VS-VSKD71.., VS-VSKE71.., VS-VSKJ71.., VS-VSKC71..

ADD-A-PAK

ADD-A-PAK Gen 7

Power Modules Standard Diodes, 80 A

PRODUCT SUMMARY

I

F(AV)

Type Modules - Diode, High Voltage

Package ADD-A-PAK Gen 7

Circuit

Two diodes doubler circuit, two

diodes common cathode, two diodes

common anode, single diode

MECHANICAL DESCRIPTION

The ADD-A-PAK Gen 7, new generation of ADD-A-PAK

module, combines the excellent thermal performances

obtained by the usage of exposed direct bonded copper

substrate, with advanced compact simple package solution

and simplified internal structure with minimized number of

interfaces.

80 A

Vishay Semiconductors

FEATURES

• High voltage

• Industrial standard package

• Low thermal resistance

• UL approved file E78996

• Designed and qualified for industrial level

• Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

BENEFITS

• Excellent thermal performances obtained by the usage of

exposed direct bonded copper substrate

• Up to 1600 V

• High surge capability

• Easy mounting on heatsink

ELECTRICAL DESCRIPTION

These modules are intended for general purpose high

voltage applications such as high voltage regulated power

supplies, lighting circuits, temperature and motor speed

control circuits, UPS and battery charger.

MAJOR RATINGS AND CHARACTERISTICS

SYMBOL CHARACTERISTICS VALUES UNITS

I

F(AV)

I

F(RMS)

I

FSM

2

t

I

2

I

t 112.5 kA2s

V

RRM

T

J

T

Stg

Revision: 05-Apr-16

110 °C 80

126

50 Hz 1500

60 Hz 1570

50 Hz 11.25

60 Hz 10.26

Range 400 to 1600 V

-40 to +150 °C

1

Document Number: 94626

A

kA2s

VS-VSKD71.., VS-VSKE71.., VS-VSKJ71.., VS-VSKC71..

Vishay Semiconductors

ELECTRICAL SPECIFICATIONS

VOLTAGE RATINGS

V

, MAXIMUM REPETITIVE PEAK

TYPE NUMBER

VOLTAGE

CODE

RRM

REVERSE VOLTAGE

V

04 400 500

06 600 700

08 800 900

VS-VSK.71

10 1000 1100

12 1200 1300

14 1400 1500

16 1600 1700

FORWARD CONDUCTION

PARAMETER SYMBOL TEST CONDITIONS VALUES UNITS

Maximum average forward current

at case temperature

Maximum RMS forward current I

Maximum peak, one-cycle forward,

non-repetitive surge current

Maximum I

Maximum I

2

t for fusing I2t

2

t for fusing I2t t = 0.1 ms to 10 ms, no voltage reapplied 112.5 kA2s

Low level value of threshold voltage V

High level value of threshold voltage V

Low level value of forward

slope resistance

High level value of forward

slope resistance

Maximum forward voltage drop V

I

F(AV)

F(RMS)

I

FSM

F(TO)1

F(TO)2

r

f1

r

f2

FM

180° conduction, half sine wave

DC at 90 °C case temperature 126

t = 10 ms

t = 8.3 ms 1570

t = 10 ms

t = 8.3 ms 1320

t = 10 ms

t = 8.3 ms 10.26

t = 10 ms

t = 8.3 ms 7.23

(16.7 % x x I

(I > x I

(16.7 % x x I

(I > x I

IFM = x I

No voltage

reapplied

100 % V

reapplied

No voltage

reapplied

100 % V

reapplied

< I < x I

F(AV)

), TJ = TJ maximum 0.83

F(AV)

< I < x I

F(AV)

), TJ = TJ maximum 2.89

F(AV)

, TJ = 25 °C, tp = 400 μs square wave 1.6 V

F(AV)

V

, MAXIMUM NON-REPETITIVE

RSM

PEAK REVERSE VOLTAGE

RRM

Sinusoidal half wave,

intitial T

RRM

), TJ = TJ maximum 0.73

F(AV)

), TJ = TJ maximum 3.22

F(AV)

V

= TJ maximum

J

I

MAXIMUM

RRM

AT T

80 A

110 °C

1500

1260

11.25

7.95

= 150 °C

J

mA

10

A

kA2s

V

m

BLOCKING

PARAMETER SYMBOL TEST CONDITIONS VALUES UNITS

Maximum peak reverse

leakage current

Maximum RMS insulation voltage V

Revision: 05-Apr-16

I

RRM

TJ = 150 °C 10 mA

INS

50 Hz

3000 (1 min)

3600 (1 s)

2

Document Number: 94626

V

VS-VSKD71.., VS-VSKE71.., VS-VSKJ71.., VS-VSKC71..

Vishay Semiconductors

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER SYMBOL TEST CONDITIONS VALUES UNITS

Junction and storage temperature range T

Maximum internal thermal resistance,

junction to case per leg

Typical thermal resistance,

case to heatsink per module

Mounting torque ± 10 %

Approximate weight

Case style JEDEC

to heatsink

busbar 3

R CONDUCTION PER JUNCTION

DEVICES

VSK.71 0.075 0.088 0.113 0.155 0.228 0.06 0.094 0.12 0.158 0.23 °C/W

Note

• Table shows the increment of thermal resistance R

SINE HALF WAVE CONDUCTION RECTANGULAR WAVE CONDUCTION

180° 120° 90° 60° 30° 180° 120° 90° 60° 30°

, T

J

Stg

R

thJC

R

thCS

DC operation 0.28

Mounting surface flat, smooth and greased 0.1

A mounting compound is recommended and the

torque should be rechecked after a period of

3 hours to allow for the spread of the compound.

®

when devices operate at different conduction angles than DC

thJC

-40 to +150 °C

°C/W

4

Nm

75 g

2.7 oz.

ADD-A-PAK Gen 7 (TO-240AA)

UNITS

Revision: 05-Apr-16

3

Document Number: 94626

VS-VSKD71.., VS-VSKE71.., VS-VSKJ71.., VS-VSKC71..

Average forward current (A)

Maximum allowable case temperature (°C)

020406080100

90

100

110

120

130

140

150

180°

120°

90°

60°

30°

RthJC (DC) = 0.28°C/W

Average forward current (A)

Maximum average forward power loss (W)

0 102030405060708090

0

20

40

60

80

100

120

180°

120°

90°

60°

30°

RMS limit

Per leg, Tj = 150°C

Peak half sine wave forward current (A)

Number of equal amplitude half cycle current pulses (N)

110100

400

600

800

1000

1200

1400

At any rated load condition and with

rated Vrrm applied following surge

Initial Tj = Tj max

@ 60 Hz 0.0083 s

@ 50 Hz 0.0100s

Per leg

Vishay Semiconductors

Fig. 1 - Current Ratings Characteristics

150

RthJC (DC) = 0.28°C/W

140

130

120

DC

110

180°

120°

90°

100

60°

Maximum allowable case temperature (°C)

30°

90

0 20406080100120140

Average forward current (A)

Fig. 2 - Current Ratings Characteristics

160

140

120

100

80

180°

120°

90°

60°

30°

DC

RMS limit

60

40

20

Maximum average forward power loss (W)

0

Per leg, Tj = 150°C

0 20 40 60 80 100 120 140

Average forward current (A)

Fig. 4 - Foward Power Loss Characteristics

Fig. 5 - Maximum Non-Repetitive Surge Current

Fig. 3 - Forward Power Loss Characteristics

Revision: 05-Apr-16

1600

1400

1200

Maximum Non-repetitive Surge Current

Versus Pulse Train Duration

Initial T j = 15 0°C

No Voltage Reapplied

Rated Vrrm reapplied

1000

800

600

400

Peak half sine wave forward current (A)

200

Per leg

0.01 0.1 1

Pulse train duration (s)

Fig. 6 - Maximum Non-Repetitive Surge Current

4

Document Number: 94626

VS-VSKD71.., VS-VSKE71.., VS-VSKJ71.., VS-VSKC71..

Total RMS output current (A)

Maximum total forward power loss (W)

Maximum allowable ambient temperature (°C)

0 20 40 60 80 100 120 140 16

RthSA = 0.5 °C/W

0.7 °C/W

1 °C/W

1.5 °C/W

2 °C/W

3 °C/W

7 °C/W

0 20406080100120140

0

20

40

60

80

100

120

140

160

180°

(Sine)

VSK.71 Series

Per leg

Tj = 150°C

DC

0

Total output current (A)

Maximum allowable ambient temperature (°C)

Maximum total power loss (W)

0 20 40 60 80 100 120 140 160

RthSA = 0.1 °C/W

0.2 °C/W

0.3 °C/W

0.4 °C/W

0.7 °C/W

1.5 °C/W

0 50 100 150 200

0

100

200

300

400

500

600

120°

(rect)

3 x VSK.71 Series

three phase bridge connected

Tj = 150°C

Vishay Semiconductors

Fig. 7 - Forward Power Loss Characteristics

600

180°

500

(sine)

180°

(rect)

400

300

200

100

Maximum total power loss (W)

single ph ase br idg e conn ected

0

0 50 100 150 200

Total output current (A)

Fig. 8 - Forward Power Loss Characteristics

RthSA = 0.1 °C/W

0.2 °C/W

0.3 °C/W

0.5 °C/W

1 °C/W

2 °C/W

2 x VSK.71 Series

Tj = 150°C

0 20 40 60 80 100 120 140 16

Maximum allowable ambient temperature (°C)

Revision: 05-Apr-16

Fig. 9 - Forward Power Loss Characteristics

5

Document Number: 94626

VS-VSKD71.., VS-VSKE71.., VS-VSKJ71.., VS-VSKC71..

- Module type

- Circuit configuration (see Circuit Configuration table)

- Current code (80 A)

- Voltage code (see Voltage Ratings table)

Device code

KD71/16

1

- Vishay Semiconductors product

2

3

4

5

521 43

VS-VS

Vishay Semiconductors

1000

Per leg

100

10

Tj = 150°C

Instantaneous forward current (A)

1

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Instantaneous forward voltage (V)

Fig. 10 - Forward Voltage Characteristics

1

Tj = 25°C

(°C/W)

thJC

0.1

0.01

Transient thermal impedance Z

Steady state value

RthJC = 0.28 °C/W

(DC operation)

0.001 0.01 0.1 1 10

Fig. 11 - Thermal Impedance Z

ORDERING INFORMATION TABLE

Per leg

Square wave pulse duration (s)

Characteristics

thJC

Revision: 05-Apr-16

6

Document Number: 94626

VS-VSKD71.., VS-VSKE71.., VS-VSKJ71.., VS-VSKC71..

VSKD...

~

(1) (3)(2)

-+

1

2

3

+- -

VSKC...

(1) (3)(2)

1

2

3

- ++

VSKJ...

(1) (3)(2)

1

2

3

-+

VSKE...

1

2

3

(3)(1)

(2)

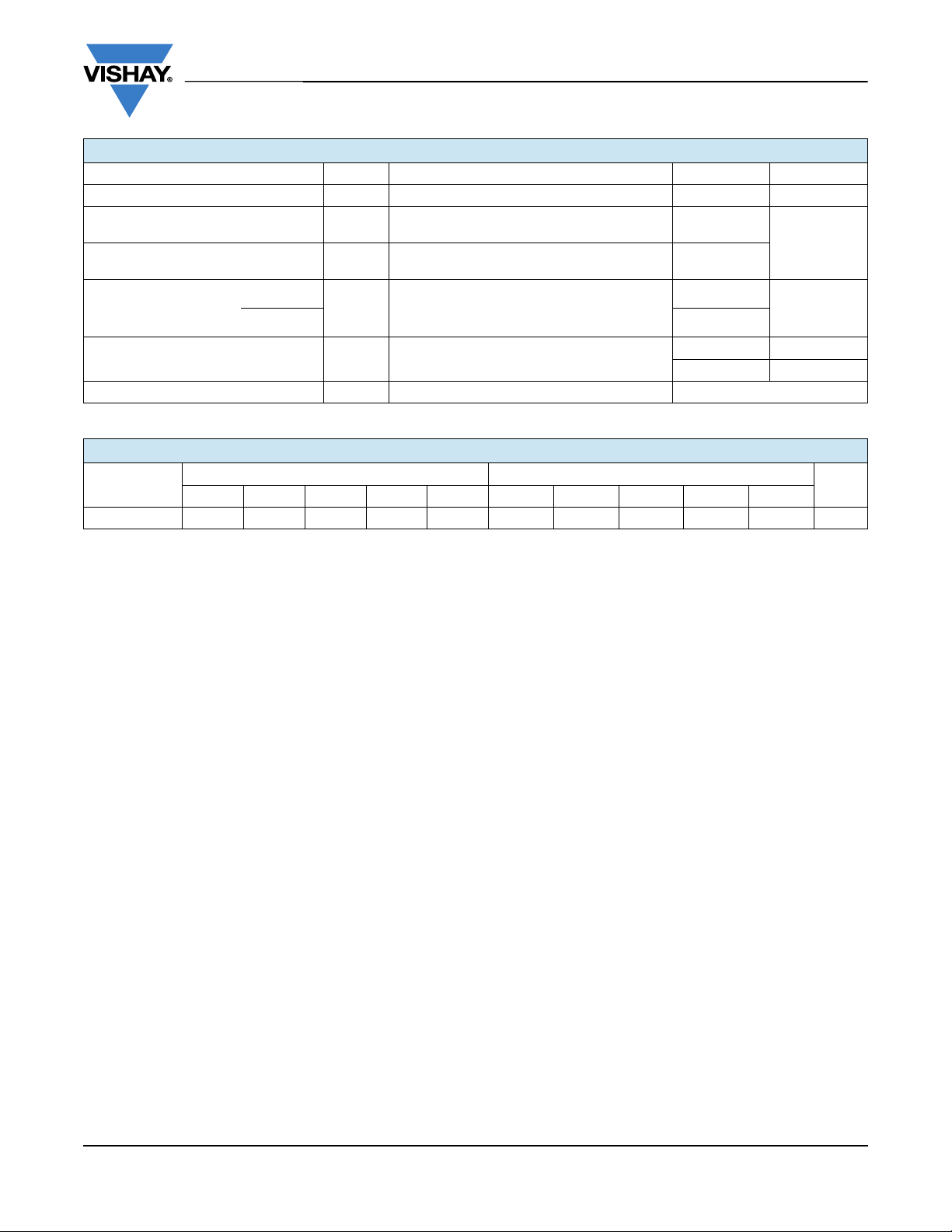

CIRCUIT CONFIGURATION

CIRCUIT DESCRIPTION

Two diodes doubler circuit D

Two diodes common cathode C

CIRCUIT

CONFIGURATION CODE

Vishay Semiconductors

CIRCUIT DRAWING

Two diodes common anode J

Single diode E

LINKS TO RELATED DOCUMENTS

Dimensions www.vishay.com/doc?95369

Revision: 05-Apr-16

7

Document Number: 94626

ADD-A-PAK Generation VII - Diode

DIMENSIONS in millimeters (inches)

Outline Dimensions

Vishay Semiconductors

Viti M5 x 0.8

Screws M5 x 0.8

18 (0.7) REF.

35 REF.

22.6 ± 0.2

30 ± 0.5

29 ± 0.5

(1 ± 0.020)

(1.18 ± 0.020)

(0.89 ± 0.008)

6.3 ± 0.2 (0.248 ± 0.008)

80 ± 0.3 (3.15 ± 0.012)

1

15 ± 0.5 (0.59 ± 0.020)

20 ± 0.5 (0.79 ± 0.020)

92 ± 0.75 (3.6 ± 0.030)

2

20 ± 0.5 (0.79 ± 0.020)

3

6.7 ± 0.3 (0.26 ± 0.012)

24 ± 0.5

(1 ± 0.020)

4 5 7 6

Document Number: 95369

Revision: 11-Nov-08 1

Legal Disclaimer Notice

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as Halogen-Free follow Halogen-Free

requirements as per JEDEC JS709A standards. Please note that some Vishay documentation may still make reference

to the IEC 61249-2-21 definition. We confirm that all the products identified as being compliant to IEC 61249-2-21

conform to JEDEC JS709A standards.

Revision: 02-Oct-12

1

Document Number: 91000

Loading...

Loading...