Page 1

Page 2

Page 3

Page 4

Page 5

HES Series Service Manual

Table Of Contents

Models HES-20, HES-30 & HES-40

Page No.

1. INTRODUCTION

A Brief History of Our Company ................................................................................................................ 1-1

®

Vogt Energy-Saving Tube-Ice

Preview .................................................................................................................................................... 1-1

Important Safety Notice............................................................................................................................... 1-2

Special precautions to be observed when charging refrigeration systems ................................................... 1-2

Safety Symbols & What They Mean ........................................................................................................... 1-3

2. RECEIPT OF YOUR TUBE-ICE® MACHINE

Inspection ................................................................................................................................................... 2-1

Machines................................................................................................... 1-1

TABLE OF CONTENTS

i

Safety Valves............................................................................................................................................... 2-2

Machine Room ............................................................................................................................................ 2-2

Storage .................................................................................................................................................... 2-2

3. HOW YOUR TUBE-ICE® MACHINE WORKS

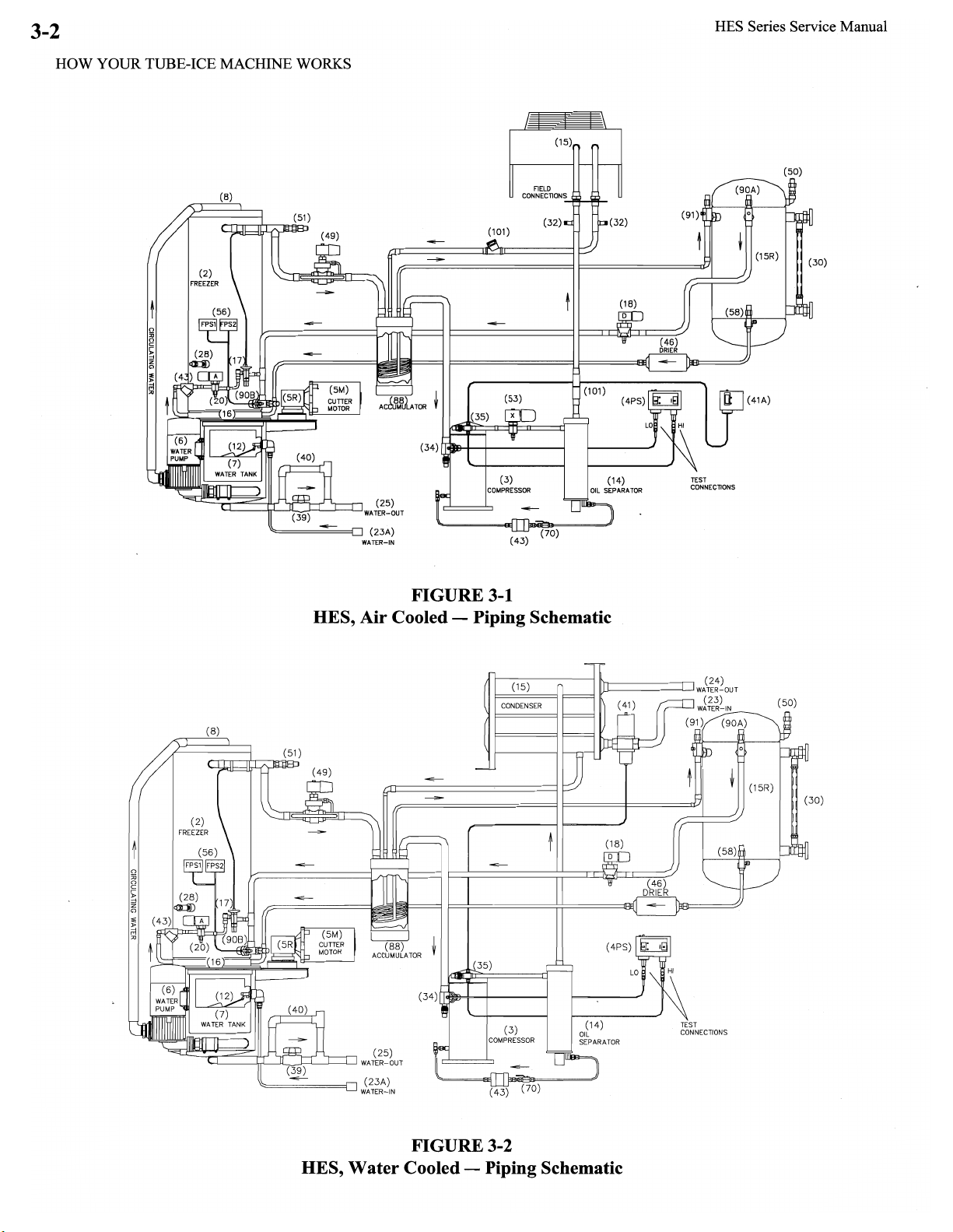

Principle of Operation ................................................................................................................................. 3-1

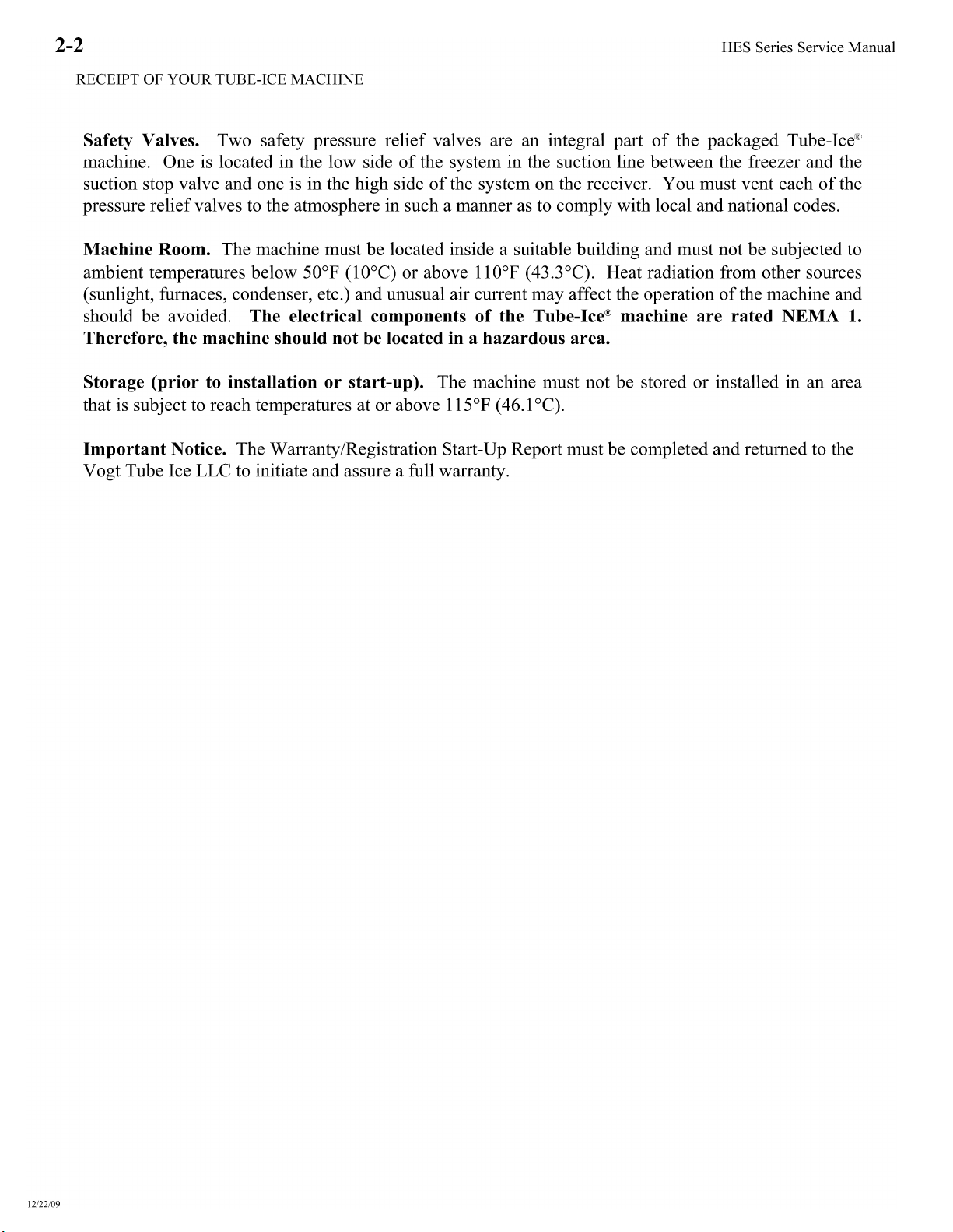

Air Cooled Piping Diagram, FIGURE 3-1 .................................................................................................. 3-2

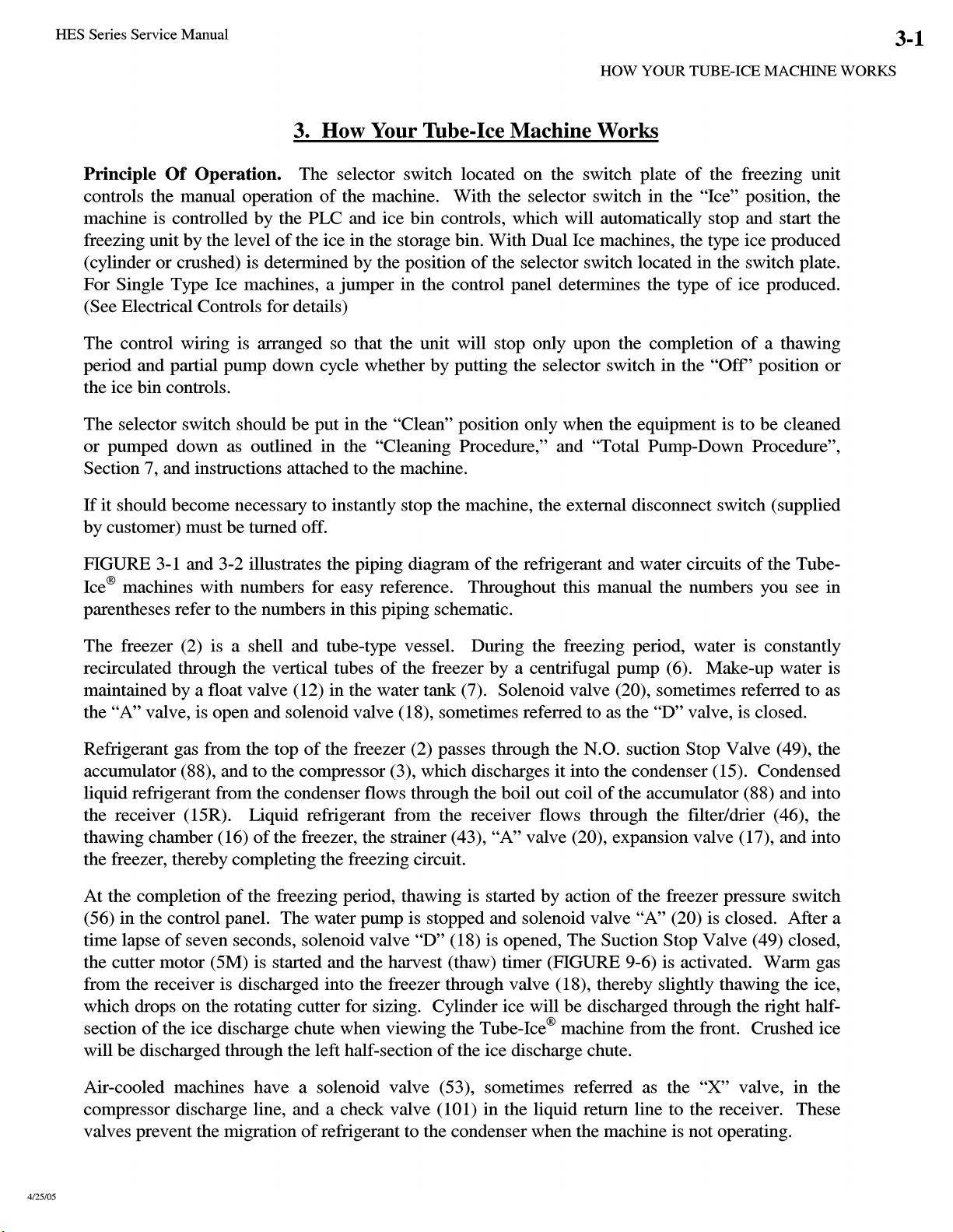

Water Cooled Piping Diagram, FIGURE 3-2.............................................................................................. 3-2

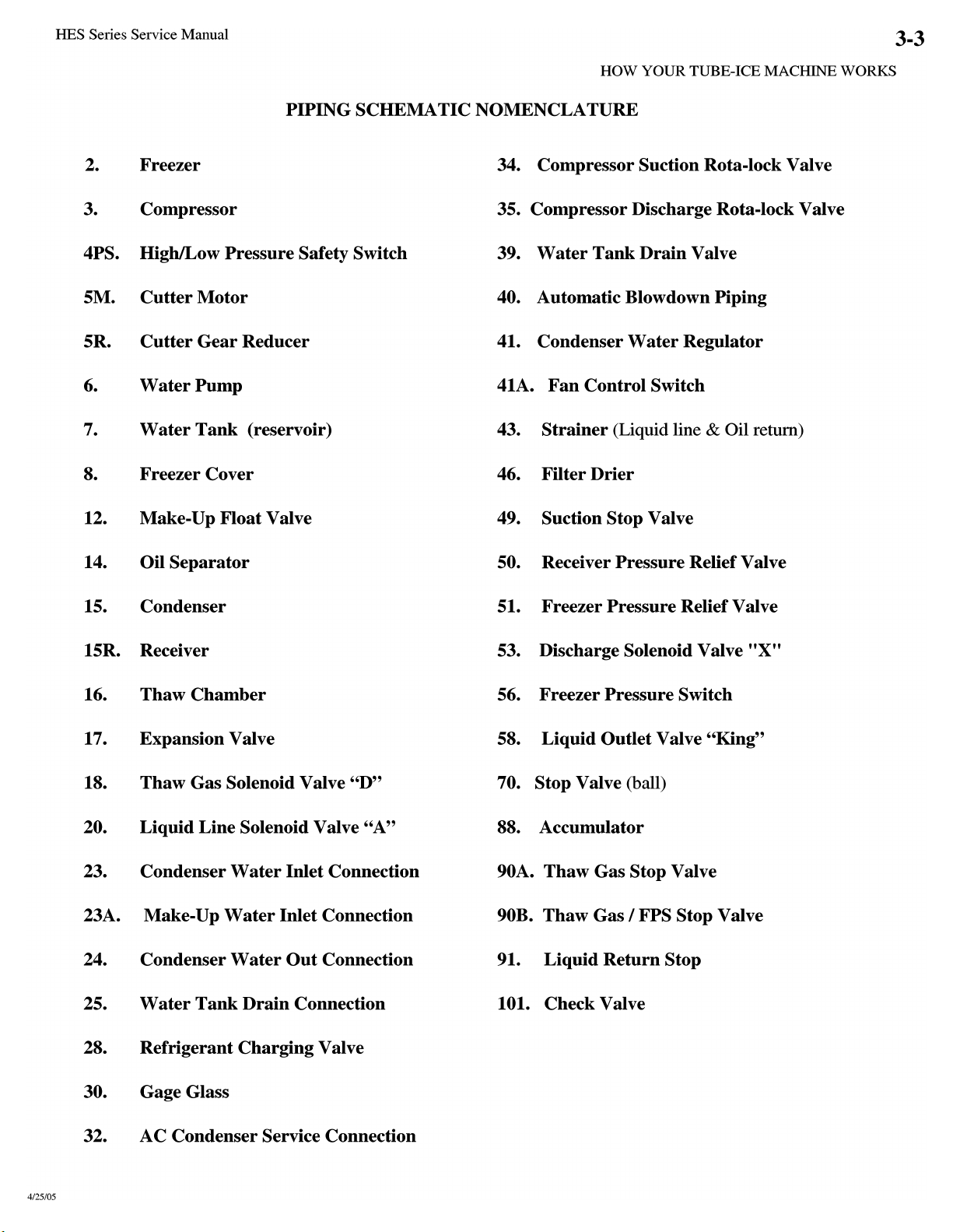

Piping Schematic Nomenclature.................................................................................................................. 3-3

How Ice Is Stored

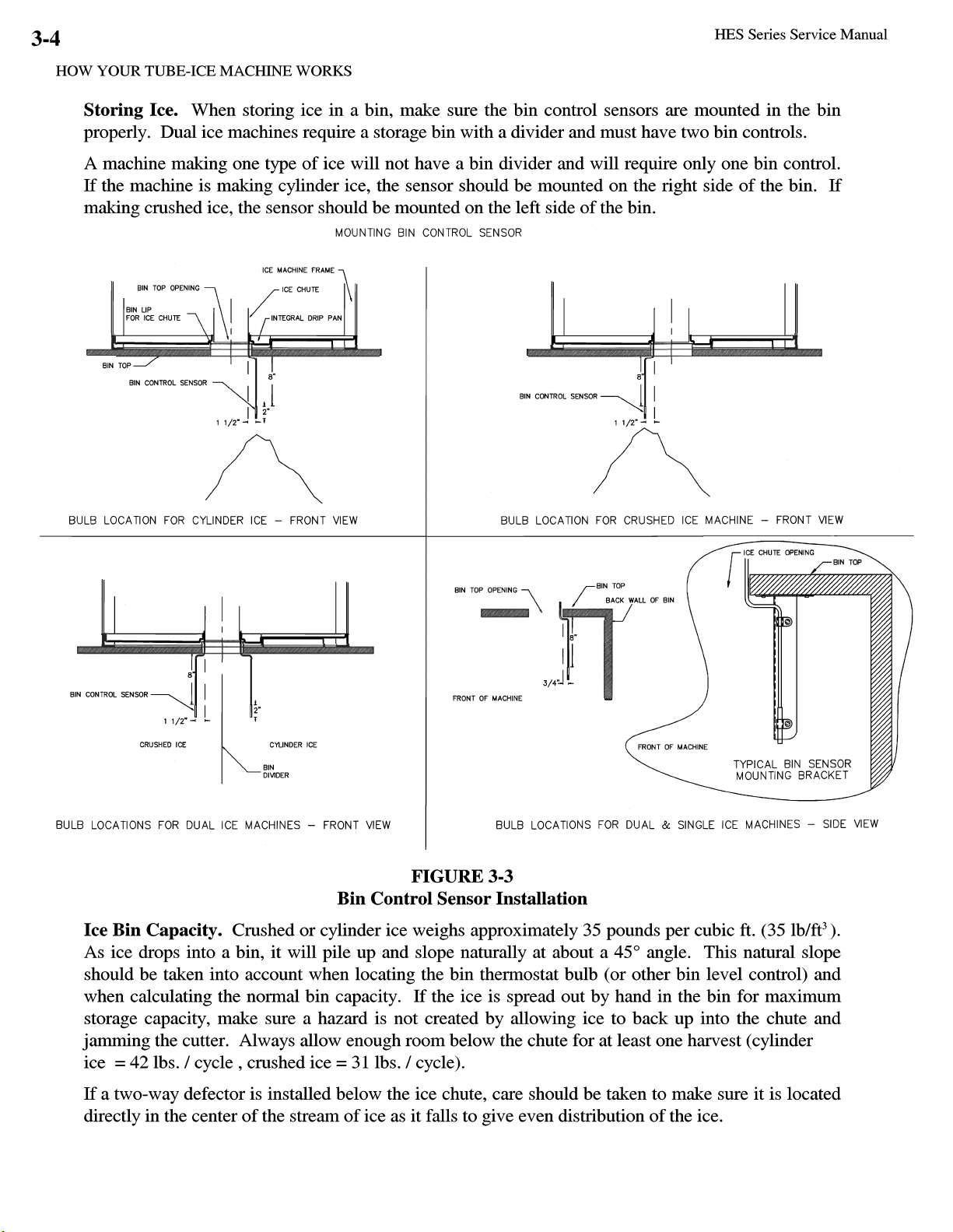

Bin Control Sensor Installation, FIGURE 3-3 ............................................................................................. 3-4

Storing Ice ................................................................................................................................................... 3-4

Ice Bin Capacity .......................................................................................................................................... 3-4

When Ice Bin Thermostats Are Not Used ................................................................................................... 3-5

Single Ice .................................................................................................................................................... 3-5

Dual Ice .................................................................................................................................................... 3-5

Crushed Ice Preferred .................................................................................................................................. 3-5

4. ELECTRICAL CONTROLS & THEIR FUNCTIONS

Control Panel, FIGURE 4-1A ..................................................................................................................... 4-1

Control Panel with Hoffman Enclosure, FIGURE 4-1B.............................................................................. 4-1

Control Panel Part Numbers, TABLE 4-1 ................................................................................................... 4-2

Description of Control Panel Parts .............................................................................................................. 4-3

Wiring and Electrical Connections, FIGURE 4-2 ....................................................................................... 4-5

Electrical Specifications, TABLE 4-2 ......................................................................................................... 4-5

5/24/11

Page 6

ii HE S Series Service Manual

TABLE OF CONTENT

Page No.

4. ELECTRICAL CONTROLS & THEIR FUNCTIONS (Cont.)

PLC Features & Functions........................................................................................................................... 4-6

PLC Display, FIGURE 4-3.......................................................................................................................... 4-6

PLC Inputs & Outputs, TABLE 4-3 ..................................................................................................... 4-6

PLC Start-Up Mode ............................................................................................................................. 4-7

PLC Stand-By Mode ............................................................................................................................ 4-7

PLC Freeze Mode ................................................................................................................................ 4-7

PLC Harvest Mode............................................................................................................................... 4-7

PLC Partial Pump-Down Mode............................................................................................................ 4-7

PLC Partial Pump-Down Time, TABLE 4-4........................................................................................ 4-7

PLC Total Pump-Down Mode.............................................................................................................. 4-7

PLC Clean Mode.................................................................................................................................. 4-8

PLC Fault Mode ................................................................................................................................... 4-8

PLC Fault Codes, TABLE 4-5 ............................................................................................................. 4-8

Copeland Performance Alert ....................................................................................................................... 4-9

Copeland Performance Alert wiring, FIGURE 4-4 ..................................................................................... 4-9

Copeland Performance Alert Codes & Lockout Configuration, TABLE 4-6 .............................................. 4-9

Machine Fault Startup Sequence, FIGURE 4-5........................................................................................... 4-10

Fault Indicator / Selector Switch Location, FIGURE 4-6............................................................................ 4-10

Dual Ice Machine (200V/208-230V) Wiring Schematic, FIGURE 4-7 ...................................................... 4-11

Single Ice Machine (200V/208-230V) Wiring Schematic, FIGURE 4-8 .................................................... 4-12

Single Ice Machine (Dual voltage -50hz) Wiring Schematic, FIGURE 4-9 ................................................ 4-13

Single Ice Machine (400V/460V) Wiring Schematic, FIGURE 4-10 ......................................................... 4-14

Air Cooled Condenser Wiring Schematic (Single Fan – 50/50 Split), FIGURE 4-11................................. 4-15

Air Cooled Condenser Wiring Schematic (Single Fan – 50/25/25 Split), FIGURE 4-12............................ 4-16

Air Cooled Condenser Wiring Schematic (Dual Fan – 50/50 Split), FIGURE 4-13 ................................... 4-17

5. MAINTENANCE

Ice-making Section...................................................................................................................................... 5-1

Cleaning Procedure ..................................................................................................................................... 5-1

Sanitizing Procedure.................................................................................................................................... 5-2

Water Distributors, FIGURE 5-1................................................................................................................. 5-4

Water Distributors, Freezer Cover, Gasket Part #'s, TABLE 5-1 ................................................................ 5-4

Water Tank.................................................................................................................................................. 5-5

Drip Pan .................................................................................................................................................... 5-5

Water Cooled Condensers ........................................................................................................................... 5-5

Draining the Condenser ............................................................................................................................... 5-6

Chemical Cleaning the Condenser............................................................................................................... 5-6

5/24/11

Page 7

HES Series Service Manual

TABLE OF CONTENTS

Page No.

5. MAINTENANCE (Cont.)

Mechanical Cleaning the Condenser ........................................................................................................... 5-6

Part I..................................................................................................................................................... 5-6

Part II ................................................................................................................................................... 5-7

Replacement Gaskets, TABLE 5 -2............................................................................................................. 5-7

Air-Cooled Condenser Cleaning.................................................................................................................. 5-8

Compressor Oil............................................................................................................................................ 5-8

Cutter Gear Reducer Oil .............................................................................................................................. 5-8

Preventive Maintenance .............................................................................................................................. 5-9

Daily Checklist ............................................................................................................................................ 5-9

Note To Manager or Owner ........................................................................................................................ 5-9

Preventive Maintenance Program................................................................................................................ 5-10

6. TROUBLESHOOTING

iii

Machine Faults ............................................................................................................................................ 6-1

PLC Fault Codes, TABLE 6-1 .................................................................................................................... 6-1

Machine Fault Indicator Light, FIGURE 6-1 .............................................................................................. 6-2

Machine Fault Startup Sequence, FIGURE 6-2........................................................................................... 6-2

PLC, FIGURE 6-3....................................................................................................................................... 6-3

PLC Inputs and Outputs, TABLE 6-2 ......................................................................................................... 6-3

Machine Will Not Run ................................................................................................................................ 6-4

Checking PLC ............................................................................................................................................. 6-4

Low Ice Capacity......................................................................................................................................... 6-5

Fault # 1, High/Low Pressure during Freeze ............................................................................................... 6-6

Fault # 2, High/Low Pressure during Harvest.............................................................................................. 6-7

Fault # 3, High/Low Pressure during Partial Pumpdown............................................................................. 6-7

Fault # 4, High/Low Pressure during Total Pumpdown .............................................................................. 6-8

Fault # 5, Short Cycle Fault......................................................................................................................... 6-9

Fault # 6, Long Cycle Fault ......................................................................................................................... 6-9

Fault # 7, Pump Motor Overload Fault........................................................................................................ 6-10

Fault # 8, Cutter Motor Overload Fault....................................................................................................... 6-10

5/24/11

7. SERVICE OPERATIONS

Machine Component Layout (Front View), FIGURE 7-1A ........................................................................ 7-1

Machine Component Layout (Side View), FIGURE 7-1B .......................................................................... 7-1

Machine Component Layout (Rear View - WC), FIGURE 7-1C ................................................................ 7-2

Machine Component Layout (Rear View - AC), FIGURE 7-1D................................................................. 7-2

Adjustable Blowdown (For Clearer Ice)...................................................................................................... 7-3

Page 8

iv HE S Series Service Manual

TABLE OF CONTENT

Page No.

7. SERVICE OPERATIONS (Cont.)

Automatic Blowdown (Harvest Cycle), FIGURE 7-2 ................................................................................. 7-3

Float Valve (Make-Up Water), FIGURE 7-3 .............................................................................................. 7-4

Circulating Water Pump, FIGURE 7-4........................................................................................................ 7-4

Circulating Water Pump Replacement Parts, TABLE 7-1........................................................................... 7-5

Water Distributors, TABLE 7-2 .................................................................................................................. 7-5

Freezer Cover, Gasket, FIGURE 7-5........................................................................................................... 7-5

Water Tank.................................................................................................................................................. 7-6

Cutter-Water Tank Assembly, FIGURE 7-6................................................................................................ 7-6

Cutter Gear Reducer .................................................................................................................................... 7-6

Gear Reducer Replacement ......................................................................................................................... 7-7

Cutter Bearing ............................................................................................................................................. 7-7

Cutter and Gear Drive ................................................................................................................................. 7-7

Ice Discharge Arrangement, FIGURE 7-7................................................................................................... 7-8

Cutter-Water Tank Parts, FIGURE 7-8 ....................................................................................................... 7-9

Cutter Drive Parts, FIGURE 7-9 ................................................................................................................. 7-10

Cutter Parts, FIGURE 7-10 ......................................................................................................................... 7-11

Thermal Expansion Valve, FIGURE 7-11................................................................................................... 7-12

TXV Part #'s, TABLE 7-3 ........................................................................................................................... 7-12

Checking Superheat..................................................................................................................................... 7-12

Recommended Superheat Setting, TABLE 7-4 ........................................................................................... 7-13

Expansion Valve Adjustment Procedure & Installation .............................................................................. 7-13

Solenoid Valves, FIGURE 7-12 .................................................................................................................. 7-14

Solenoid Valves Parts, TABLE 7-5............................................................................................................. 7-14

Freezer Pressure Switches ........................................................................................................................... 7-15

Freezer Pressure Switch (Allen-Bradley), FIGURE 7-13............................................................................ 7-15

High/Low Pressure Switch, FIGURE 7-14.................................................................................................. 7-16

Head Pressure .............................................................................................................................................. 7-17

Air-Cooled Units ......................................................................................................................................... 7-17

Condenser Fan Switch, FIGURE 7-15 ........................................................................................................ 7-17

5/26/11

Air Cooled Condenser Cleaning.................................................................................................................. 7-17

Cold Weather Kit Replacement Parts, TABLE 7-6 ..................................................................................... 7-17

Air Cooled Condenser Data, TABLE 7-7.................................................................................................... 7-18

Condenser Dimensions, FIGURE 7-16 ....................................................................................................... 7-18

Condenser Wiring, FIGURE 7-17 ............................................................................................................... 7-19

Water Cooled Units ..................................................................................................................................... 7-19

Water Regulating Valve, FIGURE 7-18...................................................................................................... 7-19

Page 9

HES Series Service Manual

7. SERVICE OPERATIONS (Cont.)

Water Regulating Valve Part #'s, TABLE 7-8............................................................................................. 7-19

Water Cooled Condenser Service ................................................................................................................ 7-20

Compressor Crankcase Heater, TABLE 7-9................................................................................................ 7-20

Compressor Motor Rotation ........................................................................................................................ 7-20

Scroll Compressor, FIGURE 7-19 .............................................................................................................. 7-21

Compressor Info, TABLE 7-10 ................................................................................................................... 7-21

Compressor Suction Rota-lock Valve, FIGURE 7-20, TABLE 7-11 .......................................................... 7-22

Compressor Discharge Rota-lock Valve, FIGURE 7-21, TABLE 7-12 ...................................................... 7-23

Short Circuit Protection, FIGURE 7-22 ...................................................................................................... 7-24

Control Circuit Protection ........................................................................................................................... 7-24

Motor Short Circuit Protection .................................................................................................................... 7-25

Motor Over Current Protection ................................................................................................................... 7-25

TABLE OF CONTENTS

Page No.

v

Overload Heater Pack Settings, TABLE 7-13 ............................................................................................. 7-25

Motor Overloads, FIGURE 7-23 ................................................................................................................ 7-25

Ice Bin Control, FIGURE 7-24 ................................................................................................................... 7-26

Programming Electronic Bin Thermostat .................................................................................................... 7-26

Bin Thermostat Mounting Location, FIGURE 7-25 .................................................................................... 7-27

Electronic Bin Thermostat Error Messages................................................................................................. 7-27

Thawing Timer, FIGURE 7-26.................................................................................................................... 7-28

Thawing Timer ............................................................................................................................................ 7-28

Selector Switch, FIGURE 7-27 ................................................................................................................... 7-28

Pumping Down Freezer ............................................................................................................................... 7-29

Pumping Down Entire System..................................................................................................................... 7-29

Removal of Refrigerant From the Machine ................................................................................................. 7-29

Refrigerant Leaks ........................................................................................................................................ 7-30

Non-Condensable Gases.............................................................................................................................. 7-30

Compressor Motor Burnout......................................................................................................................... 7-30

Cylinder Ice to Crushed Ice Conversion...................................................................................................... 7-31

Cylinder to Crushed, Terminal Block jumper Locations, FIGURE 7-28 .................................................... 7-31

Recommended Freezer Pressure Setting, TABLE 7-14............................................................................... 7-31

Freezer Pressure Switch, FIGURE 7-29 ...................................................................................................... 7-31

Recommended Ice Weights/Cycle, TABLE 7-15........................................................................................ 7-31

Single to Dual Ice Conversion..................................................................................................................... 7-31

Defrost Pressure Switch (DPS), FIGURE 7-30 ........................................................................................... 7-32

Defrost Pressure Switch Wiring, FIGURE 7-31.......................................................................................... 7-32

Oil Separator, FIGURE 7-32 ....................................................................................................................... 7-33

5/24/11

Page 10

vi HE S Series Service Manual

TABLE OF CONTENT

Page No.

8. MODEL NUMBER STRUCTURE FOR HES MACHINES................................................................. 8-1

9. TABLES AND CHARTS

Ice Capacity TABLE 9-1............................................................................................................................. 9-1

Normal Operating Vitals, TABLE 9-2 ........................................................................................................ 9-1

Temperature-Pressure Chart, TABLE 9-3 ................................................................................................... 9-2

English-Metric Conversion, TABLE 9-4..................................................................................................... 9-3

Constants, TABLE 9-5 ................................................................................................................................ 9-3

10. TECHNICAL SERVICE BULLETINS ................................................................................................ 10-1

11. INDEX .................................................................................................................................................... 11-1

5/24/11

Page 11

Page 12

Page 13

Page 14

Blank page

5/24/11

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Blank page

5/24/11

Page 23

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

4. Electrical Controls & Their Functions

FIGURE 4-1A

Control Panel (Cover Removed)

Note: Machines manufactured after May 1999 will use Allen-Bradley controls

FIGURE 4-1B

Control Panel with Hoffman Enclosure (Door Open)

4-1

5/24/11

Page 24

4-2

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

Vogt Part #

Reference Cutler-Hammer Allen-Bradley Description

12A2117G09 SAME CRUSHED ICE BIN CONTROL (DUAL ICE ONLY)

BC1

12A2117G09 SAME CYLINDER ICE BIN CONTROL

BC2

12A7516E10 12A7516E26 COMPRESSOR CONTACTOR

C

12A7518E15 12A7518E30 COMPRESSOR AUX CONTACT

12A7515E18 SAME PUMP / CUTTER MOTOR CIRCUIT BREAKER (10 AMP)

CB1

12A7515E19 SAME * CONDENSER FAN MOTOR CIRCUIT BREAKER (15 AMP)

CB2

CB3 & CB4

CPA

FPS1

FPS2

FU1-FU3

FU10 & FU20

PLC

TEST

*Note: AIR COOLED ONLY

12A7515E20

N/A 12A7700P02 COPELAND PERFORMANCE ALERT

12A7530E11 12A7516E23 CUTTER MOTOR STARTER / CONTACTOR

CU

12A7508H2108 12A7538E01 CUTTER OVERLOAD HEATERS (3.38-5.54 A) / OL RELAY (2-7 A)

12A2117E04 SAME FREEZER PRESSURE SWITCH (DUAL ICE ONLY)

12A2117E04 SAME FREEZER PRESSURE SWITCH

N/A 12A7504E13 CONDENSER FAN MOTOR FUSES, 6A, 600V (400/460V MACH)

N/A 12A7504E14 CONTROL CIRCUIT FUSES, 7A, 600V (400/460V MACH)

12A7530E11 12A7516E23 PUMP MOTOR STARTER / CONTACTOR

P

12A7508H2109 12A7538E01 PUMP OVERLOAD HEATERS (4.96-8.16 AMPS) / OL RELAY (2-7 A)

12A7500E45 12A7500E56

PB1

N/A 12A7537S06 POWER LINE FILTER (CE MACHINES ONLY)

PLF

SAME 12A7536M01 PROGRAMMABLE CONTROLLER

12A7517E18 12A7517E27 REVERSING RELAY (DUAL ICE ONLY)

R

12A7500E43 SAME 5 POSITION SELECTOR SWITCH (DUAL ICE)

SS

12A7500E44 12A7500E61

N / A N / A TERMINAL BLOCK

TB

N / A N / A TEST BLOCK (ON CUTLER-HAMMER - FACTORY USE ONLY)

12A7500E46 12A7500E65 FAULT INDICATOR LIGHT

1LT

(QTY 2)

12A7515E21 CONTROL CIRCUIT BREAKER (3 AMP)

HARVEST / START BUTTON

12A7500E75

12A7500E73

CONTACT BLOCK (FOR ALLEN-BRADLEY ONLY)

3 POSITION SELECTOR (SINGLE ICE)

CONTACT BLOCK (FOR ALLEN-BRADLEY ONLY)

TABLE 4-1

Control Panel Parts List

5/24/11

Page 25

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

Description of Control Panel Parts.

*BC1 and BC2. Bin Controls. Ice bin thermostats for automatically stopping and starting the

machine based on the ice level in the storage bin. BC1 (Crushed Ice). BC2 (Cylinder Ice).

C. Compressor Motor Contactor. Provides power to the compressor motor. Energized during

freezing and thawing. Normally closed contact provides power to the compressor crankcase heater

when the machine is off.

CB1. Pump / Cutter Motor Circuit Breaker (10 amps). Two pole magnetic circuit breaker used for

short circuit protection in the cutter or pump motor circuit. If breaker trips, power is removed from

control circuit, shutting machine down.

CB2. Condenser Fan Motor Circuit Breaker (15 amps). Two-pole thermal magnetic circuit breaker

used for short circuit protection in the condenser motor circuit. If breaker trips, power is removed from

condenser only. Machine will eventually shut off on high discharge pressure.

CB3 and CB4. Control Circuit Breaker (3 Amps). Current limiting thermal magnetic circuit breaker

used as overload and short circuit protection for crankcase heater, PLC outputs and other control circuit

components.

CPA. Copeland PerformanceAlert. Device that monitors compressor current, phase and temperature

and shuts off machine if a problem is detected.

CU. Cutter Motor Starter.

Cutler-Hammer: A three phase motor starter with adjustable bimetallic heater packs, wired for use with

single-phase motor. Cutter Motor Overload (heater packs) – Class 10 overloads rated 3.38 - 5.54 Amps

set at cutter motors FLA rating. Pull "Reset" button to test overload.

Allen-Bradley: Motor starter made of 3-pole contactor and solid-state overload relay, wired for use

with single-phase motor. Overload - Class 10 rated 2 - 7 Amps set at cutter motors FLA rating. Press

"TEST" button to test overload.

Can be configured to reset automatically (“A”) or manually (“M”). PLC controlled machines will have

the overload reset in the “automatic” position. When an overload condition occurs, an auxiliary contact

signals the PLC of a problem and shuts the machine off (PLC input light # 5 will be “off” when

overload is tripped). Will automatically reset after an overloads cool.

See Section 7, Motor Over Current Protection for details.

*FPS1 and FPS2. Freezer Pressure Switches. For regulating the ice thickness by sensing the freezer

pressure and initiating the thaw period. FPS1 (Crushed Ice). FPS2 (Cylinder Ice).

FU10 & FU20. Transformer Primary Protection Fuses - 400/460V machines only. (7A, 600V,

time delay fuses). Fuses used for transformer primary protection along with control circuit upstream of

CB3/CB4.

FU1, FU2 & FU3. Condenser Fan motor Fuses - 400/460V machines only. (6A, 600V, Time delay

fuses). Fused used for short circuit protection in the condenser motor circuit. If fuse(s) blows, power is

removed from condenser only. Machine will eventually shut off on high discharge pressure.

5/24/11

4-3

Page 26

4-4

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

P. Pump Motor Starter.

Cutler-Hammer: A three phase motor starter with adjustable bimetallic heater packs, wired for use on

single phase. Pump Motor Overload (heater packs) – Class 10 overloads rated 4.96 – 8.16 Amps set at

pump motors FLA rating. Pull "Reset" button to test overload.

Allen-Bradley: Motor starter made of 3-pole contactor and solid-state overload relay, wired for use

with single-phase motor. Overload - Class 10 rated 2 - 7 Amps set at pump motors FLA rating. Press

"TEST" button to test overload.

Can be configured to reset automatically (“A”) or manually (“M”). PLC controlled machines will have

the overload reset in the “automatic” position. When an overload condition occurs, an auxiliary contact

signals the PLC of a problem and shuts the machine off (PLC input light # 5 will be “off” when

overload is tripped). Will automatically reset after an overloads cool.

See Section 7, Motor Over Current Protection for details.

PB1. Start/ Harvest button. For starting the machine in the ice-making mode. Momentary contact or

initiating a harvest cycle if the machine is in the freeze mode. Can be used to bypass the built in 120

minute start-up mode delays as well as terminate a harvest cycle.

PLC. Programmable Logic Controller. For monitoring, sequencing, and controlling various

functions of the Tube-Ice® operation. Also has a built in thaw timer for controlling the time of the

thawing period. Thawing time is adjustable from 1 1/2 to 5 minutes.

PLF. Power Line Filter. Used on “CE” approved machines only. Used to reduce amount of noise on

incoming power lines.

*R. Reversing Relay. Switches machine to crush ice by making or breaking various circuits

concerning crushed ice production. Energized during crushed ice production only.

SS. Selector Switch.

Dual Ice machines – Five positions switch for the purpose of selecting form five different machine

modes. Clean / crushed / cylinder / Both (cyl & crushed) / off.

Single Ice machines – Three position switch for the purpose of selecting from three different machine

modes, clean / Ice / off.

1LT. Fault indicator light (24VDC light) flashes a designated number of times. A non-auto restart fault

occurs or a auto-restart fault occurs three consecutive times.

*Note: Components used in dual ice type machines only.

5/24/11

Page 27

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

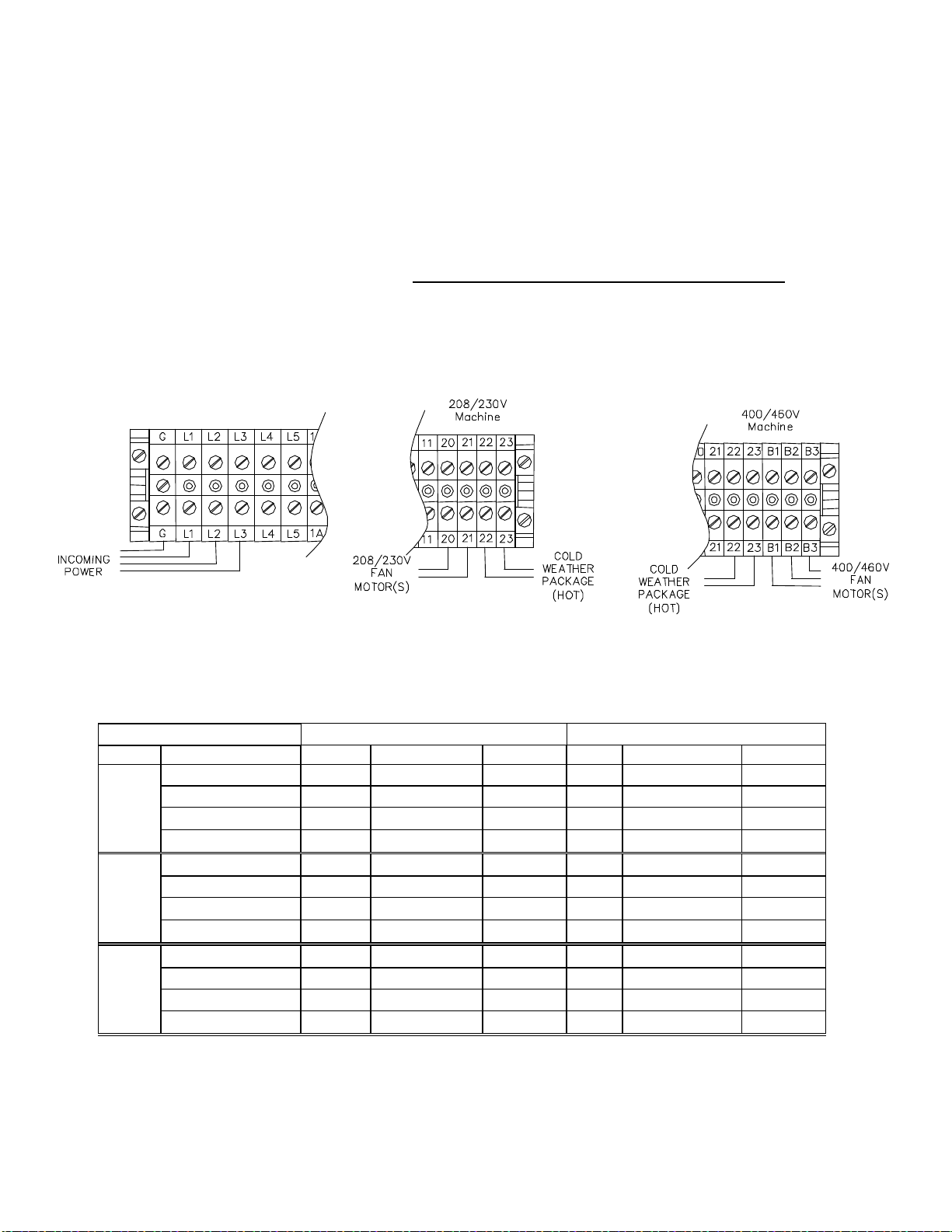

Wiring And Electrical Connection.

Refer to TABLE 4-1 below to properly size wiring connections. A fused disconnect must be

provided near the Tube-Ice® machine. Connect 3-phase power to terminals L1, L2, L3 for operation

of the Tube-Ice® machine and its controls. If one leg of the 3 phase power is higher or lower

(“Wild”), then it should be connected to terminal #L2. Connect the “Ground” wire to the “Ground”

terminal provided. On dual voltage, 50 Hz machines, the 220V single phase should be connected to

terminals L4 and L5.

Note: When initially starting the machine, the scroll compressor must be phased properly. If the

compressor is run backwards for an extended period of time, the compressor may be damaged. See

Section 7, Compressor Motor Rotation for details.

Air-cooled condenser should be wired to terminals 20,21,22 and 23 (see FIGURES 4-9, 4-10).

460V air cooled condensers should be wired to terminals B1, B2, B3, 22 & 23.

4-5

FIGURE 4-2

Terminal Block Connections

Standard Voltages: Water Cooled Air Cooled

Model Voltage F.L.A. Min. Ampacity Max. Fuse F.L.A. Min. Ampacity Max. Fuse

HES20

HES30

HES40

208/230, 3p, 60 hz 18.0 20.9 30 21.4 24.3 35

460, 3p, 60 hz 9.0 10.4 15 10.3 11.7 20

220, 3p, 50 hz 19 21.0 35 22.4 25.3 35

400, 3p, 50 hz 9.5 10.9 15 10.8 12.2 15

208/230, 3p, 60 hz 21.6 25.4 40 25.5 29.3 40

460, 3p, 60 hz 10.7 12.6 15 12.0 13.9 20

220, 3p, 50 hz 22.6 26.4 40 26.5 30.3 45

400, 3p, 50 hz 11.2 13.1 20 12.5 14.4 20

208/230, 3p, 60 hz 27.3 32.5 50 35.1 40.3 60

460, 3p, 60 hz 13.3 15.8 30 17.3 19.8 30

220, 3p, 50 hz 28.3 33.5 50 36.1 41.3 60

400, 3p, 50 hz 15.3 18.2 25 17.9 20.8 30

TABLE 4-2

Electrical Specifications

5/24/11

Page 28

4-6

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

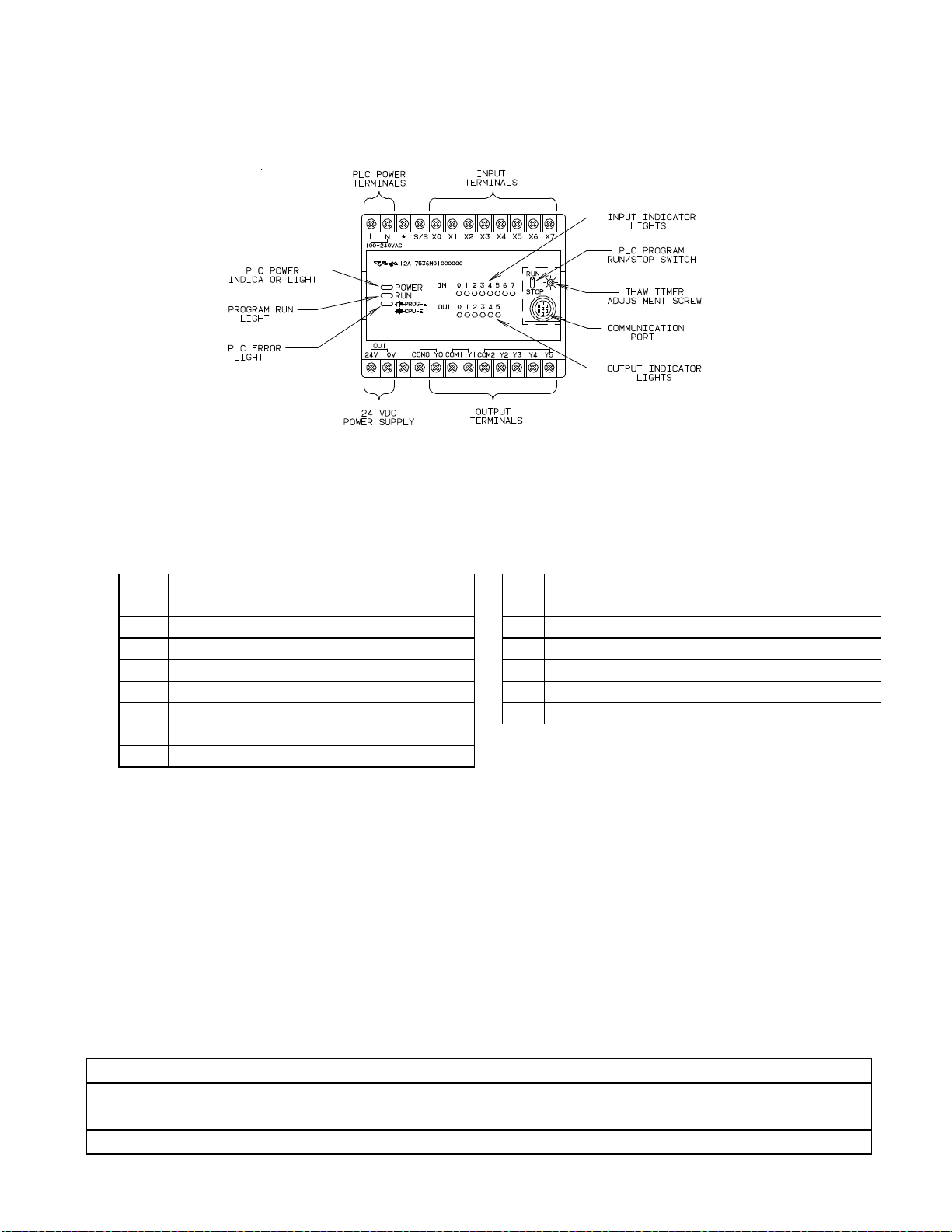

Electrical Specifications “PLC” (Programmable Logic Controller)

Sequence Of Controller & Machine Operation

NOTE: Part #12A7536M01. PLC must be pre-programmed for specific model.

FIGURE 4-3

PLC Display (Fxo shown above)

PLC Inputs PLC Outputs

# Description

0 Cylinder Ice Indicator

1 Crushed Ice Indicator

2 Freezer Pressure Switch

3 Start / Manual Harvest

4 Clean Switch

5 Pump / Cutter Overload

(“off” when tripped)

6 High / Low Pressure safety

7 N/A

(“off” when tripped)

# Description

0 Machine Fault Indicator Light

1 "A" valve

2 Compressor

3 Reversing Relay (Dual Ice only)

4 Water Pump

5 Cutter / "D" valve / Suction Stop

TABLE 4-3

PLC Inputs & Outputs

Explanation. The HES-Series Tube-Ice® machine is controlled by a PLC (Programmable Logic

Controller). The PLC controls the sequence of events and monitors the ice machine functions. The

operational sequences of the HES-Series Tube-Ice® machine can be described best as a series of eight

different modes. Each mode identifies and defines a sequence of events that occur while in that mode

and thereby cause it to move to the next mode. Only one mode is active at a time.

Start-Up Mode. The start-up mode is a function, which prevents the premature automatic starting of

the machine at the time of installation, after a power interruption, or after a safety trip. Its normal time

period is two hours. The start-up mode may be bypassed at any time by pressing the “Harvest/Start”

button to immediately advance to the standby mode.

! CAUTION !

If the power has been turned off to the machine, make sure the compressor crankcase is warm

And there is no liquid refrigerant in with the oil before restarting the unit.

! CAUTION !

5/24/11

Page 29

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

Standby Mode. The standby mode is a decision-making mode. It monitors the position of all the

various switches in the control circuit and at the proper time decides which mode to advance to next.

Freeze Mode (Freeze Cycle). The freeze mode is active during the normal ice making cycle. During

this time, the circulating water pump and compressor are running and the “A” (liquid feed) solenoid

valve and “X” solenoid valve compressor discharge (AC units only) is open.

Harvest Mode (Thaw Cycle). The harvest mode is normally initiated at the termination of the freeze

mode. At this time, the circulating water pump stops and the “A” (liquid feed) solenoid valve closes.

After seven seconds, the “D” (thaw gas) solenoid valve opens, the “SS” (suction stop) solenoid valve

closes, the cutter motor starts and the thaw timer is activated.

The harvest mode is terminated by the thaw (harvest) timer at which time the machine will begin

another freeze cycle. The harvest mode can also be terminated manually by pushing in the

“Harvest/Start” button.

NOTE: If the “Selector Switch” switch is in the “Off” position or the bin control is satisfied the

machine will advance to the partial pumpdown mode before shutting off (standby mode).

Partial Pumpdown Mode. The partial pumpdown mode precedes the normal off or standby mode. Its

purpose is to transfer a portion of the liquid from the suction accumulator and freezer into the receiver

prior to shutdown of the machine (standby mode). This will discourage any migration of liquid

refrigerant to the compressor during the off or standby mode. It is also intended to prevent any liquid

refrigerant slugging to the compressor when the machine restarts in a freeze mode.

4-7

When partial pumpdown is initiated, the “A” (liquid feed) solenoid valve is closed and the water pump

and compressor run for a set time. After this set time the compressor stops and the machine is in the

standby mode.

Model HES-20 HES-30 HES-40

Time 7 minutes 5 minutes 3 minutes

TABLE 4-4

Partial Pumpdown Time

NOTE: The PLC uses the cylinder ice pressure switch (FPS2) as a partial pumpdown safety. Do not

remove this pressure switch from the machine.

Total Pumpdown Mode. The function of the total pumpdown mode is to transfer all of the liquid

refrigerant from the freezer (evaporator) into the receiver. Total pumpdown is initiated as the first

phase of and prior to entering the “Clean” mode.

Its main purpose is to clear the freezer of liquid refrigerant and prevent possible refrigerant migration to

the compressor while running the “Clean” cycle. It can also be used to check the units total refrigerant

charge, isolate the refrigerant in the receiver while making repairs, or prepare the machine for

disconnecting and moving.

To restart the machine after a total pumpdown, put the “Selector Switch” switch in the “Ice” position

and press the “Harvest/Start” button. At this time the “A” (liquid feed) solenoid valve will open for

two minutes, allowing refrigerant to feed into the freezer before the machine starts into a freeze cycle.

5/24/11

Page 30

4-8

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

Clean Mode. The “Clean” mode is considered to be maintenance or servicing function of the machine.

During this mode only the water pump will run. The first phase of the “Clean” mode is a total

pumpdown.

! CAUTION !

Do not attempt to bypass the total pumpdown phase of the “Clean” mode. If a clean cycle is

performed without first completing a total pumpdown, the warm water being circulated through

the freezer tubes can force refrigerant to migrate to the suction accumulator and compressor

which can cause compressor damage when returning to the freeze mode.

! CAUTION !

After the total pumpdown, the water pump can be stopped by simply moving the “Selector Switch”

from the “Clean” to the “Off” position. To restart the water pump, move the “Selector Switch” back to

the “Clean” position and press the “Harvest/Start” button. (Note: If the freezer and compressor suction

pressure have come up enough to open the freezer pressure switch FPS2 and close low pressure safety

switch 4PS, the compressor will come on and pump down the freezer again.) Ice machine cleaning

solution can be circulated though the tubes to accomplish the cleaning procedure. If the water pump is

left to run in the clean mode for more than two hours, the PLC will shut the machine off. The clean

mode can be resumed by pushing the “Harvest/Start” button.

NOTE: Running in Clean mode for extended period of time can cause excessive pressure to build up in

the freezer.

At the termination of the clean mode, the machine can be returned to ice making mode by putting the

“Selector Switch” in the “Ice” position and pressing the “Harvest/Start” button. . At this time the “A”

(liquid feed) solenoid valve will open for two minutes, allowing refrigerant to feed into the freezer

before the machine starts into a freeze cycle.

Fault Mode. The HES Series (“S” for Smart) is equipped with a PLC (programmable logic

controller) that controls all aspects of the operation. One of the functions of the PLC is to shut down

the machine when a problem arises and send a signal to the fault indicator light located on the far-left

side of the electrical panel. The red light is visible through the opening in the front casing and will

blink when a problem has caused the machine to shut down (See FIGURE 4-2).

NOTE: The Fault Light will flash the designated number of times ONLY if the fault is a not a autorestart fault or a auto-restart fault that has occurred three consecutive times. For your reference,

TABLE-4-3 contains a list of fault codes.

# Description Restart Off Delay

1 High / Low Press - Freeze No N/A

2 High / Low Press - Harvest No N/A

3 High / Low Press - Partial Pumpdown No N/A

4 High / Low Press - Total Pumpdown No N/A

5 Short Cycle Yes 2 hrs

6 Long Cycle No N/A

7 Pump Motor Overload Yes 30 min

8 Cutter Motor Overload Yes 30 min

N/A Power Failure Yes 2 hrs

NOTE: The machine may be off on a fault and not flashing an error code if the fault is an auto-restart

fault and it is not the third consecutive occurrence of this fault.

TABLE 4-5

PLC Fault Codes

5/24/11

Page 31

lt must be manually reset by cycling power to the Performance Alert.

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

Copeland Performance Alert (CPA). This device is used to monitor the compressor discharge

temperature, compressor current and phase, as well as control voltage to the compressor contactor. If

a problem is detected, the compressor will shut off. The fault light on the CPA will flash a certain

number of times to indicate the fault that occurred. See table below.

NOTE: When this occurs, the ice machine will continue to run but the compressor will not be on.

The ice machine will eventually shut off on a “Long Cycle Fault”.

Some faults, referred to as “lockout” faults, will require cycling power to the Performance Alert to

reset. This can be done by switching CB1 to the “off” position for 5 seconds, then back “on”.

NOTE: If ice machine has a High/Low pressure fault, the Performance Alert can detect low control

voltage at the compressor contactor and flash 9 times. This will clear when the machine is re-start.

FIGURE 4-4

Copeland Performance Alert Wiring

Alert Codes System Conditions Description

1 High Discharge Temperature

4 Lock Rotor

6 Missing Phase

7 Reverse Phase (Scroll only)

8 Welded Contactor No demand signal but current has been detected in one

or both phases

9 Low Voltage Control voltage dips below 85V for 110V or 170V for

11 DLT Sensor Failure Discharge Temperature Sensor short or open circuit

Discharge Temperature above set point

(default 230 Deg F) adjustable 170 to 281

4 Consecutive Compressor trips after run time of 1 to

15 seconds indicating compressor won't start

Demand signal is present but current is missing in

one phase

Demand signal is present but current is not detected in

the correct sequence

220V

Note:

Faults 1, 4, 6, 7, 9 will shut off compressor with a off time of 20 minutes (adjustable from 10 to 40 minutes).

If fault 1, 4, 6 or 7 occurs ("LOCKOUT"), fau

Lockout Configuration

Code Minimum Maximum Default

1 High Discharge Temp 2 6

4 Locked Rotor 2 10

6 Missing Phase 1 10

7 Reverse Phase 1 1

4

4

10

1

TABLE 4-6

Copeland Performance Alert Codes

4-9

5/24/11

Page 32

4-10

Mode

Mode

Freeze

restart machine

Mode

Mode

Freeze

30 Minutes

restart machine

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

1 Flash -

2 Flashes -

3 Flashes -

4 Flashes -

5 Flashes -

6 Flashes -

7 Flashes -

8 Flashes -

Note:

* The Cutter or Pump overload is tripped (PLC input light 5 is “off”)

High / Low Pressure Fault during Freeze

High / Low Pressure Fault during Harvest

High / Low Pressure Fault during Partial Pumpdown

High / Low Pressure Fault during Total Pumpdown

Short Cycle Faults (3 Consecutive)

Long Cycle Fault

Water Pump Motor Overload Fault (3 Consecutive)

Cutter Motor Overload Fault (3 Consecutive)

While in the Fault Mode, if Harvest / Start Button is pressed twice and the machine does not start, one of the following is true:

* Bin control is not calling for ice or Selector switch is in the “off” position (PLC input lights 0 & 1 are “off”)

* The high / low pressure switch is tripped (PLC input light 6 is “off”)

Press Harvest / Start

Button twice to

Press Harvest / Start

Button twice to

2 Minute

Run water

pump for

Harvest

2 Minute

FIGURE 4-5

Machine Fault Startup Sequence

Freeze

Harvest

Freeze

5/24/11

FIGURE 4-6

Fault Indicator / Selector Switch Location

Page 33

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

NOTE:

USE COPPER CONDUCTORS RATED 60 °C

OR HIGHER

Machines w/Copeland Performance Alert

* Standard on machines manufactured after January 2010

FIGURE 4-7

Dual Ice Type

5/24/11

4-11

Page 34

4-12

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

NOTE:

USE COPPER CONDUCTORS RATED 60 °C

OR HIGHER

Machines w/Copeland Performance Alert

* Standard on machines manufactured after January 2010

FIGURE 4-8

Single Ice Type

5/24/11

Page 35

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

NOTE:

USE COPPER CONDUCTORS RATED 60 °C

OR HIGHER

Machines w/Copeland Performance Alert

* Standard on machines manufactured after January 2010

FIGURE 4-9

Single Ice (Dual Voltage)

50 HZ, 400V compressor, 200V controls

5/24/11

4-13

Page 36

4-14

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

NOTE:

USE COPPER CONDUCTORS RATED 60 °C

5/24/11

OR HIGHER

FIGURE 4-10

Single Ice (400V / 460V)

Machines w/Copeland Performance Alert

* Standard on machines manufactured after January 2010

Page 37

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

Wiring Connections to Air-Cooled Condenser.

FIGURE 4-11

Wiring For BOHN DVT005 with Cold Weather Valve and Single Fan,

50/50 Condenser Split

5/24/11

4-15

Page 38

4-16

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

Wiring For BOHN DVT008 with Cold Weather Valve and Single Fan,

FIGURE 4-12

50/25/25 Condenser Split

5/24/11

Page 39

HES Series Service Manual

ELECTRICAL CONTROLS & THEIR FUNCTIONS

FIGURE 4-13

Wiring For BOHN DVT012 /DVT016 with Cold Weather Valve and Two Fan,

50/50 Condenser Split

5/24/11

4-17

Page 40

Blank page

5/24/11

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

7-16

SERVICE OPERATIONS

High/Low Pressure Safety Switch. The high-low pressure switch (4PS) (FIGURE 7-14) is a twopole dual function switch. Located in the machine outside the control panel, it protects the machine

from possible damage due to abnormal pressure during operation.

The LOW pressure cut-in should be set at 40 psig (R-22), 50 psig (R-404A) and the cutout set at 20

psig (R-22), 30 psig (R-404A). After tripping at the cutout setting, the switch will reset

automatically when the pressure rises to the cut-in setting.

The HIGH-pressure cutout should be set at 300 psig (R-22) & 350 psig (R-404A). After tripping,

reset the switch manually.

Note: After a high-pressure trip, the discharge pressure must drop 50 psig before the switch can be

reset.

HES Series Service Manual

! CAUTION !

When this switch causes the machine to stop, the cause should be

identified and corrected before resuming normal operation.

See Fault Identity, Section 6, Table 6-2.

! CAUTION !

DIFFERENTIAL ADJUSTING SCREW

(CCW RAISES SETTING)

Vogt Part #: 12A2117D02

RANGE ADJUSTING SCREW

(CW RAISES SETTING)

HIGH PRESSURE ADJUSTMENT SCREW

(DIFFERENTIAL FACTORY SET AT 55 PSIG)

FIGURE 7-14

High /Low Pressure Safety Switch

NOTE: High-low pressure switch contains both high and low voltage circuits. Line numbers 12 and

X6 supply a low voltage signal to the PLC. Line numbers Y2 and 18-supply power to the

compressor contactor coil.

If it becomes necessary to install a new high/low pressure switch, the following procedure is

recommended for its adjustment:

Turn the adjusting screws clockwise to raise the pressure setting. Turn counter-clockwise to lower

the setting. Adjust the switch to the indicated pressure settings and test with an accurate gage to be

sure the switch functions properly before installation.

5/26/11

Page 77

HES Series Service Manual

Head Pressure. The head pressure should be maintained at 100-105 degF condensing during the

freeze cycle. The compressor discharge pressure can be checked at the test connection on the highlow pressure switch.

Air-Cooled Units. The condenser fan switch (FIGURE 7-15) (CPS) has a two-pole switch that is

used to regulate the head pressure. This is an adjustable pressure switch located on the right-hand

side of the machine directly controls the operation of the condenser fan motor(s). The switch is set

to cycle the fan motor(s) “On” at 210 psig (R-22), 250 psi (R-404A) and “Off” at 190 psig (R-22),

230 psi (R-404A).

CUT IN ADJUSTING SCREW

(CW LOWERS SETTING)

Vogt Part #: 12A2117F08

Condenser Fan Switch

FIGURE 7-15

CUT IN ADJUSTING SCREW

(CW RAISES SETTING)

SERVICE OPERATIONS

7-17

NOTE: Older HE and R12 machines used a single pole fan switch and a fan contactor to control the

fan motor (s). The HE S-series machine no longer uses a fan contactor.

Cleaning Air-Cooled Condenser. Visual inspection will indicate if dirt is accumulating and

clogging the fin face of the condenser. A vacuum cleaner, compressor air or a brush may be used to

remove an accumulation of dirt from the fin section of the condenser.

Condenser Description Valve Valve Rebuild Kit Replacement Coil Fan Solenoid

DVT005 5/8” N.O. 12A4200A0503 12A4199V42 12A2105C04

DVT008 7/8” N.O. 12A4200A0704 12A4199V44 12A2105C04

DVT012

DVT016

1 1/8” N.O. 12A4200A0902

12A4200A09021

Solenoid Valve Thermostats

Penn A19 Penn A319

12A4199V45

12A4199V55

12A2105C04

12A2105C25

Note: Sporlan Solenoid Valves

Sporlan Solenoid valve OE34S290 (12A4200A0902) discontinued in Aug 2006

TABLE 7-6

Cold Weather Kit Replacement Parts

5/26/11

Page 78

7-18

SERVICE OPERATIONS

Ice Machine Model

Recommended Condenser

HE20 HE30 HE40

DVT005

(DVT008)

HES Series Service Manual

DVT008

(DVT012)

Note: For continuous operation at ambient above 90 °F, use larger condenser shown in parenthesis

Total Heat Rejection:

(15°F TD)

Fans:

Full Load Amps:

Weight, lbs.:

Condenser dimensions, inches:

Recommended Line Sizes,

OD:

Connections at Condenser: Liquid (ODC)

Connections at Machine: Liquid & Discharge Gas (ODC) 1-1/8” 1-1/8” 1-1/8”

BTU/hr at 60 Hz.

BTU/hr at 50 Hz.

Number

HP, Each

Total, CFM

1 ph., 208/230V, 60 Hz

3 ph., 208/230V, 60 Hz

3 ph., 460V, 60 Hz

1 ph., 200/220V, 50 Hz

3 ph., 200/220V, 50 Hz

3 ph., 400V, 50 Hz

Net

Shipping

Operating (maximum flooded)

A (Width)

B (Length)

C (Height)

D (Leg centerline)

E (Leg centerline)

F (Clearance below)

Liquid (All lengths and orientations)

Discharge Gas Vertical Up, All lengths

Horizontal Or Down, < 75 ft.

Horizontal Or Down, > 75 ft.

Discharge Gas (ODC)

35,700

32,800

1

1/3 (1/2)

5,050 (6,450)

3.4 (3.9)

N/A

1.3 (1.3)

3.4 (3.9)

N/A

1.3 (1.3)

180 (260)

320 (390)

195 (285)

43”

39.75” (49.75”)

30” (40”)

17”-3

30” (40”)

24.5”

1/2”

5/8”

5/8”

7/8”

5/8”(7/8”)

7/8” (1 1/8”)

58,800

54,100

1 (2)

1/2

6,450 (12,400)

3.9 (7.8)

N/A

1.3 (2.6)

3.9 (7.8)

N/A

1.3 (2.6)

260 (470)

390 (520)

285 (500)

43”

49.75” (69.75”)

40” (60”)

17” - 3

40” (60”)

24.5”

5/8”

7/8”

7/8”

1-1/8”

7/8”

1 1/8”

DVT012

(DVT016)

117,500

108,100

2

1/2

12,400 (12,900)

7.8 (7.8)

N/A

2.6 (2.6)

7.8 (7.8)

N/A

2.6 (2.6)

470 (530)

520 (680)

500 (560)

43”

69.75”

60”

17” - 3

60”

24.5”

7/8”

1-1/8”

1-1/8”

1-3/8”

7/8”

1-1/8” (1-3/8”)

TABLE 7-7

Air-Cooled Condenser Data

FIGURE 7-16

Condenser Dimensions

5/26/11

Page 79

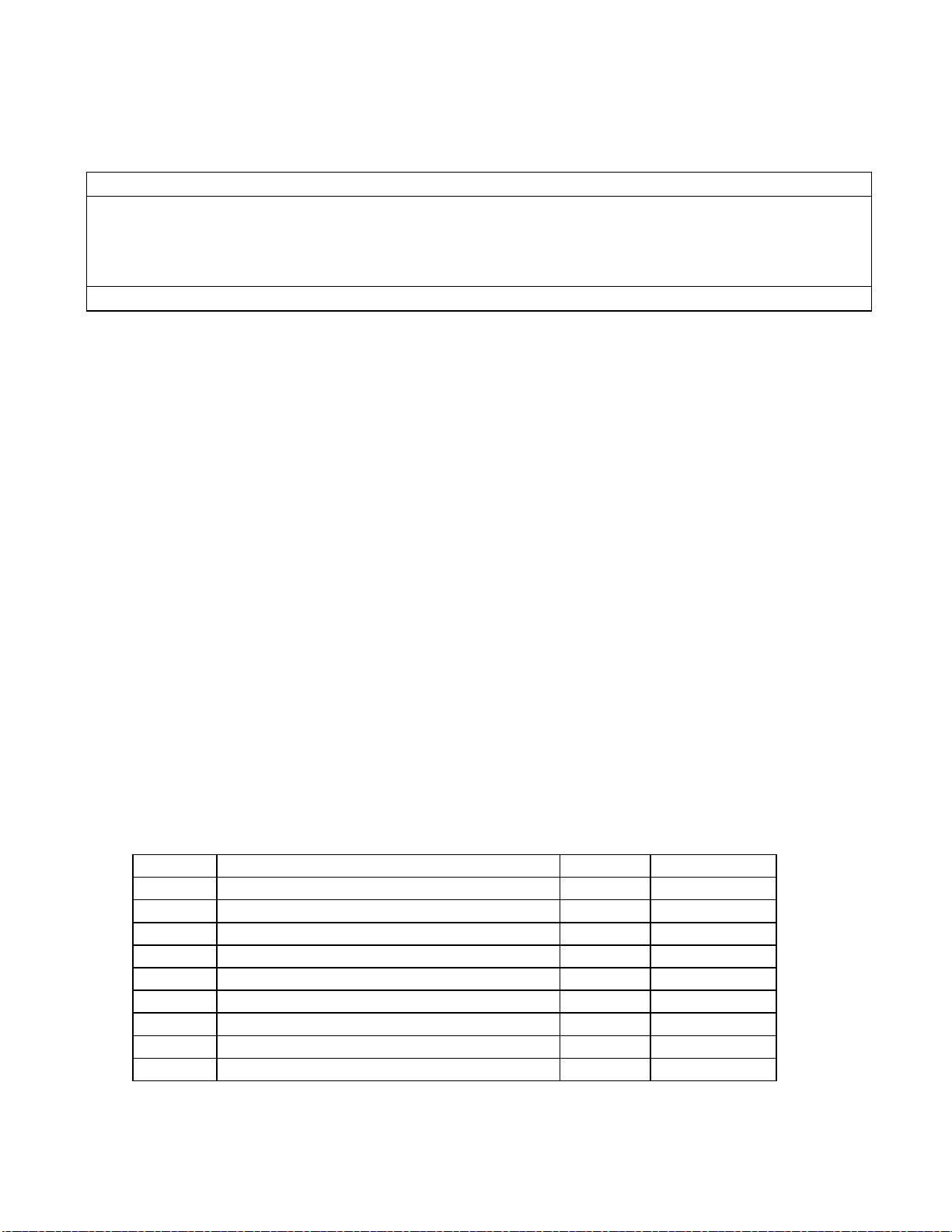

HES Series Service Manual

Wiring For BOHN DVT012 /DVT016 with Cold Weather Valve and Two Fan,

Water-Cooled Units. A water-regulating valve (FIGURE 7-18) located in the condenser water inlet line

is used to control the water flow through the condenser. This valve should be adjusted to maintain a head

pressure of 190-210 psig. Increasing the water flow lowers the head pressure and decreasing the water

flow raises the head pressure.

FIGURE 7-17

50/50 Condenser Split

7-19

SERVICE OPERATIONS

FIGURE 7-18

Water Regulating Valve

Machine Size Vogt Part #

HES-20 & HES-30

3/4” 12A4200E0605

HES-40 1” 12A4200E0802

* HES-20 & HES30

1/2” 12A4200E0402

* HES-40 1” 12A4200E0801

TABLE 7-8

Water Regulating Valves

Note: * High water pressure regulating valves (above 90 psig)

5/26/11

Page 80

7-20

SERVICE OPERATIONS

Water Cooled Condenser Service. High head pressure due to fouled condenser.

Eliminate other possible causes:

• Non-condensables

• Faulty gauge

• Refrigerant restriction

• Water regulating valve

• High inlet water temperature

• Insufficient water supply

Example

Liquid return (RCVR) Psig = 200 = 102°F (SAT)

Water outlet temperature = 95°F

Difference = 7°F

If difference is more than 10°F, cleaning is indicated. For cleaning procedure see, “Water Cooled

Condenser Cleaning”, Section 5.

HES Series Service Manual

Compressor Crankcase Heater. When electrical power is supplied to terminals L1, L2 & L3 of the

control panel, the crankcase heater is energized when the compressor is not operating. The purpose

of the crankcase heater is to keep the compressor warm to prevent the migration of refrigerant to the

compressor while the compressor is not running.

Machine Size Vogt Part #

HES-20/HES-30/HES-40 70 watts (at 230V) 12A 7509E13

TABLE 7-9

Compressor Crankcase Heaters

! CAUTION !

In case of a power interruption, or crankcase heater failure, be sure the compressor crankcase

is warm prior to restarting the machine manually

! CAUTION !

Compressor Motor Rotation. Scroll compressors must be phased properly at startup. Connect

pressure gages to the high and low side of the compressor at the High / Low Pressure safety switch.

Start machine by putting "Selector Switch" in the "Ice" position and pressing "Start / Harvest"

button. The compressor discharge pressure should start to rise as the suction pressure drops. Within

30 seconds, the discharge pressure should be approximately 180 - 200 psig. If the discharge pressure

does not rise, and the suction pressure does not drop, the compressor is running backwards. Shut

machine off power to the machine at the main disconnect and reverse wires labeled L1 and L3 in the

compressor's electrical junction box.

5/26/11

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

Page 88

Page 89

Page 90

Page 91

Page 92

Page 93

Page 94

Blank page

5/24/11

Page 95

Page 96

Blank page

5/24/11

Page 97

Page 98

9-2

HES Series Service Manual

TABLES & CHARTS

TEMPERATURE - PRESSURE CHART

FOR COMMON REFRIGERANTS

DegF R-12 R-22 R-502 R-134a MP-39 R-404a R-402a DegF R-12 R-22 R-502 R-134a MP-39 R-404a R-402a

-7.6 -3.0 0.2 -9.0 -9.1 0.0 1.2

-50

-7.2 -2.4 0.7 -8.7 -8.7 0.8 2.1

-48

-6.8 -1.7 1.5 -8.3 -8.3 1.6 2.9

-46

-6.3 -1.0 2.3 -8.0 -7.9 2.5 3.9

-44

-5.8 -0.2 3.2 -7.6 -7.4 3.4 4.9

-42

-5.4 0.5 4.1 -7.1 -7.1 5.5 5.9

-40

-4.9 1.3 5.0 -6.7 -6.6 6.5 6.9

-38

-4.4 2.2 6.0 -6.3 -6.1 7.5 8.0

-36

-3.8 3.0 7.0 -5.8 -5.6 8.6 9.2

-34

-3.3 4.0 8.1 -5.3 -5.2 9.7 10.3

-32

-2.7 4.9 9.2 -4.8 -4.4 10.8 11.6

-30

-2.1 5.9 10.3 -4.2 -4.1 12.0 12.8

-28

-1.5 6.9 11.5 -3.8 -3.4 13.2 14.1

-26

-0.8 7.9 12.7 -3.0 -2.9 14.5 15.5

-24

-0.1 9.0 14.0 -2.4 -2.2 15.8 16.9

-22

-20

-18

-16

-14

-12

-10

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

0.6 10.1 15.3 -1.8 -1.7 17.1 18.4

1.3 11.3 16.7 -1.1 -1.0 18.5 19.9

2.1 12.5 18.1 -0.4 -0.2 20.0 21.5

2.8 13.8 19.5 0.3 0.4 21.5 23.1

3.7 15.1 21.0 1.1 1.4 23.0 24.8

4.5 16.5 22.6 1.9 2.2 24.6 26.5

5.4 17.9 24.2 2.8 3.1 26.3 28.3

-8

6.3 19.3 25.8 3.6 3.9 28.0 30.2

-6

7.2 20.8 27.5 4.5 4.8 29.8 32.1

-4

8.2 22.4 29.3 5.5 5.7 31.6 34.1

-2

9.2 24.0 31.1 6.5 6.7 33.5 36.1

0

10.2 25.6 32.9 7.5 7.7 35.6 38.1

2

11.2 27.3 34.9 8.5 8.8 37.4 40.4

4

12.3 29.1 36.9 9.6 9.9 39.4 42.6

6

13.5 30.9 38.9 10.8 11.0 41.6 44.9

8

14.6 32.8 41.0 12.0 12.2 43.9 47.3

15.8 34.7 43.2 13.1 13.4 46.0 49.7

17.1 36.7 45.4 14.4 14.6 48.3 52.2

18.4 38.7 47.7 15.7 15.9 50.7 54.8

19.7 40.9 50.0 17.0 17.2 53.1 57.5

21.0 43.0 52.5 18.4 18.6 55.6 60.2

22.4 45.3 54.9 19.9 20.0 58.2 63.0

23.9 47.6 57.5 21.4 21.5 59.9 65.9

25.4 49.9 60.1 22.9 23.0 63.6 68.9

26.9 52.4 62.8 24.5 24.6 66.5 72.0

28.5 54.9 65.6 26.1 26.2 69.4 75.1

30.1 57.5 68.4 27.8 27.9 72.3 78.3

31.7 60.1 71.3 29.5 29.6 75.4 81.6

33.4 62.8 74.3 31.3 31.3 78.5 85.0

35.2 65.6 77.4 33.2 33.2 81.8 88.5

36.9 68.5 80.5 35.1 35.0 85.1 92.1

38.8 71.5 83.8 37.0 37.0 88.5 95.7

40.7 74.5 87.0 39.1 39.0 91.9 99.5

42.7 77.6 90.4 42.0 41.0 95.5 103.4

44.7 80.7 93.9 43.3 43.1 99.2 107.3

46.7 84.0 97.4 45.5 45.3 102.9 111.4

46.7 84.0 97.4 45.5 45.3 102.9 111.4

50

48.8 87.3 101.0 47.7 60.0 109.0 120.0

52

51.0 90.8 104.8 50.1 62.0 113.0 124.0

54

53.2 94.3 108.6 52.3 65.0 117.0 129.0

56

55.4 97.9 112.4 55.0 68.0 121.0 133.0

58

57.7 101.6 116.4 57.5 70.0 125.0 138.0

60

60.1 105.4 120.4 60.1 73.0 130.0 142.0

62

62.5 109.3 124.6 62.7 76.0 134.0 147.0

64

65.0 113.2 128.8 65.5 79.0 139.0 152.0

66

67.6 117.3 133.2 68.3 82.0 144.0 157.0

68

70.2 121.4 137.6 71.2 85.0 148.0 162.0

70

72.9 125.7 142.2 74.2 89.0 153.0 168.0

72

75.6 130.0 146.8 77.2 92.0 158.0 173.0

74

78.4 134.5 151.5 80.3 95.0 164.0 179.0

76

81.3 139.0 156.3 83.5 99.0 169.0 184.0

78

84.2 143.6 161.2 86.8 102.0 174.0 190.0

80

87.2 148.4 166.2 90.2 106.0 180.0 196.0

82

90.2 153.2 171.4 93.6 109.0 185.0 202.0

84

93.3 158.2 176.6 97.1 113.0 191.0 208.0

86

96.5 163.2 181.9 100.7 117.0 197.0 214.0

88

99.8 168.4 187.4 104.4 121.0 203.0 220.0

90

103.1 173.7 192.9 108.2 125.0 209.9 227.0

92

106.5 179.1 198.6 112.1 129.0 215.0 234.0

94

110.0 184.6 204.3 116.1 133.0 222.0 240.0

96

113.5 190.2 210.2 120.1 138.0 229.0 247.0

98

117.2 195.9 216.2 124.3 142.0 235.0 254.0

100

120.9 201.8 222.3 128.5 146.0 242.0 261.0

102

124.7 207.7 228.5 132.9 151.0 249.0 269.0

104

128.5 213.8 234.9 137.3 156.0 256.0 276.0

106

132.4 220.0 241.3 142.8 160.0 264.0 284.0

108

136.4 226.4 247.9 146.5 165.0 271.0 292.0

110

140.5 232.8 254.6 151.3 170.0 279.0 299.0

112

144.7 239.4 261.5 156.1 175.0 286.0 307.0

114

148.9 246.1 268.4 161.1 180.0 294.0 316.0

116

153.2 252.9 275.5 166.1 185.0 302.0 324.0

118

157.7 259.9 282.7 171.3 191.0 311.0 332.0

120

162.2 267.0 290.1 176.6 196.0 319.0 341.0

122

166.7 274.3 297.6 182.0 202.0 328.0 350.0

124

171.4 281.6 305.2 187.5 207.0 336.0 359.0

126

176.2 289.1 312.9 193.1 213.0 345.0 368.0

128

181.0 296.8 320.8 198.9 219.0 354.0 377.0

130

185.9 304.6 328.9 204.7 225.0 364.0 387.0

132

191.0 312.5 337.1 210.7 231.0 373.0 396.0

134

196.2 320.6 345.4 216.8 237.0 383.0 406.0

136

201.3 328.9 353.9 223.0 243.0 392.0 416.0

138

206.6 337.3 362.6 229.4 250.0 402.0 426.0

140

212.0 345.8 371.4 235.8 256.0 412.0 436.0

142

217.5 354.5 380.4 242.4 263.0 423.0 447.0

144

223.1 363.4 389.5 249.2 269.0 434.0 458.0

146

228.8 372.3 398.9 256.0 277.0 444.0 468.0

148

234.6 381.5 408.4 263.0 283.0 449.0 479.0

150

TABLE 9-3

All pressures are in lbs/in2 gage (psig).

5/25/11

Page 99

Page 100

Blank page

5/24/11

Loading...

Loading...