Page 1

SERVICE MANUAL

EF SERIES

GAS FRYERS

MODELS

EF3 ML-52099

EF4 ML-114943

EF5 ML-114944

- NOTICE -

This manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly qualified.

If you have attended a Vulcan Service School for this product, you

may be qualified to perform all the procedures described in this

manual.

This manual is not intended to be all encompassing. If you have not

attended a Vulcan Service School for this product, you should

read, in it's entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

P.O. BOX 696, LOUISVILLE, KY 40201-0696

TEL. (502) 778-2791

F-35641 (2-05)

Page 2

EF SERIES GAS FRYERS

CONTENTS

GENERAL .......................................................................................................................................... 3

INTRODUCTION ........................................................................................................................ 3

Models ................................................................................................................................ 3

INSTALLATION .......................................................................................................................... 3

OIL FILTERING .......................................................................................................................... 3

OPERATION .............................................................................................................................. 3

CLEANING ................................................................................................................................. 3

LIGHTING PILOT ....................................................................................................................... 3

SPECIFICATIONS ..................................................................................................................... 3

Gas Data ............................................................................................................................ 3

TOOLS ....................................................................................................................................... 3

Standard............................................................................................................................. 3

REMOVAL AND REPLACEMENT OF PARTS .................................................................................. 4

COVERS AND PANELS ............................................................................................................ 4

Door.................................................................................................................................... 4

Heat Shield......................................................................................................................... 4

BURNERS.................................................................................................................................. 5

THERMOSTAT ........................................................................................................................... 5

HIGH LIMIT ................................................................................................................................ 7

THERMOPILE ............................................................................................................................ 8

PILOT ORIFICE ......................................................................................................................... 9

PILOT ......................................................................................................................................... 9

COMBINATION VALVE ............................................................................................................ 10

FRY TANK .................................................................................................................................11

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................................... 12

MILLIVOLT CONTROLS TEST ................................................................................................ 12

THERMOSTAT CALIBRATION ................................................................................................ 12

Calibration Steps .............................................................................................................. 12

PILOT ADJUSTMENT .............................................................................................................. 13

BURNERS, NOZZLES AND ORIFICES .................................................................................. 13

Burners ............................................................................................................................. 13

Nozzles and Orifices ........................................................................................................ 13

COMBINATION VALVE REGULATOR ADJUSTMENT............................................................ 14

ELECTRICAL OPERATION ............................................................................................................. 16

CONTROL SYSTEM DESCRIPTION ...................................................................................... 16

SYSTEM CONDITION QUICK CHECK PROCEDURES ......................................................... 17

SCHEMATIC ............................................................................................................................ 17

COMPONENT FUNCTION ...................................................................................................... 17

TROUBLESHOOTING ..................................................................................................................... 18

F35641 (02-05)

— 2 —

Page 3

GENERAL

EF SERIES GAS FRYERS

INTRODUCTION

Models

This service manual was written for:

EF3, EF4 and EF5 Gas Fryers.

INSTALLATION

Generally, installations are made by the dealer

or contracted by the dealer or owner. Detailed

installation instructions are included in the

Installation and Operation Manual, which is

sent with each fryer.

OIL FILTERING

Filtering instructions are included in the

Installation and Operation Manual.

4. While still holding knob in light the pilot

with a taper. Continue to depress knob

(approximately 30 seconds) until the pilot

remains lit after the knob is released. If

pilot does not remain lit, repeat steps 2, 3

& 4.

5. Turn gas control valve knob to ON.

6. If gas supply is interrupted, repeat steps

1-5.

SPECIFICATIONS

Gas Data

MODEL NO. TUBES BTU/HR

EF3 3 90,000

EF4 4 120,000

EF5 5 150,000

OPERATION

Detailed operation instructions are included

with each fryer in the Installation and

Operation Manual.

CLEANING

Detailed cleaning procedures are included in

the Installation and Operation Manual.

LIGHTING PILOT

1. Turn thermostat OFF.

2. Turn gas control valve knob to OFF/PILOT.

Wait 5 minutes.

3. Push the gas control valve knob in.

TOOLS

Standard

• Hand tools (standard set)

• VOM with AC current tester (any quality

VOM with a sensitivity of at least 29,000

ohms per volt can be used)

• Gas test kit

• Temperature tester (thermocouple type)

• Manometer

— 3 —

F35641 (02-05)

Page 4

EF SERIES GAS FRYERS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

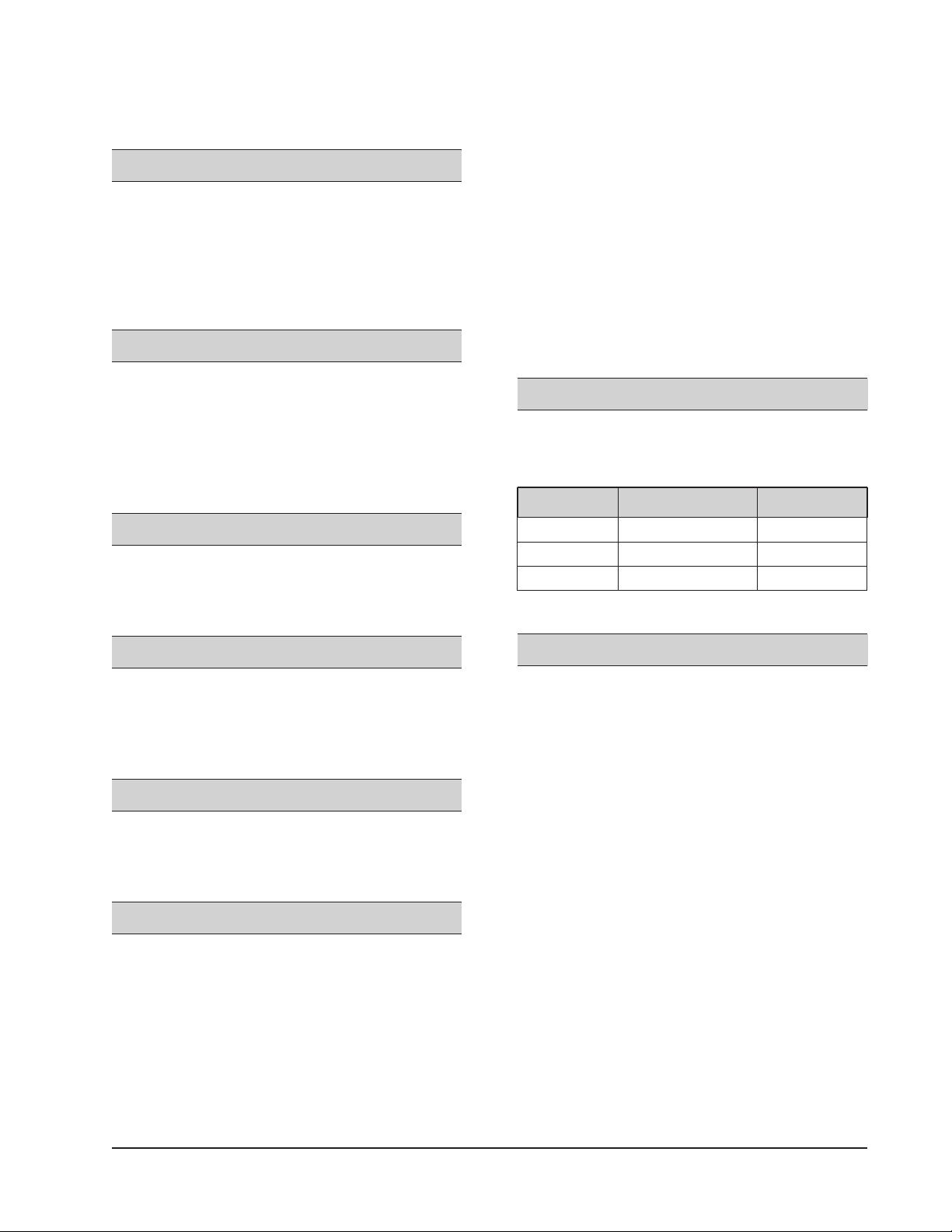

Door

1. While holding onto the door remove (2)

screws securing the door hinge to the

fryer bottom front flange (Figure 1).

Heat Shield

1. Remove screws holding heat shield in

place (Figure 2).

Figure 1

2. Prepare to catch door assembly. Once

screws and hinge are removed, the door

will drop off into your hand(s).

3. Reinstall door assembly by reversing

steps 1 & 2 above.

F35641 (02-05)

Figure 2

2. Remove heat shield.

— 4 —

Page 5

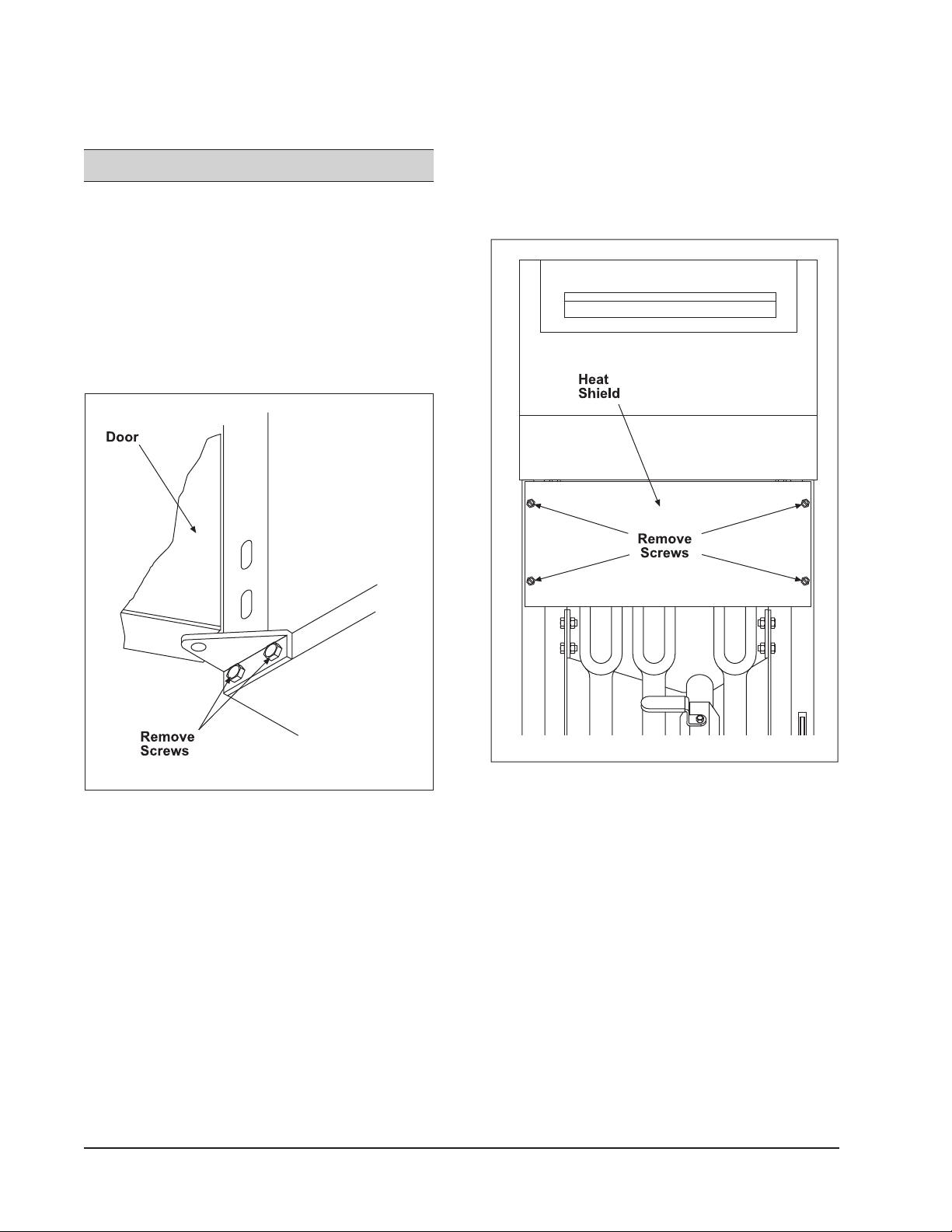

BURNERS

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Remove heat shield as outlined under

Cover and Panels. (Optional)

2. Loosen the two mounting bolts at the top

of each burner (Figure 3).

EF SERIES GAS FRYERS

Figure 3

3. Push burner up while pulling the bottom

of the burner forward to clear the burner

nozzle (Figure 4).

Figure 4

4. Reverse the procedure to install.

THERMOSTAT

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Drain shortening from fry tank.

2. Remove heat shield as outlined under

Covers and Panels.

3. Remove left burner as outlined under

Burners.

4. Remove thermostat knob by pulling knob

off thermostat shaft.

— 5 —

F35641 (02-05)

Page 6

EF SERIES GAS FRYERS

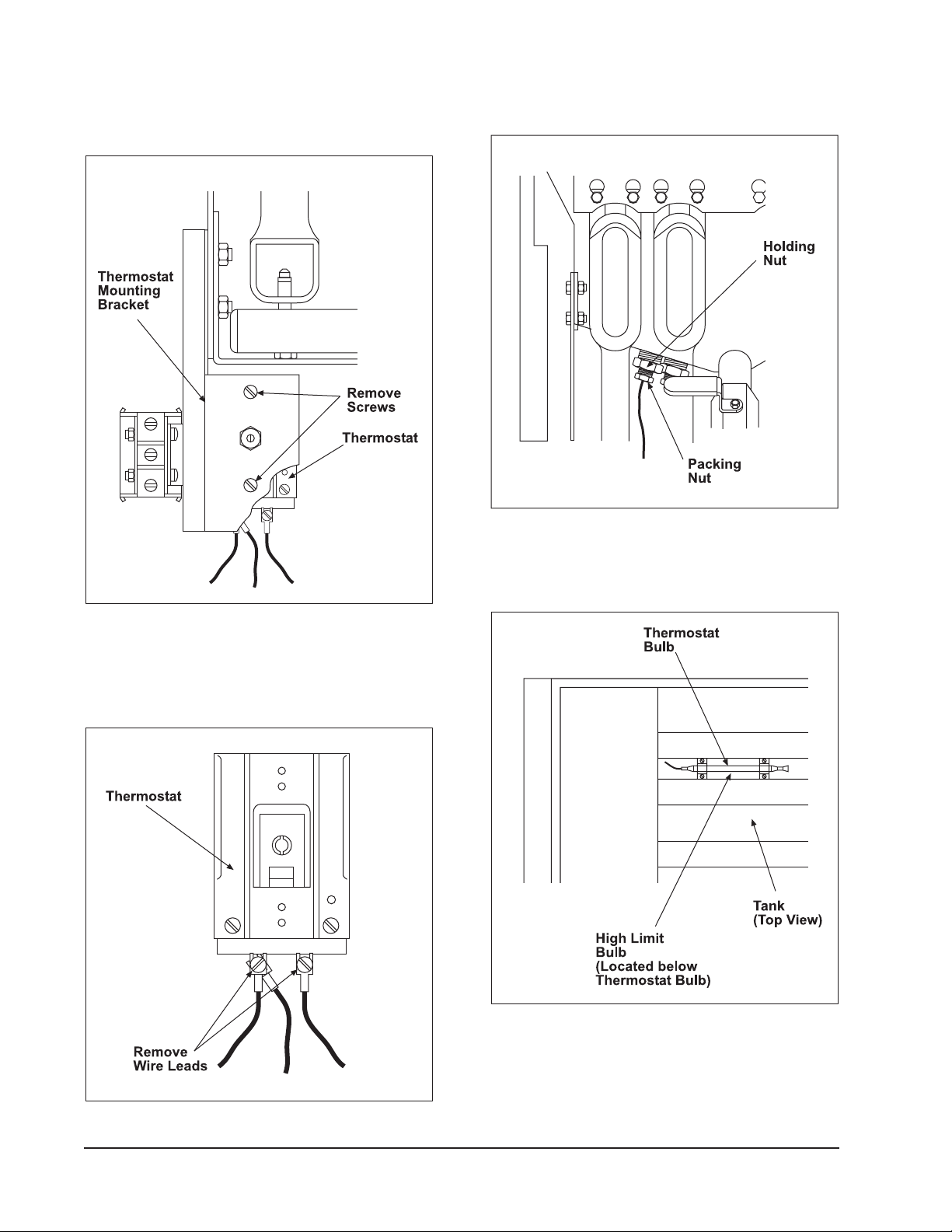

5. Remove thermostat mounting screws and

remove thermostat from mounting bracket

(Figure 5).

7. Loosen the packing nut and holding nut

(Figure 7).

Figure 7

Figure 5

6. Remove wire leads from the rear of the

thermostat, noting all connections for

reassembly (Figure 6).

8. Remove the thermostat bulb from the

clamp (Figure 8).

F35641 (02-05)

Figure 8

9. Pull the thermostat bulb through the

underside of the fry tank and remove the

thermostat assembly.

Figure 6

— 6 —

Page 7

EF SERIES GAS FRYERS

10. Reverse the procedure to install. When

installing the new thermostat assembly,

do not kink the thermostat capillary. Wrap

threads of packing nut with Teflon tape to

prevent leakage.

HIGH LIMIT

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

1. Drain shortening from fry tank.

2. Remove heat shield as outlined under

Covers and Panels.

3. Remove wire leads from high limit, noting

all connections for reassembly (Figure 9).

6. Loosen the packing nut and the holding

nut (Figure 10).

Figure 10

Figure 9

4. Remove high limit from mounting bracket.

5. Remove left burner as outlined under

Burners.

7. Remove the high limit bulb from the clamp

(Figure 11).

— 7 —

Figure 11

F35641 (02-05)

Page 8

EF SERIES GAS FRYERS

8. Pull the high limit bulb through the

underside of the fry tank and remove the

high limit.

9. Reverse the procedure to install. When

installing the new high limit assembly, do

not kink the high limit capillary. Wrap

threads of packing nut with Teflon tape to

prevent leakage.

THERMOPILE

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED

FOR LEAKS. CHECK WITH SOAP AND

WATER SOLUTION (BUBBLES). DO NOT

USE AN OPEN FLAME.

1. Remove the screw securing the Pilot/

Thermopile Assembly Bracket to the tank

front. Lower the assembly away from the

tank (Figure 12).

2. Disconnect thermopile lead wires as

outlined under High Limit.

Figure 12

F35641 (02-05)

— 8 —

Page 9

EF SERIES GAS FRYERS

3. Remove thermopile from pilot bracket by

loosening the holding nut (Figure 13).

Figure 13

4. Reverse procedure to install.

PILOT

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED

FOR LEAKS. CHECK WITH SOAP AND

WATER SOLUTION (BUBBLES). DO NOT

USE AN OPEN FLAME.

1. Remove the screw securing the Pilot/

Thermopile Assembly Bracket to the tank

front. Lower the assembly away from the

tank (Figure 12).

2. While holding assembly in the palm of

your hand remove the pilot compression

fitting at the bottom of the pilot and

disconnect the pilot tubing (Figure 12).

3. Remove thermopile as outlined under

Thermopile (set aside for reassembly).

PILOT ORIFICE

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED

FOR LEAKS. CHECK WITH SOAP AND

WATER SOLUTION (BUBBLES). DO NOT

USE AN OPEN FLAME.

1. Remove the screw securing the Pilot/

Thermopile Assembly Bracket to the tank

front. Lower the assembly away from the

tank (Figure 12).

2. While holding assembly in the palm of

your hand remove the pilot compression

fitting at the bottom of the pilot to expose

the orifice (Figure 12).

3. Replace orifice and reverse procedure to

assemble.

4. Remove (2) screws holding the pilot

assembly to the Pilot/Thermopile

Assembly Bracket and replace the old

pilot with the new assembly (Figure14).

— 9 —

Figure 14

5. Reinstall by reversing steps 1-4.

F35641 (02-05)

Page 10

EF SERIES GAS FRYERS

COMBINATION VALVE

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED

FOR LEAKS. CHECK WITH SOAP AND

WATER SOLUTION (BUBBLES). DO NOT

USE AN OPEN FLAME.

1. Disconnect fryer from main gas supply.

2. Remove heat shield as outlined under

Covers and Panels. (Optional)

3. Remove right burner as outlined under

Burners.

4. Disconnect wire leads from the

combination valve and mark for

reconnecting.

5. Disconnect pilot tubing from combination

valve (Figure 15).

6. Disconnect combination valve union and

pressure fitting (Figure 16).

Figure 16

7. Remove the combination valve from the

fryer.

8. Remove all pipe fittings from the old

combination valve if the new valve is not

supplied with fittings.

Figure 15

9. Reverse procedure to install using original

pipe fittings.

F35641 (02-05)

— 10 —

Page 11

EF SERIES GAS FRYERS

FRY TANK

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED

FOR LEAKS. CHECK WITH SOAP AND

WATER SOLUTION (BUBBLES). DO NOT

USE AN OPEN FLAME.

1. Disconnect fryer from main gas supply.

2. Remove baskets, fryer basket hanger and

crumb screen.

3. Drain oil from tank.

4. Remove heat shield as outlined under

Covers and Panels.

5. Remove screws holding fryer tank

(Figure 17).

7. Remove the manifold bracket from the

tank assembly by removing the (4) bolts

(Figure 18).

Figure 18

8. Remove thermostat and high limit as

outlined under Thermostat and High Limit.

Figure 17

6. Remove burners as outlined under

Burners.

9. Remove the screw securing the Pilot/

Thermopile Bracket Assembly (Figure 19).

Figure 19

10. Lift the fry tank up and out of cabinet.

Carefully place the tank assembly on the

floor (this procedure requires two people).

— 11 —

11. Remove the tank ball drain valve

(Figure 18).

12. Reverse the procedure to install new tank.

F35641 (02-05)

Page 12

EF SERIES GAS FRYERS

SERVICE PROCEDURES AND ADJUSTMENTS

MILLIVOLT CONTROLS TEST

1. Verify proper gas (natural or propane) is

present.

2. Check for correct wiring and secure

connections.

3. Verify the pilot flame is adjusted properly

as outlined in Pilot Adjustment.

4. If the pilot is not lit, light pilot as outlined

under Lighting Pilot. Allow the pilot to

burn for 3 to 4 minutes to stabilize.

A. If the pilot remains lit, proceed to

step 6.

B. If the pilot will not remain lit, proceed

to step 5.

5. Connect DC voltmeter to terminals

TH-PG and PG of combination valve.

Relight the pilot, hold the gas control

valve knob in and allow the pilot to burn

for 3 to 4 minutes to stabilize.

A. lf the voltage measures 450 millivolts

or greater and the pilot will not stay lit,

replace the combination valve.

B. lf the voltage is less than 450 millivolts,

measure the voltage at terminals NO

and C of high limit.

7. Turn gas control valve knob to ON. Turn

thermostat to a setting higher than the

shortening temperature.

A. If the voltage measures 150 millivolts

or more but the burners do not ignite,

replace the combination valve.

B. If the voltage is less than 150 millivolts,

measure the voltage between

terminals NO of the high limit and PG

of the combination valve.

1) If the voltage is 200 millivolts or

greater, replace the thermostat.

2) If the voltage is less than 200

millivolts, replace the combination

valve.

THERMOSTAT CALIBRATION

1. Place temperature tester in the fry tank

near the thermostat bulb.

2. Set the thermostat to 300°F and allow the

temperature to stabilize.

3. Check the temperature tester reading

against the thermostat dial reading. If

there is a variance of more than ±20°F

(280°F to 320°F), calibration is required.

1) If the voltage is 500 millivolts or

more, replace the high limit.

2) If the voltage is less than 500

millivolts, disconnect the lead wire

from terminal TH-PG of the

combination valve and remeasure

voltage at the high limit.

a. If the voltage is less than 500

millivolts, replace the thermopile.

b. If the voltage is 500 millivolts or

more, replace the combination

valve.

6. Connect DC voltmeter to terminals PG

and TH of combination valve.

F35641 (02-05)

Calibration Steps

1. Remove thermostat knob from shaft.

2. Using a small screwdriver, rotate the

setscrew inside the hollow shaft

counterclockwise to increase the

temperature or clockwise to decrease the

temperature (1/4 turn equals approximately 18°F).

3. Allow temperature to stabilize and recheck

temperature. Repeat until the temperature

falls within the limits as stated in step 3

under Thermostat Calibration.

4. Install thermostat knob and set dial to

350°

— 12 —

Page 13

5. Allow temperature to stabilize at new

setting and compare temperature tester

to dial setting. Recalibrate if the

temperature does not fall within the range

of 330°F to 370°F.

6. If the temperature does not fall within the

limits at both settings, replace the

thermostat.

PILOT ADJUSTMENT

EF SERIES GAS FRYERS

1. Light pilot as outlined under Lighting Pilot.

2. If the flame does not extend beyond the

outer edges of the pilot shield 1/2”, or

extends more than 1/2”, (Figure 20), an

adjustment is necessary.

Figure 20

3. Remove the cap covering pilot adjustment

screw, (Figure 21). Turn the recessed

pilot adjustment screw counterclockwise

to increase the size of the flame or

clockwise to decrease the size of the

flame.

Figure 21

BURNERS, NOZZLES

AND ORIFICES

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

Burners

If the burner ports become clogged, the fryer

will not operate properly. If the burner is

cracked, it must be replaced.

1. Remove burner(s) as outlined under

Burners.

2. Check burner(s) for cracks and clogged

ports.

3. If the ports are clogged, wash burner(s) in

warm, soapy water. If this does not remove

obstructions, a #37 drill bit can be used

(do not use in an electric drill; hand-turn

only).

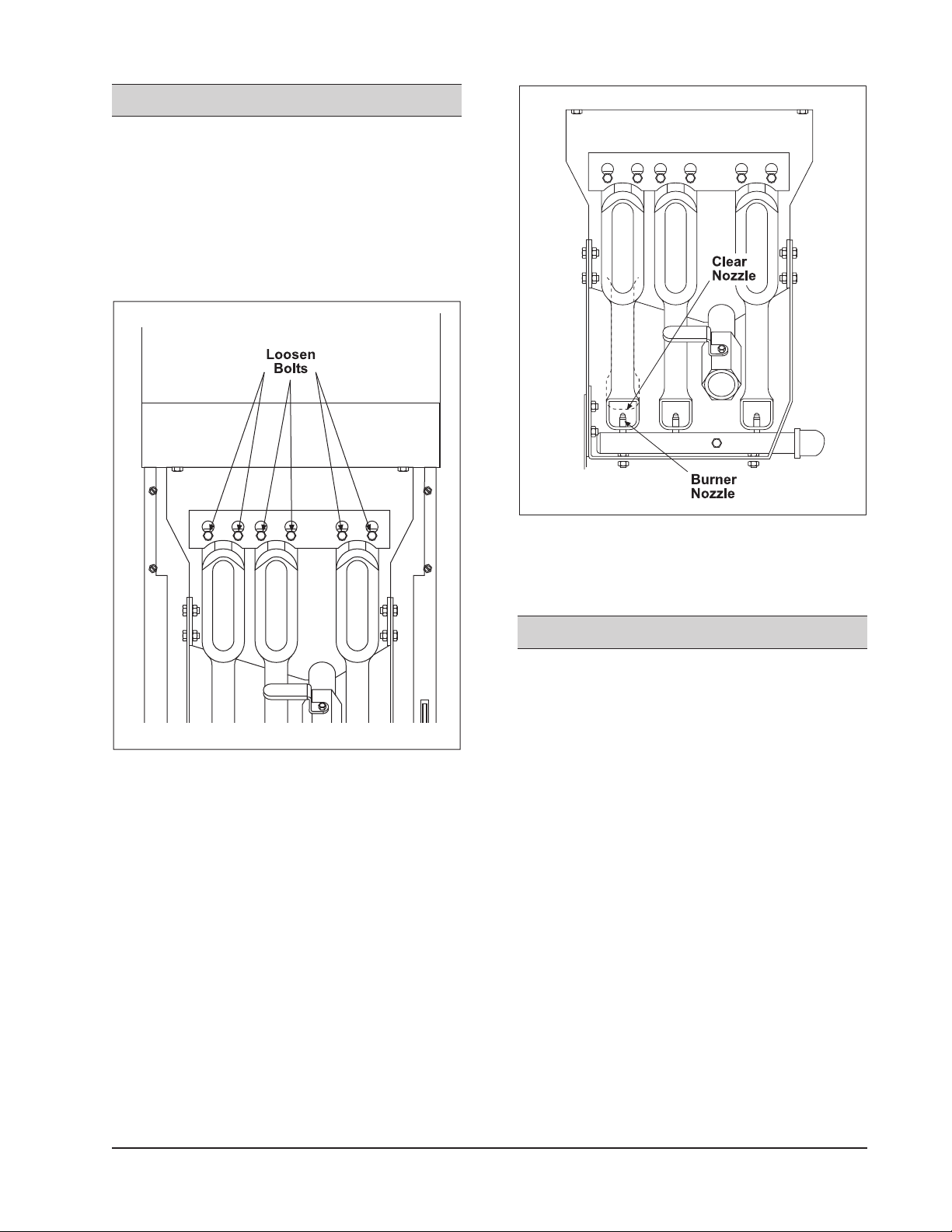

Nozzles and Orifices

— 13 —

1. Remove the burners as outlined under

Burners.

F35641 (02-05)

Page 14

EF SERIES GAS FRYERS

2. Hold the burner nozzle with channel locks

and remove the orifice, (Figure 22). Check

the orifice for obstructions or damage.

Figure 22

1. Turn the gas control valve knob to OFF

(Figure 23).

Figure 23

2. Remove the plug from the submanifold

and install pressure gauge at this point

(Figure 24).

3. If the orifice is clogged, wash the orifice in

warm, soapy water. If this does not remove

obstructions, a #37 drill bit can be used

(do not use in an electric drill; hand-turn

only).

4. With channel locks, remove the burner

nozzle (Figure 22).

5. Reverse procedure to install new burner

nozzle and orifice.

COMBINATION VALVE

REGULATOR ADJUSTMENT

WARNING: SHUT OFF THE GAS BEFORE

SERVICING.

Accurate gas pressure adjustments can only

be made with the gas on and the burner lit. If

the incoming line pressure to the valve is less

than the minimum stated, then the pressure

cannot be set correctly.

Figure 24

3. Turn on the gas and light the pilot as

outlined under Lighting Pilot.

4. Turn the gas control valve knob to ON.

5. Set the thermostat so the burners will

come on.

The combination valve is preadjusted for

natural or propane gas as specified on the

rating plate. The natural gas rating is 4” W.C.,

and the propane rating is 10" W.C.

F35641 (02-05)

— 14 —

Page 15

6. Read the pressure gauge. The manifold

pressure reading should match the

pressure rating on the data plate.

A. To adjust, remove the cap covering

the manifold pressure adjustment

screw (Figure 25). Turn the recessed

manifold pressure adjustment screw

counterclockwise to decrease

pressure or clockwise to increase

pressure.

EF SERIES GAS FRYERS

Figure 25

7. Install the cap and check for proper

operation.

— 15 —

F35641 (02-05)

Page 16

EF SERIES GAS FRYERS

ELECTRICAL OPERATION

CONTROL SYSTEM

DESCRIPTION

1. The thermopile (PG) provides the total

control voltage for this system.

A. One side of the thermopile is

connected to the common (C) of the

high limit (HL).

B. The other side of the thermopile is

connected to the normally open (NO)

contacts of the high limit.

C. The common of the high limit (below

the high limit trip temp.) is connected

through the normally closed (NC)

contacts of the high limit, through wire

3 to the combination valve pilot

connection common.

D. The other side of the pilot valve is

connected through wire 4 to wire 1 to

the high limit normally open contacts

which hold the pilot valve open.

C. When the thermostat calls for heat

(closed circuit) power from the

thermopile is then connected to the

other combination valve thermostat

connection through wire 2.

D. If the high limit trips, the thermopile is

connected across zero ohms, the

output voltage of the thermopile drops

to 0.0 millivolts, and the thermostat

coil of the combination valve drops

out, shutting the thermostat valve.

3. Total Shutdown.

A. When the high limit trips, 0.0 millivolts

will read across both coils of the

combination valve, causing both

valves to close.

B. Pilot relight cannot be accomplished

until oil cools sufficiently to allow high

limit to close.

C If any wire in the system is cut or

broken, the system will shut down.

1) If the high limit trips, connection is

made from the common to the

normally open contacts, turning

off pilot valve voltage. The gas

valve closes.

2. Thermostat Control.

A. One side of the millivolt supply is

connected through the high limit

system, as described above, to the

thermostat common (wire 3) of the

combination valve.

B. The other side of the thermopile is

connected from the normally open

contacts of the high limit to the

thermostat through wire 1.

F35641 (02-05)

— 16 —

Page 17

EF SERIES GAS FRYERS

SYSTEM CONDITION QUICK

CHECK PROCEDURES

1. Use the Pilot Lighting procedure and

check millivolts (mV) at wires 3 and 4.

A. lf the pilot lights, then pilot combination

valve and high limit are good.

B. If the pilot will not stay lit, check high

limit and open the thermopile circuit. It

should read 300 mV; if there are Ø

volts, check high limit. If the high limit

is good, replace combination valve.

C. Check for voltage at disconnected

thermopile. It should read 300 mV; if

there are Ø volts, replace thermopile.

Check high limit. If the high limit is

good, replace combination valve.

2. Turn on thermostat; burners should light.

A. lf the burner does not light, check the

following:

SCHEMATIC

1) Voltage at combination valve at

wires 2 and 4.

2) If correct voltage is present, then

check combination valve.

3) If there are Ø volts, check voltage

between wire 3 of combination valve

and wire 1 of thermostat. If correct

voltage is present, then check

resistance of the thermostat

contacts and continuity of wires

3 & 2.

Figure 26

COMPONENT FUNCTION

• Thermostat - Millivolt type with capillary

bulb, single-throw break on temperature

rise. Temperature range of 200°F to

400° F.

• Thermopile - Millivolt control with 24"

capillary. Rated to generate 500 millivolts.

• Combination Valve - Regulates gas flow

to burner and pilot. Provides pilot safety.

• High Limit - Prevents overheating of fryer

in the event of thermostat failure. Opens

at 465°F and automatically resets at

415°F.

— 17 —

F35641 (02-05)

Page 18

EF SERIES GAS FRYERS

TROUBLESHOOTING

SYMPTOM

The temperature of the

shortening drops, or

excessive recovery time is

required.

Pilot won’t stay lit. Fryer

shuts off.

Rapid shortening

breakdown, crumbs and

specks in frying compound.

CAUSE

Insufficient gas supply to

unit.

Ventilation system pulling

heat out of heat exchanger

and flue box.

Overloading fryer capacity.

Malfunctioning thermopile

or loose/dirty connection in

thermopile.

Malfunctioning shutoff

valve.

Pilot burner orifice and air

openings need cleaning.

Excessive temperature

settings (over 375° F).

Shortening not being

filtered regularly.

REMEDY

Adjust gas supply at gas combination

valve.

Relocate fryer.

Adjust loads accordingly.

Check thermopile function and

connections. Adjust or replace as

required.

Replace shutoff valve.

Clean burner orifice and air openings

as required.

Adjust temperature setting.

Adjust filtering schedule.

Incorrect preparation of

breaded food.

Do not use salt.

Allow breading time to adhere to food.

Do not allow loose flour to fall into

shortening from hands.

Do not add strainings or drippings

from meat fats to shortening.

Use correct shortening and follow

temperature recommendations.

Take out 10% to 15% of the

shortening.

Check thermostat settings with

thermometer periodically.

F35641 (02-05)

— 18 —

Page 19

EF SERIES GAS FRYERS

SYMPTOM

Leaking tank.

Pilot burner flames

adjusted properly, but

fluctuates to very low and

blows out easily.

CAUSE

Foam-over by depleted

shortening permits oil to

drip from the tank surface,

giving appearance of

leaking.

Careless draining

procedures.

Carbon buildup causes

rapid attack on tank by

promoting acid formulation.

Gas pressure too low.

Gas pressure too low at

submanifold.

REMEDY

Replace shortening.

Gas control valve knob should be in

PILOT or OFF position before

draining oil. Burners heating an empty

tank will damage tank joints.

Clean tank surfaces.

Check gas pressure on submanifold

fitting when fryer is in operation.

Check other equipment attached to

same gas line.

Adjust gas pressure at submanifold to

not less than 4.0” W.C. (natural and

mixed gas) or 10.0” W.C. for propane

gas.

— 19 —

F35641 (02-05)

Page 20

F35641 (02-05)

PRINTED IN U.S.A.

Loading...

Loading...