Page 1

HEC SERVICE MANUAL

Page 2

HEC-Series Service Manual

TABLE OF CONTENTS

Table Of Contents

Models HEC-10, HEC-20, HEC-30 & HEC-40

Page No.

1. INTRODUCTION

A Brief History of Our Company................................................................................................................ 1-1

Vogt Energy-Saving Tube-Ice® Machines................................................................................................... 1-1

Preview .................................................................................................................................................... 1-1

Important Safety Notice............................................................................................................................... 1-2

Special precautions to be observed when charging refrigeration systems................................................... 1-2

Safety Symbols & What They Mean........................................................................................................... 1-3

Tube-Ice

Assembly Drawing Model HEC-30 Air-Cooled, FIGURES 1-2A & 1-2B ................................................. 1-5&1-6

Assembly Drawing Model HEC-30 Water Cooled, FIGURES 1-3A & 1-3B............................................. 1-7&1-8

®

Machine, FIGURE 1-1............................................................................................................... 1-4

i

Piping Nomenclature................................................................................................................................... 1-9

2. RECEIPT OF YOUR TUBE-ICE® MACHINE

Inspection ................................................................................................................................................... 2-1

Safety Valves............................................................................................................................................... 2-1

Machine Room ............................................................................................................................................ 2-1

Storage .................................................................................................................................................... 2-1

3. INSTALLING YOUR TUBE-ICE® MACHINE

Installation Without Bin .............................................................................................................................. 3-1

Bin Installation ............................................................................................................................................ 3-1

Two Methods Of Lifting & Setting Machine On a Level Ice Storage Bin................................................... 3-1

Forklift-&-Blocks Method, FIGURE 3-1............................................................................................. 3-2

Forklift-&-Rope Or Lifting Straps Method, FIGURE 3-2.................................................................... 3-3

Wiring and Electrical Connection................................................................................................................ 3-4

Power Connection, FIGURE 3-3................................................................................................................. 3-4

Piping and Drain Connections..................................................................................................................... 3-5

Water Supply and Drains, TABLE 3-1........................................................................................................ 3-5

Space Diagram (Water Cooled), FIGURE 3-4 ............................................................................................ 3-6

Space Diagram (Air-Cooled), FIGURE 3-5 ................................................................................................ 3-7

Air-Cooled Condenser Installation ............................................................................................................. 3-8

Additional Refrigerant Requirements, TABLE 3-2..................................................................................... 3-9

Air-Cooled Condenser Data, TABLE 3-3 ................................................................................................... 3-10

Condenser Dimensions (Condenser pictured DD-101 or DD-131), FIGURE 3-6....................................... 3-11

10/23/01

Page 3

ii

TABLE OF CONTENTS

Page No.

Condenser Field Piping, FIGURE 3-7......................................................................................................... 3-11

Equivalent Feet of Fittings Due to Friction, TABLE 3-4 ............................................................................ 3-12

Minimum Traps For Discharge Lines, FIGURE 3-8................................................................................... 3-12

Condenser Piping, FIGURE 3-9.................................................................................................................. 3-13

Wiring For DD-41 & DD-61, FIGURE 3-10 .............................................................................................. 3-14

Wiring For DD-101 & DD-131, FIGURE 3-11 .......................................................................................... 3-14

Air-Cooled Condenser Enclosure, FIGURE 3-12........................................................................................ 3-15

Field Attachment Air-Cooled Condenser Refrigerant Tubing, FIGURE 3-13............................................ 3-16

Ice Bin Thermostat Bulb Installation........................................................................................................... 3-17

Location of Thermostat Bulbs In Ice Storage Bin, FIGURE 3-14............................................................... 3-17

Wiring For Single Thermostat Operation, FIGURE 3-15............................................................................ 3-18

Installation Review: A Checklist................................................................................................................ 3-19

4. HOW YOUR TUBE-ICE® MACHINE WORKS

HEC-Series Service Manual

Principle of Operation ................................................................................................................................. 4-1

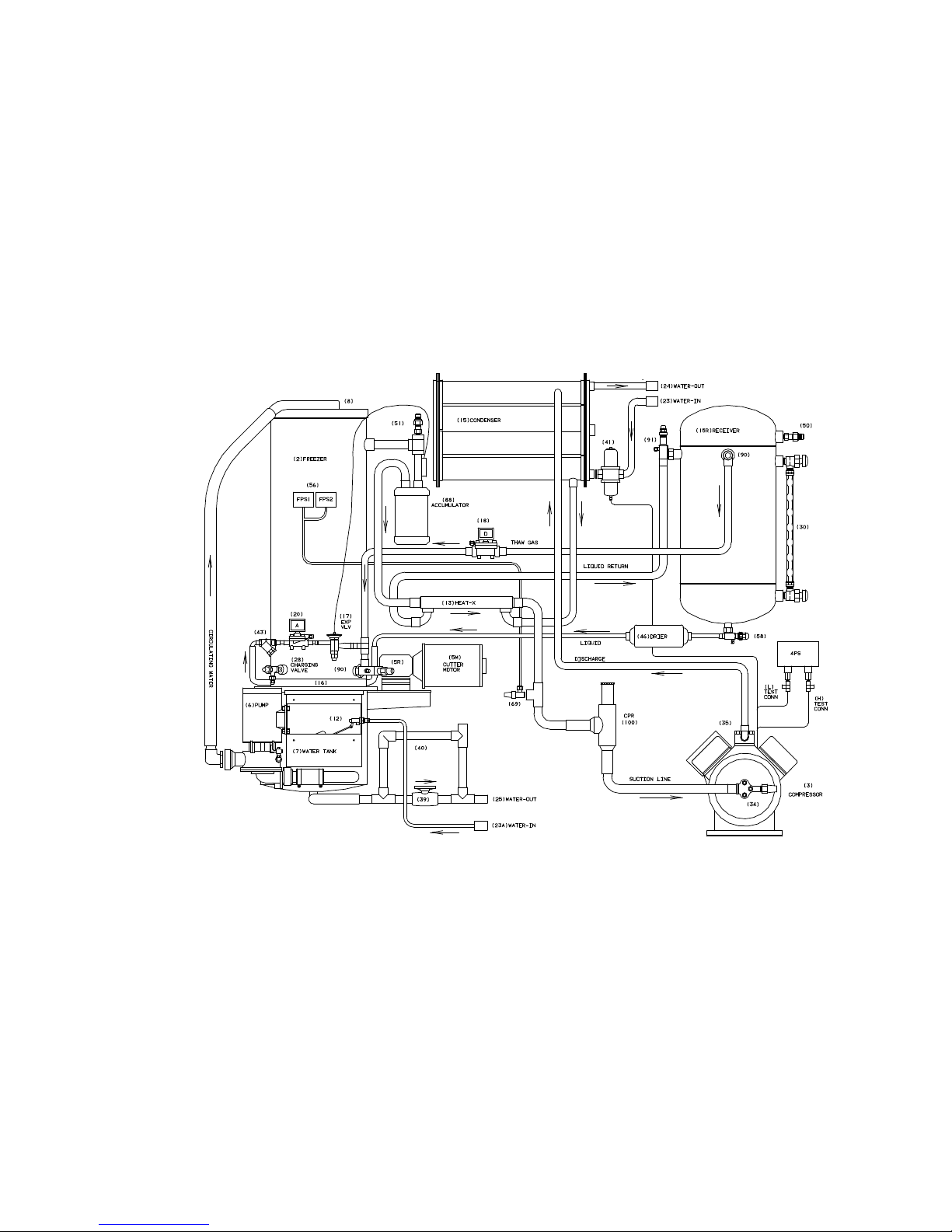

Piping Diagram With Reference Numbers, FIGURE 4-1............................................................................ 4-2

How Ice Is Stored

Dual Ice .................................................................................................................................................... 4-3

Single Ice .................................................................................................................................................... 4-4

Ice Bin Capacity.......................................................................................................................................... 4-4

Refrigeration System................................................................................................................................... 4-5

5. INITIAL START-UP AND OPERATION

Start-up Checklist........................................................................................................................................ 5-1

Solenoid Valve (Liquid Line), FIGURE 5-1 ............................................................................................... 5-2

Refrigerant Charge ...................................................................................................................................... 5-3

Total Pump Down Mode ............................................................................................................................ 5-3

Piping Schematic Air-Cooled, FIGURE 5-2................................................................................................ 5-5

Piping Schematic Water Cooled, FIGURE 5-3 ........................................................................................... 5-6

6. ELECTRICAL CONTROLS & THEIR FUNCTIONS

Control Panel, FIGURE 6-1 ........................................................................................................................ 6-1

Description of Control Panel Parts .............................................................................................................. 6-2

Switch Box, FIGURE 6-2............................................................................................................................ 6-3

Description of Switch Box Parts.................................................................................................................. 6-4

10/23/01

Page 4

HEC-Series Service Manual

Page No.

PLC Features & Functions........................................................................................................................... 6-5

PLC Control Sequence Flow Chart, FIGURE 6-3................................................................................ 6-6

PLC Mode Identification & Operation................................................................................................. 6-7

PLC Start-Up Mode.............................................................................................................................. 6-7

PLC Stand-By Mode ............................................................................................................................ 6-8

PLC Freeze Mode................................................................................................................................. 6-8

PLC Harvest Mode............................................................................................................................... 6-8

PLC Partial Pump-Down Mode............................................................................................................ 6-9

PLC Total Pump-Down Mode.............................................................................................................. 6-9

PLC Clean Mode.................................................................................................................................. 6-10

PLC Troubleshoot Mode...................................................................................................................... 6-10

PLC Fault Identity, TABLE 6-2........................................................................................................... 6-11

PLC Display, FIGURE 6-4................................................................................................................... 6-12

TABLE OF CONTENTS

iii

PLC Inputs & Outputs, TABLE 6-3..................................................................................................... 6-12

PLC Modes, FIGURE 6-5.................................................................................................................... 6-13

Machine Off (Dual Ice), FIGURE 6-6......................................................................................................... 6-14

Machine Off (Single Ice), FIGURE 6-6A.................................................................................................... 6-15

Freeze Cycle (Dual Ice), FIGURE 6-7 ........................................................................................................ 6-16

Freeze Cycle (Single Ice), FIGURE 6-7A................................................................................................... 6-17

Harvest Cycle (Dual Ice), FIGURE 6-8....................................................................................................... 6-18

Harvest Cycle (Single Ice), FIGURE 6-8A ................................................................................................. 6-19

Clean Cycle (Dual Ice), FIGURE 6-9.......................................................................................................... 6-20

Clean Cycle (Single Ice), FIGURE 6-9A..................................................................................................... 6-21

7. MAINTENANCE

Ice-making Section...................................................................................................................................... 7-1

Cleaning Procedure ..................................................................................................................................... 7-1

Water Distributors....................................................................................................................................... 7-2

Water Tank.................................................................................................................................................. 7-2

Drip Pan .................................................................................................................................................... 7-2

Water Cooled Condensers ........................................................................................................................... 7-2

Draining .................................................................................................................................................... 7-3

Chemical Cleaning....................................................................................................................................... 7-4

Mechanical Cleaning................................................................................................................................... 7-5

Part I..................................................................................................................................................... 7-5

Part II.................................................................................................................................................... 7-5

Air-Cooled Condenser Cleaning.................................................................................................................. 7-5

10/23/01

Page 5

iv

TABLE OF CONTENTS

Page No.

Lubrication .................................................................................................................................................. 7-6

Compressor........................................................................................................................................... 7-6

Cutter Gear Reducer............................................................................................................................. 7-6

Preventative Maintenance............................................................................................................................ 7-7

Daily Checklist..................................................................................................................................... 7-7

Note To Manager or Owner ................................................................................................................. 7-7

Preventive Maintenance Program......................................................................................................... 7-8

8. TROUBLESHOOTING (A Checklist)

Machine Won’t Run .................................................................................................................................... 8-1

Freeze-up Due To Extended Freezing Period.............................................................................................. 8-2

Freeze-up Due To Ice Failing To Discharge ............................................................................................... 8-3

Low Ice Capacity......................................................................................................................................... 8-4

Safety Pressure Switches Stop Machine...................................................................................................... 8-5

HEC-Series Service Manual

Motor Overload Protectors Stop Machine................................................................................................... 8-6

9. SERVICE OPERATIONS

Adjustable Blowdown (For Clearer Ice)...................................................................................................... 9-1

Automatic Blowdown (Harvest Cycle)........................................................................................................ 9-1

Float Valve (Make-Up Water)..................................................................................................................... 9-1

Expansion Valve.......................................................................................................................................... 9-1

Expansion Valve Adjustment Procedure & Installation .............................................................................. 9-2

Recommended Superheat Setting, TABLE 9-1........................................................................................... 9-2

Freezer Pressure Switches ........................................................................................................................... 9-3

Freezer Pressure Switch (Allen-Bradley), FIGURE 9-1.............................................................................. 9-3

Allen Bradley Switch................................................................................................................................... 9-4

High/Low Pressure Switch.......................................................................................................................... 9-4

High/Low Pressure Switch, FIGURE 9-2.................................................................................................... 9-5

Head Pressure.............................................................................................................................................. 9-5

Air-Cooled Units......................................................................................................................................... 9-5

Water Regulating Valve, FIGURE 9-3........................................................................................................ 9-6

Condenser Fan Switch, FIGURE 9-4........................................................................................................... 9-6

Water Cooled Units..................................................................................................................................... 9-6

Compressor Crankcase Heater..................................................................................................................... 9-6

Ice Bin Thermostat(s) Adjustments............................................................................................................. 9-6

Ice Bin Thermostat, FIGURE 9-5................................................................................................................ 9-7

Thawing Timer, FIGURE 9-6...................................................................................................................... 9-8

Thawing Timer............................................................................................................................................ 9-8

Page No.

10/23/01

Page 6

HEC-Series Service Manual

Ice Selector Switch, FIGURE 9-7................................................................................................................ 9-8

Ice Selector Switch...................................................................................................................................... 9-8

Control Circuit Protection ........................................................................................................................... 9-9

Circulating Water Pump Motor ................................................................................................................... 9-9

Condenser Cleaning..................................................................................................................................... 9-9

Air-Cooled Condenser................................................................................................................................. 9-10

Cutter Gear Reducer.................................................................................................................................... 9-10

Cutter Bearing ............................................................................................................................................. 9-10

Cutter and Gear Drive.................................................................................................................................. 9-11

Cutter-Water Tank Assembly, FIGURE 9-8................................................................................................ 9-12

Cutter-Water Tank Parts, FIGURE 9-9 ....................................................................................................... 9-13

Cutter Drive Parts, FIGURE 9-10 ............................................................................................................... 9-14

Cutter Parts, FIGURE 9-11 ......................................................................................................................... 9-15

Ice Discharge Arrangement, FIGURE 9-12................................................................................................. 9-16

TABLE OF CONTENTS

v

Pumping Down Freezer............................................................................................................................... 9-17

Removal Of Refrigerant From Machine...................................................................................................... 9-17

Refrigerant Leaks ........................................................................................................................................ 9-18

Non-Condensable Gases.............................................................................................................................. 9-18

Compressor Motor Burnout......................................................................................................................... 9-18

Solenoid Valve (Liquid Line and Thawing Gas), FIGURE 9-13................................................................. 9-19

Solenoid Valves........................................................................................................................................... 9-19

Water Distributors....................................................................................................................................... 9-19

Water Tank.................................................................................................................................................. 9-20

CPR (Crank Pressure Regulator), FIGURE 9-14 ........................................................................................ 9-20

CPR Valve Settings, TABLE 9-2................................................................................................................ 9-21

Cylinder Ice to Crushed Ice Conversion...................................................................................................... 9-21

Cylinder to Crushed, Terminal Block jumper Locations, FIGURE 9-15 ............................................. 9-21

Recommended Freezer Pressure Setting, TABLE 9-3.......................................................................... 9-22

Freezer Pressure Switch, FIGURE 9-16............................................................................................... 9-22

Recommended Ice Weights/Cycle, TABLE 9-4................................................................................... 9-23

Single to Dual Ice Conversion.............................................................................................................. 9-23

10. MODEL NUMBER STRUCTURE FOR HEC MACHINES................................................................ 10-1

10/23/01

Page 7

vi

TABLE OF CONTENTS

Page No.

11. TABLES AND CHARTS

Ice Capacity TABLE 11-1........................................................................................................................... 11-1

Normal Operating Vitals, TABLE 11-2 ...................................................................................................... 11-2

Temperature-Pressure Chart, TABLE 11-3................................................................................................. 11-3

English-Metric Conversion, TABLE 11-4................................................................................................... 11-4

12. TECHNICAL SERVICE BULLETINS .................................................................................................. 12-1

13. INDEX .................................................................................................................................................... 13-1

HEC-Series Service Manual

10/23/01

Page 8

HEC-Series Service Manual

A Brief History Of Our Company. Henry Vogt Machine Co. was founded as a small

machine shop in Louisville, Kentucky in 1880. Today, Vogt Tube Ice, LLC is one of the

world’s leading producers of ice-making equipment.

In 1938, Vogt built the first Tube-Ice® machine and revolutionized the ice-making industry.

Our first “sized-ice” machine quickly replaced the old can-ice plants, which required much

hard labor and large amounts of floor space for freezing, cutting, and crushing ice by hand.

Vogt Energy-Saving Tube-Ice Machines Are Cost Effective. Today, Vogt Tube-Ice®

machines enjoy a well-earned reputation as the most energy efficient, dependable ice-making

equipment in the world.

Using as little as one-half to one-third the energy required by competitors’ ice makers, TubeIce® machines produce the same amount of ice--in restaurants, sports arenas, packing plants,

and wholesale operations around the globe--at great savings.

In addition, Tube-Ice® machines are renowned for their long life, giving many customers more

than 35 years of dependable service. Ask someone who owns one.

Preview. All the skill in engineering and fabrication that we’ve learned in over a century of

experience is reflected in the HEC model Tube-Ice® machines. Since Vogt introduced TubeIce® machines in 1938, the process of making Tube-Ice® ice has been widely recognized as the

most economical means of production. The machine’s economic and reliable operation have

been proven over and over again, in a network of varied types of installations throughout the

world.

Furnished with your machine is the Certificate Of Test--the report of operating data which is a

record of the unit’s satisfactory operation at our factory test floor. It is evidence of our desire

to deliver to you “the finest ice-making unit ever made.”

This manual is designed to assist you in the installation, start-up, and maintenance of your

unit. Your Tube-Ice® machine will give you a lifetime of service when you install it, maintain

it, and service it properly.

Please read your manual carefully before attempting installation, operation, or servicing of this

professionally-designed piece of equipment. Also, make sure the Warranty Registration/Startup Report is completed and returned.

If you have additional questions, please call your distributor. Also, feel free to phone the

factory direct at (502) 635-3000 or toll free (800) 853-VOGT.

1-1

INTRODUCTION

1. Introduction

Henry Vogt Machine Co.

10/24/01

Page 9

1-2

INTRODUCTION

Important Safety Notice. This information is intended for use by individuals possessing

adequate backgrounds of electrical, refrigeration and mechanical experience. Any attempt to

repair major equipment may result in personal injury and property damage. The manufacturer

or seller cannot be responsible for the interpretation of this information, nor can it assume any

liability in connection with its use.

Special Precautions To Be Observed When Charging Refrigeration Systems. Only

technically-qualified persons, experienced and knowledgeable in the handling of refrigerant

and operation of refrigeration systems, should perform the operations described in this

manual. All local, federal, and EPA regulations must be strictly adhered to when handling

refrigerants.

If a refrigeration system is being charged from refrigerant cylinders, disconnect each cylinder

when empty or when the system is fully charged. A gage should be installed in the charging

line to indicate refrigerant cylinder pressure. The cylinder may be considered empty of liquid

HCFC-22 refrigerant when the gauge pressure is 25 pounds or less, and there is no frost on

the cylinder. Close the refrigerant charging valve and cylinder valve before disconnecting the

cylinder. Loosen the union in the refrigerant charging line--carefully to avoid unnecessary and

illegal release of refrigerant into the atmosphere.

Immediately close system charging valve at commencement of defrost or thawing cycle

if refrigerant cylinder is connected. Never leave a refrigerant cylinder connected to

system except during charging operation. Failure to observe either of these precautions

can result in transferring refrigerant from the system to the refrigerant cylinder, overfilling it, and possibly causing the cylinder to rupture because of pressure from

expansion of the liquid refrigerant brought on by an increase in temperature.

Always store cylinders containing refrigerant in a cool place. They should never be exposed

to temperatures higher than 125°F and should be stored in a manner to prevent abnormal

mechanical shocks.

Also, transferring refrigerant from a refrigeration system into a cylinder can be very dangerous

and is not recommended.

It is not recommended that refrigerant be transferred from a refrigeration system

directly into a cylinder. If such a transfer is made, the refrigerant cylinder must be an

approved, CLEAN cylinder--free of any contaminants or foreign materials--and must

be connected to an approved recovery mechanism with a safety shutoff sensor to assure

contents do not exceed net weight specified by cylinder manufacturer or any applicable

code requirements.

HEC-Series Service Manual

! CAUTION !

! CAUTION !

! CAUTION !

! CAUTION !

10/24/01

Page 10

HEC-Series Service Manual

INTRODUCTION

Safety Symbols & What They Mean. Prior to installation or operation of the Tube-Ice® machine,

please read this manual. Are you familiar with the installation, start-up, and operation of a Tube-Ice®

machine? Before you operate, adjust or service this machine, you should read this manual,

understand the operation of this machine, and be aware of possible dangers.

These safety symbols will alert you

when special care is needed.

Please heed.

! DANGER !

Indicates an immediate hazard and that special precautions

are necessary to avoid severe personal injury or death.

! DANGER !

! WARNING !

Indicates a strong possibility of a hazard and that an

unsafe practice could result in severe personal injury.

! WARNING !

! CAUTION !

Means hazards or unsafe practices could result

in personal injury or product or property damage.

! CAUTION !

1-3

10/24/01

Page 11

1-4

INTRODUCTION

HEC-Series Service Manual

VOGT

TUBE-ICE MACHINE

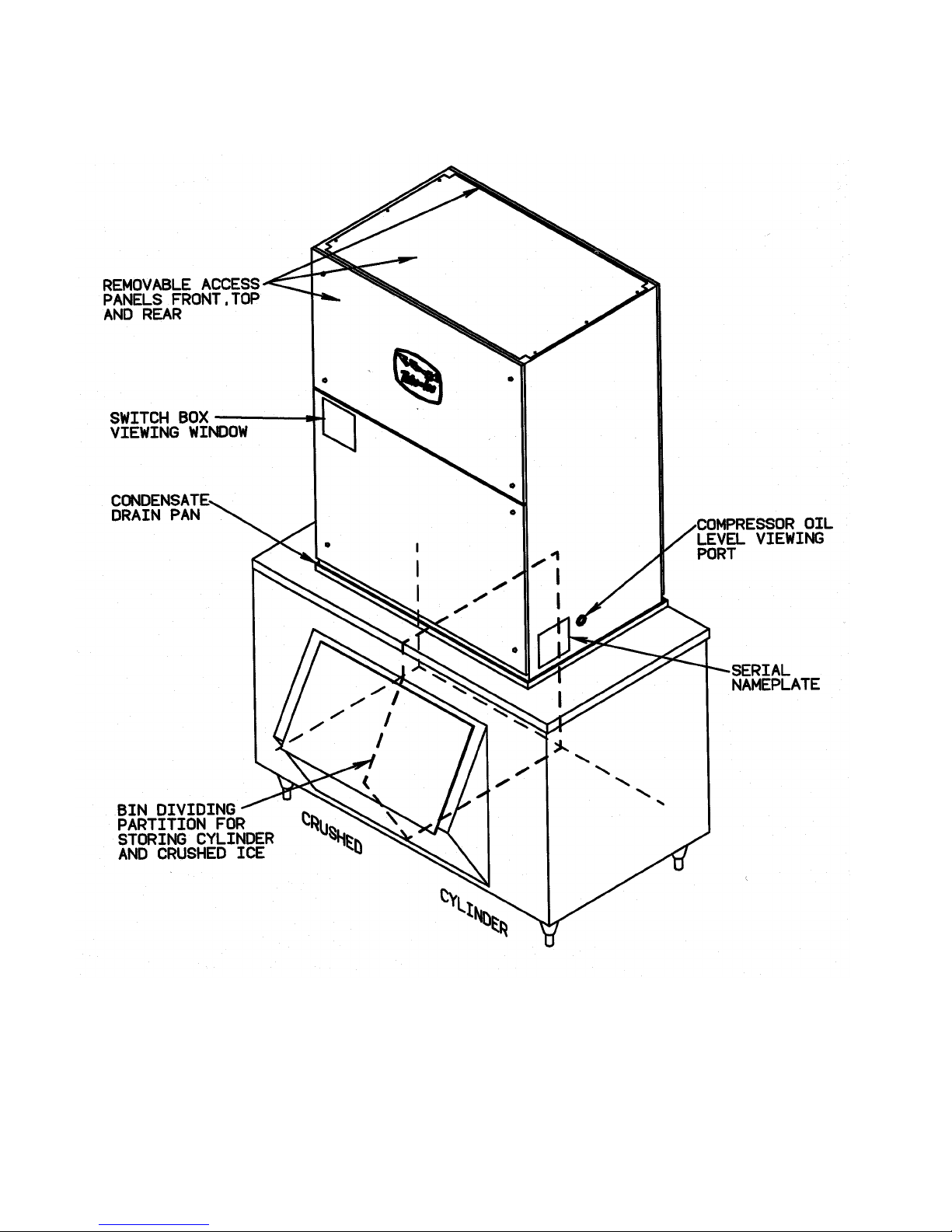

FIGURE 1-1

Tube-Ice machine shown atop a typical ice storage bin with a condensate drain pan.

The bin and drain pan are optional equipment

NOTICE! The ice storage bin is shown for illustration purposes only. Vogt Tube Ice, LLC accepts no

responsibility for the selection or use of any ice bin in conjunction with the Tube-Ice machine.

10/24/01

Page 12

HEC-Series Service Manual

1-5

INTRODUCTION

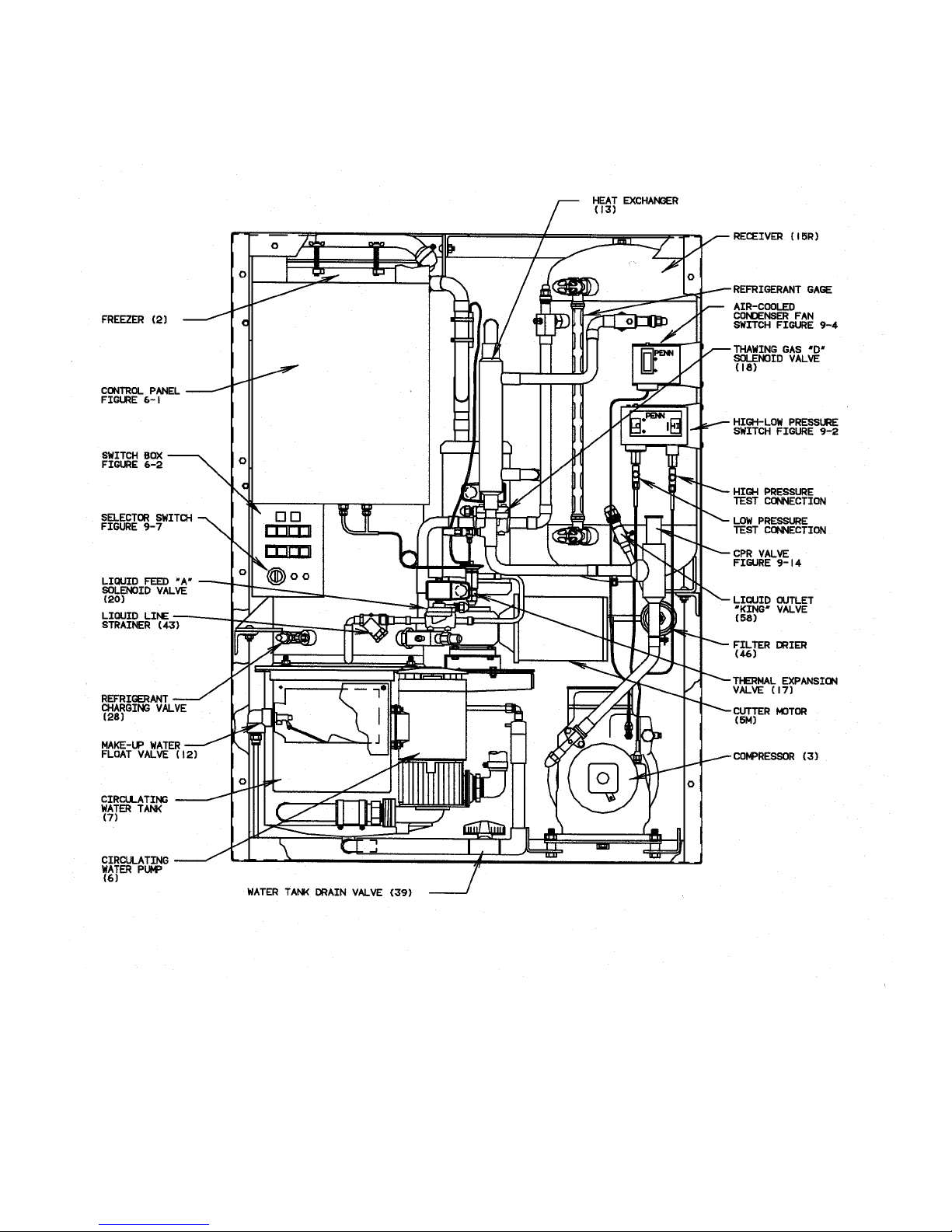

FIGURE 1-2A

Assembly Model HEC-30

Air-Cooled

Front View

10/24/01

Page 13

1-6

INTRODUCTION

HEC-Series Service Manual

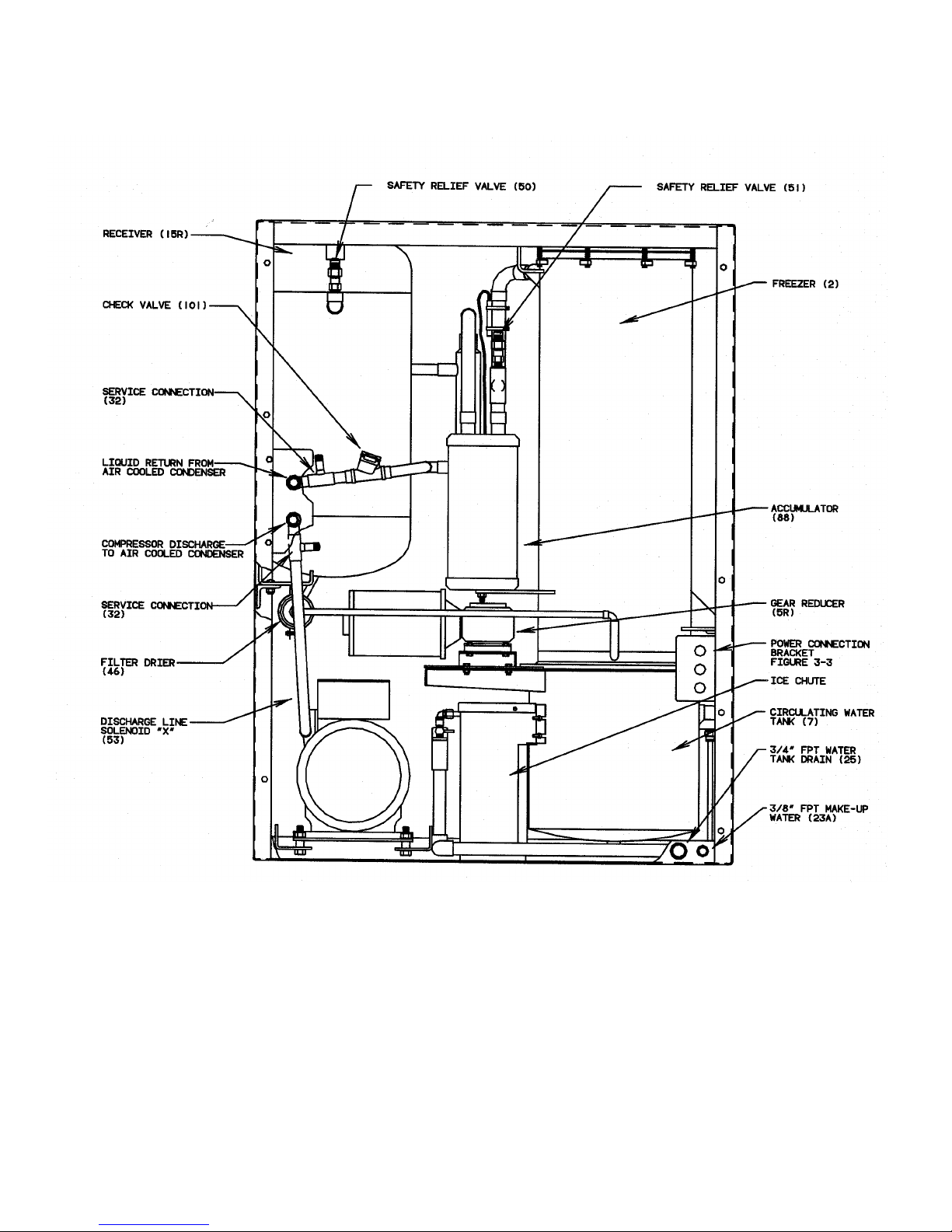

FIGURE 1-2B

Assembly Model HEC-30

Air-Cooled

Rear View

10/24/01

Page 14

HEC-Series Service Manual

1-7

INTRODUCTION

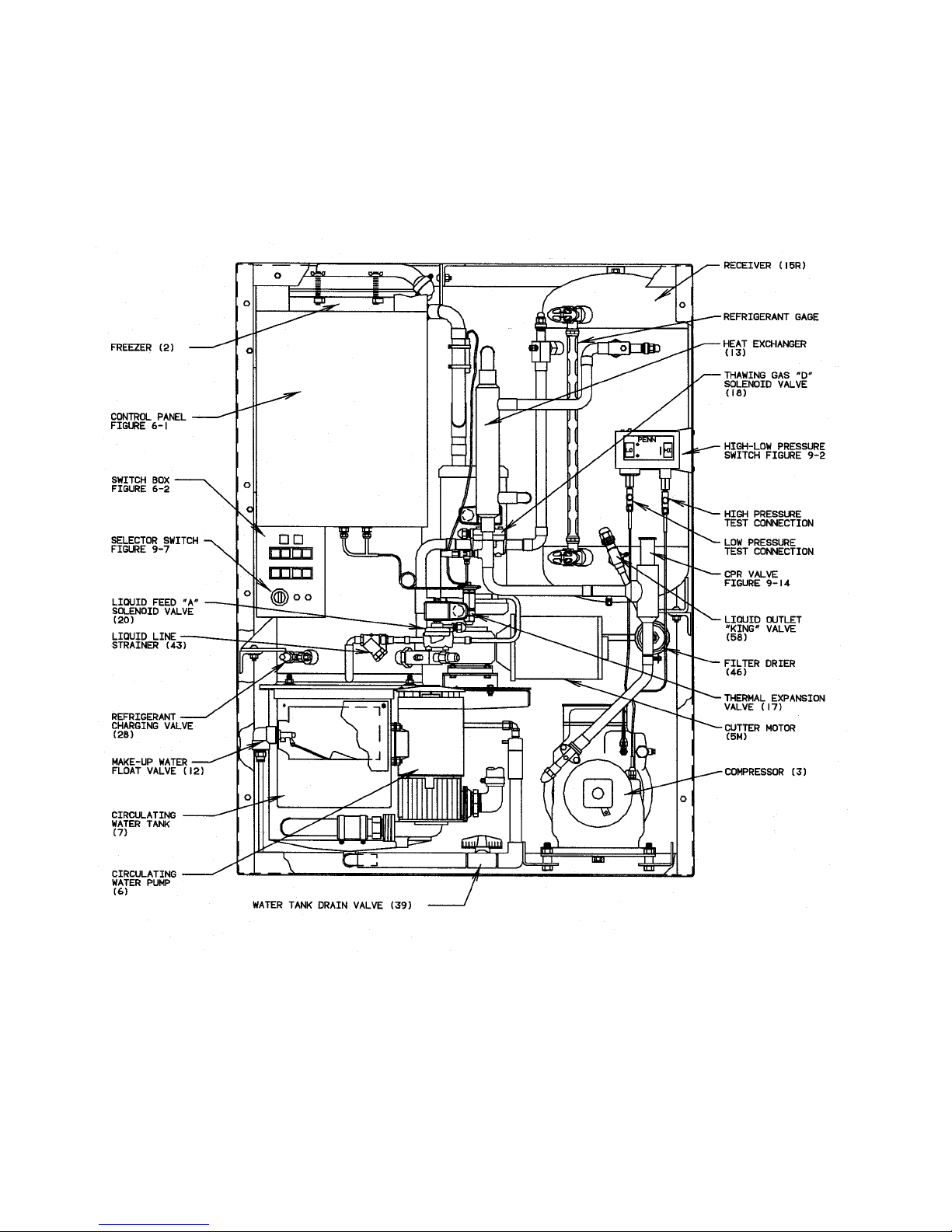

FIGURE 1-2C

Assembly Model HEC-30

Water Cooled

Front View

10/24/01

Page 15

1-8

INTRODUCTION

HEC-Series Service Manual

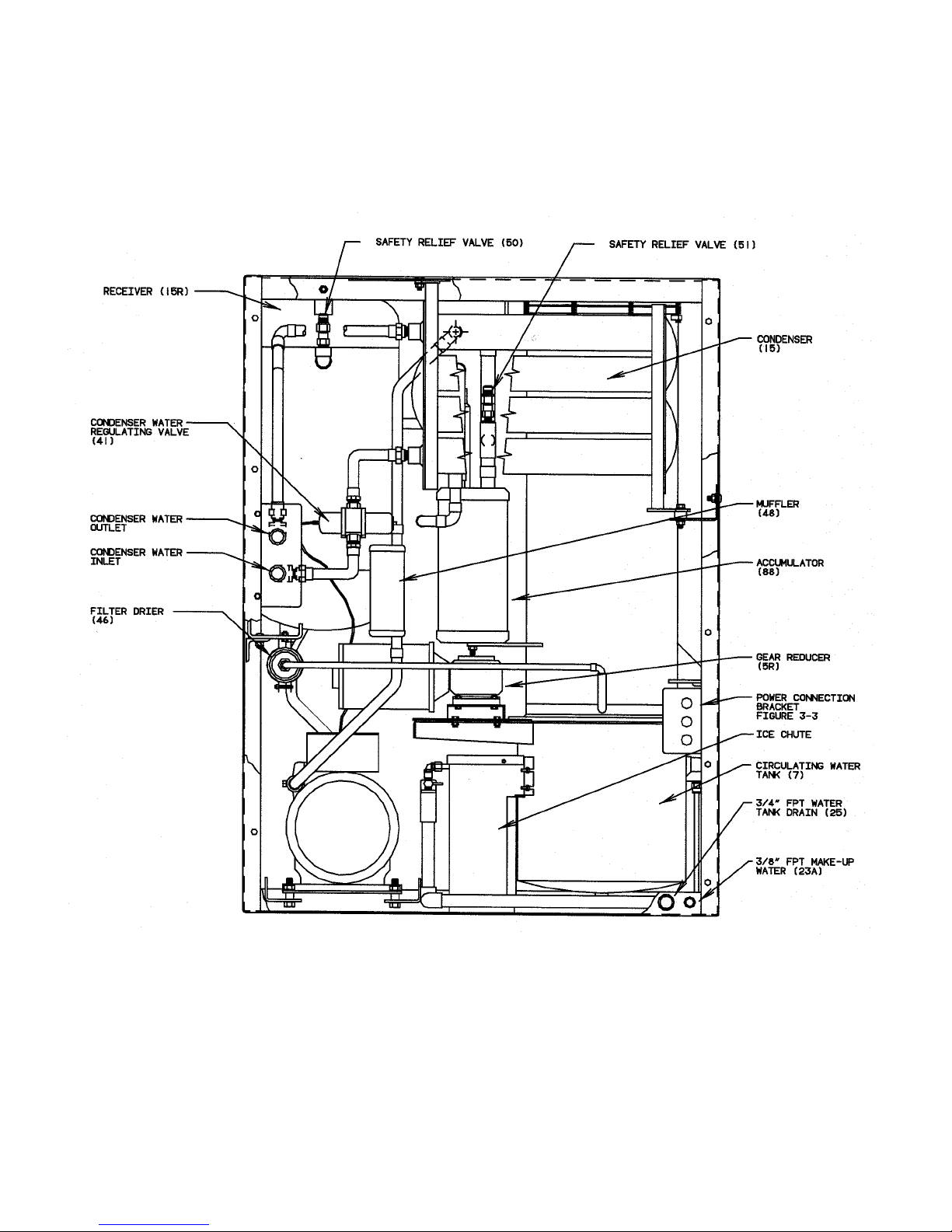

FIGURE 1-3B

Assembly Model HEC-30

Water Cooled

Rear View

10/24/01

Page 16

HEC-Series Service Manual

1. Freezer

1-9

INTRODUCTION

PIPING SCHEMATIC NOMENCLATURE

3. Compressor

4PS. High/Low Safety Pressure Switch

5M. Cutter Motor

5R. Cutter Gear Reducer

6. Water Pump

7. Water Tank (reservoir)

8. Freezer Cover

12. Make-Up Float Valve

13. Heat Exchanger

14. Condenser

15R. Receiver

16. Thaw Chamber

17. Expansion Valve

18. Thaw Gas Solenoid Valve “D”

30. Gage Glass

32. AC Condenser Service Connection

34. Compressor Suction Service Valve

35. Comp. Discharge Service Valve

39. Water Tank Drain Valve

40. Automatic Blowdown Piping

41. Condenser Water Regulating Valve

43. Strainer

46. Filter Drier

48. Muffler

50. Receiver Relief Valve

51. Freezer Relief Valve

53. Discharge Line Solenoid Valve “X”

20. Liquid Line Solenoid Valve “A”

23. Condenser Water In Connection

23A. Make-Up Water Inlet Connection

24. Condenser Water Out Connection

25. Water Tank Drain Connection

28. Refrigerant Charging Connection

56. Freezer Pressure Switch

58. Liquid Outlet Valve “King”

69. Low Pressure Stop Valve

88. Accumulator

91. Liquid Return Stop Valve

100. CPR Valve

101. Check Valve

10/24/01

Page 17

HEC-Series Service Manual

Only service personnel experienced and certified in refrigeration and qualified to work

with high voltage electrical equipment should be allowed to install or work

Inspection. As soon as you receive your machine, inspect it for any damage. If damage is

suspected, note it on the shipper’s papers (i.e., the trucker’s Bill of Lading). Immediately make a

separate written request for inspection by the freight line’s agent. Any repair work or alteration to

the machine without the permission of the Henry Vogt Machine Co. can void the machine’s

warranty.

The machine was shipped with a full charge of HCFC-22 stored in the receiver. Visually check all

lines for mechanical damage. If a leak is suspected, check all joints with a Halogen Leak Detector.

All leaks should be reported to the Henry Vogt Machine Co. to obtain authorization for repair.

Safety Valves. Two safety pressure relief valves are an integral part of the packaged Tube-Ice

machine. One is located in the low-side of the system on the freezer and one is in the high side of

the system on the receiver. You must vent each of the pressure relief valves to the atmosphere in

such a manner as to comply with local and national codes.

Machine Room. The machine must be located inside a suitable building and must not be subjected

to ambient temperatures below 50?F (10?C) or above 110?F (43.3?C). Heat radiation from other

sources (sunlight, furnaces, condenser, etc.) and unusual air current may affect the operation of the

machine and should be avoided. The electrical components of the Tube-Ice® machine are rated

NEMA 1. Therefore, the machine should not be located in a hazardous area.

Storage (prior to installation or start-up). The machine must not be stored or installed in an area

that is subject to reach temperatures at or above 115?F (46.1?C).

Important Notice. The Warranty/Registration Start-Up Report must be completed and returned to

the Henry Vogt Machine Co. to initiate and assure a full warranty.

2-1

RECEIPT OF YOUR TUBE-ICE MACHINE

2. Receipt Of Your Tube-Ice Machine

! WARNING !

on this Tube-Ice® machine.

! WARNING !

®

10/23/01

Page 18

HEC-Series Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

3. Installing Your Tube-Ice Machine

Note: A video production is available through your distributor.

Installation Without Bin. Machine must be installed on a drainable condensate drip pan.

Bin Installation. Set the bin on solid, level footing. Inside the bin you will find the four legs. Screw

these legs to the bottom of the bin. You can make MINOR leveling adjustments by using these legs

as leveling screws, as outlined in the manufacturer’s instructions.

Once the ice storage bin is level, the Tube-Ice® machine can be elevated and placed inside the

condensate drip pan on the top of the bin.

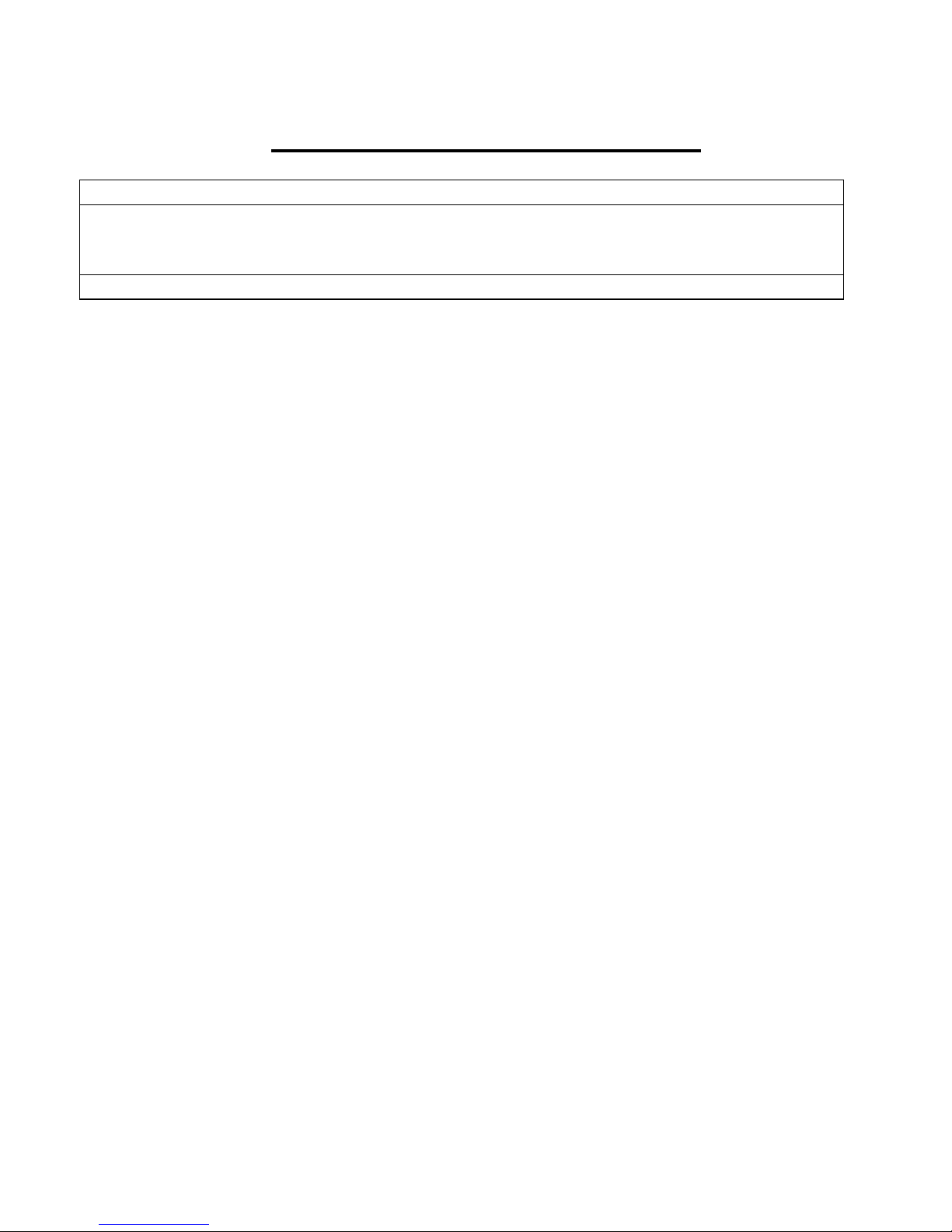

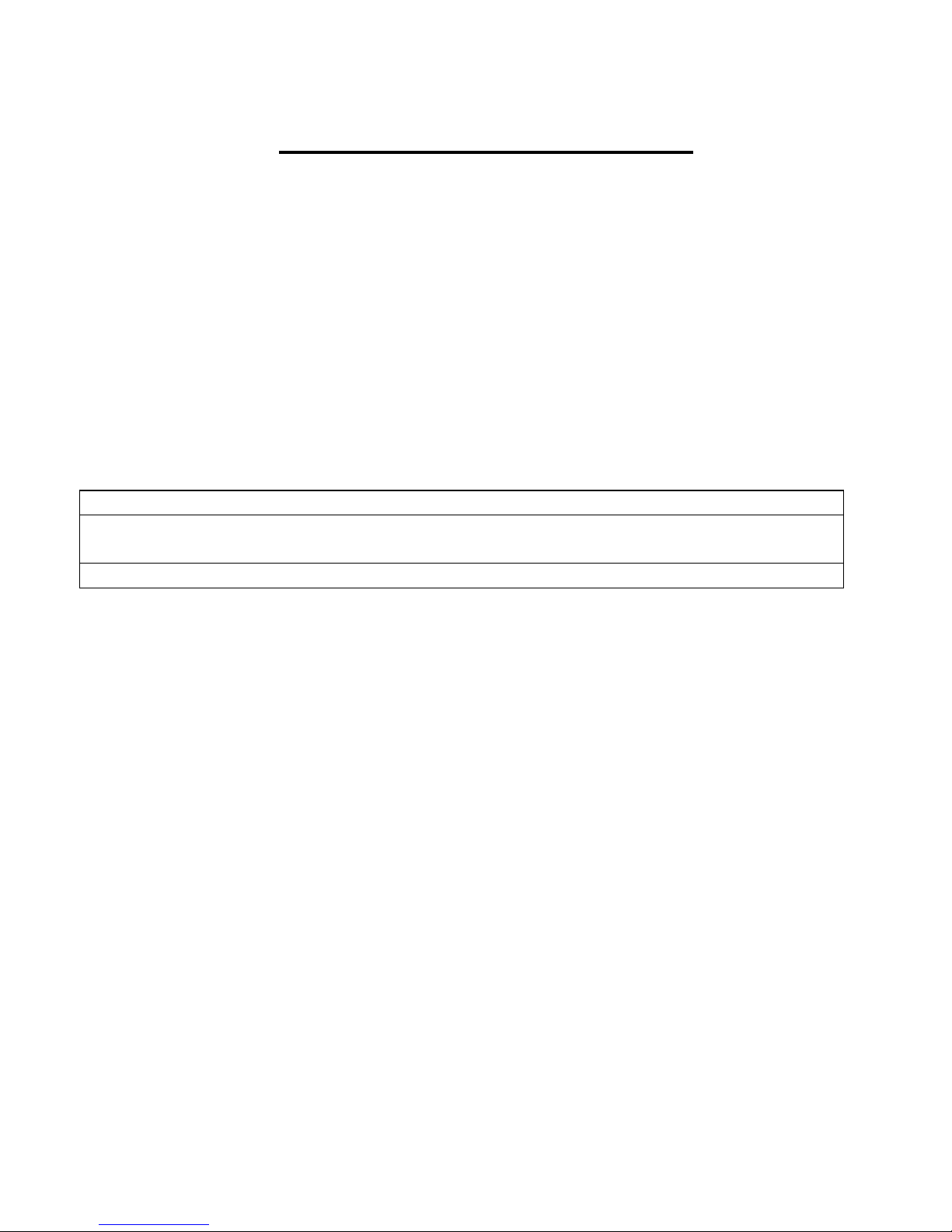

FIGURES 3-1 and 3-2 illustrate two methods of lifting & setting Tube-Ice® machine on a level ice

storage bin.

! CAUTION !

The approximate weight of the machine is 1360 pounds. Always use

equipment with adequate load-carrying capacity.

! CAUTION !

3-1

10/21/01

Page 19

3-2

INSTALLING YOUR TUBE-ICE MACHINE

HEC-Series Service Manual

You need: + forklift truck with adequate load and height capacities

+ (8) 2X4 wood blocks 8 in. long

+ (2) wooden 2X4’s measuring 3-ft. long

+ pry bar

Step 1. Position Tube-Ice® machine on forks.

The Tube-Ice® machine may be somewhat top heavy on the rear.

Step 2. Stack wood blocks in each corner of the drip pan on top of the ice storage

bin.

Step 3. Lift and set Tube-Ice® machine on wood blocks.

Step 4. Remove forklift.

Step 5. Stack 3-ft. long 2X4’s beside drip pan, overlapping front and back of bin.

Step 6. Using a pry bar with fulcrum on 2X4’s, raise side of machine enough to

remove the TOP wood blocks.

Do not remove top AND bottom blocks at the same time.

Step 7. Repeat steps 5 and 6 on other side.

Step 8. With machine sitting on one (1) block under each corner, repeat steps 5, 6,

and 7 remove remaining blocks. Drip pan flanges may bend slightly.

Step 9. Straighten bent drip pan flanges.

Step 10. Check alignment of ice chute to bin opening.

10/21/01

FIGURE 3-1

Forklift-&-Blocks Method

! CAUTION !

! CAUTION !

! CAUTION !

! CAUTION !

Page 20

HEC-Series Service Manual

3-3

INSTALLING YOUR TUBE-ICE MACHINE

FIGURE 3-2

Forklift-&-Rope or Lifting Straps Method

You need: + extra head room

+ forklift with adequate load and height capacities

+ 1/2” rope or four lifting straps to bind forks to top angles

Step 1. Remove front, rear, and top access panels.

Step 2. Position fork truck so that forks are resting flat on top angles of Tube-Ice®

machine.

Step 3. Use the rope or straps to securely bind forks to the top angles.

! CAUTION !

Be sure the bin is level and is set in its proper location.

See the space diagrams, FIGURE 3-4 and 3-5.

! CAUTION !

Step 4. Lift Tube-Ice® machine and set into drip pan of bin.

Step 5. Remove rope or straps and fork truck.

Step 6. Install front, rear and top access panels.

Step 7. Check alignment of ice chute to bin opening.

10/21/01

Page 21

3-4

INSTALLING YOUR TUBE-ICE MACHINE

Wiring And Electrical Connection.

Only service personnel experienced in refrigeration and qualified

to work with high voltage electrical equipment should be allowed

to install or work on the Tube-Ice® machine.

HEC-Series Service Manual

! WARNING !

! WARNING !

FIGURE 3-3

Electrical Connections for Machine Power & AC Connections

A fused disconnect must be provided near the Tube-Ice® machine. Connect 3 phase power to

terminals L1, L2, L3 for operation of the Tube-Ice® machine and its controls. Rotation checking of

compressor is not required for reciprocating compressors. Also, if one leg of the 3 phase power is

higher or lower (“Wild”), then it should be connected to terminal #L2. Connect the “Ground” wire to

the “Ground” terminal provided. See “Initial Start-up and Operation”, Section 5.

Scroll compressor rotation must be checked and confirmed to be correct. Attach pressure gages

to the suction & discharge service valves to make sure there is an immediate decrease in the suction

pressure and increase in discharge pressure upon start up. If not, reverse two (2) compressor wires

(L1, L2, L3) at the control panel terminal block to change direction of rotation, and check suction

and discharge pressure on start up again.

Do not switch leads directly at the compressor. Terminals L4 and L5 are for connection of single

phase 208/230 electrical supply for split voltage applications such as 460 volt, 3 phase for

compressor.

! CAUTION !

Do not attempt to start machine prior to connecting water lines

and making the following NECESSARY provisions.

Refer to FIGURES 3-4 & 3-5 (space diagrams) for correct installation.

! CAUTION !

10/21/01

Page 22

HEC-Series Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

Piping and Drain Connections. All connections are located at the rear of the machine. Look for

four water connections on the freezing unit of each water cooled machine. See Space Diagram,

FIGURE 3-4 for correct utility connections.

! CAUTION !

Exterior shut-off valves must be provided in the water inlet lines.

The minimum inlet water pressure for

satisfactory operation of the machine is 30 psig.

The maximum allowable pressure is 100 psig.

! CAUTION !

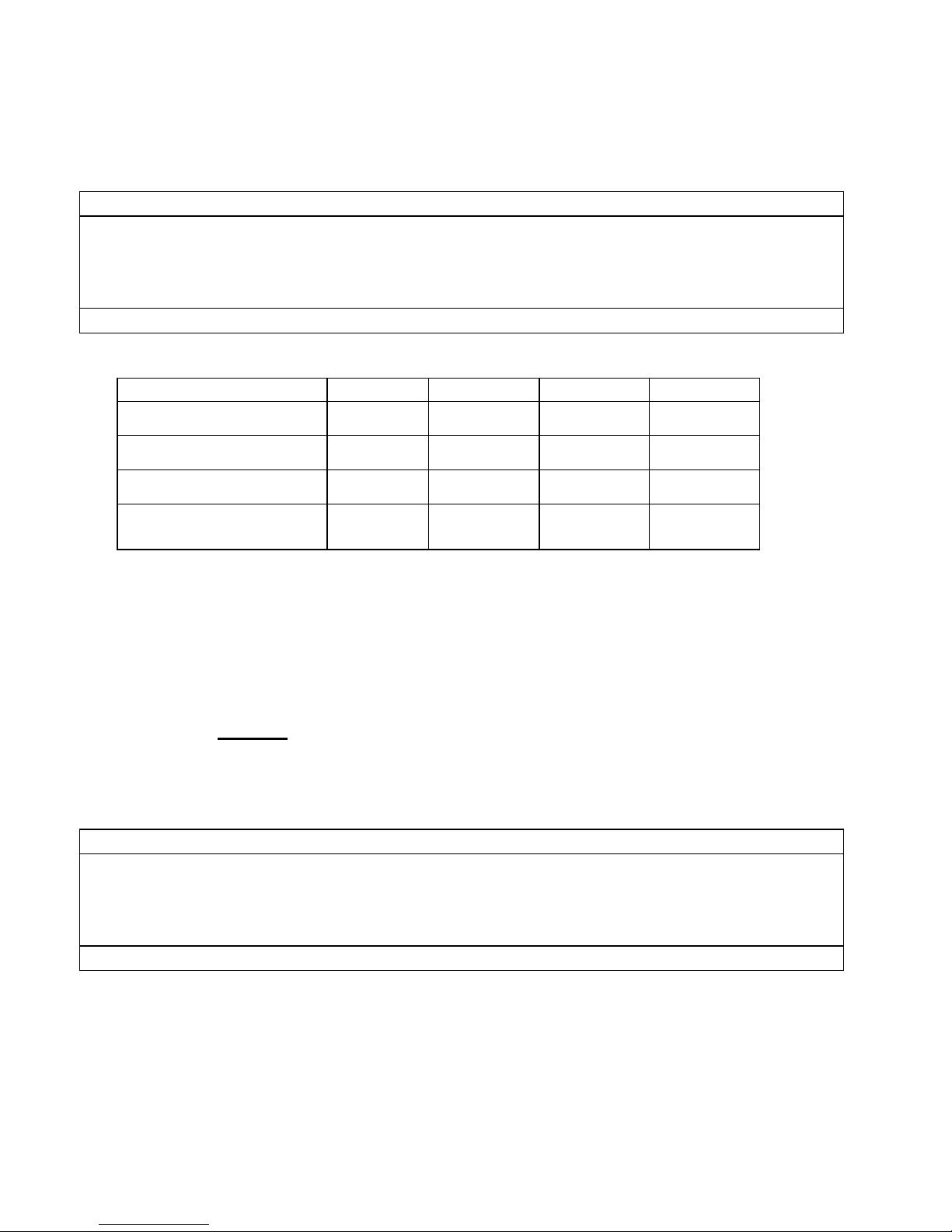

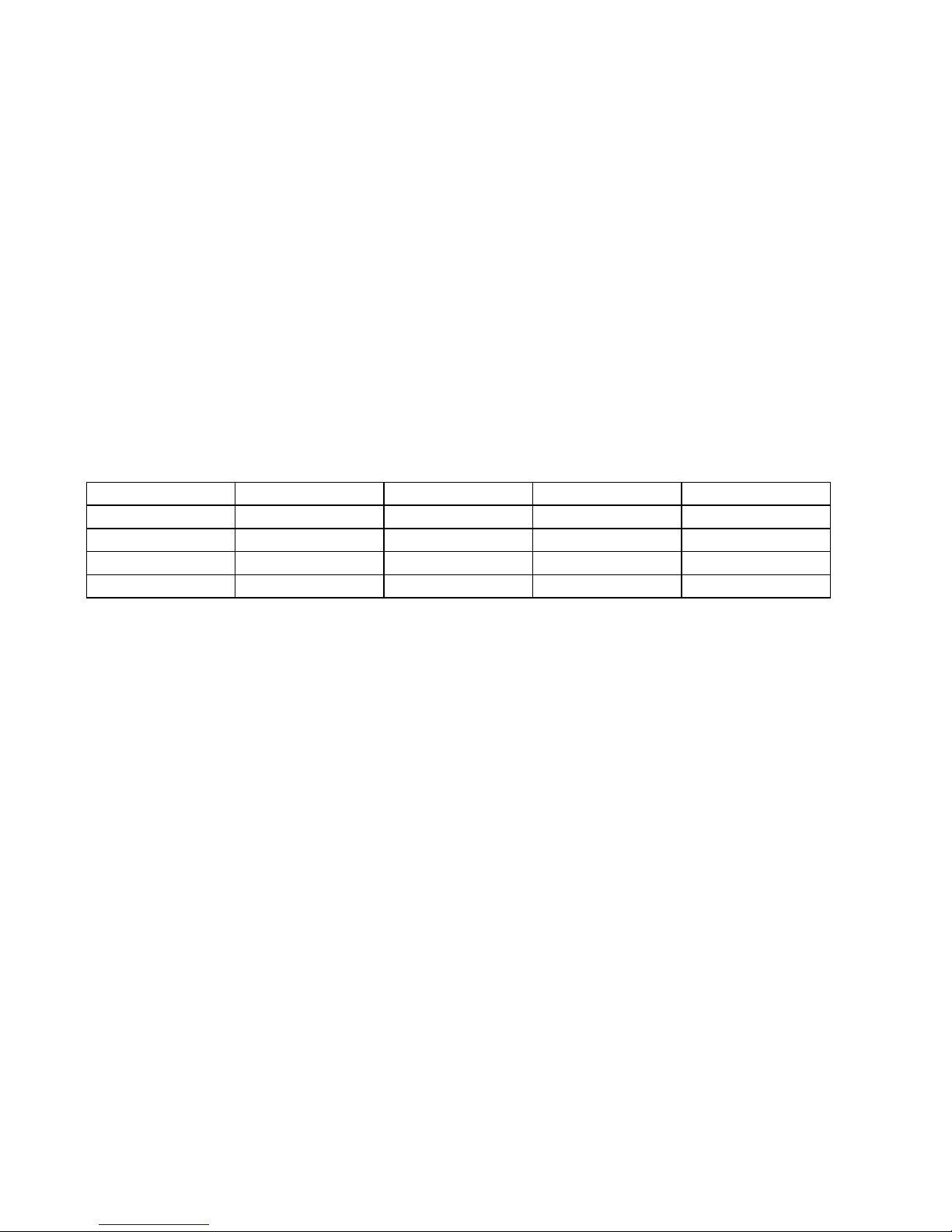

Model HEC-10 HEC-20 HEC-30 HEC-40

Make Up Water In 3/8” FPT 3/8” FPT 3/8” FPT 3/8” FPT

Water Tank Drain 3/4” FPT 3/4” FPT 3/4” FPT 3/4” FPT

Condenser Water In 3/4” FPT 3/4” FPT 3/4” FPT 1” FPT

3-5

Condenser Water Out 3/4” FPT 3/4” FPT 3/4” FPT 1” FPT

TABLE 3-1

Water Supply and Drains

When the ice machine sits on a storage bin, the bin must be provided with a drip pan for catching the

condensate from the ice machine. Separate drains for the condensate and for the bin are necessary.

See FIGURE 3-4 or 3-5 (space diagram drawings for typical water and drain connections).

Condensate drain must not run through the ice compartment of the bin.

The condenser water outlet, water pan drain, condensate drain and ice storage bin drain connections

must be extended to an open drain or sump and arranged for visible discharge.

! CAUTION !

These lines must NOT be connected into a pressure tight common header

due to the possibility that warm condenser water

may back up into the water pan, drip pan or the ice storage bin. The

condenser water outlet MUST be piped separately to the drain.

! CAUTION !

10/21/01

Page 23

HEC-Series Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

10/21/01

3-6

FIGURE 3-4

Space Diagram Water Cooled Machine

Page 24

HEC-Series Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

10/21/01

3-7

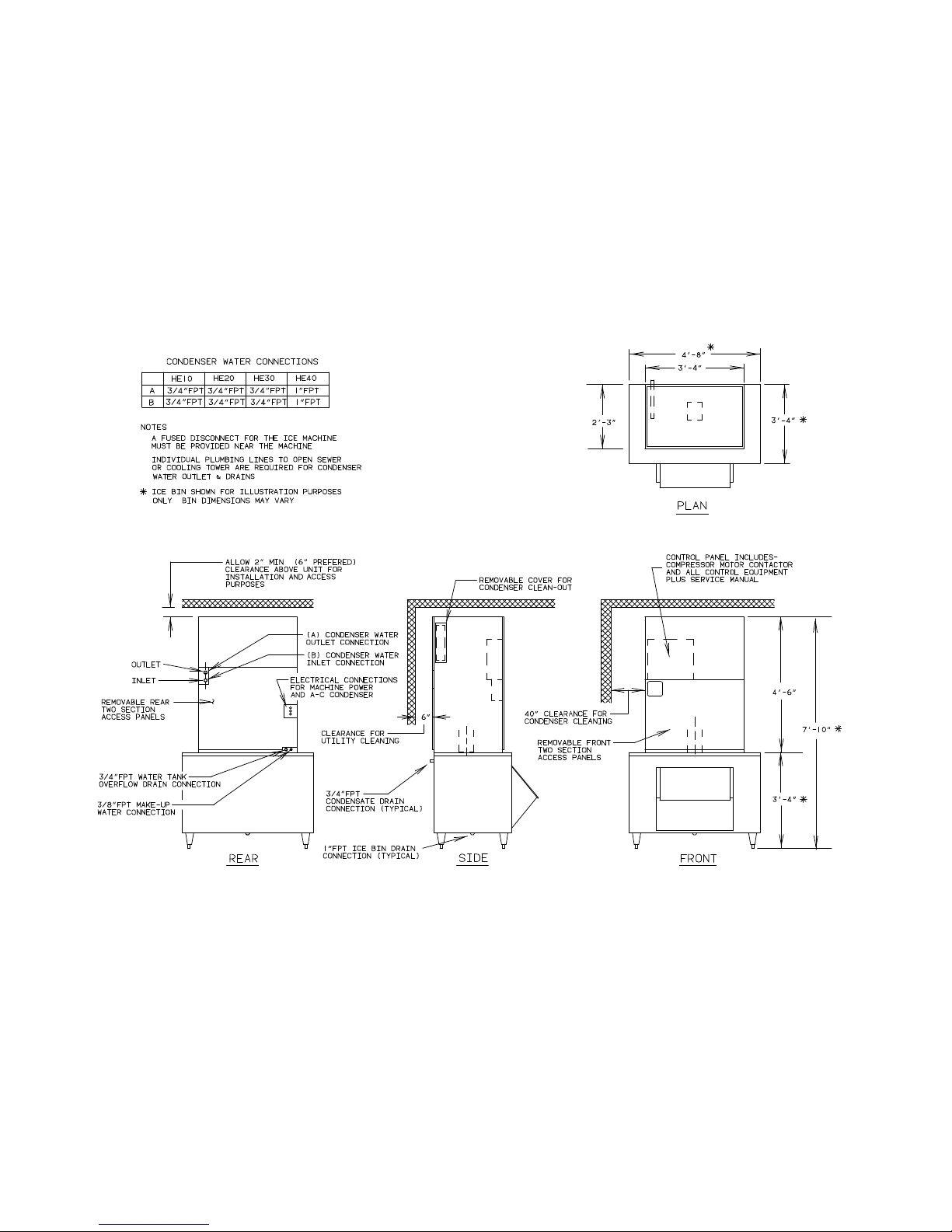

FIGURE 3-5

Space Diagram Air-Cooled Machine

Page 25

3-8

INSTALLING YOUR TUBE-ICE MACHINE

Air-Cooled Condenser Installation Instructions.

Using a non-Vogt condenser will void the compressor warranty.

Certain installation guidelines must be followed to obtain reliable operation from air-cooled ice

machines. If these guidelines are not followed, the compressor warranty will not be honored. Any

exceptions to this policy must be obtained in writing prior to installation and operation of the ice

machine.

1. Outdoor condensers must be installed with vertical air flow. Indoor condensers used for heat

recovery may be installed with either horizontal or vertical air flow.

2. The preferred condenser location is above the ice machine, with liquid refrigerant from the

condenser outlet draining freely (1/4” per foot slope) in the direction of normal operating flow

(back to the ice machine) with no traps in the liquid line.

3. If it is absolutely necessary to install the condenser below the ice machine, certain conditions

MUST be met. The refrigerant connections on the condenser must be no more than 6 feet below

the refrigerant connections on the ice machine. The return liquid line from the condenser must

rise no more than 12 feet before dropping back down to the elevation of the ice machine. When

the condenser is located below the ice machine, expect a 16 psig increase in head pressure and at

least 3% reduction in capacity.

4. Flooding head pressure controls such as Alco Headmaster are not to be used, since they cause

excessive subcooling of the returned liquid refrigerant and interfere with reliable ice harvest.

5. The discharge and liquid lines must be insulated with 1/2” thick Armaflex insulation or equal.

6. Horizontal runs in the discharge line should slope 1/4” per foot in the normal direction of flow

(away from the ice machine).

7. Traps must be installed in discharge lines at the base of all vertical risers. There should be no

intentional traps in liquid lines. Trap volume should be kept to a minimum. Typical details are

shown in FIGURE 3-8.

8. Use only ACR grade copper pipe, Type L. Recommended line sizes are shown in TABLE 3-2.

9. Distance between ice machine and condenser must not exceed 150 equivalent feet. Refer to

Condenser Equivalent Line Size worksheet.

10. Condensers must be provided with a cold weather valve kit per FIGURE 3-7. These valves

allow one-half of the condenser to be disabled in cold weather. Running the ice machine with

one half the condenser in cold weather makes it easier to maintain minimum necessary

condensing pressure, particularly in windy conditions.

HEC-Series Service Manual

! WARNING !

! WARNING !

10/21/01

Page 26

HEC-Series Service Manual

11. Condensers with multiple fans must be provided with a thermostat to turn off unneeded fans in

cold weather, per FIGURE 3-9. Turning off unneeded fans reduces on-off cycling of the fan(s)

and allows for a steadier condensing pressure.

12. When extreme cold conditions are expected or encountered (temperatures below 0°F and wind

greater than 15 MPH), it may be necessary to install a protective enclosure around the condenser.

A typical enclosure is shown in FIGURE 3-12. Other apparatuses such as louvers may be used.

Contact the factory for suggestions.

13. After installation, the field-installed lines are to be evacuated to a vacuum of 500 microns or less

and held for at least one hour. After the vacuum pump is removed, vacuum should hold at 500

microns or less for at least 5 minutes and the lines pressurized with R-22 to 25 psig minimum.

14. The volume of refrigerant supplied with the machine is sufficient to fill the condenser and

condenser lines when length of pipe (one way) is 75 feet or less. When the length of lines is

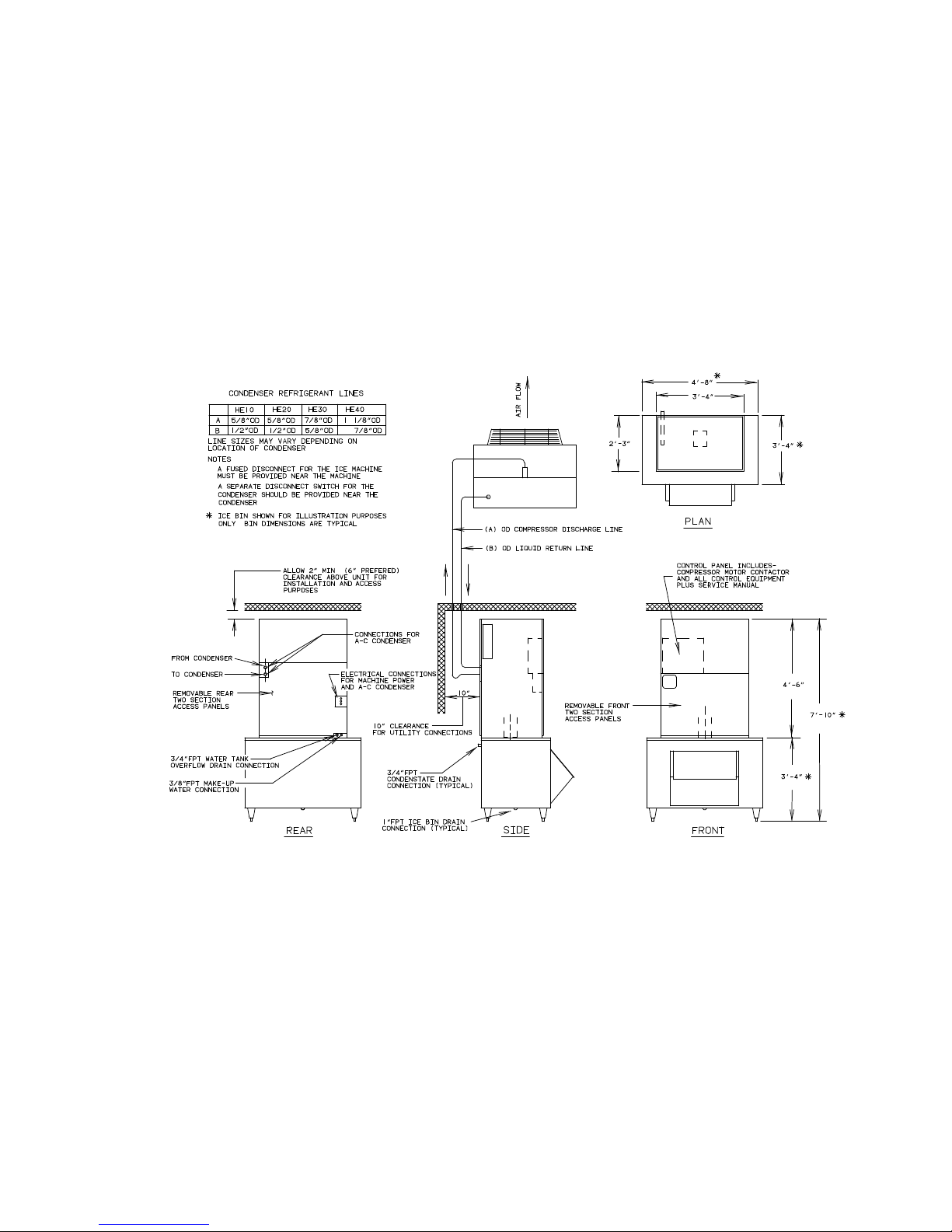

longer than 75 feet, additional refrigerant must be added as follows:

Liquid Line Size

1/2” none none none 2

5/8” none 2 4 6

7/8” none 4 8 12

1-1/8” none 6 12 18

15. All piping must be done in accordance with applicable local and national codes. Such codes may

include “The Safety Code for Mechanical Refrigeration (ANSI B9.1), and “The Code for

Refrigerant Piping” (ANSI B31.5).

The following installation guidelines are strongly suggested. While they do not affect the machine

warranty, they may be required for safe operation, and to comply with all applicable electrical and

mechanical codes.

16. Local electrical code must be checked for wiring method.

17. The installer must provide a lockable, fused disconnect switch(s) adjacent to the condenser.

18. Electrical connections between the condenser and the Tube-Ice® machine require minimum 12 ga.

wire.

19. All electrical fittings and components exposed to the weather must be suitable for outdoor

installation.

The design total heat rejection for each Tube-Ice® machine, the recommended air-cooled condenser,

and condenser physical and electrical data are shown in TABLE 3-3. Only the condensers shown are

UL listed with the ice machines. Other condensers may be individually UL listed, but are not UL

listed with the Tube-Ice® machines, and cannot be recommended by the Henry Vogt Machine Co.

3-9

INSTALLING YOUR TUBE-ICE MACHINE

75 ft. 100 ft. 125 ft. 150 ft.

Table 3-2

Pounds R-22 to Add Vs. Liquid Line Length

10/21/01

Page 27

3-10

INSTALLING YOUR TUBE-ICE MACHINE

Catalog energy efficiency ratings of the ice machines are based on use of the recommended

condenser.

Condensers supplied by Vogt must be utilized. The use of non-Vogt condensers will void the

compressor warranty. For continuous operation at ambients above 105°F, consult the factory about

using a larger condenser.

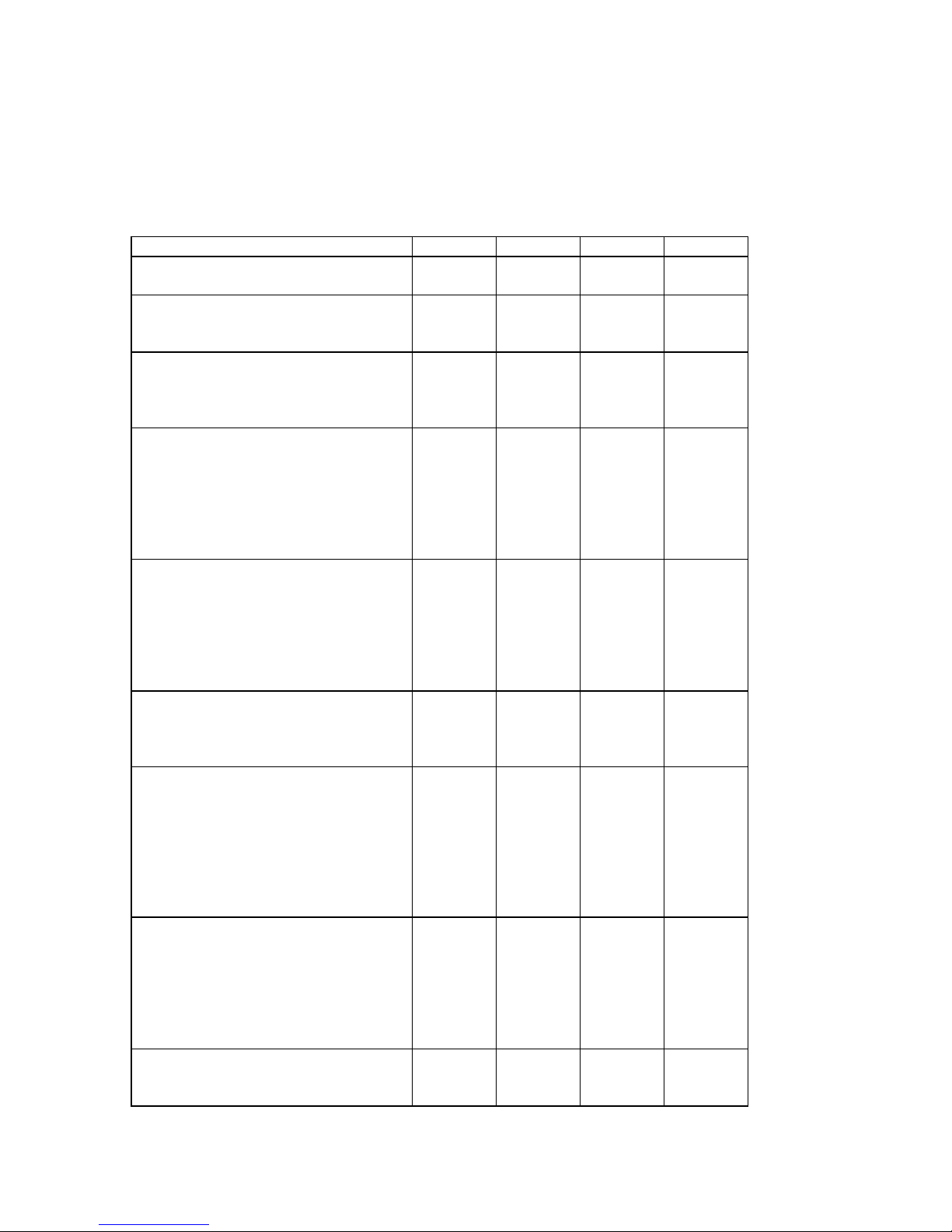

Ice Machine Model HEC-10 HEC-20 HEC-30 HEC-40

Electrical Frequency, Hz

Recommended Condenser

Total Heat Rejection:

BTU/hr at 60 hz.

BTU/hr at 50 hz.

Fans:

Number

HP, Each

Total, CFM

Full Load Amps:

1 ph., 208/230V, 60 hz.

3 ph., 208/230V, 60 hz.

3 ph., 460V, 60 hz.

1 ph., 230V., 50 hz.

3 ph., 230V., 50 hz.

3 ph., 400V., 50 hz.

Locked Rotor Amps:

1 ph., 208/230V., 60 hz.

3 ph., 208/230V., 60 hz.

3 ph., 460V., 60 hz.

1 ph., 230V., 50 hz.

3 ph., 230V., 50 hz.

3 ph., 400V., 50 hz.

Weight, lbs.:

Net

Shipping

Operating (maximum flooded)

Condenser dimensions (see FIG. 3-6),

inches:

A (Width)

B (Length)

C (Height)

D (Leg centerline)

E (Leg centerline)

F (Clearance below)

Recommended Line Sizes, OD:

Liquid

All lengths and orientations

Discharge Gas

Vertical Up, All lengths

Horiz. Or Down, < 75 ft.

Horiz. Or Down, > 75 ft.

Connections (Cond. & Ice Mach.):

Liquid (ODF)

Discharge Gas (ODF)

60/50

DD-61

28,700

23,900

1

.333

5000

2.5

N/A

N/A

3.0

N/A

N/A

7

N/A

N/A

8.2

N/A

N/A

150

195

167

39”

46”

36”

37-7/8”

37”

16”

1/2”

5/8”

5/8”

7/8’

1/2”

5/8”

60/50

DD-61

28,700

23,900

1

.333

5,000

2.5

N/A

N/A

3.0

N/A

N/A

7

N/A

N/A

8.2

N/A

N/A

150

195

167

39”

46”

36”

37-7/8”

37”

16”

1/2”

5/8”

5/8”

7/8”

1/2”

5/8”

TABLE 3-3

Air-Cooled Condenser Data

60/50

DD-101

44,500

37,100

2

.5

9,800

5.0

N/A

N/A

5.8

N/A

N/A

15

N/A

N/A

17.5

N/A

N/A

250

310

276

42”

66”

36”

40-3/8”

54”

16”

5/8”

7/8”

7/8”

1-1/8”

5/8”

7/8”

HEC-Series Service Manual

60/50

DD-131

80,400

67,000

2

.5

9,800

5.0

N/A

N/A

5.8

N/A

N/A

15

N/A

N/A

17.5

N/A

N/A

265

325

301

42”

66”

36”

40-3/8”

54”

14”

7/8”

1-1/8”

1-1/8”

1-3/8”

7/8”

1-1/8”

10/21/01

Page 28

HEC-Series Service Manual

3-11

INSTALLING YOUR TUBE-ICE MACHINE

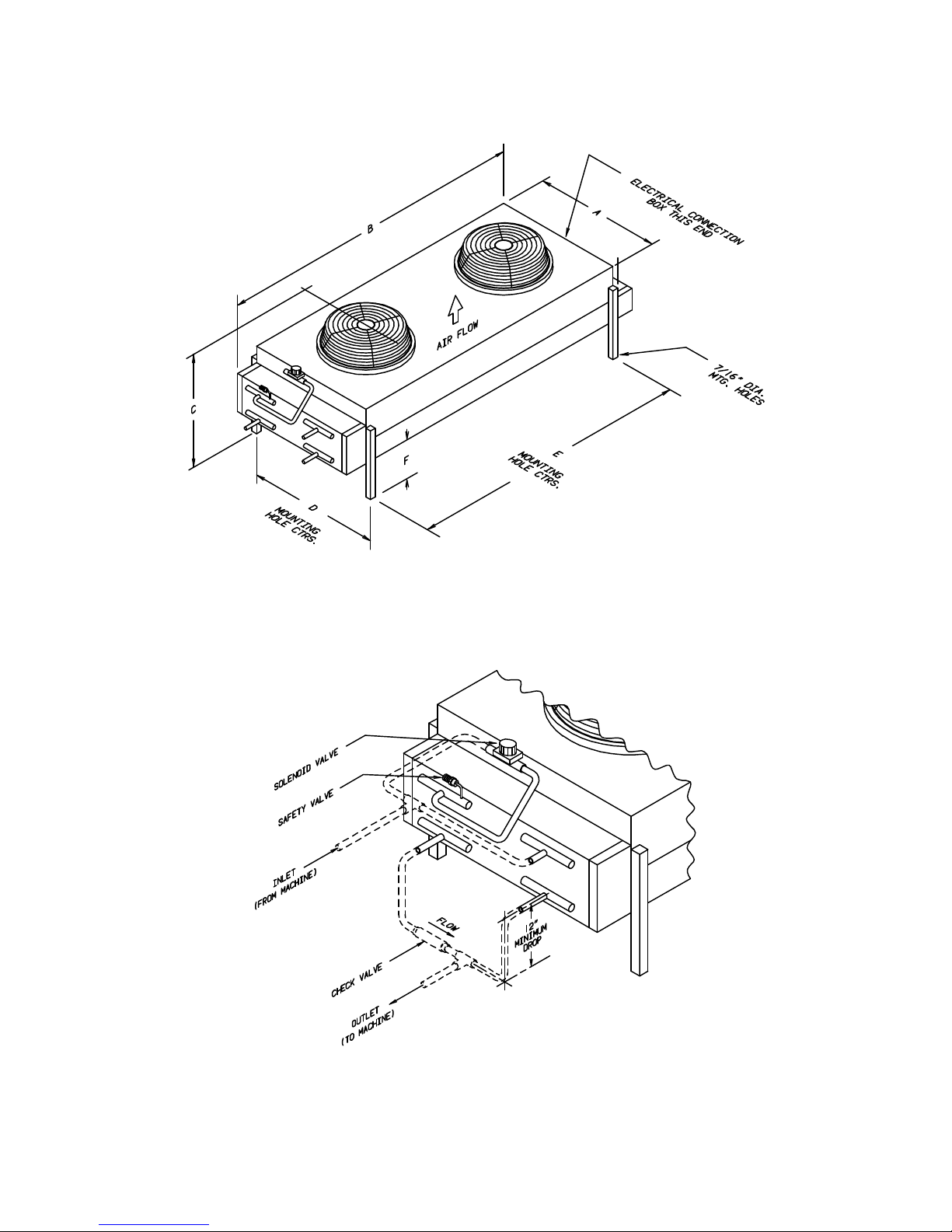

FIGURE 3-6

Condenser Dimensions (Condenser pictured: DD-101 or DD-131)

Note: Dash lines indicate customer supplied piping. The Check Valve in the return line (labeled

“Output To Machine”) is supplied with the condenser.

10/21/01

FIGURE 3-7

Condenser Field Piping

Page 29

3-12

INSTALLING YOUR TUBE-ICE MACHINE

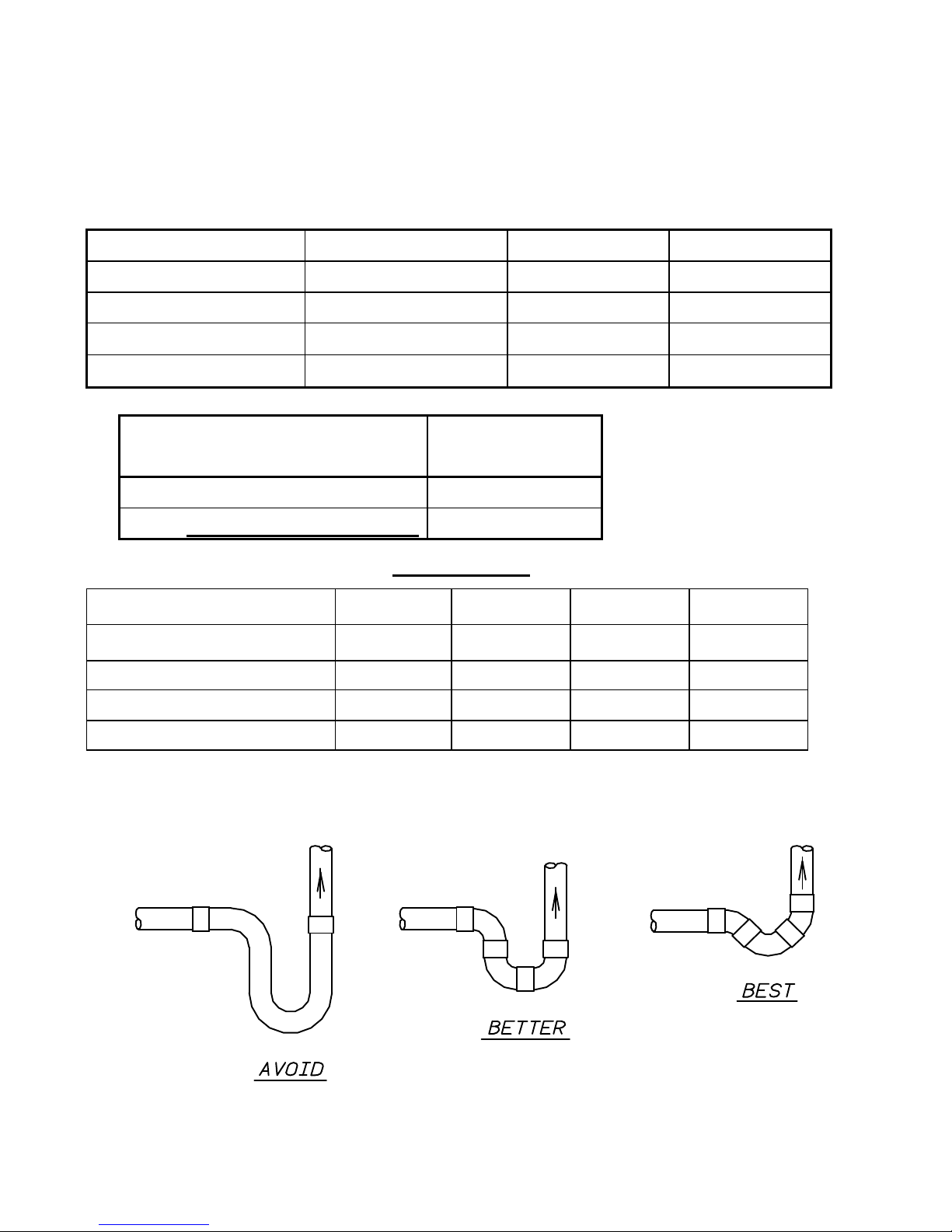

Discharge Gas Line O.D. _____________

Fitting Type Number Used Factor Total

HEC-Series Service Manual

CONDENSER EQUIVALENT

LINE SIZE WORKSHEET

Globe Valve (open)

Angle Valve (open)

45° Elbow

90° Elbow

Feet of Straight Copper

Used

Total Fitting Factor

Total Equivalent Feet

Copper Tube O.D. Type “L”

Globe Valve (open)

Angle Valve (open)

45° Elbow

Fitting Factors

1/2” 5/8” 7/8” 1 1/8”

14 16 22 28

7 9 12 15

.5 1 1 1.5

90° Elbow

1 2 2 3

TABLE 3-4

FIGURE 3-8

Minimum Traps for Discharge Lines

10/21/01

Page 30

HEC-Series Service Manual

3-13

INSTALLING YOUR TUBE-ICE MACHINE

Condenser Piping With Cold Weather Valve Kit

10/21/01

FIGURE 3-9

Page 31

3-14

INSTALLING YOUR TUBE-ICE MACHINE

Wiring For DD-61 With Cold Weather Valve and Single Fan

HEC-Series Service Manual

FIGURE 3-10

Wiring For DD-101 & DD-131 With Cold Weather Valve And Dual Fans

10/21/01

FIGURE 3-11

Page 32

HEC-Series Service Manual

3-15

INSTALLING YOUR TUBE-ICE MACHINE

10/21/01

FIGURE 3-12

Air-Cooled Condenser Enclosure

Page 33

3-16

INSTALLING YOUR TUBE-ICE MACHINE

HEC-Series Service Manual

Field Attachment, Air Cooled Condenser Refrigerant Tubing

10/21/01

FIGURE 3-13

Page 34

HEC-Series Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

Ice Bin Thermostat Bulb Installation. Each machine is equipped with an ice bin thermostat. To

assure proper protection for the machine, the control bulb of the ice bin thermostat must be located so

that ice will contact it when the bin is full. For a divided bin, locate the control bulbs as illustrated in

FIGURE 3-14. This allows space for the machine to make an additional discharge of ice AFTER the

ice contacts the bulb WITHOUT the ice building up into the discharge opening of the chute.

Note: As an option, the PLC can be programmed for your machine to produce a specified amount of

ice during a certain time each day. Consult the factory for more details.

3-17

Location Of Thermostat Bulbs In Ice Storage Bin

10/21/01

FIGURE 3-14

Page 35

3-18

INSTALLING YOUR TUBE-ICE MACHINE

The control panel is electrically connected so that the bin thermostat will stop the machine only upon

the completion of a harvest period.

When both cylinder and crushed ice are produced and separately stored in a divided bin, the control

bulb of thermostat BT1 is placed in the crushed ice section of the storage bin (left side) and the

control bulb of thermostat BT2 is placed in the cylinder ice section (right side of bin).

When the bin does not have a divider, only one thermostat is necessary. The wiring may be modified

to use only one thermostat and bulb (See “With No Divider in Bin”, Section 4 and FIGURE 3-14).

Or install both bulbs--so that the ice contacts both bulbs when the bin is full.

HEC-Series Service Manual

FIGURE 3-15

Wiring for Single Thermostat Operation (Dual Ice Type Only)

(follow instructions below)

1. Turn power off to the machine and check with volt meter to make sure panel is dead.

2. Select the thermostat which will not be used (either CRU or CYL) and disconnect wire #25 or

#26 from that thermostat.

3. Connect wires #25 & #26 to the same terminal of the thermostat to be used and extend that

thermostat bulb into the bin, mounting it as illustrated in FIGURE 3-14.

4. Turn power on to the machine and restart the machine according to instructions.

10/21/01

Page 36

HEC-Series Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

Installation Review: A CHECKLIST

Make a visual check to be sure these steps have been taken BEFORE continuing.

CHECK: _____ PRIOR TO OPENING VALVES, check all joints for leaks which may have

developed during shipment. {NOTE: The required charge of Refrigerant 22 has been isolated in the

Receiver (15R).}

CHECK: _____ All water supply and drain connections for conformity to requirements stipulated in

this manual. See FIGURES 3-4, 3-5, and TABLE 3-1.

CHECK: _____ Electrical supply for proper size of fuses and for compliance to local and national

codes. See the machine nameplate for minimum circuit ampacity and maximum fuse size.

CHECK: _____ All field installed equipment (air-cooled condenser, ice storage bin, ice spreader,

etc.) for proper installation.

CHECK: _____ The applicable portion of the warranty registration/start-up report for proper

completion.

CHECK: _____ The position of all push button switches to assure they will or will not start

automatically as desired.

NOTE: This machine is controlled by a PLC and can automatically start with power to the machine

after a two hour time lapse if the ice switch is in the on position and all other requirements are met.

3-19

10/21/01

Page 37

HEC-Series Service Manual

HOW YOUR TUBE-ICE MACHINE WORKS

4. How Your Tube-Ice Machine Works

Principle Of Operation. The manual operation of the machine is controlled by the “Ice” and “Start”

switches located in the switch box of the freezing unit. The automatic operation is controlled by the

PLC and ice bin thermostats which will automatically stop and start the freezing unit by the level of

the ice in the storage bin (NOTE: See “Ice Bin Thermostat Bulb Installation” for instructions on

installation of the control bulb of the ice bin thermostats FIGURE 3-14). The type ice produced

(cylinder or crushed) is determined by the position of the ice selector switch located in the switch box.

The control wiring is arranged so that the unit will stop only upon the completion of a thawing period

and partial pumpdown cycle whether by action of the “Ice” switch or the ice bin thermostats.

The “Clean” switch must always be set in the “Off” position (not illuminated) during normal icemaking operation. It is set on the “Clean” (illuminated) position only when the equipment is to be

cleaned or pumped down as outlined in the “Cleaning Procedure,” and “Total Pump-Down

Procedure”, Section 9, and instructions attached to the machine.

If it should become necessary to instantly stop the machine, either the external disconnect switch,

cutter overload switch, or pump overload switch must be turned off.

FIGURES 4-1, 5-2, & 5-3 illustrate the piping diagram of the refrigerant and water circuits of the

Tube-Ice machines with numbers for easy reference. Throughout this manual the numbers you see

in parentheses refer to the numbers in this piping schematic.

The freezer (2) is a shell and tube-type vessel. During the freezing period, water is constantly

recirculated through the vertical tubes of the freezer by a centrifugal pump (6). Make-up water is

maintained by a float valve (12) in the water tank (7). Solenoid valve (20), sometimes referred to as

the “A” valve, is open and solenoid valve (18), sometimes referred to as the “D” valve, is closed.

Refrigerant gas from the top of the freezer (2) passes through the accumulator (88), the heat

exchanger (13), the CPR valve (100), and to the compressor (3) which discharges it into the

condenser (15). Condensed liquid refrigerant from the condenser flows through the liquid side of the

heat exchanger and into the receiver (15R). Liquid refrigerant from the receiver flows through the

filter/drier (46), the thawing chamber (16) of the freezer, the strainer (43), “A” valve (20), expansion

valve (17), and into the freezer, thereby completing the freezing circuit.

At the completion of the freezing period, thawing is started by action of the freezer pressure switch in

the control panel. The water pump is stopped and solenoid valve “A” (20) is closed. After a time

lapse of seven seconds, solenoid valve “D” (18) is opened, the cutter motor (5M) is started and the

harvest (thaw) timer (FIGURE 9-6) is activated. Warm gas from the receiver is discharged into the

freezer through valve (18), thereby slightly thawing the ice which drops on the rotating cutter for

sizing. Cylinder ice will be discharged through the right half-section of the ice discharge chute when

viewing the Tube-Ice® machine from the front. Crushed ice will be discharged through the left halfsection of the ice discharge chute.

Air-cooled machines have a solenoid valve (53), sometimes referred as the “X” valve, in the

compressor discharge line, and a check valve (101) in the liquid return line to the receiver. These

valves prevent the migration of refrigerant to the condenser when the machine is not operating.

4-1

10/21/01

Page 38

4-2

HOW YOUR TUBE-ICE MACHINE WORKS

HEC-Series Service Manual

HEC, Water Cooled -- Piping Schematic

HEC, Air Cooled -- Piping Schematic

10/21/01

FIGURE 4-1

Page 39

HEC-Series Service Manual

HOW YOUR TUBE-ICE MACHINE WORKS

Dual ice type (crushed and cylinder).

Divider in bin (cylinder and crushed ice separately stored). With the selector switch on “Auto”,

the machine will automatically produce cylinder ice until the cylinder-ice bin is filled. This action will

open the cylinder ice thermostat switch in the cylinder ice bin and will automatically change the

machine over to crushed ice production--PROVIDED THE CRUSHED ICE BIN IS NOT FULL.

When the crushed ice bin is filled, its thermostat switch opens and stops the machine upon completion

of the harvest cycle and partial pumpdown cycle.

If cylinder ice is removed--during the freeze cycle of the crushed ice operation and the cylinder ice bin

thermostat switch closes within five minutes of that cycle, the machine will revert immediately to

cylinder ice production.

If, when producing cylinder ice, the thermostat switch for cylinder ice should open within the first five

minutes of that cycle, the machine will immediately revert to crushed ice production. The selection of

cylinder or crushed ice can be changed for that cycle only within the first five minutes of the freezing

cycle. Note that the “R” (reversing relay) is not energized when making cylinder ice.

The machine will never stop by action of the bin thermostat during any freezing operation. It will

always complete the evacuation and discharge of all the ice and completion of a partial pumpdown

cycle regardless of the causes which open either thermostat switch.

See FIGURE 3-14, “Illustration of the Bin Thermostat Bulb Installation”.

With no divider in bin (producing only ONE type ice). When there is no partition in the bin for

separating cylinder and crushed ice, you need use only one bin thermostat and bulb. By connecting

wires #25 and #26 together on the same thermostat terminal and installing that thermostat bulb in the

bin, you will have the other thermostat as a spare. You will still be able to produce cylinder or

crushed ice, whichever is desired. The deflector door assembly and chute deflector may be removed

if the bin has no divider (see FIGURE 9-14).

See FIGURE 3-15, “Wiring for Single Thermostat Operation”.

Ice Selector Switch, FIGURES 6-2 & 9-7. When the selector switch is set on either “Auto” or

“Cyl”, the machine will produce cylinder ice until the bin is filled and the thermostat switch opens,

shutting down production at the completion of the thaw mode and partial pumpdown cycle. If the

selector switch is changed to “Cru” after the unit has started a cylinder ice freeze and five minutes has

lapsed, it will complete the freeze and evacuation of the cylinder ice BEFORE changing to the

production of crushed ice. If five minutes has not lapsed, it will revert to crushed ice immediately.

With the selector switch set on “Cru”, the machine will produce crushed ice until the bin is filled and

the thermostat switch opens. It will then shut down at the completion of the thawing period and

partial pumpdown cycle. If the switch is changed to “Auto” or “Cyl” within five minutes of the

machine starting crushed ice freeze, it will switch immediately to the production of cylinder ice.

4-3

10/21/01

Page 40

4-4

HOW YOUR TUBE-ICE MACHINE WORKS

When ice bin thermostats are NOT used. With the selector switch set on either “Auto” or “Cyl”,

the machine will produce cylinder ice. If the switch is changed to “Cru” while the unit is producing

cylinder ice, after the first 5 minutes of a cycle, it will complete the freeze and evacuation of the

cylinder ice before changing to the production of crushed ice. The next cycle will produce crushed

ice.

With the switch set on “Cru” the machine will produce crushed ice. If the switch is changed to

“Auto” or “Cyl” within the first 5 minutes of a cycle, the unit will revert immediately to the

production of cylinder ice.

The selector switch will function as stated above (see FIGURES 6-2 & 9-7).

Starting and stopping of the machine must be controlled by the “Ice” switch (see FIGURE 6-2).

If an alternate bin level control is used, it must be located in a position to stop the machine prior to ice

backing up into the ice chute and jamming cutter.

Crushed Ice Preferred. A special customized PLC can be programmed and furnished as an option

to produce crushed ice first when the selector switch is in the “Auto” position. This option will still

allow the operator to select “Cyl” or “Cru” ice as desired, but will produce crushed ice and satisfy

that thermostat first then revert to making cylinder ice. Contact your distributor for details.

Single Ice Type. The machine will contain only one freezer pressure switch (FPS2) and one bin

thermostat (BT2). A selector switch (SS) and reversing relay (R) are not included. The machine will

also be supplied with an ice chute without an ice deflector door assembly (FIGURE 9-12).

Cylinder Ice. The single ice type machine will be factory adjusted to produce cylinder ice.

Crushed Ice. To convert a single ice type machine from cylinder ice to crushed ice, only small

modifications need to be made.

• Move jumper in control panel

• Adjust freezer pressure switch (FPS2)

See “Converting from cylinder ice to crushed ice”, Section 9, “Service Operations” for details.

HEC-Series Service Manual

10/21/01

Page 41

HEC-Series Service Manual

HOW YOUR TUBE-ICE MACHINE WORKS

Ice Bin Capacity. Crushed or cylinder ice weighs approximately 35 pounds per cubic ft. (35 lb/ft3 ).

As ice drops into a bin, it will pile up and slope naturally at about a 45° angle. This natural slope

should be taken into account when locating the bin thermostat bulb (or other bin level control) and

when calculating the normal bin capacity. If the ice is spread out by hand in the bin for maximum

storage capacity, make sure a hazard is not created by allowing ice to back up into the chute and

jamming the cutter. Always allow enough room below the chute for at least one harvest (approx. 40

lbs. of ice).

If a two-way defector is installed below the ice chute, care should be taken to make sure it is located

directly in the center of the stream of ice as it falls to give even distribution of the ice.

Refrigeration System (Review Before Starting Machine). The refrigeration system uses HCFC22 refrigerant, a compressor, a thermal expansion valve, a flooded evaporator (freezer), and warm

gas defrost. Following the schematic, you see that during the freeze period of the machine’s cycle,

the compressor discharge gas leaves the compressor and goes to the condenser where it is condensed

into a liquid by the removal of heat by either air or water passing through the condenser. A reservoir

of liquid is accumulated in the receiver and flows as required, passing through the filter/drier, then the

thawing chamber, (a lower separate section of the freezer). The liquid solenoid valve (the “A” valve)

being open during the operation allows the liquid to be metered by the thermal expansion valve that

opens and closes (modulates) as the temperature of the suction line dictates. The evaporator floods

with wet refrigerant that is in contact with the outside of the tubes that the ice-making water is being

circulated through. The heat contained in this water is conducted through the wall of the tubes,

lowering the temperature of the water, causing it to freeze and form a long tube of ice that adheres to

the inside of each of the freezer tubes. The flowing water keeps the accumulated ice clear by washing

separated solids down into the sump area of the water tank.

The wet suction gas leaves the freezer, passes through the accumulator, and has any remaining liquid

droplets removed by the heat contained in the high side liquid passing through the heat exchanger.

The dry gas enters the compressor and is compressed then discharged to the condenser, the

condensed liquid flows through the liquid side of the heat exchanger and to the receiver completing

the cycle.

As the ice is formed in the freezer, the suction pressure steadily reduces until it causes one of the

freezer pressure switches to close and switch the machine to a harvest period.

During the harvest period, the thawing gas solenoid valve, (The “D” valve), is open allowing the

warm high pressure gas to enter the freezer. This heat melts a thin film from the outside of the ice,

reducing the diameter and letting it fall free from the freezer tubes. The flow of thaw gas through the

freezer is controlled by the CPR (crankcase pressure regulator) valve. This valve should be set as

recommended in TABLE 9-2, “CPR Valve Setting”.

For additional information and familiarization, see “How Your Tube-Ice Machine Works,” Page 4-1,

and Piping Schematics, FIGURES 4-1, 5-7, & 5-3.

4-5

10/21/01

Page 42

HEC-Series Service Manual

INITIAL START UP AND OPERATION

5. Initial Start-Up & Operation

Start-Up Checklist

Be sure to complete and return the Warranty Registration/Start-Up report located at the front

of the manual.

In order to prepare the machine for start-up, it will be necessary to remove the front panels for access

to the various valves and for observation.

_____ 1. See that water-inlet connections are attached to the proper couplings (water cooled

units) and to water for ice making. The inlet shutoff valves should be open. The

water level in the water pan should be at a height where the make-up water float valve

will be closed when the machine is idle.

_____ 2. See that the cutter motor gear reducer is lubricated (see “Lubrication” for

instructions).

_____ 3. See that compressor crankcase oil level is at proper height of 1/4 to 3/4 of the sight

glass. (no sight glass on Carlyle scroll compressor.)

_____ 4. See that “Cutter” and “Pump” circuit breakers are in the “On” position.

_____ 5. See that the “Ice” push button switch is in the “Off” position (Button Out).

_____ 6. See that the “Clean” push button switch is set to “Off” position (Button Out).

NOTE: All valves are tagged with instructions.

_____ 7. Open compressor service valves (34 and 35), the two hand-stop valves (90) in the

thawing gas line, (91) in the condenser return line, and the hand-stop valve (58) in the

liquid line and hand-stop valve (69) to the freezer pressure switch. These valves are

tagged to indicate that they were closed for shipping purposes.

_____ 8. IMPORTANT! CHECK TO SEE that all stop valves in the various refrigerant lines

are open except charging valve (28), according to the attached tags.

_____ 9. Immediately after opening all valves, entire machine should be checked for

refrigerant leaks with electronic leak detector.

_____ 10. Close exterior disconnect switch to energize crankcase heater and power the PLC.

! CAUTION !

The crankcase heater should be energized for a MINIMUM of

2 HOURS before attempting to operate the compressor.

! CAUTION !

_____ 11. Connect a suction gage to the low pressure test connection and a high pressure gage

to the high pressure test connection. After TWO HOURS, push the “Ice” button and

the “Start” button. The machine will not operate until the low pressure raises

sufficiently (to approximately 40 psig) to close the low pressure switch (4PS) & open

the cylinder ice freezer pressure switch (FPS2).

5-1

10/21/01

Page 43

5-2

INITIAL START-UP AND OPERATION

If the machine does not start, put the “Ice” button in the “Off” position. Put the “Clean” button in the

“On” position and push the “Start” button. This will put the machine in the clean mode and tell the

PLC that the machine is pumped down. Now put the “Clean” button in the “Off” position, shutting

off the water pump, and the “Ice” button in the “On” position. When the “Start” button is pushed,

the “A” valve will open and feed liquid for 2 minutes then go to the freeze cycle.

Note: Be sure to check compressor rotation of machines with scroll compressor.

Suction pressure must decrease and discharge pressure increase immediately. To change rotation,

reverse two (2) of the three (3) compressor wires L1, L2, and L3 at the control panel terminal block.

HEC-Series Service Manual

FIGURE 5-1

Solenoid Valves

_____ 12. When the machine starts, check water level in water pan (7) to determine whether or

not water pump (6) is pumping water. It may be necessary to stop and start the

machine several times to expel air from the water pump impeller housing.

Note: Use one of the circuit breakers, “Cutter” or “Pump” to stop--for approximately 10 seconds-and start button to start the machine, if necessary to prime the pump.

! CAUTION !

If it should ever become necessary to add refrigerant to the

system, charging valve (28) is provided for this purpose.

Be sure to follow all local and federal regulations regarding

the handling of refrigerants and their illegal emission into

the atmosphere.

! CAUTION !

10/21/01

Page 44

HEC-Series Service Manual

INITIAL START UP AND OPERATION

Refrigerant Charge. Check the refrigerant level after the machine has operated for a few cycles. It

should be slightly above the operating level, as indicated on the receiver, a few minutes prior to start

of a thawing period. If this level is low at this time, sufficient refrigerant should be added to the

system to raise the level above this point. One inch (1”) is equivalent to 5 lbs. in the receiver. Add

only a small quantity (5 lbs. or less) at a time, and operate the machine several cycles to check the

level before adding additional refrigerant. Refrigerant may be added as a liquid through the charging

valve (28) only while the machine is operating. It is important that no air or other non-condensable

gases enter the system when charging refrigerant into the unit.

When adding refrigerant to the system, it may also be necessary to add lubricating oil. See

“Lubrication Compressor”, Section 7, “Maintenance”.

In order to check the total charge in the system, it is necessary to transfer all of the refrigerant to the

receiver. A total pumpdown procedure should be performed.

Total Pumpdown Mode. The function of the total pumpdown mode is to transfer all the liquid

refrigerant from the freezer (evaporator) into the receiver. Total pumpdown is initiated as the first

phase of and prior to entering the clean mode. It should only be performed when the freezer is clear

of ice.

Its main purpose is to clear the freezer of liquid refrigerant and prevent possible refrigerant migration

to the compressor while running the clean cycle. It also can be used to check the units total

refrigerant charge.

Total pumpdown is initiated by setting the selector switch to the “Cyl” position, turn “Ice” switch to

the “Off” position (allow the machine to harvest if running in a freeze cycle), press the “Clean” button

to the “On” position. At this time the compressor and water pump will run, the “A” (liquid feed)