Infrared Emitting Diode, 950 nm, GaAs

94 8553

DESCRIPTION

VSMS3700 is an infrared, 950 nm emitting diode in GaAs

technology, molded in a PLCC-2 package for surface

mounting (SMD).

VSMS3700

Vishay Semiconductors

FEATURES

• Package type: surface mount

• Package form: PLCC-2

• Dimensions (L x W x H in mm): 3.5 x 2.8 x 1.75

• Peak wavelength: λ

• High reliability

• Angle of half intensity: ϕ = ± 60°

• Low forward voltage

• Suitable for high pulse current operation

• Good spectral matching with Si

photodetectors

• Package matched with IR emitter series VEMT3700

• Floor life: 168 h, MSL 3, acc. J-STD-020

• Lead (Pb)-free reflow soldering

• AEC-Q101 qualified

• Compliant to RoHS directive 2002/95/EC and in

accordance to WEEE 2002/96/EC

• Find out more about Vishay’s Automotive Grade Product

requirements at: www.vishay.com/applications

= 950 nm

p

APPLICATIONS

• Infrared source in tactile keyboards

• IR diode in low space applications

• PCB mounted infrared sensors

• Emitter in miniature photo-interrupters

PRODUCT SUMMARY

COMPONENT Ie (mW/sr) ϕ (deg) λP (nm) tr (ns)

VSMS3700 4.5 ± 60 950 800

Note

Test conditions see table “Basic Characteristics”

ORDERING INFORMATION

ORDERING CODE PACKAGING REMARKS PACKAGE FORM

VSMS3700-GS08 Tape and reel MOQ: 7500 pcs, 1500 pcs/reel PLCC-2

VSMS3700-GS18 Tape and reel MOQ: 8000 pcs, 8000 pcs/reel PLCC-2

Note

MOQ: minimum order quantity

** Please see document “Vishay Material Category Policy”: www.vishay.com/doc?99902

Document Number: 81373 For technical questions, contact: emittertechsupport@vishay.com

Rev. 1.3, 03-Nov-09 322

www.vishay.com

VSMS3700

Vishay Semiconductors

Infrared Emitting Diode, 950 nm,

GaAs

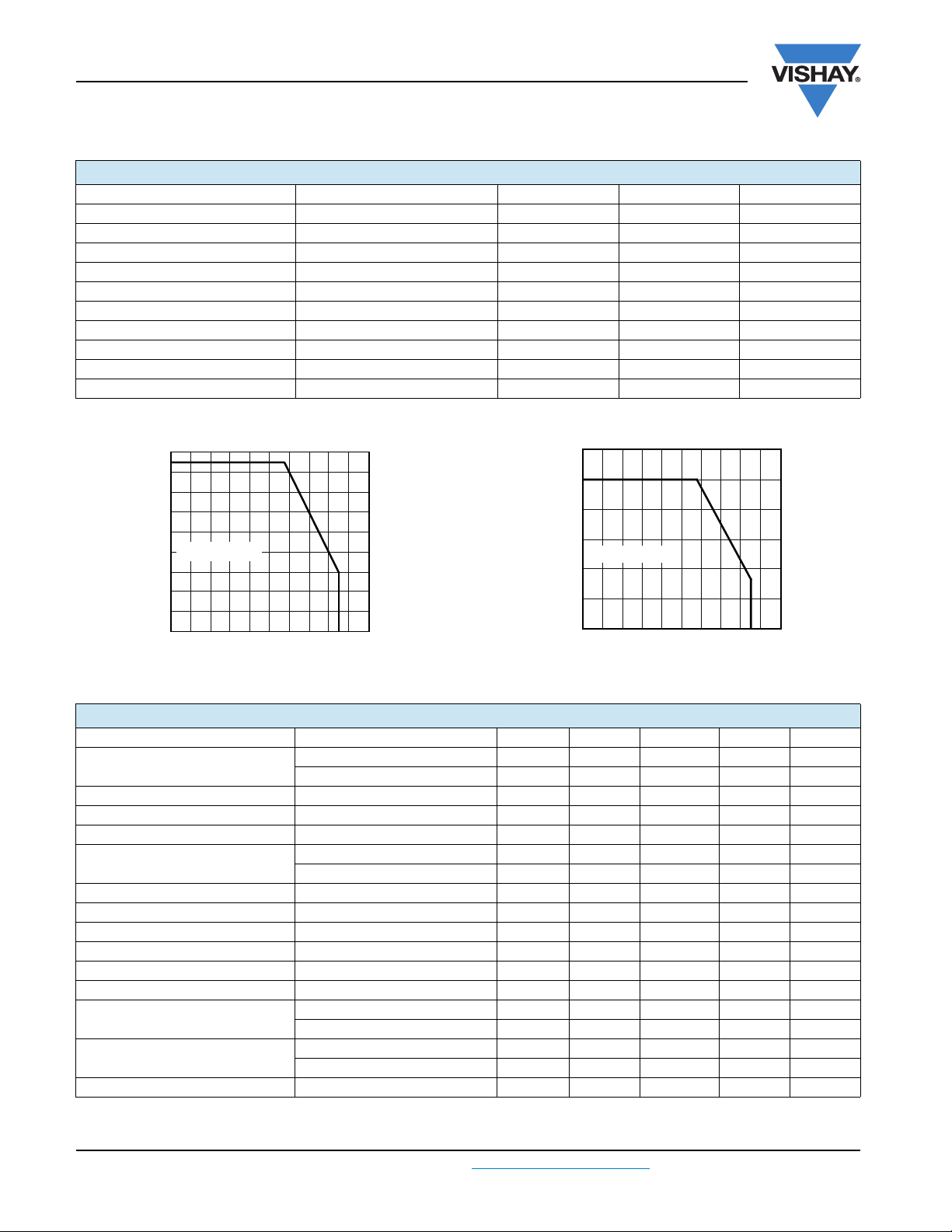

ABSOLUTE MAXIMUM RATINGS

PARAMETER TEST CONDITION SYMBOL VALUE UNIT

Reverse voltage V

Forward current I

Peak forward current t

Surge forward current t

/T = 0.5, tp = 100 μs I

p

= 100 μs I

p

Power dissipation P

Junction temperature T

Operating temperature range T

Storage temperature range T

Soldering temperature Acc. figure 11, J-STD-020 T

Thermal resistance junction/ambient J-STD-051, soldered on PCB R

R

F

FM

FSM

V

j

amb

stg

sd

thJA

Note

T

= 25 °C, unless otherwise specified

amb

180

160

140

120

100

R

80

60

40

- Power Dissipation (mW)

V

P

20

21341

= 250 K/W

thJA

0

0 102030405060708090100

T

- Ambient Temperature (°C)

amb

120

100

80

60

R

= 250 K/W

thJA

40

- Forward Current (mA)

F

I

20

0

0 10 203040 50607080 90100

21342

- Ambient Temperature (°C)

T

amb

Fig. 1 - Power Dissipation Limit vs. Ambient Temperature Fig. 2 - Forward Current Limit vs. Ambient Temperature

5V

100 mA

200 mA

1.5 A

170 mW

100 °C

- 40 to + 85 °C

- 40 to + 100 °C

260 °C

250 K/W

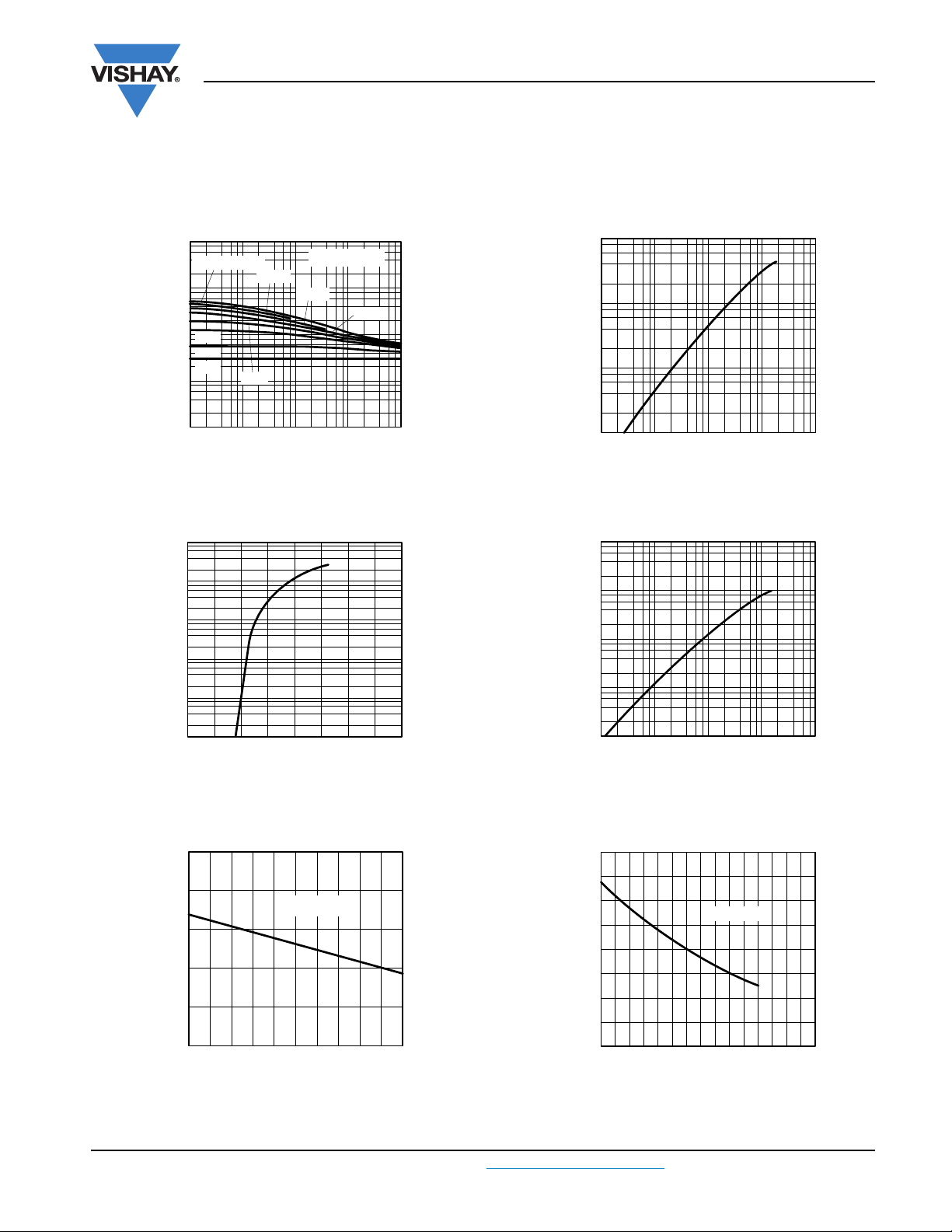

BASIC CHARACTERISTICS

PARAMETER TEST CONDITION SYMBOL MIN. TYP. MAX. UNIT

I

= 100 mA, tp = 20 ms V

Forward voltage

Temperature coefficient of V

F

F

I

= 1 A, tp = 100 μs V

F

IF = 100 mA TK

Reverse current V

Junction capacitance V

Radiant intensity

Radiant power I

Temperature coefficient of φ

e

= 0 V, f = 1 MHz, E = 0 C

R

= 100 mA, tp = 20 ms I

I

F

I

= 1.5 A, tp = 100 μs I

F

= 100 mA, tp = 20 ms φ

F

IF = 100 mA TKφ

= 5 V I

R

F

F

VF

R

j

e

e

e

e

1.6 4.5 8 mW/sr

Angle of half intensity ϕ ± 60 deg

Peak wavelength I

Spectral bandwidth I

Temperature coefficient of λ

p

Rise time

Fall time

= 100 mA λ

F

= 100 mA Δλ 50 nm

F

IF = 100 mA TKλ

I

= 20 mA t

F

I

= 1 A t

F

I

= 20 mA t

F

I

= 1 A t

F

p

p

r

r

f

f

Virtual source diameter EN 60825-1 d 0.5 mm

Note

T

= 25 °C, unless otherwise specified

amb

www.vishay.com For technical questions, contact: emittertechsupport@vishay.com

323 Rev. 1.3, 03-Nov-09

1.3 1.7 V

1.8 V

- 1.3 mV/K

100 μA

30 pF

35 mW/sr

15 mW

- 0.8 %/K

950 nm

0.2 nm/K

800 ns

400 ns

800 ns

400 ns

Document Number: 81373

VSMS3700

BASIC CHARACTERISTICS

T

= 25 °C, unless otherwise specified

amb

10 000

tp/T = 0.005

1000

100

0.2

0.5

DC

10

- Forward Current (mA)

F

I

1

0.01 0.1 1 10

95 9985

Fig. 3 - Pulse Forward Current vs. Pulse Duration

4

10

0.01

0.1

tp - Pulse Length (ms)

Infrared Emitting Diode, 950 nm,

GaAs

T

< 60 °C

amb

0.02

0.05

100

Vishay Semiconductors

100

10

1

- Radiant Intensity (mW/sr)

e

I

0.1

94 7956

10

0

1

10

I

- Forward Current (mA)

F

10

2

Fig. 6 - Radiant Intensity vs. Forward Current

1000

10

3

10

4

3

10

2

10

1

10

0

10

F

I - Forward Current (mA)

-1

94 7996

10

- Forward Voltage (V)

V

F

43210

Fig. 4 - Forward Current vs. Forward Voltage

1.2

1.1

= 10 mA

I

F

1.0

0.9

0.8

- Relative Forward Voltage (V)

F rel

V

94 7990

0.7

T

- Ambient Temperature (°C)

amb

100806040200

Fig. 5 - Relative Forward Voltage vs. Ambient Temperature

100

10

- Radiant Power (mW)

1

e

Φ

0.1

94 8012

10

10

1

0

IF - Forward Current (mA)

10

2

10

3

10

4

Fig. 7 - Radiant Power vs. Forward Current

1.6

1.2

Φ

;

I

e rel

0.8

e rel

IF = 20 mA

0.4

0

- 10 10 50 0 100

T

94 7993

- Ambient Temperature (°C)

amb

140

Fig. 8 - Relative Radiant Intensity/Power vs. Ambient Temperature

Document Number: 81373 For technical questions, contact: emittertechsupport@vishay.com

www.vishay.com

Rev. 1.3, 03-Nov-09 324

VSMS3700

Vishay Semiconductors

1.25

1.0

0.75

0.5

0.25

- Relative Radiant Power

e rel

Φ

0

900 950

94 7994

IF = 100 mA

λ - Wavelength (nm)

Infrared Emitting Diode, 950 nm,

Fig. 9 - Relative Radiant Power vs. Wavelength Fig. 10 - Relative Radiant Intensity vs. Angular Displacement

PACKAGE DIMENSIONS in millimeters

± 0.2

3.5

1000

GaAs

1.0

0.9

0.8

- Relative Radiant Intensity

0.7

e, rel

I

0.4 0.2 0

0.6

94 8013

0°

10° 20°

30°

40°

50°

60°

70°

ϕ - Angular Displacement

80°

± 0.1

1.75

0.9

Pin identification

± 0.15

CA

2.8

Ø 2.4

+ 0.15

3

2.2

Drawing-No.: 6.541-5067.01-4

Issue: 5; 04.11.08

20541

Die Position (for reference only)

X = +/- 0.2 mm centrical

Y = +/- 0.2 mm centrical

Z = 1.13 mm +/- 0.25 mm, from top of die bottom of component

2.6 (2.8)

1.6 (1.9)

technical drawings

according to DIN

specifications

Mounting Pad Layout

1.2

4

area covered with

solder resist

4

www.vishay.com For technical questions, contact: emittertechsupport@vishay.com

Document Number: 81373

325 Rev. 1.3, 03-Nov-09

VSMS3700

Infrared Emitting Diode, 950 nm,

SOLDER PROFILE

300

255 °C

250

240 °C

217 °C

200

150

100

Temperature (°C)

50

0

0 50 100 150 200 250 300

19841

max. 120 s

max. ramp up 3 °C/s

Time (s)

max. ramp down 6 °C/s

Fig. 11 - Lead (Pb)-free Reflow Solder Profile acc. J-STD-020

DRYPACK

Devices are packed in moisture barrier bags (MBB) to

prevent the products from moisture absorption during

transportation and storage. Each bag contains a desiccant.

FLOOR LIFE

Floor life (time between soldering and removing from MBB)

must not exceed the time indicated on MBB label:

Floor life: 168 h

Conditions: T

Moisture sensitivity level 3, acc. to J-STD-020.

< 30 °C, RH < 60 %

amb

max. 260 °C

245 °C

max. 30 s

max. 100 s

Vishay Semiconductors

GaAs

3.5

3.1

5.75

5.25

8.3

3.6

7.7

3.4

1.85

1.6

1.4

4.1

3.9

2.05

1.95

4.1

3.9

Fig. 13 - Tape Dimensions in mm for PLCC-2

MISSING DEVICES

A maximum of 0.5 % of the total number of components per

reel may be missing, exclusively missing components at the

beginning and at the end of the reel. A maximum of three

consecutive components may be missing, provided this gap

is followed by six consecutive components.

De-reeling direction

1.65

2.2

2.0

0.25

94 8668

94 8158

4.0

3.6

DRYING

In case of moisture absorption devices should be baked

before soldering. Conditions see J-STD-020 or label.

Devices taped on reel dry using recommended conditions

192 h at 40 °C (+ 5 °C), RH < 5 %.

TAPE AND REEL

PLCC-2 components are packed in antistatic blister tape

(DIN IEC (CO) 564) for automatic component insertion.

Cavities of blister tape are covered with adhesive tape.

Adhesive tape

Blister tape

Component cavity

Fig. 12 - Blister Tape

Document Number: 81373 For technical questions, contact: emittertechsupport@vishay.com

Rev. 1.3, 03-Nov-09 326

94 8670

The tape leader is at least 160 mm and is followed by a

carrier tape leader with at least 40 empty compartments.

The tape leader may include the carrier tape as long as the

cover tape is not connected to the carrier tape. The least

component is followed by a carrier tape trailer with a least

75 empty compartments and sealed with cover tape.

> 160 mm

Tape leader

40 empty

compartments

Carrier leader Carrier trailer

min. 75 empty

compartments

Fig. 14 - Beginning and End of Reel

www.vishay.com

VSMS3700

Vishay Semiconductors

120°

4.5

3.5

2.5

1.5

Identification

Label:

Vishay

type

group

tape code

production

code

quantity

Identification

Label:

Vishay

type

group

tape code

production

code

quantity

Fig. 15 - Dimensions of Reel-GS08

180

178

321

329

4.5

3.5

120°

2.5

1.5

Infrared Emitting Diode, 950 nm,

GaAs

COVER TAPE REMOVAL FORCE

13.00

12.75

14.4 max.

13.00

12.75

14.4 max.

10.0

10.4

8.4

9.0

63.5

60.5

94 8665

62.5

60.0

18857

The removal force lies between 0.1 N and 1.0 N at a removal

speed of 5 mm/s. In order to prevent components from

popping out of the blisters, the cover tape must be pulled off

at an angle of 180° with regard to the feed direction.

Fig. 16 - Dimensions of Reel-GS18

www.vishay.com For technical questions, contact: emittertechsupport@vishay.com

Document Number: 81373

327 Rev. 1.3, 03-Nov-09

Legal Disclaimer Notice

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000 www.vishay.com

Revision: 18-Jul-08 1

Loading...

Loading...