Page 1

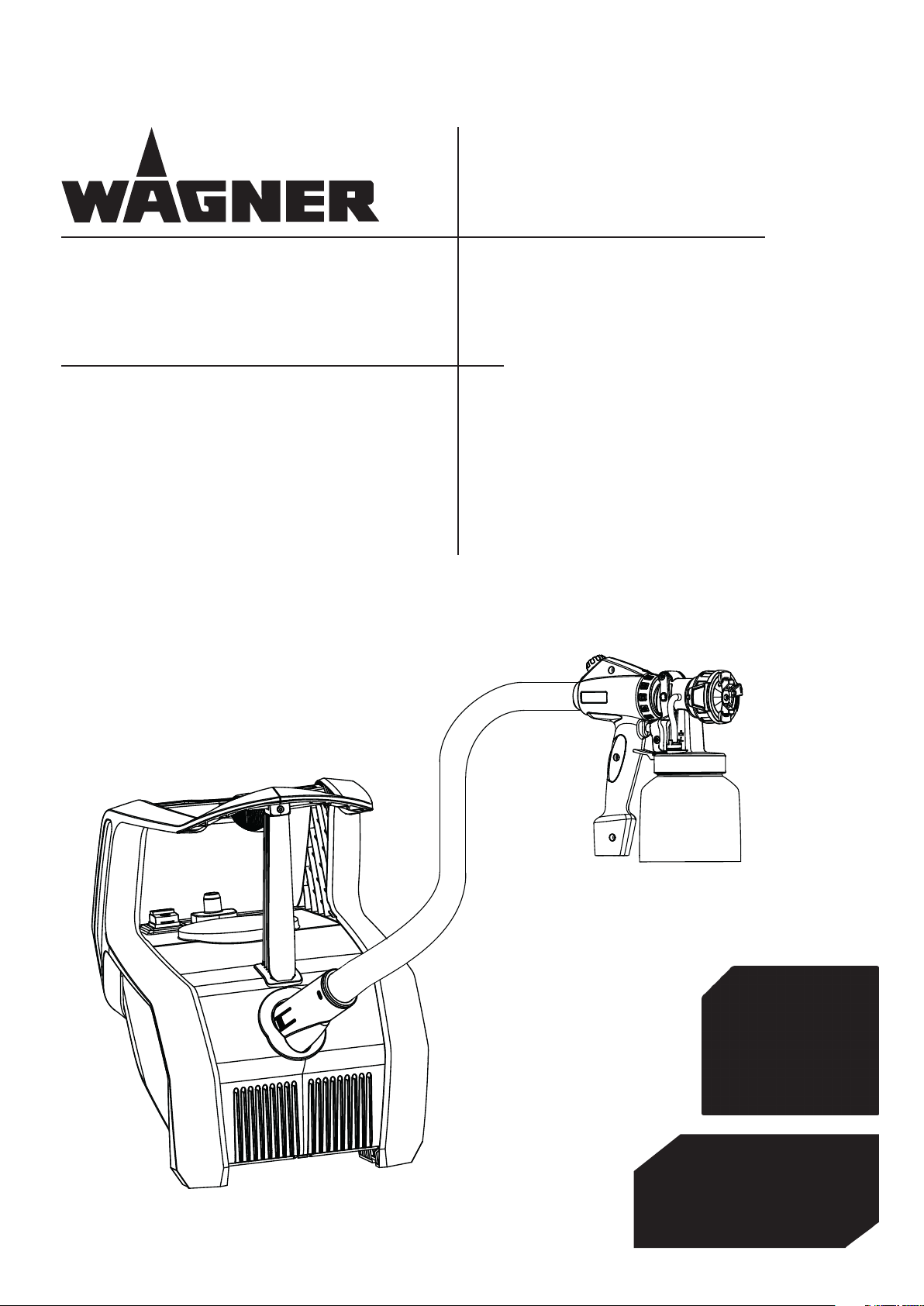

FinishControl 5000

- AUS- Operating manual 1

2339012

07/ 2014

Page 2

FinishControl 5000

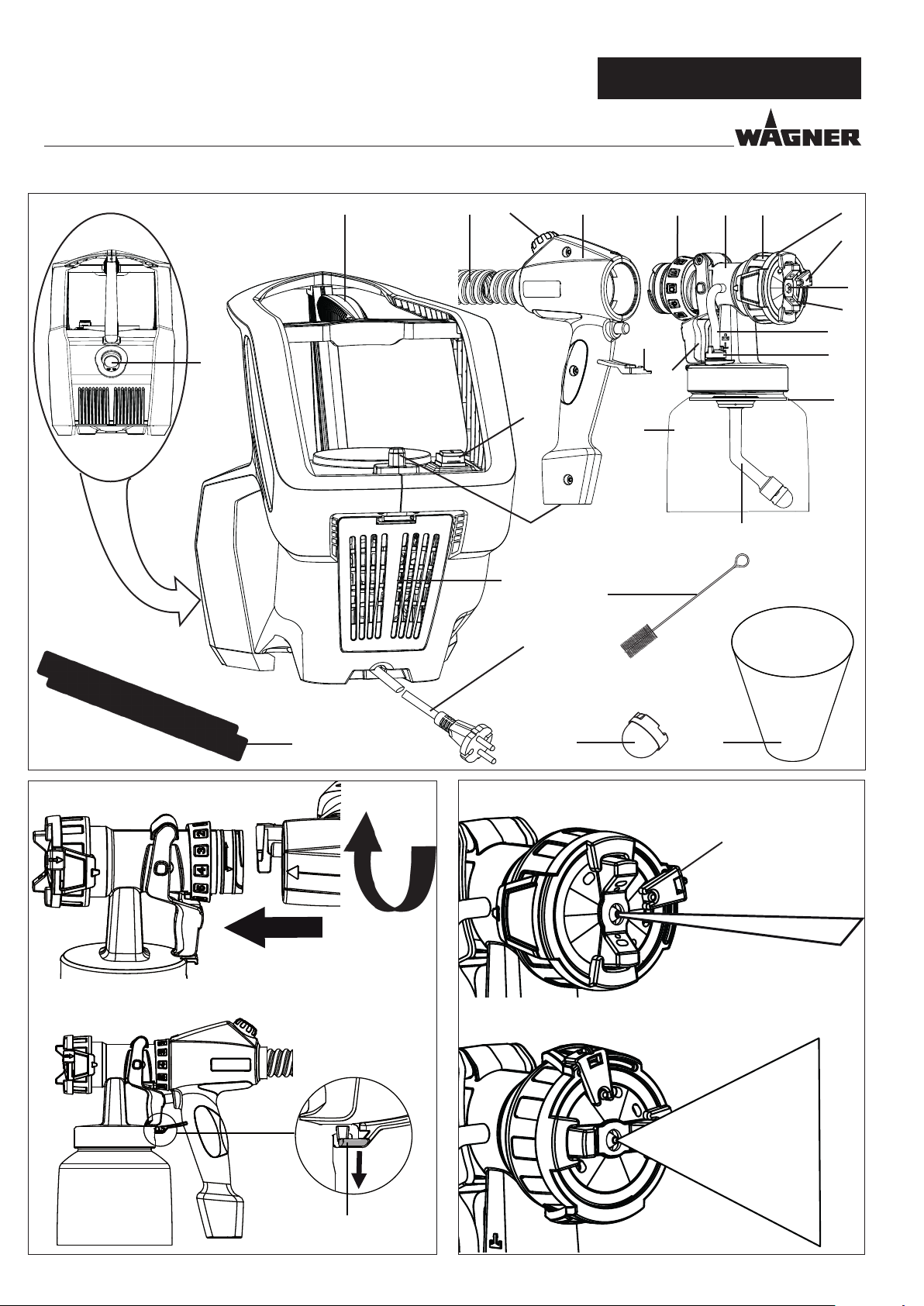

24

18

19

20

21/22

23

8910 6

13

25

7

11

12

45

3

1

2

17

16

15

14

3.

1.1.

28

2.

26

27

1

A

B

A

Page 3

FinishControl 5000

1

1

1

A

1.

2.

B

3 – 20 cm

2

1.

2.

1

Page 4

FinishControl 5000

1

2

3

4 5

1

Page 5

FinishControl 5000

1

2

3

4

3

9

10

1

2

5

1

7

8

11

12

13

14

3456

2

6

7

Page 6

AUS

i

CONTENTS

Contents

FinishControl 5000

1 SAFETY REGULATIONS _______________________ 1

2 EXPLANATORY DIAGRAM _____________________ 3

3 THE WAGNER CLICK&PAINT SYSTEM ___________ 3

3.1 Disassembly of the spray gun ____________________3

4 TECHNICAL DATA ____________________________ 4

5 INTRODUCTION TO SPRAYING USING THE XVLP

PROCEDURE _________________________________ 4

6 COATING MATERIAL __________________________ 4

6.1 Coating Materials Suitable for Use _________________4

6.2 Coating Materials Not Suitable for Use _____________4

6.3 Coating materials that can only be processed with relevant spray attachment (accessories) ______________4

6.4 Preparing the coating material ____________________4

7 SETTING THE SPRAY GUN _____________________ 5

7.1 Setting the required spray pattern _________________5

7.2 Setting the amount of material ___________________5

7.3 Setting the amount of air ________________________5

7.4 Align the feed tube _____________________________5

Explanation of symbols used

This symbol indicates a potential danger

for you or for the device.

Under this symbol you can nd important

information on how to

avoid injuries and damage to the device.

Indicates tips for use and other particularly

useful information.

Wide spray jet setting

Narrow spray jet setting

8 STARTING OPERATION _______________________ 5

9 SPRAYING TECHNIQUE _______________________ 5

10 BREAKS IN WORK ____________________________ 6

11 TRANSPORTATION ___________________________ 6

12 TAKING OUT OF OPERATION AND CLEANING ___ 6

12.1 Assembly _____________________________________6

13 MAINTENANCE ______________________________ 7

13.1 Air lter ______________________________________7

13.2 Air relief valve _________________________________7

14 CORRECTION OF MALFUNCTIONS _____________ 8

15 ACCESSORIES AND SPARE PARTS ______________ 9

15.1 Accessories ___________________________________9

15.2 Spare parts FinishControl ________________________9

15.3 Spare Parts FineSpray spray attachment ____________9

Testing of the unit ________________________________ 11

Note on disposal _________________________________ 11

Important information on product liability ____________ 11

Guarantee declaration _____________________________ 11

Wagner warranty policy ____________________________ 13

Service network __________________________________ 14

Page 7

FinishControl 5000

AUS

SAFETY REGULATIONS

1 SAFETY REGULATIONS

All local safety regulations in force must be observed.

Read the operating instructions carefully and follow the instructions laid down in them in order to avoid risks.

1. Safety at the workplace

a) Keep your workplace clean and well lit.

Disorder or unlit workplaces may result in accidents.

b) Never use the tool in hazardous areas that contain

ammable liquids, gases or dusts. Power tools

generate sparks that can ignite the dust or vapors.

c) Keep children and other persons away when using

the power tool. You can lose control of the tool if you are

distracted.

2. Electrical Safety

a) The tool plug must t into the socket. The plug may

not be modied in any form. Do not use adaptor

plugs together with protective-earthed tools.

Unmodied plugs and suitable sockets reduce the risk of

an electric shock.

b) Avoid physical contact with earthed surfaces such

as pipes, heating elements, stoves and refrigerators.

The risk through electric shock increases if your body is

earthed.

c) Keep the equipment away from rain and moisture.

The risk of an electric shock increases if water penetrates

electrical equipment.

b) Wear personal safety equipment and always wear

safety goggles. Wearing personal protective equipment,

such as dust mask, non-slip safety shoes, safety helmet

or ear protection, depending on the type of power tools,

reduces the risk of injury.

c) Avoid accidental starting-up. Ensure that the switch

is in the “OFF” position before inserting the plug

into the socket. Accidents can occur if you carry the

power tool while your nger is on the switch or if you

connect the power tool to the power supply which it is on.

d) Remove setting tools or wrenches before switching

on the power tool. A tool or wrench that is in a rotating

tool part can lead to injuries.

e) Avoid an unnatural posture. This ensures that you can

control the tool better in unexpected situations.

f) Wear suitable clothing. Do not wear wide clothing or

jewellery. Keep your hair, clothes and gloves away

from moving parts. Loose clothing, jewellery or long hair

can be caught in moving parts.

g) This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not

play with the appliance.

4. Careful Handling and Use of Power Tools

a) Do not overload the tool. Use the power tool

designed for the work that you are doing. You work

better and safer in the specied performance range if you

use the suitable power tool.

d) Do not misuse the mains lead by carrying the tool

by the lead, hanging it from the lead or by pulling

on the lead to remove the plug. Keep the lead away

from heat, oil, sharp edges or moving tool parts.

Damaged or twisted leads increase the risk of an electric

shock.

e) If you work outdoors with a power tool, only use

extension cables suitable for outdoor use. The use of

an extension lead that is suitable for outdoors reduces the

risk of an electric shock.

f) ) If you cannot avoid using the tool in a damp

environment, use a residual current operated

circuit-breaker. Using a residual current operated circuit-

breaker avoids the risk of electric shock.

3. Safety of Persons

a) Be attentive. Pay attention to what you are doing

and work sensibly with a power tool. Do not use the

tool if you are tired or under the inuence of drugs,

alcohol or medication. Just a moment of inattentiveness

while using the tool can lead to serious injuries.

b) Do not use power tools whose switch is defective. A

power tool that cannot be switched on or o is dangerous

and has to be repaired.

c) Remove the plug from the socket before carrying

out tool settings, changing accessories or putting

the tool away. This precautionary measure prevents

unintentional starting of the tool.

d) Store unused power tools so that they are

inaccessible to children. Do not let persons use the

tool who are not familiar with it or who have not

read these instructions. Power tools are dangerous

when they are used by inexperienced persons.

e) Take proper care of your tools. Check whether the

moving parts function trouble-free and do not jam,

whether parts are broken or damaged so that the

tool function is impaired. Have damaged parts repaired

before using the tool. Many accidents have their origin in

power tools that have been maintained badly.

f) Use the power tool, accessories, insert tools, etc. in

accordance with these instructions and in a fashion

specied for this special tool type. Take the working

conditions and the activity to be carried out into

consideration. The use of power tools for purposes other

than the intended ones can lead to dangerous situations.

1

Page 8

AUS

SAFETY REGULATIONS

FinishControl 5000

5. Service

a) Have your tool repaired only by qualied specialist

personnel and only with original spare parts. This

ensures that the tool safety is maintained.

b) If the supply cord is damaged, it must be replaced

by the manufacturer or it’s service agent or a

similarly qualied person in order to avoid a safety

hazard.

Safety instructions for colour application

devices

1. Risks of Fire and Explosion

Combustible gases develop in the work area

when spraying coating substances and due to the

autonomous formation of coating substances and

solvent vapors (danger zone).

Risk of re and explosion due to ignition sources in

this danger zone.

The electrically operated spray device contains

potential ignition sources (spark formation when

switching the motor on and o, when inserting and

removing the power plug, due to potential static

electricity at the spray gun)

-> Device must not be used at operating sites that fall

under the explosion protection ordinance.

-> Basic unit and mains connection must be located

outside the danger zone.

-> Do not use combustible coating substances and

cleaning agents -> observe product data sheets!

->Always seal paint or solvent containers tightly in

the vicinity of the device.

-> No ignition sources such as open re, lit tobacco

products, glowing wires, hot surfaces, sparks e.g. due

to angle grinders etc. must be present.

-> When cleaning the device with solvent do not spray

into a container with a small opening (bung hole).

Danger due to formation of an explosive gas/air

mixture.

The container into which you are spraying must be

earthed.

2. Warning: Danger of injury!

Never point spray gun at yourself, other persons or

animals.

3.

Wear breathing equipment when spraying.

The user should be supplied with a breathing mask. In order

to avoid occupational diseases, the working instructions

provided by the manufacturer of the materials, solvents

and cleaning agents used must be complied with during

preparation, working with and cleaning the equipment.

Protective clothing, gloves and, if necessary, protective skin

cream is required to protect the skin.

4.

Warning: When working with the paint spraying

system, both indoors and outdoors, care should

be taken that no solvent vapours are driven to the

motor-operated blower or that no solvent containing

vapours form in the area around the paint spraying

system. Place the motor-operated blower on the

opposite side to the object to be sprayed. When

working outdoors take wind direction into account.

When working in closed places a sucient ventilation

must be ensured to remove the solvent vapours. The

distance from the motor – operated blower to the

object to be sprayed must be at least 3 m.

5. Warning: The device is not splash proof. It should not

be used, neither outdoors in the rain nor be sprayed

with water nor immersed in liquid. Do not use the

device in damp or wet environments.

6. The units may only be used with a functional valve. If

paints rises in the ventilating hose (Fig. 1, item 17) do

not operate the unit further! Dismantle and clean the

ventilating hose, valve and diaphragm and replace the

diaphragm if necessary.

7. Do not lay the lled spray gun down.

8. Extraction systems should be installed on-site according to

the local regulations.

9. The object to be coated must be earthed.

10. Caution against dangers that can arise from the sprayed

substance and observe the text and information on the

containers or the specications given by the substance

manufacturer.

11. Do not spray any liquid of unknown hazard potential.

12. Before dismounting the spray attachment, relieve

pressure by opening the container.

13. Before working on the device, remove the power plug

from the socket.

14. Work or repairs on the electrical equipment should only

be carried out by a professional electrician, even if there

are instructions regarding such work in the operating

instructions. No liability will be accepted for improper

installation.

15. Do not sit or stand on the device. Danger of tilting/

breaking!

2

Page 9

FinishControl 5000

POS.

DESIGNATION

POS.

DESIGNATION

2 EXPLANATORY DIAGRAM FIG. 1

AUS

EXPLANATORY DIAGRAM/ CLICK&PAINT SYSTEM

1 Nozzle

2 Air cap

3 Spray jet width adjusting lever (shaping air)

4 Spray jet level adjusting ring (vertical/horizontal)

5 Union nut

6 Spray attachment complete

7 Material volume regulation

8 Gun handle

9 Air volume control

10 Air hose

11 Click&Paint catch

12

Trigger (actuates turbine starting switch

conveyed)

13 Container

14 Suction tube

material is

15 Container seal

16 Valve

17 Ventilating hose

18 Carry handle

19 ON/OFF switch (I = ON, 0 = OFF)

20 Gun mounting for park position

21 Air lter cover

22 Air lter

23 Power cable

24 Air hose connection

25 Cleaning brush

26 Fine feed tube lter (red)

Coarse feed tube lter (white)

27 Funnel (3 pcs.)

28 Air hose xing straps (2 pcs.)

3 THE WAGNER CLICK&PAINT SYSTEM

With the Wagner Click&Paint System, the front part of the gun (spray attachment) can be replaced quickly and easily.

This enables a rapid material change without cleaning, and ensures that the right tool is available for every material and application.

The following spray attachments are available:

Spray attachment Area of application

StandardSpray (yellow)

Order No. 2321 879

FineSpray (brown)

Order No. 2321 877

WallSpray (white)

Order No. 2321 880

3.1 DISASSEMBLY OF THE SPRAY GUN

For assembly, insert the spray attachment into the gun handle so that the two arrows point at each other. Turn the gun handle

90° in the arrow direction until it audibly engages. (Fig. 2)

To remove the spray attachment, push the catch (Fig. 2, A) beneath the trigger down and turn the spray attachment by 90°.

Spray attachment with slit nozzle and 1000 ml stainless steel container. Processes all standard

paints.

Spray attachment with round nozzle and 1000 ml stainless steel container. Ideal for low-viscosity

paints and glazes.

Interior wall paint spray attachment with slit nozzle and 1400 ml plastic container. Designed for

processing acrylic paints.

3

Page 10

AUS

TECHNICAL DATA/ INTRODUCTION/ PREPARING THE COATING MATERIAL

FinishControl 5000

4 TECHNICAL DATA

Voltage: 240 V~, 50 Hz

Power consumption: 1500 W

Atomizing output: 300 W

Container volume: 1000 ml

Air hose: 5 m

Power cable: 4 m

Protection class: I

Sound pressure level:*

Uncertainty K:

Sound pressure output:*

Uncertainty K:

Oscillation level:

Uncertainty K:

Weight (motor-operated blower,

air hose and spray gun): 8 kg

* The acoustic emission value was ascertained in accordance

with EN 50144-2-7:2000

84 dB (A)

4 dB (A)

97 dB (A)

4 dB (A)

<2.5 m/s²

1.5 m/s²

5 INTRODUCTION TO SPRAYING

USING THE XVLP PROCEDURE

XVLP (Extra Volume Low Pressure) is a low pressure spraying

technique, which works with a high volume of air and a low air

pressure. The greatest advantage of this spraying technique

is the low paint mist formation. This reduces the amount required to cover the object to a minimum.

As opposed to conventional application of coatings, this

method achieves a highly economical and perfect surface

quality and is, at the same time, environmentally friendly.

Function description

The paint spraying system consists of a motor-operated turbo-blower, which provides the spray gun with atomisation air

through an air hose.

In the spray gun, a part of the atomisation air is used to pressurise the container. This pressure causes the coating material

to be fed through the uptake pipe to the nozzle where it is

atomised by the rest of the atomisation air.

All settings necessary for operation (e.g. material volume) can

be conveniently made, directly on the gun.

6 COATING MATERIAL

6.1 COATING MATERIALS SUITABLE FOR USE

Solvent-based and water-soluble lacquer paints

Mordants, glazes, stains, oils, clear varnishes, synthetic enamels, coloured paints, alkyd resin varnishes, primers, radiator

paints, hammer eect enamels, anti-rust paints, special-eect

paints, textured paints

6.2 COATING MATERIALS NOT SUITABLE FOR USE

Materials that contain highly abrasive components, facade

paint, caustic solutions and acidic coating substances.

Flammable materials.

6.3 COATING MATERIALS THAT CAN ONLY BE

PROCESSED WITH RELEVANT SPRAY

ATTACHMENT ACCESSORIES

WallSpray Attachment: Interior wall paint (acrylic paints)

6.4 PREPARING THE COATING MATERIAL

Observe the manufacturer’s instructions for the

use of the coating material on the paint tin or on

the technical instruction sheet.

Coating material purity:

An absolute pre-condition for the trouble-free operation of

the ne-spray system is that the coating material is uncontaminated. If you have doubts as to the purity of the coating

material, we recommend that you rst lter it through a ne

sieve.

Processing the coating material with the FineSpray spray

attachment (brown)

Coating Material Processing Comments

Solvent-based lacquer paints

Water-soluble lacquer paints

Mordants, glazes,

stains, oils

Clear varnishes, synthetic enamels, coloured paints, alkyd

resin varnishes

observe manufacturer’s instructions

observe manufacturer’s instructions

undiluted

observe manufacturer’s instructions

Primers, radiator

paints, hammer effect enamels

observe manufacturer’s instructions

4

Page 11

FinishControl 5000

AUS

SETTING THE SPRAY GUN /STARTING OPERATION/

SPRAYING TECHNIQUE

Anti-rust paints, special-eect paints

Multicolor paints,

textured paints

observe manufacturer’s instructions

observe manufacturer’s instructions

WallSpray spray

attachment

(white) recommended

7 SETTING THE SPRAY GUN

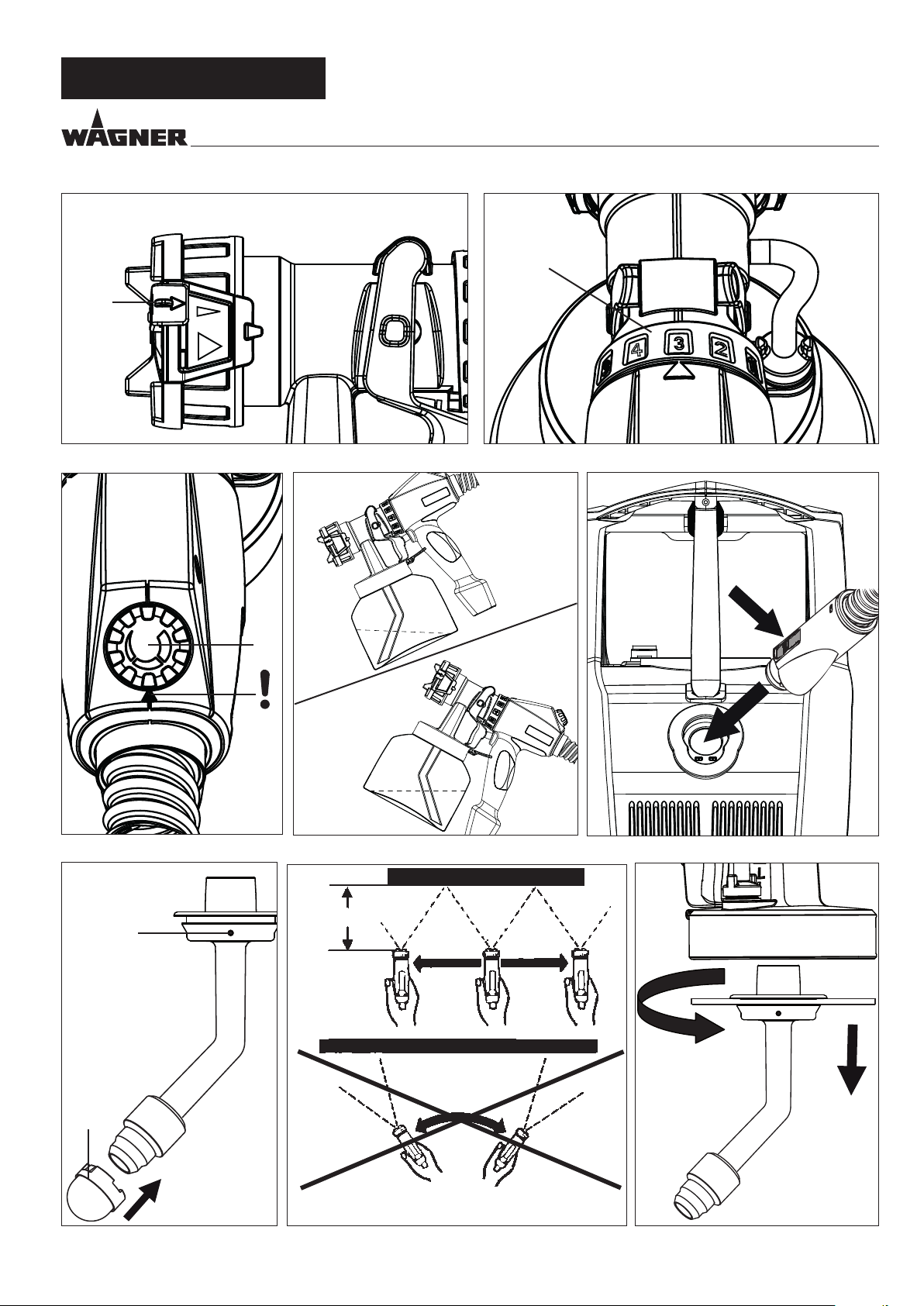

7.1 SETTING THE REQUIRED SPRAY PATTERN

Attention:

Never pull trigger while adjusting the air

cap settings.

The alignment of the spray jet can be determined by turning

the black adjusting ring (Fig. 3, 1).

A horizontal at jet

B vertical at jet

It is also possible to switch between a wide ( ) and a compact

( ) spray jet with the adjusting lever (Fig. 4, 1).

for vertical surfaces

for horizontal surfaces

8 STARTING OPERATION

Before connecting to the mains supply make sure that the

mains voltage corresponds to the operating voltage on the

rating plate. The unit must be connected with a properly

earthed shockproof socket.

1.

Squeeze the side clips together and insert the air hose onto

the basic unit. (Fig. 8)

2. Unscrew the container from the spray attachment.

3. Pour in the prepared coating material.

Fill the container

with maximum

1000 ml.

4.

Fit the appropriate lter to the feed tube depending on the

coating material used (Fig. 9, 1)

Low-viscosity coating materials

Viscous coating materials

5. Screw the container rmly onto the spray attachment.

6. Connect spray attachment and gun handle. (Fig. 2)

7. Plug in the power cable.

Switch on the main switch at the device.

8.

The device is now ready for operation.

1000ml

Fine lter (red)

Coarse lter (white)

7.2 SETTING THE AMOUNT OF MATERIAL FIG. 5)

The material volume can be adjusted incrementally from 1

(minimum) to 12 (maximum) by turning the material volume

control (Fig. 5, 1).

7.3 SETTING THE AMOUNT OF AIR FIG. 6

Turn the air volume control (Fig, 6, 1) clockwise to increase the

air volume or anti-clockwise to reduce the air volume (note

arrow on body of gun).

The correct setting of air and material volume is

crucial for atomisation and paint mist formation.

7.4 ALIGN THE FEED TUBE

If the feed tube is positioned correctly, the container

contents can be sprayed without almost any residue.

When working on lying objects:

Turn the feed tube forwards. (Fig. 7 A)

Spraying work when working on overhead objects:

Turn the feed tube rearwards. (Fig. 7 B)

9 SPRAYING TECHNIQUE

The FinishControl has a trigger with 2 pressure

points. In the rst stage the turbine is started. If

the trigger is pressed further, the material is trans-

ported.

Operate trigger on the spray gun.

Test spray a piece of cardboard to ensure correct setting of the

spray pattern, spray jet width, material and air volume.

Hold the paint spray gun upright and maintain a constant

distance of about 3 - 20 cm to the object being sprayed. (Fig.

10)

Move the paint spray gun evenly either from side to side or up

and down. If the gun is moved evenly, it will produce an even

surface nish.

Always start spraying away from the object and avoid stop-ping

spraying whilst still on the object.

In case of excessive paint mist formation, adjust the air and

material ow respectively and alter the distance from the

object.

5

Page 12

AUS

BREAKS IN WORK/ TRANSPORTATION/

TAKING OUT OF OPERATION AND CLEANING

FinishControl 5000

10 BREAKS IN WORK

1. Switch device o with main switch on the basic unit.

2. Insert spray gun into gun mounting on the device.

In using quick-drying or two-component coating

materials, do not fail to rinse unit through with

a suitable cleaning agent during the processing

period.

Important: The application life of the material can

change as a result of heating. Therefore, please

consult the material manufacturer.

11 TRANSPORTATION

1. Coil power cable around the basic unit.

2. Insert spray gun into gun mounting on the device.

3. Disconnect air hose by pressing the two side clips (Fig. 8).

4. Roll up the air hose and tie up with the xing straps.

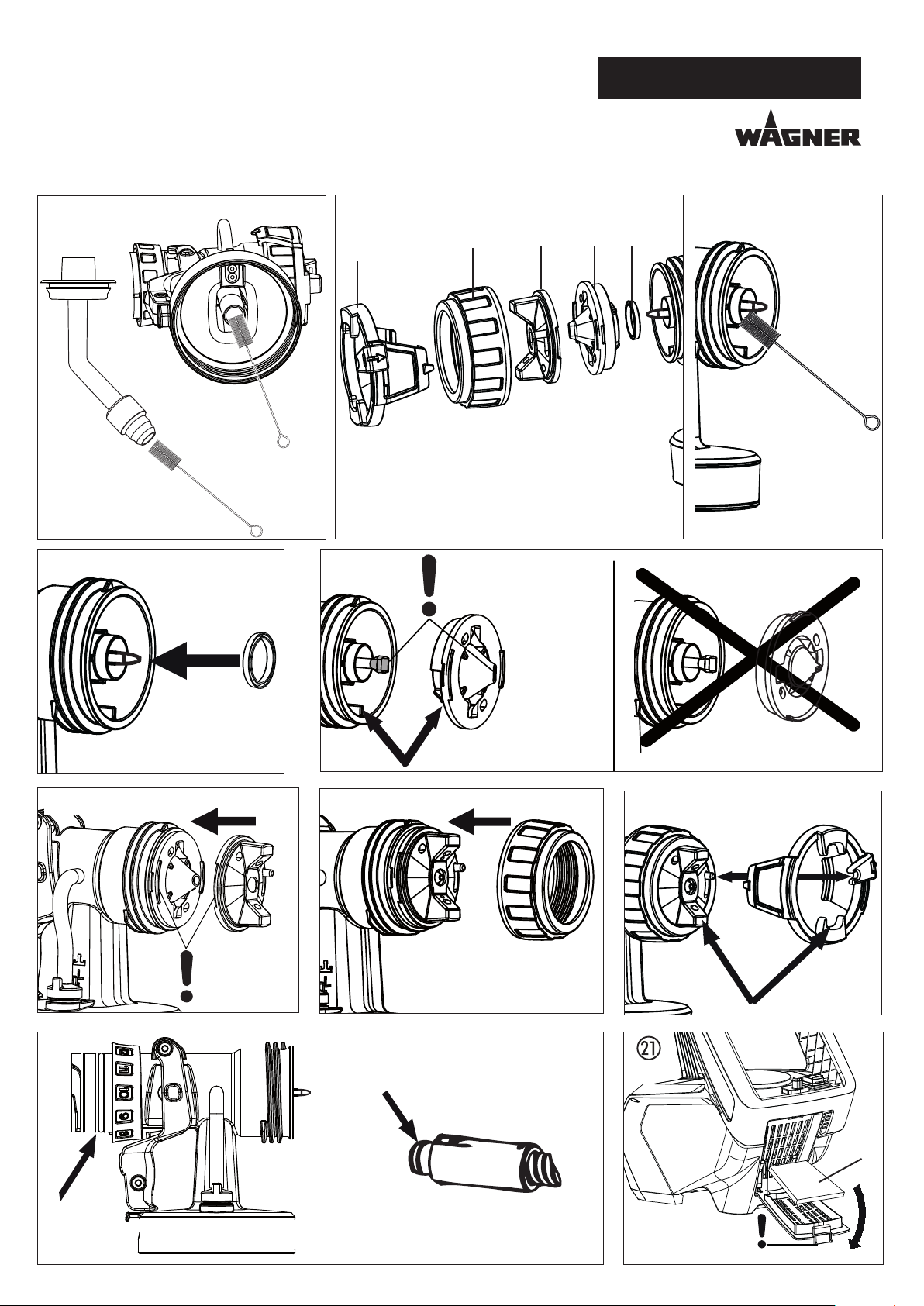

12 TAKING OUT OF OPERATION AND

CLEANING

CAUTION! Never clean seals, diaphragm

and nozzle or air holes of the spray gun

with metal objects.

The ventilation hose and diaphragm are

only solvent-resistant to a limited extent.

Do not immerse in solvent, only wipe.

11.

Remove the adjusting ring (fig. 13,1) carefully from

the union nut (2). Unscrew union nut (2), remove

air cap (3), nozzle (4) and nozzle seal (5).

Thoroughly clean all parts.

Take special care when cleaning the interstices on

the needle (Fig. 14)

Clean the outside of the spray gun and container with a

12.

cloth soaked in solvent or water.

13. Assemble the parts again (see “Assembly”).

12.1 ASSEMBLY

ATTENTION! Follow the steps described

below exactly for assembly. Otherwise

the spray attachment may be damaged.

1. Turn the machine o.

2. Divide the spray gun. Press catch (Fig. 2, A) down slightly.

Twist spray attachment and gun handle towards each

other.

ATTENTION! Electrical contacts in gun

handle. Never hold the gun handle under

water or immerse it into liquids.

Clean the housing only with a moistened

cloth.

3. Unscrew the container.

Empty the remaining coating material into the original

container.

4.

Pre-clean the container and feed tube using a

brush and suitable cleaning agent.

Clean the ventilating bore. (Fig. 9, 2)

5.

Pour solvent or water into the container. Screw the

container back on.

Do not use flammable materials for cleaning

purposes.

6. Connect spray attachment and gun handle. (Fig. 2)

7. Switch device on and ush spray attachment through with

solvent or water.

Repeat the above procedure until the solvent or water

emerging from the nozzle is clear.

8. Turn o the machine and divide the spray gun.

9.

Screw o the container and empty it.

Unscrew feed tube with container seal. (Fig. 11)

10.

Clean feed tube and suction nozzle in spray attachment

with cleaning brush. (Fig. 12)

1. Push nozzle seal onto the needle so that the groove (slot)

points away from the spray attachment. (Fig. 15)

2.

Place nozzle on the needle with recess downwards.

Attention if using WallSpray or StandardSpray:

Position of needle must be congruent with the nozzle

aperture. (Fig. 16)

3. Place air cap on nozzle (pay attention to recesses in the air

cap). (Fig. 17)

4. Screw on union nut. (Fig. 18)

5.

Snap the adjusting ring into the union nut. (Fig. 19)

Make sure that the two recesses on the adjusting ring

are engaged in the air cap clamps and that the lever for

adjusting the spray jet width is located on the pin.

6. Place the container seal from below on the feed tube and

slide it over the collar, while turning the container seal

slightly.

7. Screw the feed tube with the container seal into the body

of the gun.

In order to mount the gun more easily apply

lubricating grease (enclosed) liberally to the O-ring

at the spray attachment and to the O-ring of the

plug connection of the air hose (Fig. 20).

6

Page 13

FinishControl 5000

13 MAINTENANCE

13.1 AIR FILTER

Attention! Never operate the device with

the air lter soiled or missing, as dirt could

be sucked up and aect the operation of

the device.

Always check the air lter before starting

work.

1. Unplug the power plug.

2. Open the cover of the air lter compartment (Fig. 21).

3.

Clean (blow out) or replace the air filter (Fig. 21,1)

depending on the degree of soiling.

13.2 AIR RELIEF VALVE

If paint has entered the ventilation hose, proceed

as follows:

AUS

MAINTENANCE

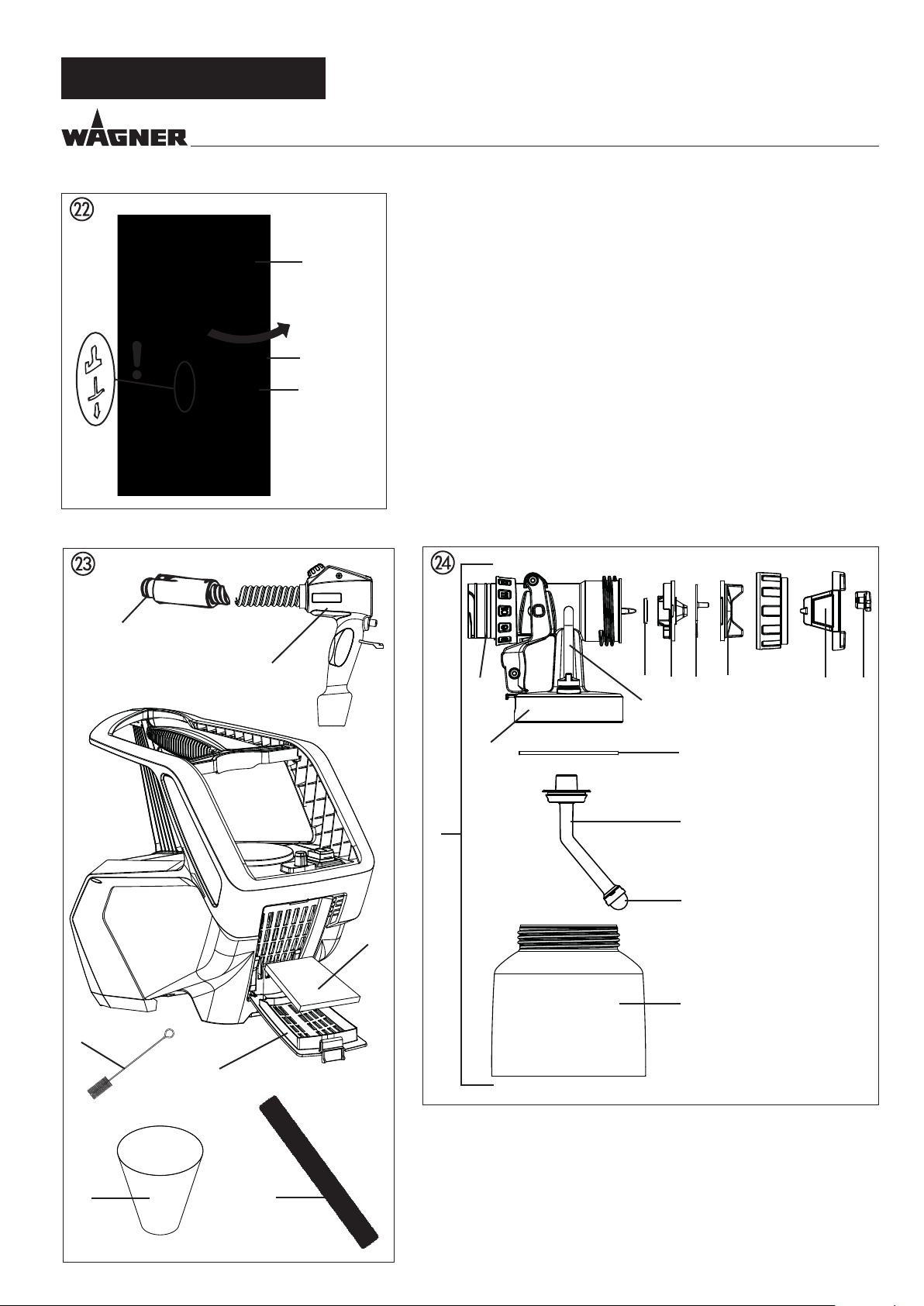

1. Pull the ventilating hose (Fig. 22, 1) at the top from the

gun body. Screw o the valve cover (2). Remove the

diaphragm (3). Clean all the parts carefully.

CAUTION! The ventilation hose and

diaphragm are only solvent-resistant to a

limited extent. Do not immerse in solvent,

only wipe.

2. Place the diaphragm in the valve cover with the pin facing

forward (Also see the marking on the gun body).

3. Turn the body of the gun upside down and screw on the

valve cover from underneath.

Place the ventilating hose on the valve cover and on the

4.

nipple at the gun body.

7

Page 14

AUS

CORRECTION OF MALFUNCTIONS

14 CORRECTION OF MALFUNCTIONS

MALFUNCTION CAUSE REMEDY

FinishControl 5000

The unit will not start

No coating material emerges

from the nozzle

Coating material drips from the

nozzle

Atomisation too coarse

Spray jet pulsates

Coating material causes “paint

tears

Excessive paint mist (overspray)• Distance to the object too large

Paint in the ventilating hose

No mains voltage

•

Device overheated

•

Nozzle clogged

•

Material volume setting too low

•

Paint container seal damaged

•

No pressure build-up in container

•

Container empty

•

Ventilation hose loose/damaged

•

Feed tube loose

•

Feed tube / feed tube lter clogged

•

Air vent on feed tube blocked

•

Diaphragm stuck

•

Air cap, nozzle or needle soiled

•

Spray attachment incorrectly

•

assembled

Nozzle loose

•

Nozzle seal worn

•

Nozzle worn

•

Needle worn

•

Material volume too large

•

Nozzle contaminated

•

Viscosity of coating material too high

•

Too little pressure build-up in

•

container

Air lter heavily soiled

•

Amount of air too low

•

Air hose damaged

•

Coating material in container running

•

out

Nozzle seal worn

•

Air lter heavily soiled

•

Feed tube loose

•

Feed tube / feed tube lter clogged

•

Too much coating material applied

•

Distance too small

•

Incorrect spray attachment

•

Too much coating material applied

•

Amount of air too high

•

Coating substance over-diluted

•

Incorrect spray attachment

•

Diaphragm soiled

•

Diaphragm defective

•

Check

•

Unplug the power plug, let the device cool

•

down approx. 30 minutes, do not bend the

hose, check the air lter, do not cover the intake

slots

Clean

•

Increase volume

•

Replace

•

Tighten container

•

Rell

•

Insert or replace

•

Insert

•

Clean or use another lter

•

Clean

•

Remove and clean (see section 13.2)

•

Clean

•

Assemble correctly (see section 12.1)

•

Tighten Union nut

•

Change

•

Change

•

Use new spray attachment

•

Reduce volume

•

Clean

•

Dilute further

•

Tighten container

•

Change (see section 13.1)

•

Increase volume

•

Check and replace if necessary

•

Rell

•

Replace

•

Change (see section 13.1)

•

Insert

•

Clean or use another lter

•

Reduce volume

•

Increase distance

•

Use another spray attachment

•

Reduce distance

•

Reduce volume

•

Reduce volume

•

Reduce degree of dilution

•

Use another spray attachment

•

Clean the diaphragm (see section 13.2)

•

Replace the diaphragm (see section 13.2)

•

8

Page 15

FinishControl 5000

15 ACCESSORIES AND SPARE PARTS

15.1 ACCESSORIES

AUS

ACCESSORIES AND SPARE PARTS

POS.

1 2321 879 StandardSpray spray attachment (yellow) (with 1000 ml container)

2 2321 877 FineSpray spray attachment (brown) (with 1000 ml container)

3 2321 880 WallSpray spray attachment (white) (with 1400 ml container)

4

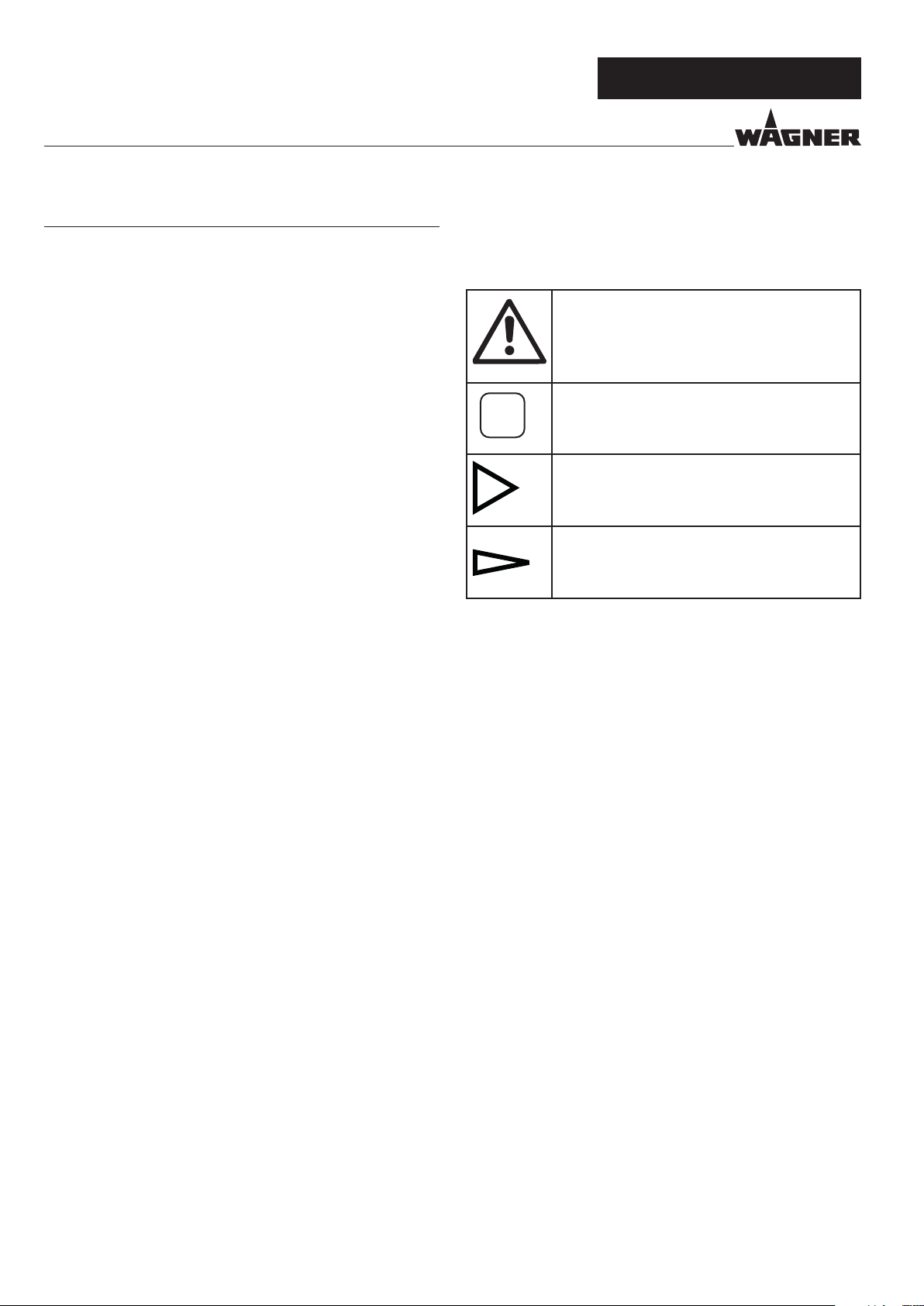

15.2 SPARE PARTS FINISHCONTROL 5000 FIG. 23

POS.

1 2312 650 Cover of air lter compartment

2 2322 446 Air lter (3 pcs.)

3 2314 573 Gun handle with air hose

4 0420 316 O-ring of air hose

5 0514 209 Cleaning brush

6 2324 745 Funnel (3 pcs.)

ORDER NO.

2324 749

ORDER NO.

DESIGNATION

Processes all standard paints.

Ideal for low-viscosity paints and glazes.

Designed for processing acrylics.

Container with cover (1400 ml)

DESIGNATION

7 2324 751 Air hose xing strap

15.3 SPARE PARTS FINESPRAY SPRAY ATTACHMENT BROWN FIG. 24

POS.

1 2321 877 FineSpray spray attachment (brown) (with 1000 ml container)

2

3 2314 591 Spray jet adjustment ring

4

5

6

7

8

9

10

11

12

ORDER NO.

2321 868

2332 579

2317 820

2314 585

2317 667

2323 934

2304 027

0417 308

2326 126

2319 223

DESIGNATION

Spray jet width adjusting lever

Union nut (brown)

Air cap

Air screen

Nozzle (R 1.8)

Nozzle seal

Ventilating hose, valve cover, diaphragm

O-ring of spray attachment

Body of gun (including position 8-10)

Container seal

13

2319 222

Feed tube

9

Page 16

AUS

SPARE PARTS AND ACCESSORIES

FinishControl 5000

POS.

14

15

ORDER NO.

2324 248

2324 249

2322 451

2315 539

DESIGNATION

Fine feed tube lter (red, 5 pc.)

Coarse feed tube lter (white, 5 pc.)

Container with cover 1000 ml

Lubricating grease

10

Page 17

FinishControl 5000

AUS

TESTING OF THE UNIT / INFORMATION ON PRODUCT LIABILITY / GUARANTEE DECLARATION

TESTING OF THE UNIT

For safety reasons, we would recommend having the device

checked by an expert as required but at least every 12 months

to ensure that it can continue to operate safely.

In the case of unused devices, the check can be postponed

until they are next started up.

All (potentially deviating) national inspection and maintenance regulations must also be observed.

If you have any questions, please contact the customer service

team at Wagner.

IMPORTANT INFORMATION ON PRODUCT LIABILITY

An EU directive valid since 01.01.1990 species that the manufacturer is only liable for his products if all the parts originate

from the manufacturer or are approved by him, and if the units

are mounted and operated properly.

If accessories or spare parts from third parties are used, liability

can be partially or completely inapplicable. In extreme cases

the responsible authorities can prohibit the use of the entire

unit (German industrial employer‘s liability insurance association and factory inspectorate).

GUARANTEE DECLARATION

(Status 01.02.2009)

1. Scope of guarantee

All Wagner professional colour application devices (hereafter referred to as products) are carefully inspected,

tested and are subject to strict checks under Wagner

quality assurance. Wagner exclusively issues extended

guarantees to commercial or professional users (hereafter

referred to as “customer”) who have purchased the product in an authorised specialist shop, and which relate to

the products listed for that customer on the Internet under

www.wagner-group.com/pro-guarantee.

The buyer’s claim for liability for defects from the purchase

agreement with the seller as well as statutory rights are not

impaired by this guarantee.

We provide a guarantee in that we decide whether to replace

or repair the product or individual parts, or take the device

back and reimburse the purchase price. The costs for materials

and working hours are our responsibility. Replaced products

or parts become our property.

2. Guarantee period and registration

With original WAGNER accessories and spare parts, compliance with all safety regulations is guaranteed.

NOTE ON DISPOSAL

In observance of the European Directive 2002/96/EC on waste

electrical and electronic equipment and implementation in

accordance with national law, this product is not to be disposed of together with household waste material but must be

recycled in an environmentally friendly way!

The guarantee period amounts to 36 months. For industrial

use or equal wear, such as shift operations in particular, or in

the event of rentals it amounts to 12 months.

Systems driven by petrol or air are also guaranteed for a 12

month period.

The guarantee period begins with the day of delivery by the

authorised specialist shop. The date on the original purchase

document is authoritative.

For all products bought in authorised specialist shops from

01.02.2009 the guarantee period is extended to 24 months

providing the buyer of these devices registers in accordance

with the following conditions within 4 weeks of the day of delivery by the authorised specialist shop.

Registration can be completed on the Internet under

www.wagner-group.com/pro-guarantee.

The guarantee certicate is valid as conrmation, as is the

original purchase document that carries the date of the purchase. Registration is only possible if the buyer is in agreement

with having the data being stored that is entered during registration.

When services are carried out under guarantee the guarantee

period for the product is neither extended nor renewed.

Once the guarantee period has expired, claims made against

the guarantee or from the guarantee can no longer be enforced.

11

Page 18

AUS

GUARANTEE DECLARATION

FinishControl 5000

3. Handling

If defects can be seen in the materials, processing or performance of the device during the guarantee period, guarantee

claims must be made immediately, or at the latest within a

period of 2 weeks.

The authorised specialist shop that delivered the device is entitled to accept guarantee claims. Guarantee claims may also be

made to the service centres named in our operating instructions. The product has to be sent without charge or presented

together with the original purchase document that includes

details of the purchase date and the name of the product. In

order to claim for an extension to the guarantee, the guarantee certicate must be included.

The costs as well as the risk of loss or damage to the product

in transit or by the centre that accepts the guarantee claims

or who delivers the repaired product, are the responsibility of

the customer.

4. Exclusion of guarantee

Guarantee claims cannot be considered

for parts that are subject to wear and tear due to use or other

-

natural wear and tear, as well as defects in the product that

are a result of natural wear and tear, or wear and tear due

to use. This includes in particular cables, valves, packaging,

jets, cylinders, pistons, means-carrying housing components,

lters, pipes, seals, rotors, stators, etc. Damage due to wear and

tear that is caused in particular by sanded coating materials,

such as dispersions, plaster, putty, adhesives, glazes, quartz

foundation.

in the event of errors in devices that are due to non-compliance

-

with the operating instructions, unsuitable or unprofessional

use, incorrect assembly and/or commissioning by the buyer

or by a third party, or utilisation other than is intended,

abnormal ambient conditions, unsuitable coating materials,

unsuitable operating conditions, operation with the incorrect

mains voltage supply/frequency, over-operation or defective

servicing or care and/or cleaning.

for errors in the device that have been caused by using

-

accessory parts, additional components or spare parts that

are not original Wagner parts.

for products to which modications or additions have been

-

carried out.

for products where the serial number has been removed or

-

is illegible

for products to which attempts at repairs have been carried

-

out by unauthorised persons.

for products with slight deviations from the target properties,

-

which are negligible with regard to the value and usability of

the device.

for products that have been partially or fully taken apart.

-

5. Additional regulations.

The above guarantees apply exclusively to products that have

been bought by authorised specialist shops in the EU, CIS,

Australia and are used within the reference country.

If the check shows that the case is not a guarantee case, repairs are carried out at the expense of the buyer.

The above regulations manage the legal relationship to us

concludingly. Additional claims, in particular for damages and

losses of any type, which occur as a result of the product or

its use, are excluded from the product liability act except with

regard to the area of application.

Claims for liability for defects to the specialist trader remain

unaected.

J. Wagner GmbH

Division Professional Finishing

Otto Lilienthal Strasse 18

88677 Markdorf

Federal Republic of Germany

Subject to modications

12

Page 19

FinishControl 5000

AUS

WAGNER WARRANTY POLICY

1st January 2012

WAGNER WARRANTY POLICY

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

This warranty is provided by WAGNER and is in addition to your rights under the Australian Consumer Law.

WAGNER products come with a warranty, from the date of proof of purchase, against any manufacturing faults and defects. The

warranty periods are as follows:

DIY Products 24 months

Semi-Professional Products DIY use 24 months

Semi-Professional use 12 months

Contractor and Commercial Products 36 months

PlastCoat Units 24 months

Hire and Rental Use 6 months

Where replacement goods are supplied, the warranty is limited to the term of the original purchase.

Warranty applies only to the original purchaser and is not transferable.

This warranty does not cover products which are damaged as a result of any of the following:

• Unsuitable or abnormal usage

• Incorrect commissioning or tting, removal or modication of any safety devices

• Repairs which are performed by unqualied or unauthorised persons, or do not involve genuine WAGNER parts

• Normal wear and tear

• Damaged in transport

• Faulty maintenance work, negligent handling, servicing or cleaning

• Unsuitable coating materials

To claim the warranty (Australia and New Zealand only) you should send or take your product (at your cost), with proof of purchase to one of the Authorised WAGNER Service Centres listed on the back of this Warranty. If found to be a warrantable claim,

WAGNER, through its Authorised Service Agents will either repair or replace the product at its option free of charge and advise

you when your replacement or repaired product is available for pick up by you.

Under this express Warranty Policy WAGNER is not liable for any loss or damage however arising as a result of the fault or defect

in the products.

This express Warranty is subject to the purchaser providing satisfactory proof of purchase within Australia or New Zealand of the

product to WAGNER or its Authorised Service Centres.

WAGNER reserves the right to perform any repairs in excess of those stated in our operating instructions.

Please note: This Warranty Policy and Procedure supersedes all other warranty policies, procedures and documentation for products sold within Australia and New Zealand.

AUSTRALIAN CUSTOMERS

Please send or take your product to any one of the Authorised WAGNER Service Centres listed on the reverse of this

form.

NEW ZEALAND CUSTOMERS

Contact the Master Distributor listed below for your nearest Authorised Service Centre:

Paintworx, 70 Lady Ruby Drive, East Tamaki NZ 1730 Telephone: (09) 271 2879

13

Page 20

AUS

AUSTRALIAN CAPITAL TERRITORY

Hume ACT Small Engines 02 6260 1828

Mitchell Paint Place 02 6241 7811

Fyshwick DRB Equipment Repairs 02 6239 1229

NEW SOUTH WALES

Rockhampton Nth Paint Place CQ 07 4928 2992

Scarborough Airless2You 0403 573 998

Tallai Sprayfix 0439 680 686

Townsville Airless & Pressure Cleaners 07 4725 8880

SOUTH AUSTRALIA

64 9 272 2840

AUTHORISED SERVICE CENTRES

FinishControl 5000

Bathurst David Catt Spray Repair 02 6332 3269

Coffs Harbour Brycker Hire 02 6652 1829

Forster Flashback Repairs 02 6555 7202

Georgetown Daynatech 02 4960 9400

Gladesville Colussi Engineering 02 9817 5433

Gosford West Gosford Power Tool Centre 02 4325 5322

Grafton South Beadman Engineering 02 6642 3047

Lake Cathie Coastal Spray 02 6585 4735

Lismore South Paint & Trade Supplies 02 6622 1147

Milperra Murphy’s Spray & Blast 02 9792 2653

Moorebank Spray Equipment Mobile 02 9822 4011

Moruya Moruya Mower & Chainsaw 02 4474 3322

Penrith Penrith Paint Specialists 02 4731 1178

Tamworth Tamworth Paint Centre 02 6762 0520

Wagga Wagga Simpson Machinery Service 02 6928 1353

Woollongong Frank Dean Airless Repairs 02 4296 2989

NORTHERN TERRITORY

Holtze Palmerston Paint Supplies 08 8932 7999

QUEENSLAND

Acacia Ridge Phillro Industries 07 3711 9589

Burpengary Glascraft 07 3888 0866

Cairns Cairns Wholesale Paint 07 4035 2000

Gladstone Earle’s Paint & Wallpaper 07 4972 3277

Kingaroy Earle’s Paint & Wallpaper 07 4162 5011

Maroochydore Suncoast Pressure Cleaners 07 5443 1139

Meadowbrook Logan ProSpray 07 3803 4276

Maryborough Earle’s Paint & Wallpaper 07 4121 5202

Milton Paint Place Superstore 07 3369 7206

Murarrie Access Industrial Products 07 3390 8199

Nerang W.A.S. 07 5596 7255

Noosaville Paint Place Noosa 07 5449 9964

Mount Gambier Attiwills Home & Industry 08 8725 6644

Lonsdale MWA 08 8294 6444

Wingfield Oliver Technologies 08 8262 2466

VICTORIA

Bairnsdale Bristol Decorator Centre 03 5153 1177

Bairnsdale Murphy’s World of Colour 03 5152 4148

Ballarat Bylsma Hire 03 5335 8397

Bayswater Spraylinks 03 9720 1710

Campbellfield Dete Australia 03 9359 6080

Dandenong Sth Paint Spot 03 9793 4599

Eltham Paint Place 03 9439 4900

Geelong Nth Kerr’s North Side 03 5278 6011

Hastings Dewtech 03 5979 1617

Oakleigh Sprayworld 03 9041 4473

Sebastopol Bylsma Hire 03 5335 8397

Shepparton Shepparton Paint Centre 03 5831 2522

Shepparton A1 Electric Motors 03 5831 7066

Wantirna South Morgan’s Paint Spot 03 9801 8011

Warrnambool Chemblast Industrial Coatings 03 5562 7636

TASMANIA

Derwent Park Paintech 03 6273 2755

Invermay Forward Mechanical Repairs 04 1736 5627

WESTERN AUSTRALIA

Bassendean Eden Systems 08 9379 3588

Welshpool All Spray 08 9358 1313

NEW ZEALAND

Contact Paintworx for nearest Service Centre

14

Wagner Spraytech Australia

14-16 Kevlar Close, Braeside, Victoria, 3195.

Customer Service 1800 924 637

Email: info@wagneraustralia.com.au

www.wagneraustralia.com.au

Loading...

Loading...