Page 1

ENGLISH

ENGLISH

Operator’s Manual

EaziClean® Can Opener

Premium™ Can Opener

BCO-2000

BCO-3000

Thank you for purchasing this Vollrath Food Processing Equipment. Before operating the equipment, read and familiarize yourself with the

following operating and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and packaging.

Use this packaging to ship the equipment if repairs are needed.

BCO-5000

BCO-6000

Product

Number

BCO-2000 EaziClean® 16” Bar Length, 1” Gear

BCO-3000 EaziClean

BCO-5000 EaziClean® 16” Bar Length, 1-1/2” Gear

BCO-6000 EaziClean® 25” Bar Length, 1-1/2” Gear

BCO-7000 EaziClean® 25” Bar Length, 1-1/2” Gear

BCO-1 Preimum™ 16” Bar Length, 1” Gear

Description

®

25” Bar Length, 1” Gear

BCO-7000

BCO-1

Item No. 2350084-1 en Rev 11/10

Page 2

Manual Food Processing equiPMent

Safety PrecautionS

To ensure safe operation, read the following statements and

understand their meaning. This manual contains safety precautions

which are explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or

maintenance information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others or

damage the equipment.

To reduce risk of injury or damage to the unit:

Check machine before each use to insure the equipment is clean.

Check for broken, nicked or dull blades and if found, replace blade.

oPeration

Prior to rst use, it is important to clean the unit. Wash the unit with warm

soapy water and rinse thoroughly to remove the thin protective oil lm.

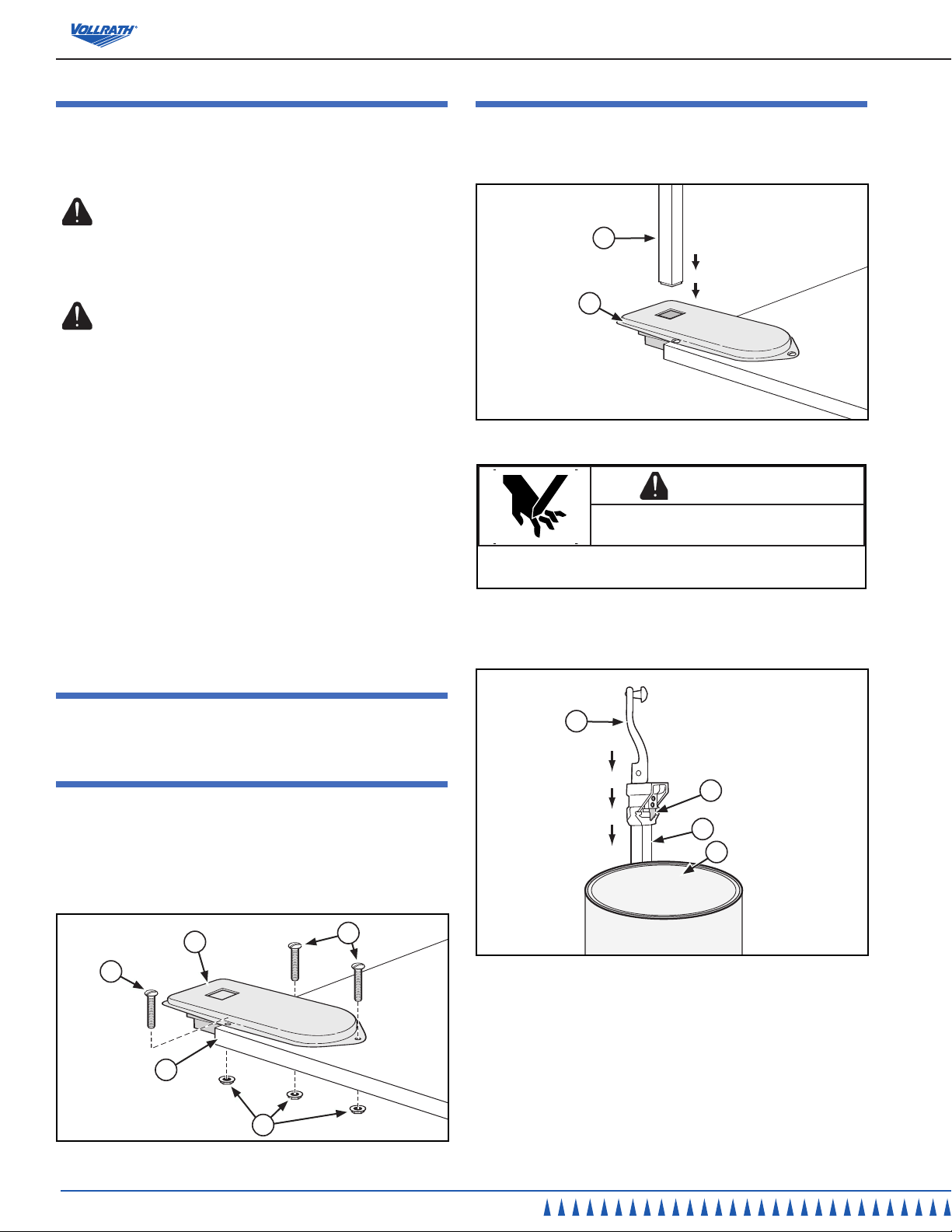

2. Place the can opener bar (A) into the base (B) as shown in Figure 2.

A

B

Figure 2. Bar into Base Installation.

WARNING

Sharp Blade Hazard.

Blades are sharp and can cause cuts.

To avoid injury from sharp blades, handle with caution. Only trained

personal should operate equipment or perform maintenance.

3. Move the handle (A) to the UP position as shown. Place the can (B)

against the bar (C). Using a swift downwards movement, punch the

blade (D) into the can lid. See Figure 3.

function and PurPoSe

Easily pierce and safely open cans.

BaSe inStallation

Installing the can opener base:

1. Choose a convenient location with a rm work surface (C) and install the

base (A) securing with the hardware (B) provided. See Figure 1.

On thin gauge work surface we suggest you t a spacer plate

underneath. This will prevent the exing of the work surface and possible

spillage of can contents during opening.

A

B

C

B

B

Figure 3. Punching the Blade into the Can.

A

D

C

B

Figure 1. Base to Work Surface Installation.

2

OperatOr’s Manual

Page 3

Manual Food Processing equiPMent

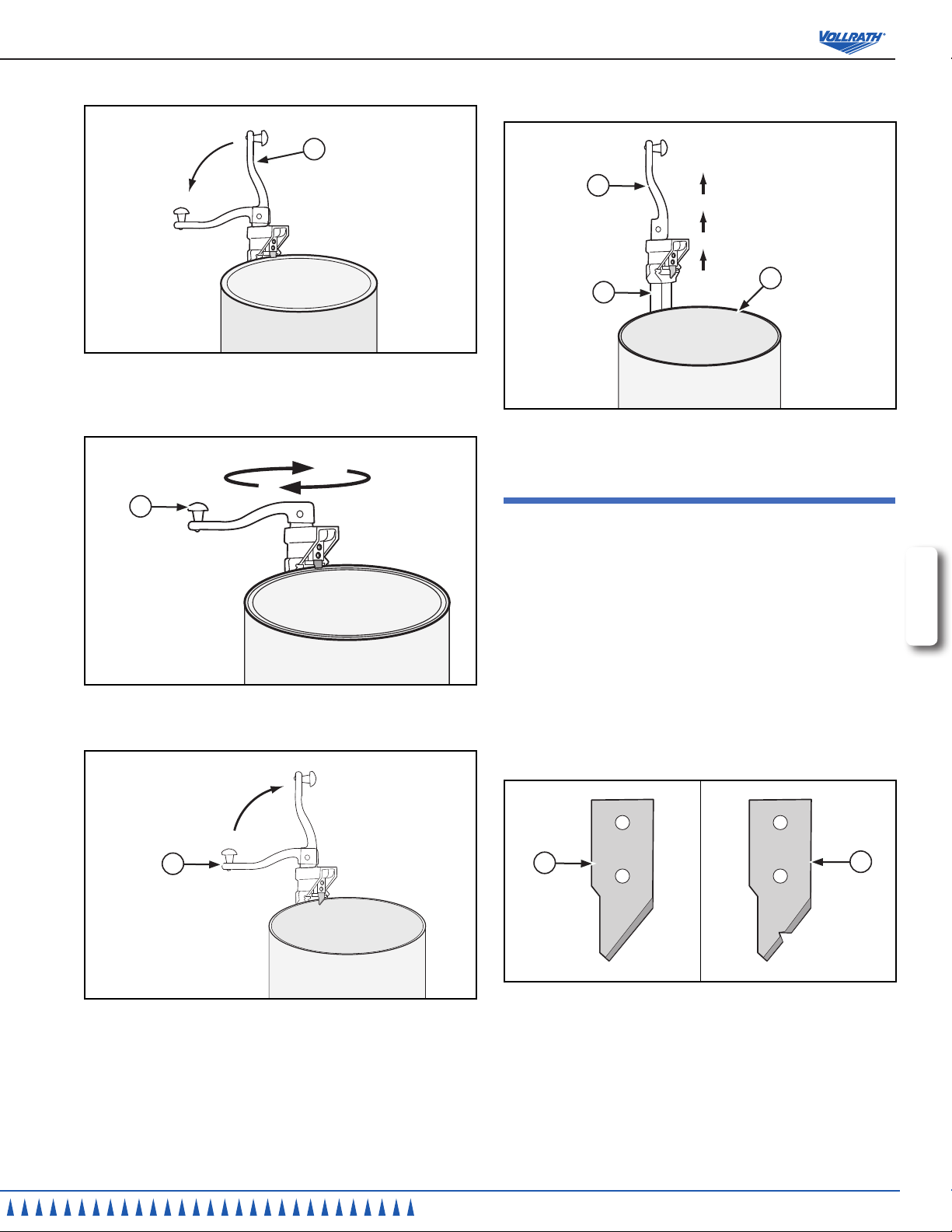

4. Lower the handle (A) to the 90° or DOWN position. See Figure 4.

A

Figure 4. Lowering the Handle.

5. Crank the handle (A) in a clockwise direction to open the can. See

Figure 5.

A

Figure 5. Rotating the Handle.

6. Lift the handle (A) to the UP position. See Figure 6.

7. Put the handle (A) to the vertical position. Raise the handle (A) and

bar (B) up. Remove the can (C) from the can opener base. See Figure 7.

A

B

C

Figure 7. Removing the Bar, Handle and Can.

cleaning

To maintain the appearance and increase the service life, clean your unit

daily.

1. Rinse or spray off the can opener thoroughly with HOT water and a

bristle brush. Remove the blade cartridge on EaziClean

®

models for

better cleaning. See REPLACING the Blade section of this manual for

details.

2. After cleaning, let the unit air dry.

NOTE:

Food acids will make blade dull and corrode the metal.

Always clean this food preparation equipment immediately

after every use.

3. Visually check the blade regularly to see that is in good condition (A).

If the blade has a nick (B), discard and replace with a new blade. See

Figure 8.

ENGLISH

A

Figure 6. Raising the Handle.

A

B

Figure 8. Blade Inspection.

4. Visually check the gear teeth for wear. Can opener will slip during

operation if the gear is warn.

OperatOr’s Manual

3

Page 4

Manual Food Processing equiPMent

rePlacing the Blade

WARNING

rePlacing the gear

Wash new parts with warm, soapy water and rinse thoroughly to remove the

thin protective oil lm.

To change the gear on EaziClean® models:

Sharp Blade Hazard.

Blades are sharp and can cause cuts.

To avoid injury from sharp blades, handle with caution. Only trained

personal should operate equipment or perform maintenance.

Wash new parts with warm, soapy water and rinse thoroughly to remove the

thin protective oil lm. Keep the sharp edge away from you when handling

blades.

To remove the blade cartridge and change the blade on EaziClean

®

models:

1. Use a tool to hold the old gear and turn the handle assembly in the

counterclockwise direction to unscrew the gear.

2. Discard the old gear.

3. If the blade cartridge was removed during gear removal it will be

necessary to align the collar (A) to the head (B). Rotate the groves

(C) so they align with ridges (D) and slide collar (A) into head (B). See

Figure 11.

1. Move the handle (A) to the position as shown in Figure 9.

A

B

D

B

C

D

E

Figure 9. Blade Cartridge and Blade Removal and Installation.

2. Lift out the blade cartridge (B).

3. Note position or direction of the blade edge. Remove blade by loosening

screws (C).

4. Discard the old blade (E) and replace with new blade. Inspect the O-rings

(D) and replace if necessary.

5. Place the new blade (E) in the correct position. Secure with the

screws (C) and O-rings (D).

To change the blade on PremiumTM models:

1. Move the handle (A) to the position shown in Figure 10.

2. Note position or direction of the blade edge. Remove the blade by

loosening screws (B).

3. Discard the old blade (C) and replace with new blade.

4. Place the new blade in the correct position. Secure with the screws (B).

Figure 11. Safe Operation Switch.

4. Move the handle (A) to the “UP” position. See Figure 10.

5. Slide the gear into position.

6. Use a tool to assure that the gear is held rmly. Lower the handle to the

“normal” position and rotate in the clockwise until tight.

7. Remove the tool.

To change the gear on PremiumTM models:

1. Use a tool to hold the old gear and turn the handle assembly in the

counterclockwise direction to unscrew the gear.

2. Discard the old gear.

3. Move the handle (A) to the “UP” position. See Figure 10.

4. Slide the gear into position.

5. Use a tool to assure that the gear is held rmly. Lower the handle to the

“normal” position and rotate in the clockwise until tight

6. Remove the tool.

B

C

A

C

D

Figure 10. Blade and Gear Removal and Installation.

4

OperatOr’s Manual

A

Page 5

Manual Food Processing equiPMent

5

2

4

3

61

69

6

68

67

Service and rePair

Please contact the qualied professional repair service listed below.

VOLLRATH Induction Repair Service • 1-800-825-6036 (USA) or www.vollrathco.com

When contacting the Authorized Professional Service Center, please be ready with the model number, serial number, and proof of purchase showing the date

the unit was purchased.

SPare PartS liSt and diagraM - PreiMuM

Callout Part Number Description

1 116 Handle Assembly (for BCO-1)

2 125 Collar Washer (for BCO-1)

3 122 Collar (for BCO-1)

4 BCO-11 Blade (for BCO-1)

5 BCO-12 1” Gear (for BCO-1)

6 BCO-3 Base (for BCO-1)

7 N/A Screws

8 N/A Washers

9 N/A Bar

tM

ENGLISH

OperatOr’s Manual

5

Page 6

Manual Food Processing equiPMent

SPare PartS liSt and diagraM - eaziclean

®

™

Callout Part Number Description

1 379080 Handle Assembly (for BCO-2000 and BCO-3000)

1 379093 Handle Assembly (for BCO-5000 and BCO-6000)

1 379094 Handle Assembly (for BCO-7000)

2 122 Collar Washer (for BCO-2000 and BCO-3000)

2 379095 Collar Washer (for BCO-5000, BCO-6000, BCO-7000)

3 379082 Collar (for BCO-2000 and BCO-3000)

3 379096 Collar (for BCO-5000, BCO-6000, BCO-7000)

4 379083 Spring (for BCO-2000 and BCO-3000)

4 379097 Spring (for BCO-5000 and BCO-6000)

4 379098 Spring (BCO-7000)

5 BCO-12 1” Gear (for BCO-2000and BCO-3000)

5 BCO-10 1-1/2” Gear (for BCO-5000, BCO-6000, BCO-7000)

6 BCO-15 Quick Release Replacement Cartridge (for BCO-2000 and BCO-3000)

6 BCO-14 Quick Release Replacement Cartridge (for BCO-5000, BCO-6000, BCO-7000)

7 BCO-16 Blade Screws and O-Ring Washers

8 BCO-11 Blade

9 BCO-3 Base

10 379090 Clamp

11 379089 Base and Clamp (Includes (Ref. Nos. 9 and 10)

12 379099 Bushing (for BCO-5000, BCO-6000, BCO-7000)

13 N/A Bar

61

2

3

6

67

8

67

613

9

6

OperatOr’s Manual

4

5

12

10

Page 7

Manual Food Processing equiPMent

Warranty StateMent for the vollrath co. l.l.c.

The Vollrath Company LLC warrants the products it manufactures and distributes against defects in materials and workmanship for a period of one year, except as specically

provided below. The warranty runs 12 months from the date of original installation. (End user receipt)

1. Refrigeration compressors – The warranty period is 5 years.

2. Replacement parts – The warranty period is 90 days.

3. Fry pans and coated cookware – The warranty period is 90 days

4. EverTite™ Riveting System – The warranty covers loose rivets

only, forever.

5. Cayenne® Heat Strips – The warranty period is 1 year plus an

additional 1 year period on heating element parts only.

6. Ultra and Professional Induction Ranges – The warranty period

is 2 years.

7. Mirage and Commercial Induction ranges - The warranty period

is 1 year.

8. ServeWell® Induction Workstations – The warranty period is one

year on the workstation table and 2 years on induction hobs.

9. Slicers – The warranty period is 10 years on gears and 5 years

on belts.

10. Mixers – The warranty period is 2 years.

11. Extended warranties are available at the time of sale.

12. Boxer Mixers – 1 Year exchange Warranty.

13. Vollrath – Redco products – The warranty period is 2 years.

14. Optio / Arkadia product lines – The warranty period is 90 days.

15. All non-stick products (i.e. fry pans and surfaces) are 90 days for

the non stick surfaces.

All products in the Jacob’s Pride® collection, including

the following, have a lifetime warranty:

• NSF Certied One-Piece Dishers

• NSF Certied Spoodle® Utensils

• NSF Certied Heavy-Duty Spoons with Ergonomic Handle

• NSF Certied Heavy-Duty Basting Spoons

• Heavy duty Turners with Ergonomic handle

• One-Piece Tongs*

• Heavy-Duty One-Piece Ladles*

• Nylon Handle Whips

• One-Piece Skimmers

• Tribute®, Intrigue®, and Classic Select® Cookware*

*Jacob’s Pride® warranty does not cover Kool-Touch®,

non stick coatings and silicone handles.

Items sold having no warranty:

• Meat Grinder Knives

• Light Bulbs in Convection Ovens and Hot Food

Merchandiser

• Oven Door Seals

• Oven Door Glass

• Hot Food Merchandisers / Display Case Glass

• Calibration and set up of gas equipment

• Slicer / Dicer blades (table top food prep) –

Redco and Vollrath

• Slicer / Dicer blades (table top food prep) –

Redco and Vollrath

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

As The Vollrath Company LLC’s only responsibility and the purchaser’s only remedy, for any breach of warranty, The Vollrath Company LLC will repair or, at its option, replace the

defective product or part without charge, except as otherwise provided below:

ENGLISH

• For refrigeration compressors and the second year of the warranty on Cayenne® Heat Strips and mixers, The Vollrath Company LLC will provide the repaired

or replacement part only; and the buyer will be responsible for all labor charges incurred in performing the repair or replacement.

• To obtain warranty service, the buyer will be responsible to return to The Vollrath Company LLC any product (other than gas equipment that is permanently

installed) weighing less than 110 lbs. or located outside of a 50-mile radius of a certied technician designated by The Vollrath Company LLC to perform

warranty repairs. If a Vollrath Technician cannot be contacted check the website for service contact points. (Please refer to the Product Catalogue for weights

and sizes of product)

• No remedy will be available for products that have been damaged by accident, carelessness, improper installation, lack of proper setup or supervision when

required, neglect, improper use, installation or operation contrary to installation and operating instructions or other causes not arising out of defects in materials or workmanship. At the buyer’s request, The Vollrath Company LLC will repair and or replace such products at a reasonable cost.

• No remedy will be available for slicers where blade has not been sharpened (Refer to owner’s manual for sharpening instructions)

• No remedy will be available for mixers damaged by changing gears while unit is running or overloading, in either case as determined by a Vollrath Certied

Technician

• Warranty work must be authorized in advance by The Vollrath Company LLC. See the operating and safety instructions for each product for detailed warranty claim procedures.

• No remedy will be available for product returned and found to be acceptable to the product specication.

• No remedy will be available under any warranty not registered as required below.

LIMITATION OF LIABILITY:

THE VOLLRATH COMPANY LLC SHALL HAVE NO LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND,

WHETHER BASED UPON NEGLIGENCE OR OTHER TORT, BREACH OF WARRANTY, OR ANY OTHER THEORY.

OperatOr’s Manual

7

Page 8

Warranty Procedure

On all warranty calls, the following process and information is required:

• All warranty claims will start with a call to Vollrath Technical Service support line.(800-628-0832).

• A technical support professional will work to diagnose the issues, and provide the details for the service solution.

• Name and phone number of person calling

• Business name, street address, city, state and zip

• Model and serial number

• Date of purchase and proof of purchase (Receipt)

• Name of dealer where unit was purchased

NOTE: Vollrath will not accept products sent without the proper procedure being followed.

Important:

TO MAKE A CLAIM FOR ANY REMEDY UNDER THIS WARRANTY, YOU MUST REGISTER YOUR WARRANTY.

register today

ONLINE: Register your warranty on-line now at www.Vollrathco.com

NO WEB ACCESS: If you do not have access to the web, kindly register by completing the warranty registration form and faxing it to The Vollrath Co. LLC ofce in the country of

purchase.

Warranty regiStration

Business naMe

Key contact naMe eMail

street address

city state ZiP code

country Phone Fax

Model iteM nuMBer

serial nuMBer - -

oPeration tyPe

R Limited Service Restaurant R Full Service Restaurant R Bars and Taverns R Supermarket

R Convenience Store R Recreation R Hotel/Lodging R Airlines

R Business/Industry R Primary/Secondary School R Colleges/University R Hospitals

R Long-Term Care R Senior Living R Military R Corrections

reason For selecting our Product

R Appearance R Full Service Restaurant R Availability R Sellers Recommendation

R Ease of Operation R Versatility of Use R Price R Brand

Would you liKe to receive our Full-line catalog and reMain on our Mailing list? R Yes R No

www.vollrathco.com

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201

U.S.A.

Main Tel: 800.628.0830

Fax: 800.752.5620

Technical Services: 800.628.0832

Service Fax: 920.459.5462

Canada Service: 800.695.8560

© 2010 The Vollrath Company, L.L.C.

Loading...

Loading...