Volkswagen Rear axle User Manual

g

Стр. 1 из 2Rear axle (front and all wheel drive), servicin

g

Volkswagen Phaeton

Rear axle (front and all wheel drive), servicin

:

Note

If components with bonded rubber bushings were

replaced or bolts/nuts on these components were

loosened, corresponding wheel suspension must be

lifted into curb weight position 40-2, Wheel

bearing, lifting to curb weight position .

Always replace self-locking nuts.

Always replaced corroded nuts and bolts.

42 - 2

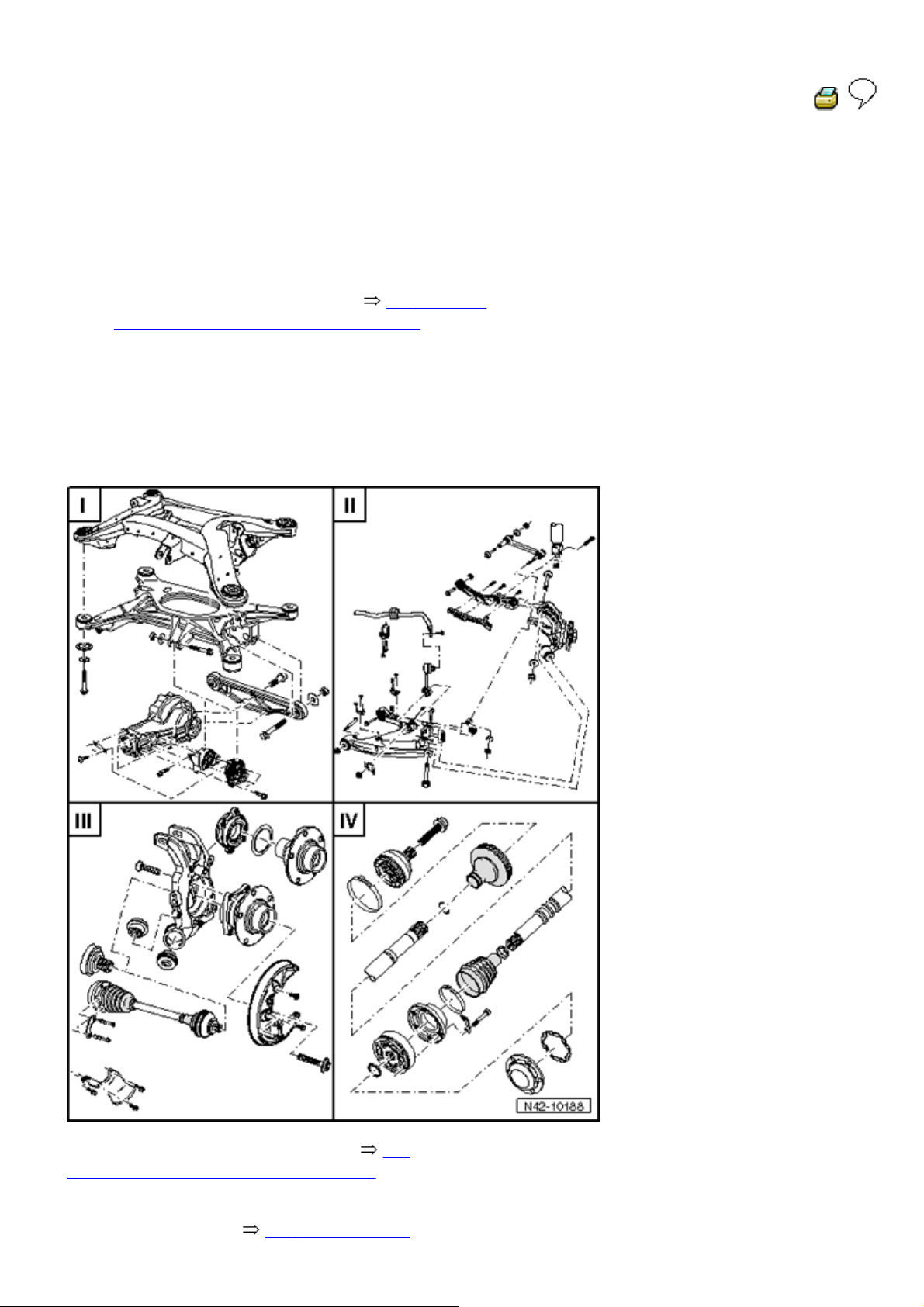

I - Subframe, assembly overview 42-

3, I - Subframe, assembly overview

II - Link, tie rod, air spring strut,

assembly overview 42-4, II - Link, tie

rod, air spring strut, assembly

g

overview

III - Wheel bearing, assembly overview

42-5, III - Wheel bearing, assembly

overview

IV - Driveshaft, assembly overview

42-6, IV - Drive axle, assembly

overview

Стр. 2 из 2Rear axle (front and all wheel drive), servicin

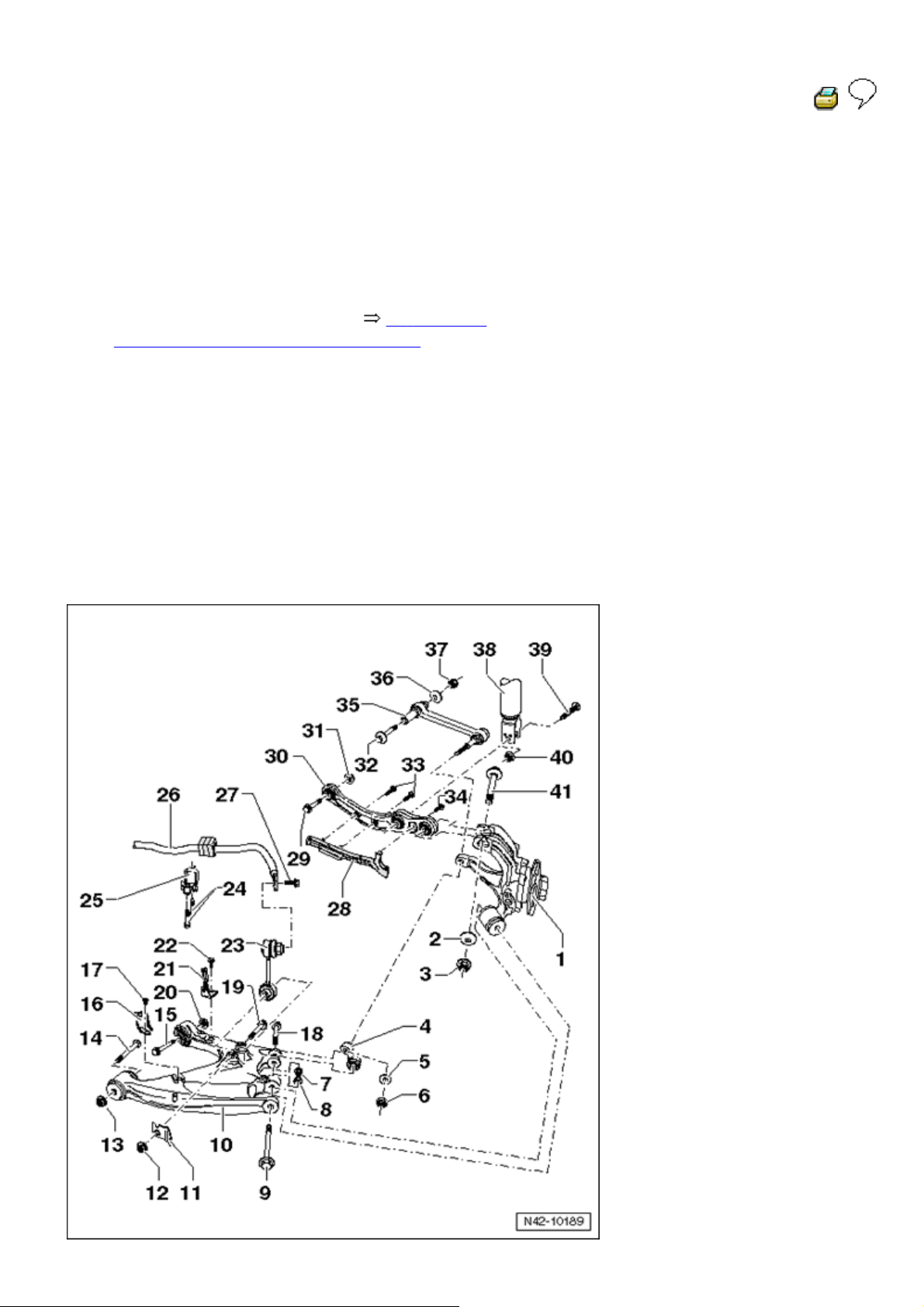

Стр. 1 из 8I - Subframe, assembly overview

42 - 3

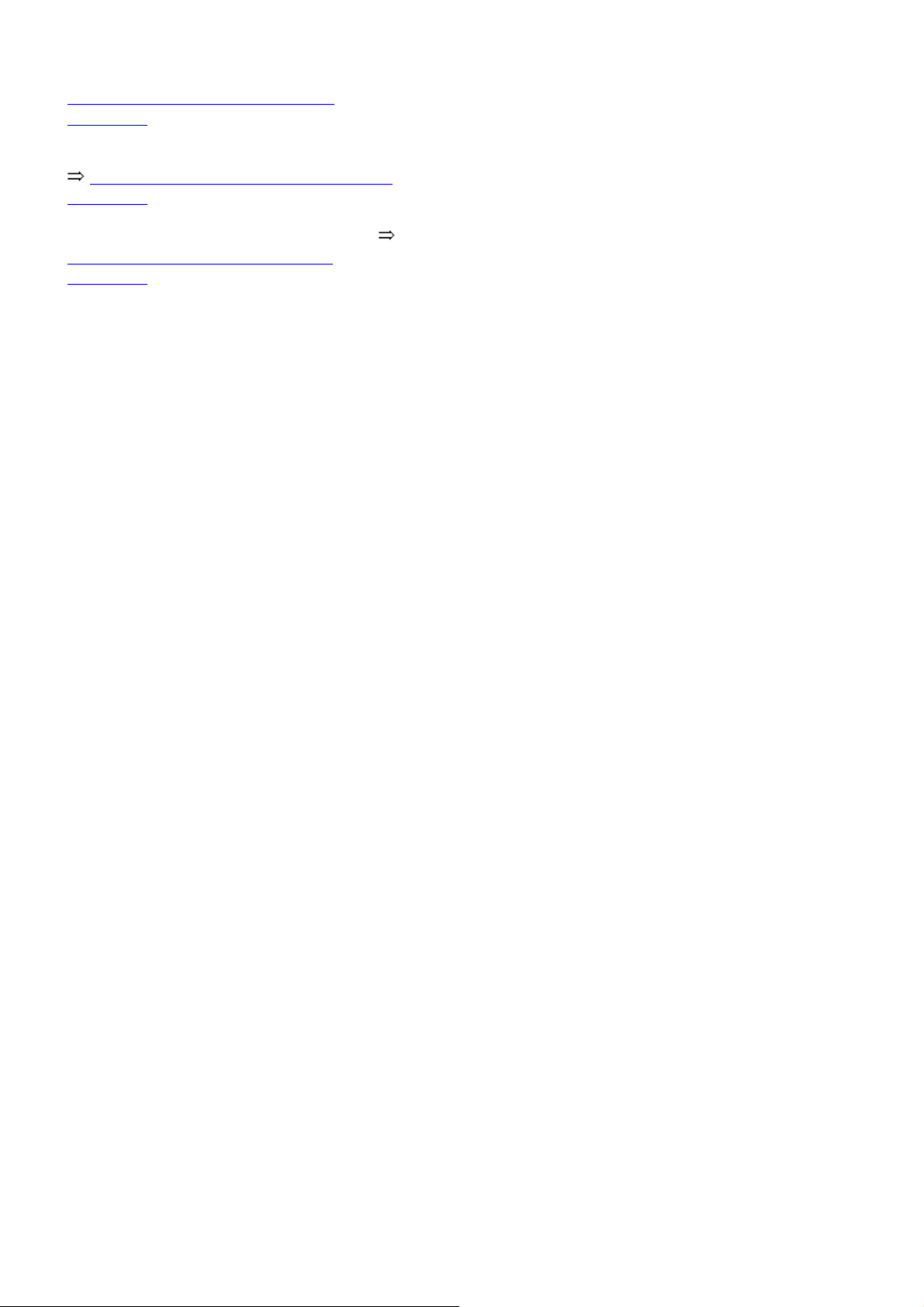

I - Subframe, assembly overview

On vehicles with front wheel drive, only

subframe and mounting components are

installed.

Final drive

Removing and installing

Repair Manual, Automatic

Transmission, Repair Group 39, Rear

final drive, removing and installing

Hex bolt

Washer

Hex nut

40 Nm

Self-locking

Always replace

Hex bolt

130 Nm plus an additional 90

Always replace

Washer

( 1 / 4 turn)

Стр. 2 из 8I - Subframe, assembly overview

Washer

Subframe

Steel version

This version is replaced in 2004

with the aluminum version

Application Electronic Parts

Catalog "ETKA"

Subframe

Aluminum version

Application Electronic Parts

Catalog "ETKA"

Hex socket head bolt

55 Nm

Washer

Hex nut

40 Nm

Self-locking

Always replace

Cross member

g

Hex bolt

Final drive support

For vehicles with V6 and W12

drivetrain

Application Electronic Parts

Catalog "ETKA"

Final drive support

For vehicles with V8 and V10

drivetrain

Стр. 3 из 8I - Subframe, assembly overview

Application Electronic Parts

Catalog "ETKA"

Hex bolt

40 Nm plus an additional 90

( 1 / 4 turn)

Always replace

Multi-point socket head bolt

20 Nm

Brace

Between rear final drive and

final drive support

For vehicles with V8 and V10

drivetrain

Application Electronic Parts

Catalog "ETKA"

Subframe, removing and installin

Стр. 4 из 8I - Subframe, assembly overview

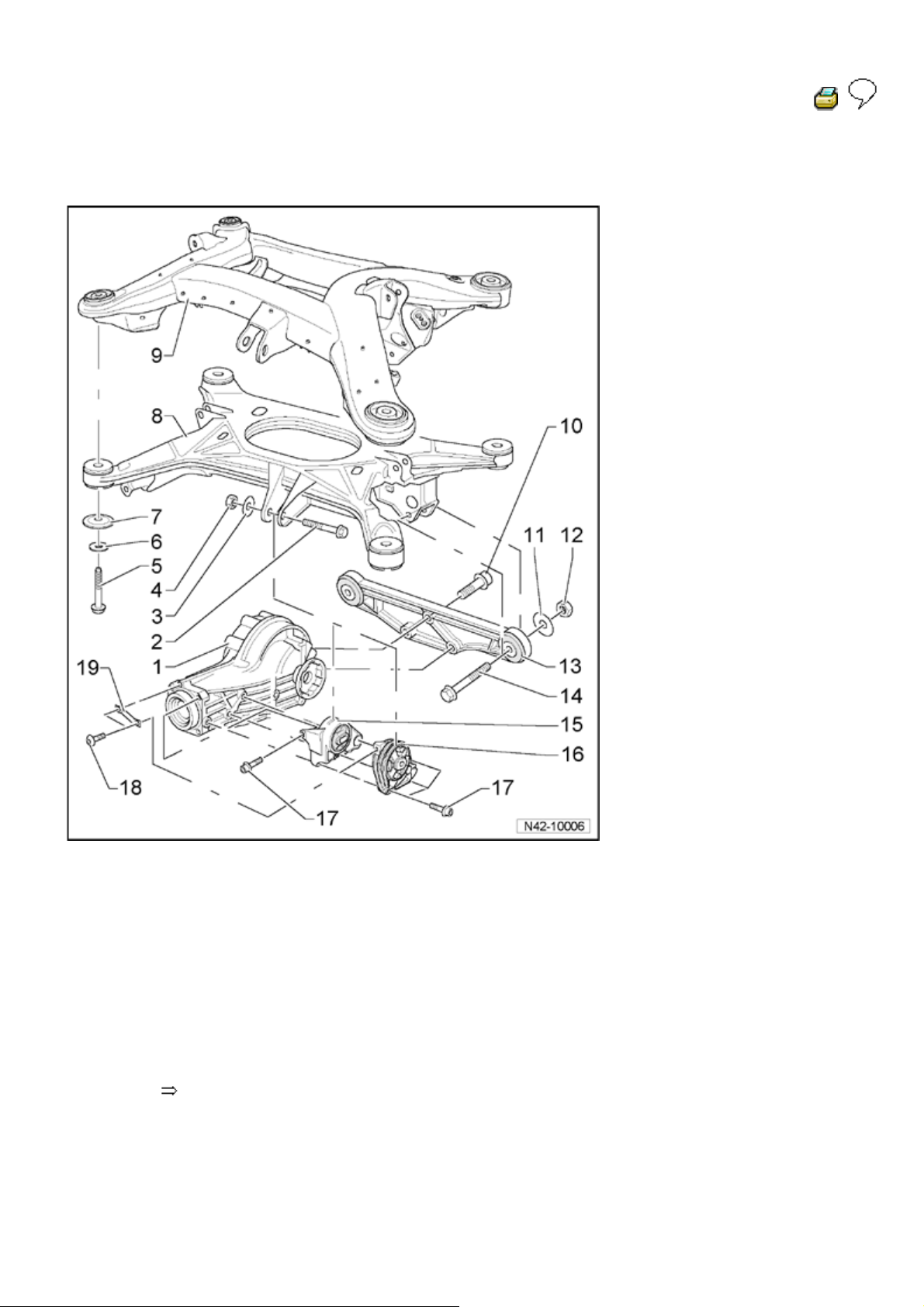

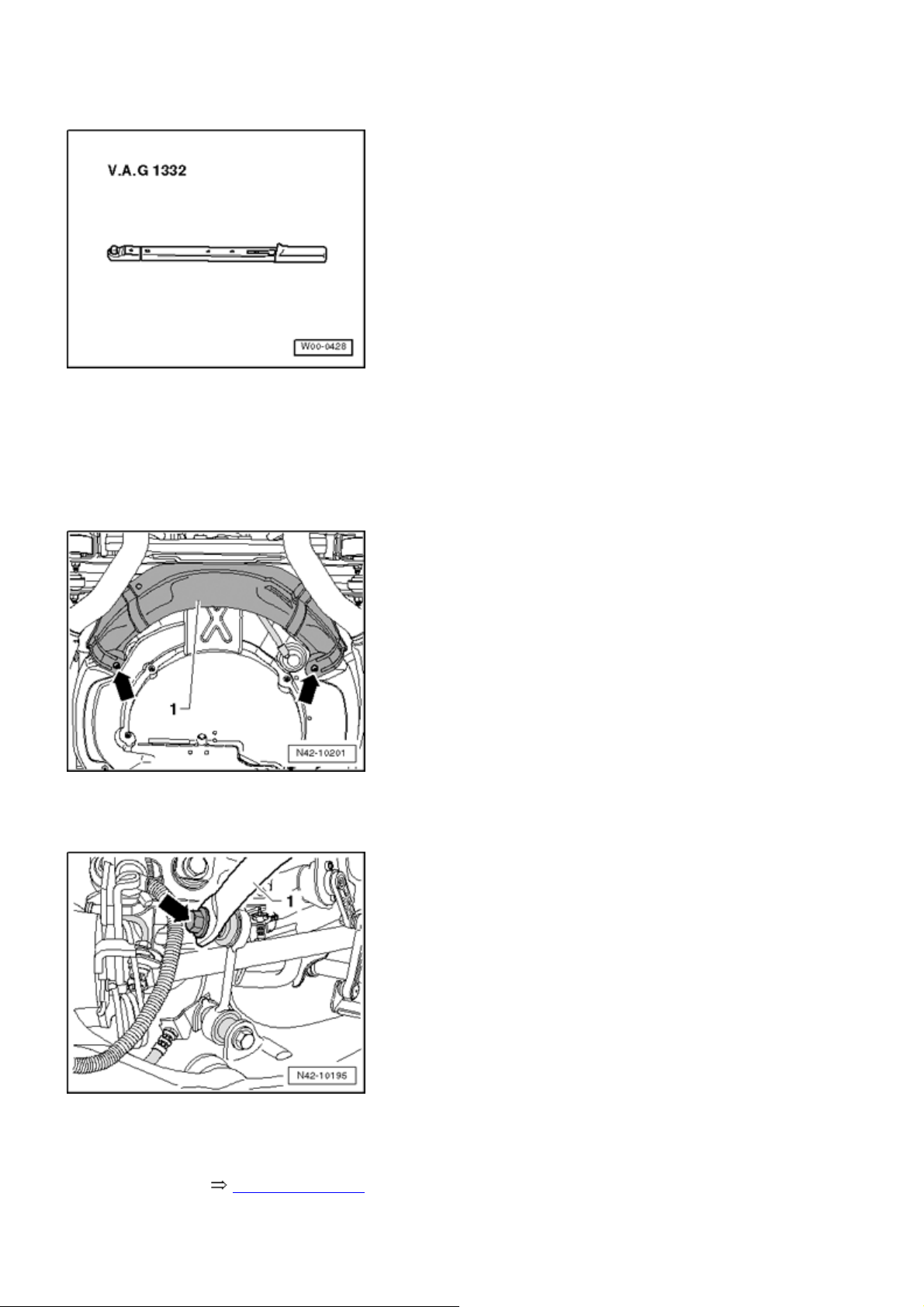

Special tools, testers and auxiliary items

required

Engine/transmission jack V.A.G

1383 A

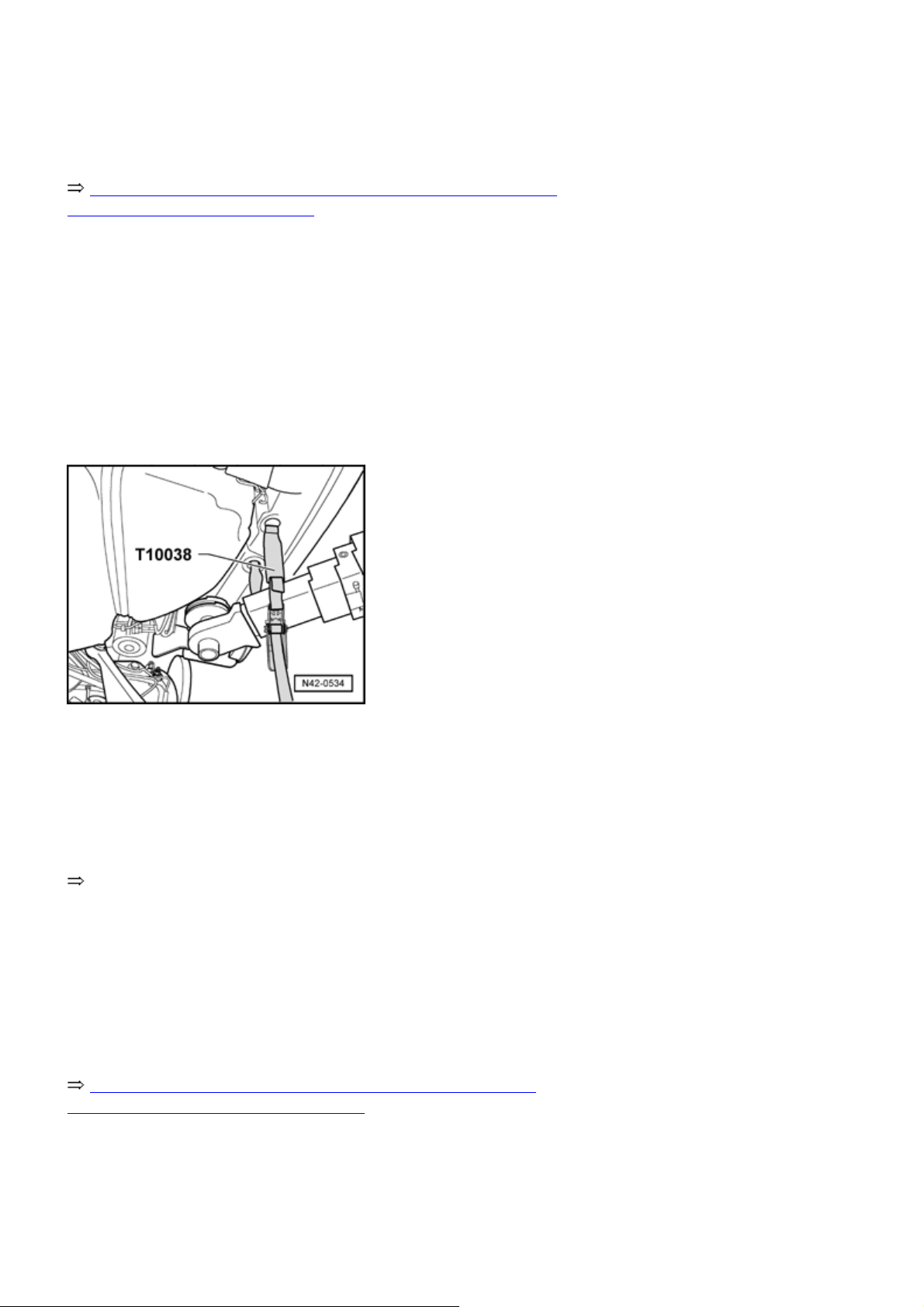

Tightening strap T10038

Torque wrench V.A.G 1332

Removing

- Brake pedal loading device V.A.G 1869/2 .

- Remove rear wheels.

- Remove rear cover on rear bumper

Repair Manual, Body Exterior, Repair Group 63, Bumper

cover, removing and installing

.

- Disconnect all electrical wires from body to rear axle.

Note:

Secure vehicle to hoist to continue procedure.

Стр. 5 из 8I - Subframe, assembly overview

- Remove plugs (2 per vehicle side).

- Secure vehicle to hoist lifting arm with Tensioning Strap

T10038 .

- Remove rear section of exhaust system

Repair Manual, Engine Mechanical, Fuel Injection

Ignition, Repair Group 26, Exhaust system parts, removing

and installing

- Disconnect brake lines.

- Remove brake cable from rear axle

Repair Manual, Brake System, Repair Group 46, Rear

brake cable, removing and installing

.

Стр. 6 из 8I - Subframe, assembly overview

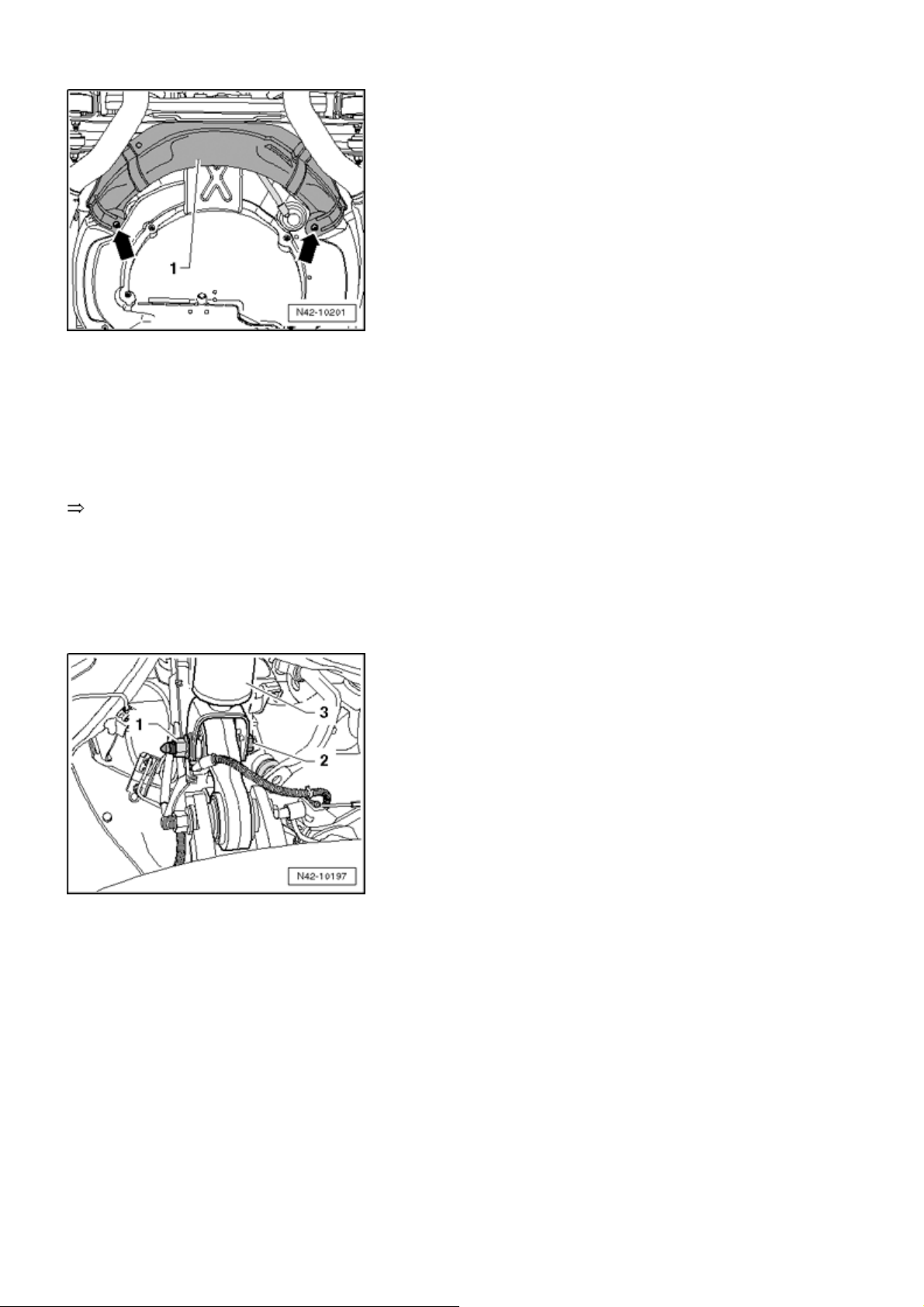

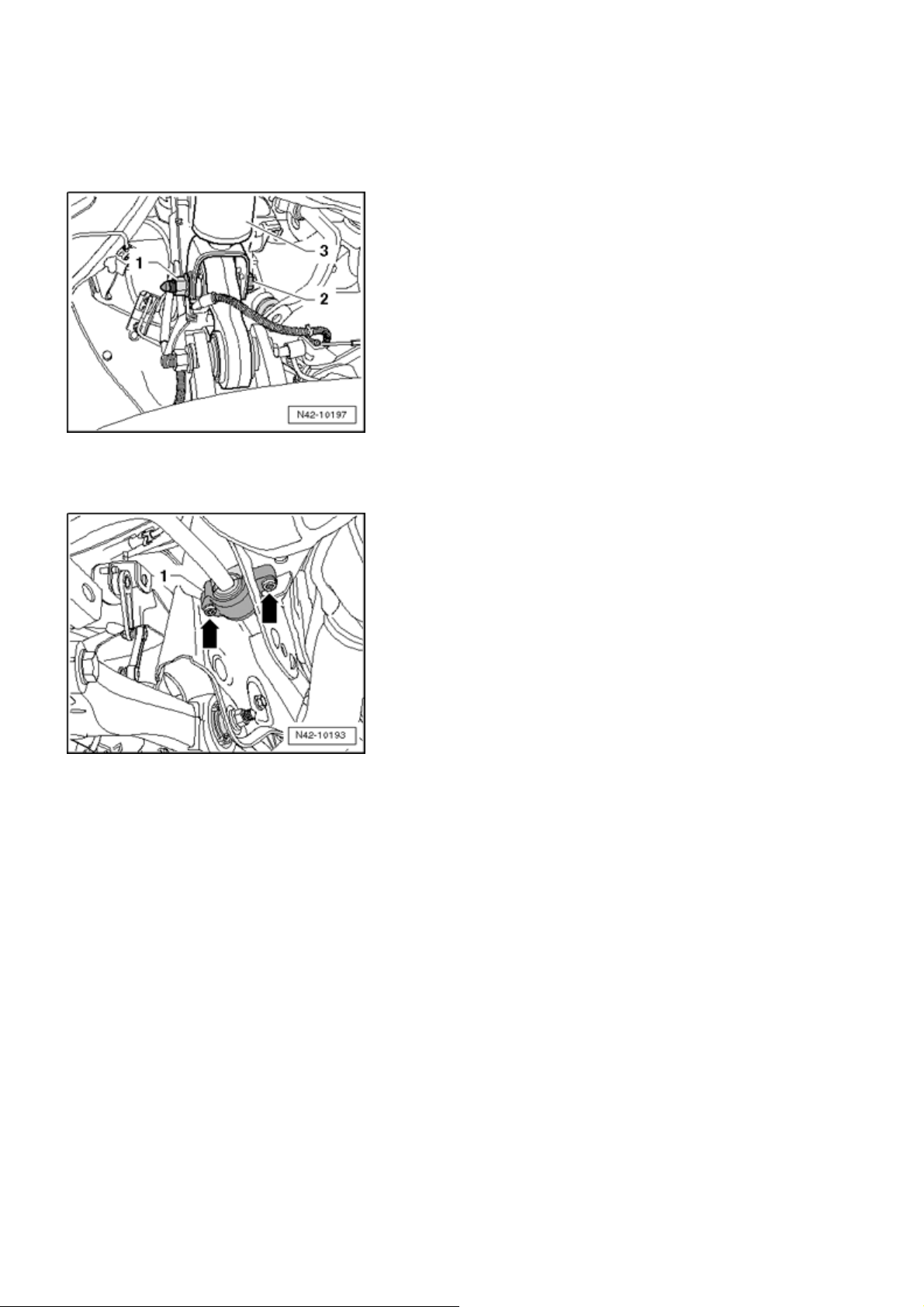

- Remove heat shield

from spare wheel well

- 1 -

- arrows -

.

- Remove drive shaft from rear final drive and tie up to body

Repair Manual, Automatic Transmission, Repair Group

39, Drive shaft, removing and installing

.

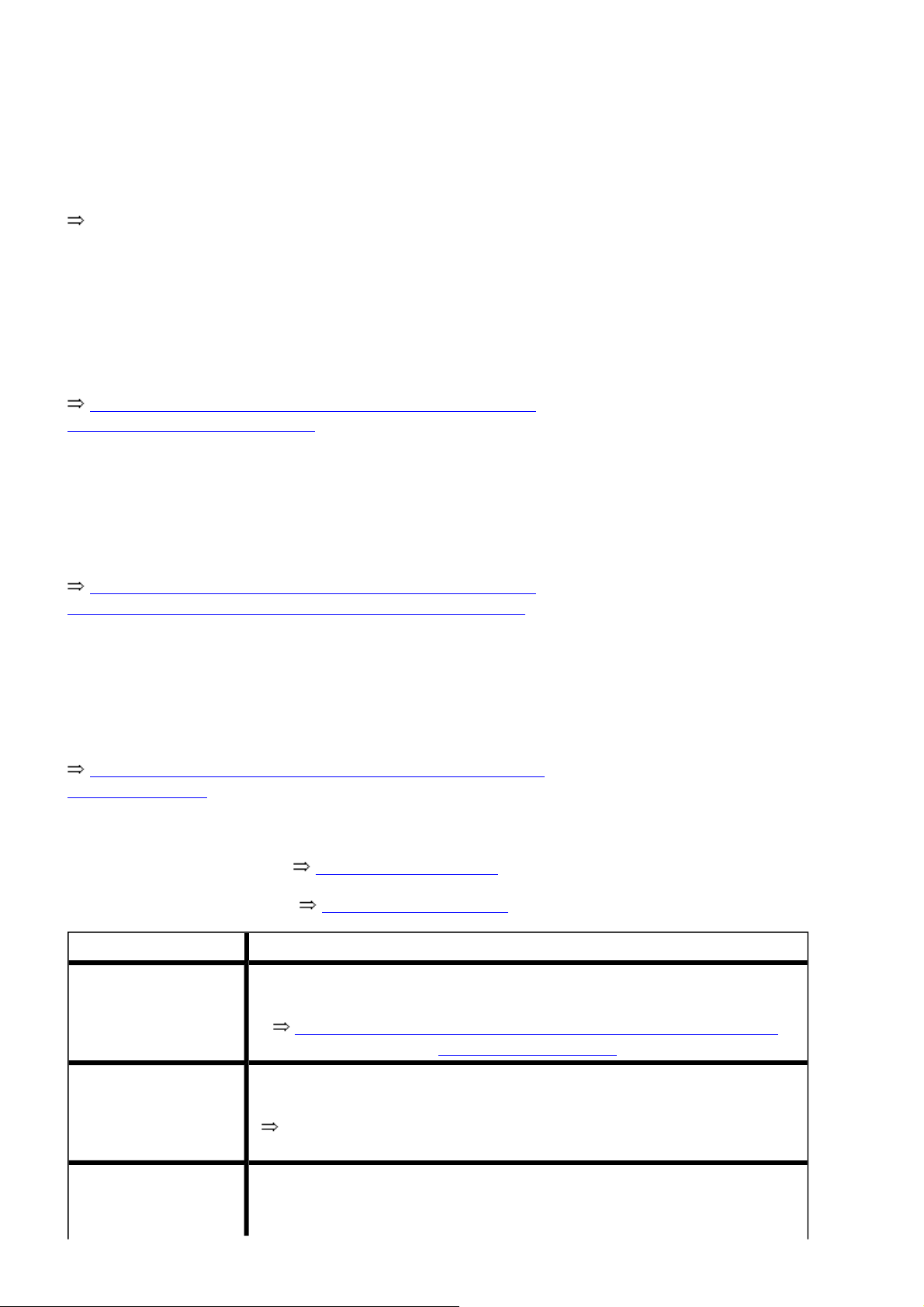

- Place engine/transmission jack V.A.G 1383 A with

Support 1359/2 below final drive.

- Remove nut

strut

to center of vehicle.

- 3 -

- Remove subframe from body.

- Slowly lower rear axle.

Installing

, remove bolt

- 1 -

and press air spring

- 2 -

Installation is in reverse order of removal, note the

following:

- Tighten subframe with bolts originally installed. Replace

these with new bolts after vehicle alignment.

- Tighten bolts originally installed to specified torque

Стр. 7 из 8I - Subframe, assembly overview

without additional tightening.

- Tighten drive shaft to rear final drive

Repair Manual, Automatic Transmission, Repair Group

39, Drive shaft, removing and installing

.

- Attach brake caliper to brake carrier

Repair Manual, Brake System, Repair Group 46, Rear

brakes, servicing; Disc brakes

.

- Adjust parking brake

Repair Manual, Brake System, Repair Group 46, Rear

brakes, servicing; Disc brakes; Parking brake, adjusting

.

- Bleed brake system

Repair Manual, Brake System, Repair Group 47, Brake

system, bleeding

.

- Install wheels and tighten 44-2, Wheel mounting .

- Perform vehicle alignment 44-3, Wheel alignment .

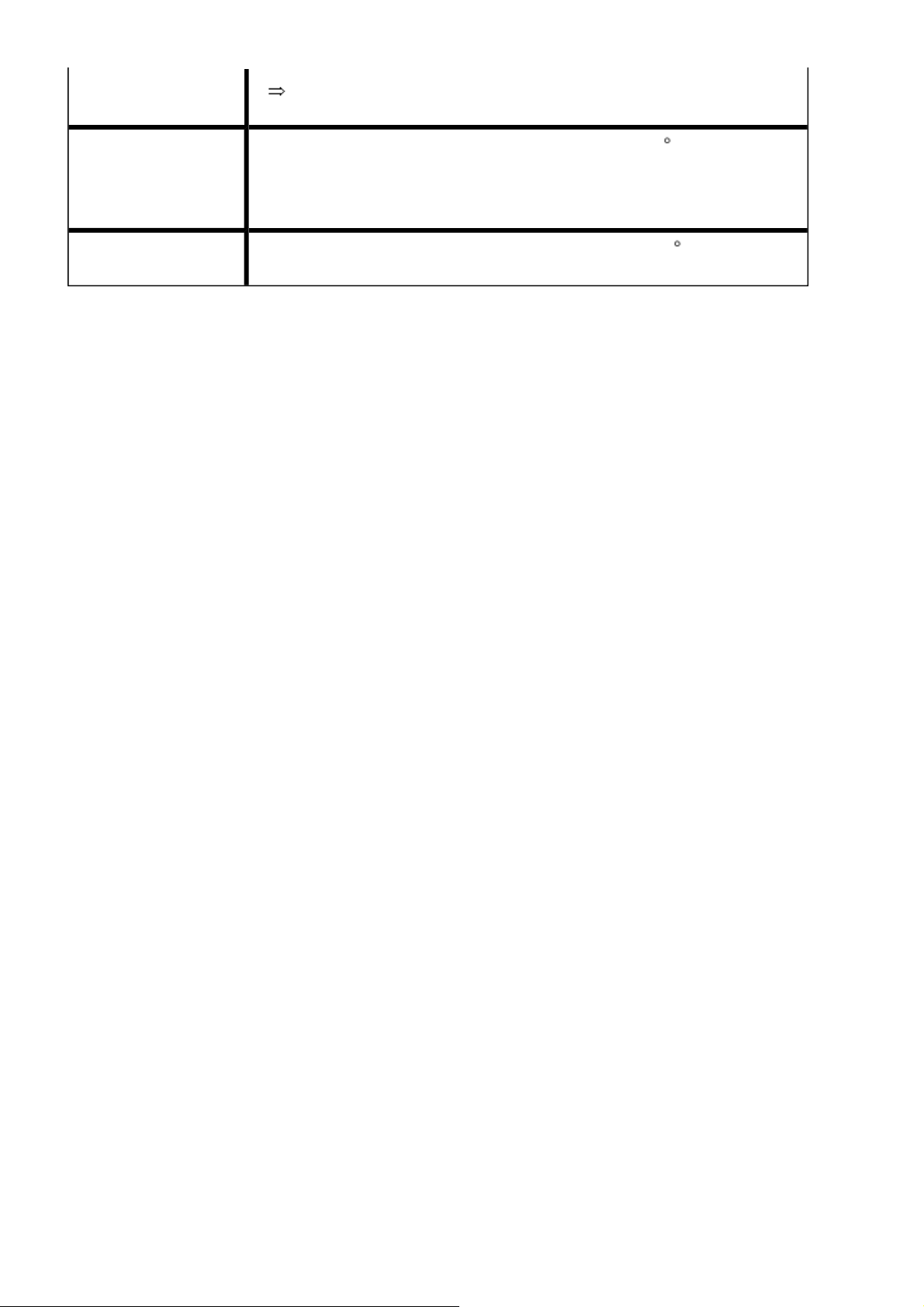

Tightening torque

Bumper to body

Repair Manual, Body Exterior, Repair Group 63, Bumper cover,

removing and installing

Exhaust system to

body

Repair Manual, Engine Mechanical, Fuel Injection Ignition, Repair

Group 26, Exhaust system components, removing and installing

Drive shaft to body

and final drive

Repair Manual, Automatic Transmission, Repair Group 39, Drive

shaft, removing and installing

Стр. 8 из 8I - Subframe, assembly overview

Air spring damper to

80 Nm plus an additional 1 / 4 turn (90 )

lower link

1)

2)

Subframe to body

1)

1)

Always use new nuts and bolts

2)

Tighten bolts and nuts in curb weight position

130 Nm plus an additional 1 / 4 turn (90

II - Link, tie rod, air spring strut, assembly overview

:

Note

If components with bonded rubber bushings were

replaced or bolts/nuts on these components were

loosened, corresponding wheel suspension must be

lifted into curb weight position 40-2, Wheel

bearing, lifting to curb weight position .

Welding and straightening work on supporting or

wheel carrying components of the suspension is not

permitted.

Стр. 1 из 31II - Link, tie rod, air spring strut, assembly overview

42 - 4

Always replace self-locking nuts.

Always replaced corroded bolts and nuts.

Wheel bearing housing

Removing and installing

42-5, Wheel bearing housing,

removing and installing

Wheel bearing unit, removing

and installing 42-5, Wheel

bearing unit, removing and

installing

Eccentric washer

Hex nut

95 Nm

Self-locking

Стр. 2 из 31II - Link, tie rod, air spring strut, assembly overview

Always replace

Coupling rod

For tie rod to lower link

Removing and installing

42-4, Tie rod to lower link

connecting links, removing

and installing

Washer

Hex nut

95 Nm

Self-locking

Always replace

Hex nut

Hex nut

80 Nm plus an additional

turn (90 )

Self-locking

Always replace

80 Nm plus an additional

1

/

4

1

/

4

turn (90 )

Self-locking

Always replace

Hex head bolt

Lift the wheel bearing housing

before fastening

Always replace

Lower link

Removing and installing

42-4, Lower link, removing

and installing

Стр. 3 из 31II - Link, tie rod, air spring strut, assembly overview

Bracket

Hex nut

50 Nm plus an additional 1 /

turn (90 )

Self-locking

Always replace

Lift wheel bearing housing

before fastening

Hex nut

Self-locking

Always replace

Hex head bolt

4

80 Nm plus an additional

turn (90

Always replace

Lift wheel bearing housing

before fastening

Hex head bolt

1

/

4

Стр. 4 из 31II - Link, tie rod, air spring strut, assembly overview

80 Nm plus an additional

Always replace

Lift wheel bearing housing

Bracket

Hex bolt

10 Nm

Hex bolt

Lift wheel bearing housing

1

/

turn (90

before fastening

before fastening

replace after every removal

4

Hex bolt

Always replace

Hex nut

Self-locking

Always replace

Connecting link for vehicle level

sensor

Do not pull connecting link

from ball joint!

Hex bolt

10 Nm

Coupling rod

For stabilizer bar to lower link

Removing and installing

42-4, Stabilizer bar to lower

link connecting links,

removing and installing

Multi-point socket head bolt

25 Nm

Stabilizer bar clamp

Stabilizer bar

Removing and installing

42-4, Stabilizer bar, removing

and installing

Hex bolt

Стр. 5 из 31II - Link, tie rod, air spring strut, assembly overview

65 Nm plus an additional

turn (90 )

Always replace

Cable channel

Hex bolt

80 Nm plus an additional

turn (90 )

Always replace

Upper link

Removing and installing

42-4, Upper link, removing

and installing

1

/

4

1

/

4

Hex nut

Self-locking

Always replace

Eccentric bolt

For toe adjustment

Bolt

Bolt

Tie rod

Removing and installing

g

42

-4, Tie rod, removing and

installing

Eccentric washer

Hex nut

95 Nm

Self-locking

Always replace

Lift wheel bearing housing

before fastening

Стр. 6 из 31II - Link, tie rod, air spring strut, assembly overview

Air spring strut

The air spring damper

protective boot must not

sustain any indentations!

Removing and installing

42-4, Air spring strut,

removing and installing

Hex bolt

80 Nm plus an additional

turn (90

Always replace

Hex nut

Self-locking

1

/

4

Always replace

Eccentric bolt

For camber adjustment

Air spring strut, removing and installin

Special tools, testers and auxiliary items required

Стр. 7 из 31II - Link, tie rod, air spring strut, assembly overview

Torque wrench V.A.G 1331

Removing

During assembly work, make sure that no indentations

form on boot of air spring strut!

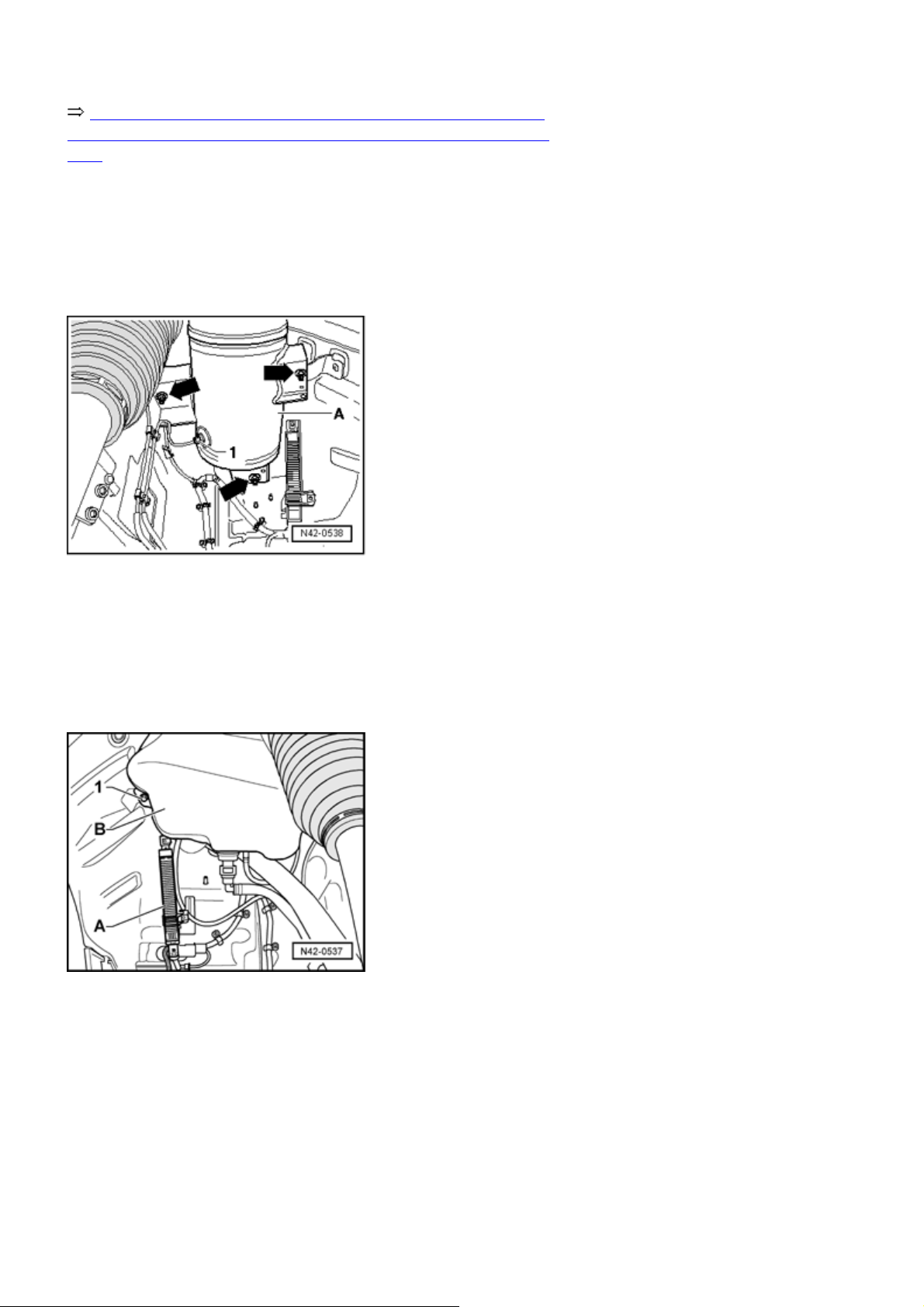

- Remove level control system sensor bolt

from lower

- 2 -

link.

- Remove nut

strut

to center of vehicle.

- 3 -

, remove bolt

- 1 -

- Remove wheel housing liner

and press air spring

- 2 -

Repair Manual, Body Exterior, Repair Group 66, Wheel

housing liner, removing and installing; Rear wheel housing

liner

.

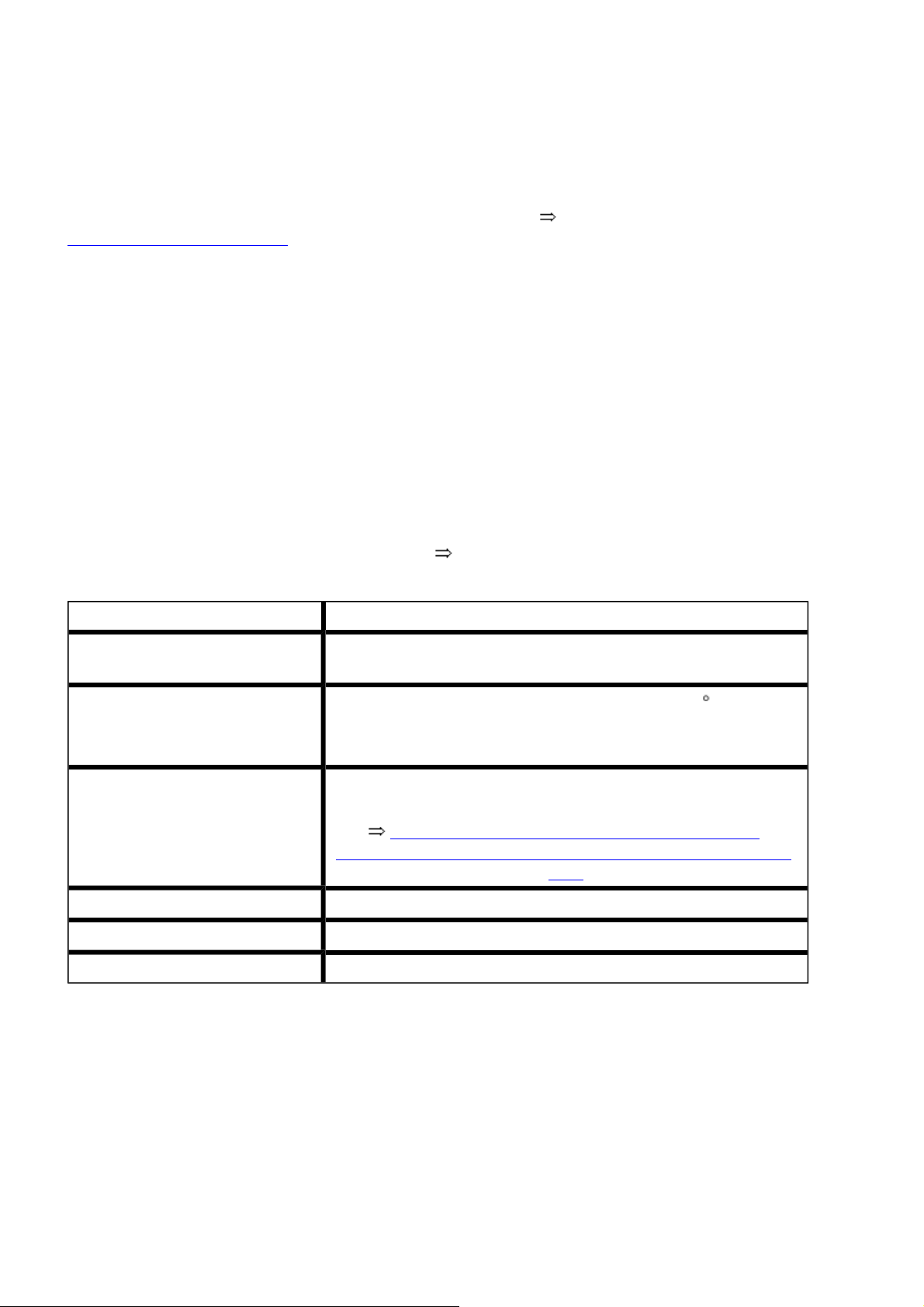

Left rear

- Remove air line (yellow) from reservoir. Seal off both air

connections after air is released.

Стр. 8 из 31II - Link, tie rod, air spring strut, assembly overview

- Remove reservoir

nuts

- arrows -

- Disconnect damper adjustment switching valve electrical

connector.

Right rear

.

by removing air line

- A -

and hex

- 1 -

- Remove hex screw

as possible.

- Disconnect damper adjustment switching valve electrical

connector.

- Remove air line from air spring strut and seal off both

connectors.

Continued for all vehicles

The wheel bearing housing must be pulled down slightly so

and move tank

- 1 -

as far down

- B -

that the strut can be removed.

g

If air spring strut is to be replaced, first read the following

42-4, Air spring strut, filling .

Стр. 9 из 31II - Link, tie rod, air spring strut, assembly overview

Installing

Installation is in reverse order of removal, note the

following:

During assembly work, make sure that no indentations

form on boot of air spring shock absorber!

- Insert air spring strut and tighten.

- Attach air spring strut to link.

- Raise wheel bearing housing to tighten.

- Check basic setting of level control system Vehicle

Diagnosis, Testing and Information System VAS 5051 .

Tightening torque

Connecting link from vehicle

10 Nm

level sensor to lower link

Air spring strut to lower link

1)

2)

80 Nm plus an additional 1 / 4 turn (90 )

Wheelhouse liner to body

Repair Manual, Body Exterior, Repair Group 66,

Wheelhouse liner, removing and installing; Rear wheelhouse

liner

Air line to air spring strut 5 Nm

Reservoir to body 9 Nm

Air spring strut to body 30 Nm

1)

Always use new nuts and bolts

2)

Tighten bolts and nuts in curb weight position

Air spring strut, fillin

Special tools, testers and auxiliary items required

Стр. 10 из 31II - Link, tie rod, air spring strut, assembly overview

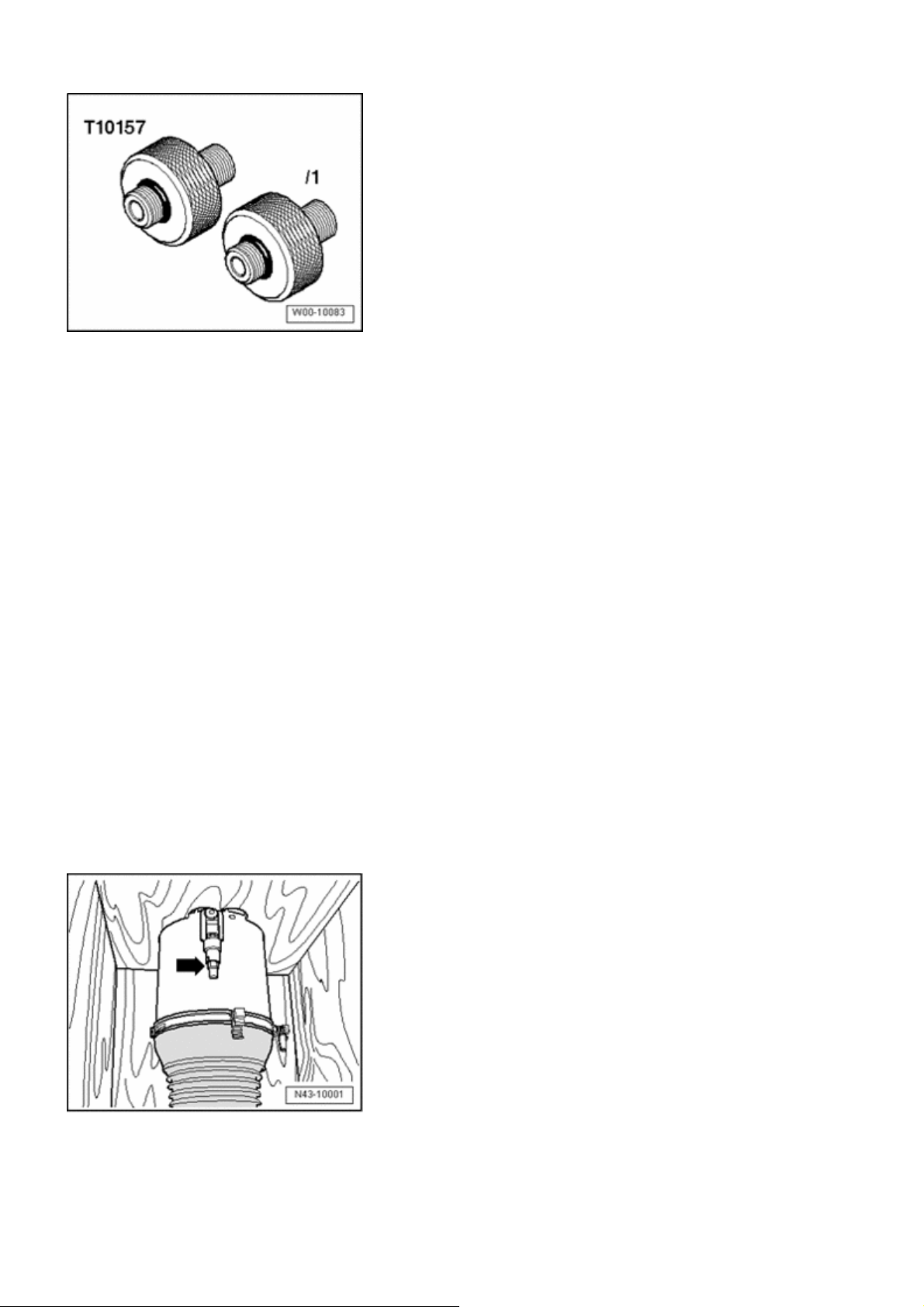

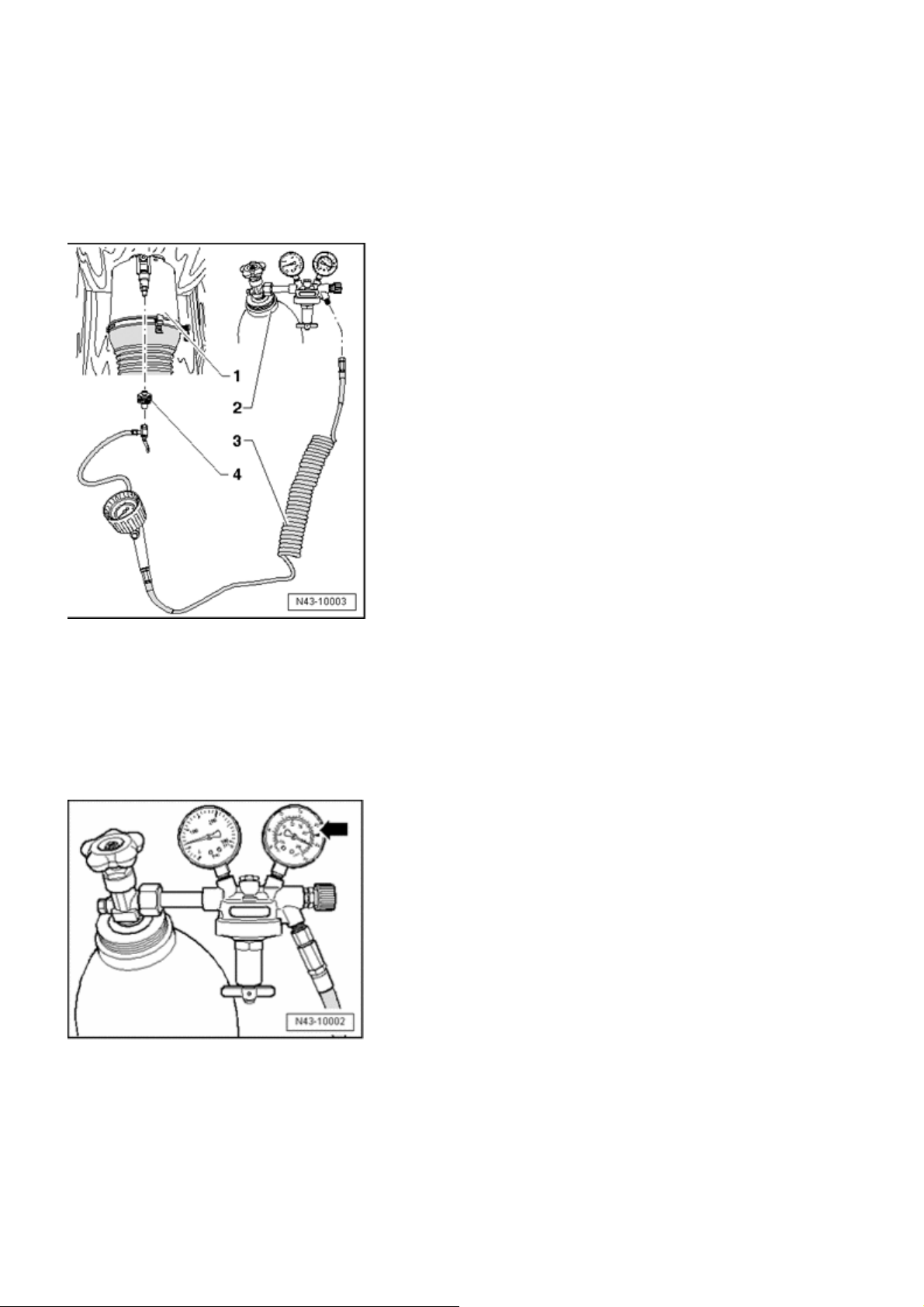

Adapter T10157

Air suspension strut charger VAS 6231 , not

illustrated

Steel gas cylinder filled with Argon or Corgon, not

depicted

Note:

Air spring struts are supplied as replacement parts

with a minimum pressure. By sitting in storage for

extended periods this minimum pressure can

diminish (just like a tire). Before the air spring strut is

removed from its packaging, this minimum pressure

must be controlled and restored by "refilling" . Without

this necessary refilling, folds can form in the underfilled air spring boot. These folds cause damage

which can lead to premature failure.

- Remove cover from packaging.

- Remove union bolt

- arrow -

from residual pressure

retaining valve. Illustration shows front air spring strut.

- Close steel gas bottle pressure valve.

Volkswagen Technical Site: http://volkswagen.msk.ru http://vwts.info http://vwts.ru

огромный архив документации по автомобилям Volkswagen, Skoda, Seat, Audi

- Become familiar with relevant rules for prevention of

accidents for pressurized containers and technical gases.

Стр. 11 из 31II - Link, tie rod, air spring strut, assembly overview

- Connect air spring filler unit VAS 6231 and adapter

T10157 as shown in illustration.

Air spring strut in packaging

Steel gas bottle for argon, corgon with gauges

Air spring filler unit VAS 6231

Adapter T10157

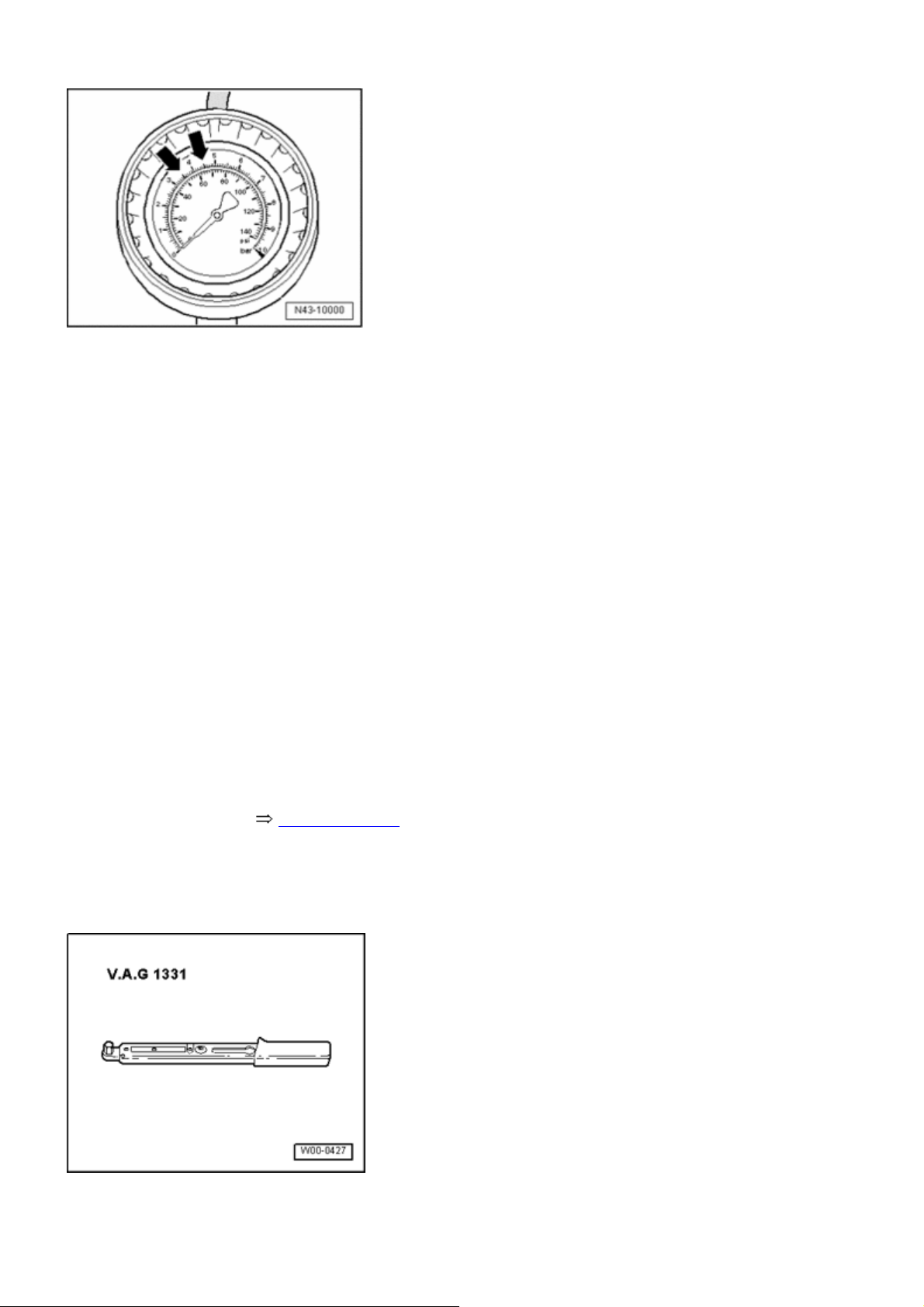

- Set flow rate limiter gauge to 2.0 L/min

-arrow-

.

- Fill gas into air spring strut using several individual

pressure bursts.

g

The display only shows a correct gas pressure if the

"oscillatory pressure" of the residual pressure retaining

valve is overcome. The "oscillatory pressure" is at approx.

3.5 bar. When the display reaches 3.5 to 4.5 bar, air spring

damper is sufficiently filled with gas.

Стр. 12 из 31II - Link, tie rod, air spring strut, assembly overview

- Make sure gas pressure does not exceed 4.5 bar when

filling.

- Disconnect air spring filler unit VAS 6231 from adapter

T10157 . This dissipates the gas above an internal

pressure of 3.5 bar.

Minimum pressure is reproduced, air spring strut can be

removed from packaging.

- After installation, first drive the vehicle at high ride height

and then at normal ride height. Repeat this sequence once

more.

By moving the ride height settings twice, the majority of the

gas is exchanged with filtered air from the air supply motor.

- Install air spring strut 42-4, Installing .

Stabilizer bar, removing and installin

Special tools, testers and auxiliary items required

Torque wrench V.A.G 1331

Стр. 13 из 31II - Link, tie rod, air spring strut, assembly overview

Torque wrench V.A.G 1332

Removing

- Remove wheels.

- Remove heat shield

- 1 -

.

from spare wheel well

- arrows -

- Remove stabilizer bar

links

- arrow -

.

from left and right connecting

- 1 -

- Remove tie rod 42-4, Removing .

Стр. 14 из 31II - Link, tie rod, air spring strut, assembly overview

- Remove nut

strut

to center of vehicle.

- 3 -

- Remove bolts

, remove bolt

- 1 -

- arrows -

- 2 -

evenly on both sides.

- Turn stabilizer bar so that clamps

of notches on subframe.

- Remove clamps

from stabilizer bar brackets.

- 1 -

and press air spring

can be guided out

- 1 -

- Turn stabilizer bar so that connecting link mounts face

downward.

- Guide stabilizer bar out toward left.

Installing

- Guide in stabilizer bar from left over exhaust system.

- Place clamps on stabilizer bar bracket. Make sure longer

clamp tab faces opposite to direction of travel.

Стр. 15 из 31II - Link, tie rod, air spring strut, assembly overview

- Turn stabilizer bar in subframe so that clamps

into subframe notches.

- Install bolts

and tighten to specified torque.

- Move air spring strut

upward.

- Insert bolt

- arrows -

and tighten nut

- 2 -

hand-tight evenly on both sides

outward on link bracket and

- 3 -

to specified torque.

- 1 -

- 1 -

project

- Install tie rod 42

- Tighten stabilizer bar

- arrow -

.

-4, Installing .

at left and right connecting links

- 1 -

Loading...

Loading...