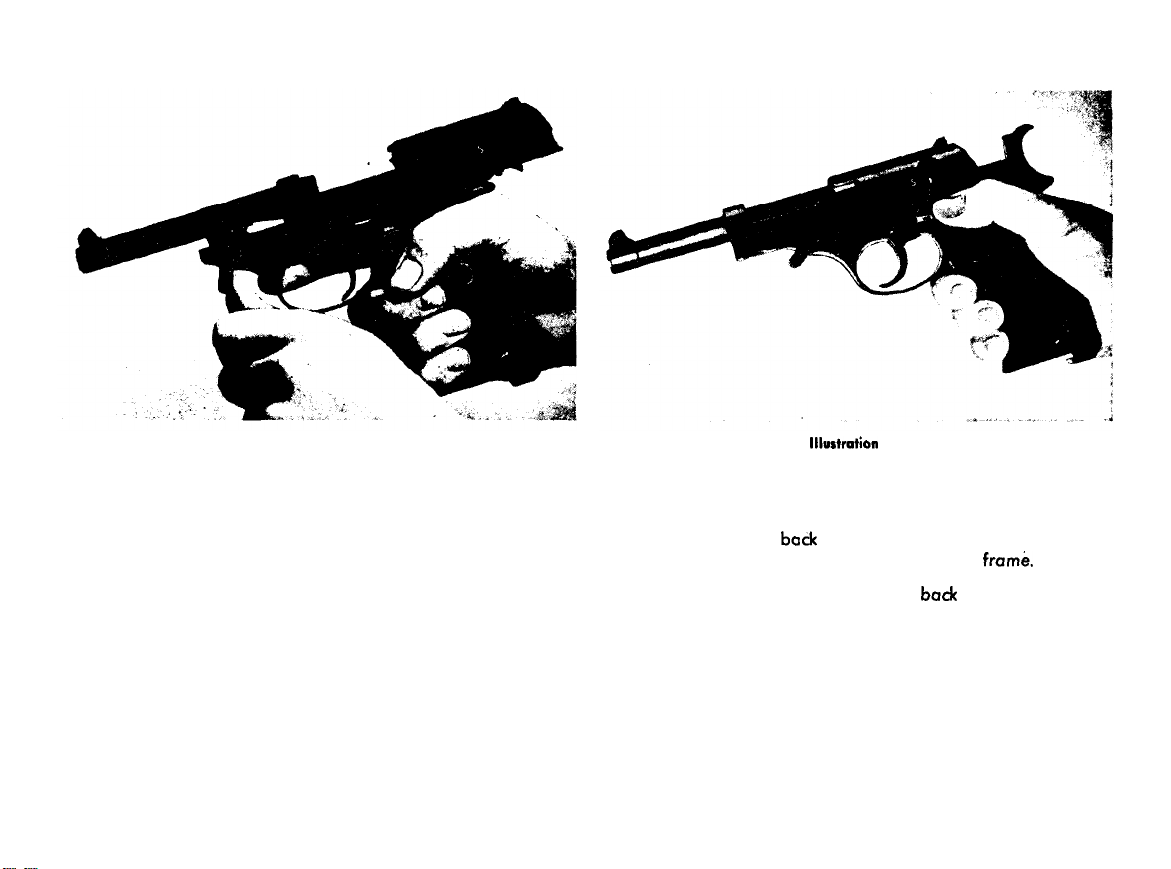

Dismantling

The barrel catch lever having been pushed down, the slide

should now be pulled

slightly and then be allowed

to move forward so as to be separated from the

Alternatively, the slide may be drawn

with the left

hand while the right thumb depresses the breech catch

lever. Following this, the slide may be allowed to glide

forward and off the frame unit.

12

Page 14

19

Illustration

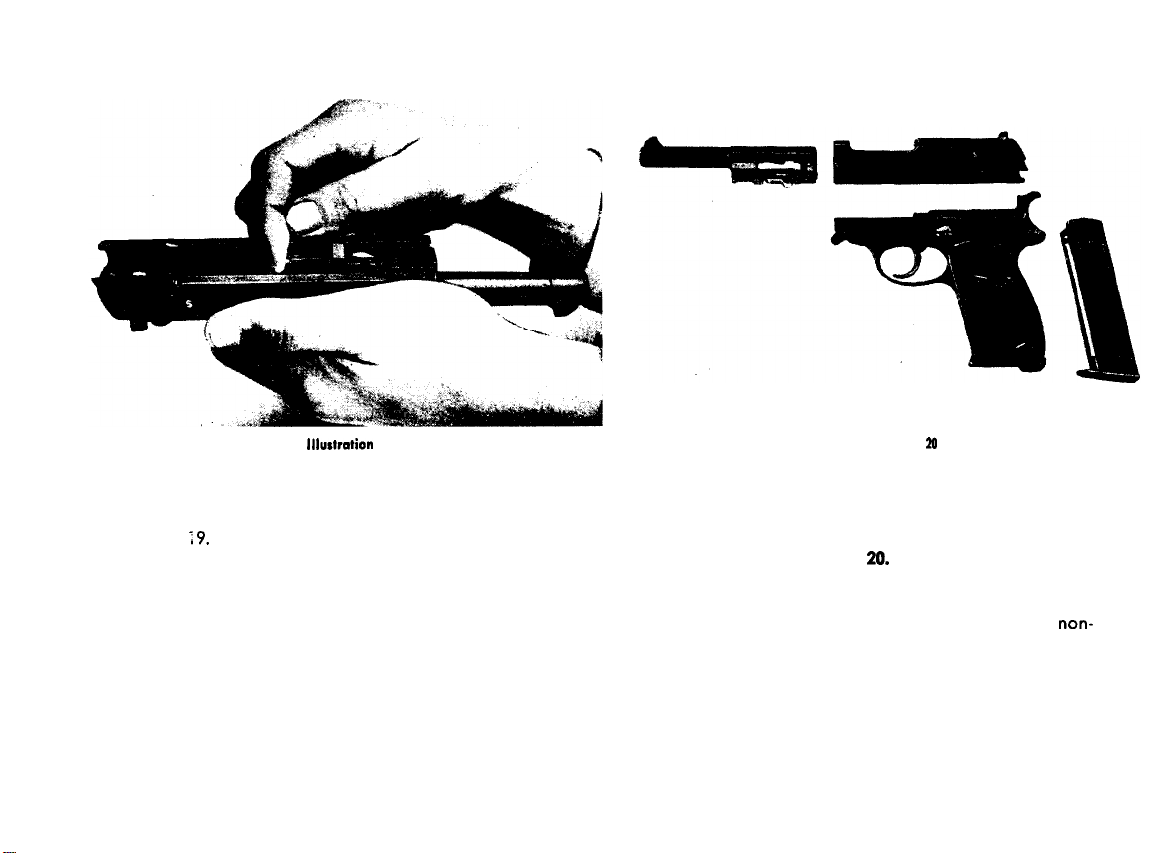

Separating the barrel from the slide

Hold the slide upside-down in the left hand as shown in

lilustration

Press the small internal locking bolt towards the muzzle end with your right index finger. The

barrel can then be readily taken out of the slide unit.

13

Cleaning the component parts

The pistol has now been partly stripped and split up into

its four main units: barrel, slide, frame (grip), and magazine, as shown in Illustration

These components can

now be cleaned and oiled.

The barrel, the grooves of the slide, and the grip unit

should be lubricated with a good, acid-free, and

resinous oil, and the barrel should then be wiped dry

again.

Any further dismantling should be carried out only if there

is an uncommonly great amount of dirt present in these

parts. Any such work, however, should be entrusted to

skilled craftsmen.

Page 15

Illustration 21

Illustration 22

The re-assembling of the

out in the opposite order to

on is a propriately carried

of

In order

to avoid damage during this process, it IS important that

the following explanations and Illustrations be observed:

It is particularly important to realize that re-assembling

can be carried out only while the pistol is in a ‘safe’ state,

i. e., the hammer must be ‘down’. First, re-fit the barrel to

the slide. When attochin this re-assembled unit to the

grip unit, ensure that the

IS pressed upwards with the left thumb in the manner

bolt below the chamber

shown in Illustration 21. The slide unit can now be freely

pushed back over the frame to without any fear of damage to the recoil springs, the or the frame.

The three protruding parts

trip lever’

must be

ejector, release lever, and

ushed downwards so as to permit

the slide to run freey back over the top of the frame

(the three components in question are indicated by ar-

rows in lliustration 22).

14

Page 16

Assembling

Insert the empty magazine into the grip, then pull the slide

bock until the latter engages and stays open. Now push

the barrel catch lever bath into its normal locking position

with the left thumb, as shown in Illustration 23.

15

Finally, push the breech locking lever downwards with the

right thumb and at the same time pull the slide back with

the left hand, then let the slide move forward.

The P 38 is now once again in its complete original state,

safe, and ready for further service.

Page 17

Test Target with test group of the WALTHER Self-loading

Pistol P 38, Cal. 9 mm Parabellum.

Ranges and Performance:

Sighting range . . . . . . . .

50 m = 54.681 yds.

Range of shot, approximately 1,600 m = 1,750yds.

Depth of penetration:

Range

Material

25 m

17.34 yds

50 m

i4.68 yds.

200m

18.72 yds.

ins.

35 cm

ins.

25 cm

ins.

23 cm

9 ins.

cut

clean

through

through

Loose soil

Sand

Pine wood

Sheet iron, 2 mm (0.0787”)

thick, hit at an angle

of 90 degrees

36 cm

14 ins.

26 cm

23 cm

9 ins.

cut

clean

through

Ammunition

The ammunition for the P 38 is the pistol cartridge

Calibre 9 mm Parabellum.

31 cm

12 ins.

21 cm

ins.

17cm

ins.

cut

clean

16

Page 18

14

18

54

Illustration 26

Page 19

The Components of the

Pistol P 38

UNIT I: Barrel

Barrel

Front sight

Locking-piece

Locking pin

V-spring

UNIT II: Slide

Slide body

Cover

Signal-pin

Rear sight

Extractor

Firing pin

Firing pin

Spring to No. 12

Extractor pin

Limit stop pin

Firing pin spring

Signal pin spring

10

11

12

13

14

15

16

17

18

Sofety lever unit

Rest pin

Rest pin spring

UNIT Ill: Grip

Frame

Rest pin

Rest pin spring

6

7

8

9

Trigger connector

Cocking-piece

Barrel catch lever

Striker rod

Relief piece

Release lever

Ejector

Recoil spring guide pins

Hammer pin

Cocking piece pin

Recoil springs

Striker rod spring

Trigger rod spring

19

21

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

Cocking piece spring

Hammer

Hammer trap

Pins to Nos.39 & 40

Hammer trap spring

Trigger

Sleeve

Trigger spring

Magazine holder

Catch lever

Grip plate, right

Grip plate, left

Grip plate screw

UNIT IV: Magazine

Magazine casing

Feeder platform

Magazine bottom lock

Magazine bottom

Feeder spring

41

42

43

44

45

46

47

48

49

51

52

53

54

55

18

Page 20

Illustration 27

Conversion Unit Cal. 4 mm (M 20)

for the Pistol P 38

with Steel Adaptor

comprising:

Insertion barrel (liner) with spring washer and

locking nut

3 steel adaptor

Ejector tool

Cleaning rod

Additional steel adaptor cartridges supplied upon request

and against payment of extra

cost.

Conversion Unit Cal. 4 mm (M

with loading tool, for the Pistol P 38

comprising:

Insertion barrel (liner) with spring washer and

lock nut

Loading Tool

Ejector Tool

Cleaning Rod

19

28

Page 21

Instructions for the use of the Conversion Units

(as shown in Illustrations 27 and 28)

Conversion units, developed for the world-renowned

and having proved a great success, are now also available for the pistol model P 38.

These conversion units make it possible to use the small Cal. 4 mm (M 20) cartridges for all

indoor practice shooting.

Fitting

Remove the slide in the usual manner (see page 12). Insert the conversion barrel (liner)

into the barrel of the P 38, apply the spring washer and the lock nut, and tighten up with

the aid of the ejector tool by applying the latter to the groove.

Shooting practice by using the steel cartridge adaptors

Insert a Cal. 4 mm cartridge into each steel adaptor, then feed the latter into the magazine in the normal manner, and insert the magazine into the grip of the P 38. Next, feed

a round into the chamber as demonstrated in illustrations 10 and 11. The pistol is now

ready for use. After firing the shot, pull the slide back with the left hand, thereby ejecting the steel adaptor containing the empty case from the chamber. The next ‘live’ adaptor

may now be brought into the chamber by letting the slide move forward, thus closing the

breech.

Shooting practice with the aid of the loading tool

Remove the magazine from the P 38, pull the slide fully back, and push the barrel catch

lever (breech lock) upwards. The slide will now stay open. Now insert a 4 mm

into the chamber by using the loading tool, and release the slide by pulling the latter

slightly back. Let the slide move forward and close the breech. The shot may now be fired.

After discharging the round, open the breech and push the empty case out of the chamber

by means of the ejector tool. The empty case will readily drop out through the magazine

shaft.

pistol models PP and PPK

20

Page 22

Holster for the Pistol P 38

Cal. 9 mm Parabellum

Made of harness leather,

dull black finish outside and

smooth inside. External

magazine pocket. Two loops

for attachment to a belt.

Page 23

Poge

Illustration

Page

General reference:

Description of pistol

Sectional view of pistol

Graphic Descriptions:

Automatic

‘Double Action’ shooting

‘Single Action’ shooting

Process of firing

Operating the safety lever:

a) when the hammer is

b) when the hammer is not

Directions for the use and handling:

Loading

Filling the magazine

mechanism

5

6

6

7

7

8

8

1

4

10

1

1

2

3

4

5

6

7

8

9

Introducing the first cartridge

‘Single Action’ shooting

‘Double Action’ shooting

Rendering the P 38 safe

The emptied magazine

Un-loading

Dismantling

Detaching the barrel

Cleaning

Assembling

Test target and performance

Description of components

Conversion Units Cal. 4 mm

De Luxe case

Holster

9

9

10

10

11

11

12

13

13

16

17618

21

21

11

12

13

14

15

16

19

21-24

25

29

Page 24

A tradition of over

of

experience

years

in the manufacture of precision-built

and

weapons

name.

Loading...

Loading...