Wagner HIGH PERFORMANCE AIRLESS SPRAYER User Manual

R

505

HIGH PERFORMANCE

AIRLESS SPRAYER

OWNER'S MANUAL

Easy Does It From Set Up to Clean Up

Read Warnings Assemble Cart

Prepare to Prime

Set Pressure

Spray Short Term Storage

Attach Tip to Gun

Attach Suction Set

OR

Attach Return Hose

Questions? ... Need Help?

Prime PumpAttach Paint Hose

Clean Up

Maintenance

PRINTED IN THE U. S. A.

Optional Hopper Accessory

Wagner maintains a toll-free help line for you should

you have any comments or problems with this Wagner

product. Call us first ....for answers fast...

Wagner Technical Service

1-800-328-8251

Hours: Weekdays: 8:00 - 4:30 Central Time

Weekends: 9:00 - 4:00 Central Time

1

Form No. 0270993-11/93

CONTENTS

General Description ....................................................... 2

Safety Precautions ......................................................3-6

Extension Cord............................................................... 7

Grounding Instructions ................................................... 7

Pressure Relief Procedure ............................................. 8

Set Up ....................................................................... 9-11

Priming .................................................................... 12-14

Spraying ..................................................................15-18

Short Term Storage...................................................... 19

Cleanup and Long Term Shutdown ........................ 20-22

Maintenance........................................................... 23, 24

Optional Hopper ........................................................... 25

Trouble Shooting .................................................... 26, 27

Parts Lists ............................................................... 28-30

Accessories List ........................................................... 31

Warranty........................................................ Back Cover

Components:

The shipping carton for your 505 Painting System contains the following components:

Cart frame with wheels, motor and pump attached.

Cart handle

Pail bracket/cart foot

Suction set and return tube

Spray gun and filter

Spray tip and gasket

Three bolts, washers and wing nuts

25-foot 3/16-inch higher pressure hose

Spare Outlet Spring, P/N 0047485

Spare Tip Seal , P/N 0156713

Return tube fitting , P/N 0088715

Operator’s manual

General Description

ARE LOCATED IN THE

LITERATURE SET WITH

REGISTRATION CARD

The Wagner 505 High Performance Airless Sprayer is a

precision power tool used for spraying many types of

materials. It is a relatively simple machine to operate,

however, a basic understanding of its components is

necessary.

Read and follow this instruction manual carefully for proper

operating instructions, maintenance and safety

information.

Specifications

Weight: ................................................... 27 lbs. (12 kg )

Capacity: ...............................................Up to 1/3 gallon

(1-1/4 liters) per minute

Power Source: ............................ 1/3 HP Electric Motor,

totally enclosed, fan cooled.

Power Requirement: ......................... 15 amp minimum

circuit on 115 VAC, 60 HZ current.

Generator – 15 amp A/C.

Spraying Pressure: .............................. Up to 2,500 psi.

Safety Features: .................. Spray gun safety lock and

pressure diffuser; built-in tip safety

guard; priming knob for safe

pressure release.

Portability:........................ Compact design, light weight

for easy movement.

Capability: ............................ Sprays a variety of paints,

oil base, latex, primers, stains,

preservatives and other nonabrasive

materials, including pesticides and

liquid fertilizers.

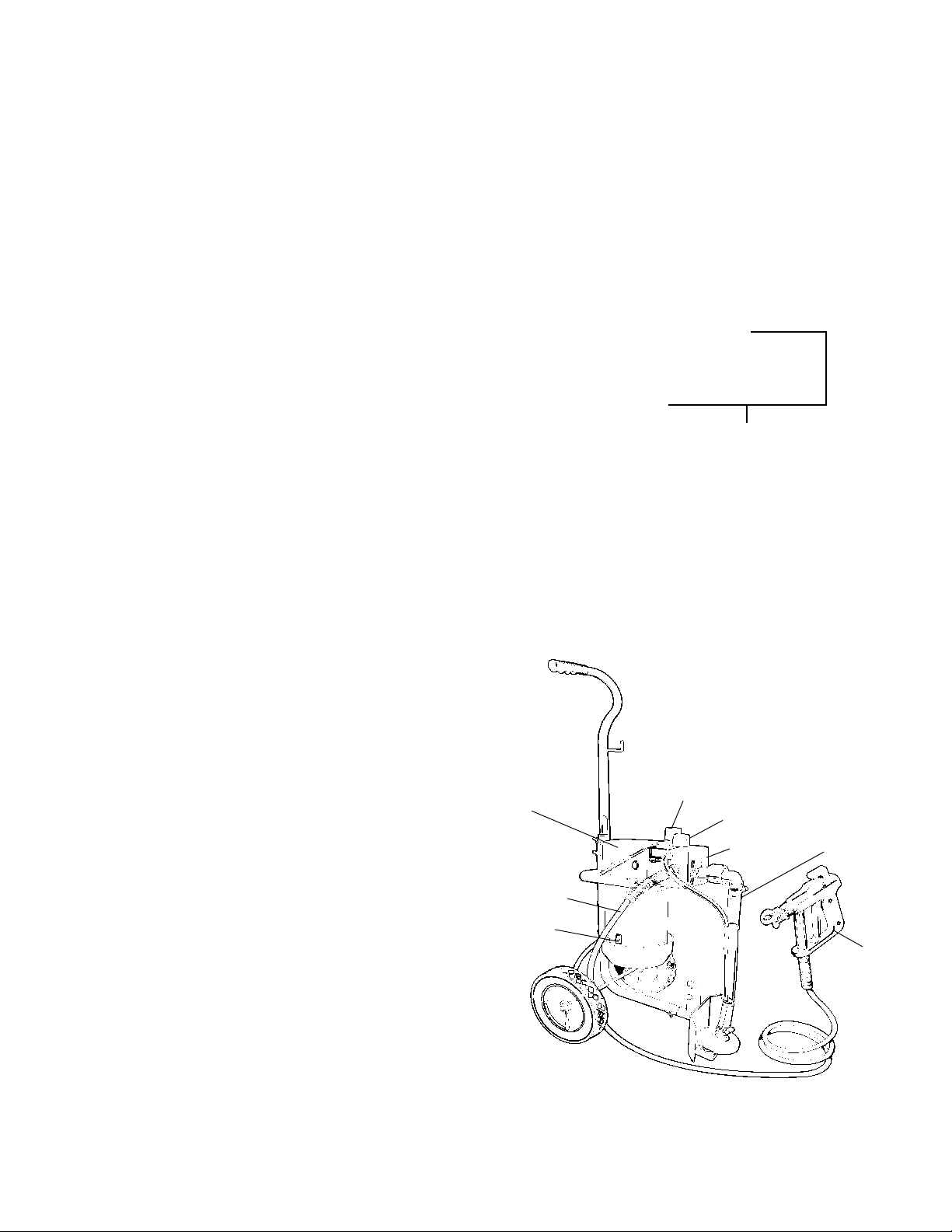

Hydraulic Pump

Paint Hose

On/Off Switch

Pressure Control

Knob

Priming Knob

Paint Block

Figure 1 – Wagner 505 Airless Sprayer

Suction Set

Spray Gun

2

SAFETY PRECAUTIONS

This manual contains information which must be read and understood before using the equipment. When you come to an

area which has one of the following symbols, pay particular attention and make certain to heed the safeguard.

WARNING

Important safety information indicates a hazard which may cause serious injury or loss of life.

CAUTION

Important information that tells how to prevent damage to equipment or how to avoid causes of minor injuries.

Notes: Gives important information which should be given special attention.

CAUTION

THIS UNIT IS PROVIDED WITH A THERMALLY PROTECTED AUTOMATIC RESET. IF AN OVERLOAD

OCCURS THE THERMALLY PROTECTED AUTOMATIC RESET DISCONNECTS THE MOTOR FROM THE

POWER SUPPLY.

• Motor will restart without warning when protector automatically resets.

• Always disconnect motor from power supply before working on equipment.

• When thermally protected automatic reset disconnects the motor from the power supply, relieve pressure by

turning priming valve to "prime" A .

• Turn ON-OFF switch OFF.

CAUTION: THE CAUSE OF THE OVERLOAD SHOULD BE CORRECTED BEFORE RESTARTING. (SEE

TROUBLE SHOOTING )

3

WARNING

HAZARD

Injection Injury - A high pressure stream of paint pro-

duced by this equipment can pierce the skin and

underlying tissues, leading to serious injury and possible amputation.

PREVENTION

• Maximum operating range of the gun - 2500 PSI fluid

pressure.

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to come in contact

with the fluid stream. DO NOT come in contact with a fluid

stream created by a leak in the fluid hose.

• NEVER put hand in front of the gun. Gloves will NOT

provide protection against an injection injury.

• ALWAYS lock the gun trigger,shut fluid pump off and

release all pressure before servicing, cleaning tip guard,

changing tips, or leaving unattended. Simply turning off

the electrical power will not release pressure in the

system. The Prime Spray Valve must be turned to the

prime A position to relieve the pressure.

• ALWAYS have the tip guard in place while spraying. The

tip guard provides some protection against injection

injuries but is mainly a warning device.

DO NOT TREAT AS A SIMPLE CUT! Injectioncan lead to amputation. See a physician immediately.

NOTE TO PHYSICIAN: Injection into the skin

is a traumatic injury. It is important to treat the

injury surgically as soon as possible. DO

NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings

injected directly into the blood stream. Consultation with a plastic surgeon or reconstructive hand surgeon may be advisable.

•

ALWAYS remove spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking, abuse

etc. A leak is capable of injecting material into the skin.

The paint hose should be inspected before each use.

• NEVER use a spray gun which does not have a trigger

lock and trigger guard in place and in working order.

• All accessories must be rated at or above 2500 P.S.I.

(Includes spray tips, guns, extensions, and hose).

• In case of skin injection see physician immediately.

Refer to Cleaning Instructions.

4

WARNING

HAZARD PREVENTION

Explosion or fire - Solvent and paint fumes can explode or

ignite, causing property damage and or severe injury.

• Exhaust and fresh air introduction must be provided to

keep the air within the spray area free from accumulation

of flammable vapors.

• Avoid all ignition sources such as static electricity sparks,

open flames such as pilot lights, hot objects such as

cigarettes, and sparks from connecting and disconnecting power cords and working light switches.

• Fire extinguishing equipment must be present and in

working order.

• Keep the pump away from spray area to avoid solvent

and paint fumes. The pump contains arcing parts which

emit sparks.

• Do not spray paints and other inflammable fluids which

have a flashpoint below 21° C (70° F). (Flashpoint is the

temperature at which a fluid begins giving off a sufficient

amount of flammable vapor that could ignite when exposed to a flame or spark.)

• High velocity flow of material through equipment may

develop static electricity. The equipment being used, and

objects in and around the spray area must be properly

grounded to prevent static discharge and sparks.

• Use only conductive or grounded high pressure fluid

hoses for airless applications. Be sure that gun is grounded

through hose connections.

• Power cord must be connected to a grounded circuit.

(See proper grounding instructions.)

• Follow the material and solvent manufacturer's safety

precautions and warnings.

• WHEN FLUSHING EQUIPMENT use lowest possible

pressure.

5

WARNING

HAZARD

Explosion hazard incompatible materials - May cause

property damage or severe injury.

Hazardous vapors - Paints, solvents, insecticides, and

other materials may be harmful if inhaled causing severe nausea, fainting, or poisoning.

General - May cause property damage or severe injury.

PREVENTION

• DO NOT USE BLEACH.

• DO NOT use halogenated hydrocarbon solvents.

• Halogenated hydrocarbon solvents such as methylene

chloride and 1,1,1 - Trichlorethane are not compatible

with aluminum and may cause an explosion. If unsure of

a material’s compatibility with aluminum, contact your

coatings supplier.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled. Read all instructions with the

mask to insure that it will provide the necessary protection

against the inhalation of harmful vapors.

• Read all instructions and safety precautions before operating.

• Comply with all appropriate local, state and national

codes governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have

been adopted under Occupational Safety and Health Act.

These standards, particularly the General Standards,

Part 1910 and construction Standard, Part 1926, should

be consulted.

• This high pressure airless pump is designed to be used

with authorized parts only. When using this pump with

parts that do not comply with the minimum specifications

and safety devices of the pump manufacturer, the user

assumes all risks and liabilities.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover or damage or movement of couplings.

If any of these conditions exist, replace the hose immediately. Never repair a paint hose. Replace it with another

grounded hose.

• All hoses, swivels, guns, and accessories used with this

unit must be pressure rated at or above 2500 PSI.

• DO NOT spray on windy days.

6

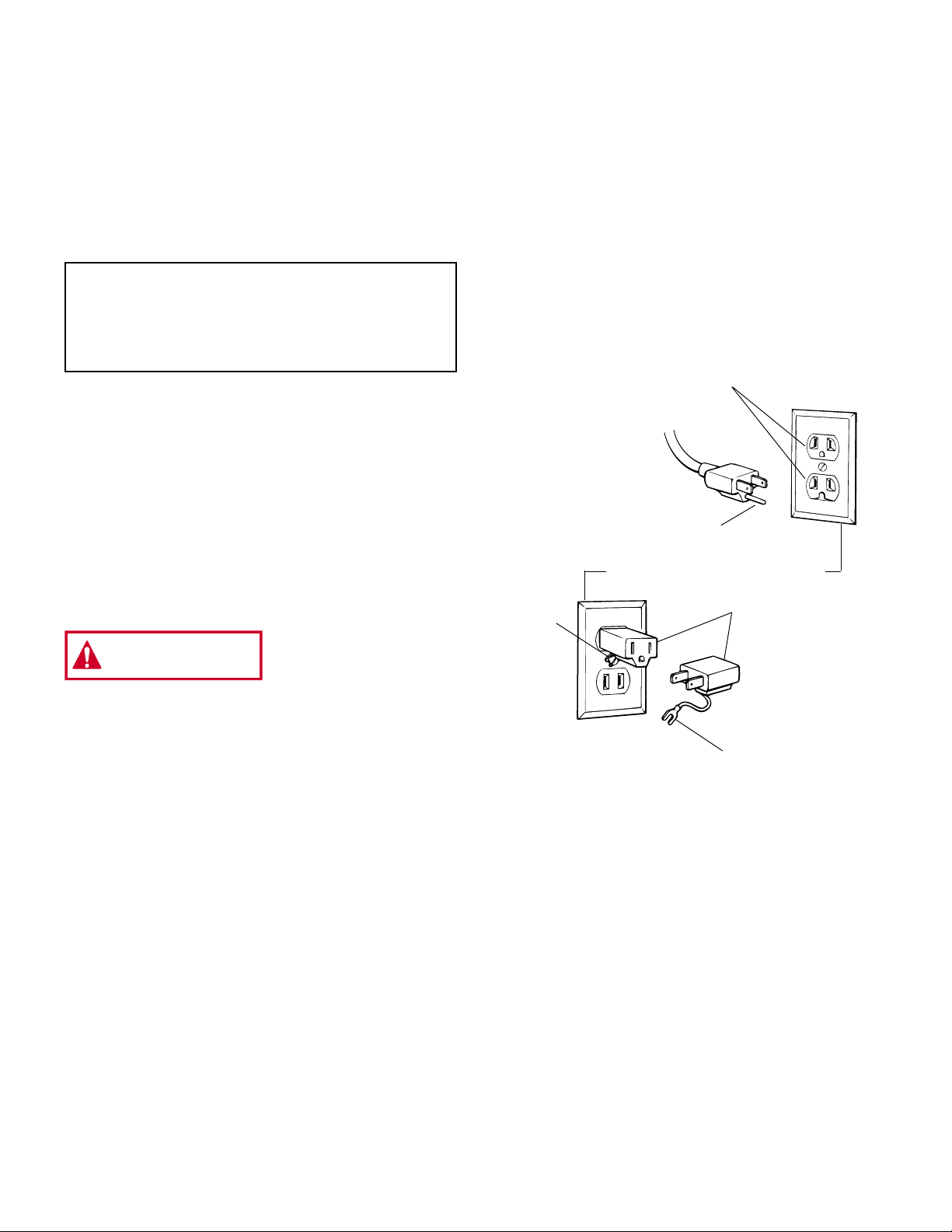

Extension Cord

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the

plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure to

use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. A 14 or 12

gauge cord is recommended.

NOTE: More than 100 feet of extension cord is not

recommended. Use more paint hose, not more

extension cord. Shorter extension cords will assure

maximum electrical power for proper operation.

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This

product is equipped with a cord having a grounding wire

with an appropriate grounding plug. The plug must be

plugged into an outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

Improper installation of the

WARNING

grounding plug can result in a

risk of electric shock.

This product is for use on a nominal 120 volt circuit, and has

a grounding plug that looks like plug illustrated in Figure 2

(A) below. A temporary adapter which looks like the adapter

illustrated in Figure 2 (B) and (C), may be used to connect

this plug to a 2 pole receptacle as shown in Figure 2 (B) if

a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded

outlet as shown in Figure 2 (A) can be installed by a

qualified electrician. The green colored rigid ear lug, or the

like extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in

place by a metal screw.

Grounded

Outlet

Grounding Pin

(A)

Cover of Grounded Outlet Box

Metal

Screw

Adapter

(C)

If repair or replacement of the cord or plug is necessary, do

not connect the green grounding wire to either flat blade

terminal. The wire with insulation having an outer surface

that is green with or without yellow stripes is the grounding

wire and must be connected to grounding pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if

in doubt as to whether the product is properly grounded. Do

not modify the plug provided; if it will not fit the outlet, have

the proper outlet installed by a qualified electrician.

(B)

Figure 2 – Grounding Methods

7

Tab for

Grounding Screw

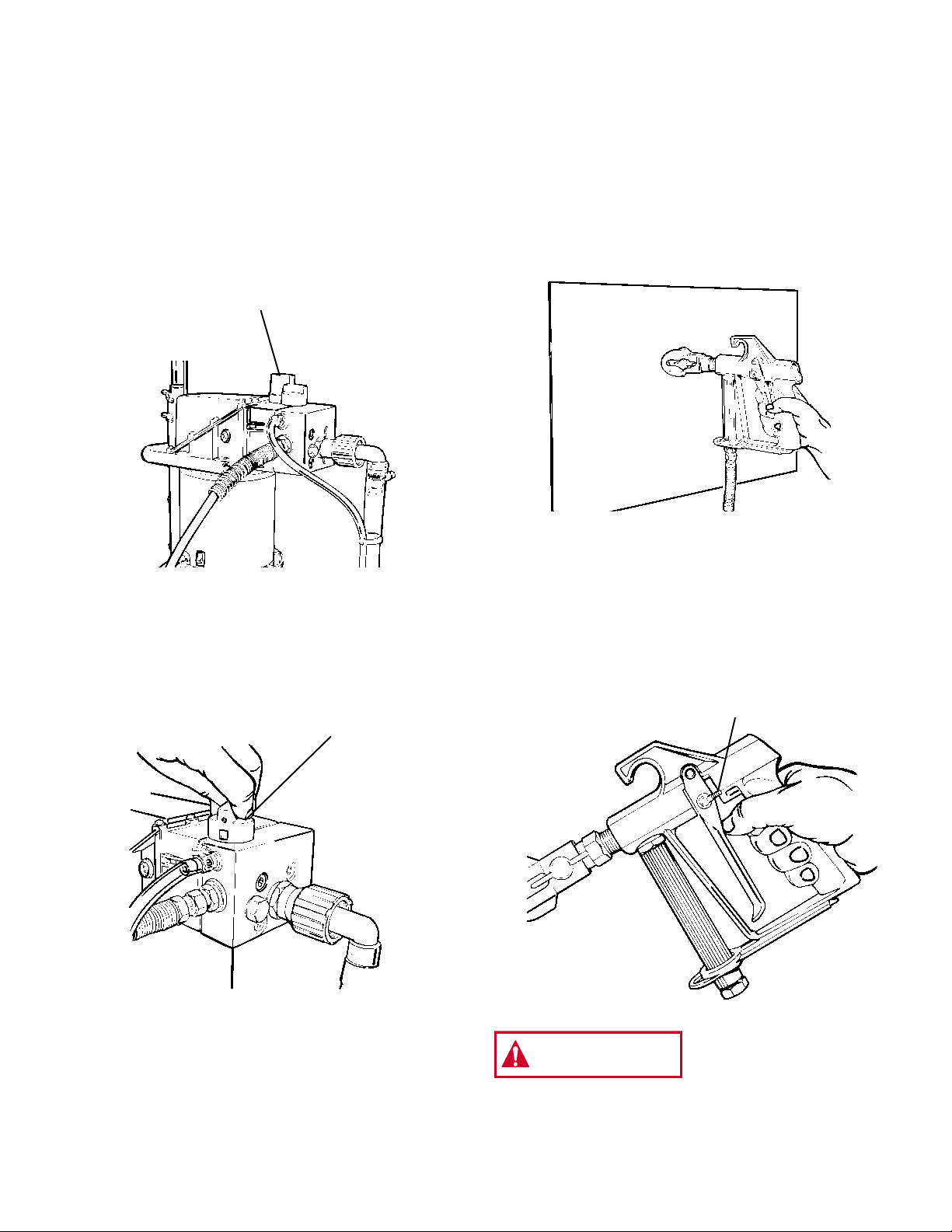

Pressure Relief Procedure

Follow this procedure after the unit is assembled and before any operation which involves the spray gun such as

changing tips or accessories, or cleaning and maintenance.

1. Make sure PRESSURE CONTROL KNOB is at its lowest

setting (counterclockwise).

Pressure Control

Knob

2. Turn PRIMING KNOB to PRIME A position.

3. Trigger gun to remove any pressure which may still be

in the hose.

4. Lock gun trigger in the Off position.

Prime A

Spray B

Knob

Trigger Lock

Injection hazard possible. Do

WARNING

place. NEVER trigger gun unless tip is completely turned

to the spray or unclog position. ALWAYS engage trigger

lock before removing, replacing or cleaning tip.

not spray without tip guard in

8

SET-UP

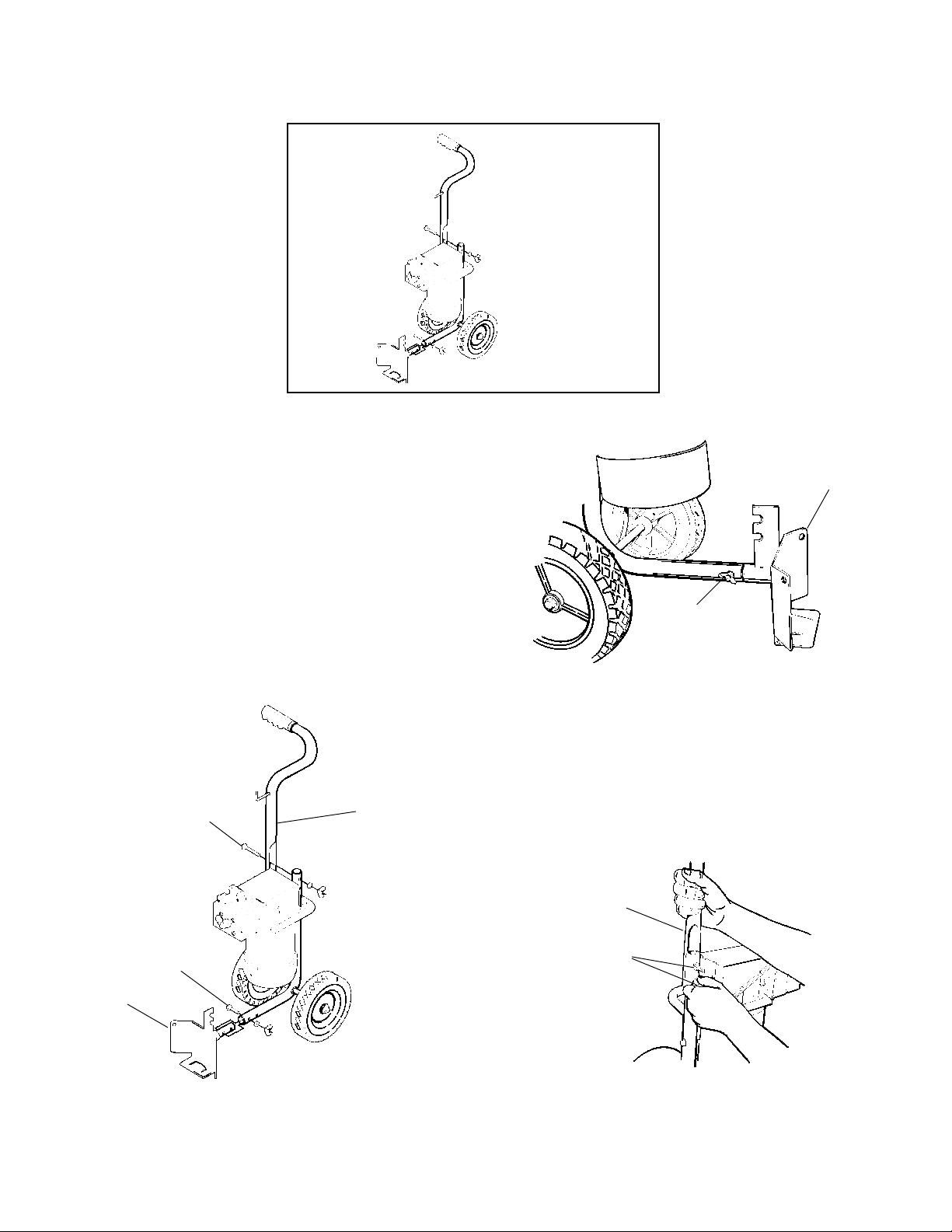

ASSEMBLE CART

Tools needed:

Some assembly is required to get your Wagner 505

Airless Sprayer ready to go. You will need two adjustable

wrenches, a screw driver and a pair of pliers.

Pail Bracket

NOTE: Sprayer should remain unplugged during

assembly.

1. Slide pail bracket (1) onto cart frame and attach with

one bolt, washer and wing nut (2). See Figure 2 and

Figure 3 A. This bracket helps to keep the sprayer

stable in addition to providing a rest for the paint

bucket and a catch for the bucket handle.

4

2

3

Bolt, washer

and wing nut

Figure 3A - Attaching Pail Bracket

2. Attach cart handle (3). Face the hose hook toward the

front of the unit. Use two bolts, washers and wing nuts

(4), tightening securely. See Figure 3B.

Cart Handle

Bolt, washer

and wing nut

1

Figure 2 – Cart Assembly Diagram

Figure 3B - Attaching Cart Handle

9

SET-UP

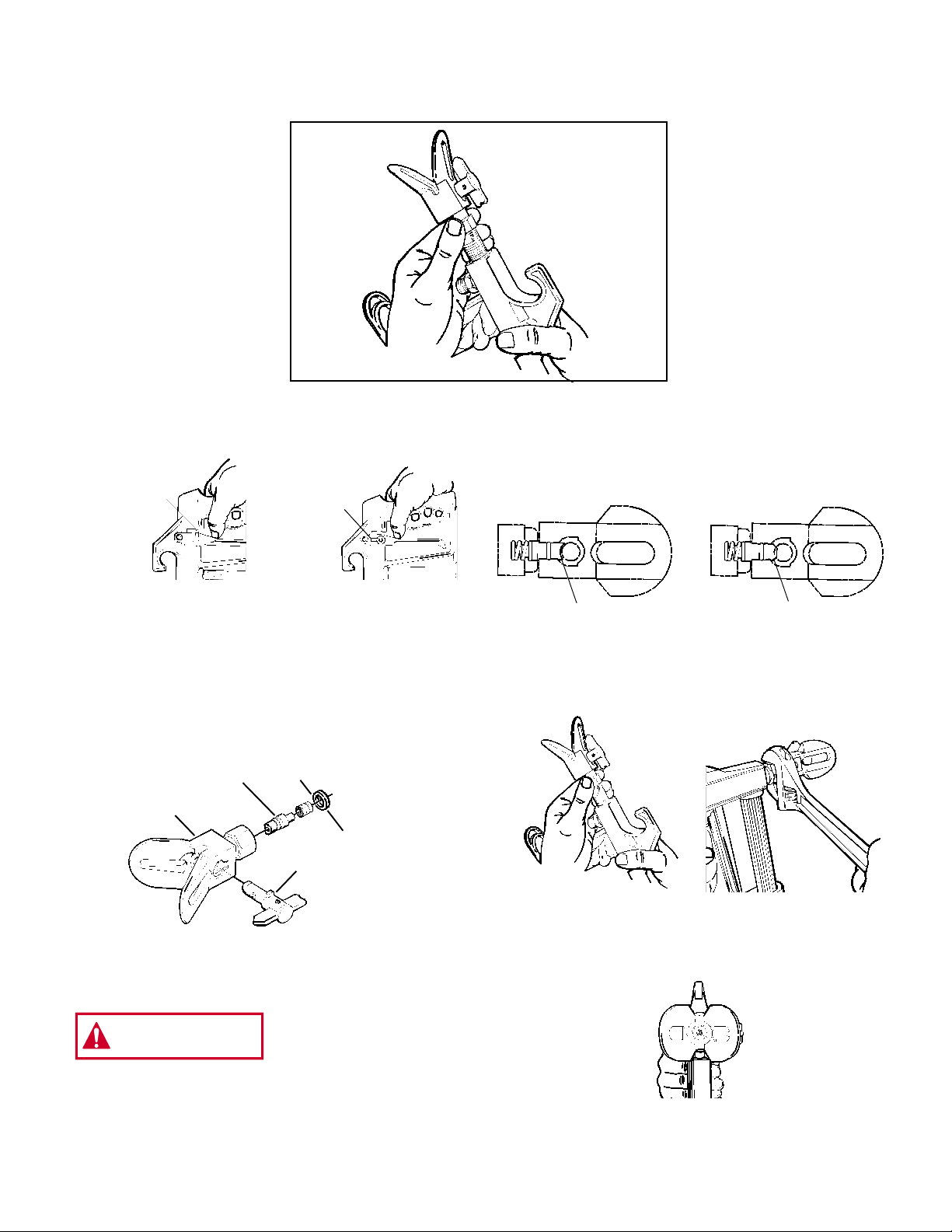

ATTACH TIP TO GUN

1. Lock gun. See Figure 4.

Locked

Position

Figure 4 - Gun in Locked & Unlocked Position

2. If spray tip is not pre- assembled, (See Figure 5)

insert tip (1) into tip guard, (2) and turn 90° coun-

terclockwise to spray position (arrow pointing away

from gun). Cylinder of tip forms a stop for the seal (3).

Insert seal (3) aligning the curve of the seal with the

curve of the tip.

3

2

Unlocked

Position

4

Red Seal

1

3. Check seal alignment by removing tip and inspecting

tip guard visually, See Figure 6. If needed, remove

seal (3) and replace until properly aligned. Replace

tip to spray position, (arrow away from gun). Insert

red seal (4).

Correct Way

Figure 6 - Spray Tip Assembly

4. Attach spray tip to gun. Tighten nut first by hand,

then tighten with a wrench. See Figure 7.

Wrong Way

Figure 5 – Spray Tip Assembly

WARNING

out tip guard in place. Never trigger gun unless tip is in

the spray or unclog position. Always engage trigger lock

before removing, replacing or cleaning tip.

POSSIBLE INJECTION

HAZARD. Do not spray with-

Figure 7- Attach Tip to Gun

NOTE: When attaching tip to gun, align tip guard as

shown in Figure 8. Then tighten with wrench.

Figure 8 - Vertical Tip Pattern

10

Loading...

Loading...