Service Manual

Trucks

Group 00

Release 02

Dismantling manual for Volvo Trucks

20068517

Foreword

The descriptions and service procedures contained in this manual are based on designs

and methods studies carried out up to January 2005.

The products are under continuous development. Vehicles and components produced

after the above date may therefore have different specifications and repair methods.

When this is judged to have a significant bearing on this manual, supplementary service

bulletins will be issued to cover the changes.

The new edition of this manual will update the changes.

In service procedures where the title incorporates an operation number, this is a

reference to V.S.T. (Volvo Standard Times).

Service procedures which do not include an operation number in the title are for general

information and no reference is made to V.S.T.

The following levels of observations, cautions and warnings are used in this Service

Documentation:

Note: Indicates a procedure, practice, or condition that must be followed in order to have

the vehicle or component function in the manner intended.

Caution: Indicates an unsafe practice where damage to the product could occur.

Warning: Indicates an unsafe practice where personal injury or severe damage to the

product could occur.

Danger: Indicates an unsafepractice where serious personal injury or death could occur.

Volvo Truck Corporation

Göteborg, Sweden

Order number: 20068517

© 2005 Volvo Truck Corporation, Göteborg, Sweden

All rights reserved. No part of this publication may be reproduced, stored in

retrieval system, or transmitted in any forms by any means, electronic,

mechanical, photocopying, recording or otherwise, without the prior written

permission of Volvo Truck Corporation.

ENG20676

Group 00 Dismantling manual for Volvo Trucks

Disassembly instructions

Contents

“Introduction” page 2

“Volvo and the environment” page 3

“The Volvo environmental policy” page 3

“Legislation, protection and safety regulations” page 3

“Recycling” page 4

“Labelling” page 4

“Hazardous waste” page 4

“Chemicals and fluids” page 5

“Plastics” page 5

“Metals” page 5

“Handling hazardous waste” page 5

“Equipment” page 7

“General recommendations and preparations” page 7

“Emptying of components” page 8

“Disassembly instructions” page 17

1

Group 00 Dismantling manual for Volvo Trucks

Introduction

Volvo’s three core values are quality, safety and respect

for the environment.

Correct handling also reduces costs and makes best use

of the economic value of components and material.

This manual has been prepared as one element of this

respect for the environment, to provide general guidelines

and information for the dismantling of a Volvo truck.

The aim is to give comprehensive information on how

dismantling should take place, whilst leaving a certain

amount of flexibility to permit a workshop to devise its

own methods and procedures for the work of dismantling,

and also to ensure that harmful waste and other material

that could cause harm to people or the environment is

handled in an environmentally correct manner.

This information is of a general nature because this

manual is applicable to different types of truck, which

means that certain details may vary between different

truck models. However the important information still

applies.

For more detailed information and working instructions

refer to the other service information in the respective

groups from 1 to 9.

2

Group 00 Dismantling manual for Volvo Trucks

Volvo and the environment

Respect for the environment is, along with safety and

quality, one of the three Volvo core values.

Taking care of the environment expresses the concern

of the Volvo Group to actively improve its environmental

work and to reduce the effect on the environment of

the products and processes involved in its business

operations.

The Volvo environmental policy

The environmental policy of the Volvo Group is built up

around the following strategies:

Overview

•

The company’s products are placed in a larger

context where efforts are concentrated on reducing

the effects on the environment of the products and

processes in the business at every stage of the life

cycle, from the original ideas to dismantling and waste

handling. Customers, society in general, distributors

and subcontractors are also included in this chain.

Continuous improvement

•

Environmental work shall be integrated and followed

up in all respects to maintain continual improvement.

This is expressed in the Volvo environmental policy, that

shall permetate through, not only vehicle manufacture,

but the whole life cycle of each vehicle, including the

dismantling process and disposal of the remains.

Technical development

•

The requirement for care of the environment shall be

achieved through active research and development

within such areas as transport, legislation and

reduction of the effects on the environment of products,

also aiming to reduce the use of environmentally

harmful material.

Efficient use of resources

•

The whole life cycle shall be taken into account in

respect of products and processes in order to utilise

resources as efficiently as possible and to facilitate

waste handling.

Legislation, protection and safety regulations

All dismantling operations shall take place in accordance

with applicable national legislation and ordinances in the

areas of the environment, health and worker protection.

This includes all work, handling, sorting, transportation,

storage and other treatment of components, chemicals,

filters and other material.

Respect shall be shown for land, surface water and

sewage to avoid their pollution. Harmful substances and

dangerous waste shall be handled and treated in well

ventilated spaces in accordance with legislation and

regulations.

Local safety instructions shall be familiar to and respected

by the staff.

Environmentally harmful waste shall be transported by a

carrier that has been approved by the authorities.

Volvo’s own white, gray and bvlack chemical lists shall

be followed.

The work of dismantling involves contact with many

substances that can pose risks to both the environment

and health. It is therefore necessary to have the right

knowledge, equipment and preparations in order to

minimise these risks and to create the conditions for a

safe job.

T1007905

3

Group 00 Dismantling manual for Volvo Trucks

Recycling

Trucks are manufactured on the premise that as much as

possible of their material can be recycled, and more than

90% of today’s trucks consist of recyclable material.

The easiest material to recycle is metals, but in certain

cases the shape and installation of components can

hinder the recycling process.

During truck development the LCA method (Life Cycle

Analysis) is used to evaluate whether certain proposed

materials should be used or avoided. Some types of

material are completely forbidden within Volvo, whilst

others may be used in only limited quantities.

Labelling

During the work of dismantling plastics, metal, chemicals,

fluids and other material should be sorted and taken care

of in a suitable way in accordance with local legislation

and regulations. Material that is labelled shall be handled

in the prescribed manner. To facilitate the identification

and sorting of various materials Volvo has issued a

number of standards for labelling of material.

Material can be recycled in different ways:

Component recycling

•

Removed components used as second-hand spare

parts, such as engines and gearboxes.

Material recycling

•

Material recycling means that the material is reclaimed

and used again, such as glass recycling.

Energy recovery

•

Energy reclamation means that the stored energy

in waste is utilised. Various kinds of energy can be

extracted by burning detail parts and components.

Disposal by dumping

•

If waste cannot be recycled or reclaimed, disposal by

dumping may be an alternative, i.e. detail parts that

cannot be recycled in any way may be dumped.

Plastics

STD 103-0002 “Material identification and labelling of

plastic articles” is an application of European legislation

concerning the definition of coding standards for

components and material in vehicles in accordance

with the European Parliament and Council Directive

2000/53/EC on end-of life vehicles.

Rubber

Rubber is labelled in accordance with STD 5052,21

“Colour marking of rubber articles”. This standard also

contains regulations for labelling rubber hoses with text.

Hazardous waste

A truck contains a number of different materials and

chemicals that can have a negative effect on the

surrounding environment and on human health, if not

handled properly.

All dismantled products must be dealt with in accordance

with local legislation and regulations.

Metals

Metals are labelled in accordance with STD 5052,11

“Labelling of metallic objects”.

Particular respect shall be shown in the case of contact

with such material, fluids and chemicals.

Refer to the Volvo “Dealer Operating Standard” for more

detailed information.

T1006282

4

Group 00 Dismantling manual for Volvo Trucks

Chemicals and fluids

Fluids and other chemicals that can be found in Volvo

trucks include engine and transmission oils, brake fluid,

lubricating grease, fuel, clutch fluid, coolant, washer fluid,

glycol, sulphuric acid, urea solution and refrigerant.

All chemicals and fluids shall be drained or removed from

the vehicle that is to be scrapped.

Plastics

Plastics can be divided into two groups: thermosetting

plastics and thermoplastic resins.

The fluids from a truck can be reclaimed for either their

material or energy content.

For information concerning oil and fluid volumes refer

to the service information “Lubrication service and oil

changing”, Group 175.

Thermoplastic resins can be recycled by melting them

down.

Thermosetting plastics are in general difficult to recycle

and can only be recycled as filling material or as fuel.

These plastics have a low energy value.

Metals

The use of certain metals leads to their accumulation in

the biosphere, namely many poisonous metals such as

lead and mercury that can be present in batteries, lamps

and electronic equipment. Most of the weight of a truck,

about 90%, consists of the metals iron and steel, but also

present are aluminium, brass, copper, nickel, tin, bronze

and molybdenum in smaller amounts.

Handling hazardous waste

Chemicals and fluids

Oil

•

After draining can be cleaned and re-used, or burned

for energy reclamation.

Make sure that no oil is poured out into drains! This

can cause problems for waste water purifying plants.

Contact the local authority for information.

Ensure that oil is not polluted by other fluids such

as water, coolant or solvents, as polluted oil is much

more difficult and expensive to recycle.

Solvents

•

Solvents can be cleaned and re-used.

Plastics shall only be burned in approved incineration

stations!

Metals are the materials that are normally the easiest to

recycle. Most metals can be recycled but not have their

energy reclaimed.

Iron and steel should be separated from other metals,

such as aluminium, copper and brass.

Coolant

•

Coolant can be recycled.

The fluid is toxic and can contain heavy metals, so

it should never be poured on to the ground, into

drains or watercourses.

Brake fluid

•

Brake fluid can be recycled, or burned for energy

reclamation.

Never pour brake fluid into drains!

Brake fluid should not be polluted if it is to be

recycled, this makes the process much more

expensive.

Nover pour solvents into drains, this is deemed

hazardous waste in most countries.

Neverpour solvents on to the ground as this pollutes

the both the land and its ground water.

Urea solution

•

Urea solution cannot be reused.

Urea solution must not be poured in to drains, it

must be collected in a separate container.

Do not allow urea solution to come into contact

with other chemicals. Spills must be wiped up with

absorbing agent.

Refrigerant

•

Refrigerant can be recycled, but if this is not possible, it

should be taken in hand by a certified refrigerant disposal

company.

Glycol

•

Can be recycled after purification by distillation.

Glue

•

Cannot be recycled. In addition its presence can

reduce the chances of recycling other material.

Washer fluid

•

Can be filtered and re-used.

Sulphuric acid

•

Can be purified and re-used.

5

Group 00 Dismantling manual for Volvo Trucks

Other material

Batteries

•

Truck batteries shall be taken care of by an authorised

waste disposal company. Smaller or other types of

battery contain valuable metals that can be reclaimed

and re-used.

Fluorescent lamps and tubes, components

•

containing mercury and switches.

These components shall be taken care of by an

authorised waste disposal company.

In most countries it is illegal to dump batteries, as

this can cause serious harm to humans and animals.

Lead is highly toxic and accumulates in the body

over time.

Sulphuric acid is extremely corrosive.

Air bags and belt tensioners

•

Air bags and belt tensioners must be dealt with in

accordance with local legislation and regulations.

CAUTION

Air bags and belt tensioners contain explosive

substances and must always be handled with extreme

care. Refer also to Volvo Policy and “Safe Working

Practices för SRS-airbag”.

Oil filters and other filters

•

Filters can be efficiently re-used after draining,

reclaiming the energy from paper and rubber parts,

and recycling clean metal.

Filters contain oil and other harmful substances.

Check local legislation and regulations for handling

these.

Never dump this type of component as rubbish, as

they are dangerous to humans and animals. In most

countries this is illegal.

Gas discharge lamps

•

Gas discharge lamps contain mercury and are

hazardous waste. They must not be dumped as

rubbish. These components shall be taken care

of by an authorised waste disposal company.

Brake discs and drums

•

These parts can be re-used and the metal parts can

be recycled.

In earlier truck models these components may

contain asbestos. Take precautions to minimise

the amount of asbestos dust being spread while

working.

Rubber

•

Can be difficult to reclaim and also may contain

chlorine or fluorine. Mainly in truck tyres, that can be

ground down and re-used as raw material for new

tyres, or burned to reclaim the energy.

Rubber may only be burned in approvedincineration

plants, as the smoke can cause serious air pollution.

Laminated glass

•

The glass can be recycled.

Electrical and electronic waste

•

These components contain valuable and recycleable

components, along with a number of chemicals (PCB,

heavy metals, etc.) with characteristics that are

environmentally harmful. Other parts can be burned to

reclaim energy.

Never dump hazardous electrical and electronic

waste.

Wood products

•

Can be recycled, or burned for energy reclamation.

Paper

•

Paper, cardboard and paperboard should be sorted

and recycled, but burning to reclaim energy is also an

alternative.

Paint

•

Waste paint may be hazardous as many paints contain

hazardous metals such as lead, cadmium, barium and

chrome.

6

Group 00 Dismantling manual for Volvo Trucks

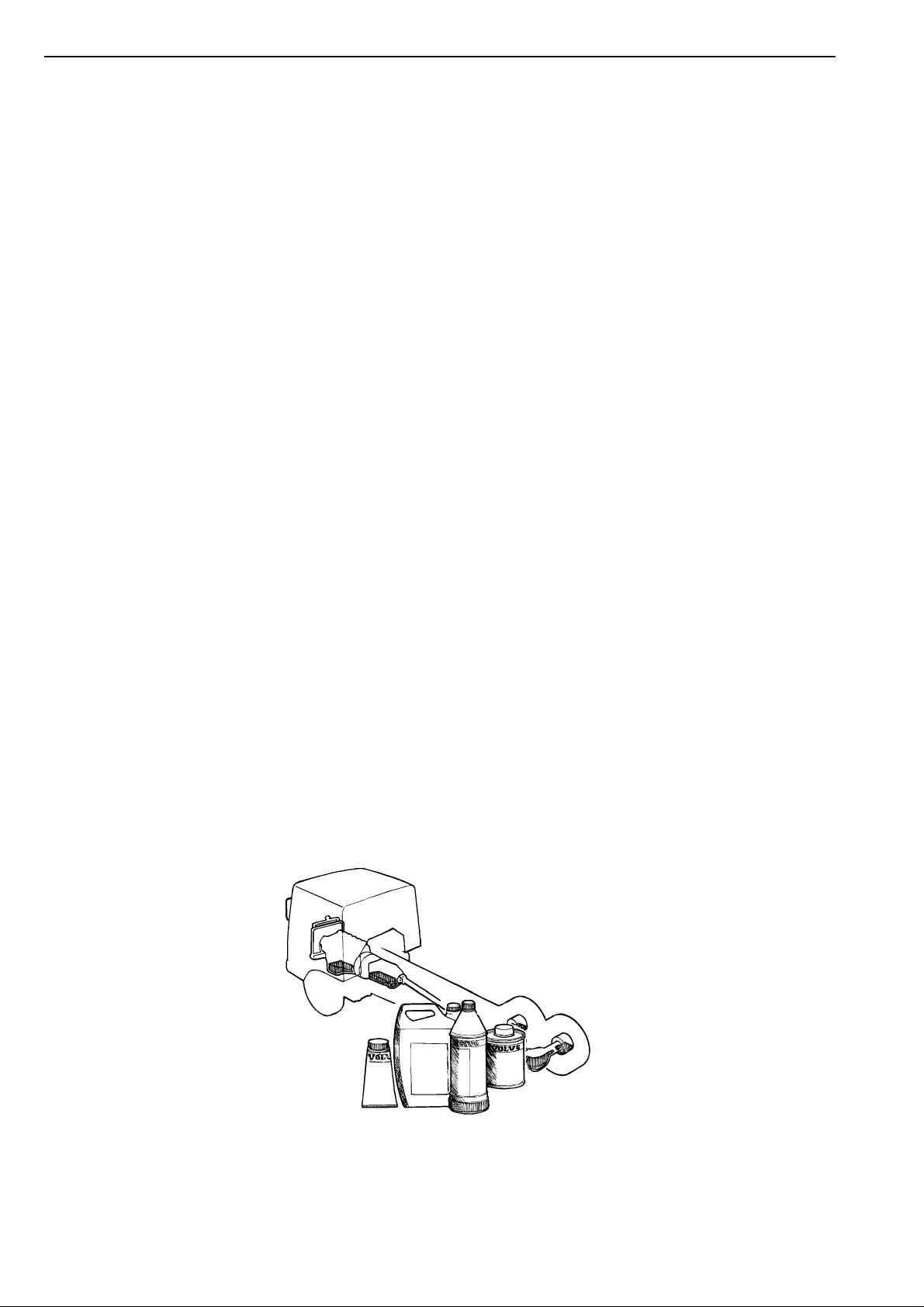

Equipment

Local

Tools

The work of dismantling should be carried out in well

ventilated premises that are equipped in accordance with

health and safety protection and other legislation and

regulations.

Equipment for fire extinguishing, first aid and eye washing

should be accessible in the premises!

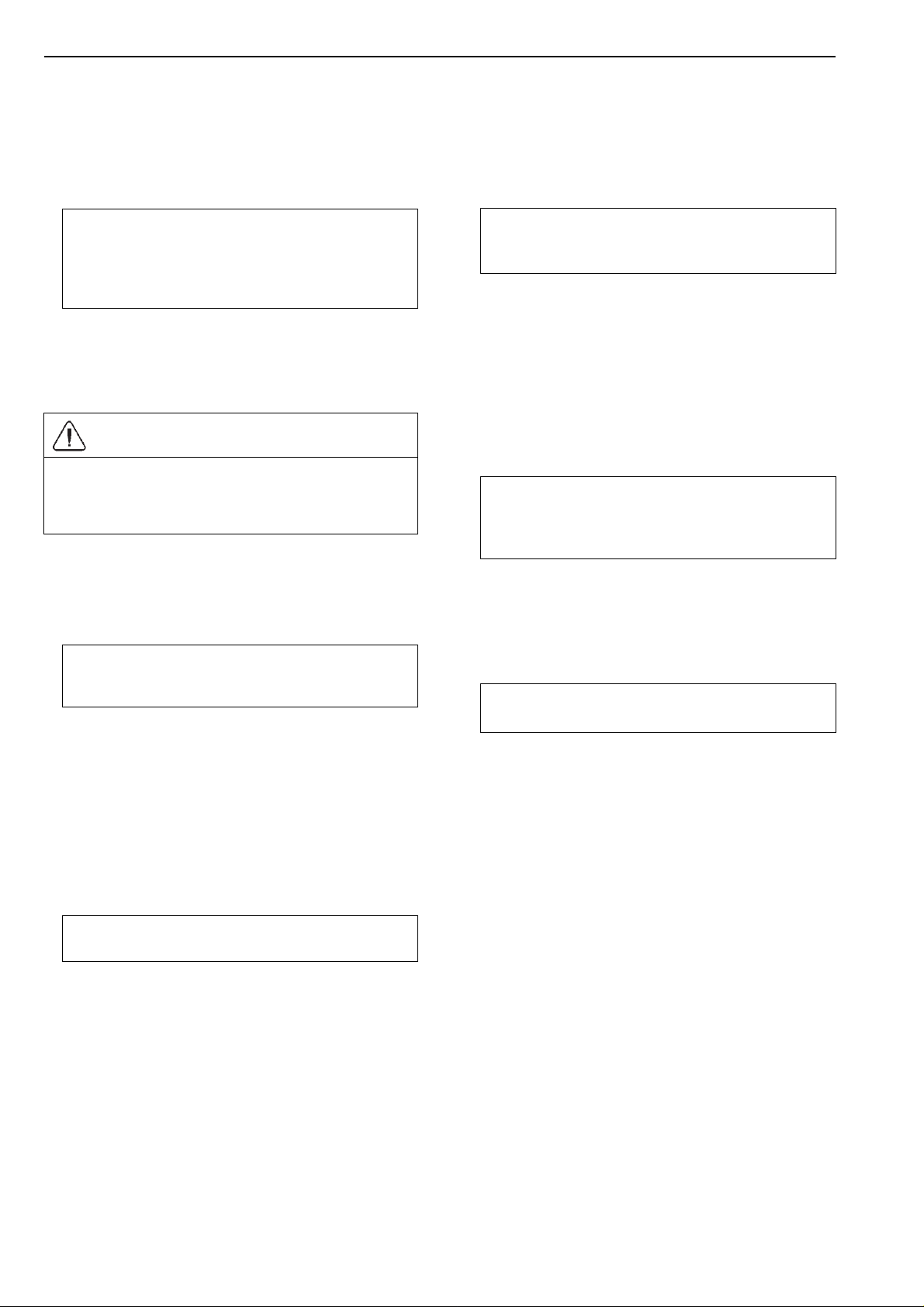

Protective equipment

At various times during dismantling personal protective

equipment is to be used when necessary. This includes

protective clothing and footwear,safety goggles, gloves,

ear defenders, helmets and face masks.

It is important that the work of dismantling is carried out

using suitable tools from both the environmental and

worker safety aspects. Volvo therefore recommends that

dismantling workshops invest in this type of equipment.

Among the tools that could be highly suitable for

dismantling are: equipment for draining refrigerant,cutting

torches, welding or similar equipment, lifting gear, stands,

crowbars, adjustable wrenches, hammers and nut drivers.

T1006290

T1006289

General recommendations and preparations

It can be good to bear the following recommendations

in mind when dismantling:

Assess first which parts of the ruck can be recycled

•

or reclaimed, and use this as a starting point when

determining the dismantling procedure.

Before dismantling begins the pressure in the SCR

•

system must be released and the urea solution

emptied out. This process begins automatically when

the engine is switched off. Wait 2 minutes after

switching off the engine before commencing any work

on the vehicle.

Note: If the electrical power is switched off or interrupted

in any other way before the emptying procedure is

completed, for example with the ADR, main circuit breaker

or by removing a battery pole cable, the SCR system will

not be emptied and may continue to retain pressure!

Urea is highly corrosive to metal and can damage

•

electrical connectors. If urea solution comes into

contact with disconnected electrical connectors, the

urea solution spreads rapidly through the wiring and

oxidises the metal.

Before commencing dismantling, switch off the electric

•

current and disconnect the batteries. Then begin by

removing the SRS system.

Release the pressure in a controlled way!

•

Drive the air suspension as low as possible before

commencing dismantling!

Note that it is very important to separate and sort

•

the various fluids, plastics and metals throughout the

entire process.

If the vehicle is very dirty it should first be washed.

•

Lift off any additional superstructure before

•

commencing dismantling of the truck.

Empty loose parts out of the cab before starting to

•

dismantle.

Put removed items out of the way while the work is

•

going on, so that they do not get in the way and pose a

risk to the work.

As cables and material is released or dismantled,

these should be cleared away and sorted.

When removing pressure hoses, note that there is a

•

risk that they may still be pressurised. Do not release

the whole hose at once, first loosen it carefully and let

any oil or air it may contain leak out first. Then release

the whole hose.

7

Group 00 Dismantling manual for Volvo Trucks

Emptying of components

Components should be emptied as much as possible

before dismantling commences.

Some drain locations may become easier to access later

during the work.

See below for the components that are involved, although

these are not in any particular order.

For more detailed information and working instructions

refer to the other service information in the respective

groups from 1 to 9.

Fluids and chemicals shall be handled, separated and

stored in a suitable way and in accordance with local

legislation and regulations.

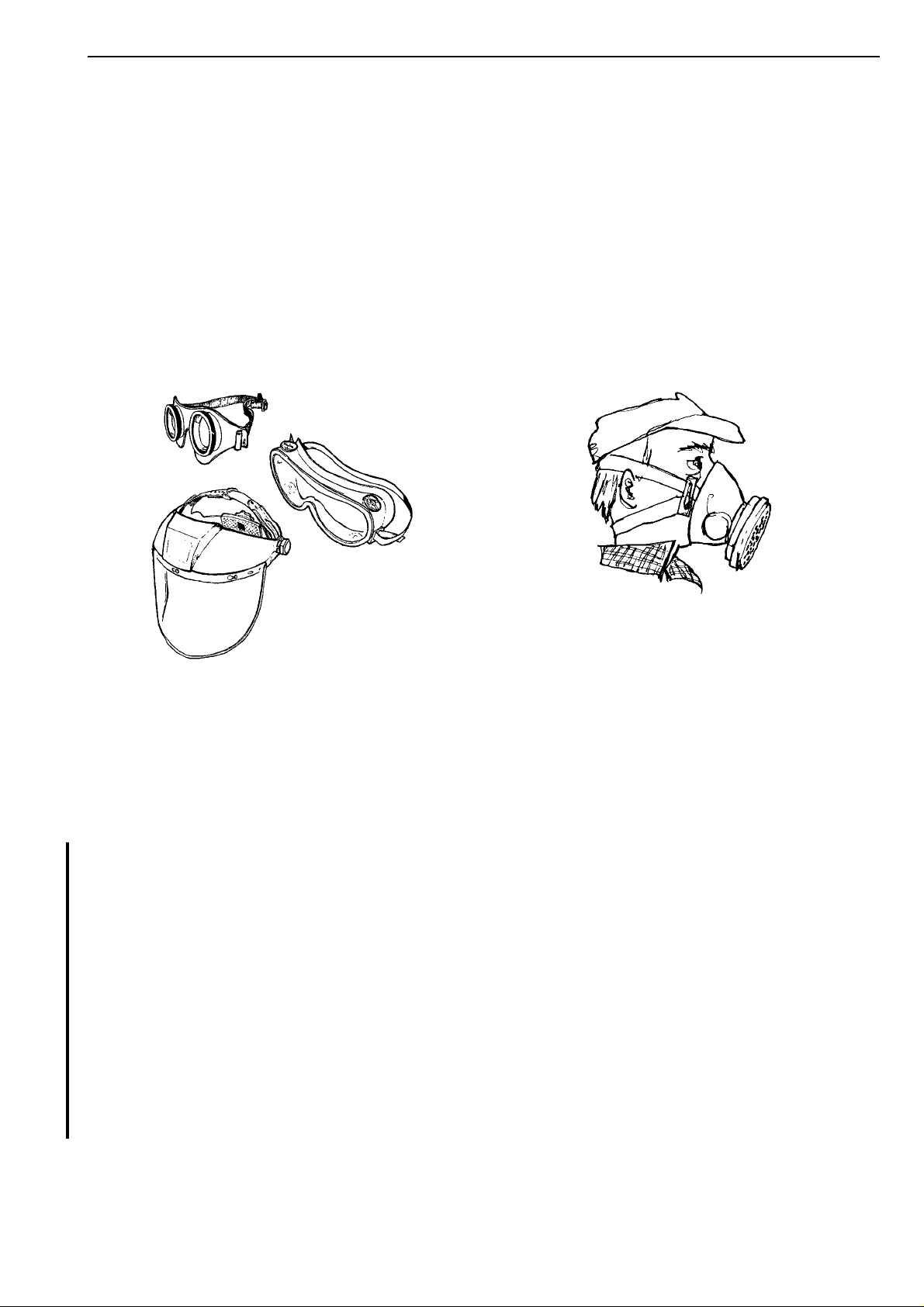

Engine, oil and filters

Drain the engine oil through the drain plug (A).

Remove the engine filters; the full flow filter (B) and

bypass filter (C).

WARNING

Be careful! Use protective goggles, gloves and face

masks where necessary.

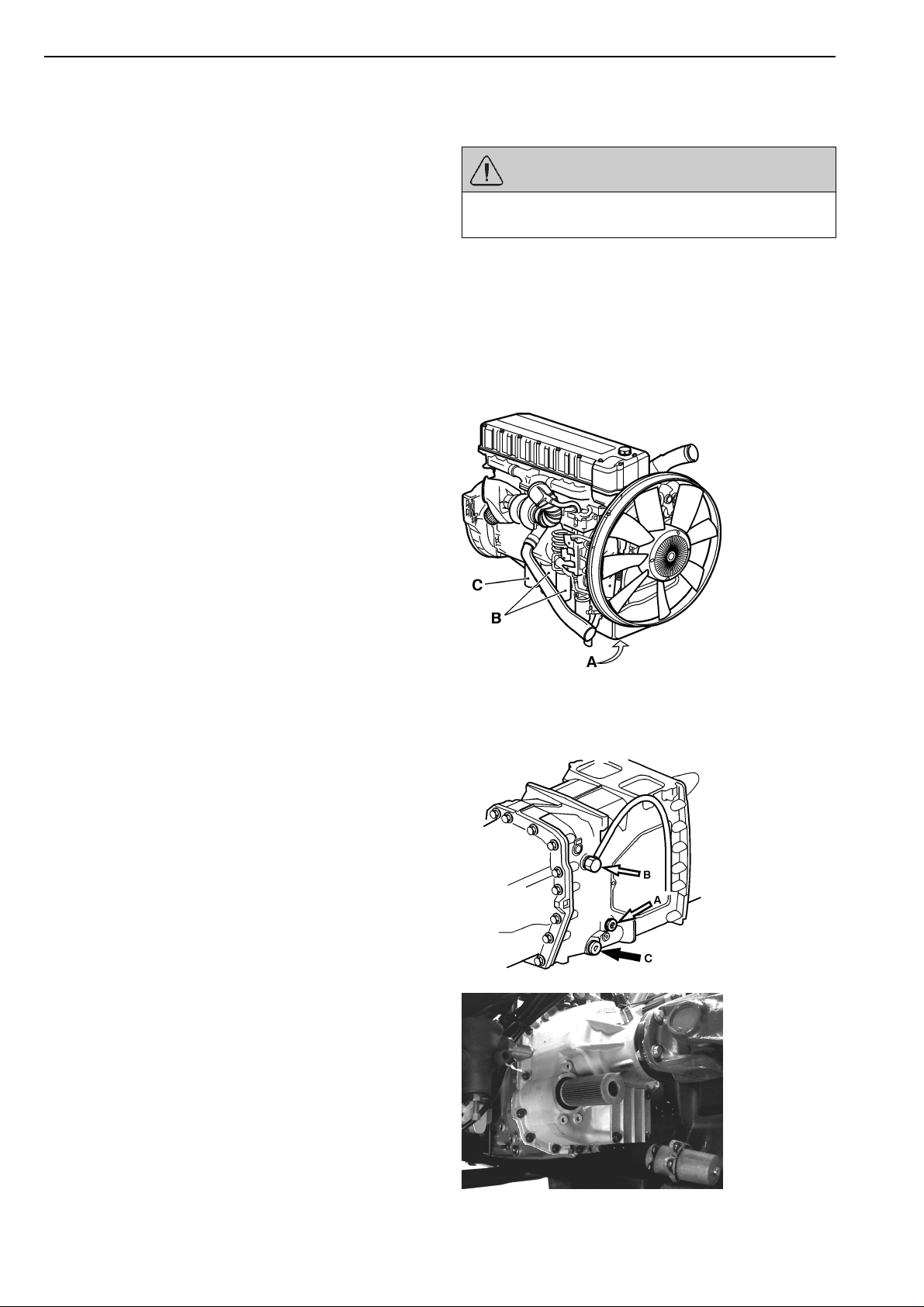

Manual gearbox, oil and filter

Drain and empty the gearbox oil through the drain plug

(C).

Unscrew the oil filter housing and remove the seal and

oil filter.

T1007362

T1006756

T1006780

8

Group 00 Dismantling manual for Volvo Trucks

Gearbox with compact retarder, oil filter

Remove the oil filter (H) from the oil filter housing. Cover

(D), gasket (E), adapter (F) and stay tube (G).

ZF gearbox, oil

Topping-up and drain plugs (1 and 2).

T1006939

Automatic gearbox, oil and filter

Drain the oil by removing the oil sump drain plug (B), and

unscrew the oil filters (A).

Final drive, oil

Topping-up and drain plugs (A) and (B).

C1000039

T1006796

T1007372

9

Group 00 Dismantling manual for Volvo Trucks

Final drive with hub reduction, oil

Topping-up and drain plugs (A and B).

The oil in the hub shall be drained separately.

Drain plug (1).

T1007372

Retarder, oil

Drain plug (D), topping-up plug (A), vent plug (E).

Transfer gearbox, oil

Drain plug (C), topping-up plug (B), level plug (A).

T1007412

T0008610

10

T1007656

Group 00 Dismantling manual for Volvo Trucks

Power take-off, oil draining and filter removal

Drain plug (B), level/topping-up plug (A).

Water separator, filter

Remove the filter.

T1007654

Driven front axle, oil

Front axle wheel gears. Drain plug (A), level/topping-up

plug (B).

Front axle differential carrier. Drain plug (B).

T2019100

T1007659

T4017902

11

Group 00 Dismantling manual for Volvo Trucks

Urea tank

Remove the filler cap from the urea tank. Remove the

drain plug. Empty the urea tank.

Note: If urea solution comes into contact with

disconnected electrical connectors, the urea solution

spreads rapidly through the wiring and oxidises the metal,

which can damage the connectors and cabling.

Urea filter

Remove the drain plug and drain the filter housing.

Remove the urea filter (A) from the pump unit.

Note: If urea solution comes into contact with

disconnected electrical connectors, the urea solution

spreads rapidly through the wiring and oxidises the metal,

which can damage the connectors and cabling.

T2023070

Fuel tank

Empty the tank by removing the drain plug.

T1008641

T2017418

12

Group 00 Dismantling manual for Volvo Trucks

Fuel filter

Remove the fuel filter.

Fuel tank ventilation filter

T2021550

Remove the filter.

T1006941

13

Group 00 Dismantling manual for Volvo Trucks

Air cleaner filter element

Remove the filter.

T2006750

T2006751

Coolant

Empty the coolant tank by removing the drain plug.

Coolant filter

Remove the coolant filter.

T0008145

14

T2007230

Group 00 Dismantling manual for Volvo Trucks

Air drier, drying compound

Take the dring element out of the air drier.

Air conditioning unit, filter and emptying refrigerant tank and air conditioning water.

T5008850

Note: Refrigerant is classified as environmentally

hazardous material and shall be dealt with by certified

personnel in accordance with local legislation and

regulations.

Empty the refrigerant out of the air conditioning system.

Remove the air conditioner filter.

T1007376

T1007375

15

Group 00 Dismantling manual for Volvo Trucks

Clutch fluid

Empty the clutch fluid by removing the drain plug.

Cab tilt pump, oil

Drain the oil.

T1008225

Pneumatic system, emptying

Carefully release the compressed air.

Washer fluid

Empty the washer fluid out of the washer tank.

T8010177

T7006867

16

T1007366

Group 00 Dismantling manual for Volvo Trucks

Disassembly instructions

The following instructions do not describe dismantling in

detail, but outline the procedures, to permit flexibility and

self-determined working routines.

For more detailed information and working instructions

refer to the other service information in the respective

groups from 1 to 9.

The information is general, so that it can be applied to

different truck models.

Switch the main power switch off and disconnect the batteries.

Ensure that the ignition has been switched off for at least two minutes before removing the electrical supply, so that the

SCR system has time to empty out the urea solution and release its pressure.

Note: Batteries are classified as environmentally

hazardous material and require special handling in

accordance with applicable legislation and regulations.

T3017783

Dismantling the SRS system.

Carefully follow the dismantling instructions in service information Group 8.

Control unit (1), air bag module (2), slip ring (3) and belt tensioner (4).

Emptying of components is described above and not

repeated here.

T3017758

T8008552

WARNING

Confirm that there is no current in the vehicle before

commencing work on the SRS system.

SRS components shall be handled and stored in

accordance with local legislation and regulations.

DANGER

Certain parts of the SRS contain explosives.

Explosives can cause personal injury or death if

handled incorrectly.

DANGER

Both heat and electrical current can damage the

control unit. Open flames are an accident risk as they

can cause air bags or belt tensioners to trigger.

17

Group 00 Dismantling manual for Volvo Trucks

Clear the exterior of the cab of plastics and sheet

•

metal detail parts.

Remove the front hatches, detach and remove

cabling, hoses and other such material.

Remove the underbody protection, bumpers and

•

plastic detail parts from the front and side of the

cab.

T7009910

T8010453

T8010454

18

Group 00 Dismantling manual for Volvo Trucks

Lift off the cab using lifting equipment.

•

Remove all internal detail parts from the cab.

•

The windscreen, side glass, instruments, internal

fittings and other components such as fans and air

conditioning equipment.

T8010451

Then cut or shear the remaining parts of the cab into smaller pieces for scrapping.

T8010455

T8010452

19

Group 00 Dismantling manual for Volvo Trucks

Remove the washer fluid tank, lighting housings,

•

cab tipping pump and electrical motor, and such

nearby components as the parking heater and

water pump.

T8010456

20

T8010457

Group 00 Dismantling manual for Volvo Trucks

Remove the fuel tank using lifting equipment.

•

Clean the area.

On vehicles with an SCR system, lift out the

•

urea tank (1) and remove the other SCR system

components, namely the pump module (2), dosing

unit (3), silencer (4), hoses, lines and pipes.

T2022092

Note: If urea solution comes into contact with

disconnected electrical connectors, the urea solution

spreads rapidly through the wiring and oxidises the metal,

which can damage the connectors and cabling.

T2022985

21

Group 00 Dismantling manual for Volvo Trucks

Remove the silencer, lower air intake and air

•

cleaner along with the associated hoses and

piping.

Remove the battery box and all air tanks from the

chassis, clean all round the chassis.

T2022094

T3018037

22

Group 00 Dismantling manual for Volvo Trucks

Remove the coolant tank and lift off the complete

•

coolant system with its various components and

detail parts with lifting equipment.

T2022091

23

Group 00 Dismantling manual for Volvo Trucks

Remove the cab tilt cylinder with its associated

•

detail parts.

Take off the rocker cover and clean the components

•

and detail parts around the engine.

T8010458

24

T2022093

Group 00 Dismantling manual for Volvo Trucks

Remove the clutch cylinder and other components

•

and detail parts around the gearbox.

T4020999

Lift out the gearbox and where applicable the

•

retarder, using lifting equipment.

Then detach the retarder from the gearbox.

Remove the servo pump.

T4021000

25

Group 00 Dismantling manual for Volvo Trucks

Lift out the engine using lifting equipment.

•

Then remove the mounted components such as

the alternator, air conditioning pump, fan and

starter motor.

Removethe air drier,steering gear and surrounding

•

pipes, hoses and components.

T5014148

T2022097

T6009539

26

Group 00 Dismantling manual for Volvo Trucks

Remove all detail parts from the chassis frame.

After this the chassis frame should be clean and ready to be cut into pieces.

Put the chassis on stands and cut it into suitable size pieces for disposal.

WARNING

Support the chassis by sections! Otherwise there is a

risk of serious personal injury!

Remove the brake actuators or cylinders and other

•

detail parts around the tyres. Be careful!

T5014149

Separate the wheels from the axles and the tyres

•

from their rims.

Remove the tyres, drive axles, differential lock,

gears, shafts and crown wheel.

T4011554

T4021001

If necessary, cut up or divide the remaining parts of the chassis frame and dismantled parts into smaller

pieces for scrapping.

Sort out the tyres, wires, metal and plastic detail parts.

27

Feedback

One of our objectives is that workshop personnel should have access to correct and

appropriate service manuals where it concerns fault tracing, repairs and maintenance

of Volvo vehicles.

In order to maintain the high standards of our literature, your opinions and experience

when using this manual would be greatly appreciated.

If you have any comments or suggestions, make a copy of this page, write down your

comments and send them to us, either via telefax or mailing directly to the address

listed below.

To

To

Volvo Parts Corporation

Dept. Technical Support Service 31820

S-405 08 GÖTEBORG

Fax: +46 31 661060

Comments/proposals

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

From

.......................................................................

.......................................................................

.......................................................................

.......................................................................

.......................................................................

.......................................................................

.......................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

Concerns Service Manual: ...........................................................................................................................

20068517 English 0000.4.06

Volvo Truck Corporation

Göteborg, Sweden

Loading...

Loading...