End-User Configuration Guide

ICE Tool

Intelligent Control Engineering

Version 2.3.2.281

Installation

EN

Part No. V4096-8001

www.vintenradamec.com

Copyright © 2012

All rights reserved.

Original Instructions: English

All rights reserved throughout the world. No part of this document may be stored in a retrieval system,

transmitted, copied or reproduced in any way, including, but not limited to, photocopy, photograph,

magnetic or other record without the prior agreement and permission in writing of the Vitec Group plc.

Disclaimer

The information contained in this manual is believed to be correct at the time of printing. Vitec Videocom

Ltd reserves the right to make changes to the information or specifications without obligation to notify any

person of such revision or changes. Changes will be incorporated in new versions of the publication.

We are making every effort to ensure that our manuals are updated on a regular basis to reflect changes

to product specifications and features. Should this manual not contain information on the core functionality

of your product, please let us know. You may be able to access the latest revision of this manual from our

website.

Vitec Videocom Ltd reserves the right to make changes to product design and functionality without

notification.

Trademarks

All product trademarks and registered trademarks are the property of The Vitec Group Plc.

All other trademarks and registered trademarks are the property of their respective companies.

Published by:

Vitec Videocom Ltd

Supports Technical Publications Department

Western Way, Bury St Edmunds

Suffolk IP33 3TB

United Kingdom

Email: technical.publications@vitecgroup.com

Safety and About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installing ICE Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PC Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using ICE Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Starting ICE Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adding Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Opening Devices and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Renaming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Rebooting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

About ICE Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Head Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Identifying Individual Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Head Axis Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

GP I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

VR Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Copying Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exporting Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Contents

1

Safety and About this Manual

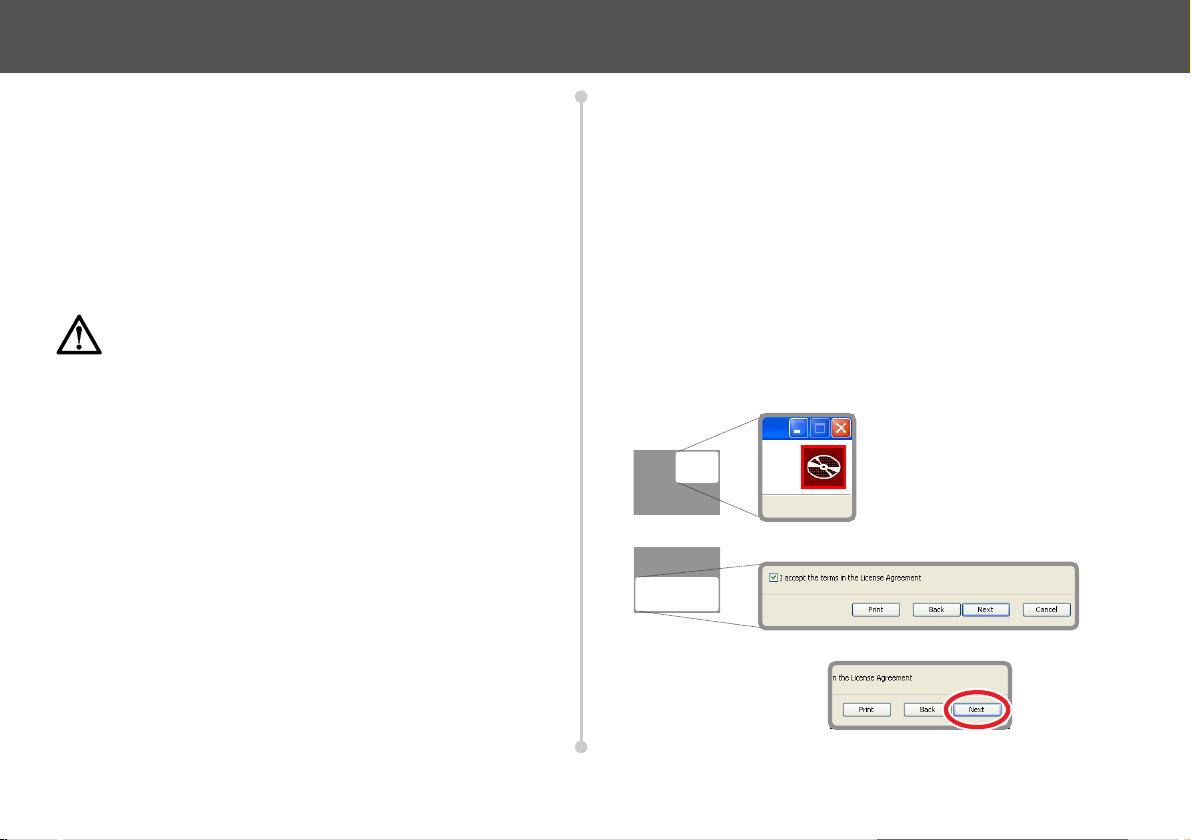

Bottom half of the window

Top right hand quarter

of the window

Important information on the safe installation and operation of this

product. Read this information before operating the product. For

your personal safety, read these instructions. Do not operate the

product if you do not understand how to use it safely. Save these

instructions for future reference.

Warning Symbols Used in these Instructions

Safety cautions are included in these instructions. These safety

instructions must be followed to avoid possible personal injury and

avoid possible damage to the product.

WARNING!

Where there is a risk of personal injury or injury to others,

comments appear supported by the warning triangle symbol.

Where there is a risk of damage to the product, associated

equipment, process or surroundings, comments appear

supported by the word ‘Caution’.

Intended Use

The ICE Tool software is designed to be installed on a desktop or laptop

computer and then connect to ICE compatible robotic support

equipment via an Ethernet interface. The primary function of the ICE

Tool software is to assist in the configuration of an ICE robotic system.

Safety when Working with Robotic Equipment

In normal operation remote-controlled equipment can move suddenly

and without warning. Since audible warnings are not suitable for use

within the studio environment, it is recommended that only trained

personnel be allowed to work in the active areas where remotecontrolled heads and pedestals are located. The safe operating zone is

a minimum of 1 m (3 ft). Do not operate robotic equipment if you cannot

see it.

2

About this Manual

The ICE Tool has been designed as a configuration software

application compatible with the range of Vinten Radamec ICE robotic

devices. The ICE Tool is available for installation from the USB stick

supplied with any ICE product.

This manual covers the installation of the ICE Tool onto a desktop,

laptop or controller PC, how to operate it and the configuration

functions available to the user.

Using this Manual

This manual uses zoomed screenshots to display the relevant area of

the screen or window. The user is guided to the relevant area by a

series of navigation icons which indicate the portion of the screen being

zoomed. Two examples are shown below:

A specific feature is further

highlighted using a red

outline ring.

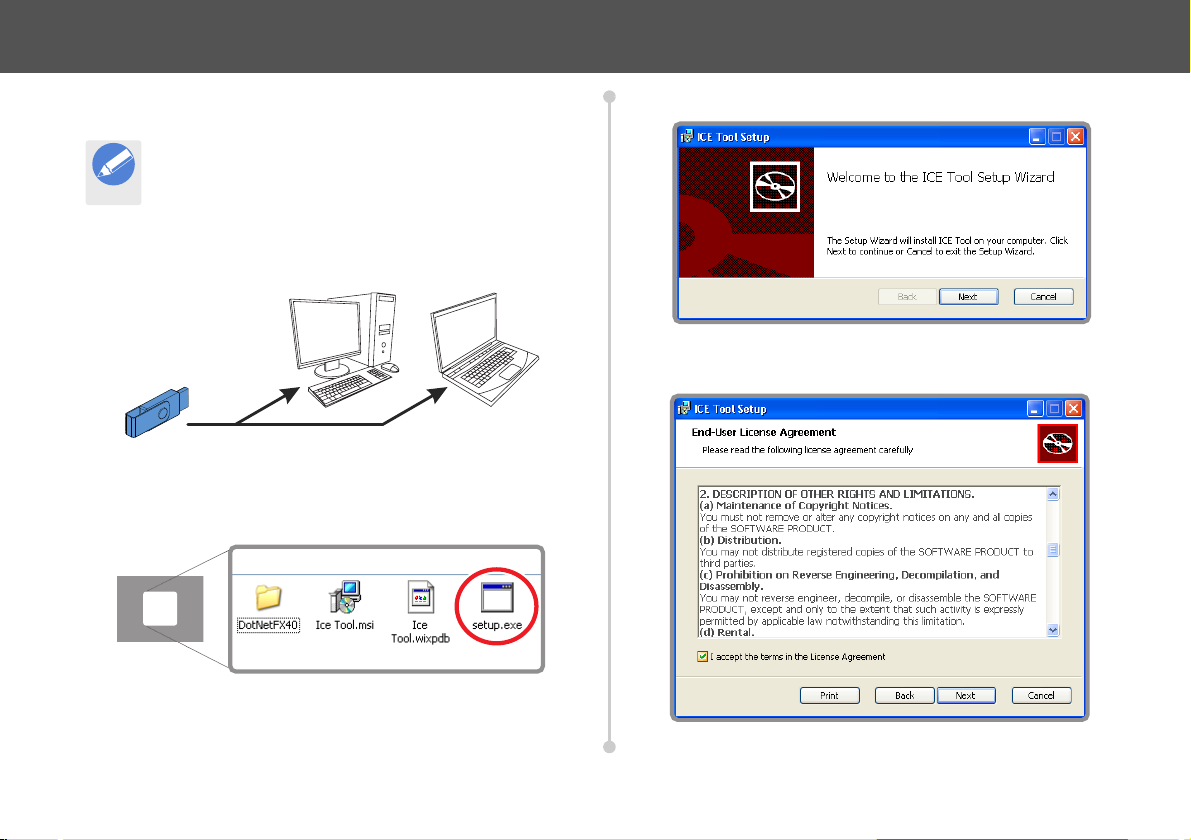

Installing ICE Tool

Note

ICE Tool can be installed onto a computer running Windows® XP or

Windows® 7.

If an older version of ICE Tool is present on the PC, it must

be uninstalled using Add/Remove Programs in the control

panel.

1. Insert the Vinten Radamec USB stick drive into a spare USB port

on the desktop or laptop PC.

2. Open Windows Explorer and view the contents of the USB stick

drive. Locate and open the ICE Tool folder. Double-click on the file

Setup.exe to start the installation.

3. The ICE Tool Setup window opens. Click Next to continue.

4. Select the check box to agree to accept the terms of the license

agreement. Click Next.

3

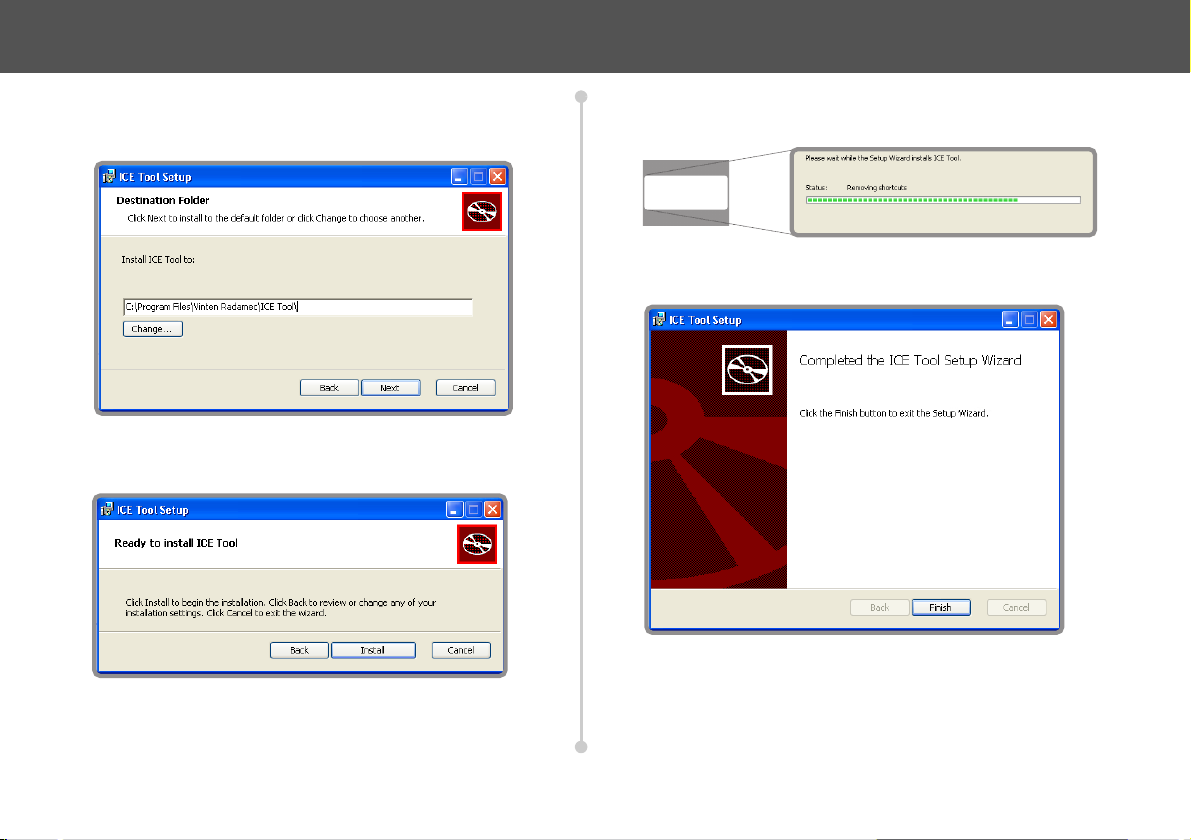

Installing ICE Tool

5. Select a location for ICE Tool to install to (the default location of

Program Files\Vinten Radamec\ICE Tool\ is recommended).

Click Next.

6. Click Install to proceed with the installation. Click Back to review

or change any of the installation settings.

7. Installation is automatically performed by the ICE Tool Setup

Wizard and displayed with a progress indicator.

8. When installation is complete, click Finish to exit the ICE Tool

Setup window.

4

PC Ethernet Connections

OR

Note

OR

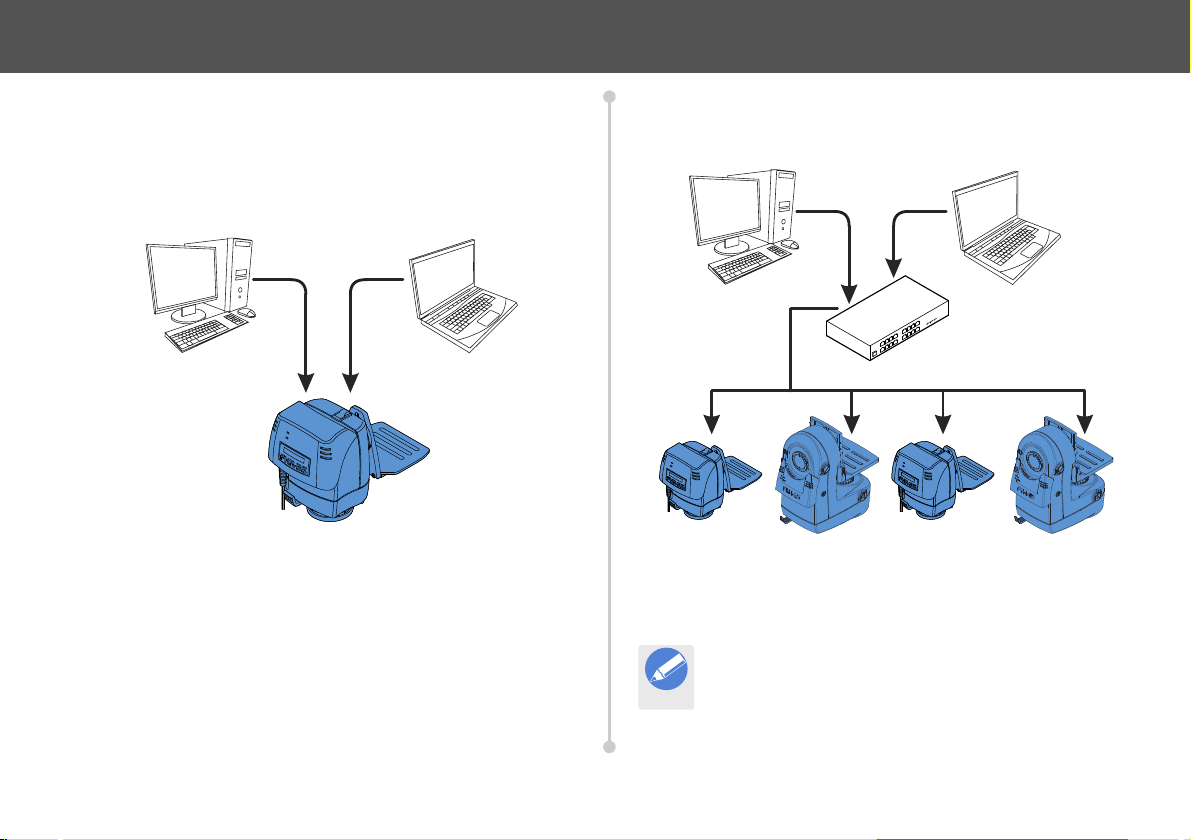

The computer installed with ICE Tool is connected to ICE robotic

devices using an Ethernet connection. This can be in two different

configurations:

Directly to one device - Direct Ethernet connection between

1

the PC and one ICE robotic device.

.

This is useful to configure a new device such as a robotic head in

isolation from a control system.

Across a robotic system to many devices - Ethernet

2

connection between the PC and a control system via a router

or network.

This gives access to all of the ICE devices within a system, but still

gives the flexibility to configure individual devices. Each ICE device in

a system is assigned a unique IP address.

ICE Tool can be installed onto a VRC or LCS controller

computer and used to connect to any ICE device in the

system.

5

Ethernet Configuration

Note

Note

The Ethernet settings on the computer must be configured to

successfully connect to an ICE device.

If ICE Tool has been installed on a VRC or LCS controller

computer, the Ethernet settings do not require further

configuration.

In a standard robotic system setup, the IP addresses assigned to

devices are in the range 198.9.200.X. The computer IP address must

be changed to this range for successful connection.

In a non-standard installation where a different range of IP addresses

has been used, the computer IP address must be changed to match

this configuration.

If the ICE device is using DHCP it is not necessary to

change the computer address to connect successfully.

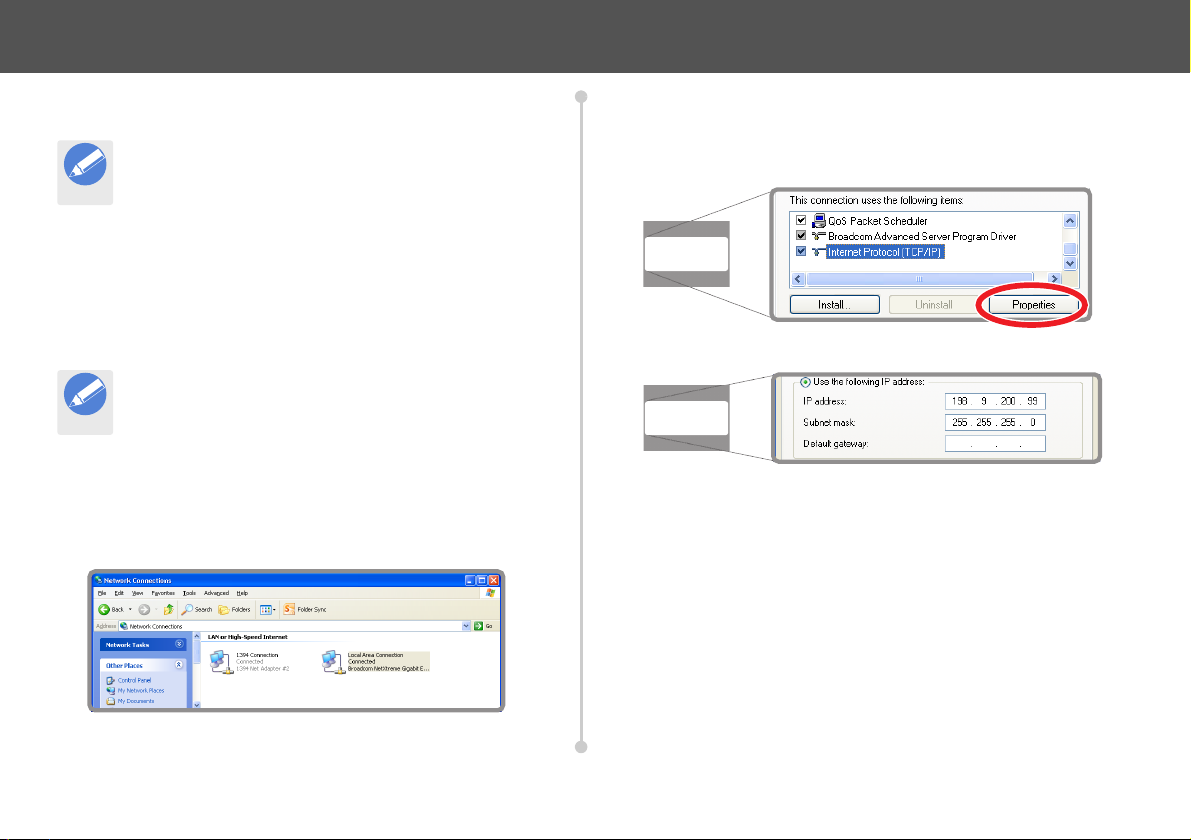

Changing the IP address Using Windows XP

1. From the Windows Start menu navigate to Control Panel >

Network Connections to open the Network Connections

window.

2. Right-click on the Local Area Connection icon and select

Properties from the menu.

3. Scroll down and select Internet Protocol (TCP/IP) and click the

Properties button.

4. The Internet Protocol (TCP/IP) Properties window opens.

a) Make a note of any current configuration settings in this

window so that they can be restored when required.

b) Click to select the Use the following IP address option.

c) Enter 198.9.200.99 (or an address appropriate for the device

or system) into the IP address field.

d) Press the Tab key to automatically populate the Subnet mask

field.

5. Click Ok to save the changes and exit the window.

6. Click Close to exit the Local Area Connection Properties

window.

6

Ethernet Configuration

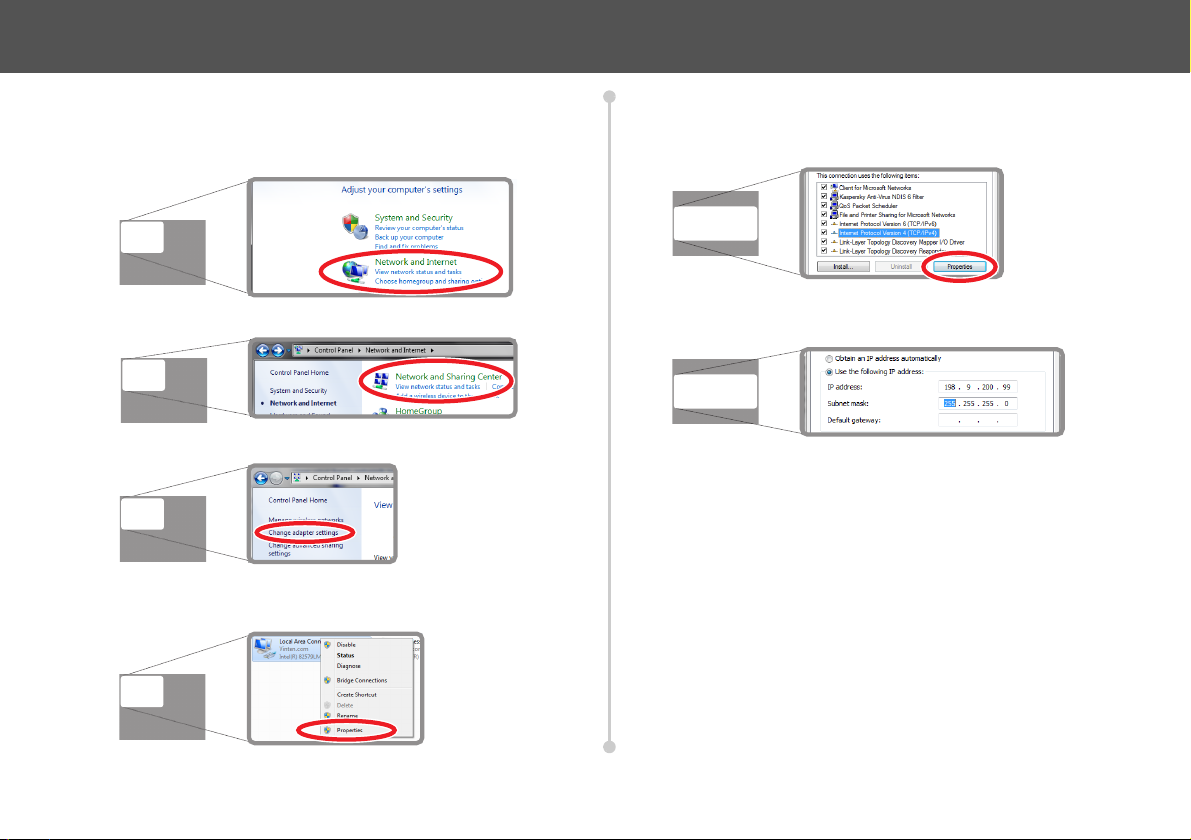

Changing the IP address Using Windows 7

1. From the Windows Start menu click to select Control Panel.

2. Click to select Network and Internet.

3. Click to select Network and Sharing Center.

4. Click on Change adaptor settings.

5. Right-click on the active local area connection and select

Properties from the menu.

6. The Local Area Connection Properties window opens. Click to

select Internet Protocol Version 4 (TCP/IPv4).

7. Click the Properties button.

8. The Internet Protocol Version 4 (TCP/IPv4) Properties window

opens.

a) Make a note of any current configuration settings displayed,

so that they can be restored when required.

b) Click to select the Use the following IP address option.

c) Enter 198.9.200.99 (or an address appropriate for the device

or system) into the IP address field.

d) Press the Tab key to automatically populate the Subnet mask

field.

9. Click Ok to save the changes and exit the window.

10. Click Ok again to exit the Local Area Connection Properties

window.

7

Using ICE Tool

Note

Starting ICE Tool

When ICE Tool has been successfully installed and an Ethernet

connection has been established:

1. From the Windows Start menu navigate to All Programs >

Vinten Radamec > Ice Tool or double-click on the ICE Tool icon

on the desktop to launch the software application.

2. The ICE Tool Login

window opens. Ensure

the default Customer

Mode is selected from

the drop-down menu

and click Continue.

Adding Devices

When ICE Tool has successfully loaded following login, the main ICE

Too l window opens. The left hand field displays a tree structure for

navigating to available ICE devices.

1. Expand the Available Hosts tree structure. Expand the product

folder(s) containing the ICE devices.

2. Right-click on the host ID of a device and select Add Host(s). This

adds the device onto the System tree for connection with ICE

Tool.

Robotic devices can also be added by selecting System >

Add Host from the top menu bar. Select the required

device(s) and click Ok. If required, all available devices can

be added to the System tree for connection with ICE Tool.

The ICE device(s) added can now be configured using ICE Tool.

8

General Device Configuration

Note

Removing Devices

If an ICE device is no longer required to be connected to ICE Tool, or it

has been added in error:

1. Right-click on the host ID of the ICE device, then select Delete.

2. When the confirmation window appears, click Yes to delete the

ICE device from the system.

The delete function is also available on the product folder to

remove all ICE devices of the same type from the System

tree simultaneously.

Opening Devices and Components

To open an ICE device for configuration:

1. Expand the System tree structure and then the required product

folder (example shown is FHR35)

2. Expand the host ID structure of the required ICE device (example

shown is 620-5B4). The individual components of the device are

displayed.

3. The active components of the ICE device are represented by

green icons . Right-click on the required component and select

Open to enter the specific component configuration window.

9

General Device Configuration

Note

Note

Ethernet Configuration

The Ethernet settings of an ICE device are accessed and configured

using ICE Tool.

1. Open the required ICE device for configuration.

2. Right-click on the Hcm component of the device and select Open.

3. The Hcm window opens.The Network Configuration field

displays the current Ethernet settings.

In the example shown Use DHCP is selected. This allows

the device to assign its own IP address on a DHCP network.

4. To change the Ethernet configuration to a specific IP address:

a) If enabled, deselect Use DHCP in the Static Configuration

area.

b) Enter the required IP address and subnet mask in the

appropriate fields (example shown is for a standard VRC

control system setup).

c) Click Apply to save the new configuration.

Use the Default button to return the Ethernet configuration

to the factory settings.

10

General Device Configuration

Note

Renaming Devices

Every ICE device has a unique host ID number. However, ICE Tool can

be used to assign a user friendly name to a device to make

identification easier in a multi-device system.

1. In the Hcm configuration window click Set Name.

2. Enter a new name in the field when prompted (example shown is

Head 1).

3. Click Ok. The new host name will take effect and is displayed at

the top of the host ID structure.

Rebooting Devices

Single or multiple devices can be rebooted using ICE Tool. This

function could be used after software upgrades, or if a device or system

has become unresponsive.

1. Select the required device(s) for reboot as shown below:

Right-Click on: Select: Action

The host ID of a

single device.

The product

folder.

The System

icon.

Reboot. Only the selected device will

Reboot All. All devices of the same product

Reboot All

Hosts.

reboot.

type will be rebooted.

All devices connected to the

current session of ICE Tool will

be rebooted.

2. The selected device(s) will reboot but remain added to ICE Tool.

About ICE Tool

Information can be obtained about the current ICE Tool installation by

selecting Help > About from the top menu bar. The current version of

the software is displayed, together with the current device components

supported.

The host can also be renamed by right-clicking on the host

ID number and selecting Set Name.

11

Head Configuration

ICE Tool is used to configure settings and parameters on an ICE robotic

pan and tilt head such as the FHR-35 or FH/FHR-145.

Identifying Individual Heads

In a multi-head system, the identity of individual heads may be unclear

or difficult to establish. ICE Tool provides a function to assist with head

identification.

1. Right-click on the host ID number of a head in the System tree

and select Toggle Identify.

2. The corner LED

indicators on the

selected head flash to

identify its connection

with ICE Tool.

3. Right-click and select

Toggle Identify again

to switch the LED

function off.

Head Axis Configuration

ICE Tool is used to configure an offset reference position on the pan

and tilt axes. Soft limits can also be configured to restrict the drive range

of the head and an attached servo lens.

Opening the Head Configuration Window

Expand the Host ID structure of the required head.

1.

2. Right-click on the Head component and select Open.

3. The Head window opens. All aspects of head axis configuration

can be accessed in this window.

12

Setting Reference Positions

Note

Note

The axis reference positions on the head provide a fixed point from

which other parameters such as soft limits can be configured. These

positions can be changed using ICE Tool to help adapt the head’s axes

to a specific installation. Standard reference positions are set as zero

degrees. On the tilt axis this position is set with the tilt cradle horizontal

(tilt lock can engage). However, an offset reference position can be

configured at a specific angle if required.

To set standard zero reference positions on the pan and tilt axes:

1. Manually or robotically move the head about the pan and tilt axes

to approximately the mid-range points required for the installation.

If required, only one axis can be moved and configured.

2. If the head has been moved manually, click Enable.

Head Configuration

Clicking Clr Pan or Clr Tilt will remove the new reference

values if a mistake is made.

4. Click Apply to save the new configuration. The Position

Feedback fields will display zero degrees and the offset encoder

values for the head will be displayed in the Head Offset fields.

To set a specific offset value, for example 90° on the tilt axis:

1. Enter the required value in the relevant Head Offset axis field

(example shown is +90 in tilt).

3. In the Head Offset area of the configuration window click Set Pan

and Set Tilt (or the relevant axis if just one reference position is

being set).

2. Click Apply to save the new reference position.

When an offset reference position has been set, clicking Clr

Pan or Clr Tilt will reset the axes reference position values

back to zero.

13

Head Configuration

Note

Note

Setting the Soft Limits

CAUTION! Risk of product damage. On a head with

mechanical hard limits, the soft limits must be set inside the

drive range set for the hard limits.

The procedure shown here allows the user to adjust all of

the head’s soft limits. However if required, ICE Tool can be

used to configure or change just one soft limit value.

Manually or robotically move the pan axis to the required minimum

1.

limit position.

2. If the head has been moved manually, click Enable.

3. Click Set Pan in the Min Limits area.

4. To move the head manually again, click Disable. To drive to the

next position robotically leave the head enabled

5. Manually or robotically move the pan axis to the required

maximum position and click Set Pan in the Max Limits area.

6. Repeat steps 1 and 2 to set the tilt axis minimum and maximum

limits, clicking Set Tilt in the Min Limits and Max Limits areas.

7. Click Apply to store the settings in the head. Click Default to

return all head configuration to the factory settings.

Clicking either Clr Pan or Clr Tilt in the Min Limits or Max

Limits fields will remove the relevant new soft limit value if

an error is made.

Entering Limit Values Directly

Soft limit values can also

be entered directly into

the Max Limits and Min

Limits fields. Click Apply

to store the new values.

14

Head Configuration

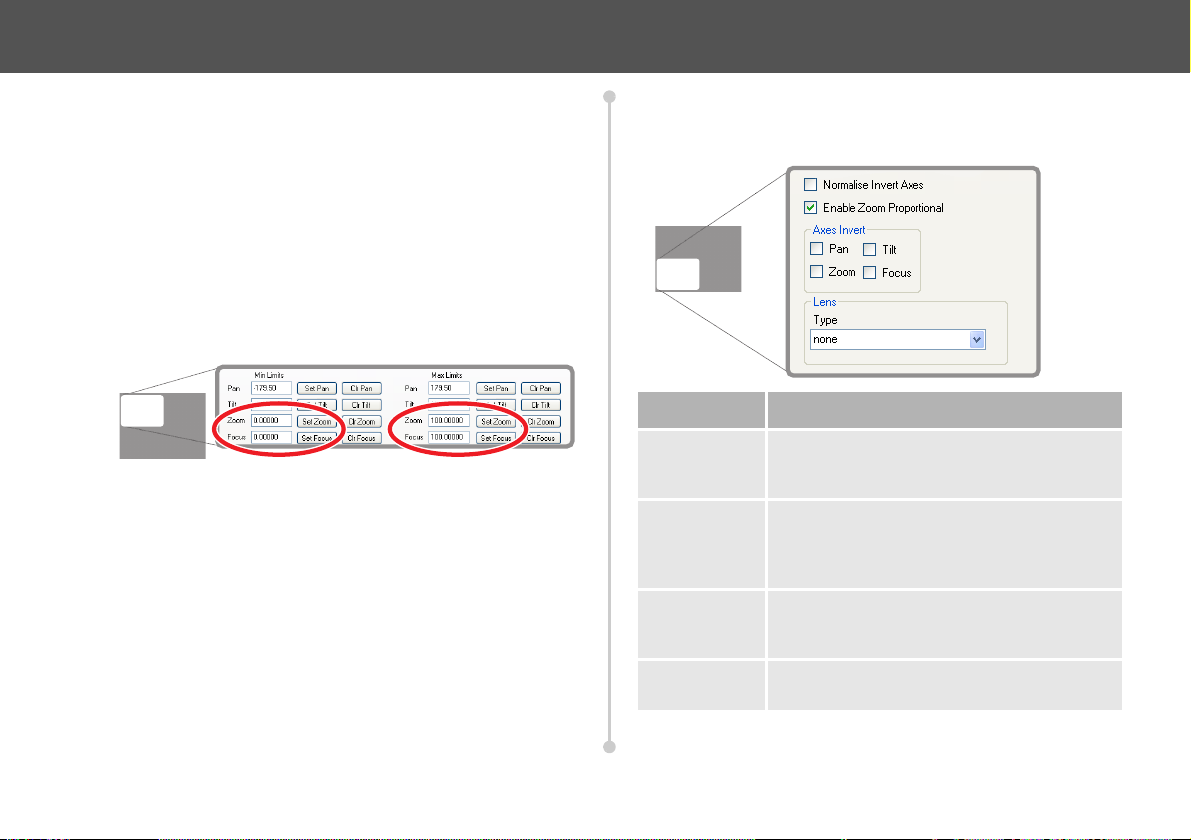

Setting the Servo Lens Soft Limits

Soft limits can also be applied to zoom and focus if a servo lens is

connected to the head. This is useful to restrict the range of the lens

drives away from the mechanical hard stops.

1. Move zoom and focus to the required minimum positions or enter

an encoder count value in the Min Limits field.

2. Click the Set Zoom and Set Focus buttons

3. Click Apply to store the new limits.

4. Repeat steps 1 to 3 to set the required maximum positions in the

Max Limits fields.

General Axis Configuration

The following settings can also be changed in the head configuration

window:

Setting Use

Normalise

Invert Axes

Enable Zoom

Proportional

Axes Invert Selecting a check box in this field reverses the

Lens Type Select the required lens type from the drop-

Select if the head is mounted upside down

from the ceiling. Pan and tilt axes are reversed

to give standard control on an inverted mount.

Select to enable the speed of pan and tilt

movement to be proportional to the zoom

angle (zoomed in slower, and zoomed out

faster).

direction of the axis when controlled using a

joystick.

down menu.

Click Apply to store and activate any configuration changes.

15

Head Configuration

Note

GP I/O Configuration

The function of the four data channels on the GP I/O socket of the head

are enabled and configured using ICE Tool. The channels can be

configured to function as inputs or outputs.

CAUTION! Risk of product damage. Ensure that the

auxiliary device connected to the GP I/O socket is

compatible with the input/output settings configured using

ICE Tool.

1. Right-click on the Gpio component and select Open.

2. The Gpio window opens. The four channels are labelled GPIO-0

to GPIO-3.

3. In the Direction fields, configure the required channels as outputs

or inputs by clicking Out or In.

4. To enable an output channel, click Turn O n for the required

channel. The button toggles to become a Tur n O ff function and

the status of the channel changes to ON.

If a channel is configured as an input, the Tur n On button is

not available.

5. Any configuration changes made remain in effect after the Gpio

window is closed .

16

Head Configuration

VR Configuration

On an ICE head with VR compatibility, ICE Tool is used to enable and

configure the VR settings. Changes can be made to the VR data output

standards.

1. Right-click on the Vri component and select Open.

2. The Vri window opens. The following configuration settings can be

changed:

a) An identification number can be assigned to a VR head in a

multi-camera system. This number is then transmitted as part

of the VR data packet. Enter a number in the Camera Id field.

b) To output the VR data as serial comms, click to select SERIAL

from the Output Comms Type drop-down menu. Click to

select the required data rate in the Serial Settings field.

c) To output the VR data on Ethernet, click to select UDP from

the Output Comms Type drop-down menu. Enter the

connection details of the VR hardware in the Receiver

Address and Receiver Port fields.

d) If the VR data output is not synchronised with a genlock signal,

select the Allow Free Running check box.

17

Head Configuration

e) To enable the head to start transmitting VR data, select the

Enable VR Tracking check box.

3. Click Apply to store and enable any configuration changes to take

effect.

Copying Configurations

The configuration settings on a head can be transferred to another

head of the same type. This saves time when setting up a system with

identical heads. It is also possible to transfer the configuration of just

one component of a head, such as the VR or Ethernet settings.

Copying Head Configuration

Right-click on the host ID of the head with the required

1.

configuration and select Copy Configuration.

2. Right-click on the host ID of the recipient head for the copied

configuration and select Paste Configuration.

3. When the confirmation window appears, click Yes to paste the

configuration into the head. Click No to abort the procedure.

Copying Component Configuration

Right-click on the required individual component of a head and

1.

select Copy Configuration. Configuration settings can be copied

and pasted from the Hcm, Head and Vri components.

2. Right-click on the correct component of the recipient head and

select Paste from the menu. When the confirmation window

appears, click Yes to confirm and paste the configuration file into

the recipient head, or No to abort.

18

Exporting Configurations

Note

The configuration of a head or head component can be saved as a file

for future use with ICE Tool. The file can also be used to load on to

heads in another system.

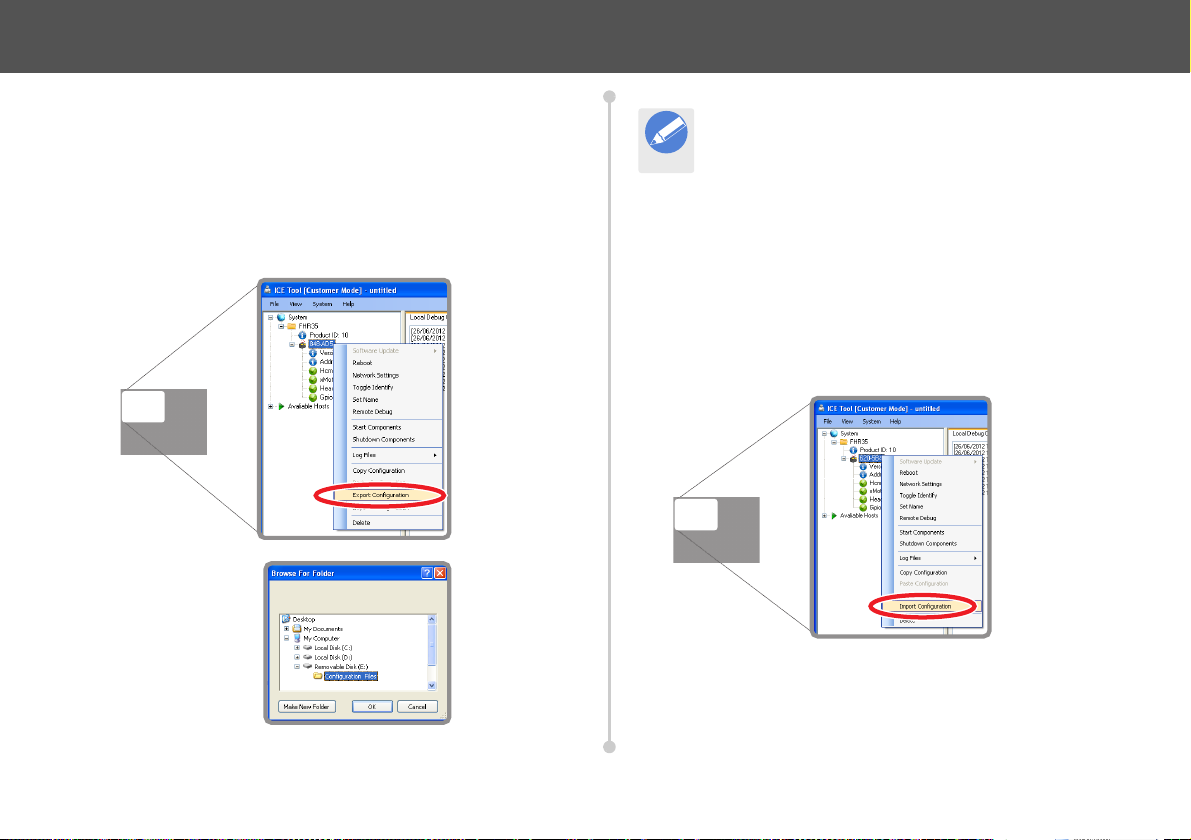

Exporting Head Configuration

Right-click on the host ID of the head with the required

1.

configuration and select Export Configuration.

2. In the Browse For

Folder window

select a folder

location to store

the configuration

file and click Ok.

Head Configuration

Alternatively, use the Make New Folder button to create a

storage folder for the configuration file.

3. The configuration file is saved in the selected folder location and is

named using the host ID number of the head in the format HostID_config.xml.

Importing Head Configuration

Stored configuration files can be retrieved and loaded onto recipient

heads when required.

1. Right-click on the recipient head host ID and select Import

Configuration.

2. In the Open window, browse to the folder containing the required

configuration file.

19

Head Configuration

3. Click to select the file and click Open.

4. When the confirmation window appears, click Yes to import the

configuration from the file into the device. Click No to abort the

procedure.

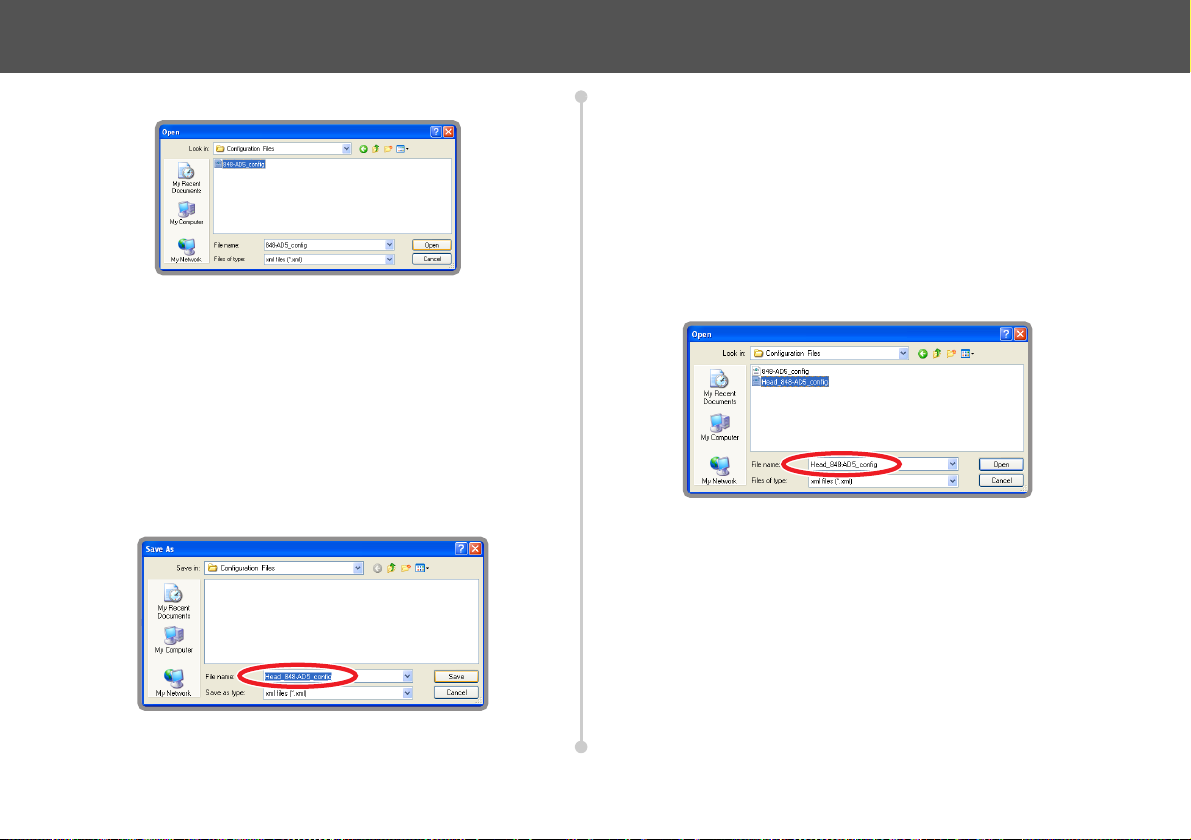

Exporting Component Configurations

1. Right-click on the required individual component of a head and

select Export Configuration. Configuration settings can be

exported from the Hcm, Head and Vri components.

2. In the Save As window select a folder location to store the

component configuration file and click Save.

3. The component configuration file will be saved in the selected

folder location and is named using the component name and host

ID number of the head in the format Component_Host-

ID_config.xml.

Importing Component Configurations

Right-click on the correct component of the recipient device and

1.

select Import Configuration.

2. In the Open window, browse to the folder containing the required

configuration file. Click to select the file and click Open.

3. When the confirmation window appears, click Yes to confirm and

paste the component configuration file into the recipient head

component. Click No to abort the procedure.

20

VAVinten Radamec

itec Group brand

Publication part No. V4096-4985/1

Loading...

Loading...