Wagner 980 Owner’s Manual

Safety Information ................................. 2

Parts and Components ............................. 3

Assembly ........................................ 4

Painting ......................................... 5

Changing Accessories .............................. 5

Cleanup ....................................... 6_7

Optional Cleanup ................................ 8_9

Cleanup and storage tips .......................... 10

Maintenance .................................... 10

Troubleshooting .................................. 11

Registration card ................................. 11

Parts List .................................... 32_33

Warranty ....................................... 34

Consignes de securite ............................. 12

Pieces et composants ............................. 13

Assemblage ..................................... 14

Peinture ........................................ 15

Changement d'accessoires ......................... 15

Nettoyage .................................... 16-17

Nettoyage facultatif ............................. 18-19

Conseils concernant le nettoyage et le rangement ....... 20

Entretien ....................................... 20

Depannage / Carte d'enregistrement du produit ......... 21

Liste des pi_ces ............................... 32-33

Garantie ........................................ 34

Neures d'ouverture du Service technique :

du lunde au vendredi, de 8 h a 4:30 h, heure normale du Centre

1-800-760-3844

Or visit us on the world wide web!

iO visitenos en Internet!

Monday through Friday, 8:00 am to 4:30 Central Time

Technical service hours:

EspaSol : Tabla de Contenido

Informaci6n de seguridad .......................... 22

Piezas y componentes ............................ 23

Ensamblaje ..................................... 24

Pintura ......................................... 25

C6mo cambiar los accesorios ....................... 25

Limpieza ..................................... 26-27

Limpieza opci6nal .............................. 28-29

Sugerencias de limpieza y almacenamiento ............ 30

Mantenimiento ................................... 30

Soluci6n de problemas/Targeta de registro del producto .... 31

Liste de piezas ................................ 32-33

Garanfia limitada ................................. 35

Horatio del servicio tecnico:

De lunes a viernes, de 8 a.m. a 4:30 p.m., Nora Central

&Necesita Ayuda?

Ll&menos primero para

obtener respuestas r_pidas.

Llame a la [nea gratuita de

Wagner si quiere hacer un

comentario o tiene problemas

con este producto de Wagner.

0506. Form No. 0514825D

To reduce the risks of fire or e×plosion, electrical shock and the injury to persons, read and understand all instructions included in

this manual, Be familiar with the controls and proper usage of the equipment.

iMPORTANT

kWARNING ]] Indicates a hazardous situation which, if not

HAZARD: EXPLOSION OR FiRE

Solvent and paint fumes can explode or ignite, causing property damage

and/or severe injury.

PREVENTION:

= Exhaust and fresh air introduction must be provided to keep the air

within the work area free from accumulation of flammable vapors.

Avoid all ignition sources such as static electricity sparks, open flames,

pilot lights, hot objects, cigarettes, and sparks from connecting and

disconnecting power cords or working light switches.

• Fire extinguishing equipment must be present and in working order.

Do not use materials with a flashpoint below 100° F (38° C). A fluid's

flashpoint is the temperature at which vapors from the fluid could ignite

if exposed to a flame or spark. Consult your paint supplier for

information about a fluid's flashpoint.

Keep the unit in a well ventilated location away from the work area.

The pump contains arcing parts which emit sparks.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials may be harmful if

inhaled, causing severe nausea, fainting, or poisoning.

= Use a respirator or mask whenever there is a chance that vapors may

be inhaled. Read all instructions with the mask to insure that it will

provide the necessary protection against the inhalation of harmful

vapors.

HAZARD: GENERAL

May cause property damage or severe injury.

• Read all instructions and safety precautions before operating any

equipment. Never leave the unit running while unattended. Unplug

whenever not in use.

Never immerse the unit into any liquid.

• Comply with all appropriate local, state and national codes governing

ventilation, fire prevention, and operation.

• This paint roller system is designed to be used with authorized parts

only. When using this system with parts that do not comply with the

minimum specifications and safety devices of the system manufacturer,

the user assumes all risks and liabilities.

• Before each use, check all hoses for cuts, leaks, abrasion or bulging of

cover or damage or movement of couplings. If any of these conditions

exist, call Customer Service. Never repair a paint hose, replace it with

a new one.

Additional warnings are contained On the tag molded to the I

electrical cord of the uni t Be sur e to read th S ta g before

operating the unit.

avoided, could result in death or serious injury.

Specifications

Flow rate ........................... 10-12 oz. per minute

Power sou rce ................... 120 VAC

Power requirement ........... 60 Hz current.

Capability .......................... Most oil and water based paints and stains. Do not

use with lacquers, lacquer thinners or any other

solvent with a flash point below 100 ° F (38°C).

General Description

This high performance power roller is a precision power tool used for both

interior and exterior painting and may be used with both water (latex) and oil

based paints.

Use of oil-based paints must be limited to only those paints which can

be cleaned with mineral spirits. Latex paints can be cleaned with

soapy, lukewarm water. DO NOT use hot water when cleaning or

flushing the unit.

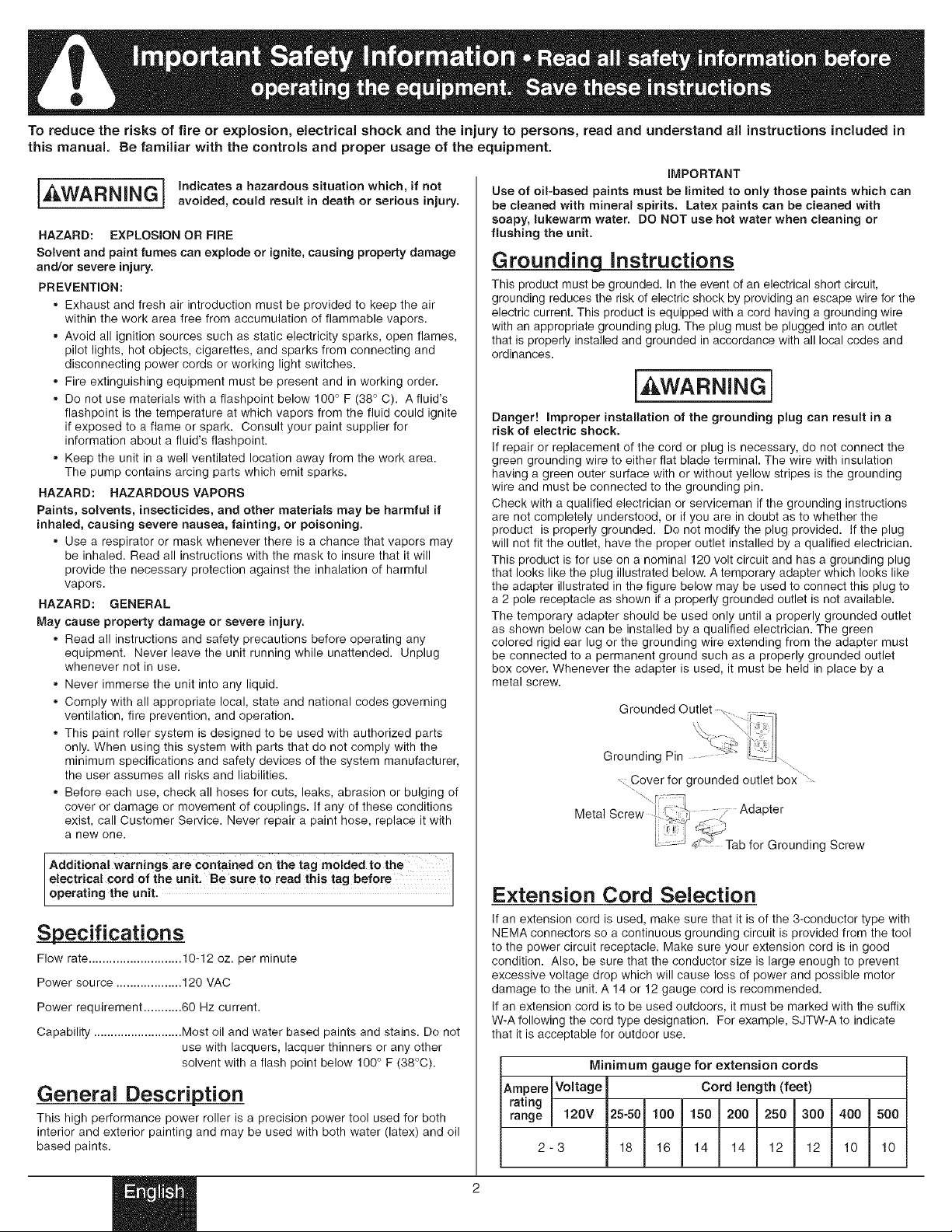

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire for the

electric current. This product is equipped with a cord having a grounding wire

with an appropriate grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded in accordance with all local codes and

ordinances.

[IkWARNING I

Danger! Improper installation of the grounding plug can result in a

risk of electric shock.

if repair or replacement of the cord or plug is necessary, do not connect the

green grounding wire to either flat blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is the grounding

wire and must be connected to the grounding pin.

Check with a qualified electrician or serviceman if the grounding instructions

are not completely understood, or if you are in doubt as to whether the

product is properly grounded. Do not modify the plug provided. If the plug

will not fit the outlet, have the proper outlet installed by a qualified electrician.

This product is for use on a nominal 120 volt circuit and has a grounding plug

that looks like the plug illustrated below. A temporary adapter which looks like

the adapter illustrated in the figure below may be used to connect this plug to

a 2 pole receptacle as shown if a properly grounded outlet is not available.

The temporary adapter should be used only until a properly grounded outlet

as shown below can be installed by a qualified electrician. The green

colored rigid ear lug or the grounding wire extending from the adapter must

be connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by a

metal screw.

Grounding Pin

....Cover for grounded outlet box ..............

Metal

Tab for Grounding Screw

Extension Cord Selection

If an extension cord is used, make sure that it is of the 3-conductor type with

NEMA connectors so a continuous grounding circuit is provided from the tool

to the power circuit receptacle. Make sure your extension cord is in good

condition. Also, be sure that the conductor size is large enough to prevent

excessive voltage drop which will cause loss of power and possible motor

damage to the unit. A 14 or 12 gauge cord is recommended.

If an extension cord is to be used outdoors, it must be marked with the suffix

W-A following the cord type designation. For example, SJTW-A to indicate

that it is acceptable for outdoor use.

Minimum gauge for extension cords

Ampere Vomtage Cord mength (feet)

rating

range 120V 25-50 100 150 200 250 300 400 500

2-3 18 16 14 14 12 12 10 10

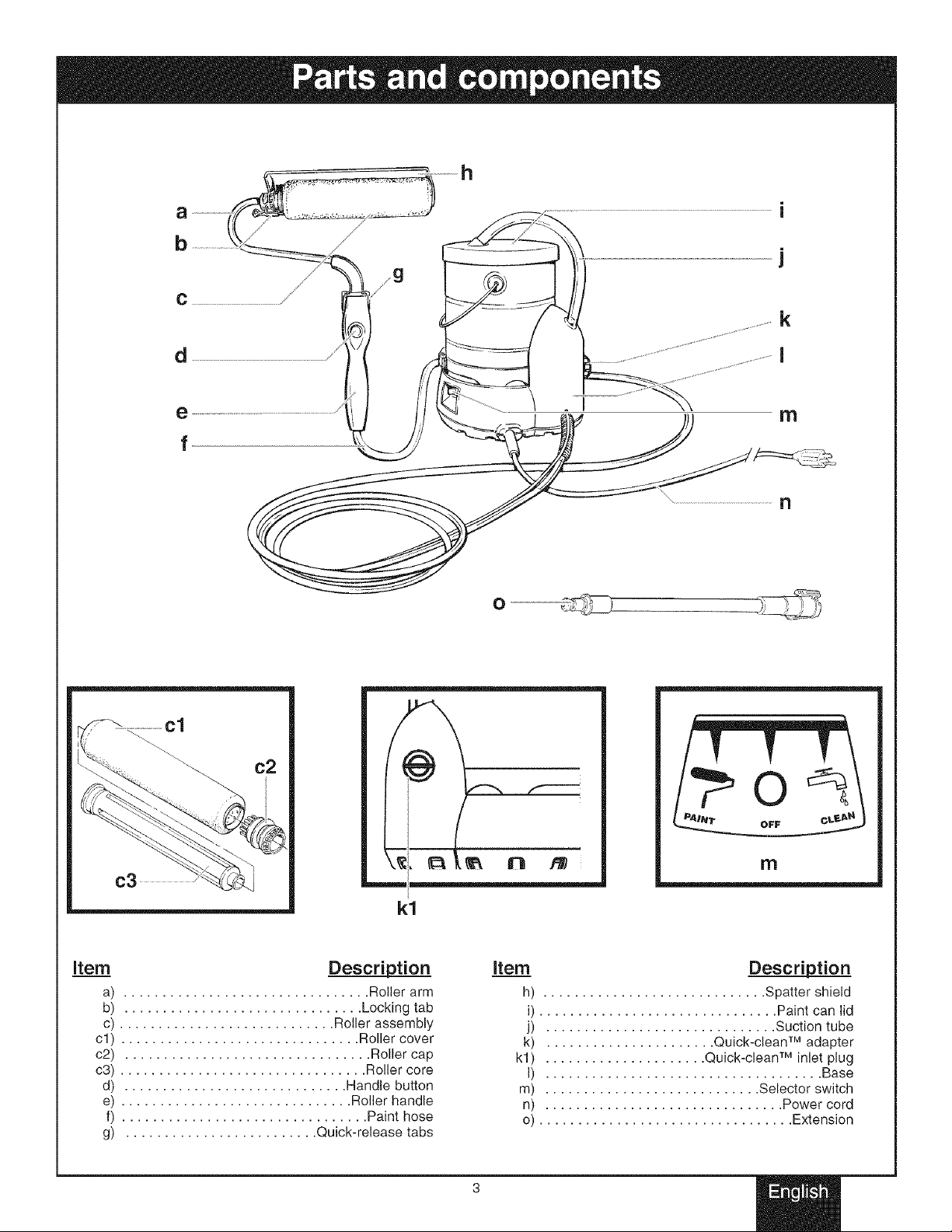

d

e

f

÷

item Description

a) ................................ Roller arm

b) ............................... Locking tab

c) ............................ Roller assembly

cl) ............................... Roller cover

c2) ................................ Roller cap

c3) ................................ Roller core

d) ............................. Handle button

e) .............................. Roller handle

f) ................................ Paint hose

g) ......................... Quick-release tabs

m

kl

item Description

h) ............................. Spatter shield

i) ............................... Paint can lid

j) .............................. Suction tube

k) ...................... Quick-clean TM adapter

kl) ..................... Quick-clean TM inlet plug

I) .................................... Base

m) ............................ Selector switch

n) ............................... Power cord

o) ................................. Extension

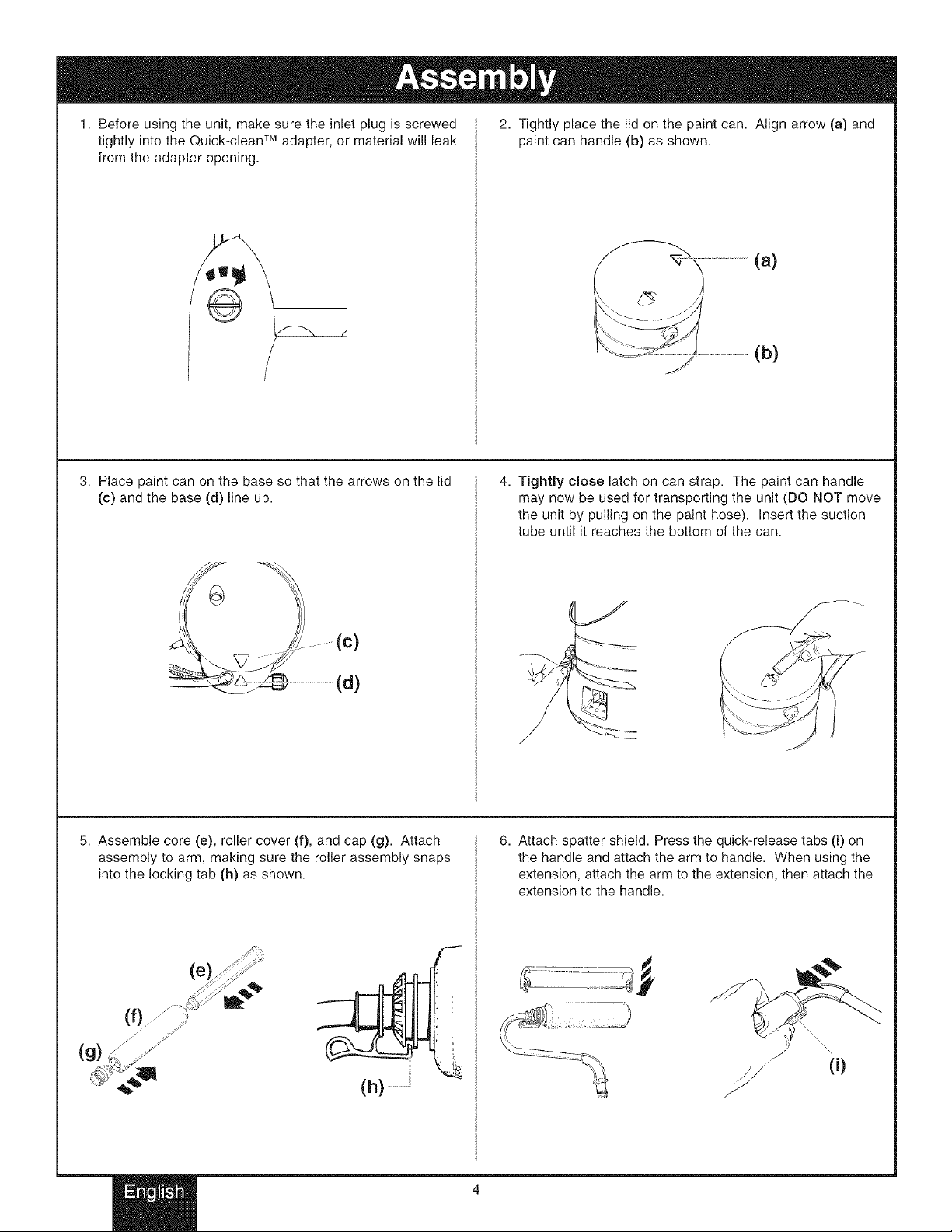

1.Beforeusingtheunit,makesuretheinletplugisscrewed

tightlyintotheQuick-cleanTMadapter,ormaterialwillleak

fromtheadapteropening.

2.Tightlyplacethelidonthepaintcan.Alignarrow(a)and

paintcanhandle(b)asshown.

(a)

(b)

3. Place paint can on the base so that the arrows on the lid

(c) and the base (d) line up.

5. Assemble core (e), roller cover (f), and cap (g). Attach

assembly to arm, making sure the roller assembly snaps

into the locking tab (h) as shown.

4. Tightly close latch on can strap. The paint can handle

may now be used for transporting the unit (DO NOT move

the unit by pulling on the paint hose). Insert the suction

tube until it reaches the bottom of the can.

t

6. Attach spatter shield. Press the quick-release tabs (i) on

the handle and attach the arm to handle. When using the

extension, attach the arm to the extension, then attach the

extension to the handle.

(f)

(h)..............

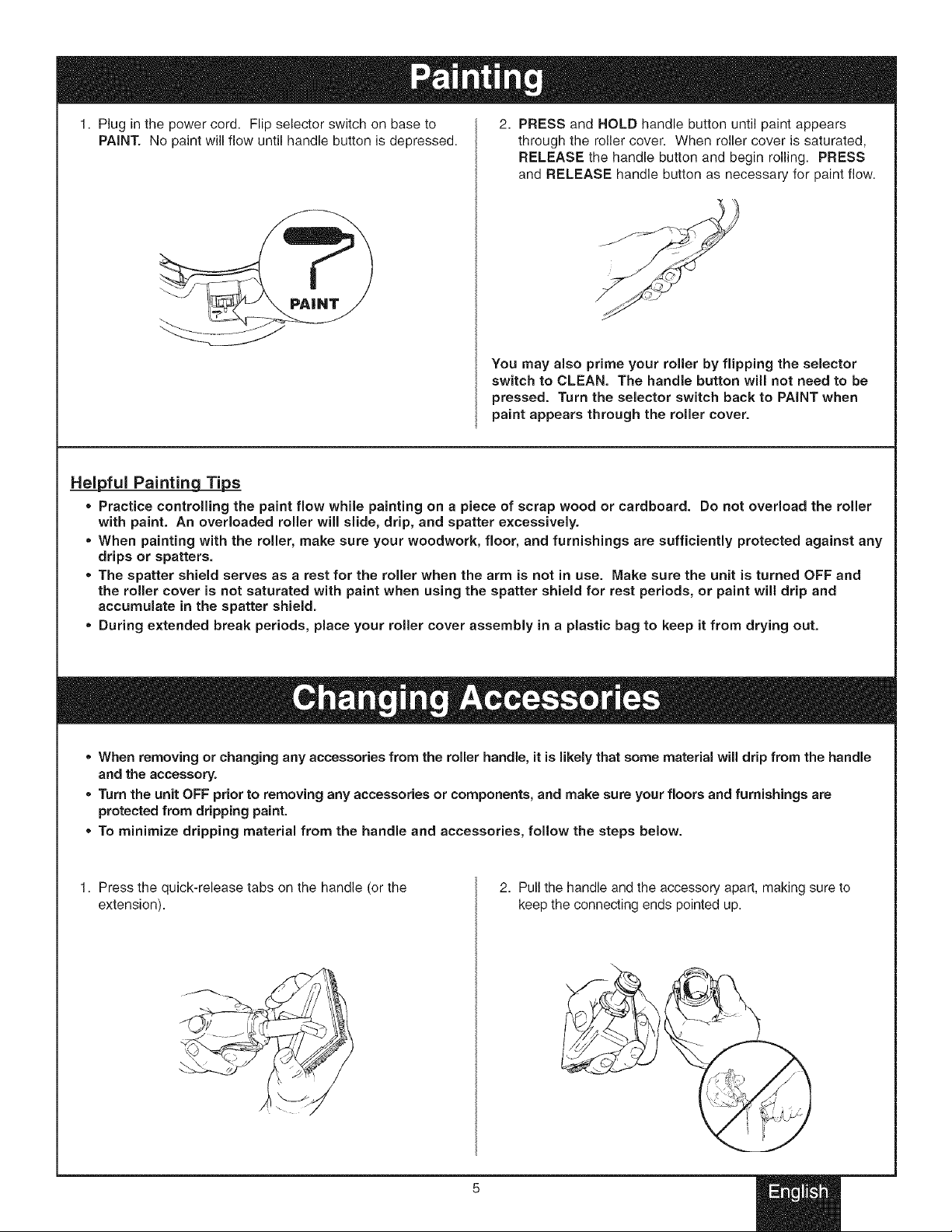

1.Pluginthepowercord.Flipselectorswitchonbaseto

PAINT. No paint will flow until handle button is depressed.

2. PRESS and HOLD handle button until paint appears

through the roller cover. When roller cover is saturated,

RELEASE the handle button and begin rolling. PRESS

and RELEASE handle button as necessary for paint flow.

You may also prime your roller by flipping the selector

switch to CLEAN. The handle button will not need to be

pressed. Turn the selector switch back to PAINT when

paint appears through the roller cover.

Helpful Painting Tips

, Practice controlling the paint flow while painting on a piece of scrap wood or cardboard. Do not overload the roller

with paint. An overloaded roller will slide, drip, and spatter excessively.

When painting with the roller, make sure your woodwork, floor, and furnishings are sufficiently protected against any

drips or spatters.

• The spatter shield serves as a rest for the roller when the arm is not in use. Make sure the unit is turned OFF and

the roller cover is not saturated with paint when using the spatter shield for rest periods, or paint will drip and

accumulate in the spatter shield.

During extended break periods, place your roller cover assembly in a plastic bag to keep it from drying out.

When removing or changing any accessories from the roller handle, it is likely that some material will drip from the handle

and the accessory.

o Turn the unit OFF prior to removing any accessories or components, and make sure your floors and furnishings are

protected from dripping paint.

• To minimize dripping material from the handle and accessories, follow the steps below.

1. Press the quick-release tabs on the handle (or the

extension).

2. Pull the handle and the accessory apart, making sure to

keep the connecting ends pointed up.

Loading...

Loading...