Vogt 05TA Service Manual

05TA

TUBE-ICE® MACHINE

(Includes model P118F/HE100)

Manual Part Number 12A4171M06

Revision 1

Service Manual

$5000

NOTICE

This manual is the property of the owner of this particular Tube-Ice® machine.

Model #____________________ Serial #____________________.

It is to be left on the premises with this machine at all times. After startup, it should be stored in a safe place where it can be readily available when needed for future reference in maintaining troubleshooting or servicing.

Failure to comply with this notice will result in unnecessary inconvenience and possible additional expenses.

This manual is intended as an informational tool for the installation, operation, maintenance, troubleshooting, and servicing of this equipment. If an existing situation calls for additional information not found herein, we suggest that you contact your distributor first. If further assistance or information is needed, please feel free to contact the factory at 502-635-3000 or FAX at 502-635-3024.

IMPORTANT: The Warranty Registration/Start-Up Report found in the front of this manual is to be completed and returned to the factory promptly after the official start-up.

Please return to: |

TUBE ICEâ, LLC |

|

Suite #19 |

|

1000 W. Ormsby Ave. |

|

Louisville, KY 40210 |

Tube Ice L.L.C. |

|

|

|

Vogt Order Number: ____________________ |

|

1000 W. Ormsby |

|

|

|

|

|

Louisville, KY 40210 |

|

|

|

THIS FORM MUST BE SENT TO |

|

(502) 635-3235 |

|

|

|

VOGT TO ACTIVATE WARRANTY |

|

FAX #502-635-3024 |

|

|

|

|

|

Warranty Registration / Start-Up Form

(Medium & Large Machines)

Model Number: __________________________ Serial Number: __________________________

This form must be filled out completely and signed by the customer in order to assure acceptance by Vogt.

Date of Start-Up: _______________________________ |

Form Completed By: _____________________________________ |

|||||||

AC Condenser Model Number: _____________________ |

AC Condenser Serial Number: _____________________________ |

|||||||

Water Treatment System? |

Yes |

No |

Manufacturer: ____________________ |

Model: ________________________ |

||||

Bin Manufacturer: _______________________ |

Model: _________________________ |

Bin Capacity: _______ lbs. |

||||||

|

|

|

|

|

|

|

|

|

Distributor |

|

|

|

|

|

|

|

|

Company Name: ____________________________________________ |

Phone: _______________________ |

|||||||

Address: ____________________________________ |

City: _________________________ State: ___________ Zip: ___________ |

|||||||

Service Company |

|

|

|

|

|

|

|

|

Company Name: ____________________________________________ |

Phone: _______________________ |

|||||||

Address: ____________________________________ |

City: _________________________ State: ___________ Zip: ___________ |

|||||||

|

|

|

|

|

|

|

|

|

Customer (location of equipment) |

|

|

|

|

|

|

|

|

Company Name: ____________________________________________ |

Phone: _______________________ |

|||||||

Address: ____________________________________ City: _________________________ State: ___________ Zip: ___________

PRE-OPERATION CHECK

Machine room suitable 50°F minimum, 110°F maximum

Power Supply ______ V _____ PH _____ HZ (machine not running) Crankcase heater on for 2 hours minimum, prior to start

All valves opened or closed as tagged Water supply and drains connected properly

Sufficient make-up water supply (minimum 30 PSIG)

Leak checked entire system (including AC condenser if applicable)

AC condenser cold weather temperature setting(s) |

|

|

Solenoid ________ Fan________ |

|

|

AC condenser installed above machine |

Yes |

No |

Approx. _____ft. |

|

|

AC condenser line length (in equivalent feet) ____________

AC condenser properly piped — all lines insulated Bin control(s) installed properly

Instruction manual and warranty certificate left on-site

Name of person left with: __________________________________

OPERATION CHECK

Power Supply ______ V _____ PH _____ HZ (machine running) Compressor oil level, i.e. 1/4 – 1/2 – 3/4: ______

Compressor, pump , cutter & other motor direction of rotation correct Compressor amps (Start of freeze cycle) L1_____ L2_____ L3_____

Cutter motor amps RLA__________ Actual __________

Water pump amps RLA__________ Actual __________

Condenser motor amps (if applicable) _________

Incoming potable water temperature: _____°F All water distributors in place (visually inspected) Make-up water float valve adjusted properly

Clear ice |

Yes |

No |

Bin control(s) operate(s) properly to stop and start machine with ice on them

Hour meter in control panel connected and operating

Suction Pressure: End of freeze ________ End of harvest ________

Discharge Pressure: End of freeze ________ End of harvest ________

Test |

Make-up Water |

Freeze Time |

Harvest Time |

|

First Ice Out |

All Ice Out |

Avg. Hole |

Ice |

Ice |

|

Cycle |

Temp |

Min/Sec |

Min/Sec |

|

Min/Sec |

Min/Sec |

Size |

Lb. Per Harvest |

Lb. Per Day |

|

#1 |

|

|

|

|

|

|

|

|

|

|

#2 |

|

|

|

|

|

|

|

|

|

|

#3 |

|

|

|

|

|

|

|

|

|

|

#4 |

|

|

|

|

|

|

|

|

|

|

Note: Ice lb. per day can be found by: |

ice lb. per harvest |

|

×1440 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

(freeze time + harvest ti me)

Remarks:

Technician Signature: ___________________________ End User Signature:_____________________________

I certify that I have performed all of the above procedures.

Vogtâ

Tube-Iceâ Machines

Installation, Service Manual and Parts Catalog #12A4171M06

05TA Model

05TA Service Manual

i

TABLE OF CONTENTS

TA OF CONTENTS

Vogt® TUBE-ICE® MACHINES

Model 10TA (Includes P18FXT)

Page No.

1. INTRODUCTION |

|

A Brief History Of Our Company ........................................................................................................................... |

1-1 |

Vogt Energy-Savings Tube-Ice® Machines ............................................................................................................. |

1-1 |

Preview ............................................................................................................................................................. |

1-1 |

Important Safety Notice.......................................................................................................................................... |

1-2 |

Special Precautions To Be Observed When Charging Refrigeration Systems........................................................... |

1-2 |

Safety Symbols and What They Mean .................................................................................................................... |

1-3 |

Assembly Drawing Model 10TA (P18FXT) Air-Cooled, FIGURES 1-1, 1-2, & 1-3 ................................................ |

1-4, 1-5, 1-6 |

Assembly Drawing Model 10TA (P18FXT) Water Cooled, FIGURES 1-4, 1-5, & 1-6 ............................................ |

1-7, 1-8, 1-9 |

2. RECEIPT OF YOUR TUBE-ICE MACHINE |

|

Inspection ............................................................................................................................................................. |

2-1 |

Safety Valves ......................................................................................................................................................... |

2-1 |

Machine Room....................................................................................................................................................... |

2-2 |

Storage (prior to installation and start-up) .............................................................................................................. |

2-2 |

Vogt Model Nomenclature, FIGURE 2-1................................................................................................................ |

2-2 |

3. INSTALLING YOUR TUBE-ICE MACHINE |

|

Piping and Drain Connections, TABLE 3-1 ........................................................................................................... |

3-1 |

Space Diagram (Air-Cooled Machine), FIGURE 3-1 .............................................................................................. |

3-2 |

Space Diagram (Water Cooled Machine), FIGURE 3-2 .......................................................................................... |

3-3 |

Wiring and Electrical Connection FIGURE 3-3 ...................................................................................................... |

3-4 |

Electrical Specifications, TABLE 3-2........................................................................................................ |

3-4 |

Phase Check, Voltage and Current unbalance ......................................................................................................... |

3-5 |

Rotation Check ...................................................................................................................................................... |

3-5 |

Air-Cooled Condenser Installation Instructions....................................................................................................... |

3-6 |

Pounds of R-22 to Add Vs. Liquid Line Length, TABLE 3-3 .................................................................................. |

3-7 |

Air-Cooled Condenser Data, TABLE 3-4................................................................................................................ |

3-8 |

Condenser Dimensions, FIGURE 3-4 ..................................................................................................................... |

3-9 |

Condenser Field Piping (Cold Weather Valve Kit), FIGURE 3-5............................................................................ |

3-9 |

Equivalent Feet Due To Friction, TABLE 3-5......................................................................................................... |

3-10 |

Minimum Traps For Discharge Lines, FIGURE 3-6................................................................................................ |

3-10 |

Wiring For DD-591 and DD-661 Condensers (3 phase motors), FIGURE 3-7 ......................................................... |

3-11 |

Cooling Tower ....................................................................................................................................................... |

3-12 |

Ice Bin Thermostat Sensor ..................................................................................................................................... |

3-12 |

Typical Bin Sensor Mounting, FIGURE 3-8 ........................................................................................................... |

3-12 |

Programming Electronic Bin Thermostat ................................................................................................................ |

3-13 |

Installation Review: A Checklist ........................................................................................................................... |

3-14 |

ii

05TA Service Manual

TABLE OF CONTENTS |

Page No. |

4. HOW YOUR TUBE-ICE MACHINE WORKS |

|

Principle of Operation ............................................................................................................................................ |

4-1 |

Freeze Period ......................................................................................................................................................... |

4-2 |

Harvest Period ....................................................................................................................................................... |

4-2 |

Piping Nomenclature.............................................................................................................................................. |

4-2 |

Water Cooled Piping Schematic, FIGURE 4-1........................................................................................................ |

4-3 |

Air-Cooled Piping Schematic, FIGURE 4-2 ............................................................................................................ |

4-4 |

5. START-UP AND OPERATION |

|

Refrigeration System Review ................................................................................................................................. |

5-1 |

Refrigerant Charge................................................................................................................................................. |

5-1 |

Start-up Procedure ................................................................................................................................................. |

5-2 |

Control Panel Switch Layout, FIGURE 5-1............................................................................................................. |

5-2 |

Shut-down Procedure ............................................................................................................................................. |

5-3 |

Operating Tips ....................................................................................................................................................... |

5-3 |

Adding Refrigerant ................................................................................................................................................ |

5-4 |

6. ELECTRICAL CONTROLS & THEIR FUNCTIONS |

|

Control Panel (Cover On), FIGURE 6-1 ................................................................................................................. |

6-1 |

Control Panel (Cover Removed), FIGURE 6-2........................................................................................................ |

6-2 |

Control Panel Components and Part Numbers, TABLE 6-1 .................................................................................... |

6-3 |

Electrical Schematic All Voltages 50-60 Hz. Across Line Start, FIGURE 6-3 ......................................................... |

6-4 |

Compressor Schematic Detail All Voltages, 50-60 Hz., FIGURE 6-4 ...................................................................... |

6-5 |

7. MAINTENANCE |

|

Preventive Maintenance ......................................................................................................................................... |

7-1 |

Preventive Maintenance Form ................................................................................................................................ |

7-2 |

Ice-Making Section ................................................................................................................................................ |

7-3 |

Cleaning Procedure ................................................................................................................................................ |

7-3 |

Water Distribution System ..................................................................................................................................... |

7-4 |

Water Distributors ................................................................................................................................................. |

7-4 |

Number of Water Distributors Per Tube Size, TABLE 7-1...................................................................................... |

7-4 |

Average Hole Size In Tube-Iceâ, TABLE 7-2 ......................................................................................................... |

7-4 |

Water Tank............................................................................................................................................................ |

7-4 |

Freezer Cover ........................................................................................................................................................ |

7-4 |

Water Cooled Condensers ...................................................................................................................................... |

7-5 |

Water Cooled Condensers, Checking Operation...................................................................................................... |

7-5 |

Water Cooled Condensers, Draining....................................................................................................................... |

7-5 |

Water Cooled Condensers, Chemical Cleaning ....................................................................................................... |

7-6 |

Water Cooled Condensers, Mechanical Cleaning.................................................................................................... |

7-6 |

Lubrication ............................................................................................................................................................ |

7-7 |

Lubrication, Compressor.............................................................................................................................................. |

7-7 |

Compressor Recommended Lubricants, TABLE 7-3..................................................................................................... |

7-7 |

Cutter Gear Reducer Lubrication............................................................................................................................ |

7-8 |

05TA Service Manual

iii

|

TABLE OF CONTENTS |

|

Page |

No. |

|

8. TROUBLESHOOTING |

|

List Of Symptoms .................................................................................................................................................. |

8-1 |

Machine Won’t Run............................................................................................................................................... |

8-1, 8-2 |

Freeze-Up Due To Extended Freezing Period ......................................................................................................... |

8-2 |

Freeze-Up Due To Ice Failing To Discharge ........................................................................................................... |

8-3 |

Poor Ice Quality ..................................................................................................................................................... |

8-3 |

Low Ice Capacity.................................................................................................................................................... |

8-4 |

Low Compressor Oil Level..................................................................................................................................... |

8-4 |

High Head Pressure (Water Cooled)....................................................................................................................... |

8-5 |

High Head Pressure (Air-Cooled)........................................................................................................................... |

8-5 |

9. SERVICE OPERATIONS |

|

Adjustable Blowdown (For Clearer Ice).................................................................................................................. |

9-1 |

Automatic Blowdown (Harvest Cycle).................................................................................................................... |

9-1 |

Float Valve (Make-Up Water)................................................................................................................................ |

9-1 |

Float Switch........................................................................................................................................................... |

9-1 |

Hand Expansion Valve........................................................................................................................................... |

9-2 |

Capillary Bypass .................................................................................................................................................... |

9-2 |

Freezer Pressure Switch ......................................................................................................................................... |

9-2, 9-3 |

Freezer Pressure Switch (Allen-Bradley), FIGURE 9-1........................................................................................... |

9-2 |

High/Low Pressure Switch ..................................................................................................................................... |

9-3 |

High/Low Pressure Switch, FIGURE 9-2................................................................................................................ |

9-3 |

Head Pressure ........................................................................................................................................................ |

9-4 |

Water Cooled Units................................................................................................................................................ |

9-4 |

Air-Cooled Units.................................................................................................................................................... |

9-4 |

Water Regulating Valve, FIGURE 9-3A ................................................................................................................. |

9-4 |

Condenser Fan Switch, FIGURE 9-3B.................................................................................................................... |

9-4 |

Compressor Crankcase Heater................................................................................................................................ |

9-5 |

Compressor Motor Protection, Electronic ................................................................................................ |

9-5 |

High Potential Testing ...................................................................................................................... |

9-6 |

Field Troubleshooting....................................................................................................................... |

9-6, 9-7 |

Electronic Module and Compressor Terminal Board Connections, FIGURE 9-4 ................................ |

9-7 |

Oil Pressure Safety Control .................................................................................................................................... |

9-8 |

Oil Pressure Sensor .......................................................................................................................... |

9-8 |

Oil Pressure Module......................................................................................................................... |

9-8 |

Thawing Timer, FIGURE 9-5................................................................................................................................. |

9-9 |

Thawing Timer ...................................................................................................................................................... |

9-9 |

Control Circuit Protection ...................................................................................................................................... |

9-9 |

Condenser Cleaning ............................................................................................................................................... |

9-9 |

Air-Cooled Condenser............................................................................................................................................ |

9-9 |

Cutter Gear Reducer .............................................................................................................................................. |

9-9 |

iv

05TA Service Manual

TABLE OF CONTENTS |

Page No. |

Pump Down ........................................................................................................................................................... |

9-10 |

Removal Of Refrigerant From Machine.................................................................................................................. |

9-10 |

Refrigerant Leaks................................................................................................................................................... |

9-11 |

Non-Condensable Gases......................................................................................................................................... |

9-11 |

Compressor Motor Burnout .................................................................................................................................... |

9-11 |

Solenoid Valves ..................................................................................................................................................... |

9-12 |

Thawing Gas Solenoid Valve ( “D” Valve), FIGURE 9-6A..................................................................................... |

9-12 |

Liquid Feed Solenoid Valve ( “A1” & “A2” Valve), FIGURE 9-6B........................................................................ |

9-12 |

Circulating Water Pump Motor .............................................................................................................................. |

9-13 |

Capacity Control Valve (Compressor Unloader) ..................................................................................................... |

9-13, 9-14 |

Copeland Compressor Unloader Valve, FIGURE 9-7.............................................................................................. |

9-13 |

Loaded Operation (Freeze Period) ...................................................................................................................... |

9-14 |

Unloaded Operation (During Thaw Only) ........................................................................................................... |

9-14 |

Component Removal and Replacement Operations ................................................................................................. |

9-14 |

Cutter Motor .................................................................................................................................................... |

9-14 |

Cutter Gear Reducer......................................................................................................................................... |

9-14 |

Water Tank Removal........................................................................................................................................ |

9-15 |

Cutter & Bearing Removal/Installation ............................................................................................................. |

9-15 |

Cutter Assembly, FIGURE 9-8 ............................................................................................................................... |

9-16 |

Cutter Parts (Cylinder Ice), FIGURE 9-9 ................................................................................................................ |

9-17 |

Cutter Drive Parts, FIGURE 9-10........................................................................................................................... |

9-18 |

Crushed Ice Production .......................................................................................................................................... |

9-19 |

10. OPTIONS AND ACCESSORIES |

|

PLC (Programmable Logic Controller) .................................................................................................................. |

10-2 |

Reduced Voltage Compressor Motor Starter .......................................................................................................... |

10-14 |

Power Monitor ...................................................................................................................................................... |

10-17 |

11. TABLES AND CHARTS |

|

P118F Ratings (60 Hz., 30 HP), TABLE 11-1 ........................................................................................................ |

11-2 |

P118F Ratings (50 Hz., 35 HP), TABLE 11-2 ........................................................................................................ |

11-3 |

P118F Capacity Ratings, TABLE 11-3 ................................................................................................................... |

11-4 |

Condenser Water Usage, TABLE 11-4 ................................................................................................................... |

11-5 |

Make-up Water Usage (gpm), TABLE 11-5............................................................................................................ |

11-5 |

Normal Operating Vitals, TABLE 11-6.................................................................................................. |

11-5 |

Recommended Spare Parts List.............................................................................................................. |

11-6 |

Temperature - Pressure Chart for Common Refrigerants, TABLE 11-7................................................... |

11-7 |

Conversion Factors: English to Metric, TABLE 11-8.............................................................................. |

11-8 |

Constants, TABLE 11-9......................................................................................................................... |

11-8 |

12. INDEX

05TA Service Manual |

1-1 |

INTRODUCTION

1. Introduction

TUBE ICEâ, LLC

A Brief History Of Our Company. Henry Vogt Machine Co. was founded as a small machine shop in Louisville, Kentucky in 1880. In 1938, Vogt built the first Tube-Ice® machine and revolutionized the ice-making industry. Our first “sized-ice” machine quickly replaced the old can-ice plants, which required much hard labor and large amounts of floor space for freezing, cutting, and crushing ice by hand.

Today , TUBE ICEâ, LLC carries on the tradition as one of the world’s leading producers of icemaking equipment.

Vogt Energy-Saving Tube-Ice Machines Are Cost Effective. Today, Vogt Tube-Ice® machines enjoy a well-earned reputation as the most energy efficient, dependable ice-making equipment in the world.

Using as little as one-half to one-third the energy required by competitors’ icemakers, Tube-Ice® machines produce the same amount of ice--in restaurants, sports arenas, packing plants, and wholesale operations around the globe--at great savings.

In addition, Tube-Ice® machines are renowned for their long life, giving many customers more than 35 years of dependable service. Ask someone who owns one.

Preview. All the skill in engineering and fabrication that we have learned in over a century of experience, is reflected in the 05TA model Tube-Ice® machines. Since Vogt introduced Tube-Ice® machines in 1938, the process of making Tube-Ice® ice has been widely recognized as the most economical means of production. The machine’s economic and reliable operations have been proven over and over again, in a network of varied types of installations throughout the world.

Furnished with your machine is the “Certificate Of Test”--the report of operating data that is a record of the unit’s satisfactory operation on our factory test floor. It is evidence of our desire to deliver to you “the finest ice-making unit ever made.”

This manual is designed to assist you in the installation, start-up, and maintenance of your unit. Your Tube-Ice® machine will give you a lifetime of service when you install it, maintain it, and service it properly.

Please read your manual carefully before attempting installation, operation, or servicing of this professionally designed piece of equipment.

If you have additional questions, please call your distributor. Also, feel free to phone the factory direct at (502) 635-3000.

8/13/01

1-2 |

05TA Service Manual |

INTRODUCTION

Important Safety Notice. This information is intended for use by individuals possessing adequate backgrounds of electrical, refrigeration and mechanical experience. Any attempt to repair major equipment may result in personal injury and property damage. The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

Special Precautions To Be Observed When Charging Refrigeration Systems. Only technically qualified persons, experienced and knowledgeable in the handling of refrigerant and operation of refrigeration systems, should perform the operations described in this manual. All local, federal, and EPA regulations must be strictly adhered to when handling refrigerants.

If a refrigeration system is being charged from refrigerant cylinders, disconnect each cylinder when empty or when the system is fully charged. A gage should be installed in the charging line to indicate refrigerant cylinder pressure. The cylinder may be considered empty of liquid R-22 refrigerant when the gauge pressure is 25 pounds or less, and there is no frost on the cylinder. Close the refrigerant charging valve and cylinder valve before disconnecting the cylinder. Loosen the union in the refrigerant charging line--carefully to avoid unnecessary and illegal release of refrigerant into the atmosphere.

!CAUTION !

Immediately close system charging valve at commencement of defrost or thawing cycle if refrigerant cylinder is connected. Never leave a refrigerant cylinder connected to system except during charging operation. Failure to observe either of these precautions can result in transferring refrigerant from the system to the refrigerant cylinder, over-filling it, and possibly causing the cylinder to rupture because of pressure from expansion of the liquid refrigerant.

!CAUTION !

Always store cylinders containing refrigerant in a cool place. They should never be exposed to temperatures higher than 125°F and should be stored in a manner to prevent abnormal mechanical shocks.

Also, transferring refrigerant from a refrigeration system into a cylinder can be very dangerous and is not recommended.

!CAUTION !

It is not recommended that refrigerant be transferred from a refrigeration system directly into a cylinder. If such a transfer is made, the refrigerant cylinder must be an approved, CLEAN cylinder--free of any contaminants or foreign materials--and must be connected to an approved recovery mechanism with a safety shutoff sensor to assure contents do not exceed net weight specified by cylinder manufacturer or any applicable code requirements.

! CAUTION !

8/13/01

05TA Service Manual |

1-3 |

INTRODUCTION

Safety Symbols & What They Mean. Prior to installation or operation of the Tube-Ice® machine, please read this manual. Are you familiar with the installation, start-up, and operation of a Tube-Ice® machine? Before you operate, adjust or service this machine, you should read this manual, understand the operation of this machine, and be aware of possible dangers.

These Safety Symbols will alert you

when special care is needed.

Please heed.

!DANGER !

Indicates an immediate hazard and that special precautions are necessary to avoid severe personal injury or death.

! DANGER !

!WARNING !

Indicates a strong possibility of a hazard and that an unsafe practice could result in severe personal injury.

! WARNING !

!CAUTION !

Means hazards or unsafe practices could result in personal injury or product or property damage.

! CAUTION !

8/13/01

1-4 |

05TA Service Manual |

INTRODUCTION

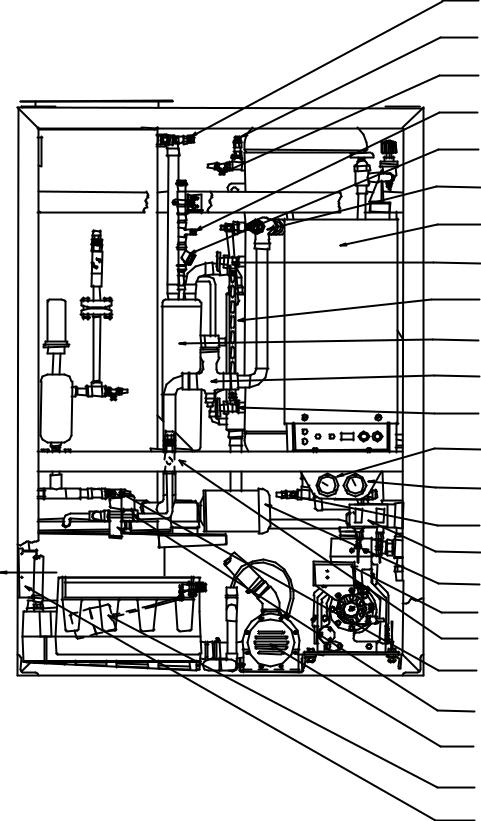

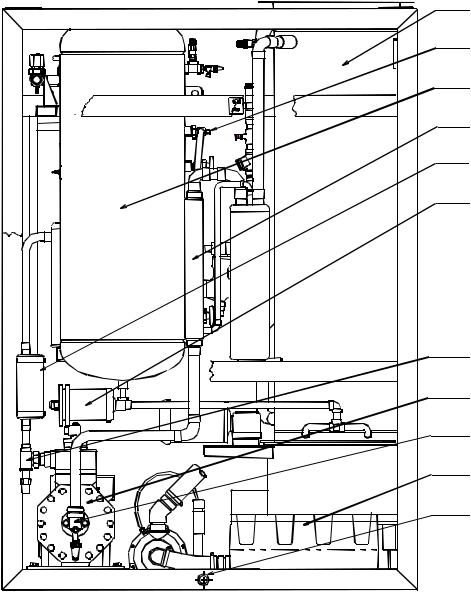

(51) FREEZER SAFETY VALVE

(50) RECEIVER SAFETY VALVE

(59) RECEIVER PURGE VALVE |

1/4” FLARE |

(32) CONDENSER SERVICE |

CONNECTION |

(101) CHECK VALVE |

(90) THAWING GAS |

STOP VALVE |

(1) CONTROL PANEL |

(31) RECEIVER GAGE GLASS |

STOP VALVE |

(30) RECEIVER GAGE GLASS |

(88) SUCTION ACCUMULATOR/ |

HEAT EXCHANGER |

(18) THAW GAS SOLENOID |

VALVE (“D” VALVE) |

(31) RECEIVER GAGE GLASS |

STOP VALVE |

(1PG) LOW PRESSURE GAGE |

(2PG) HIGH PRESSURE GAGE |

(44) RECEIVER DRAIN VALVE |

(4PS) DUAL HIGH/LOW |

PRESSURE SWITCH |

(5M) CUTTER MOTOR |

(94) OIL PRESSURE SWITCH |

1/4” FLARE |

(17) HAND EXPANSION VALVE |

(28) CHARGING VALVE |

(20) LIQUID LINE SOLENOID

VALVE (“A” VALVE)

(6) CIRCULATING WATER PUMP

(12) MAKE-UP WATER FLOAT

ICE DISCHARGE

FIGURE 1-1

Assembly (Air-Cooled)

Front View

8/13/01

05TA Service Manual |

1-5 |

INTRODUCTION

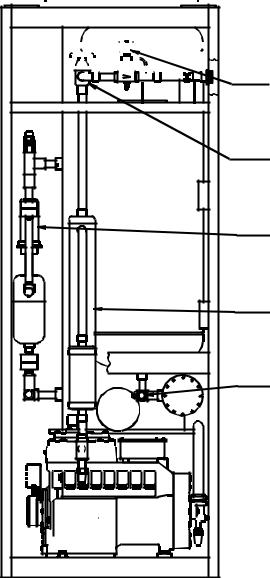

(2) FREEZER

(91) LIQUID RETURN STOP VALVE

(15R) RECEIVER

(13) HEAT EXCHANGER

(48) COMPRESSOR

(46) LIQUID LINE

(35) COMPRESSOR DISCHARGE

(3) COMPRESSOR

(34) COMPRESSOR SUCTION

(7) WATER TANK

(25) WATER TANK DRAIN

FIGURE 1-2

Assembly (Air-Cooled)

Rear View

8/13/01

1-6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

05TA Service Manual |

INTRODUCTION |

|

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

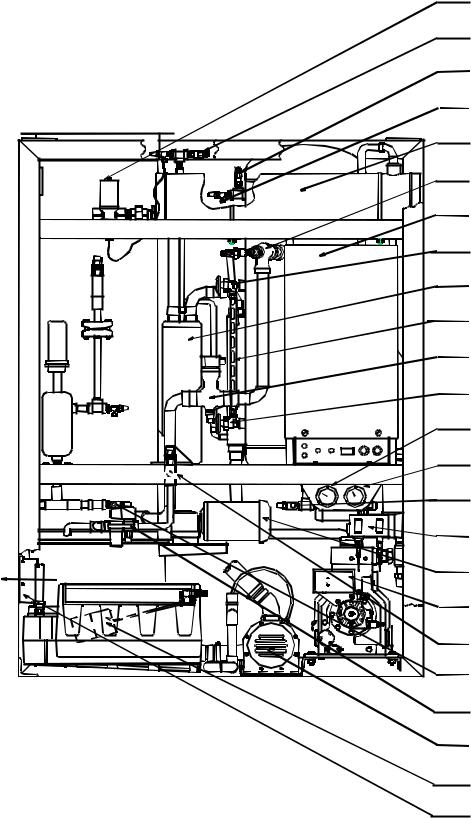

(53) COLD WEATHER SOLENOID VALVE (“X” VALVE)

(55) DISCHARGE LINE STOP VALVE

(22) FLOAT SWITCH

(14) OIL SEPARATOR

(34) LIQUID OUTLET STOP VALVE (KING VALVE)

FIGURE 1-3

Assembly (Air-Cooled)

Right Side View

8/13/01

05TA Service Manual |

1-7 |

INTRODUCTION

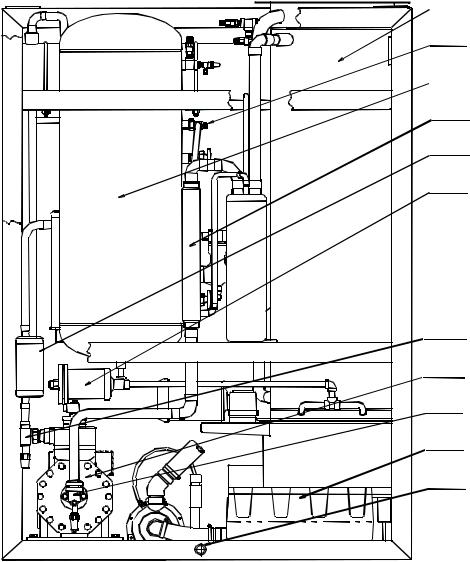

(41) CONDENSER WATER REGULATOR

(51) FREEZER SAFETY VALVE

(50) RECEIVER SAFETY VALVE 5/8” FLARE

(59) RECEIVER PURGE VALVE 1/4” FLARE

(15) CONDENSER

(90) THAWING GAS STOP VALVE

(1) CONTROL PANEL

(31) RECEIVER GAGE GLASS STOP VALVE

(88) SUCTION ACCUMULATOR/ HEAT EXCHANGER

(30) RECEIVER GAGE GLASS

(18) THAW GAS SOLENOID VALVE (“D” VALVE)

(31) RECEIVER GAGE GLASS STOP VALVE

(1PG) LOW PRESSURE GAGE

(2PG) HIGH PRESSURE GAGE

(44) RECEIVER DRAIN VALVE

(4PS) DUAL HIGH/LOW PRESSURE SWITCH

(5M) CUTTER MOTOR

(94) OIL PRESSURE SWITCH 1/4” FLARE

(17) HAND EXPANSION VALVE VALVE (“A” VALVE)

(28) CHARGING VALVE

(20) LIQUID LINE SOLENOID

(6) CIRCULATING WATER PUMP

(12) MAKE-UP WATER FLOAT

ICE DISCHARGE

FIGURE 1-4

Assembly (Water Cooled)

Front View

8/13/01

1-8 |

05TA Service Manual |

INTRODUCTION

(2) FREEZER

(2) FREEZER

(91) LIQUID RETURN STOP VALVE

(15R) RECEIVER

(15R) RECEIVER

(13) HEAT EXCHANGER

(48) COMPRESSOR DISCHARGE MUFFLER

(46) LIQUID LINE FILTER DRIER

(48) COMPRESSOR DISCHARGE SERVICE VALVE

(3) COMPRESSOR

(48) COMPRESSOR SUCTION SERVICE VALVE

(7) WATER TANK

(48) WATER TANK DRAIN CONNECTION 1” FPT

FIGURE 1-5

Assembly (Water Cooled)

Rear View

8/13/01

05TA Service Manual

(22) FLOAT SWITCH

(22) FLOAT SWITCH

(14) OIL SEPARATOR

(58) LIQUID OUTLET STOP VALVE (KING VALVE)

1-9

INTRODUCTION

FIGURE 1-6

Assembly (Water Cooled)

Right Side View

8/13/01

05TA Service Manual |

2-1 |

RECEIPT OF YOUR TUBE-ICE MACHINE

2. Receipt Of Your Tube-Ice Machine

!WARNING !

Only service personnel experienced in refrigeration and qualified to work with high voltage electrical equipment should be allowed to install or work on this Tube-Ice® machine.

!WARNING !

Inspection As soon as you receive your machine, inspect it for any damage. If damage is suspected, note it on the shipper’s papers (i.e., the trucker’s Bill of Lading). Immediately make a separate written request for inspection by the freight line’s agent. Any repair work or alteration to the machine without the permission of the Tube-Ice, LLC can void the machine’s warranty.

The machine was shipped with a full charge of refrigerant stored in the receiver. Visually check all lines for mechanical damage. If a leak is suspected, check all joints with a Halogen Leak Detector. All leaks should be reported to the Henry Vogt Machine Co. to obtain authorization for repair.

!CAUTION !

The approximate weight of the machine is 2450 pounds. Always use equipment with adequate load carrying capacity.

!CAUTION !

The machine frame has lifting lugs at each corner in the top for eyebolts and hooks to be used for lifting purposes if desired. Lifting lugs should be used whenever possible.

!CAUTION !

The Tube-Ice® machine is top heavy.

Secure to avoid tipping.

! CAUTION !

If a forklift is used, make sure its capacity is sufficient. The forks must be wide enough apart to prevent tipping sideways and must extend beyond the extremities of the frame base structure. The machine needs to be bound in place to prevent tipping.

Safety Valves Two safety pressure relief valves are an integral part of the packaged Tube-Ice® machine. One is located in the low-side of the system on the freezer, and one is in the high side of the system on the receiver. Vent each of the pressure relief valves to the atmosphere in such a manner as to comply with local and national codes.

Machine Room The machine must be located inside a suitable building and must not be subjected to ambient temperatures below 50°F (10°C) or above 110°F (43.3°C). Heat from other sources (sunlight, furnaces, condenser, etc.) and unusual air current may affect the operation of the machine and should be avoided. The electrical components of the Tube-Ice® machine are rated NEMA 1. Therefore, the machine should not be located in a hazardous area or sprayed with water. The machine should be installed on a drainable condensate drip pan or in an area where water will not

8/13/01

2-2 05TA Service Manual

RECEIPT OF YOUR TUBE-ICE MACHINE

stand but will readily drain away from the machine. See Space Diagram for clearances and utility connections, FIGURES 3-1 and 3-2.

Storage (prior to installation or start-up). that may reach temperatures 115°F (46.1°C)

The machine must not be stored or installed in an area or above.

!CAUTION !

This equipment contains HCFC-22 or HFC-404a refrigerant under pressure. Do not store in an area exposed to temperatures above 115°F (46°C)

or in direct sun at temperatures above 105°F (40°C).

!CAUTION !

The machine nameplate is located on the front of the control panel. The model number and machine description are located in the top left hand corner. The following figure can be used to verify that the correct model has been received.

Nominal Capacity

"02K" - 2000 lbs/day "03K" - 3000 lbs/day "04K" - 4000lbs/day "03T" - 3 tons/day "05T" - 5 tons/day "10T" - 10 tons/day "25T" - 25 tons/day "50T" - 50 tons/day "80T" - 80 tons/day

("K" = 1000's lbs/day, "T" = tons/day)

XXXX – XXXX – XXXX – XXX

(Consult Specifications for Actual Capacity)

Model Variation

A number assigned to indicate major variations within any one family series.

Basic Configuration

"P" - Package

"L" - Low-side

"H" - High-side

Tube Size (in 1/4's of an inch) "4" - 1"

"5" - 1 1/4" "6" - 1 1/2" "8" - 2"

|

Refrigerant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

"F" - R-22 |

|

|

Type of Ice |

|

|

|

|

|||

|

"A" - Ammonia |

|

|

"B" - Cylinder |

|

|

|

|

|||

|

"H" - R-404a |

|

|

|

|

|

|

||||

|

|

|

"K" - Crushed |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

"D" - Dual Ice (Cru & Cyl) |

|

|

|

|

||

|

|

|

|

|

"L" - 1 1/2" Long Cylinder |

|

|

|

|

||

|

|

|

|

|

"X"- 2” Long Cylinder |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical Codes |

|

|

|

|

|

|

|

||

|

|

|

|

Condenser Type |

|

||||||

|

|

"26" - 208/230-3-60 |

|

|

|

||||||

|

|

|

|

|

|||||||

|

|

|

|

"AC" - Air Cooled |

|

||||||

|

|

"46" - 460-3-60 |

|

|

|

|

|||||

|

|

|

|

|

"WC" - Water Cooled |

|

|||||

|

|

"56" - 575-3-60 |

|

|

|

|

|||||

|

|

|

|

|

"HP" - High Pressure Water Cooled |

|

|||||

|

|

"25" - 200-3-50 |

|

|

|

|

|||||

|

|

|

|

|

"SW" - Sea Water |

|

|||||

|

|

"45" - 400-3-50 |

|

|

|

|

|||||

|

|

|

|

|

"NC" - No Condenser |

|

|||||

|

|

"21" - 230-1-60 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Product Variation Codes (An alphanumeric designator assigned to specific variations.) "000 or Blank" – Standard Product

If unsure of the product code shown on your machine please consult the factory.

Figure 2-1

Vogt Model Nomenclature

8/13/01

05TA Service Manual |

3-1 |

INSTALLING YOUR TUBE-ICE® MACHINE

3. Installing Your Tube-Ice® Machine

!WARNING !

Only service personnel experienced and certified in refrigeration and qualified to work with high voltage electrical equipment should be allowed to install or work

on this Tube-Ice® machine.

!WARNING !

Important Notice.

The Warranty Registration / Start-Up Form must be completed and returned to Vogt Tube-Ice® to initiate and assure a full warranty. A postage paid envelope is provided or you may fax the report to 800-770-8648.

Piping and Drain Connections

Figure 3-1 (Air Cooled) and 3-2 (Water Cooled) show locations and sizes for all connections.

!CAUTION !

External shut-off valves must be provided in the water inlet lines.

The minimum inlet water pressure for satisfactory operation of the machine is 30 psig. The maximum allowable pressure is 100 psig.

!CAUTION !

Make-up |

Water Tank |

Condenser |

Condenser |

Water In |

Drain* |

Water In |

Water Out* |

1/2” MPT |

1” FPT |

1 1/4” FPT |

1 1/4” FPT |

TABLE 3-1

Water Supply and Drain Sizes

The condenser water outlet and water tank drain connections must be extended to an open drain or sump, arranged for visible discharge. Do not trap the water tank drain line, as this will interfere with the operation of the automatic blowdown system.

!CAUTION !

These lines must NOT be connected into a pressure tight common header

due to the possibility that warm condenser water may back up into the water tank. The condenser water outlet MUST be piped separately to the drain.

!CAUTION !

Note: Due to variations in water quality by geographic location, water filtering or treatment may be required to reduce maintenance and inhibit hardness buildup on machine components (tubes, valves). Consult your local water treatment company for recommendations and equipment.

8/13/01

3-2 |

05TA Service Manual |

INSTALLING YOUR TUBE-ICE® MACHINE

FIGURE 3-1

Connections and Space Diagram (Air Cooled Machine)

8/13/01

05TA Service Manual |

3-3 |

INSTALLING YOUR TUBE-ICE® MACHINE

FIGURE 3-2

Connections and Space Diagram (Water Cooled Machine)

8/13/01

3-4 |

05TA Service Manual |

INSTALLING YOUR TUBE-ICE® MACHINE

Wiring and Electrical Connection

!WARNING !

Only service personnel experienced in refrigeration and qualified to work with high voltage electrical equipment should be allowed to install or work on the Tube-Ice® machine.

!WARNING !

Refer to TABLE 3-2 below to properly size wiring connections. A fused disconnect must be provided near the Tube-Ice® machine. Connect 3 phase power to terminals L1, L2, L3 for operation of the Tube-Ice® machine and its controls. Rotation checking of cutter motor and water pump is required (see following section). Also, if one leg of the 3 phase power is higher or lower (“Wild”), then it should be connected to terminal #L2. Connect the “Ground” wire to the “Ground” lug provided.

FIGURE 3-3

Control Panel Power Connections

Standard Voltages |

|

Water Cooled |

|

|

Air Cooled |

|

|

|

|

|

|

|

|

||

F.L.A. |

Min. Ampacity |

Max. Fuse |

F.L.A. |

Min. Ampacity |

Max. Fuse |

||

|

|||||||

208/230, 3ph, 60 Hz |

66.9 |

81.8 |

145 |

76.9 |

91.8 |

155 |

|

460, 3ph, 60 Hz |

32.7 |

39.9 |

70 |

37.2 |

44.4 |

75 |

|

220, 3ph, 50 Hz |

73.3 |

89.8 |

160 |

83.3 |

99.8 |

170 |

|

400, 3ph, 50 Hz |

37.2 |

45.4 |

80 |

42.2 |

50.4 |

85 |

TABLE 3-2

Electrical Specifications

8/13/01

05TA Service Manual |

3-5 |

INSTALLING YOUR TUBE-ICE® MACHINE

Phase Check

!CAUTION !

DO NOT attempt to start machine without priming pump and insuring proper rotation of both cutter and pump.

Refer to FIGURE 3-1 & 3-2 (space diagram) for connection locations.

!CAUTION !

Cutter and pump motor rotation are factory synchronized but must be checked at installation. For ice production, the cutter disc, as viewed at the ice discharge opening should turn from left to right (crushed rotation should be from right to left). The pump rotation should match the marking on the pump housing. The pump will need to be primed by starting the machine in the clean mode and allowing it to run for several minutes. To change direction of rotation for both, cutter and pump, disconnect power and reverse L1 and L3 (incoming power wires) at the compressor motor contactor.

Voltage Unbalance Voltage unbalance can cause motors to overheat and fail.

The maximum voltage unbalance between any two legs should be no greater than 2%.

Example: Supply Voltage = 230-3-60

Voltage Readings: |

AB = 220 Volts |

|

|

BC = 225 Volts |

Average = (220 + 225 + 227)/3 = 224 Volts |

|

AC = 227 Volts |

|

(AB) 224-220 = 4 |

Volts (Highest Deviation) |

|

(BC) 225-224 = 1 |

Volts |

% Voltage Unbalance = 100 x (4/224) = 1.78% “Acceptable” |

(AC) 227-224 = 3 Volts |

|

|

Important: If the supply voltage phase unbalance is more the 2%, contact your local electric utility company.

Current Unbalance Voltage unbalance will cause a current unbalance, but a current unbalance does not necessarily mean that a voltage unbalance exists. A loose terminal connection or a buildup of dirt or carbon on one set of contacts would cause a higher resistance on that leg than on the other two legs. Current follows the path of least resistance, therefore if terminal connection L1 is loose or dirty, L2 and/or L3 will have higher current. Higher current causes more heat to be generated in the motor windings.

The maximum acceptable current unbalance is 10%.

Example:

Current Readings: |

L1 = 96 Amps |

|

||

|

|

|

L2 = 91 Amps |

Average = (96 + 91 + 98)/3 = 95Amps |

|

|

|

L3 = 98 Amps |

|

(L1) |

96-95 |

= 1 Amps |

|

|

(L2) |

95-91 |

= 4 Amps (Highest Deviation) |

% Current Unbalance = 100 x (4/95) = 4.2% “Acceptable” |

|

(L3) |

98-95 |

= 3 Amps |

|

|

8/13/01

3-6 |

05TA Service Manual |

INSTALLING YOUR TUBE-ICE® MACHINE

Air-Cooled Condenser Installation Instructions

!WARNING !

These installation guidelines must be followed to obtain reliable operation from air cooled ice machines.

IF THESE GUIDELINES ARE NOT FOLLOWED THE COMPRESSOR WARRANTY WILL NOT BE HONORED.

!WARNING !

1.Use only Vogt approved condensers. Any exceptions to this policy must be obtained in writing from Vogt prior to installation and operation of the ice machine.

2.Outdoor condensers must be installed with vertical air flow. Indoor condensers used for heat recovery may be installed with either horizontal or vertical air flow.

3.The condenser must be mounted above the ice machine.

4.Horizontal runs in the liquid return line should slope 1/4” per foot with liquid refrigerant draining freely in the direction of normal operating flow (back to the ice machine) with no traps in the liquid line.

5.Horizontal runs in the discharge line should slope 1/4” per foot in the normal direction of flow (away from the ice machine).

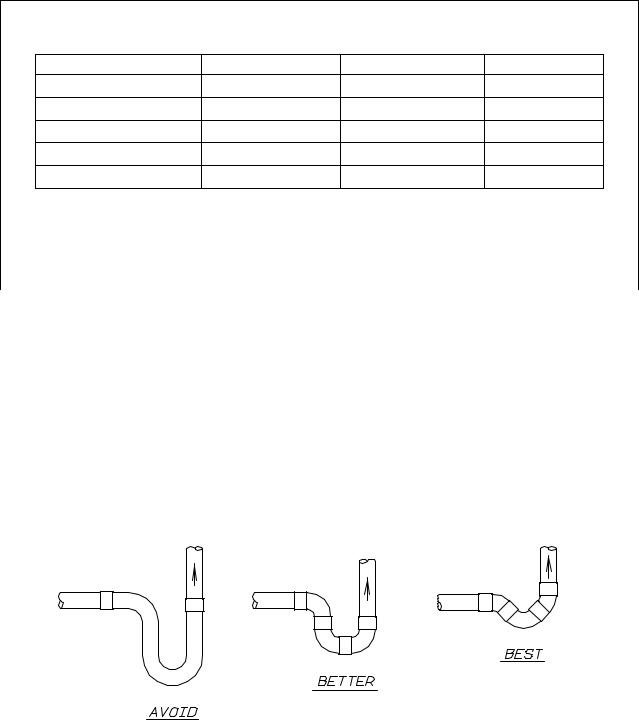

6.Traps must be installed in discharge lines at the base of all vertical risers. There should be no intentional traps in liquid lines. Trap volume should be kept to a minimum. Long vertical rises should have traps every 20 feet. Typical details are shown in FIGURE 3-7.

7.Flooding head pressure controls such as Alco Headmaster are not to be used since they cause excessive subcooling of the returned liquid refrigerant and interfere with reliable ice harvest.

8.The discharge and liquid lines must be insulated with 1/2” thick Armaflex insulation or equal.

9.Use only ACR grade copper pipe, Type L. Recommended line sizes are shown in TABLE 3-3.

10.For field attachment instructions, see FIGURE 3-4.

11.Distance between ice machine and condenser must not exceed 150 equivalent feet. Refer to Condenser Equivalent Line Size worksheet (see TABLE 3-5 ).

12.Condensers must be provided with a cold weather valve kit per FIGURE 3-8. These valves allow one-half of the condenser to be disabled in cold weather. Running the ice machine with one-half of the condenser in cold weather makes it easier to maintain minimum necessary condensing pressure particularly in windy conditions.

13.Condensers with multiple fans must be provided with a thermostat to turn off unneeded fans in cold weather. Turning off unneeded fans reduces on-off cycling of the fan(s) and allows for a steadier condensing pressure and more consistent warm gas for ice harvesting.

8/13/01

05TA Service Manual |

3-7 |

INSTALLING YOUR TUBE-ICE® MACHINE

14.When extreme cold conditions are expected or encountered (temperatures below 0°F and wind greater than 15 MPH), it may be necessary to install a protective enclosure around the condenser. Apparatuses such as louvers may also be used for varying conditions. Contact the factory for suggestions.

15.After installation, the field installed lines are to be evacuated to a vacuum of 500 microns or less and held for at least one hour. After the vacuum pump is removed, vacuum should hold at 500 microns or less for at least 5 minutes.

16.The machine is shipped with a full operating charge of refrigerant sufficient to fill the condenser and connecting lines. If the condenser piping is longer than 50 feet (one way), additional R-22 or R-404a may need to be added to retain enough refrigerant in the receiver for thawing purposes (see table. Refer to the operating level mark on the receiver and charge accordingly. Each 1” of liquid level in the receiver equals approximately 5.5 pounds of R-22 or R-404a.

Liquid Line Size |

|

75 ft. |

100 ft. |

125 ft. |

150 ft. |

1/2” |

|

none |

None |

None |

2 |

5/8” |

|

none |

2 |

4 |

6 |

7/8” |

|

none |

4 |

8 |

12 |

1-1/8” |

|

none |

6 |

12 |

18 |

|

|

|

TABLE 3-3 |

|

|

|

Pounds of R-22 to Add vs. Liquid Line Length |

|

|||

17.All piping must be done in accordance with applicable local and national codes. Such codes may include “The Safety Code For Mechanical Refrigeration” (ANSI B9.1) and “The Code For Refrigerant Piping” (ANSI B31.5).

18.The following installation guidelines are strongly suggested. While they do not affect the machine warranty, they may be required for safe operation and to comply with all applicable electrical and mechanical codes:

a.Local electrical code must be checked for wiring method.

b.The installer must provide a disconnect switch(s) adjacent to the condenser.

c.Electrical connections between the condenser and the Tube-Ice® machine require

minimum 12 ga. wire.

d.All electrical fittings and components exposed to the weather must be suitable for outdoor installation.

The design total heat rejection for each Tube-Ice® machine, the recommended air-cooled condenser, and condenser physical and electrical data are shown on the next page. Specified energy efficiency ratings of the ice machines are based on use of the recommended condenser and approved piping practices.

Recommended condensers provide the indicated total heat rejection at 90°F ambient, 100°F condensing. Tube Ice, LLC is not responsible for head pressure problems if other than the recommended condensers are used. For continuous operation at ambient temperature above 105°F, consult the factory about using a larger condenser.

8/13/01

3-8 |

05TA Service Manual |

INSTALLING YOUR TUBE-ICE® MACHINE

Ice Machine Model |

05TA |

05TA |

|

Electrical Frequency, Hz. |

60 |

50 |

|

Recommended Condenser |

DD-311 |

DD-361 |

|

Total Heat Rejection (BTU/hr) |

181,200 |

193,250 |

|

Fans: |

|

|

|

Number |

5 |

5 |

|

HP, Each |

1/2 |

1/2 |

|

Total CFM |

22,000 |

22,500 |

|

Full Load Amps (FLA): |

|

|

|

3 ph., 208/230V., 60 hz. |

9.0 |

9.0 |

|

3 ph., 460V., 60 hz. |

4.5 |

4.5 |

|

3 ph., 190V., 50 hz. |

-- |

9.0 |

|

3 ph., 380V., 50 hz. |

-- |

4.5 |

|

Locked Rotor Amps (LRA): |

|

|

|

3 ph., 208/230V., 60 hz. |

33.0 |

-- |

|

3 ph., 460V., 60 hz. |

16.5 |

-- |

|

3 ph., 190V., 50 hz. |

-- |

33.0 |

|

3 ph., 380V., 50 hz. |

-- |

16.5 |

|

Weight, lbs.: |

|

|

|

Net |

610 |

660 |

|

Shipping |

760 |

810 |

|

Operating (Maximum flooded)R-404a |

648 |

705 |

|

Condenser Dimensions, inches |

|

|

|

A |

(Width) |

28 3/4” |

28 3/4” |

B |

(Length) |

180 1/8” |

180 1/8” |

C |

(Height) |

41 5/8” |

41 5/8” |

D |

(Leg centerline) |

27” |

27” |

E |

(Leg centerline) |

147 5/8” |

147 5/8” |

F |

(Clearance below) |

14 5/8” |

14 5/8” |

Recommended Line Sizes, OD |

|

|

|

Liquid |

|

|

|

|

All lengths and orientations |

1 1/8” |

1 1/8” |

Discharge Gas |

|

|

|

|

Vertical Up, all lengths |

1 1/8” |

1 1/8” |

|

Horiz. or Down, < 75 ft. |

1 1/8” |

1 1/8” |

|

Horiz. or Down > 75 ft. |

1 1/8” |

1 1/8” |

Connections (Cond. & Ice Mach.): |

|

|

|

Liquid (ODF) |

1 1/8” |

1 1/8” |

|

Discharge Gas (ODF) |

1 3/8” |

1 3/8” |

|

Ice Machine Model |

05TA |

05TA |

|

TABLE 3-4

Air-Cooled Condenser Data

8/13/01

05TA Service Manual |

3-9 |

INSTALLING YOUR TUBE-ICE® MACHINE

FIGURE 3-4

Condenser Dimensions (Condenser pictured: DD-231)

Note: Dash lines indicate customer supplied piping.

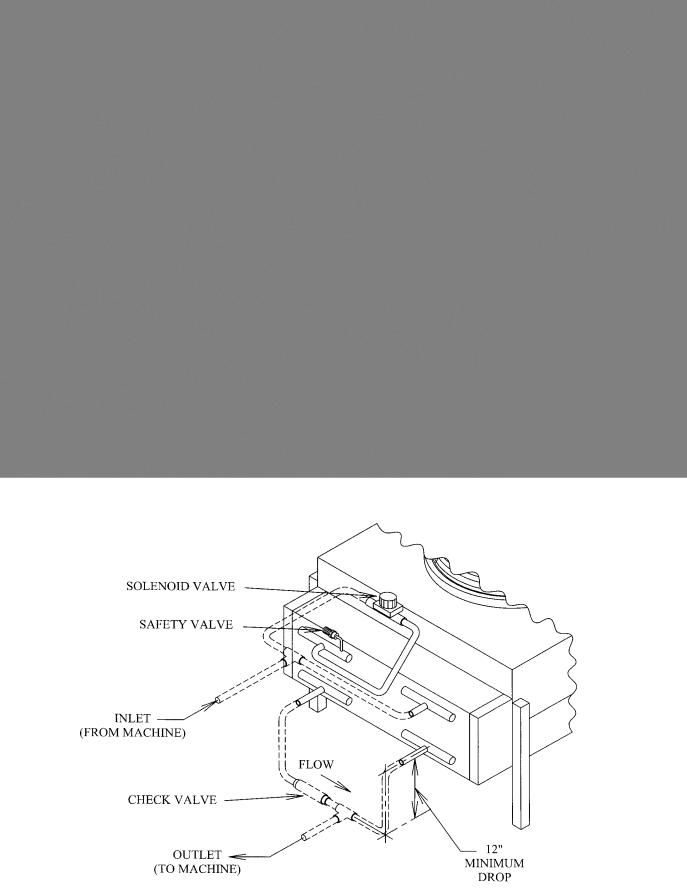

FIGURE 3-5

Condenser Field Piping (Cold Weather Valve Kit)

8/13/01

3-10 |

05TA Service Manual |

INSTALLING YOUR TUBE-ICE® MACHINE

CONDENSER EQUIVALENT LINE SIZE WORKSHEET

Discharge Gas Line O.D. ___________________

Fitting Type Number Used Factor Total

Globe Valve (open)

Angle Valve (open)

90° Elbow

45° Elbow

Tee

|

Feet of Straight Copper Used |

|

|

|

|

|||

|

|

Total Fitting Factor |

|

|

|

|

||

|

Total Equivalent Feet |

|

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

Copper Tubing Type “L” |

|

1 1/8” O.D. |

1 3/8” O.D. |

1 5/8” O.D. |

2 1/8” O.D. |

|||

|

Globe valve (open) |

|

28 |

36 |

42 |

|

57 |

|

|

Angle valve (open) |

|

15 |

18 |

21 |

|

28 |

|

|

90o Elbow |

|

3 |

4 |

4 |

|

5 |

|

|

45o Elbow |

|

1.5 |

2 |

2 |

|

2.5 |

|

|

Tee (90° turn through) |

|

6 |

8 |

9 |

|

12 |

|

|

Tee (straight through) |

|

2 |

2.5 |

2.8 |

|

3.5 |

|

TABLE 3-5

Equivalent Feet Due To Friction

FIGURE 3-6

Minimum Traps For Discharge Lines

*Note: Each recommended line size is based on use of Type “L” copper tubing at a maximum equivalent distance of 150 feet. See TABLE 3-5 for equivalent feet of valves and fittings.

8/13/01

05TA Service Manual |

3-11 |

INSTALLING YOUR TUBE-ICE® MACHINE

Air-Cooled Condenser Wiring

FIGURE 3-7

Wiring For #DD-311 and #DD-361 Condenser

(3 phase motors)

Air-Cooled Connections (See FIGURE 3-1 for connection sizes)

Follow these procedures to make a tight joint:

1.Silver solder or braze condenser tubing ends to the female Rota-lock connectors.

2.Remove dust caps if used, making sure that component plastic seals are intact.

3.Wipe off connector and spud threaded surfaces with a clean cloth to prevent the inclusion of dirt or any foreign material in the system.

4.Connector coupling nut should be screwed onto Rota-lock spud using the proper amount of torque.

Spud Size |

Amount of Torque |

7/8” |

50-60 FT LBS |

1 1/8” |

80-100 FT LBS |

1 3/8” |

100-110 FT LBS |

TABLE 3-6

Rota-lock Connector Torque Ratings

8/13/01

Loading...

Loading...