SE-500

Elevation Unit

Operators

Guide

AB-300134

AutoCam

Vinten

AutoCam™

SE-500

Servo Elevation Unit

Installation

and

Operating Instructions

Publication Part No. AB-300134

Issue 1

Copyright¤ Vinten Broadcast Limited 2003

All rights reserved throughout the world. No part of this document may be stored in a retrieval system,

transmitted, copied or reproduced in any way including, but not limited to, photocopy, photograph,

magnetic or other record without the prior agreement and permission in writing of Vinten Broadcast

Limited.

Vinten and AutoCam are registered trademarks of Vinten Broadcast Limited.

Printed in Great Britain by DPS, Newmarket, Suffolk

Foreword

This manual provides Safety, Installation and Operating Instructions for the AutoCam SE-500 Servo

Elevation Unit.

WARNING!:Read the Safety Section on page 7 before using this elevation unit or

attempting any adjustment or repair.

It is recommended that this manual is read carefully and the illustrations studied prior to operating the

elevation unit. Attention to the details contained herein will ensure that the elevation unit will operate

efficiently with the minimum of attention over a long service life.

To order spare parts or to obtain further information, application should be made to Vinten Broadcast

Limited or to your local distributor, or visit our website at www.vinten.com.

NOTE: Information contained in this document is subject to change.

Vinten Broadcast Ltd reserves the right, without notice, to make changes in

equipment design or performance as progress in engineering, manufacturing or

technology may warrant.

3

4

Contents

Page

Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety - Read This First! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warning symbols in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Critical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Technical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Manual outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 1 - Introduction and Description

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Base assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Telescopic column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2 - Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tools you will need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unpacking and assembling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electrical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 3 - Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Positioning the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Powering up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Powering down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 4 - Servicing

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Routine checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5

6

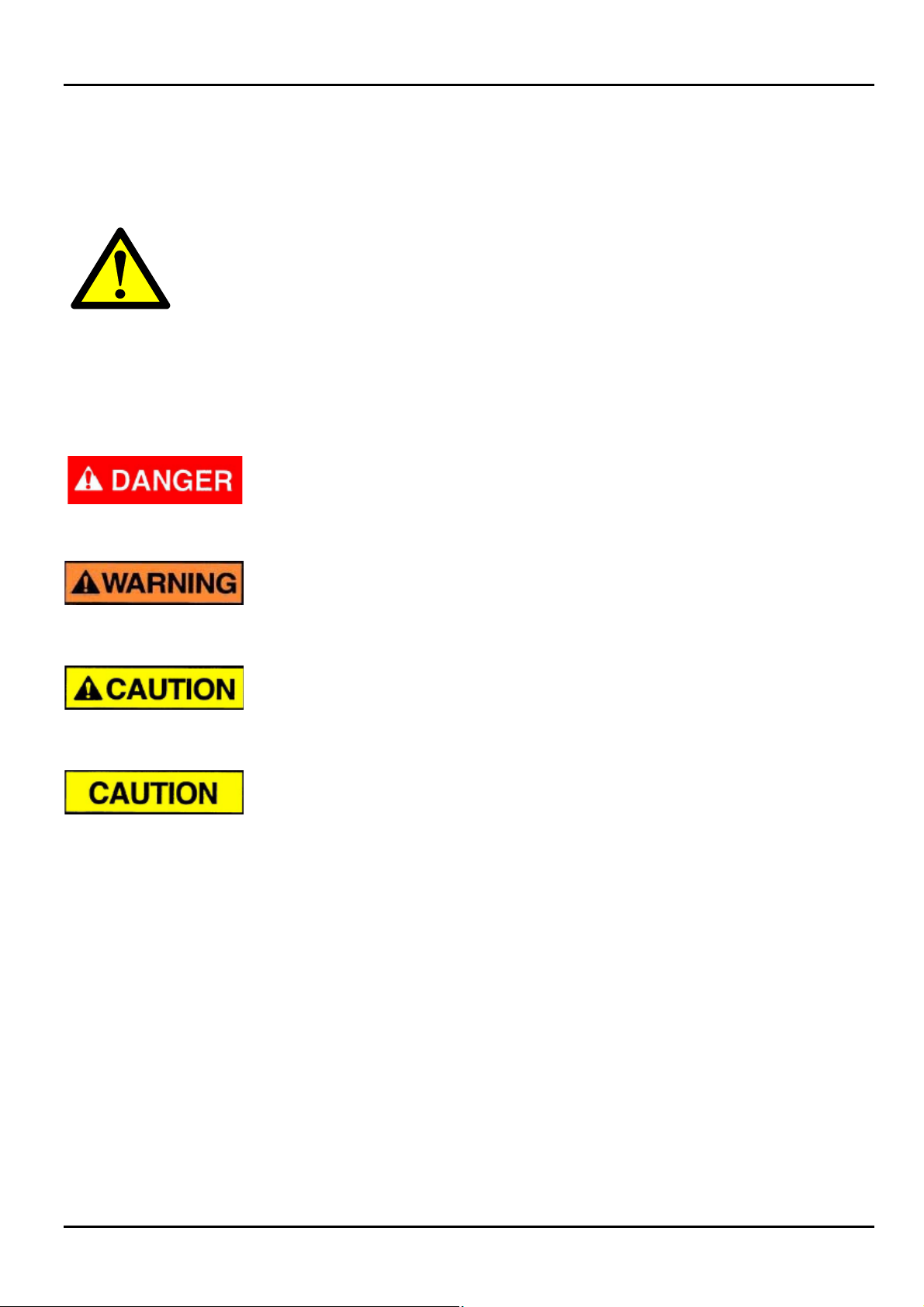

Safety - Read This First!

Warning symbols in this manual

Where there is a risk of personal injury, injury to others, or damage to the elevation unit or

associated equipment, comments appear, highlighted by the word WARNING! and

supported by the warning triangle symbol.

Warning symbols on the equipment

Various colored safety labels are attached to the AutoCam equipment to alert you to hazardous situations.

The labels and their meaning are described below.

DANGER (with a red background) indicates an

imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING (with an orange background) indicates

a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION (with a yellow background) indicates a

potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION (with a yellow background, but without

the Safety Alert symbol) indicates a potentially

hazardous situation which, if not avoided, may

result in property damage.

7

Safety issues

Safety issues including important warnings, risks and related topics are covered in this section of the

manual. It is very important that this information be available to all personnel who will work on or near the

AutoCam equipment.

Very important warnings

WARNING!:To avoid personal injury, always exercise caution when working in

the vicinity of energized pan/tilt heads and elevation units as they can start to

move without any warning.

WARNING!:Unless it is impossible, you should always de-energize the elevation

unit and head before working on any part of the elevation unit, the head, the

camera/lens, or any associated equipment.

Customer responsibility

It is the customer’s responsibility to ensure that the workplace is safe. In normal operation, the remote

controlled elevation units, heads and payloads in an AutoCam system can move suddenly and without

warning. Since audible warnings are out of the question in normal television applications, it is

recommended that only trained personnel be allowed to work in the active areas where the remote

controlled elevation units, heads and payloads are located. As part of the training, personnel must be

made aware of the hazards of working in a robot environment, including the specific hazards listed below.

The forces are sufficient to cause personal injury, or injury to others and therefore, caution is essential.

Safe working environment

WARNING!:Each of the remote controlled elevation units should be within the

view of the operator of the AutoCam system at the controller. Before and during

remote operation, the controller operator must verify visually that the active

area is clear. If personnel are too close to one of the elevation units that is about

to move, the operator can prevent the motion from starting, or stop the motion

after it has started.

If the direct line of sight is obstructed in your installation, it is recommended

that one or more viewing cameras are installed to cover the active areas and

allow the operator to view the entire workspace at all times.

8

Safe operating zone and elevation unit footprint

WARNING!:The safe operating zone for personnel is a minimum of 3 feet (1m)

outside of the elevation unit footprint. This allows time for the personnel to

avoid a elevation unit that starts to move at its maximum speed of approximately 1 foot per second (0.3m per second).

The elevation unit footprint is typically larger than the elevation unit base itself.

In most installations, the teleprompter is the piece of equipment mounted on the

head that protrudes the furthest beyond the base of the elevation unit. Or, it may

be the manual control bars on the rear that protrude the furthest. The footprint

must take into account the overhang of the teleprompter and/or manual control

bars as the head pans around.

If your operating practices require personnel to work less than 3 feet (1m) outside the elevation unit footprint, you must make sure that they are trained and

are aware of the hazards of working in a robot environment, including the specific hazards listed below. The forces are sufficient to cause personal injury, or

injury to others and therefore, caution is essential.

Warning signs

Warning signs should be displayed prominently in the workplace as a reminder to trained personnel, and

a primary warning to untrained personnel and visitors.

A typical sign might read:

WARNING:

Robotic Pedestals, Heads &

Cameras

Move Suddenly

Without Warning

9

Elevation units and heads can start unexpectedly

WARNING!:The hazards associated with robotic camera systems are only

slightly different than those associated with operating a camera under conventional manual control. The speeds and camera weights are similar. The main difference is that with automation, the operator is normally not near the cameras,

and it is more difficult to verify that the area is clear. For personnel working on

or near the elevation units, they must be aware that the equipment can start

moving unexpectedly. All personnel should be trained and aware of the hazards

of robotic elevation units and heads, and the fact that they can move at any

time. They must be trained on how far the elevation units, heads and payloads

can move, the speeds involved, and the need to stay back an appropriate distance. Most adjustments to the camera and head, such as balancing and camera calibration, should be made with the system de-energized. However, if

adjustments are absolutely necessary while the elevation unit and/or head is

powered, they should only be made by trained technical personnel familiar with

the AutoCam robotics system. They must understand that the elevation unit or

head can move unexpectedly at any time, and they must position themselves so

that any motion would not cause them personal harm. When the robotic heads

move, the speeds involved are fairly slow. However, the equipment is still capable of generating sufficient force to cause injury. Therefore, it essential that you

exercise caution. In particular, be aware that the teleprompter is usually the fastest swinging element. Any failure of the system could possibly cause one or

more axes to move on their own, but the speeds and forces should not be

noticeably greater than those encountered during normal use.

Pinch points

WARNING!:Particular care should be exercised around possible points where

you could get pinched, such as the tilt cradle. Here, the forces can be somewhat

greater, due to the short lever arm.

Sharp edges

WARNING!:If the lens, teleprompter or other camera attachments have sharp

edges that could cause injury, make sure they are padded or protected.

10

Critical data

Mass

Servo elevation unit 32.6 kg (71.7 lb)

Load

Maximum payload 45.5 kg (100 lb)

Power Supply

Power supply 27 Vdc, 50 Watts

11

Technical specification

Weight 32.6 kg (71.7 lb)

Minimum height (to mounting face) 89.3 cm (35.1 in.)

Maximum height (to mounting face) 128.3 cm (50.5 in.)

Stroke 39 cm (15.4 in.)

Transit doorway width 68 cm (26.8 in.)

Maximum Payload 45.5 kg (100 lb)

Maximum Velocity 24.4 mm/s (1 in./sec)

Power Supply 27 Vdc, 50 Watts

12

Technical support

If you are based in North, South or Central America and need technical support on the AutoCam system,

contact Vinten Inc. at:

709 Executive Blvd.

Valley Cottage, NY 10989

USA

Phone:1-888 4 VINTEN (1-888-484-6836) - Toll free in the U.S.A.

+1 845-268-0100

Fax:+1 845-268-0113

Or, if you are based outside of North, South or Central America, contact Vinten Broadcast Limited at:

Western Way

Bury St. Edmunds

Suffolk IP33 3TB

ENGLAND

Phone: +44 (0) 1284 752121

Fax: +44 (0) 1284 750560

13

Manual outline

Safety - Read

This First!

Chapter 1 - describes the SE-500 elevation unit

Chapter 2 - contains step-by-step instructions for

Chapter 3 - contains step-by-step operating instructions

Chapter 4 - details servicing, including cleaning, routine

covers important safety issues

assembling the elevation unit and fitting the

pan & tilt head

checks and adjustments

14

Chapter 1 - Introduction and Description

15

(7)

(6)

(1)

(2)

(3)

16

(4)

(5)

Fig 1.1 SE-500 servo elevation unit (with HS-105P pan and tilt head)

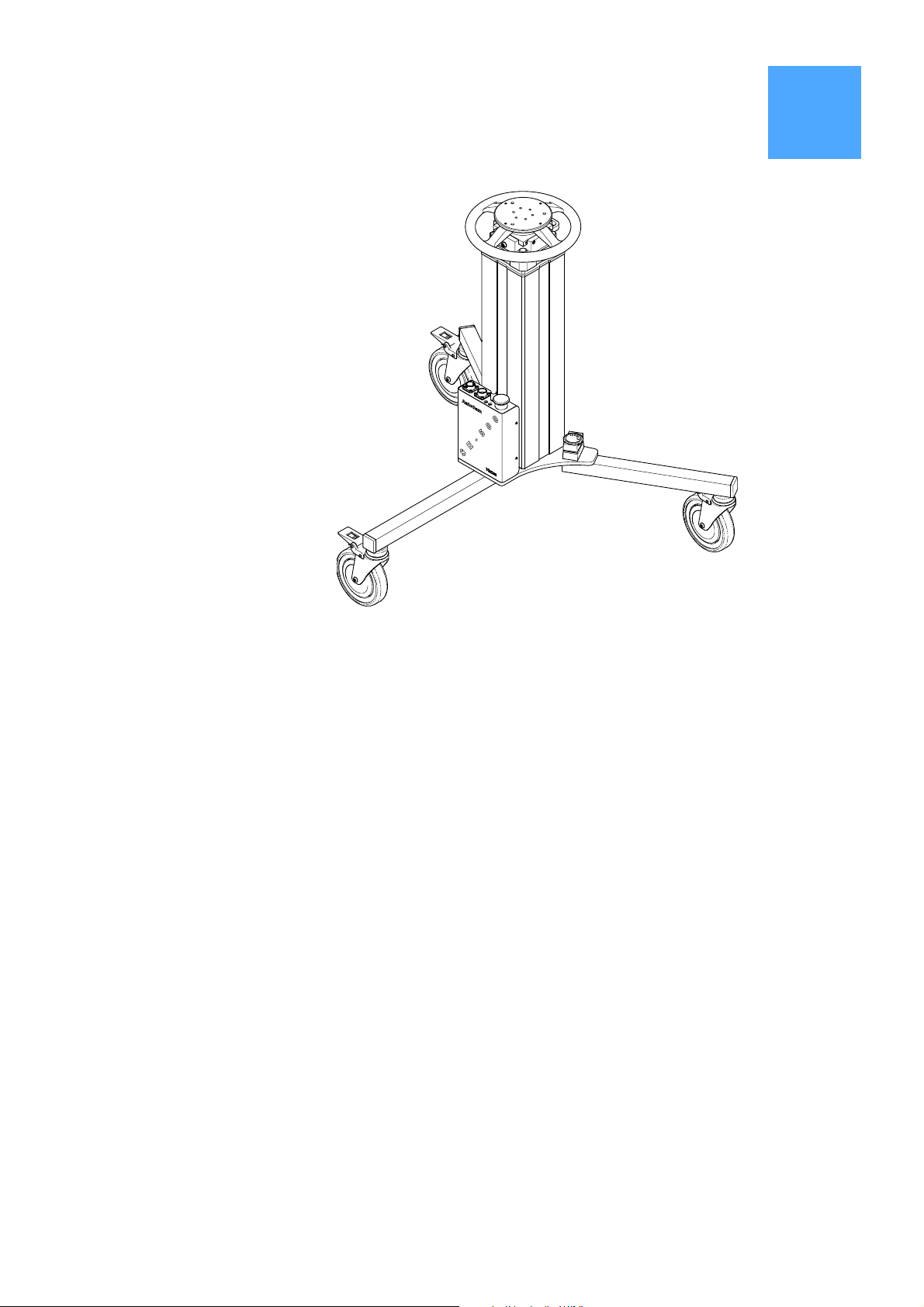

Introduction

The SE-500 servo elevation unit (Fig 1.1) is a fixed pedestal with an electrically-operated telescopic

column designed to support a payload of up to 45.5 kg (100 lb). The camera height may be adjusted

through a 39 cm (15.5 in.) range.

Designed for use with the AutoCam HS-102P or HS-105P pan and tilt heads and the Series 200 control

system, the SE-500 allows stored height positions to be recalled with pan, tilt, zoom and focus as

required.

Description

The elevation unit consists of three main assemblies: a base assembly, an electrically-operated telescopic

column and a control box.

Base assembly

The base is carried on three 152.4 mm (6 in.) castoring wheels (5), each fitted with a brake. A cable clamp

is provided (4).

Telescopic column

The single-stage telescopic column (3) consists of a fixed assembly, which is secured to the base, and a

concentric, square-section moving stage. A steering ring (2) and mounting plate (7) are located on the top

of the moving stage.

Control box

The control box (6), on which is mounted a STOP switch, two LEDs and three connectors (Fig 2.4), is

secured to the base, adjacent to the telescopic column.

Power supply

All of the power for the elevation unit and pan and tilt head is derived from a rack-mounted power supply.

If an HS-102P pan and tilt head is installed on the elevation unit, then a PS27-5R power supply is used. In

the case of an HS-105P, a PSD27-5R power supply is used.

The serial data to control the elevation unit and head is carried through the same cable.

17

18

Chapter 2 - Installation

19

Introduction

This chapter focuses on the mechanical aspects of unpacking and assembling the servo elevation unit and

mounting a pan and tilt head.

WARNING!:TO PREVENT PERSONAL INJURY, AND FOR PROPER PERFORMANCE OF THE EQUIPMENT IT IS ESSENTIAL THAT THE PROCEDURES IN THIS

MANUAL ARE FOLLOWED EXACTLY.

Tools you will need

You will need the following tools to assemble the servo elevation unit and mount the pan and tilt head

1. A set of hex wrenches (metric and US sizes)

(6.1)

(6.2)

(6.3)

(3)

(6)

(3.1)

20

Fig 2.1 Assembling the elevation unit

Unpacking and assembling

(1)

If not already done, unpack and assemble the servo elevation unit as follows (Fig 2.1):

1. Open the box containing the servo elevation unit. Remove and set aside any accessory items and

packing material. Locate the base assembly, the telescopic column and the control box

2. Secure the telescopic column (3) to the base with four M10 screws (3.1). Ensure the telescopic

column is oriented with the connector nearest the control box position.

3. Remove four M3 screws (6.1) securing the control box cover (6.2). Secure the control box (6) to

the base with four M4 screws (6.3). Ensure the control box is oriented with the STOP button to the

right. Refit the control box cover and secure with four M3 screws.

4. Set the assembled servo elevation unit upright and apply the wheel brakes.

(2)

(3.6)

(3.5)

(3.4) (3.3)

(3.2)

(2.1)

(2.2)

(2.3)

Fig 2.2 Installing the pan and tilt head

21

Install the pan and tilt head as follows (Fig 2.2):

NOTE: To install the pan and tilt head, it is necessary to dismantle the upper part of the

telescopic column

1. Remove four screws (3.3) securing the square plate (3.5) and assembled steering ring/adaptor

plate to the telescopic column.

2. Remove four screws (3.4) securing the assembled steering ring/adaptor plate to the square plate

(3.5).

3. Remove four screws (2.3), washers (2.2) and rubber washers (2.1) securing the steering ring (2)

to the adaptor plate (3.2).

4. Secure the adaptor plate to the base of the pan and tilt head using the appropriate screws (3.6):

4.1 HS102P - six off10/32 in. UNC.

4.2 HS105P - three off 1/4 in. UNC.

5. Secure the steering ring (2) to the adaptor plate (3.2) with four screws (2.3), washers (2.2) and

rubber washers (2.1).

6. Secure the assembled steering ring/adaptor plate to the square plate (3.5) with four screws (3.4).

7. Position the assembled pan and tilt head, adaptors and steering ring on the telescopic column

and secure with four screws (3.3).

Electrical installation

A typical SE-500 system configuration is shown in Fig 2.3. Installation of the controller and other

equipment is described in the User manuals for those products.

Electrical connections are made via the three connectors on the control box.

1. Locate the cables supplied with your equipment (See table below).

2. Connect the POWER/DATA connector on the head to the PWR/DATA OUT connector on the

control box (Fig 2.4) using cable SP-CAB-8.

3. Run the power/data cable (SP-CAB-xx) from the power supply through the cable clamp on the

base to provide strain relief. Loop the cable to the PWR/DATA IN connector on the control box.

Run the power/data cable alongside the camera triax (or multicore) cable and any other cables

that connect to the camera system in the installation.

NOTE: The cable clamp may be repositioned on either side of the telescopic column.

22

1. Connect the ELEVATION connector on the control box to the connector at the top of the

telescopic column using cable AM056-9001.

2. Tighten the cable clamp

Fig 2.3 A typical SE-500 installation

Connect From Cable Type Connect To

Control system/power supply SP-CAB-xx(M) PWR/DATA IN on control box

PWR/DATA OUT on control

box

ELEVATION on control box AM056-9001 Connector on telescopic column

NOTE: In the figure and table above, ‘xx’ denotes the cable length in feet, ‘xx(M)’ the length in metres.

SP-CAB-8 PWR/DATA on pan and tilt head

23

PWR/DATA IN

CONNECTOR

PWR/DATA OUT

CONNECTOR

PWR/DATA OUT

CONNECTOR

EMERGENCY STOP

SWITCH

PWR PRESENT

LED

DATA PRESENT

LED

Fig 2.4 Electrical connections

Install the rest of the equipment in your system as described in the relevant User Manual(s).

Power up the elements of your system as described in the relevant User Manual(s).

24

Chapter 3 - Operation

25

Introduction

This chapter covers operation of the servo elevation unit and is limited to the switches, controls and other

features on the unit itself. Operating procedures for controlling the servo elevation unit and pan and tilt head

remotely are described in the User Manual for the specific controller in the installation.

Positioning the unit

Position the servo elevation unit as required and apply all three wheel brakes.

1. To apply the brake, push down on the lever (5.2) situated above the wheel

2. To release, press down on the centre ‘pop-up’ lever (5.1), which is raised when the brake is on.

(5.1)

(5.2)

26

Fig 3.1 Wheel brakes

Powering up

Before powering up the servo elevation unit, make sure that the area around the unit is clear.

WARNING!:At power up, the column and payload will drop to minimum height.

Ensure that no-one will be hit by the payload.

1. Ensure the emergency STOP switch (Fig 2.4) on the control box is pressed.

2. Turn on the power supply.

3. Twist the emergency STOP switch clockwise to release it. The green PWR LED on the control box

will illuminate, the elevation unit will drive to its lowest position and the pan and tilt head will

initialise. The yellow DATA LED will only illuminate if the control system is operative and the

elevation unit and the pan and tilt head will then drive to their previous position.

Powering down

Always power down the head before the elevation unit.

1. Press the STOP switch.

2. Switch off and/or disconnect the SE-500 power supply if required.

27

28

Chapter 4 - Servicing

29

General

The SE-500 elevation unit is robustly made to high engineering standards and little attention is required to

maintain serviceability save regular cleaning. Attention to the following points will ensure a long and useful

service life with minimum need for repair.

Cleaning

During normal studio use, the only cleaning required should be a regular wipe over with a lint-free cloth.

Dirt accumulated during storage or periods of disuse may be removed with a semi-stiff brush. Particular

attention should be paid to the sliding faces on the telescopic column..

NOTE: Do NOT use oil or grease on any exposed part of the column. This is unnecessary and

traps dirt which acts as an abrasive.

Use only detergent-based cleaners. Do NOT use solvent- or oil-based cleaners,

abrasives or wire brushes to remove accumulations of dirt, as these damage the

protective surfaces.

Routine checks

During normal use, check all electrical cable for fouling and wear.

Repair

In the unlikely event of mechanical or electrical problems in the SE-500 servo elevation unit, it is generally

recommended that the unit be returned to the factory if possible. However, if this is not possible, the

SE-500 Service Manual should be utilized to repair the unit in the field.

WARNING!:Repairs should only be performed by qualified personnel, who are

familiar with the equipment.

30

Index

Entries in italics refer to Figures

PagePage

A

Assembling 21

Assembling the elevation unit 20

B

Base assembly 17

C

Cleaning 30

Control box 17

Critical data 11

D

I

Installation 19

assembling 21

electrical 22

tools 20

unpacking 21

Introduction 17

Introduction and Description 15

O

Operation 25

positioning the unit 26

powering down 27

Description 17

base assembly 17

control box 17

power supply 17

telescopic column 17

E

Electrical connections 24

Electrical installation 22

Elevation unit footprint 9

powering up 27

Pinch points 10

Positioning the unit 26

Power supply 17

Powering down 27

Powering up 27

R

Repair 30

Routine checks 30

31

Index (Cont)

Entries in italics refer to Figures

PagePage

S

Safe operating zone 9

Safety

customer responsibility 8

pinch points 10

read this first 7

safe operating zone and

elevation unit footprint 9

safe working environment 8

safety issues 8

sharp edges 10

very important warnings 8

warning signs 9

warning symbols in this manual 7

T

Technical specification 12

Technical support 13

Telescopic column 17

Tools 20

Typical SE-500 installation 23

U

Unpacking 21

V

Warning signs 9

Warning symbols in this manual 7

Warning symbols on the equipment 7

warning symbols on the

equipment 7

Safety issues 8

SE-500 servo elevation unit 16

Servicing 29

cleaning 30

repair 30

routine checks 30

Sharp edges 10

Wheel brakes 26

32

Loading...

Loading...