Page 1

Air-Cooled Condenser

Installation Instructions

Revision Date: 12/21/98

Page 2

HES Series Air-Cooled Installation Instructions

These installation guidelines must be followed to obtain reliable operation from

air-cooled ice machines. If these guidelines are not followed, the compressor

1. Use only Vogt approved condensers. Any exceptions to this policy must be obtained in writing

prior to installation and operation of the ice machine.

2. Outdoor condensers must be installed with vertical air flow. Indoor condensers used for heat

recovery may be installed with either horizontal or vertical air flow.

3. The condenser must be mounted above the ice machine, with liquid refrigerant from the

condenser outlet draining freely (1/4” per foot slope) in the direction of normal operating flow

(back to the ice machine) with no traps in the liquid line.

4. Flooding head pressure controls such as Alco Headmaster are not to be used, since they cause

excessive subcooling of the returned liquid refrigerant and interfere with reliable ice harvest.

5. The discharge and liquid lines must be insulated with 1/2” thick Armaflex insulation or equal.

6. Horizontal runs in the discharge line should slope 1/4” per foot in the normal direction of flow

(away from the ice machine).

7. Traps must be installed in discharge lines at the base of all vertical risers. There should be no

intentional traps in liquid lines. Trap volume should be kept to a minimum. Typical details are

shown in FIGURE-10. Long vertical runs should have traps every 20 feet.

8. Use only ACR grade copper pipe, Type L. Recommended line sizes are shown in TABLE-3.

9. Distance between ice machine and condenser must not exceed 150 equivalent feet. Refer to

Condenser Equivalent Line Size worksheet. (see TABLE-5)

10. Condensers must be provided with a cold weather valve kit per FIGURE-9A. These valves

allow one-half of the condenser to be disabled in cold weather. Running the ice machine with

one half the condenser in cold weather makes it easier to maintain minimum necessary

condensing pressure, particularly in windy conditions. The coil thermostat should be set to close

at 35?F. for multiple fan condensers or 50?F for single fan condensers.

11. Condensers with multiple fans must be provided with a thermostat to turn off unneeded fans in

cold weather. Turning off unneeded fans reduces on-off cycling of the fan(s) and allows for a

steadier condensing pressure. The fan thermostat should be set at 50?F.

12. When extreme cold conditions are expected or encountered (temperatures below 0?F and wind

greater than 15 MPH), it may be necessary to install a protective enclosure around the condenser.

Other apparatuses such as louvers may be used. Contact the factory for suggestions.

! WARNING !

warranty will not be honored.

! WARNING !

2

Page 3

HES Series Air-Cooled Installation Instructions

13. After installation, the field-installed lines are to be evacuated to a vacuum of 500 microns or less

and held for at least one hour. Use ¼” access connection located on compressor discharge line

and liquid return line (32). After the vacuum pump is removed, vacuum should hold at 500

microns or less for at least 5 minutes and the lines pressurized with R-22 to 25 psig minimum.

14. The volume of refrigerant supplied with the machine is sufficient to fill the condenser and

condenser lines when length of pipe (one way) is 75 feet or less. When the length of lines is

longer than 75 feet, additional refrigerant must be added as noted below. Instructions for adding

refrigerant are included further in these instructions.

Liquid Line Size 75 ft. 100 ft. 125 ft. 150 ft.

1/2” none None None 2

5/8” none 2 4 6

7/8” none 4 8 12

1-1/8” none 6 12 18

Pounds R-22 to Add Vs. Liquid Line Length

15. All piping must be done in accordance with applicable local and national codes. Such codes may

include “The Safety Code for Mechanical Refrigeration (ANSI B9.1), and “The Code for

Refrigerant Piping” (ANSI B31.5).

16. The following installation guidelines are strongly suggested. While they do not affect the

machine warranty, they may be required for safe operation, and to comply with all applicable

electrical and mechanical codes.

TABLE - 3

17. Local electrical code must be checked for wiring method.

18. The installer must provide a lockable disconnect switch(s) adjacent to the condenser. The power

is fused at the machine by a 15 amp breaker.

19. Electrical connections between the condenser and the Tube-Ice

®

machine require minimum 12

ga. wire. See FIGURE-11 &12.

20. All electrical fittings and components exposed to the weather must be suitable for outdoor

installation.

The design total heat rejection for each Tube-Ice® machine, the recommended air-cooled condenser,

and condenser physical and electrical data are shown in TABLE-2. Only the condensers shown are

UL listed with the ice machines. Other condensers may be individually UL listed, but are not UL

listed with the Tube-Ice® machines, and cannot be recommended by Vogt Tube-Ice. Catalog energy

efficiency ratings of the ice machines are based on use of the recommended condenser.

Condensers supplied by Vogt must be utilized. The use of non-Vogt condensers will void the

compressor warranty. For continuous operation at ambient above 105?F, consult the factory about

using a larger condenser.

3

Page 4

HES Series Air-Cooled Installation Instructions

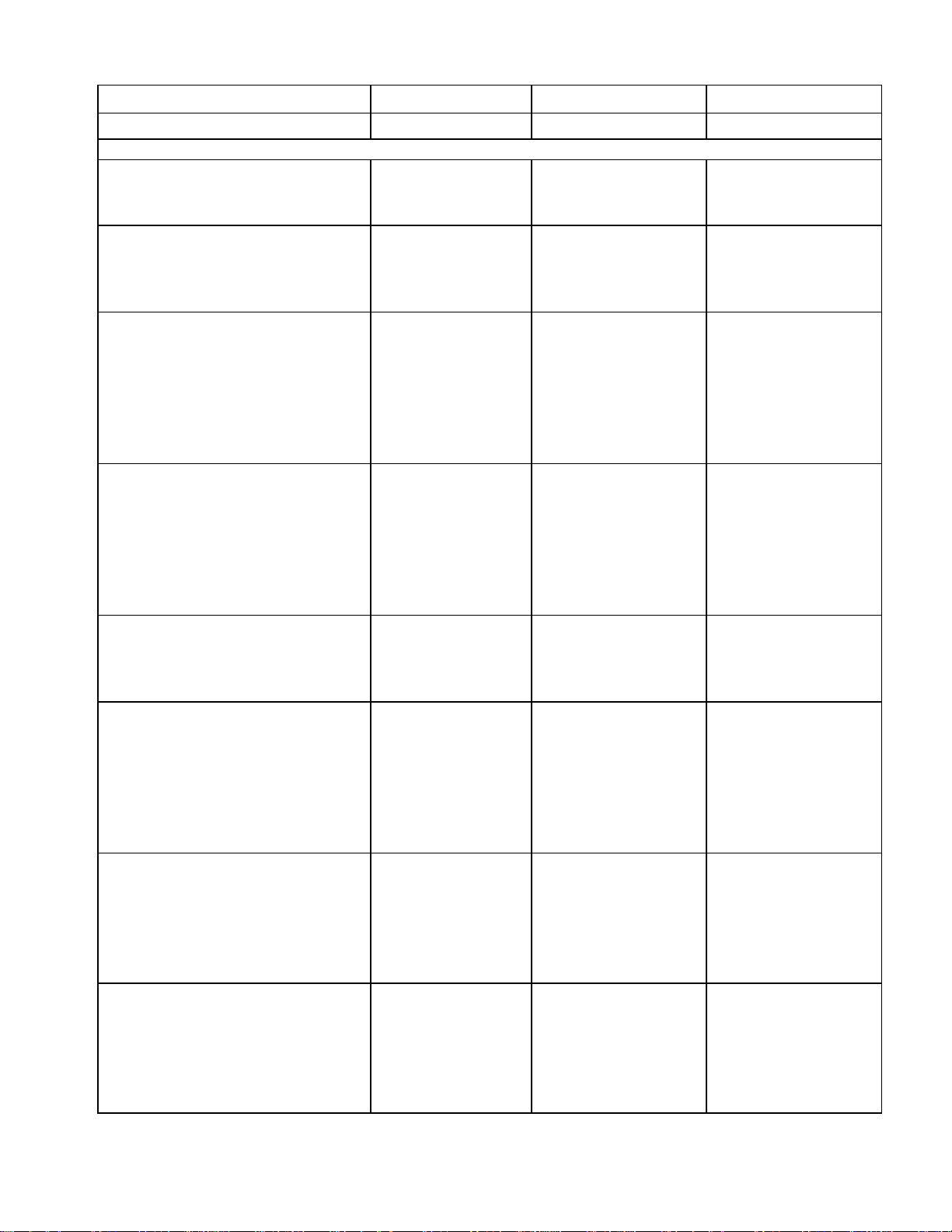

Ice Machine Model HE20 HE30 HE40

Recommended Condenser HDD-61 (HDD-101) HDD-101 (HDD-131) HDD-131 (HDD-191)

Note: For continuous operation at ambients above 105 °F, use larger condenser shown in parenthesis

Total Heat Rejection:

BTU/hr at 60 Hz.

BTU/hr at 50 Hz.

Fans:

Number

HP, Each

Total, CFM

Full Load Amps:

1 ph., 208/230V, 60 Hz

3 ph., 208/230V, 60 Hz

3 ph., 460V, 60 Hz

1 ph., 200/220V, 50 Hz

3 ph., 200/220V, 50 Hz

3 ph., 400V, 50 Hz

Locked Rotor Amps:

1 ph., 208/230V, 60 Hz

3 ph., 208/230V, 60 Hz

3 ph., 460V, 60 Hz

1 ph., 200/220V, 50 Hz

3 ph., 200/220V, 50 Hz

3 ph., 400V, 50 Hz

Weight, lbs.:

Net

Shipping

Operating (maximum flooded)

Condenser dimensions, inches:

A (Width)

B (Length)

C (Height)

D (Leg centerline)

E (Leg centerline)

F (Clearance below)

Recommended Line Sizes, OD:

Liquid (All lengths and orientations)

Discharge Gas

Vertical Up, All lengths

Horizontal Or Down, < 75 ft.

Horizontal Or Down, > 75 ft.

Connections at Condenser:

Liquid (ODC)

Discharge Gas (ODC)

Connections at Machine

Liquid (ODC)

Discharge Gas (ODC)

28,700

23,900

1

1/3

5,000

2.5

N/A

N/A

3.0

N/A

N/A

7

N/A

N/A

8.2

N/A

N/A

150

195

167

38-7/8”

45-1/2”

36-1/8”

37-7/8”

37”

16-1/8”

1/2”

5/8”

5/8”

7/8”

1/2”

5/8”

1-1/8”

1-1/8”

TABLE - 4

Air-Cooled Condenser Data

4

44,500

37,100

2

1/2

9,800

8.0

N/A

N/A

5.8

N/A

N/A

15

N/A

N/A

17.5

N/A

N/A

250

310

276

41-3/8”

66”

36-1/8”

40-3/8”

54”

16-1/8”

5/8”

7/8”

7/8”

1-1/8”

5/8”

7/8”

1-1/8”

1-1/8”

80,400

67,000

2 (3)

1/2 (1/2)

9,800 (15,500)

8.0 (12)

N/A

N/A

5.8 (8.7)

N/A

N/A

15 (23)

N/A

N/A

17.5 (27)

N/A

N/A

265 (370)

325 (440)

301 (405)

41-3/8” (41-3/8”)

66” (105)

36-1/8” (36-1/8”)

40-3/8” (40-3/8”)

54” (94”)

13-3/4” (13-3/4”)

7/8” (7/8”)

1-1/8” (1-1/8”)

1-1/8” (1-1/8”)

1-3/8” (1-3/8”)

7/8” (7/8”)

1-1/8” (1-3/8”)

1-1/8”

1-1/8”

Page 5

HES Series Air-Cooled Installation Instructions

Ice Machine Model HE60 / P112F HE100 / P118F P18FXT

Recommended Condenser HDD-231(HDD-261) HDD-311 (HDD-361) HDD-591 (HDD-661)

Note: For continuous operation at ambients above 105 °F, use larger condenser shown in parenthesis

Total Heat Rejection:

BTU/hr at 60 Hz.

BTU/hr at 50 Hz.

Fans:

Number

HP, Each

Total, CFM

Full Load Amps:

1 ph., 208/230V, 60 Hz

3 ph., 208/230V, 60 Hz

3 ph., 460V, 60 Hz

1 ph., 200/220V, 50 Hz

3 ph., 200/220V, 50 Hz

3 ph., 400V, 50 Hz

Locked Rotor Amps:

1 ph., 208/230V, 60 Hz

3 ph., 208/230V, 60 Hz

3 ph., 460V, 60 Hz

1 ph., 200/220V, 50 Hz

3 ph., 200/220V, 50 Hz

3 ph., 400V, 50 Hz

Weight, lbs.:

Net

Shipping

Operating (maximum flooded)

Condenser dimensions, inches:

A (Width)

B (Length)

C (Height)

D (Leg centerline)

E (Leg centerline)

F (Clearance below)

Recommended Line Sizes, OD:

Liquid (All lengths and orientations)

Discharge Gas

Vertical Up, All lengths

Horizontal Or Down, < 75 ft.

Horizontal Or Down, > 75 ft.

Connections at Condenser:

Liquid (ODC)

Discharge Gas (ODC)

Connections at Machine:

Liquid (ODC)

Discharge Gas (ODC)

122,000

101,700

3 (3)

1/2 (1/2)

15,000 (14,000)

N/A

6.0 (6.0)

2.7 (2.7)

N/A

6.0 (6.0)

3.0 (3.0)

N/A

19.8 (19.8)

9.9 (9.9)

N/A

19.8 (19.8)

9.9 (9.9)

400 (520)

475 (595)

436 (566)

41-3/8” (41-3/8”)

105” (105”)

36-1/8” (36-1/8”)

40-3/8” (40-3/8”)

94” (94”)

13-3/4” (11-3/4”)

1-1/8” (1-1/8”)

1-1/8” (1-1/8”)

1-1/8” (1-1/8”)

1-3/8” (1-3/8”)

1-1/8” (1-1/8”)

1-3/8” (1-5/8”)

1-1/8”

1-1/8”

TABLE – 4A

Air-Cooled Condenser Data

5

181,200

151,000

5 (5)

1/2 (1/2)

22,500 (22,000)

N/A

10.0 (10.0)

4.5 (4.5)

N/A

10.0 (10.0)

5.0 (5.0)

N/A

33 (33)

16.5 (16.5)

N/A

33 (33)

16.5 (16.5)

610 (660)

700 (770)

667 (726)

28-3/4” (28-3/4”)

180-1/8” (180-1/8”)

41-5/8” (41-5/8”)

27” (27”)

147-5/8” (147-5/8”)

14-5/8” (14-5/8”)

1-1/8” (1-1/8”)

1-3/8” (1-3/8”)

1-3/8” (1-3/8”)

1-5/8” (1-5/8”)

1-1/8” (1-5/8”)

1-5/8” (1-5/8”)

1-1/8”

1-3/8”

249,900

278,250

5 (5)

3/4 (3/4)

33,000 (32,500)

N/A

17.0 (17.0)

8.5 (8.5)

N/A

17.0 (17.0)

8.5 (8.5)

N/A

60 (60)

30 (30)

N/A

60 (60)

30 (30)

1175 (1200)

1325 (1350)

1221 (1258)

57” (57”)

180-1/8” (180-1/8”)

45-5/8” (45-5/8”)

55-1/4” (55-1/4”)

147-5/8” (147-5/8”)

14-5/8” (14-5/8”)

1-3/8” (1-3/8”)

1-3/8” (1-3/8”)

1-3/8” (1-3/8”)

1-5/8” (1-5/8”)

1-3/8” (1-3/8”)

2-1/8” (2-1/8”)

1-1/8”

1-3/8”

Page 6

HES Series Air-Cooled Installation Instructions

FIGURE - 9

Condenser Dimensions (Condenser pictured: DD-101 or DD-131)

Note: Dash lines indicate customer supplied piping. The Check Valve in the return line (labeled

“Output To Machine”) is supplied with the condenser.

FIGURE – 9A

Condenser Field Piping

6

Page 7

HES Series Air-Cooled Installation Instructions

CONDENSER EQUIVALENT

LINE SIZE WORKSHEET

Discharge Gas Line O.D. _____________

Fitting Type Number Used Factor Total

Globe Valve (open)

Angle Valve (open)

45? Elbow

90? Elbow

Feet of Straight Copper Used

Total Fitting Factor

Total Equivalent Feet

Copper Tube O.D. Type “L”

Globe Valve (open)

Angle Valve (open)

45? Elbow

90° Elbow

Fitting Factors

1/2” 5/8” 7/8” 1 1/8”

14 16 22 28

7 9 12 15

.5 1 1 1.5

1 2 2 3

TABLE - 5

FIGURE - 10

Minimum Traps for Discharge Lines

7

Page 8

HES Series Air-Cooled Installation Instructions

Refrigerant Connections to Air-Cooled Condenser.

MACHINE FRAME ANGLE

HE20 – HE40 ONLY

ROTALOCK SPUD

HE20 – HE60 (both lines)

P118 and P18XT (liquid return line)

1 1/4” – 12 Threads

P118 and P18XT (discharge line)

1 3/4” – 12 Threads

TEFLON SEAL

HE20 – HE60 (both lines)

P118 and P18XT (liquid return line)

PART #: 12A 2600T01 (1 1/4” – 12 Threads)

P118 and P18XT (discharge line)

PART #: 12A2600T03 (1 3/4” – 12 Threads)

ROTALOCK FIELD CONNECTOR

HE20 – HE60 (both lines)

P118 and P18XT (liquid return line)

PART #: 12A 2396A0501

1 1/8” IDS X 1 1/4” – 12 Threads

P118 and P18XT (discharge line)

PART #: 12A2396A0601

1 3/8” IDS X 1 3/4” – 12 Threads

FIGURE - 11

Field Attachment, Air Cooled Condenser Refrigerant Tubing

FOLLOW THESE PROCEDURES TO MAKE A TIGHT JOINT

1. Solder or braze condenser tubing ends to the female Rotalock connectors.

2. Remove dust caps if used, making sure that component plastic seals are intact.

3. Wipe off connector and spud threaded surfaces with a clean cloth to prevent the inclusion of dirt,

or any foreign material in the system.

4. Connector coupling nut should be screwed onto Rotalock spud using the proper amount of torque

(See TABLE-6).

Spud Size Amount of Torque

1/2” – 5/8” 30-40 FT LBS

7/8” 50-60 FT LBS

1 1/8” 80-100 FT LBS

TABLE – 6

Torque Ratings

8

Page 9

HES Series Air-Cooled Installation Instructions

Power

Motor (s)

Wiring Connections to Air-Cooled Condenser.

Air cooled condenser should be wired to terminals 20,21,22 and 23 (see FIGURE - 12).

Main

Main Power

Connections

Fan

Condenser

Connections

Cold

Weather

Package

(Hot)

NOTE: All four wires must be run from the ice machine to the remote air cooled condenser.

FIGURE - 12

Ice Machine Terminal Block Connections

FIGURE - 13

Wiring For HDD-61 With Cold Weather Valve and Single Fan

9

Page 10

HES Series Air-Cooled Installation Instructions

Wiring Connections to Air-Cooled Condenser (Cont.)

FIGURE - 14

Wiring For HDD-101 & HDD-131 With Cold Weather Valve And Dual Fans

FIGURE - 15

Wiring For HDD-191, HDD-231 & HDD-261 With Cold Weather Valve And Three Fans

10

Page 11

HES Series Air-Cooled Installation Instructions

Wiring Connections to Air-Cooled Condenser (Cont.)

FIGURE - 16

Wiring For HDD-311, HDD-361, HDD-591 & HDD-661 With Cold Weather Valve And Five Fans

Condenser Description

HDD-61 5/8” N.O.

12A4200A0503 12A4199V42 12A2105C04 12A2117G05

Solenoid Valve Thermostats

Valve Valve

Rebuild Kit

Replacement

Coil

Penn

(fan)

Ranco

(solenoid)

N/A

Solenoid

HDD-101 7/8” N.O.

12A4200A0704 12A4199V44 12A2105C04 12A2117G05 12A2117G06

Solenoid

HDD-131 1 1/8” N.O.

12A4200A0902 12A4199V45 12A2105C04 12A2117G05 12A2117G06

Solenoid

HDD-191

HDD-231

1 3/8” N.O.

Solenoid

12A4200A1102 12A4199V45 12A2105C04 12A2117G05 12A2117G06

HDD-261

HDD-311

HDD-361

HDD-591

HDD-661

Note: Sporlan Solenoid Valves

1 5/8” N.O.

Solenoid

12A4200A1104 12A4199V47 12A2105C04 12A2117G05 12A2117G06

TABLE – 7

Kramer Cold Weather Kit Replacement Parts

11

Loading...

Loading...