Page 1

Vortex 5-20x50 Riflescope

At Vortex Optics, the need for high-performance,

precision optics is the driving force behind all

that we do.

That’s why we carefully built the Razor HD riflescope

TM

to provide shooters with the ultimate long range tactical

riflescope. Built on an incredibly tough one piece 35mm

main tube and using a state-of-the-art optical system

and erector mechanism, the Razor 5–20x50 delivers

superior accuracy and rugged reliability under the

harshest conditions.

Specifications . . . . . . . . . . . . . . . . . . 3

Adjustments . . . . . . . . . . . . . . . . . . . 4

Mounting . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . 19

Vortex Service and Repair Policy . . . 20

1

Page 2

The Vortex Razor HD 5-20x50 Riflescope

RZR Zero Stop and Elevation

Adjustment Knob

Objective Lens

Side Parallax Focus

Magnification

Adjustment Ring

Radius Bar

(3) Turret Cap

Retaining Screws

Windage

Adjustment Knob

Zero Reference

Line

MagView

Reticle Focus

Illumination Knob

and Battery Cover

Razor 5–20x50 Riflescope Specifications

Waterproof Yes

Fogproof Argon gas purging

Length 15.8 inches (402 mm)

Mounting Length 6.9 inches (175 mm)

Weight 35.2 ounces (1000 g)

Eye Relief 3.9 inches (100 mm)

Field of View 5x: 22.0 feet /100 yards (4.2°)

20x: 5.76 feet /100 yards (1.1°)

Recoil Tested Rated for .50 BMG

Battery CR2032

(Eyepiec e) (Sunshade)

1.7”

(43mm)

4.0” (102mm)

2.5”

(64mm)

6.9” (175mm)

Adjustment Specifications

Reticle Style EBR 1 - MOA EBR 2 - MRAD

Windage 125 MOA 36 mrads

Elevation 125 MOA 36 mrads

Per Rotation 15 MOA 5 mrads

Per Click 1/4 MOA 1/10 mrads

Accessories included with the Razor HD

Flip cap lens cover with killFLASH

4-inch sunshade

35mm bubble level

2mm hex wrench

15.8” (402m m)

2.9”

(74mm)

4.9” (125mm) 4.0” (102mm)

®

ARD

2.3”

(58mm)

23

Page 3

Riflescope Adjustments

Windage and Elevation Adjustments

Vortex 5–20x50 Razor riflescopes incorporate precision

finger adjustable elevation and windage knobs with audible

and tactile clicks.

To make adjust ments:

Elevation

Adjustment Knob

1. Turn the adjustment

knob in the appropriate

direction: Up/Down or

Left/Right as indicated by

the arrows.

2. Move the knobs in the

direction you wish the

Windage

Adjustment Knob

bullet’s point-of-impact to change.

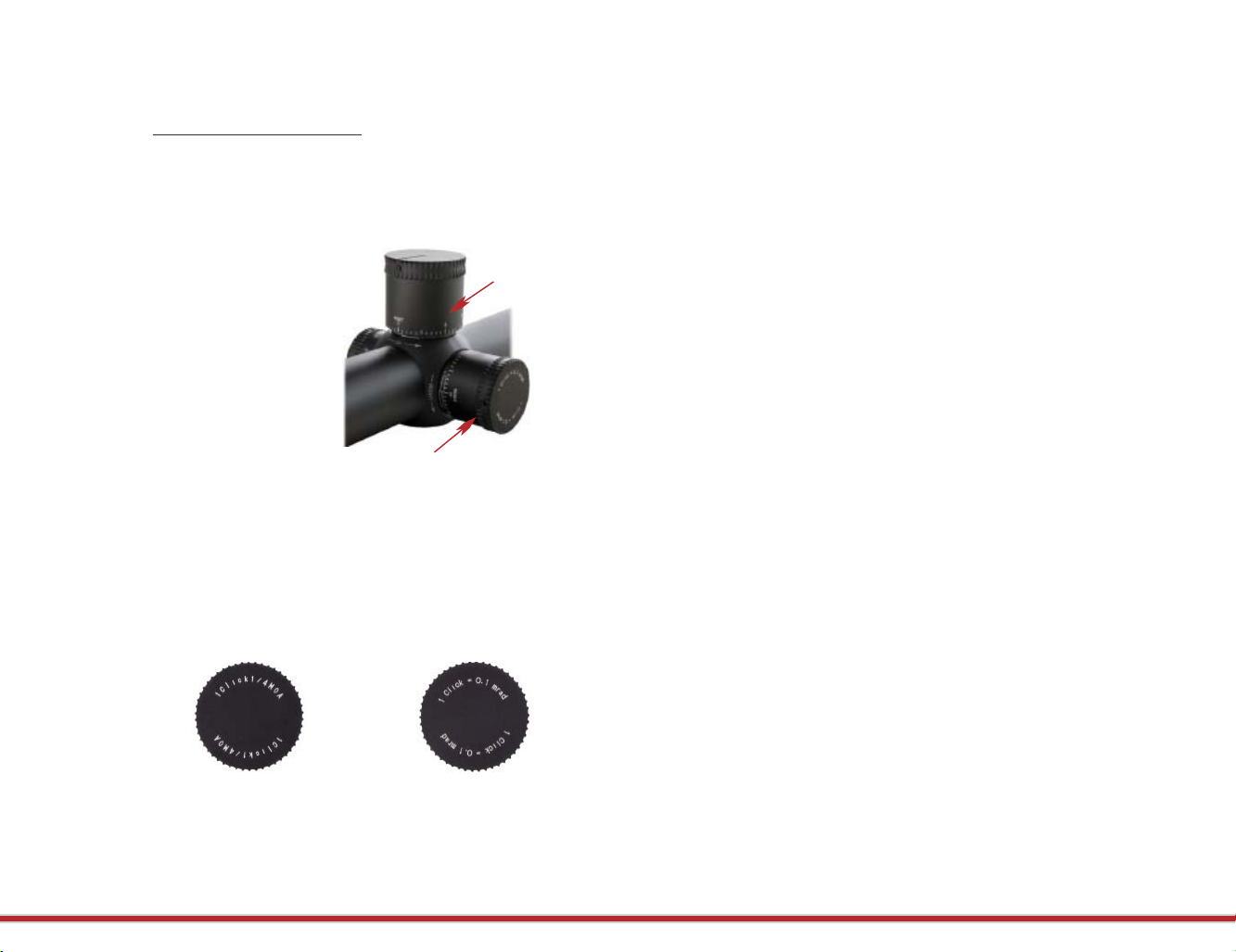

Depending on which version you have purchased, your Razor

5–20x50 riflescope will feature adjustments scaled in MOAs

or mrads. If you are unsure of which scale is used, reference

the top of the adjustment turret.

MOA Adjustments

Most shooters are familiar with the minute–of-angle

(MOA) system commonly used in hunting riflescopes.

MOA measurements are based on degrees and minutes: 360

degrees in a circle, 60 minutes in a degree, for a total of

21,600. When comparing MOAs and mrads, 3.44 MOAs

are equal to 1 mrad. These angular measurements are used

for ranging and correcting for the bullet’s trajectory drop in

riflescopes.

Each click will move the point-of-impact 1/4 MOA. 1/4

MOA closely corresponds to .26 inches at 100 yards, .52

inches at 200 yards, .78 inches at 300 yards, etc.

Example: At a 100 yard sight-in distance, it will take four clicks of

the knob to move a bullet’s point-of-impact 1.05 inches.

MRAD Adjustments

The milliradian (mrad for short) is a form of angular

measurement similar in concept to a degree although much

finer. A degree is 1/360 of a circle; a milliradian is 1/6283 of

a circle.

If the adjustment is in MOAs,

the turret will display

“1 Click = ¼ MOA”.

Each click will move the point-of-impact 1/10 mrad. 1/10

mrad equals .36 inches at 100 yards (1 cm at 100 meters), .72

inches at 200 yards (2 cm at 200 meters), 1.08 inches at 300

If the adjustment is in mrads,

the turret will display

“1 click = 1/10 mrad”.

yards (3 cm at 300 meters), etc.

Example: At a 100 yard sight-in distance, four clicks will move the

bullet’s point-of-impact 1.44 inches. At 100 meters, four clicks will

move the point-of-impact four centimeters.

45

Page 4

Reticle Focusing

Parallax Adjustment

Vortex Razor riflescopes use a fast focus eyepiece designed

to quickly and easily adjust the focus on the riflescope’s

reticle.

Try to make this

particular adjustment

quickly, as the eye will

try to compensate for an

out-of-focus reticle.

Adjust the reticle focus

To adjust the reticle focus:

1. Look through the riflescope at a blank white wall

or up at the sky.

2. Turn the eyepiece focus knob in or out until the reticle

image is as crisp as possible.

Note: Once this adjustment is complete, it will not be necessary

to re-focus every time you use the rifl escope. However, because your

eyesight may change over time, you should re-check this adjustment

periodically.

The Razor HD 5–20x50 riflescope uses a side focus parallax

adjustment which, when

properly set, eliminates

parallax errors. Properly

setting a side focus parallax

adjustment is a quick

procedure. When properly

set, the target image should

be sharp and crisp.

To set the parallax:

1. First, be sure the reticle is

correctly focused (see Reticle

Focusing).

2. As accurately as possible,

Parallax is a phenomenon that

results when the target image

does not quite fall on the same

optical plane as the reticle within

the scope. When the shooter’s eye

is not precisely centered in the

eyepiece, there can be apparent

movement of the target in relation

to the reticle, which can cause a

small shift in the point of aim.

Parallax error is most problematic

for precision shooters using high

magnifi cation.

match the yardage number

(distance you are shooting) on

side focus parallax adjustment

knob to the indicator arrow on

the scope body.

3. Check the setting for

accuracy by moving your head

back and forth while looking

through the scope. The setting

is correct if there is no apparent

Adjust the side parallax knob

movement between the reticle

and target. If there is apparent movement, adjust the focus knob

slightly until the movement is eliminated.

67

Page 5

Turret Rotation

Vortex Razor riflescopes incorporate the Radius Bar to

visually assist in keeping track of

Radius Bar

turret rotations. By watching the

position of the bar while making

elevation adjustments, the shooter

is able to quickly track full, half and

quarter rotations. To get the most

benefit from the Radius Bar, the “0”

mark on the turret must be indexed with the zero reference

line on turret post.

Illumination Adjustments

The Vortex Razor HD 5–20 x 50 riflescope uses a variable intensity

reticle illumination system to aid in low light performance. To

activate the illumination, rotate the adjustment knob in a clockwise

direction. The illumination knob allows for 11 levels of brightness

intensity; an off click between each level allows the shooter to turn

the illumination off and return to a favored intensity level with just

one click. The top setting (11) is visible in the daytime, depending on

the background color. Settings below 11 are for low light use when

the user’s eyes have adjusted to lower light levels. Lowest settings are

for use with night vision devices.

To cha nge batter ies:

Battery Cap

1. Unscrew the outer cap with a coin.

2. Remove the CR2032 battery.

3. Replace with a new CR2032 battery.

Variable Power Adjustments

To change magnifications, turn the

MagView

magnification ring to the desired

level. The Vortex MagView system

will provide a low light reference

for magnification level.

RZR Zero Stop Adjustment

Vortex Razor 5–20x50 riflescopes incorporate the RZR

Zero Stop feature. After the rifle

is sighted in, the RZR Zero

Stop allows fast, easy return to

the original zero point when

large multi-revolution elevation

corrections have been dialed into

the riflescope.

Without a zero stop, the shooter must pay very careful

attention when dialing large corrections needing multiple

revolutions of the elevation knob. If the shooter loses track of

the number of revolutions, the original zero point may become

lost. Because of the RZR Zero Stop, the elevation knob on

Vortex Razor scopes can be quickly spun back to the original

zero without having to carefully count revolutions. Once the

RZR Zero Stop is set, the elevation knob will stop turning at

the original zero point when being returned from a temporary

elevation correction. Learn how to adjust the RZR Zero Stop

in the Bore Sighting and Range Sight-in sections.

89

Page 6

Riflescope Mounting

To get the best performance from your Vortex Razor

riflescope, proper mounting

is essential. Although not

difficult, the correct steps

must be followed. If you

are unsure of your abilities,

it would be best to use

the services of a qualified

gunsmith.

Centering of the Reticle

The Vortex Razor HD riflescope is pre-set from the factory

with the reticle in the center of the adjustment ranges. This is

the best position to begin sight-in.

If you have changed the settings and wish to reset the

reticle to the center, this can be done easily:

1. Loosen the elevation turret cap retaining screws and remove

the elevation cap.

2. Loosen the eleveation zero stop lock screws.

3. Turn the windage and elevation turrets clockwise until

stopped.

4. Turn windage and elevation turrets counter-clockwise 4.25

full rotations to approximately center the reticle.

Rings and Bases

Mount an appropriate base and matching rings to your rifle

according to the manufacturer’s instructions. The Vortex Razor

5–20x50 riflescope requires 35mm rings.

Vortex Optics highly

recommends using the

matched Vortex Optics

Omega 35mm precision

ring sets which may

be purchased from

an authorized Vortex

riflescope dealer. These

rings will mount to

any quality Weaver or

Use 35mm rings for the Razor 5–20x50

Picatinny type base.

If using aftermarket rings, use the lowest ring height that

will give complete clearance of scope and rifle—avoiding

any contact with barrel, receiver, bolt handle or any

other part of the rifle. A low mounting will help assure

proper cheek weld, aid in establishing a solid shooting

position, and promote fast target acquisition.

At this point, the riflescope is ready for bore sighting (see

Bore Sighting section).

10 11

Page 7

Eye Relief and Reticle Alignment

Bubble Level

Place the riflescope on bottom ring halves and loosely

install the upper ring halves. Before tightening the

scope ring screws, adjust for maximum eye relief to

avoid injury from recoil:

1. Set the riflescope to the middle of its magnification range.

2. Slide the riflescope as far forward as possible in the rings.

3. While viewing through the riflescope in a normal

shooting position, slowly slide the riflescope back towards

the shooter’s face—paying attention to the field of view.

as the full view is visible

, stop.

Just

4. Without disturbing the front-back placement, rotate the

riflescope until the vertical crosshair exactly matches the

vertical axis of the rifle. Use a reticle leveling tool, hanging

weight on a rope (see next page), or an adjustable set of

feeler gauges for this procedure.

Use of an adjustable set of feeler

gauges between a one-piece base

and fl at bottom section of the

rifl escope to square the rifl escope

(and reticle) to the base.

After the riflescope is in the rings and the reticle matches

the vertical axis of

the rifle, the bubble

level may be mounted

Vertical Reference

to the riflescope

tube. Attach the level

to a location on the

scope tube that allows

Bubble Level

good visibility while

in shooting position

and does not block

view of parallax or

windage knobs. Most

shooters will prefer

mounting the level on

the forward section of

the riflescope tube.

Confirm the vertical orientation of the reticle.

1. Confirm the vertical orientation of the reticle by hanging

a weight from a heavy cord at a distance out in front of the

riflescope.

Square the riflescope to the base.

5. After aligning the reticle, tighten and torque the ring

screws down per the manufacturer’s instructions.

12 13

2. Visually level the bubble between lines and tighten screws

using thumb and forefinger on short end of hex wrench.

Page 8

Bore Sighting and RZR Zero Stop Preparation

Initial bore sighting of the riflescope will save time and

money at the range. This can be done by removing the bolt

and sighting through the barrel on a bolt action rifle, or

using a mechanical or laser bore sighter.

Preparing the RZR Zero Stop for setting:

1. Begin by turning the elevation knob clockwise until it stops.

2. Loosen, but do not remove, the three elevation turret cap

retaining screws.

3. Lift the elevation turret cap up and off the

(3) Turret

Cap Screws

turret. This will reveal the scale markings to

be used for sight in.

Sight-in Adjustment

Scale

4. Next, loosen, but do not remove, the three elevation zero stop

lock screws.

(3) Zero Stop

Note: No initial adjustments are necessary

Lock Screws

on the windage knob.

If using a mechanical or laser bore sighter, set up

using the manufacturer’s instructions. Make windage

and elevation adjustments until the reticle crosshair

is aligned with the adjustment pattern or laser dot.

Note: You will not feel “clicks” as the elevation knob is adjusted—

this is normal. The “clicks” will return after fi nal zero stop is set at

the rifl e range. Use the graphic number scale to track adjustments.

Bore sighting a bolt action rifle can be done without a

mechanical or laser bore sighter:

1. Place the rifle solidly on a rest and remove the bolt.

2. Sight through the bore at a target approximately 100

yards away.

3. Move the rifle and rest until the target is visually

centered inside the barrel.

4. With the target centered in the bore, make windage

and elevation adjustments until the reticle crosshair is also

centered over the target.

Important

Do not re-tighten elevation zero stop lock screws or replace the turret

cap at this time; these will be tightened after the fi nal sight-in.

14 15

Page 9

Range Sight-In and RZR Zero Stop Set

After the riflescope has been bore-sighted, final

sight-in and RZR Zero Stop set should be done at the

range using the exact ammunition expected to be used

while shooting. Sight in and zero the riflescope at the

preferred distance. 100 yards is the most common

zero distance, although a 200 yard zero may be

preferred for long distance applications.

Be sure the reticle is in focus (see Reticle Focusing) and

set the parallax adjustment to match the distance being

used for sight-in:

1. Following all safe shooting practices, fire a three-shot

group as precisely as possible.

2. Next, adjust the reticle to match the approximate

center of the shot group (see section on Windage and

Elevation Adjustment). As previously noted in the section on

bore sighting, the elevation turret cap turret should be removed

and zero stop lock screws should be loosened.

3. If the rifle is very solidly mounted and cannot be

moved, simply look through the scope and adjust the

reticle until it is centered on the fired group.

4. Carefully fire another three-shot group and see if the

bullet group is centered on the bullseye.

This procedure can be repeated as many times as

necessary to achieve a perfect zero.

After satisfactory zero has been obtained, the RZR zero

stop can be set:

1. Re-tighten the three zero stop lock screws. Do not over tighten:

thumb and forefinger on the short end of supplied hex wrench

will be sufficient.

2. Replace elevation turret cap, being sure to align “0” mark

on cap with the zero reference line on scope body. Push the cap

straight down and avoid turning while doing this.

3. Be sure the cap is fully down and re-tighten elevation cap

retaining screws. Do not overtighten: using thumb and forefinger

on short end of hex wrench will be sufficient.

Note: To re-zero for a different load, repeat complete bore sighting and range

sight-in procedures. It is important to always begin any sight-in adjustments

by turning elevation turret clockwise until fully stopped.

Re-Indexing Zero Mark on Windage Knob

If desired, the windage knob may be re-indexed to zero after

sight-in. This will allow an easy return to the zero point if

temporary windage corrections are dialed in the field.

1. After completing the final sight-in, fully loosen the three

windage turret cap retaining screws and carefully pull the turret

cap straight off. Re-position with the “0” mark on the cap aligned

with the zero reference line on the turret post and push the cap

straight down. Avoid rotating while pushing down.

2. Be sure the cap is fully down and re-tighten windage knob

retaining screws. Do not overtighten: using thumb and forefinger

on short end of hex wrench will be sufficient.

16 17

Page 10

Maintenance

Troubleshooting

Cleaning

The Vortex Razor riflescope requires very little

routine maintenance other than periodically cleaning

the exterior lenses. The exterior of the scope may be

cleaned by wiping with a soft, dry cloth.

When cleaning the lenses, be sure to use products that are

specifically designed for use on coated optical lenses.

• Be sure to blow away any dust or grit on the lenses

prior to wiping the surfaces.

• Using your breath, or a very small amount of water or

pure alcohol, can help remove stubborn things like dried

water spots.

Lubrication

All components of the Vortex Razor HD are permanently

lubricated, so no additional lubricant should be applied. If

possible, avoid exposing your Vortex riflescope to direct

sunlight or any very hot location for long periods of time.

Please check the following items prior to returning a

rif lescope for service.

Many times, problems thought to be with the

scope are actually mount problems. Verify use of

correct base and rings for the rifle and that these are

correctly oriented and tightened. The scope should not

twist or move in the rings.

Insufficient windage or elevation adjustment range

can indicate an incorrect base, alignment problems

with mount holes drilled in base or rifle’s receiver, or

alignment problems with barrel and receiver.

If the rifle is failing to group well, there are several

things to easily check:

• Be sure the rifle’s action is bedded correctly, and all

mounting screws are properly tightened.

• The rifle’s barrel and action should be clean and free

of excessive oil or copper fouling.

Note: Other than to remove the turret caps, do not attempt to

disassemble any components of the rifl escope. Disassembling of

rifl escope may void warranty.

18 19

• Also, some rifle/ammunition combinations simply

don’t work well together—try shooting different

ammunition and see if accuracy improves.

• Over torquing rings.

Page 11

Vortex Service and Repair Policy

Unconditional Lifetime Warranty

Vortex Optics wants you to shoot

and use your Razor HD riflescope

under any conditions with

complete confidence—that’s why

our warranty is straightforward

and simple:

Unconditional Lifetime

• Fully transferable

Warranty

• No warranty card needed

• No receipt needed

Rest assured, if this riflescope should ever require repair, all

you need to do is contact Vortex for absolutely free service.

Call 800-426-0048 or e-mail service@vortexoptics.com.

Vor tex O pt ic s

2120 West Greenview Drive

Middleton, Wisconsin 53562

USA

Patents Pending on MagView System, Radius Bar, RZR Zero Stop

Dual Use for Shooting Tactical / Hunting

vortexoptics.com

20

Loading...

Loading...