Page 1

The Lupo

Design and function

Self-Study Programme No. 201

1

0

2

o

N

E

M

S

M

A

R

G

O

PR

Y

D

U

T

S

-

F

L

E

Page 2

The Lupo, a new addition to the

subcompact family, extends the

Volkswagen product range.

In spite of its compact dimensions, the Lupo

boasts a specification which stands comparison

with any saloon and is rounded off by a

distinctive design.

Environmental pollution kept to a minimum by

using fuel-efficient, low-emission and quiet

engines as well as recycleable and recycled

plastic parts.

The Lupo conforms to all internationally

recognised safety standards for head-on

collision, side impact, offset collision and rear

collision as well as for rollover.

The small and highly manoeuvrable vehicle

is simply likeable, chic and natural.

The Self-Study Programme

is no Workshop Manual.

2

SSP 201_130

Please always refer to the relevant

Service Literature for all inspection,

adjustment and repair instructions.

SSP 201_134

SSP 201_131

New Important

Note

Page 3

At a glance

The Lupo .......................................................................

Vehicle dimensions, aerodynamics

The car and the environment

Environmental protection, recycling

Body ..............................................................................

Safety bodyshell,

paintwork structure and corrosion protection, high-strength body panels

Soundproofing, Isofix, fabric sliding roof

Front and rear bumpers

Restraint system, airbags

Engines ..........................................................................

Engine-gearbox combination

Engines, roller cam follower,

Power transmission ......................................................

Manual gearbox 085 and gear selection

Manual gearbox 002 and gear selection

Automatic gearbox and gate selection

4

10

18

26

Fuel system ................................................................... 29

Running gear ................................................................

Steering

Front axle/rear axle

Brake system

Front and rear brakes

ESBS

Electrical system ..........................................................

Vehicle electrical system/components

Fitting locations of control units,

Dash panel insert, central locking

Radio generation ’99

Heating, air conditioning system ...............................

Heating, air conditioning system,

Radiator fan control unit,

high pressure sender, system overview, functional diagram

30

38

48

Service ...........................................................................

Special tools

55

3

Page 4

The Lupo

The small LUPO achieves great things in terms

of safety, quality, performance, running gear

and equipment.

• Safety

The safety bodyshell, belt

tensioners, front airbags

and side airbags mean that the

little Lupo is no baby when it

comes to safety.

SSP 201_174

SSP 201_133

• The running gear

The suspension strut front axle with

wishbones, as well as the torsion beam

rear axle are a winning team and place

the LUPO firmly on the road.

SSP 201_080

4

Page 5

• Equipment level

A 4-seater or 5-seater version can

be specified. Easy Entry seats are

standard for the driver and front

passenger. They exceed the

standard specification.

Also available for the LUPO is a

complete range of extras ranging

from the electric fabric sliding roof

and the air conditioning system to

the navigation system.

• Quality

The Lupo also meets

Volkswagen's recognised

quality standard:

• Narrow body joints

• High-quality materials

SSP 201_168

SSP 201_132

SSP 201_131

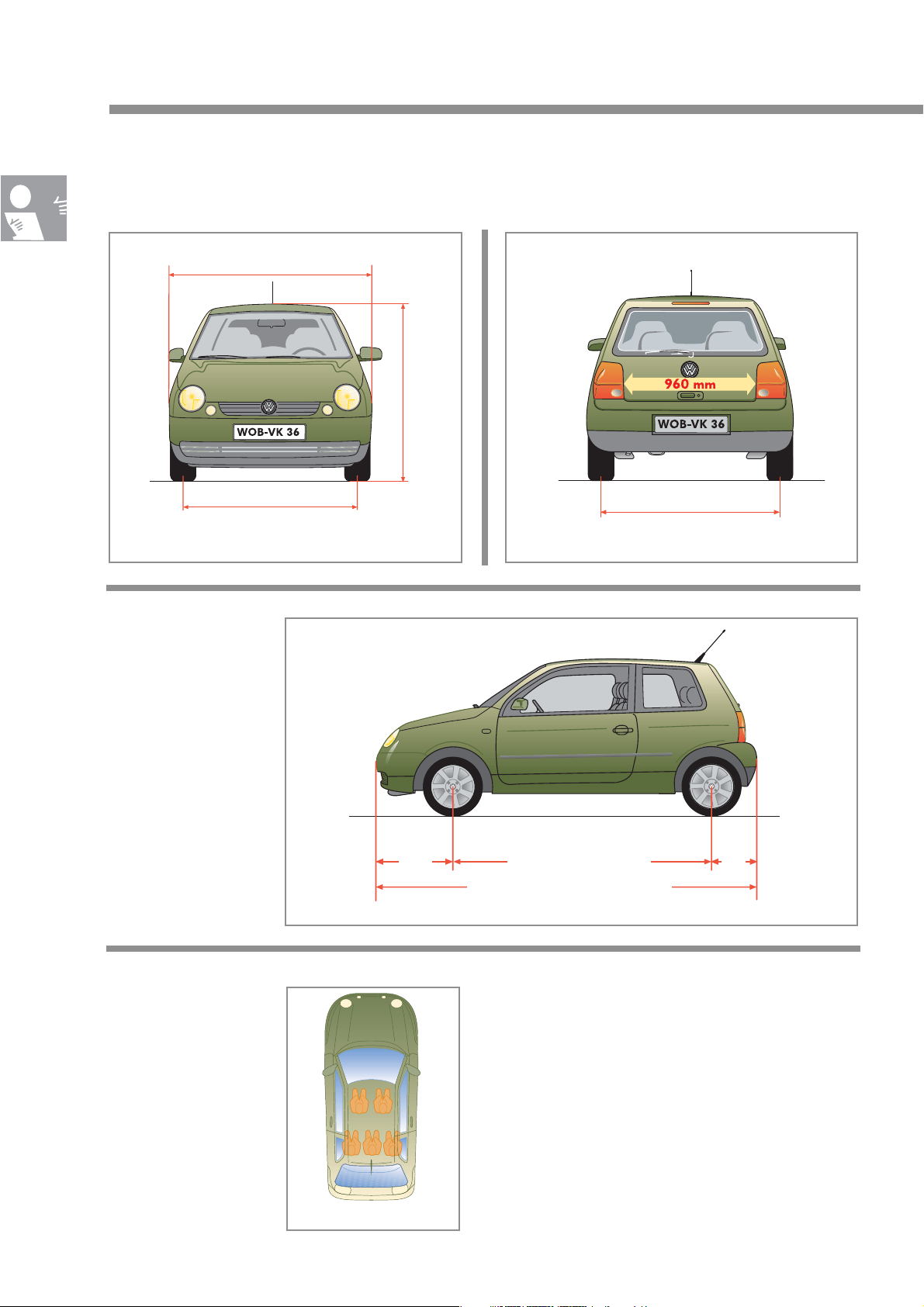

• Engines and gearboxes

A choice of four petrol engines and

one

diesel engine in combination with

a 5-speed manual gearbox and a

4-speed automatic gearbox will be

available when the LUPO is

launched on the market.

5

Page 6

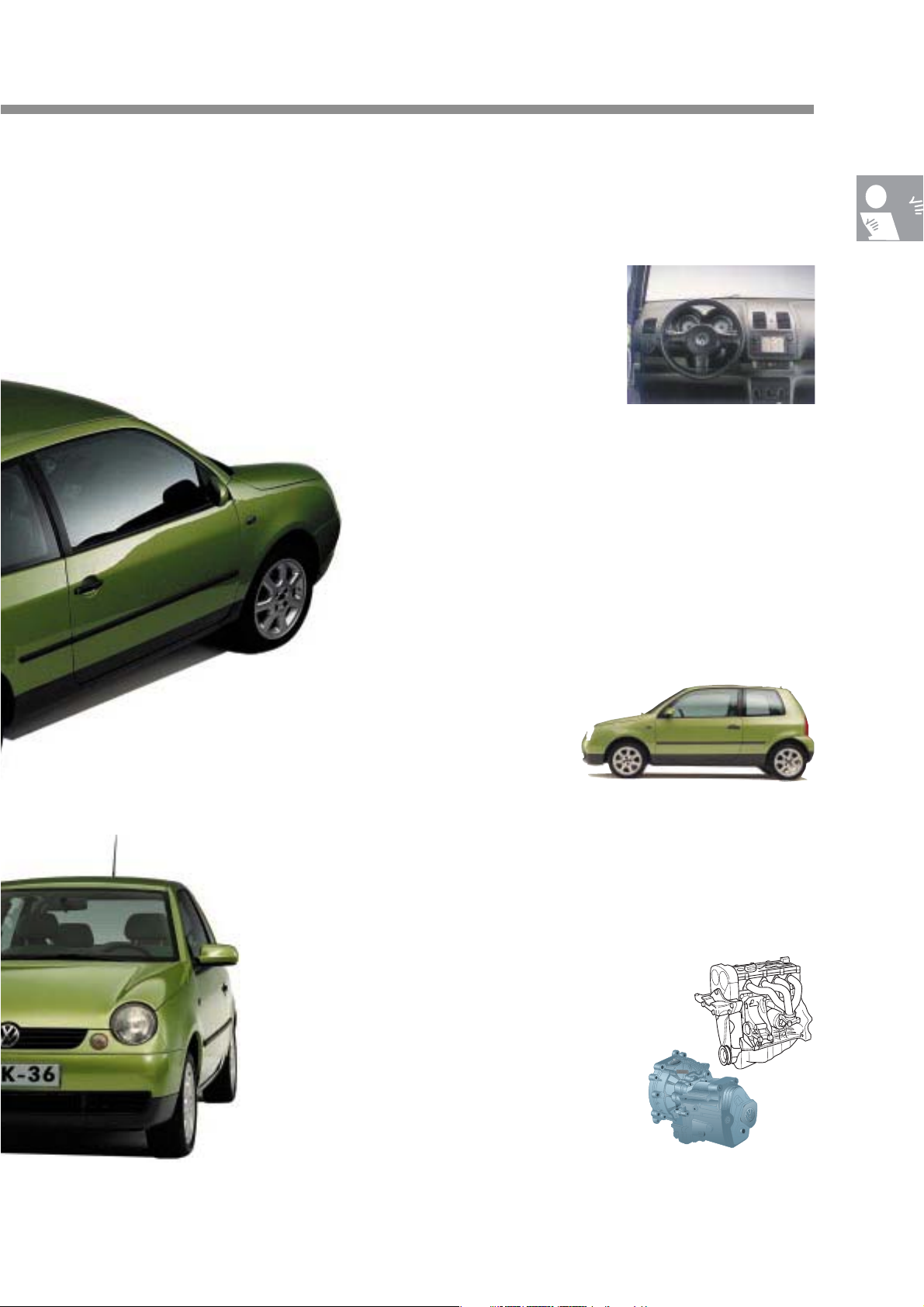

The Lupo

Vehicle dimensions

Width: 1639 mm

Front track width: Rear track width:

1387 mm (4 1/2 J x 13)

1371 mm (5 1/2 J x 13, 6 J x 14)

With a maximum

length of 3527 mm, the

LUPO belongs to the

subcompact class.

m

m

0

6

4

t: 1

h

ig

e

H

SSP 201_010

Tank capacity

34 litres

1400 mm (4 1/2 J x 13)

1384 mm (5 1/2 J x 13, 6 J x 14)

SSP 201_011

The Lupo offers space

for 4 or 5 persons,

depending on the

equipment level.

729

mm

Wheelbase: 2323 mm

Length: 3527 mm

The luggage compartment has a capacity of

139 or 792 litres. The rear seat backrest can be

folded down. The inclination of the rear seat

backrest can be adjusted in two stages in order

475

mm

SSP 201_012

to enlarge the luggage compartment.

SSP 201_007

6

Page 7

Aerodynamics

cd = 0.32

Aerodynamic

drag

D = 0.62 m

2

A = 1.94 m

SSP 201_018 SSP 201_130

2

One of the main goals in the

development of the LUPO's

aerodynamics was to

streamline the bodyshell in

such a way as to eliminate

additional measures to

improve the vehicle’s

aerodynamics, measures

which involve higher costs

and weight.

SSP 201_020

A streamlined bumper with integral front spoiler,

optimised door mirror, small gap and joint

dimensions as well as flush-fitting windows and

headlights minimise aerodynamic drag and wind

noise.

7

Page 8

The car and the environment

In addition to households, industry,

power stations, heating stations and

industrial agriculture, the car is one

of the principal sources of air

pollution.

Global annual CO2 emissions caused by man

Source: Technical University of Vienna

Other modes of transport

Ocean-going ships

Air traffic

Trucks and buses

Passenger cars

Industry

Power stations and heating

stations

Combustion of biomass

House fires and small

consumers

SSP 201_005

CO2 emissions constitute

approx. 50 percent of the

greenhouse gases which are

responsible for the "manmade" phenomenon of

global warming. Industry,

power stations, households

and small consumers are

responsible a good two thirds

of CO

emissions. Road traffic

2

worldwide accounts for

approx. 12 percent of CO

2

emissions, whereas cars

contribute less than 6 percent.

For Volkswagen, reducing fuel consumption, and

Fuel consumption of cars

supplied by Volkswagen in Germany

along with it CO2 emissions, is one of its main

goals in the development of new automobiles. We

have agreed to reduce the fuel consumption of our

new vehicles by 25 percent between 1990 and

2005. During the period from 1990 to 1995, we

achieved a 10 percent reduction. We plan to

achieve another 15 percent reduction within the

next ten years. The so-called "3-litre car" (a car

Polo SDI

3-litre car

Source: VOLKSWAGEN AG

8

SSP 201_006

which consumes 3 litres of fuel per 100 km) is a

major step towards low-CO

-emission vehicles,

2

both for production and during operation.

Page 9

Recycling

Volkswagen, in association with

disposal firms, runs a Workshop

Disposal Programme. This process

is co-ordinated through the

distribution centre or the importer

in charge in accordance with

prevailing national legislation.

These components can be disposed of

without posing a burden on the environment:

Wo

r

k

s

h

o

g

is

to

e

n

ive

s

ia

r

p

m

m

a

in

p

D

i

s

p

m

m

o

s

a

l

o

t

ive

f

re

e

m

a

e

n

t

d

i

s

p

o

s

a

l

m

w

l

w

id

e

ra

n

g

e

p

o

n

e

h

a

rg

e

c

o

n

c

a

s

t

e

o

f

fe

r

o

f

n

e

r

n

d

is

s

f

t

s

a

n

d

i

n

g

t

h

e

p

o

o

s

a

l

r

e

:

o

f

a

c

o

o

f

c

t

t

e

r

s

a

n

d

o

s

a

Pr

o

D

a

u

m

e

d

Ad

v

ic

e

n

v

i

ro

I

n

e

x

p

e

n

o

t

h

s

e

r

it

e

m

•

Starter batteries

•

Laminated glass windscreens

•

Airbags and belt tensioner

(not fired)

Brake fluid

•

Coolant

•

Shock absorbers

•

Plastic bumpers

•

Radiator grilles

•

Plastic fuel tanks

•

Wheel housing liners

•

Wheel covers

•

Lock carriers/subframes

•

Old tyres

•

SSP 201_013

SSP 201_009

9

Page 10

Body

Development

of the safety bodyshell

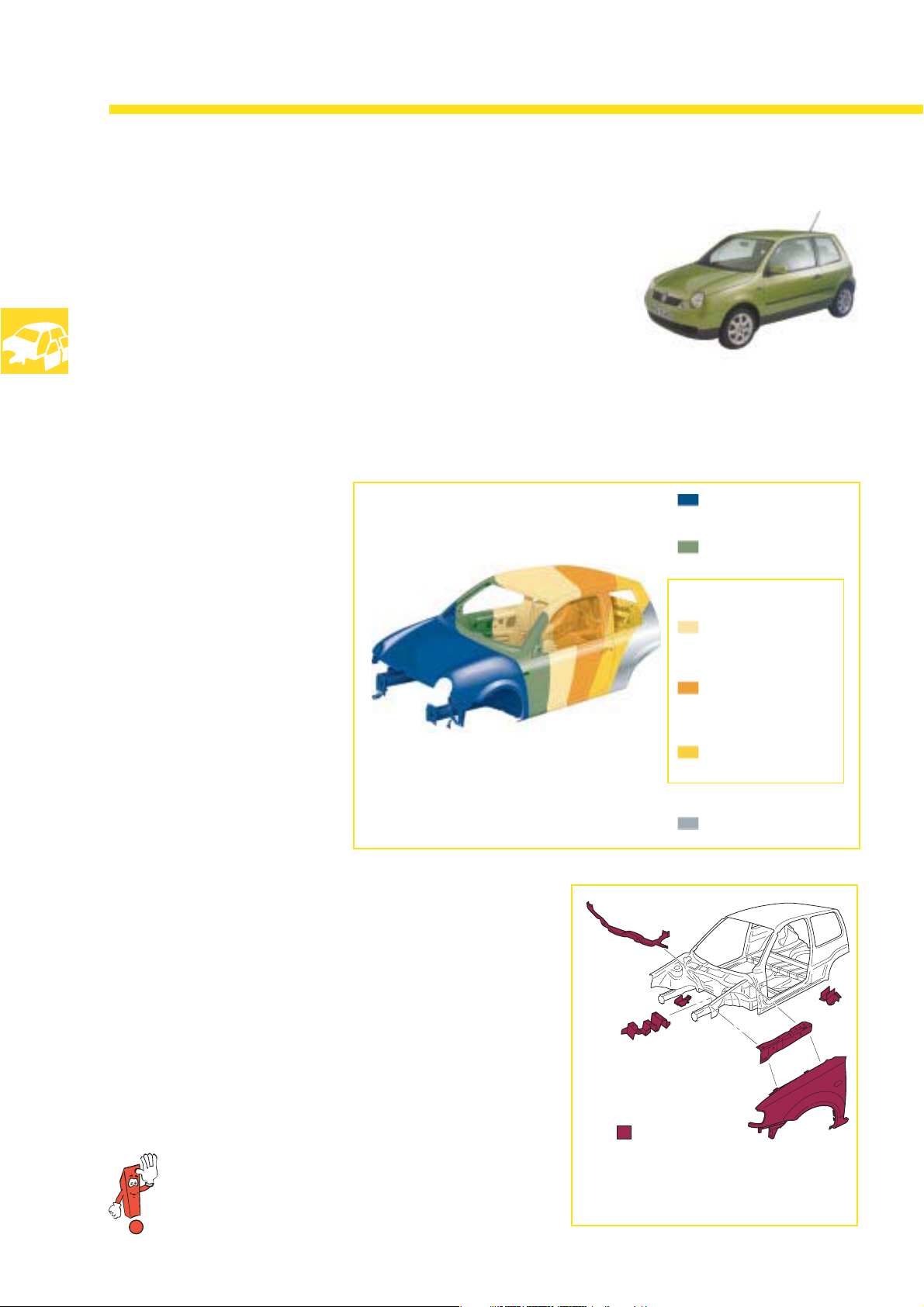

The blueprint for development of the

LUPO's body was the Polo ‘95.

A key development goal was to design a body

whose occupant cell offers a high level of

dimensional stability in crash situations.

During a head-on collision,

the impact energy is absorbed

via 2 crash planes:

SSP 201_021

In the 1st crash plane, the side re-inforcement in

the doors located directly behind the bumper

cover, transmits the impact energy to the side

members. The energy is then distributed evenly

to the centre tunnel and re-inforced side

members.

In the 2nd crash plane, the wheelhouse side

members transfer the impact energy via the door

re-inforcements to the rear end.

In the event of a rear collision,

the side re-inforcement in the doors behind the

bumper cover transmits the force to the side

members.

The body side panel which is almost fully

enclosed on the inside helps to absorb more

energy.

= 1st crash plane

= 2nd crash plane

SSP 201_046

10

= 1st crash plane

= 2nd crash plane

SSP 201_046

Page 11

In the event of a side impact,

the re-inforced A- and B-pillars, the strong side

members and the almost fully integrated inner

panel of the door minimise deformation of the

occupant cell.

The side impact re-inforcement in

the door, the door-glass channel reinforcement and the intermediate

padding produce an optimal barrier

against the force of impact.

Door-glass

channel re-

inforcement

SSP 201_024

The closed door is securely

anchored to the side member by

means of a bracket on the

underside. During a side impact, it

prevent the door from intruding into

the occupant cell.

Padding

Side

impact

reinforce

ment in

the door

Bolt-on

bracket

Plastic guide

SSP 201_026

SSP 201_025

11

Page 12

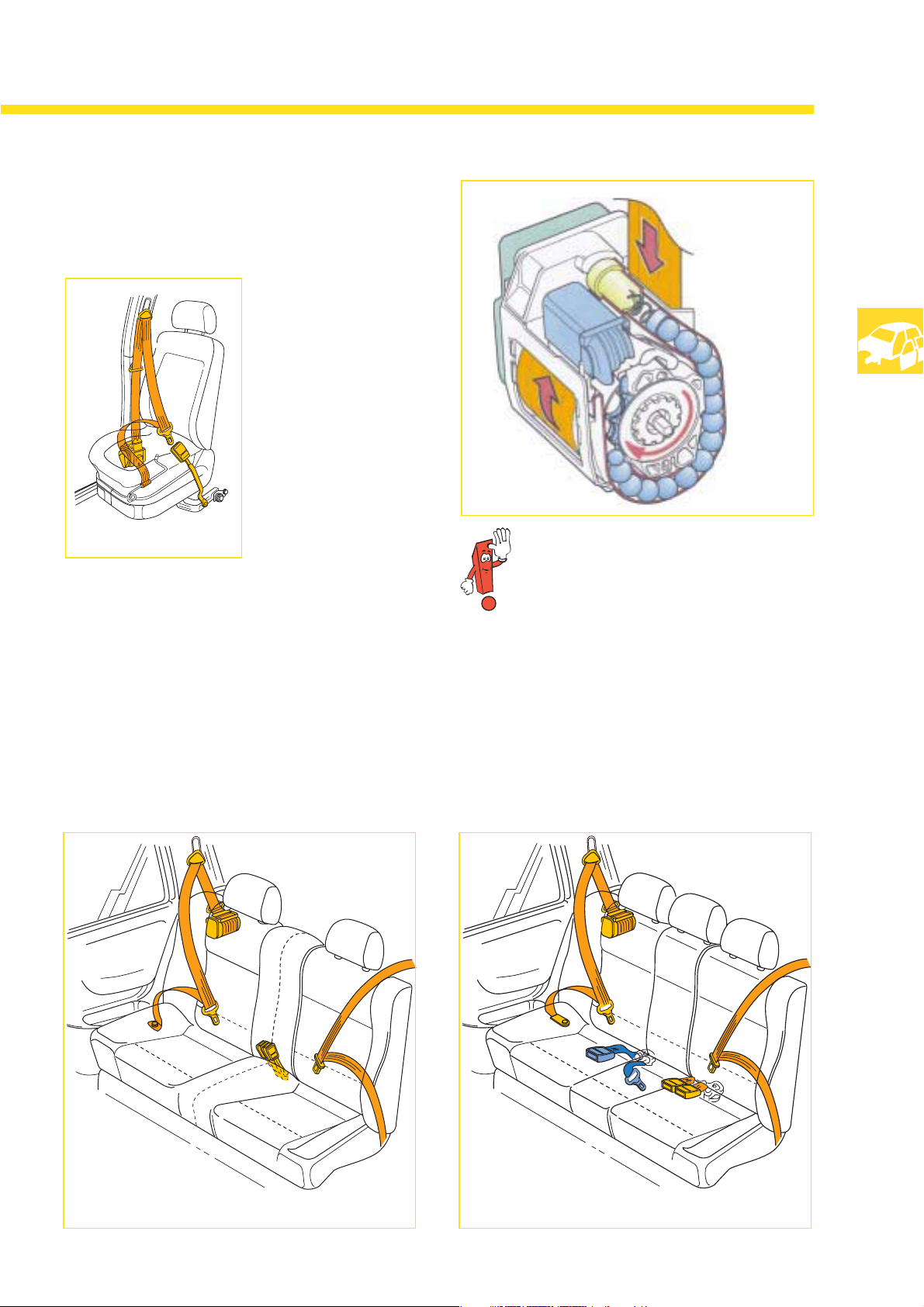

Body

The body of the

LUPO has

features which surpass the norm for this class:

-

Long-term corrosion protection

-

Fully-galvanised body

Crash performance in acordance with VW's

-

safety standard

Modular design

-

Narrow ioints

-

Paintwork structure

and corrosion protection

Environmentally friendly, waterdilutable paints are:

The cathodic cataphoresis,

-

filler, top coat (met. base

coat,

solid base coat )

Galvanised sheet steelLegend:

Zinc phosphatisation

Water based

Cathodic

immersion

cataphoresis

Filler coat

All outer panel are

-

electroplated.

All inner panels are hot-dip

-

galvanised.

SSP 201_027

High-strength body panels

are also used in the LUPO.

They are not as thick as conventional body panels and, as a

result, weigh less but are stronger.

High-strength body panels have the task of absorbing and

distributing energy during a crash in a more controlled

manner.

They absorb vibrations at the rear axle mount.

You can find detailed information regarding

high-strength sheet-metal panels in Self-Study

Programme No. 200.

Top coat

Clear coat

High-strength body

panels

SSP 201_028

12

Page 13

F

Bitumen-based heat-shrinkable and adhesive

foils of various thickness as well as felt parts and

carpeting are used for soundproofing purposes.

The adhesive foils absorb the vibrations which

occur in various areas of the body. Felt parts

absorb noise by interrupting the sound wave.

The Isofix child safety seat fastening

is fitted in the LUPO as standard.

There are 4 retaining eyelets below the rear

seats, which make it possible to install two child

safety seats with the Isofix fastening system. The

retaining eyelets are welded to the floorpan

assembly and hold the child safety seat securely

during a crash.

F

B

FBFelt parts

Heat-shrinkable/

adhesive foils

B

B

F

SSP 201_029

The electric fabric sliding roof

In addition to the electrically-operated glass

sliding/tilting roof, an electrically-operated

fabric sliding roof is also available for the LUPO.

The roof spoiler allows the vehicle to be driven

without any draught and quietly with the sunroof

open, even at high speed.

The electric fabric sliding roof is identical

to the sunroof used in Polo model ‘95.

SSP 201_030

Fabric sliding roof

Sunroof opening

Roof spoiler

SSP 201_031

13

Page 14

Body

The front and rear bumpers

comprise a side re-inforcement in the doors and

a bumper cover.

Front

The front bumper cover

comprises 2 components

The front and rear bumper covers are capable of

absorbing impact energy at speeds of up to 4

kph without damage.

Higher impact speeds of up to approx. 15 kph

are absorbed by the side re-inforcement in the

doors without deformation of the side members.

The side members only become deformed as a

result of a severe impact.

Side re-inforcement in

the doors

The upper section is painted

in the body

colour

Rear

Side re-

inforcement in the

doors

SSP 201_032

Bumper

cover

14

SSP 201_034

Page 15

The restraint system

and the airbags

Seat belts

Front:

They have ball-type

tensioners which are

fired both

mechanically and

pyrotechnically.

SSP 201_171

SSP 201_170

For more detailled information on the belt

tensioners, please refer to

Self-Study Programme No. 192.

3-point seat belt concepts for the rear seats

Standard equipment The 5-seater version is also equipped with a lap

belt for the middle seat.

SSP 201_173SSP 201_172

15

Page 16

Body

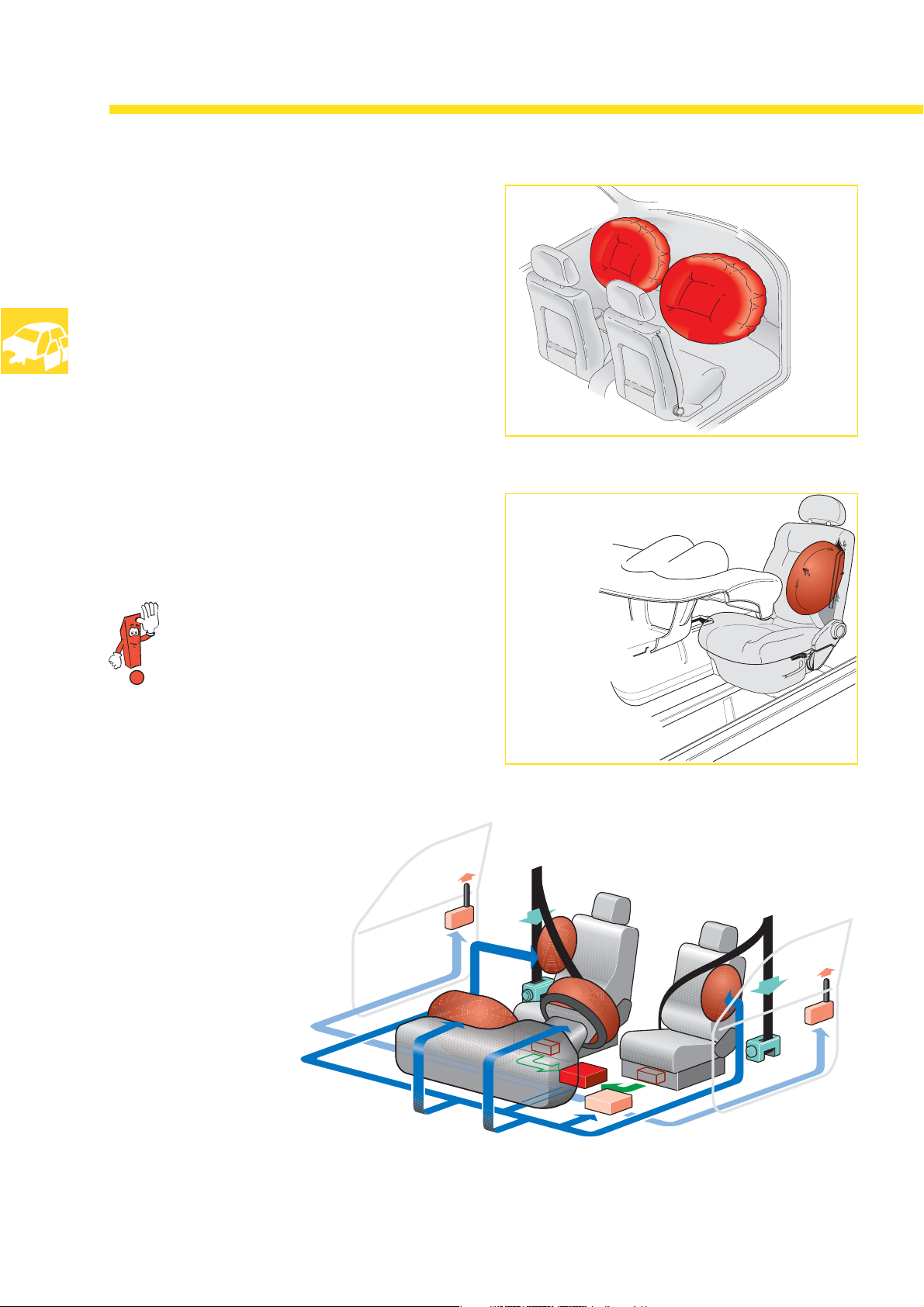

The front airbags

have a volume of 57 litres for male/female

drivers

and a volume of 95 litres for the front passenger.

At production launch, a 120-litre front

passenger's airbag will be used. It will be

identical to the airbag used in the Golf ’98.

The 120-ltr. front passenger's airbag cannot be

replaced by the 95-ltr. airbag, therefore it can

only be replaced in accordance with the original

equipment level.

The side airbags

SSP 201_174

have a volume of 12 litres.

All gas generators contain acid-free propellant.

The function of the restraint system

during severe accidents

The restraint system prevents

contact occurring between the

shoulder and head area with

the steering wheel or dash

panel insert.

SSP 201_175

16

Once the firing threshold

is attained, the airbag

control unit transmits the

"Open central locking (CLS)" signal

to the CLS control unit.

SSP 201_176

Page 17

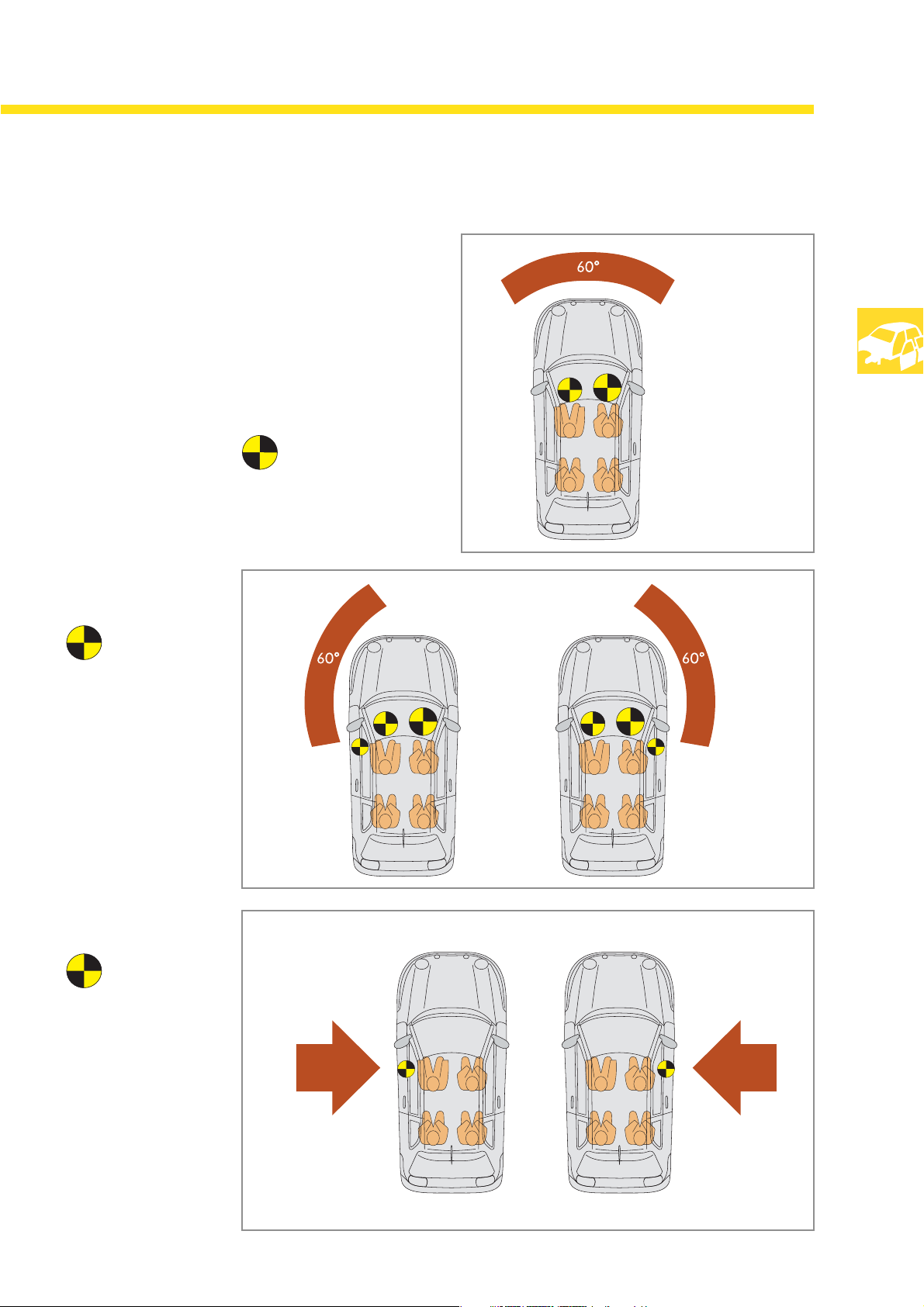

The airbag system

As of a defined degree of accident severity and

the

the associated delay period, the appropriate

airbags are triggered depending on the impact

side and the angle of impact.

Head-on collision

The driver's and front

passenger's airbags

are triggered.

Side/head-on

collision

SSP 201_102

The driver's, front

passenger's and side

airbags are triggered.

Side impact

Only the side airbag

which is actually

required to protection

the vehicle's

occupants is triggered.

This considerably

reduces repair costs

after an accident.

SSP 201_103

SSP 201_104

17

Page 18

Engines

The engine-gearbox combination

Engines Gearbox

1.0-ltr.

37 kW petrol engine with camshaft in block

1.4-ltr.

16V 55 kW petrol engine

5-speed

manual

gearbox

085

4-speed

automatic

gearbox

001

5-speed

manual

gearbox

002

18

1.4-ltr.

16V 74 kW petrol engine

1.7-ltr.

44 kW SDI engine

1.0-ltr.

37 kW rocker lever petrol engine

Page 19

The 1.0-ltr. 37 kW petrol engine

is an advanced version of the proven 1.0-ltr.

aluminium engine with the camshaft in block

SSP 201_038

Features of the engine mechanicals are:

Aluminium cylinder crankcase with press-fitted

•

cast iron cylinder liners

Cylinder head with single overhead camshaft•

Bucket tappets with hydraulic adjusters•

Features of the engine management system

are:

Motronic MP 9.0 (refer to Self-Study

•

Programme No. 168)

Sequential injection•

Rotating ignition voltage distribution•

Selective knock control•

Conforms to exhaust emission standards EU III

•

and D3

Power output

crankshaft

80

70

60

40 120

30

20

10

0

1000 3000 5000

0

2000 4000 6000

Engine speed rpm

Torque

Nm

200

180

160

14050

100

80

60

40

SSP 201_041

Specifications

Engine code “ALL“

4-cylinder inline engine

Valves per cylinder 2:

Displacement

Bore 70.6 mm

Stroke 67.1 mm

Compression ratio 10.5 : 1

Max. output 37 kW

:

:

:

:

:

999 cm

3

at 5000 rpm

Max. torque 86 Nm at

:

3000 to 3600 rpm

Engine management Bosch Motronic

:

MP 9.0

Fuel type unleaded 95 RON

:

Knock control allows the engine to be operated

alternatively with unleaded 91 RON fuel but with

a slight reduction in power output and torque.

19

Page 20

Engines

The new engine generation:

Overview

The 1.4-ltr. engines described on the

following pages belong to a new generation

of petrol engines.

All have:

a new cylinder head with valve activtion

•

via roller cam follower

Aluminium cylinder block•

•

An engine speed sensor which is

integrated in the flange for the crankshaft

sealing ring at the flywheel end

static high-voltage distribution•

All conform to

exhaust emission standards EU III

and D3.

Cylinder head

The camshafts are mounted in the

camshaft housing. The camshaft housing

also acts as the valve cover.

SSP 201_049

SSP 201_044

Camshaft

Roller cam follower

20

The valves and hydraulic support elements

are fitted in the cylinder head.

The roller cam follower engages in the

support element and abut the end of the

valve stem.

Illustration of the 16V engine

Camshaft

Hydraulic

support

element

SSP 201_050

Page 21

Valve activation

by roller cam follower

Conventional cam follower

The roller cam follower

Slip face

Counterbearing

(adjustable)

SSP 201_052

Roller running

in needle

bearings

The cam glides over the slip face of the cam

follower. As a result, high friction losses occur

and the cam follower is subjected to mechanical

stress.

Valve clearance is adjusted manually via the

adjustable counter-bearing.

The roller cam follower (depressed)

Hydraulic

support

element

SSP 201_053 SSP 201_054

The cam of the roller cam follower rolls off a

roller running in needle bearings.

The cam stroke is transmitted to the valve stem

with minimal friction loss.

Oil duct

The hydraulic support element replaces the

manually adjustable counter-bearing. It acts as

the pivot for the roller cam follower and assumes

the task of automatic valve clearance adjustment.

Lubrication and filling are performed via an oil

channel in the cylinder head.

For more detailled information, please

refer to Self-Study Programme No. 196.

21

Page 22

Drive units

The 1.4-ltr. 16V 55 kW petrol engine

SSP 201_043

Features of the engine mechanicals:

Aluminium cylinder crankcase•

Press-fitted cast iron cylinder liners•

Cylinder head with roller cam followers•

Secondary belt drive•

Primary catalytic converter integrated in the

•

exhaust manifold

Conforms to exhaust emission standards EU III

•

and D3

Power output

kW

80

70

60

40 120

30

20

10

0

1000 3000 5000

0

2000 4000 6000

Engine speed rpm

Torque

Nm

200

180

160

14050

100

80

60

40

SSP 201_045

Specifications

Engine code “AKQ“

4-cylinder inline engine

Valves per cylinder 4:

Displacement

Bore 76.5 mm

Stroke 75.6 mm

Compression

:

1390 cm

:

:

:

10.5 : 1

3

ratio

Max. output 55 kW

:

at 5000 rpm

Max. torque 128 Nm

:

at 3300 rpm

Engine management Magneti Marelli 4AV:

Fuel type unleaded 95 RON

:

22

For more detailed information, please

refer to Self-Study Programme No. 196.

Knock control allows the engine to be operated

alternatively with unleaded 91 RON fuel but with

a slight reduction in power output and torque.

Page 23

The 1.4-ltr. 16V 74 kW petrol engine

The basic engine is the 1.4-ltr.-16V 55 kW petrol

engine.

SSP 201_147

Power output

kW

80

70

Torque

Nm

200

180

The key differences compared to the

1.4-ltr. 16 V 55 kW petrol engine

Stronger pistons•

Cylinder head with larger intake

•

and exhaust ducts

Modified camshaft timing•

Modified intake module•

Modified exhaust system•

Aluminium oil sump for increased rigidity of

•

higher-performance engine

conforms to exhaust emission standards EU III

•

and D3

Specifications

Engine code “ANM“

4-cylinder in-line engine

Valves per cylinder 4:

60

40 120

30

20

10

0

1000 3000 5000

0

2000 4000 6000

Engine speed rpm

For more detailed information, please

refer to Self-Study Programme No. 196.

160

14050

100

80

60

40

SSP 201_048

Displacement

Bore 76.5 mm

Stroke 75.6 mm

Compression ratio 10.5 : 1

Max. output 74 kW

:

1390 cm

:

:

:

:

3

at 6000 rpm

Max. torque 128 Nm

:

at 4500 rpm

Engine management Magneti Marelli 4 AV:

Fuel type unleaded 98 RON

:

The knock control also allows the engine to be

operated alternatively with unleaded 91 RON

fuel with a slight reduction in power output and

torque.

23

Page 24

Drive units

the 1.7-ltr. 44 kW SDI diesel engine

e

h

t

s

i

Features of the engine

mechanicals:

Diesel direct injection engine•

Th

r.

t

l

-

9

.

1

d

e

m

r

e

t

n

i

e

h

t

s

i

h

t

i

w

DI

T

i

t

f

a

h

s

e

t

a

e

n

i

g

n

e

c

i

s

a

b

e

Naturally aspirated engine•

•

Displacement was reduced

to 1.7-ltr. from 1.9-ltr. by

modifying the crankshaft

stroke.

The external crankcase

B

i

t

c

e

j

n

i

p

m

u

p

n

o

r

to

u

b

i

r

t

s

i

d

h

c

s

o

•

breather has been deleted.

•

The gases in the crankcase

are diverted into the intake

duct via the oil return ducts

and the valve cover.

SSP 201_055

•

Two-stage EGR valve for

better metering of the

exhaust gas recirculation

conforms to exhaust emission

•

standards EU III

Power output

kW

80

70

60

40 120

30

20

10

0

1000 3000 5000

0

2000 4000 6000

Engine speed rpm

Torque

Nm

200

180

160

14050

100

80

60

40

Specifications

Engine code “AKU“

4-cylinder inline engine

Valves per cylinder 2:

Displacement 1.7-ltr.

Bore 79.5 mm

Stroke 86.4 mm

Compression ratio 19.5 : 1

Max. output 44 kW

:

:

:

:

:

at 4200 rpm

Max. torque 115 Nm

:

at 2200-3000 rpm

Mixture preparation Bosch distributor

:

injection pump

and electronic control

unit EDC 15

24

SSP 201_057

Fuel type min. 45 CN

:

Page 25

The 1.0-ltr. 37 kW petrol engine

is an improved version of the 1.3-ltr. engine fitted

in the Skoda Felicia.

( for certain markets only )

SSP 201_037

Features of the engine mechanicals are:

The valve is driven via a camshaft in block

•

(ohv), tappets, push rods and rocker levers

The cylinder crankcase is made of die cast

•

aluminium

“wet-type" cast iron cylinder liners •

The crankshaft runs in 3 bearings•

Features of the engine management system

are:

Multipoint injection•

Static high-voltage distribution•

Conforms to exhaust emission standards EU III

•

and D3

Power output

kW

80

70

60

40 120

30

20

10

0

0

1000 3000 5000

For more detailed information, please

refer to Self-Study Programme No. 203.

2000 4000 6000

Engine speed rpm

Torque

Nm

200

180

160

14050

100

80

60

40

SSP 201_039

Specifications

Engine code “AHT“

4-cylinder in-line engine

Valves per cylinder 2:

Displacement

Bore 72 mm

Stroke 61.2 mm

Compression ratio 10 : 1

Max. output 37 kW

:

:

:

:

:

997 cm

3

at 5000 rpm

Max. torque 84 Nm

:

at 3250 rpm

Engine management Siemens Simos 2P:

Fuel type unleaded 95 RON

:

Knock control allows the engine to be operated

alternatively with unleaded 91 RON fuel with a

slight reduction in power output and torque.

25

Page 26

Power transmission

The 5-speed manual gearbox 085

is fitted in petrol engines with overhead camshaft

s

e

t

d

n

a

d

e

i

Tr

n

i

d

e

t

t

i

f

o

s

l

a

synchronisation

1st and 2nd gear

R

u

c

le

e

s

eve

n

to

s

r

n

y

m

r

Po

Double

e

s

ro

h

c

low

e

l

g

-

c

d,

e

t

e

h

t

5

9

˚

o

s

i

r

a

e

d

e

s

i

n

n

tio

o

m

m

is

n

a

h

and in the diesel engine.

The total transmission ratio

matched to the installed

engine version is spread

by means of different gear

ratios and final drive ratios.

The gearbox is assigned to

the engine via the gearbox

code.

The gear selection system

Gear engagement is via a gate selector lever

and gear selector cable.

Gate selector cable

SSP 201_062

Gear selector

cable

26

SSP 201_063

Thanks to the selector cables, the swinging

motion of the engine only has a minimal effect

on the gear lever. As a result, gears can be

selected with greater precision.

Page 27

The 5-speed manual gearbox 002

is exclusive with the 1.0-ltr. rocker lever petrol

engine “AHT“, an improved version of the 1.3-ltr.

engine in the Skoda Felicia.

( for certain markets only )

Technical features:

5-speed manual gearbox•

Reverse gear is

•

unsynchronised

Two-part aluminium

•

gearcase

•

The end cover and the

engine suspension have

been modified.

Common oil filling for

•

gearbox and final drive

Final drive via drive shaft

•

flanges

Trie

d

a

n

d

te

ste

d

g

e

a

rb

ox

a

d

o

p

te

d

fro

m

th

e

C

a

d

d

y

p

icku

p

A gear change

is performed by a selector rod.

SSP 201_060

Selector rod

Guide

Selector

housing

The gear lever is mounted on

two bearing bolts in a guide in

floating configuration. A cable

pull transmits the relative

movement of the engine to the

guide. This reduces oscillation

at the gear lever.

The gears can therefore be

engaged with greater

precision.

Cable pull

SSP 201_061

27

Page 28

Power transmission

The 4-speed automatic gearbox 001

is available for 1.4-ltr. 16V 55 kW petrol engine

e

h

t

s

i

“AKQ“.

P

h

t

n

i

t

c

e

l

E

o

c

d

e

e

p

s

-

4

5

9

'

o

l

Po

e

y

l

l

a

c

i

n

ro

d

e

l

l

ro

t

n

ox

b

r

a

e

g

d

e

t

t

i

f

o

s

l

a

y

l

s

u

o

i

rev

Gear selection

The individual drive positions, the parking lock

and neutral are selected mechanically with the

gate selector lever.

SSP 201_064

Technical features:

Ravigneaux planetary gear•

•

Torque converter

with integrated lock-up

clutch

•

Solenoid valves at the valve

body for electro-hydraulic

control

•

Common oil supply

for planetary gear and

final drive

in out

The control unit records the

incoming sensor signals

during vehicle operation,

evaluates these signals and

activates the individual

solenoid valves.

The integrated dynamic shift

program automatically selects

the "Eco" shift characteristic or

"Sport" shift characteristic.

SSP 201_065

For more detailed information, please refer to in

Self-Study Programme No. 176 “4-speed

Automatic Gearbox 001“ .

28

Page 29

The fuel tank

of the LUPO is located in the crash-protected

area in front of the rear axle.

It has a volume of 35 litres.

Petrol engines

The activated charcoal canister

is located at the front righthand side of the vehicle.

The activated charcoal

absorbs fuel components from

fuel vapours.

Fuel system

P

rove

n

E

le

ctric

in

te

rio

r

ta

n

k p

u

m

p

G

ra

vity

p

re

f va

m

ssu

lve

te

d

ch

a

re

lie

Activa

syste

Quick-release couplings are used

for installing the fuel pipes.

rco

re

a

l ca

n

iste

r

SSP 201_051

Act. char. canister

SSP 201_059

The fuel gauge sender is attached to

the fuel pump housing.

SSP 201_047

Quick-release

couplings

Fuel pump

Sender

Diesel engines

Diesel-engined vehicles do not require a fuel

pump or activated charcoal canister. The fuel

gauge sender, in combination with the intake

manifold

SSP 201_058

for the intake, form a single unit. The fuel pump

is an integral part of the distributor injection

pump.

29

Page 30

Running gear

The running gear

of the LUPO is identical to the Polo’95.

s

le

u

d

o

m

n

sio

n

e

sp

u

S

ro

g

e

th

co

la

u

d

o

m

p

u

To

m

r sy

Fro

s

r

S

p

i

risin

e

t

n

n

o

re

ste

e

t

a

g

m

g

n

i

r

e

l

x

a

m

a

e

b

e

l

x

a

r

The running gear has been adapted to the

LUPO, making allowance for driving safety and

driving comfort.

The following pages will present you

with the following items:

•

The steering

•

The front axle

•

The rear axle

•

The brakes

•

The traction control systems

SSP 201_080

30

Page 31

The steering

comprises a safety steering column which is

height-adjustable and a mechanical steering

gear.

The safety steering column

m

m

9

3

1

5

0

SSP 201_066

S

u

sp

e

n

sio

n

m

o

d

u

le

s

o

d

u

la

r syste

m

g

n

n

i

c

a

l

g

e

a

r

e

e

r

i

n

g

th

co

m

p

risin

g

Pow

g

e

M

s

ro

u

p

m

S

a

fe

ty

ste

e

rin

co

lu

m

e

c

h

a

t

e

e

r

i

n

g

e

r

s

t

a

r

e

G

The safety steering column can be

compressed by up to 150 mm during

m

m

a crash. This reduces the injury risk

for the driver.

Power steering

Depending on performance and wheel size, the

LUPO is equipped with power steering.

The two track rods for

power steering and

mechanical steering

are adjustable.

SSP 201_067

31

Page 32

Running gear

The front axle of the LUPO

comprises suspension struts and wishbones. The

suspension struts are bolted to the wheel bearing

housing and the wishbones are bolted to the

subframe by rubber mountings.

e

th

m

o

s fr

le

u

d

o

m

n

sio

n

e

sp

u

S

u

ro

G

Wh

la

u

d

o

m

p

s

n

e

p

s

u

S

s

ra

f

b

u

S

a

e

b

l

e

e

o

h

m

ste

r sy

n

o

i

t

u

r

t

e

m

g

n

i

r

g

n

i

s

u

For more detailed information regarding this axle

in respect of castor, shock absorption

characteristics and the track-stabilising kingpin

offset, please refer to Self-Study Programme No.

166.

32

SSP 201_068

The Lupo with power

steering has an antiroll bar on the front

axle.

Anti-roll bar

SSP 201_069

Page 33

The rear axle

is a torsion beam axle.

S

co

Th

u

sp

e

n

sio

n

m

o

d

u

le

m

p

risin

g

G

ro

u

p

m

e

s

o

d

u

la

r syste

m

Toe and camber design are defined by design

and are non-adjustable. For vehicle alignment,

the ascertained values can only be compared

with the nominal values in the Workshop

Manual.

Shock absorbers

SSP 201_070

To

rsio

n

b

e

e

r a

e

a

x

le

n

d

e

l b

e

a

rin

ra

tio

n

re

a

S

e

co

w

h

g

e

n

Springs and dampers

are positioned separately.

m

-

g

SSP 201_072

SSP 201_083

The bonded rubber bushes of the rear axle

have been fitted rotated through 45°.

This reduces noise transmission from the

road to the body.

33

Page 34

Th

e

Running gear

The brake system

The standard equipment comprises:

rd

a

d

n

sta

re

s a

m

ite

g

in

llow

fo

e

t

n

e

m

ip

u

q

ll ve

a

in

ra

b

s:

icle

h

l

a

n

o

g

a

i

D

u

d

k

ra

b

ra

B

d

-

d

a

Lo

re

u

s

s

re

p

e

k

t

i

l

p

s

t

i

u

rc

i

c

-

l

a

m

e

t

s

y

s

e

vo

r

e

s

e

k

t

n

e

d

n

e

p

e

re

r

to

a

l

u

g

ventilated front disc brakes•

self-adjusting rear drum brakes•

For added active safety, the anti-lock braking

system ITT Mark 20 IE is available with electronic

brake pressure distributor.

34

SSP 201_073

Page 35

The front brakes

Ventilated

disc brakes

up to 55 kW

dia. 239 mm x 18 mm

SSP 201_074

as of 74 kW

dia. 256 mm x 20 mm

SSP 201_071

The rear brakes

Drum brakes to 55 kW Disc brakes for 74 kW and above

dia. 180 x 30 mm

without ABS

dia. 200 x 40 mm

with ABS

SSP 201_075 SSP 201_076

dia. 232 x 9 mm

Alu. sliding caliper

35

Page 36

Running gear

The

ElectronicStabilityBrakeSystem

improves track stability and steerability when the

vehicle is being braked by activating the brakes

selectively.

ESBS is an improved software in the

ITT Mark 20 IE control unit.

It utilises the sensors and actuators from the antilock braking system system.

SSP 201_077

SSP 201_078

Understeer

If a vehicle is braked heavily in a corner, the

wheel location forces acting on the front wheels

are reduced.

As the vehicle has forwards momentum, its

pushes towards the outer edge of the corner

over the front axle.

This driving situation is termed “understeer“.

In vehicles with ESBS, the ABS control unit

recognises this driving situation and responds by

altering the speeds of the individual wheels as

appropriate.

The anti-lock braking system reduces the brake

pressure applied to the front axle. This increases

the wheel location forces and the vehicle retains

its directional stability.

36

SSP 201_079

Page 37

SSP 201_081

Oversteer

If the vehicle is steered into a corner too sharply

at high speed and if the brakes are applied

heavily, the rear will break away towards the

outer edge of the corner.

This driving situation is referred to as “oversteer“.

The ABS control unit recognises this situation and

responds by reducing the speed of the rear

wheels and reducing the brake pressure applied

to the wheels on the inside of the corner. This

increases the wheel traction forces acting on the

wheels on the inside of the corner and the vehicle

rear end retains its directional stability.

SSP 201_082

Malfunctioning of the ESBS can neither be

diagnosed nor repaired, because a vehicle's

driving dynamics cannot be reproduced with

workshop facilities.

37

Page 38

Electrical system

Decentralised vehicle electrical

system

The layout of the electrical system is

decentralised, i.e. the basic component parts of

the electrical system are located at different

fitting locations.

The main components are:

Main fuse box at the battery•

•

Relay carrier, coupling station, potential

distributor and fuse holder behind the dash

panel insert

Coupling station at A-pillar,

•

left and right

Vehicle-specific wiring harness•

Diagnosis plug•

Coupling station

A-pillar

Main fuse box

Diagnosis plug

Coupling station at A-pillar

Fuse holder

Relay

carrier

Battery

38

Bracket at en-gine

bulkhead

Pot. distributor

Coupling station

SSP 201_095

Page 39

The components of the

decentralised vehicle electrical

system

SSP 201_090

Main fuse box

Here, the electrical system is protected by fuses

directly behind the battery.

•

The alternator, cabin power supply, glow plug

system and the air conditioning system are

protected by metal fuses.

The ABS system and the radiator fan are

•

protected by micro-fuses (Little Fuse).

In the current flow diagram, the fuses positioned

here have the code designation “SA“.

100 19

1515153015151515151515151515303020

167

100 19

1515153015151515151515151515303020

Relay carrier

167

Used for mounting the relays for standard

equipment and optional extras.The relay carrier

is fixed by two retaining lugs.

SSP 201_091

Coupling station below relay carrier

The connections to the vehicle electrical system

are made in the coupling station by means of

colour-coded and mechanically coded

connectors (e.g. engine compartment, dash

panel insert). The potential distributor is located

on the left next to the coupling station (threaded

terminal, terminal 30).

SSP 201_092

39

Page 40

Electrical system

The components of the

decentralised vehicle electrical

system

Fuse-holder

100 19

1515153015151515151515151515303020

167

Two different fuses are used to protect the

electrical circuit.

Mini-fuse rated for max. 15A-

Micro-fuse (Little Fuse) rated for over 15 A-

SSP 201_093

This combination offers the following

advantages:

More fuses within the same construction space-

More electrical circuits protected by individual

-

fuses

In the current flow diagram, the fuses positioned

here have the code designation “SB“.

SSP 201_097

SSP 201_087

Coupling station at A-pillar

The connections to the doors, e.g. loudspeakers,

central locking and power windows, are located

in this coupling station.

Diagnosis plug

Fitting location: in dash panel insert, behind

oddments tray.

40

Page 41

The fitting locations of the control

units

Airbag control unit

on gearbox tunnel

Engine control unit

Automatic gearbox

control unit

ABS control

unit

Control unit for

radiator fan

Control unit for

central locking/above

relay carrier

Control unit for

immobiliser/above fuseholder

SSP 201_094

41

Page 42

Electrical system

The dash panel insert

The distinctive design of the dash panel insert

comprises two instrument clusters.

The rev counter comprising:

- Fuel indicator

The speedometer comprising:

- Odometer and trip recorder

9

8

0

1_

0

2

P

S

S

- Coolant temperature display

- Digital clock

- and warning lamps

40

30

20

50

60

10

0

Setting buttons for digital clock Reset button for trip recorder and

- Service Interval Display

- Indicator

- and warning lamps

70

SSP 201_098

Service Interval Display

42

Technical features:

•

LEDs are used exclusively for illumination and

as warning lamps.

Blue instrument lighting with luminous red

•

pointers.

•

The analogue displays (rev counter, speedometer, fuel gauge and coolant temperature)

are activated by stepping motors with

software-controlled damping.

Connected to vehicle electrical system by

•

means of a 32-pin connector.

The same version of the dash panel insert is

•

used for all model variants.

The Lupo has the same self-diagnosis (address

•

word 17) as in the Polo ‘98.

Page 43

The immobiliser

The immobiliser has a separate control unit

which is equivalent to the 2nd generation in

design and function and comprises an additional

variable code. The control unit is behind the dash

panel insert via the fuse holder.

The self-diagnosis function (address word 25) is

identical to the POLO ‘98.

Functional description:

After turning on the ignition, the transponder

transmits a fixed code via the reader coil to the

immobiliser control unit. If this code matches the

code stored in the immobiliser control unit, a

random number generator generates a variable

code. This variable code is transmitted to the

transponder in the car key fob. A secret

arithmetic operation is now started in the

transponder and in the immobiliser control unit.

The transponder transmits its result to the

immobiliser control unit which recognises the

correct car key by comparing this result with its

own result.

A variable code is then cross-checked between

the immobiliser control unit and engine control

unit. Once a match has been established, the

vehicle is ready for operation.

Engine control unit

Transponder

Reader coil

Immobiliser control unit

SSP 201_099

43

Page 44

Electrical system

The central locking system

In vehicles that are also equipped with power

windows, a control unit is integrated in the

The central locking system, in combination with

manual window lifters, is available as an

optional extra. The motors for central locking are

activated directly by the central control unit.

window lifter motor for operation and force

limitation. With this version also, the motors for

the central locking and window lifters are

activated directly by the central control unit.

The central locking comprises the following

functions:

•

Electric motor operated central locking

system with SAFE function for locking the

doors and tailgate.

Doors are locked and unlocked with interior

•

•

Convenience opening of the power windows

as well as convenience locking of the window

lifters and sliding/tilting roof is possible via

the door lock cylinder.

Self-diagnostic capability (address word 35).•

Lock - Unlock button

Interior light and boot light control.• Anti-theft warning system with radio-wave

•

remote control as an option

•

The airbag control unit unlocks the doors if it

recognises that the vehicle has been involved

in a crash.

Window lifter motor

and control unit

Contact switch for antitheft warning system

(option)

Tailgate actuator motor

Alarm signal horn

(option)

Window lifter motor with

control unit

Operating unit

Central module

SSP 201_096

44

Page 45

Radio generation ‘99

The

BETA

and

GAMMA

fundamentally revised from a technical

viewpoint and their design has been updated.

The alpha radio system is available with

unchanged technology and design.

.

radio systems have been

Control panel

The figures show the user interface of the

and

GAMMA

radio systems with removable

control panel.

Radio system

BETA

Radio system

GAMMA

BETA

SSP 201_124

SSP 201_118

The main new features of the

and

GAMMA

Display lighting in blue, button and

•

radio systems are:

buttons backlit in red.

•

Optionally available with

permanent or removable control

panel.

BETA

SSP 201_119

•

New menu adjustments,

e.g. balance or bass, and on-screen

menu assistance are possible.

•

The convenience anti-theft device

saves recoding the radio system,

e.g. after cutting off the power

supply for servicing.

Self-diagnostic capability•

45

Page 46

Electrical system

The

BETA

radio system

The new functional features are:

30-station memory•

•

The loudspeaker balance on the left and

right can be adjusted with the BAL (Balance)

button.

SSSSpeed-dependent volume adaption /

•

AA

GGGGAAAALLLLAA

Prepared for connecting CD changer •

•

Playback of calling or called party through

all loudspeakers while conducting a

telephone call.

Slider for removing the

control panel

The convenience anti-theft device

To commission the radio, the four-digit code

number of the electronic anti-theft device must

be entered.

When the NO contact is closed, a

communication link is established between the

radio and the dash panel insert via the selfdiagnosis wire (K wire).

If the supply is cut off, e.g. to carry out work on

the electrical system, the radio checks whether

the dash panel insert is the same as before

voltage cut-off after inserting the ignition key and

turning on the ignition.

SSP 201_127

If the radio recognises the dash panel insert, the

radio is again ready for operation without having

to reenter the four-digit code number a delay of

several seconds.

However, if the radio is fitted in another vehicle,

the four-digit code number must be re-entered.

46

Page 47

The

GAMMA

radio system

offers the following new features in addition to

the functional features of the

BETA

:

•

If the vehicle has a Highline dash panel

insert, the frequency and the station name

are displayed.

The above-specified combination is currently not

available for the LUPO.

•

With the TIM function, up to 9 traffic

announcements of a selected TP station can

be recorded automatically.

Max. total duration is 4 minutes.

When the radio is on, every traffic information

message is recorded as soon as TP appears in

the display. When the radio is off, record

mode can be activated by briefly pressing the

TIM button. The memory automatically stores

traffic information messages for a 24-hour

period.

Once this period of time has elapsed or when

the radio is switched on, the standby function

ends.

•

Due to programme content, e.g. classical

music or rock music, the various stations have

a different basic volume.

The radio adjusts the basic volume by

automatically adapting the volume, provided

that the stations have been programmed in

the station keys.

For more detailed information regarding the

subject of Radio Reception/Basics, please refer to

Self-Study Programme No. 147 “Radio Systems

´94“.

The CD player

The new CD player can be

combined with the

and

GAMMA

radio

BETA

systems.

The fitting location is

above or below the radio,

SELECT

depending on the vehicle

model.

To select CD player mode and

CD changer mode

The CD player can play back one music CD at a

time. The CD player is operated by means of the

radio buttons.

CD

CD IN

CD eject buttonSELECT button

CD CHANGERCD PLAYER

CD

SSP 201_125

The CD player can also be combined with a 6disc CD changer which has been optimised in

size.

47

Page 48

Heating, air conditioning

For heater and air conditioner operation in the

LUPO, two equipment variants are available:

a heater or-

a manually operated

heater and air conditioner

Heater

As in other models, too, fresh air/air

recirculation mode is possible for added

comfort.

Air recirculation mode can be switched on

and off with the air recirculation button

Air recirculation mode is switched off

automatically when the rotary switch for air

distribution is set to "Defrost".

The depressed air recirculation button

is released mechanically.

This keeps any moist cabin air, e.g. due to

wet clothing, away from windscreen.

Manual air conditioner

In the case of the manual air conditioning

system, the driver or front passenger

controls the interior climate. Air conditioning

mode can be switched on or off by pressing

the AC button (Air Conditioning).

SSP 201_106

SSP 201_107

48

The fresh air/air recirculation flap

isoperated by electric motor. All other flaps

are activated via Bowden cables.

An electronic high pressure sender

records the overall refrigerant pressure

curve.

SSP 201_108

SSP 201_109

Page 49

High pressure sender G65

is integrated in the high-pressure pipe of the

refrigerant circuit.

It records the refrigerant pressure and transduces

the physical quantity of "pressure" into an

electrical signal.

It is an electronic pressure sensor which replaces

the air conditioner pressure switch F 129 used

previously.

Unlike the pressure switch for the air

conditioning system, not only the defined

pressure thresholds but also the overall pressure

characteristic of the refrigerant are recorded.

SSP 201_110

The high pressure sender is currently fitted in

petrol-engined vehicles with air conditioning

system.

Signal utilisation:

By evaluating the signal, the engine control unit

and the radiator fan control unit recognise the

load which the air conditioner compressor exerts

on the engine.

Signal failure:

If the radiator fan control unit does not detect a

pressure signal, the air conditioner compressor is

switched off.

Self-diagnosis “fault message“:

Plus-points:

-

In idling mode, engine speed can be

adapted exactly to the power consumption of

the air conditioner compressor.

-

The cut-in and cut-out cycles of the radiator

fan settings are staggered by a short delay

time. This ensures that the speed variations of

the cooling fan are barely perceptible in

idling mode and enhances comfort

particularly in vehicles with less powerful

engines.

The high pressure sender is stored in the fault

memory of the engine electronics.

e.g.: 00819 high pressure sender G65

“Signal too low“

49

Page 50

Heating, air conditioning

Function of the high pressure sender

The refrigerant pressure is sent to a silicon

crystal. A characteristic of this silicon crystal is

that its electrical resistance changes as soon as it

is “bent“. This is dependent on pressure level and

curve.

At low pressurea

If the crystal is only “bent“

minimally, the resistance change

is equally as a small as the

voltage change.

The silicon crystal, together with a

microprocessor, is integrated in the sensor and

supplied with voltage.

Changes in the resistance of the silicon crystal

and the resulting voltage changes in the crystal

are processed by the microprocessor and

converted into a pulse-width modulated output

signal (PWM).

Low pressure

Silicon crystal

(resistance)

Pulse-width modulated signal (PWM)

The pulse-width modulated signals are

generated at a frequency of 50 Hz.

This results in a period duration

of 20 ms, which is equivalent to 100%.

The pulse width at a low pressure of

1.4 bar is 2.6 ms. This is equivalent to 13% of the

period duration.

Voltage

Microprocessor

Pulse-width modulated

signal

SSP 201_111

Period duration

20 ms ≈ 100%

Pulse width

2.6 ms

Low pressure

13% ≈ 1.4 bar

SSP 201_113

50

Page 51

At high (rising) pressure

is the crystal thickness “bent“.

The resistance increases in

direct proportion to the

voltage change.

Pulse-width modulated signal (PWM)

High pressure

Silicon crystal

(resistance)

Voltage

Microprocessor

Pulse-width modulated

signal

SSP 201_112

The pulse width increases in direct proportion to

increasing pressure.

The pulse width at a high pressure of 37 bar is

18 ms.

This is equivalent to 90% the period duration.

Period duration

20 ms ≈ 100%

Pulse width

18 ms

High pressure

90% ≈ 37 bar

SSP 201_114

51

Page 52

Heating, air conditioning system

Radiator control unit J293

has been improved technically, and its function

has been adapted to the new high pressure

sender G65.

It will be fitted with the high pressure sender, and

its distinguishing design features are its modified

plug connections.

The functions are:

SSP 201_121

-

Activating/de-activating the next higher

radiator fan setting and the solenoid

coupling of the air conditioner compressor

-

Monitoring the overall pressure

characteristic of the refrigerant by evaluating

the pulse-width modulated signal (PWM)

from the high pressure sender

-

Bi-directional signal exchange with

the engine and gearbox control unit

Test function:

The control unit currently does not have selfdiagnostic capability. For details of test

possibilities, please refer to the current

Workshop Manual on the "Heating/air

conditioning system".

52

Page 53

System overview

Switch for

A/C system

E 35

Ambient

temperature

switch

F 38

Gearbox control unit

J . . .

Engine ctrl unit

J . . .

Radiator fan

control unit

J 293

High press.

sender

G 65

Radiator fan

V 7

Solenoid coupling

N 25

Thermoswitch for

radiator fan

F 18

SSP 201_116

53

Page 54

Heating, air conditioning system

Functional diagram

A/+

F18

V7

E9

1234

0

SA4 SB27SA8SA7

J 293

N25

SB48

F38

E35

G65

Engine control unit

engine control unit

Gearbox control unit

V2

N 24

SSP 201_117

54

Colour

codes:

Components

Battery positive terminalA/+

Switch for fresh air blowerE 9

Switch for air conditioning systemE 35

Thermoswitch for radiator fanF 18

Ambient temperature switchF 38

High pressure senderG 65

Radiator fan control unitJ 293

N 24

Series resistor for fresh air blower

with safety thermal cut-out

Input signal

Output signal

SB 27

SA 4

SA 8

SA 7

SB 48

V 2

Positive

terminal

Earth

Solenoid couplingN25

Fuse in

fuse holder/relay board

Fuse in

fuse holder/battery

Fuse in

fuse holder/battery

Fuse in

fuse holder/battery

Fuse in

fuse holder/relay board

Fresh air blower

Cooling fanV 7

Bidirectional

PWM signal

Page 55

Here you can see the new

special tools and workshop

equipment

LLLLaaaasssshhhhiiiinnnngggg ssssttttrrrraaaapppp set (2 pcs.)

T 100 38

Service

SSP 201_192

Application Before removing the rear axle, the Lupo must be

lashed to the support arms of the lifting platform.

For this purpose, the plugs must first be removed from the side

members. The lashing straps on the left and right must then be

fed through the holes in the side members and lashed securely.

If the vehicle is not lashed securely, there is the danger

that the vehicle will slide off the lifting platform

because the front end of the vehicle bears most of the

weight.

SSP 201_193

55

Page 56

Service.

201

For internal use only. © VOLKSWAGEN AG, Wolfsburg

All rights reserved. Technical specifications subject to change without notice.

740.2810.15.00 Technical status: 08/97

! This paper is produced from

non-chlorine-bleached pulp.

Loading...

Loading...