Page 1

Form No. 0156934C 9709

Español Français English

R

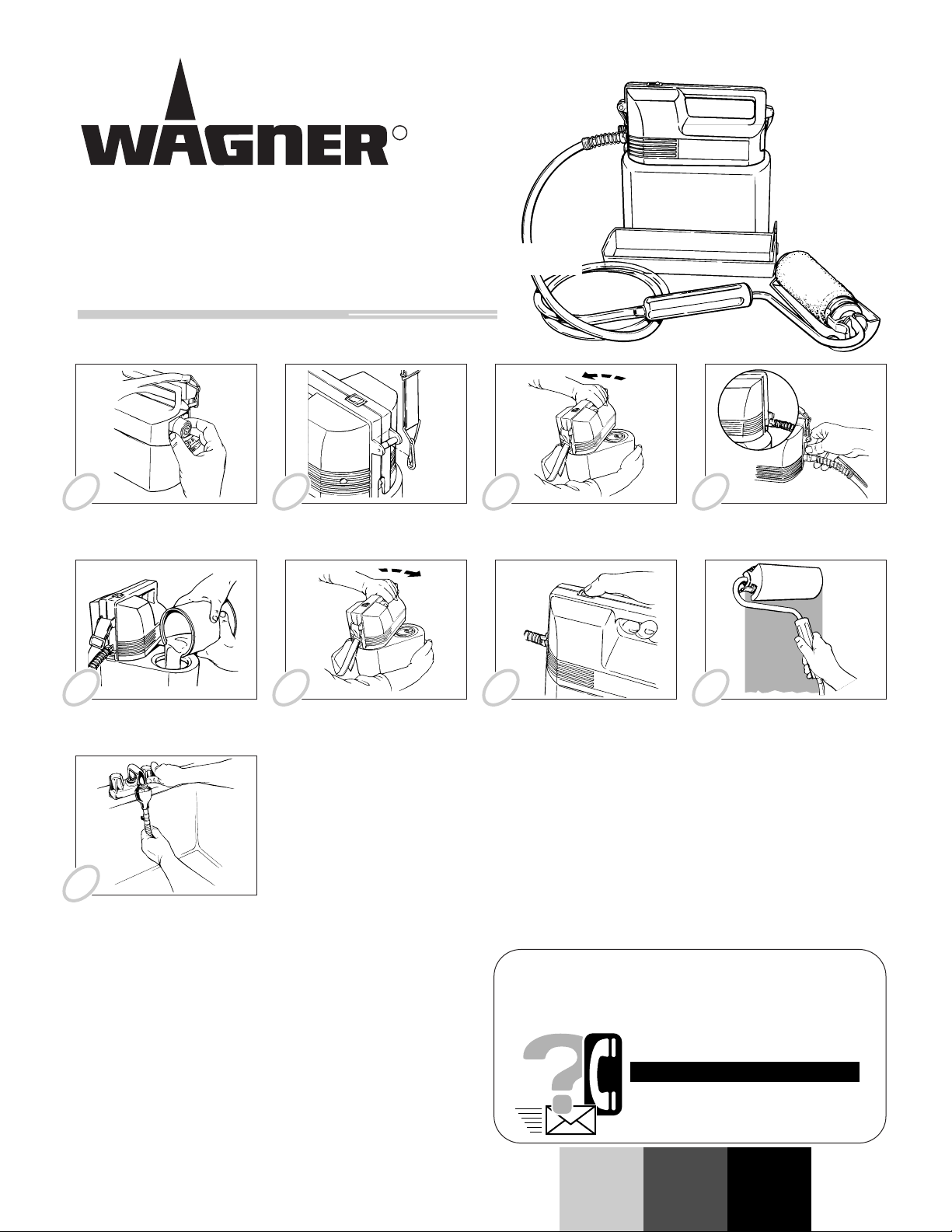

Cordless Power Roller

Owner’s Manual

Gude d’utilisation • Manual del propietario

Q

uick-start

Easy does it from setup to cleanup:

1-800-328-8251

Wagner Technical Service

Need help? Call us first for answers fast.

Call Wagner toll-free if you have any comments

or problems with this Wagner product.

Weekdays:

Weekends:

8:00 - 4:30 Central time

9:00 - 4:00 Central time

1770 Fernbrook Lane, Minneapolis, MN 55447

Install the batteries

Insérer les piles

Instalar las pilas

Attach the strap

Fixer la bandoulière

Conectar la correa

Remove the drive housing

Enlever du logement du mécanisme

Extraer el mecanismo impulsor

Attach the hoses

Fixation des tuyaux flexibles

Conectar las mangeras

Attach the drive housing

Fixation du logement du mécanisme

Conectar el mecanismo impulsor

Press the on/off switch

Appuyer sur le bouton marche/arrêt

Oprimir el botón de encendido

/ apagado

Apply paint

Appliquer la peinture

Aplicar pintura

Fill the fluid tank

Remplir le réservoir à liquides

Llenar el depósito de fluidos

Cleanup

Nettoyage

Limpieza

Read this manual for complete instructions.

Ce manuel contient les instructions

complètes.

Lea este manual para obtener instrucciones

completas.

1

5

9

2

6

3

7

4

8

Page 2

R

2 ©1997 Wagner Spray Tech. All rights reserved.

English

Table of Contents

PRODUCT REGISTRATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PARTS LISTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ASSEMBLING THE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the batteries and attaching the strap

Removing and Attaching the Drive Housing to the Fluid Tank

Attaching the Fluid Hose

Filling the Fluid Tank

USING THE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pump On/Off Switch

Applying Paint

CLEANUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Quick Cleanup

Detailed Cleanup

STORING THE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Registration Card

Send in your Wagner product registration card. Proper registration

will serve as proof of purchase in the event your original receipt

becomes misplaced or lost. Returning this card will not affect

warranty coverage, but may expedite the processing of your warranty

and enable you to contact us in the event of loss or theft. The

additional information will also help us to develop new products that

best meet your needs and desires. THANK YOU!

Accessories

9” x 3/8” roller cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0155206

9” x 3/4” roller cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0155209

9” x 1-1/4” roller cover. . . . . . . . . . . . . . . . . . . . . . . . . . . 0155209

Ball check assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0156270

Check valve assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . 0156276

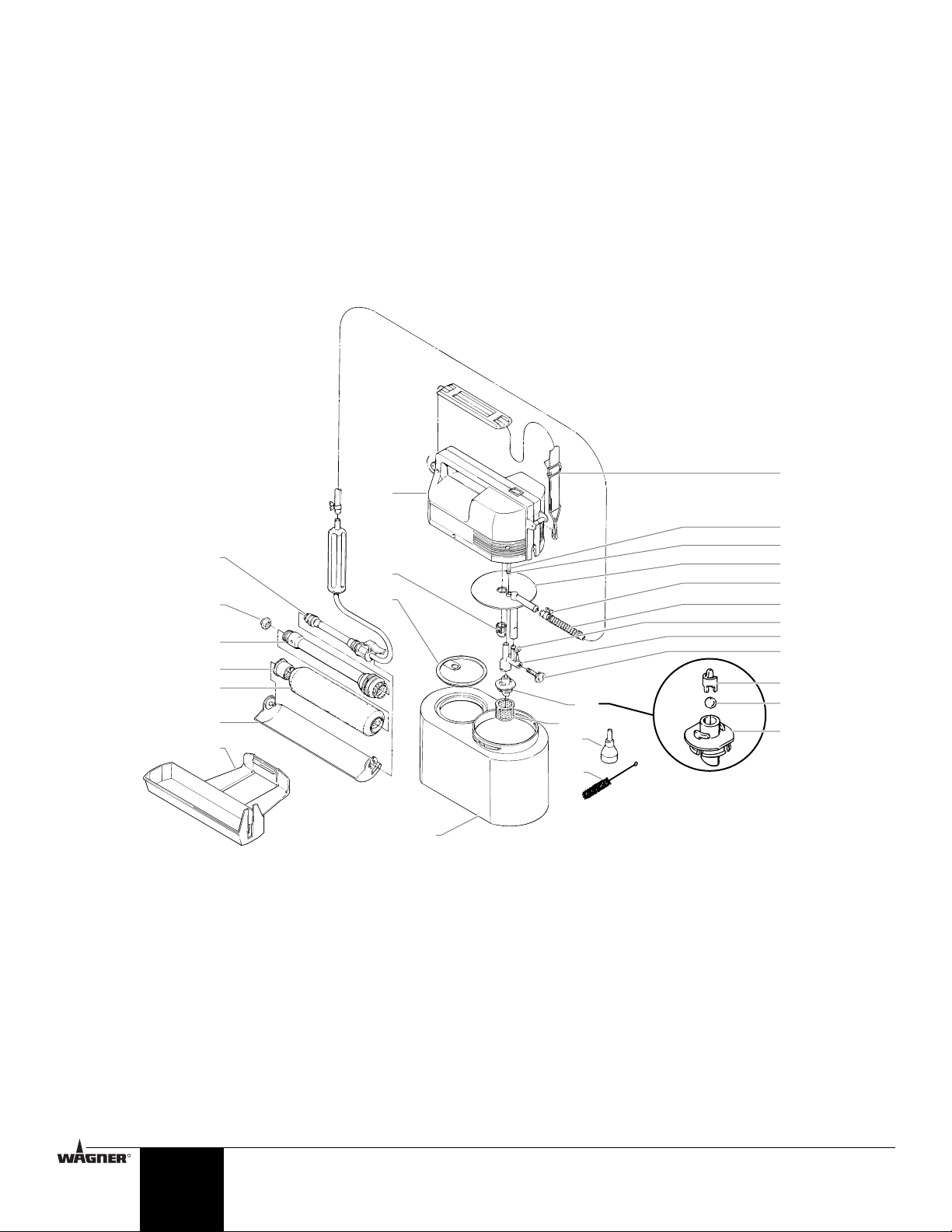

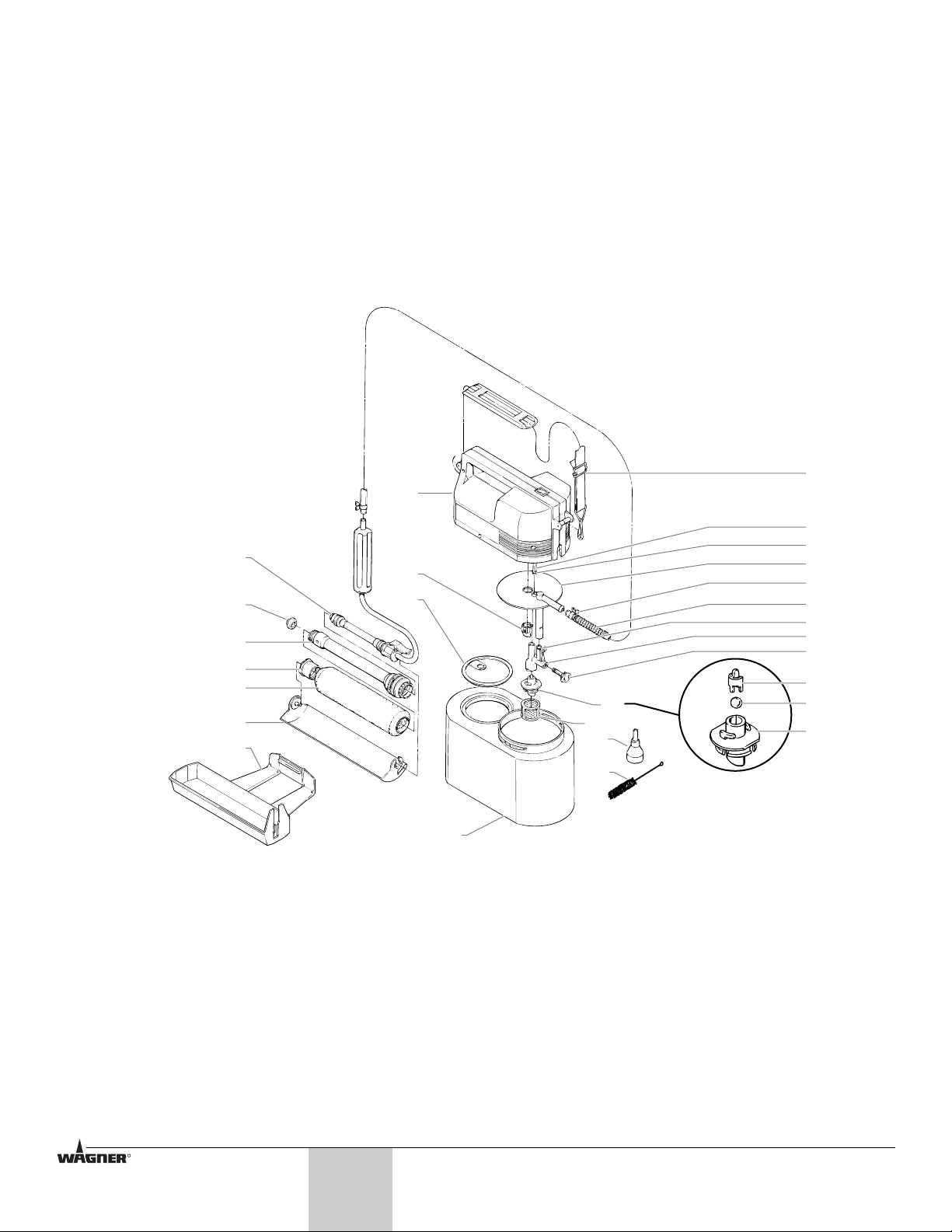

1 0156400 Strap Assembly

2 0156595 Piston

3 0327312 O-Ring

4 0156596 Pump, Upper

5 0327226 Clip, Spring

6 0156471 Spring, Anti-kinking

7 0327327 O-Ring

8 0156579 Pump, Lower

9 0156276 Valve Cap Assembly

10 0156270 Inlet Valve Assembly

11 0156582 Retainer, Inlet Ball

12 0156464 Ball, Inlet

13 0156580 Body, Valve

14 0016551 Filter

15 0156421 Adapter, Faucet

16 0280346 Brush

17 0156607 Container, Fluid

18 0156606 Tray, Roller

19 0156566 Shield, Splatter

20 0155206 Roller Cover, 3/8"

0155208 Roller Cover, 3/4" Opt.

21 0156556 Cap, End

22 0156559 Core, Roller

23 0245401 Seal

24 0156290 Arm, Roller

25 - - - - - - Drive Housing

26 0156585 Cap, Pump Retaining

27 0156409 Cover

1

2

3

4

5

6

7

8

9

11

12

13

10

14

15

16

25

24

23

22

21

20

19

18

26

27

17

Parts Listing

Page 3

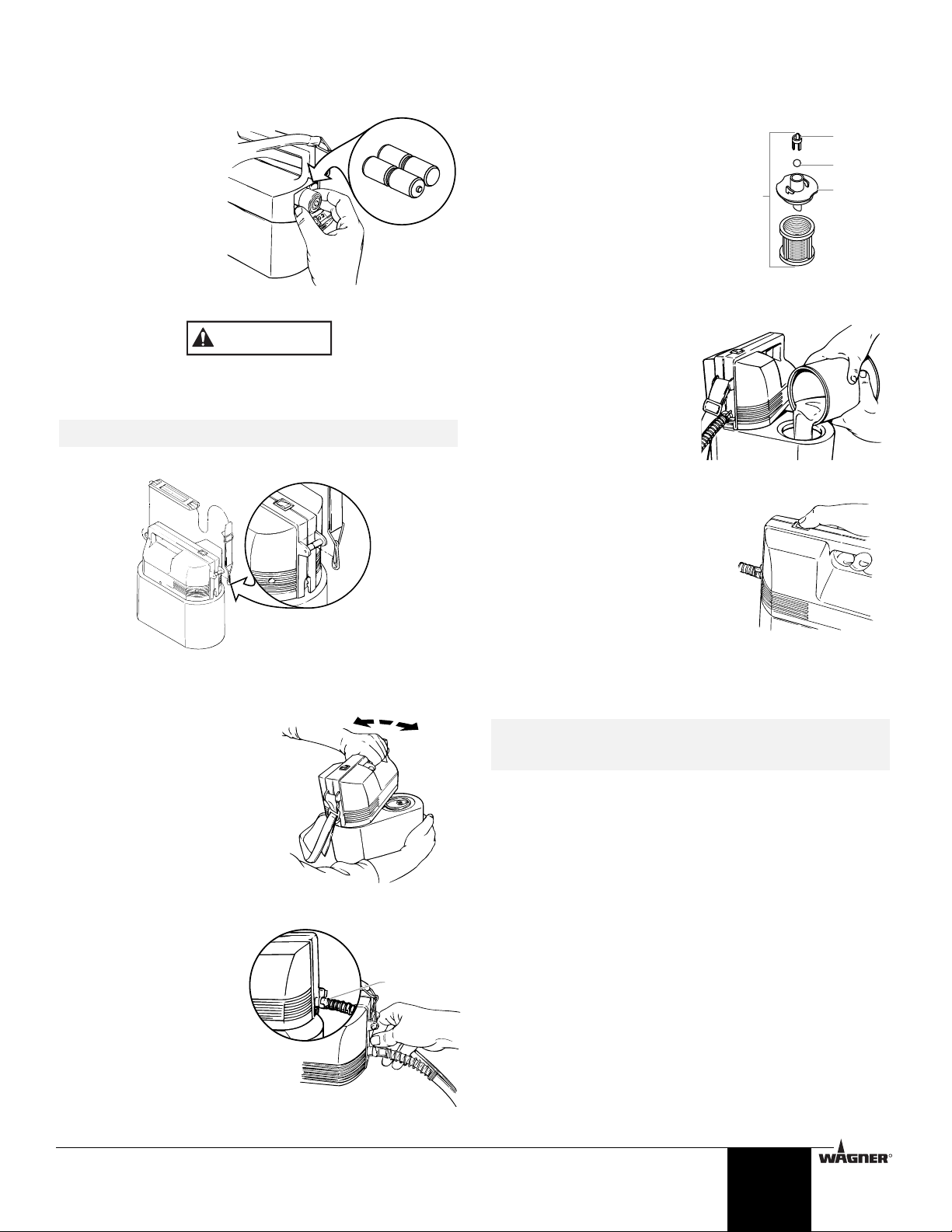

Assembling the Roller

Installing the Batteries and Attaching the Strap

1. Open the battery

door. The battery

door is located on

the drive housing.

2. Insert the batteries

in the proper

direction.

Improper installation of batteries may cause batteries to

overheat and leak acid. Acid may cause severe injury and/or

property damage.

3. Attach the strap to the loops on the drive housing.

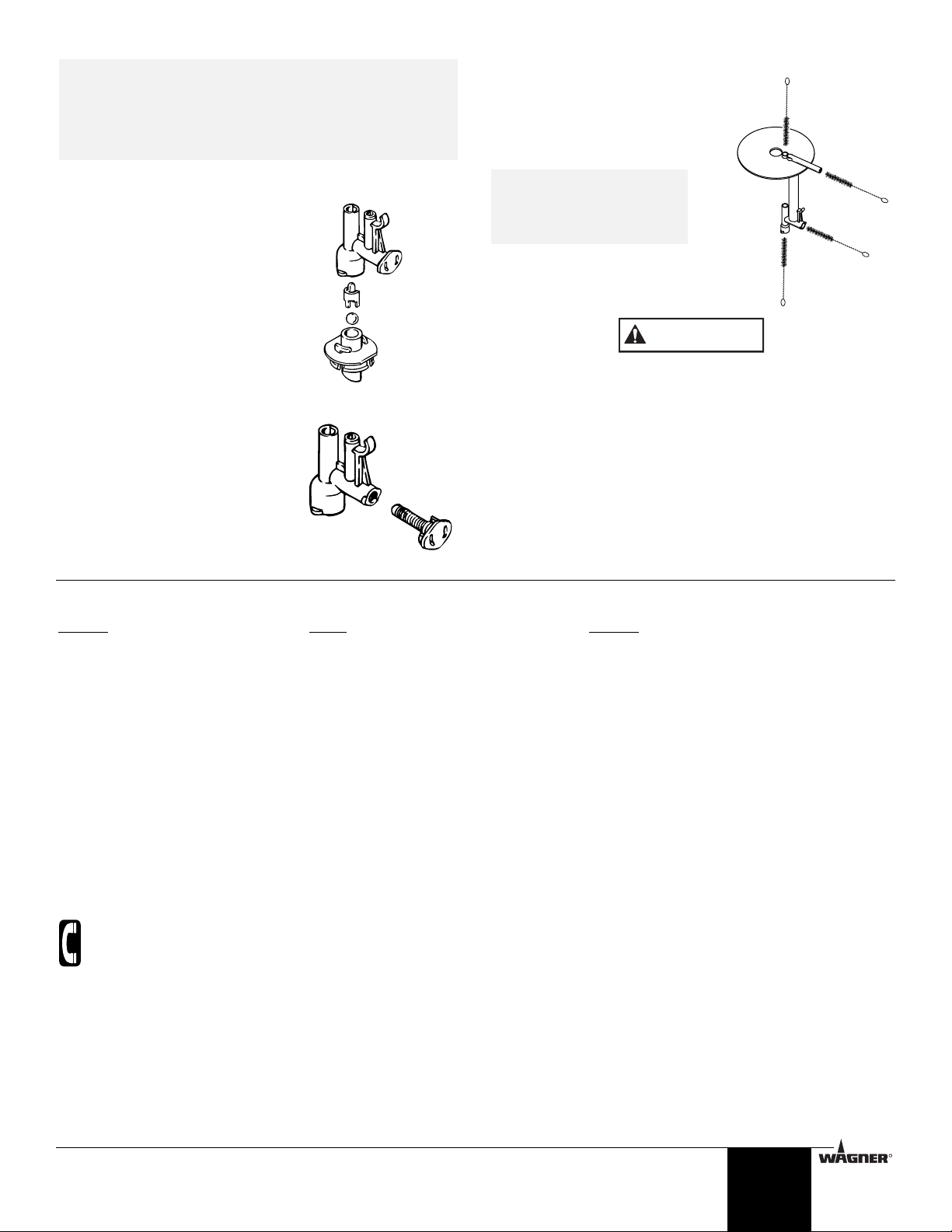

Removing and Attaching the Drive Housing to the Fluid Tank

1. Remove the drive housing by

turning the drive housing

counterclockwise.

2. Attach the drive housing by

setting it onto the fluid tank at

a 90° angle and turning

clockwise.

Attaching the Fluid Hose

1. Slide the fluid hose through

the anti-kinking spring and

the spring clip.

2. Push the fluid hose to the

port on the side of the

drive housing.

3. Slide the spring clip over

the fitting to keep the hose

securely in place.

4. Slide the anti-kinking

spring up against spring

clip.

Checking the Inlet Valve

If the unit is new or has been stored for an extended period of time

the inlet ball can become stuck and the pump may be difficult to

prime. To check:

1. Turn the valve body

counterclockwise and pull

down to remove.

2. Shake the inlet valve

assembly gently. If it does

not rattle, remove the inlet

ball retainer and clean the

ball.

3. Reassemble the inlet valve.

Filling the Fluid tank

1. Place the drive housing on the fluid tank at a 90° angle.

2. Remove the fluid tank cap

and fill the tank with paint.

3. Wipe the lip, threads, and

body of the fluid tank to

remove any spilled or

splattered material.

4. Replace the cap and lock the

drive housing securely onto

the fluid tank.

Using the Roller

The On/Off switch has two speeds for

controlling the paint flow – High and

Low. Choose the setting which is

appropriate for your application. If too

much paint is being delivered to the

roller on High speed, use the Low

speed setting. If paint flow is still too

great, shut the roller off, then turn back

on when more paint is needed.

Applying Paint

Begin rolling as paint appears to saturate the roller cover. If paint is

flowing faster than you can roll,turn the pump off until more paint is

needed.

NOTE: Do not place the roller below the level of the paint when

not in use. Paint will siphon to roller even if motor and

pump are turned off.

Inlet Ball

Retainer

Ball

Inlet Ball

Holder

Inlet Valve

Assembly

Fluid Hose

Close

Open

NOTE: Use high quality alkaline batteries only.

CAUTION

+

+

-

-

+

-

+

R

©1997 Wagner Spray Tech. All rights reserved. 3

English

Page 4

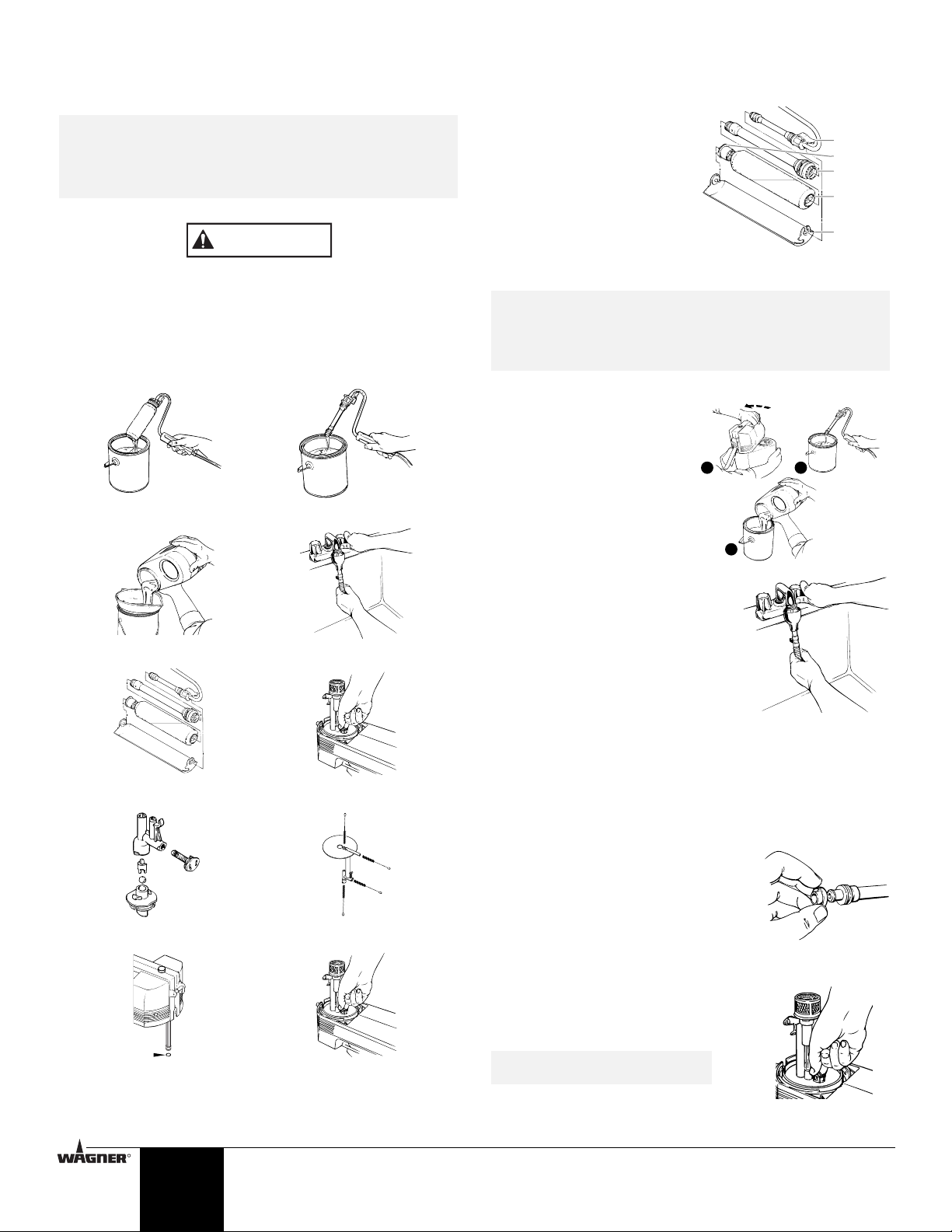

Cleanup

A thorough cleaning after each use of the roller is important to keep

it in good working order.

Do not turn the roller upside down or on its side. If liquid gets

inside the drive housing it could damage the unit.

Quick Cleanup

The following steps outline the basic cleanup procedures. For more

detailed instructions on how to perform each step, refer to the

Detailed Cleanup section in this manual.

1. Clean the roller cover. 2. Remove paint in hose.

3. Empty fluid tank. 4. Clean hose.

5. Clean roller handle. 6. Remove the pump assembly.

7. Remove and clean the valves. 8. Clean the pump assembly.

9. Clean and lubricate the 10. Reassemble the pump and

piston and O-ring. attach it to the drive housing.

Detailed Cleanup

Cleaning the Roller Cover

1. Pull one end of the splatter

shield out of the end cap and

slip opposite end off of the

roller handle.

2. Press the locking tab and

remove the roller cover and

roller core.

3. Unscrew the end cap and

slide the roller cover off of the

roller core.

4. Clean the roller cover with the appropriate solvent.

Removing Paint from the Hose and Container

1. Remove the drive housing

from fluid container.

2. Hold the roller handle over

the paint pail and run the

pump to remove excess

paint from hose and pump.

3. Pour remaining paint from

container back into paint pail.

Cleaning the Hose

Thoroughly

For Latex:

1. Remove the hose from the motor

compartment.

2. Insert the hard plastic tube of the

faucet adapter into the paint hose.

3. Push the adaptor over a faucet.

4. Slowly increase the water pressure

and run water through the hose and

handle until the water come out clean.

For Oil:

1. Fill the paint container with the appropriate solvent

recommended by the paint manuafacturer.

2. Circulate the solvent through hose and roller arm for several

minutes.

Cleaning the Roller Handle Assembly

1. Remove the seal from the end of the

roller handle. Note the direction of the

lip for correct replacement.

2. Clean the handle and seal thoroughly.

3. Apply a thin layer of petroleum jelly to

the seal.

4. Replace the seal in the proper direction.

Removing the Pump from the Drive Housing

1. Turn the retaining nut on the pump

counterclockwise.

2. Pull out the pump assembly.

3. Wipe excess paint off of the piston.

4. Apply a thin layer of petroleum jelly to the pump O-Ring.

NOTE: The piston will remain

attached.

1 2

3

NOTE: For latex, clean roller cover, core and end cap

thoroughly in warm soapy water.

For oil-based paints, clean roller cover, core and end

cap in the appropriate solvent recommended by the

paint manufacturer.

Tab

End Cap

Core

Cover

Shield

CAUTION

NOTE: When using latex paint, use warm soapy water for

cleaning parts. When using oil paint, the appropriate

solvent is often mineral spirits. Always follow the paint

manufacturer's recommendations for appropriate solvent.

Not recommended for lacquer and other hard solvents.

R

4 ©1997 Wagner Spray Tech. All rights reserved.

English

Page 5

Cleaning the Valves

Cleaning the Inlet Valve

1. Press down on the locking

tab and pull the valve

assembly out.

2. Turn valve body

counterclockwise and remove.

3. Remove the ball retainer and

inlet ball.

4. Remove the filter basket and

thoroughly clean all parts in

warm, soapy water or the

appropriate solvent.

Cleaning the Outlet Valve

1. Turn valve cap assembly counter

clockwise remove.

2. Clean all parts in warm, soapy

water or the appropriate solvent.

Cleaning the Pump Housing

1. Clean pump housing with warm,

soapy water or the appropriate

solvent using the brush supplied.

2. Apply a thin layer of petroleum

jelly to the pump O-Ring.

Storing the Roller

Clean, dry, and lubricate the system thoroughly before storing.

Do not store with liquids inside unit. Storing the unit in cold

temperatures can cause the liquids to freeze and expand,

causing pressure to build and break parts. Let the equipment

come up to room temperature before operating.

When storing the roller for more than a day, take the following

precautions:

1. Remove the batteries.

2. Remove the hose from the pump fitting.

3. Store the hose in a large loop. If it is bent, it could be damaged.

CAUTION

NOTE: Be sure to clean all

small parts

thoroughly. Paint will

act as an adhesive

when dry.

NOTE: Remove the pump carefully or the piston may come off.

If the piston comes off, reassemble by sliding piston

onto the brass piston connecting rod.

NOTE: Wipe excess paint off the drive housing with an

appropriate solvent. DO NOT IMMERSE UNIT IN

SOLVENT OR OTHER LIQUID.

R

©1997 Wagner Spray Tech. All rights reserved. 5

English

Troubleshooting

Problem Cause Solution

The pump will not run. There is little or no power. Put in new high quality alkaline batteries.

The batteries are not in properly. Put the batteries in properly.

The pump on/off button was not pressed. Press and release the pump on/off button.

The pump has seized up. Clean the piston and pump housing.

The motor and piston run but The batteries are low. Put in new high quality alkaline batteries.

there is little or no fluid flow. The fluid hose is leaking. Tighten the fluid hose securely.

The inlet, outlet, or relief valves are dirty. Clean the inlet and outlet valves.

The fluid in the fluid tank is low. Fill the fluid tank.

The piston O-ring is worn. Replace the piston O-ring.

The piston has slipped off the brass axle. Snap the piston back on the axle

Paint leaks from the roller core. The seal is not in place. Check and place the seal properly.

Roller cover slides on the wall. Too much paint pumped to roller. Press and release the pump on/off button to turn the

the pump off until more paint is needed.

The seal is not lubricated. Remove the seal, lubricate and replace.

Have you tried the recommendations above and are still having problems? In the United States, call our toll-free

consumer service at 1-800-328-8251 Monday through Friday between 8:00 AM and 4:30 PM Central time or between 9:00

AM and 4:00 PM Saturday or Sunday, or contact an authorized service center.

Page 6

R

6 ©1997 Wagner Spray Tech. Tous droits réservés.

Français

Table des matières

ENREGISTREMENT DU PRODUIT . . . . . . . . . . . . . . . . . . . . . . 6

LISTE DES PIÉCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ASSEMBLAGE DU ROULEAU . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation des piles et fixation de la bandoulière

Retrait et fixation du logement du mécanisme d’entraînement au

réservoir à liquides

Raccordement des flexible à fluides

Remplissage du réservoir à liquides

UTILISATION DU ROULEAU. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Bouton marche/arrêt de la pompe

Application de la peinture

NETTOYAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Nettoyage rapide

Nettoyage à fond

RANGEMENT DU ROULEAU . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CARTE D’ENREGISTREMENT DU PRODUIT

Veuillez retourner la carte d'enregistrement du produit ci-jointe. Cette

carte servira de preuve d'achat si vous égarez ou perdez le reçu

original. L'information figurant sur cette carte n'aura aucune incidence

sur cette garantie; elle accélérera toutefois le traitement de votre

garantie et vous permettra de communiquer avec nous en cas de

perte ou de vol. Cette information supplémentaire nous aidera

également à mettre au point de nouveaux produits qui répondent le

mieux à vos besoins et à vos goûts. Nous vous remercions de votre

collaboration.

Accessoires

Couvre-rouleau 22,8 cm x 0,95 cm . . . . . . . . . . . . . . . . . 0155206

Couvre-rouleau 22,8 cm x 1,9 cm . . . . . . . . . . . . . . . . . . 0155209

Couvre-rouleau 22,8 cm x 3,2 cm . . . . . . . . . . . . . . . . . . 0155209

Ensemble valve à boulet. . . . . . . . . . . . . . . . . . . . . . . . . 0156270

Valve unidirectionnelle. . . . . . . . . . . . . . . . . . . . . . . . . . . 0156276

1

2

3

4

5

6

7

8

9

11

12

13

10

14

15

16

25

24

23

22

21

20

19

18

26

27

17

1 0156400 Bandoulière

2 0156595 Piston

3 0327312 Joint torique

4 0156596 Pompe supérieure

5 0327226 Pince-ressort

6 0156471 Ressort anti-torsion

7 0327327 Joint torique

8 0156579 Pompe inférieure

9 0156276 Capuchon du clapet

10 0156270 Clapet d’alimentation

11 0156582 Retenue de la bille du clapet d’alimentation

12 0156464 Bille du clapet d’alimentation

13 0156580 Corps du clapet

14 0016551 Filtre

15 0156421 Adaptateur de robinet

16 0280346 Brosse

17 0156607 Réservoir à peinture

18 0156606 Plateau du rouleau

19 0156566 Pare-éclaboussures

20 0156100 Revêtement de rouleau, 9,5 mm

0156010 Revêtement de rouleau opt., 1,9 cm

21 0156556 Capuchon d’extrémité

22 0156559 Noyau du rouleau

23 0245401 Garniture

24 0156290 Bras du rouleau

25 - - - - - - Ensemble rouleau

26 0156585 Capuchon de retenue de pompe

27 0156409 Couvercle

Liste des piéces

Page 7

R

©1997 Wagner Spray Tech. Tous droits réservés. 7

Français

Assemblage du Rouleau

Installation des piles et fixation de la bandoulière

1. Ouvrir le couvercle

du compartiment

des piles. Le volet

du logement des

piles se trouve sur

le carter

d’entraînement.

2. Glisser les piles

dans le logement

en les orientant

dans le sens correct.

Installant les batteries fautivement peut faire des batteries à

surchauffer et fuir l'acide. L'acide peut vous blesser et

propriété de dommages.

3. Fixer les courroies dans les boucles du logement du

mécanisme d'entraînement.

Enlèvement et fixation du carter d’entraînement

au réservoir à liquide

1. Pour enlever le carter

d’entraînement, tourner le

carter dans le sens inverse

des aiguilles d’une montre.

2. Pour remettre le carter

d’entraînement, visser le

boîtier du moteur jusqu’à ce

que l’on entende un déclic

indiquant qu’il est à la position

correcte.

Fixation de tuyaux à liquide

1. Glisser le tuyau flexible

dans le ressort anti-torsion

et dans la pince-ressort.

2. Fixer le tuyau flexible à

l’orifice situé sur le côté du

boîtier du moteur.

3. Glisser la pince-ressort

par-dessus le raccord, de

façon à maintenir le tuyau

fermement en place.

4. Remonter le ressort antitorsion contre la pince-ressort.

Vérification du clapet d’alimentation

Si l’appareil est neuf ou a été entreposé pendant une période

prolongée, il est possible que la bille du clapet soit collée, rendant

difficile l’amorçage de la pompe.

1. Dévisser le corps du clapet et

le tirer vers le bas pour

l’enlever. Secouer délicatement l’ensemble du clapet

d’alimentation.

2. Si l’on n’entend pas de

cliquetis, enlever la retenue

de la bille et nettoyer la bille.

3. Remonter les pièces et passer à l’opération suivante.

Pour remplir le réservoir à liquides

1. Placer le boîtier du moteur assemblé sur le réservoir à peinture.

2. Enlever toute trace de produit

déversé ou éclaboussé sur le

bec, les filets et le corps du

réservoir à liquides au moyen

d'un linge.

3. Remettre le bouchon en place.

4. Visser le boîtier du moteur

jusqu’à ce que l’on entende un déclic indiquant qu’il est à la

position correcte.

Utilisation du Rouleau

L’interrupteur marche/arrêt à deux

vitesses permet de contrôler le débit de

peinture - Haut (High) et Bas (Low).

Choisir le réglage en fonction de

l’application. Si une trop grande

quantité de peinture alimente le rouleau

quand l’interrupteur est sur Haut, le

régler sur Bas. Si le débit est encore

trop élevé, arrêter l’appareil et le

remettre en marche quand le débit devient insuffisant.

Appliquer la peinture

Commencer à rouler dès que la peinture apparaît pour saturer le

revêtement du rouleau. Si la peinture arrive plus vite que l’on ne

peut la rouler, arrêter le moteur jusqu’à ce que davantage de

peinture soit nécessaire.

NOTA: Si l’on cesse d’utiliser le rouleau à peinture, ne pas le

placer en dessous du niveau du réservoir de peinture

car celle-ci s’écoulerait jusqu’au rouleau, même si le

moteur est arrêté.

Support de

la bille

Bille

Corps de la

clapet

d'alimentation

Tuyaux à

liquide

Fermé

Ouvert

NOTA: Utiliser uniquement des piles alcalines de haute qualité.

AVERTISSEMENT

+

+

-

-

+

-

+

Page 8

Nettoyage

Un nettoyage à fond après chaque utilisation est important afin de

garder en bon état de fonctionnement.

Ne pas tourner le rouleau à l'envers ni sur le côté. Si du liquide

entrait dans le carter du moteur, l’appareil pourrait être endommagé.

Nettoyage rapide

Les étapes suivantes décrivent la méthode de nettoyage de base.

Pour de plus amples renseignements sur la manière de procéder, se

reporter à la section Nettoyage à fond du présent manuel.

1. Nettoyage du revêtement 2. Élimination de la peinture se

du rouleau. trouvant dans le tuyau flexible.

3. Vidage du résevoir de peinture.4. Nettoyage du tuyau flexible.

5. Nettoyage du manche de rouleau.6. Séparation de la pompe.

7. Nettoyage du clapets.. 8. Nettoyage de la pompe.

9. Nettoyage et lubrifier 10. Fixation de la pompe au

le piston et o-ring. carter d’entraînement.

Nettoyage à fond

Nettoyage du revêtement du rouleau

1. Sortir une extrémité du pare-éclaboussures du capu-chon

d’extrémité en la tirant et glisser l’extrémité opposée hors du

manche de rouleau.

2. Appuyer sur la languette de blocage et retirer le revêtement du

rouleau ainsi que le rouleau.

3. Dévisser le capuchon d’extrémité et glisser le revêtement hors

du rouleau.

4. Nettoyer le revête-ment de rouleau dans un diluant approprié.

Élimination de la peinture se trouvant dans le tuyau flexible

1. Séparer le boîtier du moteur

du réservoir de peinture.

2. Tenir le manche du rouleau

au-dessus du pot de

peinture et actionner le

moteur pour éliminer

l’excédent de peinture se

trouvant dans le tuyau

flexible et la pompe.

3. Reverser dans le pot de

peinture le reste de peinture

se trouvant dans le réservoir.

Nettoyage du manche de rouleau

Pour la peinture au latex:

1. Débrancher le tuyau flexible

du boîtier du moteur

2. Le fixer à l’adaptateur de

robinet en introduisant le tube

en plastique dur dans le tuyau

flexible à peinture.

3. Pousser l’adaptateur sur le robinet.

4. Augmenter lentement la pression de l’eau et laisser couler l’eau

dans le tuyau flexible et dans le manche jusqu’à ce que l’eau

ressorte propre.

Pour la peinture à huilel:

1. Remplir le réservoir de peinture avec le diluant approprié.

2. Faire circuler le diluant dans le tuyau flexible et dans le bras de

rouleau pendant plusieurs minutes.

Nettoyage du manche de rouleau

1. Enlever le joint se trouvant à l’extrémité du

manche du rouleau. Remarquer l’orientation

de la lèvre pour remettre le joint

correctement en place.

2. Nettoyer à fond le manche et le joint.

3. Appliquer une mince couche de vaseline sur le joint pour

s’assurer de son montage correct.

4. Veiller à remettre le joint en place dans le sens correct.

Séparation de la pompe

1. Séparer la pompe de l’ensemble du moteur en dévissant

l’écrou de retenue et en tirant la pompe.

2. Essuyer le piston pour enlever l’excédent de peinture.

3. Appliquer une mince couche de vaseline sur le joint torique de

la pompe.

NOTA: Le piston reste attaché.

1 2

3

NOTA: Pour la peinture au latex: Nettoyer à fond le revête-

ment de rouleau, le rouleau et le capuchon d’extrémité

dans de l’eau tiède savonneuse.

Pour la peinture à huilel: Nettoyer le revête-ment de

rouleau, le rouleau et le capuchon d’extrémité dans un

diluant approprié (très probablement de l’essence

minérale — suivre les recom-mandations de l’étiquette

du pot de peinture quant aux diluants appropriés).

AVERTISSEMENT

NOTA: Lors de l’utili-sation de peinture au latex, se servir

d’eau tiède savonneuse pour nettoyer les pièces. Lors

de l’utilisation de peinture à l’huile, le diluant approprié

est généralement l’essence minérale. Toujours suivre

les recommandations du fabricant de peinture afin

d’employer le diluant approprié. Non recommandé pour

les laques et diluants solidifiés.

R

8 ©1997 Wagner Spray Tech. Tous droits réservés.

Français

Page 9

R

©1997 Wagner Spray Tech. Tous droits réservés. 9

Français

Nettoyage des soupapes

Nettoyage de la soupape d’admission

1. Appuyer sur la languette de blocage

et sortir l’ensemble de la soupape.

2. Retirer le corps de soupape en le

tournant dans le sens antihoraire.

3. Sortir le dispositif de retenue de la

bille, ainsi que la bille d’entrée.

4. Enlever le panier du filtre et nettoyer

à fond toutes les pièces avec de

l’eau tiède savonneuse ou un

solvant approprié.

Nettoyage de la soupape de sortie

1. Retirer l’ensemble du capuchon de

la soupape en le tournant dans le

sens antihoraire.

2. Nettoyer à fond toutes les pièces

avec de l’eau tiède savonneuse ou

un solvant approprié.

Nettoyage du corps de la pompe

1. 1. Nettoyer le corps de la pompe

avec de l’eau tiède savonneuse

ou un solvant approprié à l’aide

de la brosse fournie à cet effet.

2. 2. Appliquer une mince couche

de vaseline sur le joint torique de

la pompe.

Rangement du Rouleau

Nettoyer, sec et lubrifier l’appareil soigneusement. Ne pas

ranger avec des liquides à l’intérieur de l’appareil. Si le

pulvérisateur est rangé dans un endroit où il fait froid, tout

liquide à l’intérieur risque de geler et de se dilater, provoquant

une augmentation de la pression et éventuellement la casse de

pièces. Permettre à l’appareil de revenir à la température

ambiante avant de s’en servir.

Lorsqu’on range le pulvérisateur pour plus d’une journée, il convient

de prendre les précautions suivantes :

1. Enlever les piles.

2. Enlever le tuyau du raccord de la pompe.

3. Ranger le tuyau en le roulant en une grande boucle. Si le tuyau

est trop courbé, il peut être endommagé.

AVERTISSEMENT

NOTA: S’assurer de

nettoyer à fond

toutes les petites

pièces. La peinture

sèche agit comme

un adhésif.

NOTE: Séparer la pompe avec précautions car le piston risque

de sortir. Si le piston sort, remonter l’ensemble en

glissant le piston sur la bielle en laiton.

NOTE: Retirer l’excédent de peinture se trouvant sur le carter

du moteur en l’essuyant avec un diluant approprié. NE

PAS PLONGER LE MOTEUR DANS LE DILUANT NI

DANS AUCUN AUTRE LIQUIDE.

Dépannage

Problème Cause Solution

La pompe ne marche pas. Il y a très peu d’énergie, ou il n’y a pas Installer de nouvelles piles alcalines de haute qualité.

d’énergie du tout.

Les piles ne sont pas bien installées dans Remettre les piles dans la position correcte.

leur logement.

La pompe s’est grippée. Nettoyer le piston et le carter de la pompe.

L’entraînement et le piston marchent, Les piles n’ont que peu d’énergie. Installer de nouvelles piles alcalines de haute qualité.

mais le liquide s’écoule très peu ou

ne s’écoule pas du tout.

Il y a des fuites au tuyau à liquide. Serrer le tuyau à liquide pour le bloquer solidement

en place.

La soupape d’admission ou la soupape de Nettoyer les soupapes d’admission et de sortie.

sortie est encrassée.

Le niveau du liquide dans le réservoir est bas. Remplir le réservoir à liquide.

Le joint torique du piston est usé. Remplacer le joint torique.

Le piston a glissé hors de l'axe en laiton. Replacer le piston sur l'axe.

La peinture fuit par le milieu du rouleau Le joint n’est pas en place. Vérifier que le joint est placé correctement.

Le revêtement du rouleau dérape sur le mur Trop de peinture. Arrêter le moteur jusqu’à ce que davantage

de peinture soit nécessaire.

Joint non lubrifié. Retirer le joint, le lubrifier et le remonter

Si vous avez essayé les recommandations indiquées ci-dessus et des problèmes persistent, aux États-Unis, communiquez avec

notre service à la clientèle en composant le numéro sans frais 1-800-328-8251, entre 8 h et 16 h 30, heure du Centre, du lundi au

vendredi, ou entre 9 h et 16 h le samedi ou le dimanche, ou bien communiquez avec un centre d’entretien agréé.

Page 10

R

10 ©1997 Wagner Spray Tech. Reservados todos los derechos.

Español

Indice

REGISTRAR EL PRODUCTO . . . . . . . . . . . . . . . . . . . . . . . . . 10

LISTADE REPUESTOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CÓMO ENSAMBLAR EL RODILLO. . . . . . . . . . . . . . . . . . . . . 11

Cómo instalar las baterías y colocar la correa

Cómo quitar y colocar la caja de la transmisión al tanque de

fluidos

Cómo colocar las manguera de fluido

Llene el recipiente con pintura

CÓMO USAR EL RODILLO. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LIMPIEZA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Limpieza rápida

Limpieza a fondo

ALMACENAMIENTO DEL RODILLO . . . . . . . . . . . . . . . . . . . . 13

TARJETA PARA REGISTRAR EL PRODUCTO

Envíenos la tarjeta de registro del producto. El registro adecuado

servirá como comprobante de compra en el caso de que extravíe o

no pueda encontrar el recibo de compra. La devolución de la tarjeta

no afectará la duración de la garantía, pero podrá acelerar el

proceso de ésta lo que le permitirá contactarse con nosotros en caso

de pérdida o robo. La información adicional que nos brinde nos

servirá para crear nuevos productos que satisfagan aún más sus

necesidades y deseos. ¡GRACIAS!

Accessories

Forro de rodillo de 22,8 cm x 0,95 cm . . . . . . . . . . . . . . . 0155206

Forro de rodillo de 22,8 cm x 1,9 cm. . . . . . . . . . . . . . . . 0155209

Forro de rodillo de 22,8 cm x 3,2 cm. . . . . . . . . . . . . . . . 0155209

Conjunot de retención de bola. . . . . . . . . . . . . . . . . . . . . 0156270

Válvula unidireccional . . . . . . . . . . . . . . . . . . . . . . . . . . . 0156276

1

2

3

4

5

6

7

8

9

11

12

13

10

14

15

16

25

24

23

22

21

20

19

18

26

27

17

1 0156400 Conjunto de la tira

2 0156595 Pistón

3 0327312 Anillo O

4 0156596 Bomba superior

5 0327226 Sujetador, resorte

6 0156471 Resorte anti-dobleces

7 0327327 Anillo O

8 0156579 Bomba, inferior

9 0156276 Conjunto de la tapa de válvula

10 0156270 Conjunto de la válvula de entrada

11 0156582 Retén, bola de entrada

12 0156464 Bola, entrada

13 0156580 Estructura, válvula

14 0016551 Filtro

15 0156421 Adaptador, grifo

16 0280346 Brocha

17 0156607 Envase, pintura

18 0156606 Bandeja, rodillo

19 0156566 Protección, salpicaduras

20 0156100 Forro del rodillo, 3/8 pulg.

0156010 Forro del rodillo, 3/4 pulg., opcional

21 0156556 Tapa, extremo

22 0156559 Centro, rodillo

23 0245401 Sello

24 0156290 Brazo, rodillo

25 - - - - - - Unidad de rodillo

26 0156585 Tapa, retén de la bomba

27 0156409 Tapa

Lista de repuestos

Page 11

R

©1997 Wagner Spray Tech. Reservados todos los derechos. 11

Español

Cómo ensamblar el rodillo

Cómo instalar las baterías y colocar la correa

1. Retire la cubierta

de las pilas La

puerta del

compartimiento de

las baterías está

ubicada sobre la

caja de la

transmisión.

2. Inserte las baterías

en la dirección

adecuada.

La instalación de las pilas incorrectamente puede hacer las

pilas para recalentar y escapar ácido. El ácido lastimará y

dañará propiedad.

3. Enganche la correa a los aros que están en la cubierta del

mecanismo impulsor.

Cómo quitar y colocar la caja de la transmisión al tanque de fluidos

1. Quite la caja de la

transmisión dándole vuelta a

la caja en dirección opuesta a

las agujas del reloj.

2. Coloque la caja de la

transmisión sobre el tanque

de fluidos dele vuelta en

dirección de las agujas del reloj

hasta que calce sobre el

tanque de fluidos.

Cómo colocar las manguera de fluido

1. Deslice la manguera a

través del resorte antidobleces y la presilla del

resorte.

2. Conecte la manguera al

puerto ubicado al lado del

compartimiento del motor.

3. Deslice la presilla del

resorte sobre la unión para

asegurar la manguera.

4. Deslice el resorte

antidobleces hasta que

toque la presilla del resorte.

Revise la válvula de admisión

Si la unidad es nueva o si no se ha usado por un período

prolongado, es posible que la bola de admisión se pegue y que sea

difícil cebar la bomba.

1. Presione la

lengüeta de

seguridad y retire

el conjunto de la

válvula.

2. Gire el cuerpo de

la válvula en

sentido contrario

a los punteros del

reloj.

3. Retire el retén de la bola y la bola de admisión.

4. Retire el armazón del filtro y limpie completamente todas las

piezas con agua tibia y jabón o con un solvente adecuado.

Llene el recipiente con pintura

1. Instale el compartimiento del motor ya montado en el recipiente

de pintura y gire en sentido contrario a los punteros del reloj.

2. Retire la tapa del recipiente y

llénelo con pintura.

3. Limpie la punta, las roscas y

el cuerpo del tanque de

fluidos para remover las

sustancias que puedan

haberse chorreado o goteado.

4. Vuelva a colocar la tapa y gire

el compartimiento del motor en

sentido contrario a los punteros

del reloj hasta escuchar el clic que indica la posición correcta.

Utilización del rodillo

El interruptor de encendido/apagado

(On/Off) tiene dos velocidades para

controlar el flujo de pintura — Alta y

Baja. Escoja la selección que

corresponda a su aplicación. Si fluye

demasiada pintura al rodillo en alta

velocidad, use la selección de

velocidad baja. Si el flujo de pintura a

ún es demasiado, apague la unidad y

vuelva a encenderla cuando se necesite más pintura.

Aplicar pintura

Comience a rodar a medida que la pintura aparece y satura la

cubierta del rodillo. Si la pintura fluye más rápido de lo que usted

puede pintar, apague el motor hasta que se necesite más pintura.

NOTA: Asegurarse de que la manguera de aire esté conectada

al mecanismo impulsor. Si la manguera de aire no está

conectada, el motor no funcionará.

Sostén

de la bola

Bola

Cuerpo de la

válvula de

entrada

Mangueras

de fluido

Cerrado

Abierto

NOTA: Use solamente baterías alcalinas de alta calidad.

PRECAUCION

+

+

-

-

+

-

+

Page 12

R

12 ©1997 Wagner Spray Tech. Reservados todos los derechos.

Español

Limpieza

Es importante efectuar una limpieza a fondo del rodillo para

mantenerlo en buenas condiciones.

No acueste ni voltee el rodillo. Si entra líquido en la caja del

motor, podría dañar el rociador.

Limpieza rápida

Los siguientes pasos detallan los procedimientos básicos de

limpieza. Para instrucciones más detalladas sobre cada paso,

refiérase a la sección de limpieza a fondo de este manual.

1. Limpie la cubierta del rodillo. 2. Elimine la pintura de la

manguera.

3. Vacíe el recipiente de pintura. 4. Limpie la manguera.

5. Limpie de la manija del rodillo. 6. Retire la bomba.

7. Limpie la válvulas. 8. Limpie la bomba.

9. Limpie y lubrique el émbolo 10. Vuelva a ensamblar la

y el aro tórico. bomba y conéctela a la

cubierta del mecanismo

impulsor.

Limpieza a fondo

Limpie la cubierta del rodillo

1. Jale uno de los extremos del

protector contra manchas hacia

afuera del capacete y deslice el

extremo opuesto fuera de la manija

del rodillo.

2. Presione la lengüeta de seguridad y

retire la cubierta del rodillo y el

centro del rodillo.

3. Desatornille el capacete y retire la

cubierta del rodillo.

Elimine la pintura de la manguera

1. Retire el

compartimiento del

motor del recipiente de

pintura.

2. Sostenga la manija del

rodillo sobre el cubo de

pintura y arranque el

motor para eliminar el

exceso de pintura de la

manguera y de la

bomba.

3. Vacíe los restos de

pintura del recipiente al cubo de pintura.

Limpie la manguera a fondo

Para pintura látex:

1. Retire la manguera del

compartimiento del motor.

2. Introduzca el tubo plástico

resistente en la manguera de

pintura para conectarla al adaptador

de grifo.

3. Empuje el adaptador sobre el grifo.

4. Aumente lentamente la presión del agua, haga correr el agua

por la manguera y la manija hasta que el agua salga limpia.

Para pintura al óleo:

1. Llene el recipiente de pintura con un solvente adecuado.

2. Haga circular el solvente a través de la manguera y el brazo

del rodillo durante varios minutos.

Limpie el conjunto de la manija del rodillo

1. Retire el sello del extremo de la manija

del rodillo. Fíjese en la dirección de la

punta para volver a colocarla

correctamente.

2. Limpie completamente la manija y el sello.

3. Aplique una delgada capa de vaselina al

sello para asegurar un montaje adecuado.

4. Asegúrese de volver a colocar el sello en la dirección adecuada.

Retire la bomba

1. Para retirar la bomba del conjunto del motor, gire la tuerca de

retención en el sentido contrario a los punteros del reloj.

2. Retire el conjunto de la bomba.

3. Elimine el exceso de pintura del pistón.

4. Aplique una delgada capa de vaselina al sello O de la bomba.

NOTA: El pistón seguirá unido al conjunto.

1 2

3

NOTA: Para pintura látex, Limpie completamente la cubierta, el

centro y el capacete del rodillo con agua tibia y jabón.

Para pintura al óleo, limpie la cubierta, el centro y el

capacete del rodillo con un solvente adecuado.

PRECAUCION

NOTA: Al utilizar pintura látex, limpie las piezas con agua tibia y

jabón. Al utilizar pintura al óleo, se recomienda utilizar

solventes derivados del petróleo. Siempre siga las

recomendaciones del fabricante de la pintura sobre el uso

de solventes. No se recomienda utilizar laca ni otros

solventes fuertes.

Page 13

R

©1997 Wagner Spray Tech. Reservados todos los derechos. 13

Español

Limpie la válvulas

Limpie el conjunto de la válvula de admisión

1. Oprimir la lengüeta de seguridad y sacar el

conjunto de la válvula.

2. Girar la estructura de la válvula en sentido

contrario a las agujas del reloj y extraer.

3. Extraer el retén de la bola y la bola de

admisión.

4. Extraer el armazón del filtro y limpiar

completamente todas las piezas con agua

tibia y jabón o con un solvente apropiado.

Limpieza de la válvula de salida

1. Girar el conjunto de la tapa de la

válvula en sentido contrario a las

agujas del reloj y extraer.

2. Limpiar todas las piezas con agua

tibia y jabón o con un solvente

apropiado.

Limpieza de la caja de la bomba

1. Limpiar la caja de la bomba con agua

tibia y jabón o con un solvente apropiado

utilizando el cepillo que se suministra.

2. Aplicar una capa fina de vaselina al

anillo en O de la bomba.

Almanenamiento del rodillo

Limpio, seco y lubricar el sistema completamente antes de

almacenarlo. No lo almacene con líquidos dentro de la unidad.

Si se almacena el rociador a temperaturas frías, puede causar

que los líquidos se congelen y se expandan, lo cual causaría la

acumulación de presión y la rotura de las piezas. Deje que el

equipo alcance la temperatura ambiente antes de ponerlo en

funcionamiento.

Al almacenar el rodillo durante más de un día, tomar las siguientes

precauciones:

1. Extraer las pilas.

2. Extraer la manguera de la conexión de la bomba.

3. Almacenar la manguera doblándola para que forme un aro

grande. Si se dobla, la manguera puede dañarse.

PRECAUCION

NOTA: Asegurarse de limpiar a fondo

todas las piezas pequeñas. La

pintura actuará como

adhesivo cuando se seque.

NOTA: Extraer con cuidado la bomba ya que el pistón se sale con

mucha facilidad. Si se sale el pistón, volver a montarlo

deslizándolo en la varilla de conexión de bronce del pistón.

NOTA: Limpiar el exceso de pintura de la cubierta del mecanismo

impulsor con un solvente apropiado. NO SUMERGIR LA

UNIDAD EN SOLVENTE NI EN NINGUN OTRO LIQUIDO.

Solución de problemas

Problema Causa Solución

La bomba no funciona. Hay poca o ninguna energía eléctrica. Coloque nuevas baterías alcalinas de alta calidad.

No se colocaron correctamente las baterías. Coloque las baterías correctamente.

No se está apretando el gatillo. Apriete el gatillo.

La bomba está obstruida. Limpie el pistón y la caja de la bomba.

La transmisión y el émbolo funcionan, Las baterías están bajas. Coloque nuevas bateríes alcalinas de alta calidad.

pero hay muy poco o ningún fluido. La manguera de fluidos tiene escapes. Apriete firmemente la manguera de fluidos.

Las válvulas de entrada o salida están sucias. Limpie las válvulas de entrada y salida.

El fluido del tanque está bajo. Llene el tanque de fluidos.

El anillo en O del émbolo está desgastado. Cambie el anillo en O del émbolo.

El filtro de la boquilla está obstruido. Limpie el filtro de la boquilla.

El émbolo se ha separado del eje de bronce. Vuelva a colocar el émbolo sobre el eje.

Hay filtración de pintura en el centro Exceso de pintura Coloque el motor en la posición O hasta que se

del rodillo necesite más pintura

La cubierta se resbala en la muralla El sello no está lubricado Retire el sello, lubrique y vuelva a montar

Si usted ha seguido las recomendaciones anteriores y aún tiene problemas, en los Estados Unidos, llame gratis a nuestro

Departamento de Servicio al Cliente, al 1-800-328-8251, de lunes a viernes, entre las 8:00 AM y las 4:30 PM Hora del Centro;

o entre las 9:00 AM y 4:00 PM, sábado o domingo; o póngase en contacto con un Centro de Servicio Autorizado.

Page 14

Page 15

Page 16

R

16 ©1997 Wagner Spray Tech. All rights reserved.

Wagner One Year Limited Warranty - Keep on file - English

This product manufactured by Wagner Spray Tech Corporation (Wagner), is warranted to the original retail purchaser against defects in

material and workmanship for one year from date of purchase if operated in accordance with Wagner's printed recommendations and

instructions. This product is designed for home use only. If this product is used for professional/rental purposes, this warranty applies only for

30 days from date of purchase.

This warranty does not cover damage resulting from improper use, accidents, user's negligence or normal wear. This warranty does not

cover defects or damages caused by service or repair performed by anyone other than a Wagner Authorized Service Center. This warranty

does not apply to accessories.

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO ONE YEAR FOR

HOME USE AND 30 DAYS FOR PROFESSIONAL/RENTAL USE FROM DATE OF PURCHASE.

WAGNER SHALL NOT IN ANY EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER

FOR BREACH OF THIS WARRANTY OR ANY OTHER REASON.

If any product is defective in material and/or workmanship during the applicable warranty period, return it with proof of purchase,

transportation prepaid to any Wagner Authorized Service Center. Contact Wagner Technical Service at 1770 Fernbrook Lane, Minneapolis,

MN 55447 or telephone 1-800-760-3844 for authorized service center locations. Wagner's Authorized Service Center will either repair or

replace the product (at Wagner's option) and return it to you, postage prepaid.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion of incidental or consequential damages, so the

above limitation and exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Garantie limitée d’une année de la société Wagner – GARDEZ DANS VOS DOSSIERS – Français

Ce produit, fabriqué par la société Wagner Spray Tech (« Wagner »), est garanti au premier acheteur au détail contre toute défectuosité de

matériau ou d’exécution, pour une période d’une année à compter de la date d’achat, pourvu que l’on se serve du produit en suivant les

recommandations et consignes écrites de Wagner. Ce produit est destiné à l’usage domestique seulement. Si on l’utilise pour des fins

professionnelles ou pour la location, la présente garantie ne s’applique que pendant une période de 30 jours à compter de la date d’achat.

La présente garantie ne s’applique pas aux dégâts entraînés par une utilisation incorrecte, par un accident, par la négligence de l’usager ou

par l’usure normale. La présente garantie ne s’applique non plus aux défectuosités ou dommages résultant de l’entretien ou de la réparation

que fait une personne quelconque qui ne soit pas membre d’un centre d’entretien agréé de Wagner. La présente garantie ne s’applique pas

aux accessoires.

TOUTE GARANTIE IMPLICITE DE QUALITÉ MARCHANDE OU D’ADAPTATION À UN USAGE PARTICULIER EST LIMITÉE À UNE

PÉRIODE D’UNE ANNÉE POUR L’UTILISATION DOMESTIQUE ET DE 30 JOURS POUR UNE UTILISATION PROFESSIONNELLE OU DE

LOCATION, À COMPTER DE LADATE D’ACHAT.

WAGNER NE SERA EN AUCUN CAS RESPONSABLE DE DOMMAGES ACCESSOIRES OU INDIRECTS DE QUELQUE NATURE QUE CE

SOIT, À LA SUITE D’UNE INOBSERVATION DE LA PRÉSENTE GARANTIE OU POUR UNE AUTRE RAISON QUELCONQUE.

Si un produit est défectueux en ce qui concerne les matériaux ou l’exécution pendant la période de garantie applicable, vous devez le

retourner, avec une preuve d’achat et frais de port payés, à n’importe quel centre d’entretien agréé de Wagner. Pour connaître l’emplacement

des centres d’entretien agréés de la société, communiquez avec le service technique de Wagner au 1770 Fernbrook Lane, Minneapolis, MN

55447 USA, ou téléphonez au 1-800-760-3844. Le centre d’entretien agréé de Wagner réparera ou remplacera le produit (à la discrétion de

Wagner) et vous le retournera par la poste, avec frais de port payés.

Certaines provinces interdisent les restrictions sur la durée d’une garantie implicite ou l’exclusion des dommages accessoires ou indirects. Il

se peut donc que la restriction et l’exclusion énoncées ci-dessus ne s’appliquent pas à vous.

Le présente garantie vous accorde des droits juridiques spécifiques, et vous avez peut-être d’autres droits, qui peuvent varier d’une province

à l’autre.

Garantía limitada de un año de Wagner – MANTENGALAARCHIVADA – Español

Este producto fabricado por Wagner Spray Tech Corporation (Wagner) es garantizado al comprador original al por menor contra defectos en

el material y la mano de obra por un año a partir de la fecha de compra si se opera siguiendo las recomendaciones e instrucciones impresas

de Wagner. Este producto ha sido diseñado solamente para uso doméstico. Si se usa para propósitos profesionales o de alquiler, esta

garantía se aplica solamente por 30 días a partir de la fecha de compra.

Esta garantía no cubre daños que resulten del uso inadecuado, accidentes, negligencia del usuario o desgaste normal. Esta garantía no

cubre defectos ni daños causados en mantenimiento o reparaciones realizados por alguien que no sea un Centro de Servicio Autorizado por

Wagner. Esta garantía no se aplica a los accesorios.

TODA GARANTIA IMPLICITA DE COMERCIABILIDAD O APTITUD PARA UN PROPOSITO PARTICULAR ESTA LIMITADAA UN AÑO PARA

USO DOMESTICO Y A TREINTA DIAS PARA USO PROFESIONAL O DE ALQUILER A PARTIR DE LA FECHA DE COMPRA.

WAGNER NO SERA RESPONSABLE BAJO NINGUNA CIRCUNSTANCIA POR NINGUN DAÑO INCIDENTALO INDIRECTO DE NINGUNA

CLASE, YA SEA POR VIOLACION DE ESTA GARANTIA O CUALQUIER OTRA RAZON.

Si cualquier producto resulta defectuoso en sus materiales y/o mano de obra durante el periodo de garantía aplicado, devuélvalo con el

comprobante de compra, flete pagado anticipadamente, a cualquier Centro de Servicio Autorizado por Wagner. Póngase en contacto con el

Departamento de Servicio Técnico de Wagner en 1770 Fernbrook Lane, Minneapolis, MN 55447 o llame por teléfono al

1-800-760-3844 para averiguar las ubicaciones de los Centros de Servicio Autorizados. El Centro de Servicio Autorizado de Wagner

reparará o cambiará el producto (a criterio de Wagner) y se lo devolverá a usted con el porte pagado anticipadamente.

Algunos estados no permiten limitaciones a la duración de una garantía implícita ni la exclusión de daños incidentales o indirectos, de modo

que la limitación y exclusión anteriores puede que no se apliquen a usted.

Esta garantía le da a usted derechos legales específicos y usted podría tener también otros derechos que varían de un estado a otro.

Loading...

Loading...