Page 1

RIFLESCOPE

riflescope Manual

1-4x24 with Uncapped Turrets

Page 2

RIFLESCOPE

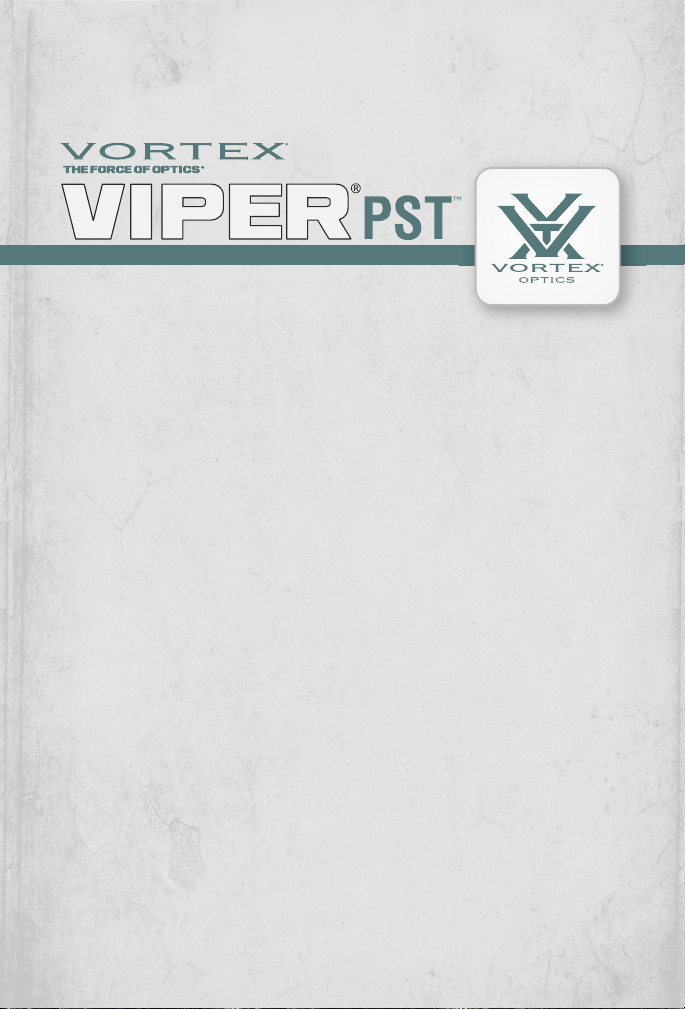

The VorTex® Viper® pSTTm 1-4x24 rifleScope

Specifically designed for the tactical, law enforcement and

committed precision shooting communities, the Viper®PST 1–4x24

riflescopes offer the highest levels of performance and reliability.

With features such as matched turret/reticle subtensions, CRS zero

stop mechanisms and precision ranging reticles, the Viper PSTs are

ready for any situation.

Fast Focus Eyepiece

Illumination

Ocular

Lens

Reticle Focus

Magnification

Adjustment Ring

Adjustment Knob

MagView Indicator

Elevation

Adjustment Knob

Turret Shroud

Dual Use: Shooting Tactical / Hunting

US Patent 7,937,879

Windage Adjustment

Knob

Objective

Lens

3 2

Page 3

Second Focal Plane Reticle

This PST riflescope model uses a second focal plane (SFP) reticle.

The advantage of a SFP reticle is that it always maintains the same

appearance. Shooters using reticle hashmarks should be aware that

the listed subtensions used for estimating range, holdover, and wind

drift correction are only accurate at the 4x magnification.

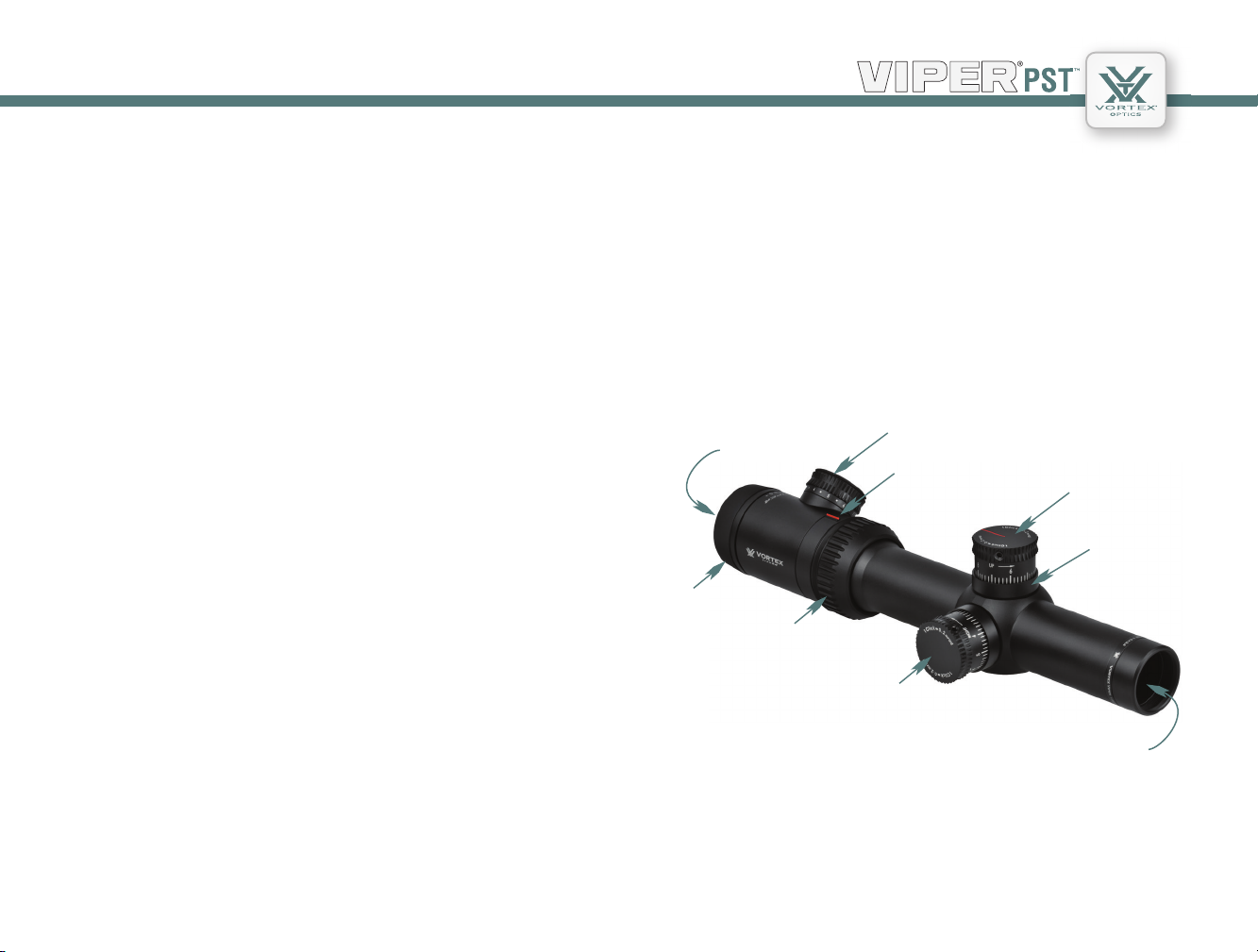

The Subtension Scale: MOA or MRAD

Depending on which version you have purchased, your Viper PST

1–4x24 riflescope will feature adjustments and reticles scaled in MOAs

or mrads. If you are unsure of which scale is used, reference the top of

the adjustment turret.

If the adjustment is in MOAs,

the turret will display

“1 Click = 1/2 MOA”.

Both minute-of-angle (MOA) and milliradian (mrad) unit of arc scales

are effective when ranging or adjusting riflescope for bullet trajectory.

If the adjustment is in mrads,

the turret will display

“1 click = .2 mrad”.

RIFLESCOPE

MOA Adjustments

MOA unit of arc measurements are based on degrees and minutes.

There are 360 degrees in a circle and 60 minutes in a degree for a total

of 21,600 minutes (MOA) in a circle. A minute of angle will subtend

1.05 inches at a distance of 100 yards. Viper PST 1–4x24 riflescopes

with MOA adjustments use 1/2-minute clicks which subtend .52 inches

at 100 yards, 1.05 inches at 200 yards, 1.57 inches at 300 yards, etc.

MRAD Adjustments

Mrad unit of arc measurements are based on the radian. A radian is the

angle subtended at the center of a circle by an arc that is equal in length

to the radius of the circle. There are 6.283 radians in all circles and

1000 milliradian in a radian for a total of 6283 milliradians (mrads) in a

circle. An mrad will subtend 3.6 inches at a distance of 100 yards. Viper

PST 1–4x24 riflescopes with mrad adjustments use .2 mrad clicks which

subtend .72 inches at 100 yards, .1.44 inches at 200 yards (4 cm at 200

meters), 2.16 inches at 300 yards (6 cm at 300 meters), etc.

5 4

Page 4

RIFLESCOPE

rifleScope AdjuSTmenTS

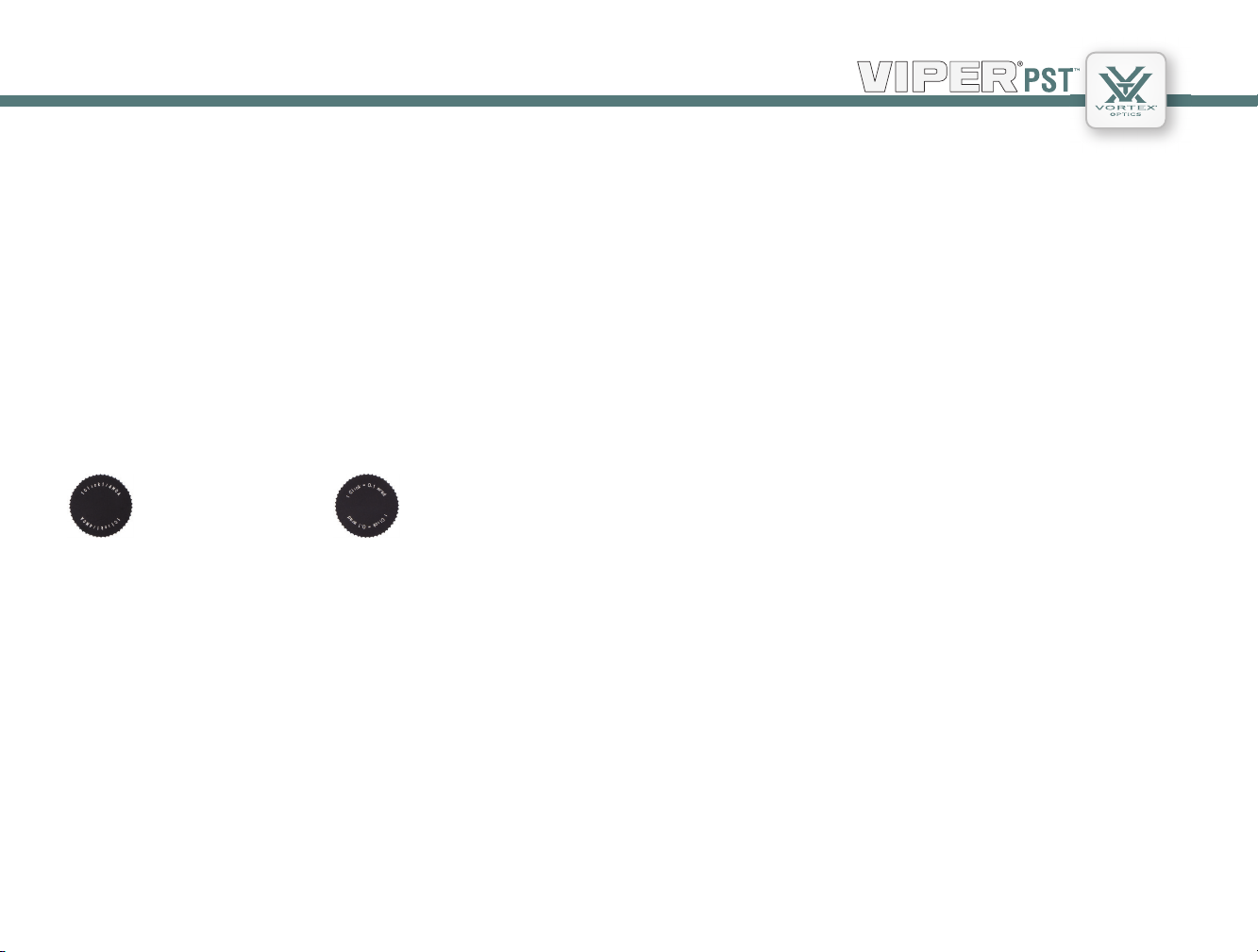

Reticle Focus

Vortex Viper PST riflescopes use a fast focus eyepiece designed to quickly

and easily adjust the focus on the riflescope’s reticle.

To adjust the reticle focus:

1. Look through the riflescope at a

blank white wall or up at the sky.

2. Turn the eyepiece focus knob in

or out until the reticle image is as

crisp as possible.

Adjust the reticle focus.

Note: Try to make this particular adjustment quickly, as the eye will try to

compensate for an out-of-focus reticle.

Once this adjustment is complete, it will not be necessary to re-focus

every time you use the riflescope. However, because your eyesight may

change over time, you should re-check this adjustment periodically.

Warning

Looking directly at the sun through a riflescope, or any optical instrument,

can cause severe and permanent damage to your eyesight.

About Parallax

Windage and Elevation Adjustments

Vortex Viper PST riflescopes incorporate precision finger adjustable elevation

and windage dials with audible clicks.

Elevation

To make adjustments:

1. Turn the adjustment knob in the

appropriate direction: Up/Down or

Left/Right as indicated by the arrows.

2. Following the directional arrows,

turn the knobs in the direction you wish

the bullet’s point-of-impact to go to.

MOA Adjustments

With each click of the Viper PST moving the point-of-impact 1/2 MOA,

it will take two clicks of the knob to move a bullet’s point-of-impact 1.05

inches at a 100 yard sight-in distance.

MRAD Adjustments

With each click of the Viper PST moving the point-of-impact .2 mrad

(.72 inches), two clicks will move the bullet’s point-of-impact 1.44 inches

at a 100 yard sight-in distance. At 100 meters, two clicks will move the

point-of-impact four centimeters.

Knob

Windage Knob

This Viper PST 1-4x24 riflescope does not have a parallax focus and is

factory focussed at a distance of 100 yards. Using good consistent shooting

form and cheek weld when shooting at distances other than 100 yards will

minimize most error problems associated with parallax.

7 6

Page 5

RIFLESCOPE

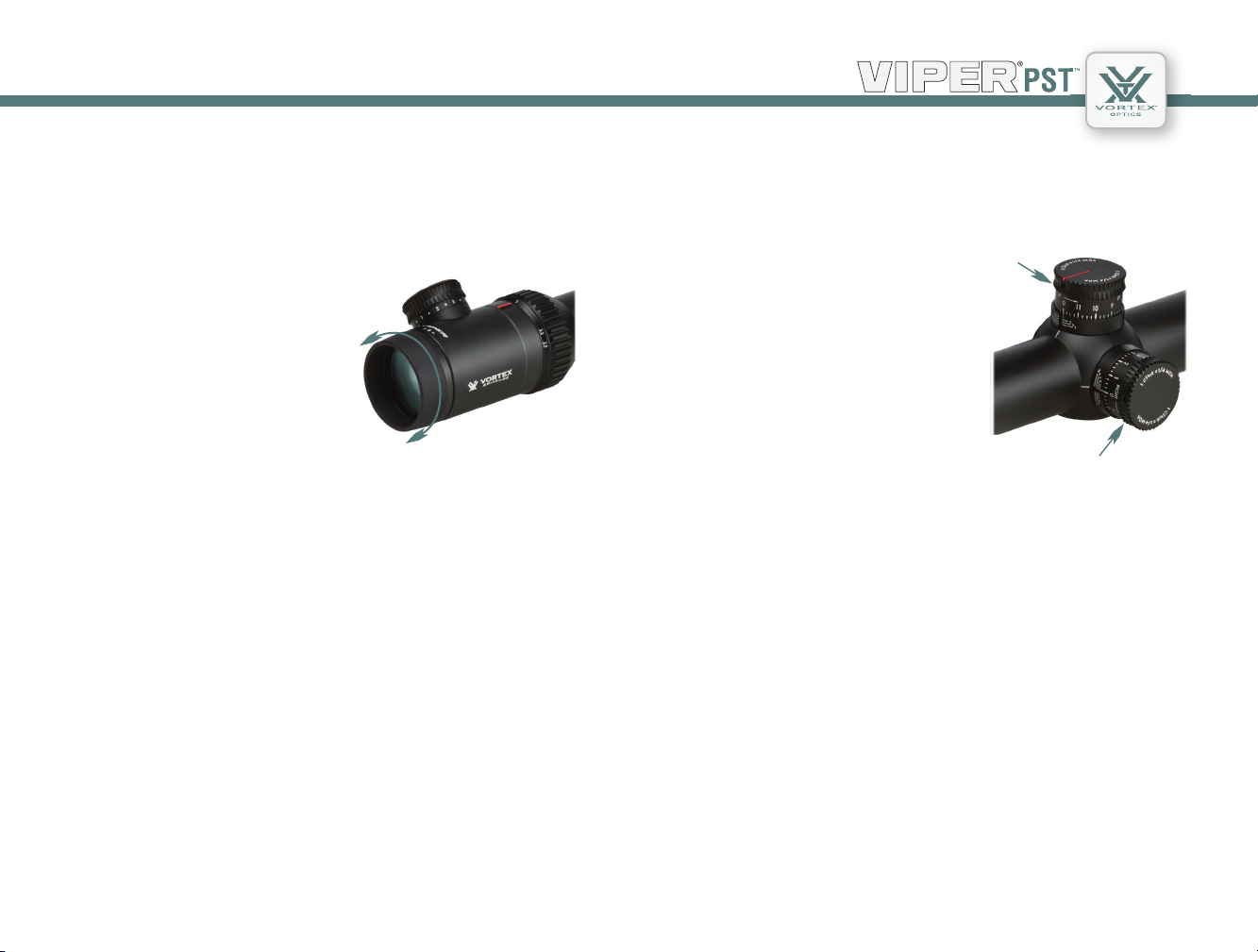

Variable Power Adjustments

To change magnifications, turn the magnification ring to the desired level.

The patented Vortex MagView

system will provide a low light

Magnification

Ring

MagView

reference for magnification level.

Illumination Adjustments

The Vortex Viper PST riflescopes

use a variable intensity reticle

illumination system to aid in low

light performance. To activate the

illumination, rotate the adjustment

knob in either direction.

The illumination knob allows for 10 levels of brightness intensity; an off

click between each level allows the shooter to turn the illumination off

and return to a favored intensity level with just one click.

Illumination

Knob

Replacing the Battery

1. Unscrew the outer cap with a coin.

2. Remove the battery.

3. Replace with a new CR2032 battery.

4. Re-install the outer battery cap and be sure to fully tighten it down.

Battery Cap

9 8

Page 6

RIFLESCOPE

Turret Rotation

Vortex Viper PST riflescopes incorporate Vortex’s patented Radius Bar

to visually assist in keeping track

of turret rotations. The radius

bar provides a quick visual

reference that allows the shooter

to confirm:

• Knob orientation is correct

Turret Cap

Retaining

Screw

and has not shifted as a result of

accidental contact.

• Knob orientation is at the

zero point when using the CRS

feature.

• By watching the position of

the bar while making elevation adjustments, the shooter is able to quickly

track full, half and quarter rotations.

To get these benefits from the Radius Bar, the “0” mark on the turret must

be indexed with the zero reference line on turret post (see Setting the

CRS Stop and Indexing Elevation Knob section on page 17).

Radius Bar

Zero Reference Lines

Customizable Rotational Stop (CRS)

Vortex Viper PST riflescope elevation turrets incorporate the unique

CRS rotation stop feature. After the rifle is sighted in, the design of the

CRS allows a shooter to quickly and easily return to an original zero

point when using the elevation turret to dial-in temporary bullet drop

corrections.

The CRS feature is particularly useful when dialing large multi-

revolution elevation corrections. Without this feature, the shooter

must pay very careful attention when dialing these large corrections.

If the shooter loses track of the number of revolutions, the original

zero point may become lost when returning the adjustment. Viper PST

riflescopes equipped with the CRS allow the elevation dial to be quickly

spun back to original zero without having to carefully count revolutions

or clicks.

Once the CRS shims are installed after sight-in, the elevation dial will

stop turning shortly past the original zero point when being returned

(turning clockwise direction) from a temporary elevation adjustment.

The shooter can then turn the elevation knob a partial turn in a

counter-clockwise direction until the zero reference and radius bar are

correctly aligned—achieving the original zero point.

See CRS shim installation in the

Bore Sighting and Final Range

Sight-in sections.

CRS Shims

11 10

Page 7

RIFLESCOPE

rifleScope mounTing

To get the best performance from your Vortex Viper PST riflescope,

proper mounting is

essential. Although not

difficult, the correct

steps must be followed.

If you are unsure of your

abilities, it would be best

to use the services of a

qualified gunsmith.

Centering of the Reticle

The Vortex Viper PST riflescope is pre-set from the factory with the reticle

in the center of the adjustment ranges.

If you have changed the settings and wish to approximately reset the reticle

to the center, this can be done easily:

1. Turn the windage or elevation dial as far as possible in either direction.

Do not force the dial. As soon as any resistance is felt, stop turning.

2. Carefully count the dial rotations while turning the dial back in the

opposite direction. Stop turning as soon as resistance is felt.

3. Turn the dial the other direction to half the amount of rotations

counted in step one.

Rings and Bases

Mount an appropriate base and matching rings to your rifle according

to the manufacturer’s instructions. The Vortex Viper PST riflescopes

require 30 mm rings.

Ring height for Viper PST 1–4x24 riflescopes will depend on the firearm

and mount being used. Consult the ring and base manufacturer for

suggested heights..

Use 30 mm rings.

AR-style rifles will usually require an extra-high mounting height on a

specialized cantilever-style mount such as the Vortex ADR-X cantilever

ring mount (shown above).

Complete this procedure for both windage and elevation dials to

approximately center the reticle.

13 12

Page 8

RIFLESCOPE

Eye Relief and Reticle Alignment

After installing the bottom ring halves on the mounting base, place the

riflescope on the bottom ring halves and loosely install the upper ring

halves. Before tightening the scope ring screws, adjust for maximum

eye relief to avoid injury from recoil:

1. Set the riflescope to the middle of its magnification range.

2. Slide the riflescope as far forward as possible in the rings.

3. While viewing through the riflescope in a normal shooting position,

slowly slide the riflescope back towards the shooter’s face—paying

attention to the field of view. Just as the full view is visible, stop.

4. Without disturbing the front-back placement, rotate the riflescope

until the vertical crosshair exactly matches the vertical axis of the rifle.

Use of a reticle leveling tool, a weight hung on a rope, flat feeler gauges,

or bubble levels will help with this procedure.

5. After aligning the reticle, tighten and torque the ring screws down

per the manufacturer’s instructions.

Bore Sighting

Initial bore sighting of the riflescope will save time and money at the

range. This can be done by using a mechanical or laser bore sighter

according to the manufacturer’s instructions or by removing the bolt

and sighting through the barrel on some rifles.

To visually bore sight a rifle:

1. Place the rifle solidly on a rest and remove the bolt.

2. Sight through the bore at a target approximately 100 yards away.

3. Move the rifle and rest until the target is visually centered inside the

barrel.

4. With the target centered in the bore, make windage and elevation

adjustments until the reticle crosshair is also centered over the target.

Using bubble levels

to square the

riflescope to the

base.

Visually bore-sighting a rifle.

15 14

Page 9

RIFLESCOPE

Final Range Sight-In and CRS Stop Set

After the riflescope has been bore-sighted, final sight-in and CRS

stop set should be done at the range using the exact ammunition

expected to be used while shooting. Sight in and zero the riflescope at

the preferred distance. 100 yards is the most common zero distance,

although a 200 yard zero may be preferred for long range applications.

Note: Be sure the reticle is in focus (see Reticle Focus section on page 6).

1. Following all safe shooting practices, fire a three-shot group as

precisely as possible.

2. Next, adjust the reticle to match the approximate center of the shot

group (see Windage and Elevation Adjustment section on page 7).

Note: If the rifle is very solidly mounted and cannot be moved, simply

look through the scope and adjust the reticle until it is centered on the

fired group.

3. Carefully fire another three-shot group and see if the bullet group is

centered on the bullseye.

This procedure can be repeated as many times as necessary to achieve a

perfect zero.

Setting the CRS Stop and Indexing Elevation Knob

After obtaining a satisfactory zero, the CRS stop can be set if desired:

1. Loosen the three turret cap retaining screws on the elevation turret.

Gently pull the turret cap straight up and off of the turret post, being

careful not to rotate the turret post.

2. Slide the CRS shims on the center section of the turret post below the

V-grooved part.

Place CRS shims

in this groove.

Alternate shim installation direction

with each shim.

Use as many shims as necessary to

completely fill up the space. Do not try to

force in a last shim once the clearance is

very close—a tiny remaining gap is normal.

17 16

Page 10

RIFLESCOPE

3. After filling the center gap on the post with shims, replace the elevation

cap.

4. Align the turret cap so the “0” mark on the cap matches up with

the “0” reference line on the turret shroud.

Again, be sure not to rotate the actual turret

mechanism in the process.

5. Re-tighten the retaining screws, but do not

overtighten. Use of thumb and forefinger on

the short end of the hex wrench will provide

Align the elevation turret cap.

sufficient force.

Indexing the Windage Knob

1. Loosen the three retaining screws on windage turret cap.

2. Carefully rotate the cap until the “0” mark on the cap matches up with

the “0” reference line on the turret post. Be sure that the cap is freely

turning and that you don’t rotate the actual turret mechanism.

3. Re-tighten the windage knob retaining screws, but do not overtighten.

Use of thumb and forefinger on the short end of the hex wrench will

provide sufficient force.

Once the windage and elevation knobs

are correctly indexed to the zero mark,

temporary corrections can be safely dialed

into the scope without worry of losing the

original zero.

Using the CRS Zero Stop

Once the CRS shims are installed, the elevation dial will stop turning

shortly past the original zero point when being returned (turning

clockwise direction) from a temporary elevation adjustment.

Turn the elevation knob a partial turn in a counter-clockwise direction

until the Radius Bar is

correctly aligned with scope

axis and zero marks match.

This setting will match the

original zero point.

Note: If re-zeroing at a

future time, be sure to

Point at which the knob stops turning.

remove all CRS shims

before sight-in.

Correct alignment for zero point.

Align the windage turret cap.

19 18

Page 11

RIFLESCOPE

mAinTenAnce

Cleaning

The fully waterproof and fogproof Vortex Viper PST riflescope requires

very little routine maintenance other than periodically cleaning the

exterior lenses. The exterior of the scope may be cleaned by wiping with a

soft, dry cloth.

When cleaning the lenses, be sure to use products, such as the Vortex Fog

Free cleaning products or Lens Pen, that are specifically designed for use

on coated optical lenses.

• Be sure to blow away any dust or grit on the lenses prior to wiping the

surfaces.

• Using your breath, or a very small amount of water or pure alcohol, can

help remove stubborn things like dried water spots.

Lubrication

All components of the Vortex Viper PST riflescopes are permanently

lubricated, so no additional lubricant should be applied.

Note: Other than to remove the turret caps, do not attempt to

disassemble any components of the riflescope. Disassembling of riflescope

may void warranty.

Storage

If possible, avoid exposing your Vortex riflescope to direct sunlight or any

very hot location for long periods of time.

TroubleShooTing

Sighting-in Problems

Many times, problems thought to be with the scope are actually

mount problems. Be sure the mounts are tight to the rifle and the

scope is secured so it doesn’t twist or move in the rings.

An insufficient windage or elevation adjustment range may indicate

problems with the base mount, base mount holes drilled in the rifle’s

receiver, or barrel/receiver alignment.

Check for Correct Base and Ring Alignment

1. Re-center the scope reticle (see Centering of the Reticle section

on page 12).

2. Attach bore sighter, or remove bolt and visually boresight rifle.

3. Look through the scope. If the reticle appears way off center on

the boresighter image or when compared to the visually centered

target when looking through rifle’s bore, there may be a problem with

the bases or rings being used. Confirm that correct base and rings are

being used—and in the proper orientation.

Grouping Problems

There are many issues that can cause poor bullet grouping.

• Maintain a good shooting technique and use a solid rest.

• Check that all screws on rifle’s action are properly tightened.

• Be sure rifle barrel and action are clean and free of excessive

oil or copper fouling.

• Check that rings are correctly torqued per the manufacturer’s instructions.

• Some rifles and ammunition don’t work well together—try different

ammunition and see if accuracy improves.

21 20

Page 12

The Vip WArrAnTy

We build optics based on our commitment to your absolute satisfaction.

That’s why Vortex products are unconditionally guaranteed and we make

this Very Important Promise to you—a Very Important Person.

Rest assured that in the event your Viper PST becomes damaged or

defective, Vortex Optics will repair or replace

the riflescope at no charge to you. Call

Vortex Optics at 800-426-0048 for prompt,

professional, and friendly service.

Vortex Optics

2120 West Greenview Drive

Middleton, WI 53562

service@vortexoptics.com

Visit www.vortexoptics.com for more information. Canadian customers

may visit www.vortexcanada.net for customer service information.

Note: The VIP warranty does not cover theft, loss, or deliberate damage

to the product.

Unlimited

Unconditional

Lifetime Warranty

RIFLESCOPE

23 22

Page 13

Loading...

Loading...