APS Scanner

Installation and Configuration Guide

Absolute Positioning System

Installation

Part No. V4109-0001

V4109-0002

EN

www.vintenradamec.com

Copyright © 2013

All rights reserved.

Original Instructions: English

All rights reserved throughout the world. No part of this document may be stored in a retrieval system,

transmitted, copied or reproduced in any way, including, but not limited to, photocopy, photograph,

magnetic or other record without the prior agreement and permission in writing of the Vitec Group plc.

Disclaimer

The information contained in this manual is believed to be correct at the time of printing. Vitec Videocom

Ltd reserves the right to make changes to the information or specifications without obligation to notify any

person of such revision or changes. Changes will be incorporated in new versions of the publication.

We are making every effort to ensure that our manuals are updated on a regular basis to reflect changes

to product specifications and features. Should this manual not contain information on the core functionality

of your product, please let us know. You may be able to access the latest revision of this manual from our

website.

Vitec Videocom Ltd reserves the right to make changes to product design and functionality without

notification.

Trademarks

All product trademarks and registered trademarks are the property of The Vitec Group Plc.

All other trademarks and registered trademarks are the property of their respective companies.

Published by:

Vitec Videocom Ltd

Supports Technical Publications Department

Western Way, Bury St Edmunds

Suffolk IP33 3TB

United Kingdom

Email: technical.publications@vitecgroup.com

Contents

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Components and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Left Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Right Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

APS Scanner Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

APS Scanner Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Configuring the APS Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Reflective Target Installation . . . . . . . . . . . . . . . . . . . . . . . . . 8

The APS Scanner User Interface . . . . . . . . . . . . . . . . . . . . . 8

Creating a Landmark Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Starting Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Target Type Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Landmark Map Scanning. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adding Additional Targets to a Landmark Map . . . . . . . . . . 12

Adding Additional Landmark Maps . . . . . . . . . . . . . . . . . . . 13

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Landmark Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Position Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

APS Scanner Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LCD Display Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

General Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1

Safety

Important information on the safe installation and operation of

this product. Read this information before operating the product.

For your personal safety, read these instructions. Do not operate

the product if you do not understand how to use it safely. Save

these instructions for future reference.

Warning Symbols Used in these Instructions

Safety cautions are included in these instructions. These safety

instructions must be followed to avoid possible personal injury and

avoid possible damage to the product.

WARNING!

Where there is a risk of personal injury or injury to others,

comments appear supported by the warning triangle symbol.

Where there is a risk of damage to the product, associated

equipment, process or surroundings, comments appear

supported by the word ‘Caution’.

ELECTRIC SHOCK

Where there is a risk of electric shock, comments appear

supported by the hazardous voltage warning triangle.

Intended Use

The Fusion Absolute Positioning System (APS) scanner is designed to

be installed by a qualified engineer onto a Fusion pedestal. It is

designed to provide accurate positional information used to control the

pedestal in television studios where APS targets have been installed.

Electrical Connection

WARNING! Risk of electric shock. Always check cables for

signs of damage. Damaged cables can cause personal injury

and/or damage the equipment.

CAUTION! All connections to other devices must be made

using shielded cables.

Mounting and Installation

WARNING! Installation of this product must only be

performed by qualified and trained electrical engineers.

WARNING! Always ensure that all power and auxiliary

communications cables are routed so that they do not

present any danger to personnel. Take care when routing

cables in areas where robotic equipment is in use.

Water, Moisture and Dust

WARNING! Protect the product from water, moisture and

dust. The presence of electricity near water can be

dangerous.

Operating Environment

CAUTION! The product should not be used outside the

operating temperature limits. Refer to the product Technical

Specifications for the operating limits for the product.

Cleaning

WARNING! Risk of electric shock. Always disconnect and

isolate the product from the power supply before cleaning.

CAUTION! Do not use solvent or oil-based cleaners,

abrasives or wire brushes. Only use detergent-based

cleaners.

2

Safety and About this Manual

Maintenance

WARNING! The fitting of non-approved parts and

accessories, or the carrying out of non-approved alterations

or servicing can be dangerous and could affect the safety of

the product. It may also invalidate the terms and conditions

of the product warranty.

Safety when Working with Robotic Equipment

In normal operation remote-controlled equipment can move suddenly

and without warning. Since audible warnings are not suitable for use

within the studio environment, it is recommended that only trained

personnel be allowed to work in the active areas where remotecontrolled heads and pedestals are located. The safe operating zone is

a minimum of 1 m (3 ft).

Safety Notes for Operators

Operators must familiarise themselves with the working footprint of the

robotic head, including all associated equipment (lens, zoom and focus

controls, viewfinder, prompter, etc.) to prevent inadvertent collisions or

injury to personnel.

If personnel are too close to a head or pedestal that is about to move,

the operator should prevent the motion from starting or stop the motion

if it has started.

We strongly recommend that the operator verifies visually that the

active area is clear of hazards and personnel, both before and during

remote operation.

About this Manual

The APS scanner is supplied either pre-installed onto the pedestal by

a service engineer in the studio, or pre-installed from the factory fitted

onto a new pedestal. This manual covers the operation and

configuration of the APS scanner and important safety instructions.

The APS scanner will only function in a studio with APS reflective

targets installed. For more information on the correct installation of the

APS reflective targets, refer to the APS Reflective Targets Installation

Guide, publication part No. V4109-4981.

Using this Manual

In some sections this manual uses zoomed screenshots to display the

relevant area of the screen or window. The user is guided to the

relevant area by a series of navigation icons which indicate the portion

of the screen being zoomed. Two examples are shown below:

Top right hand quarter

of the window

Bottom half of the window

A specific feature is further

highlighted using a red

outline ring.

3

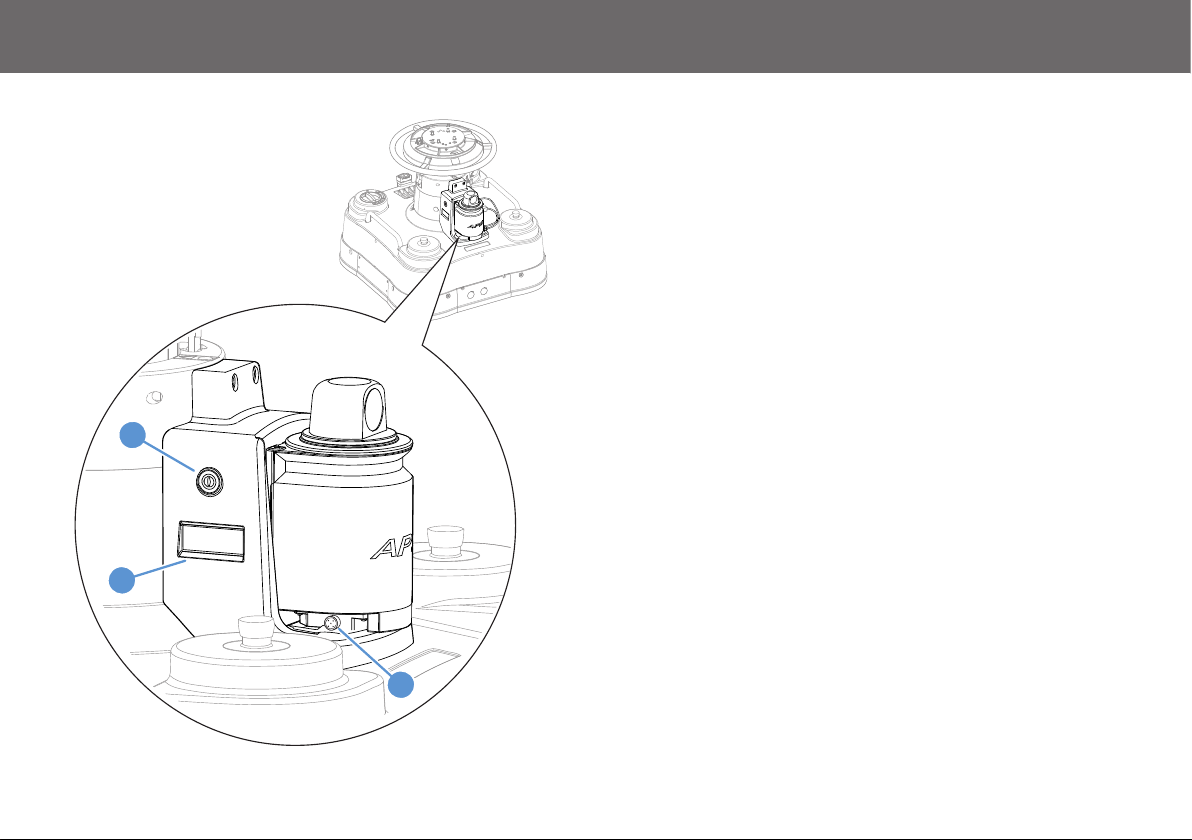

Components and Connections

Left Side View

3

2

1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RS232 Socket

2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .LCD display

3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power switch

1

4

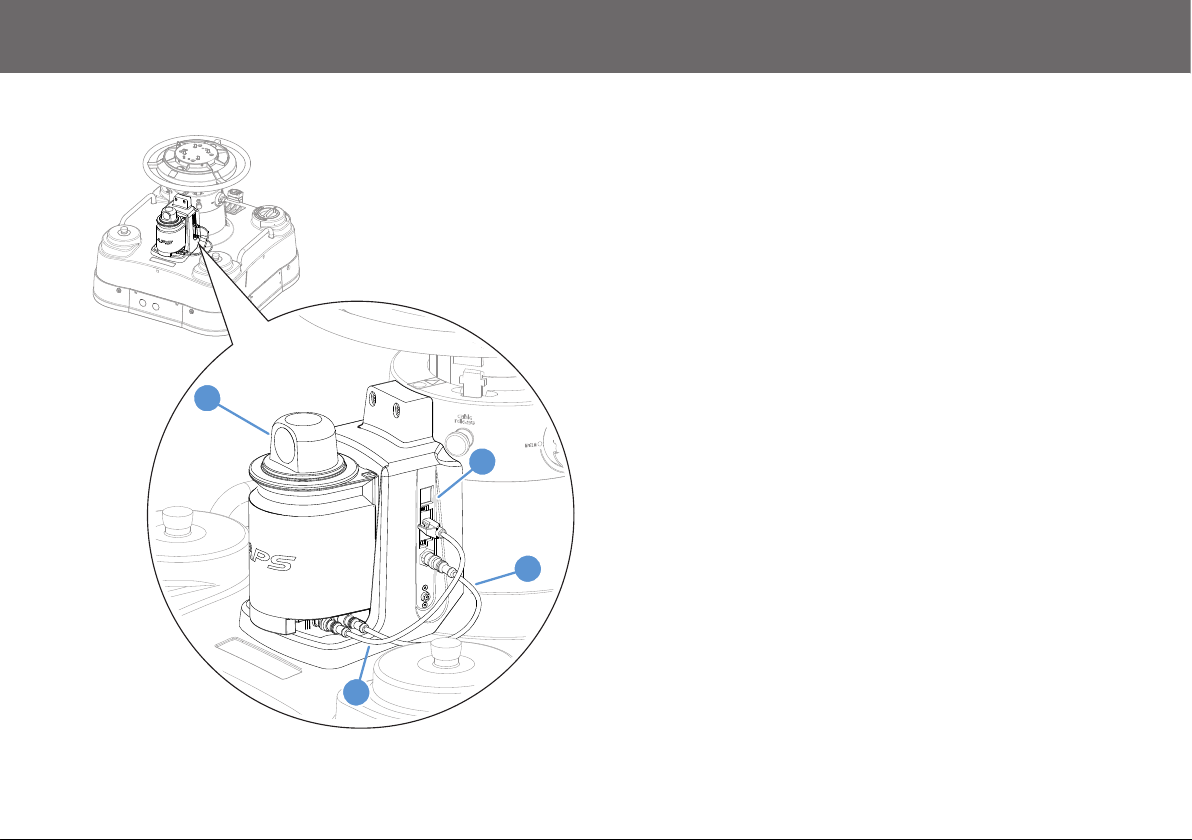

Right Side View

4

Components and Connections

5

6

4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rotating laser scanner head

5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ethernet ports

6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power interconnecting cable

7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Data interconnecting cable

7

5

Installation

APS Scanner Function

When operational, the APS scanner provides absolute positioning data

for the pedestal. This is achieved with a rotating infrared laser scanner

head. When the infrared beam is reflected back from the APS reflective

targets installed in the studio, the absolute position of the pedestal on

the studio floor can be established and sent to the control system.

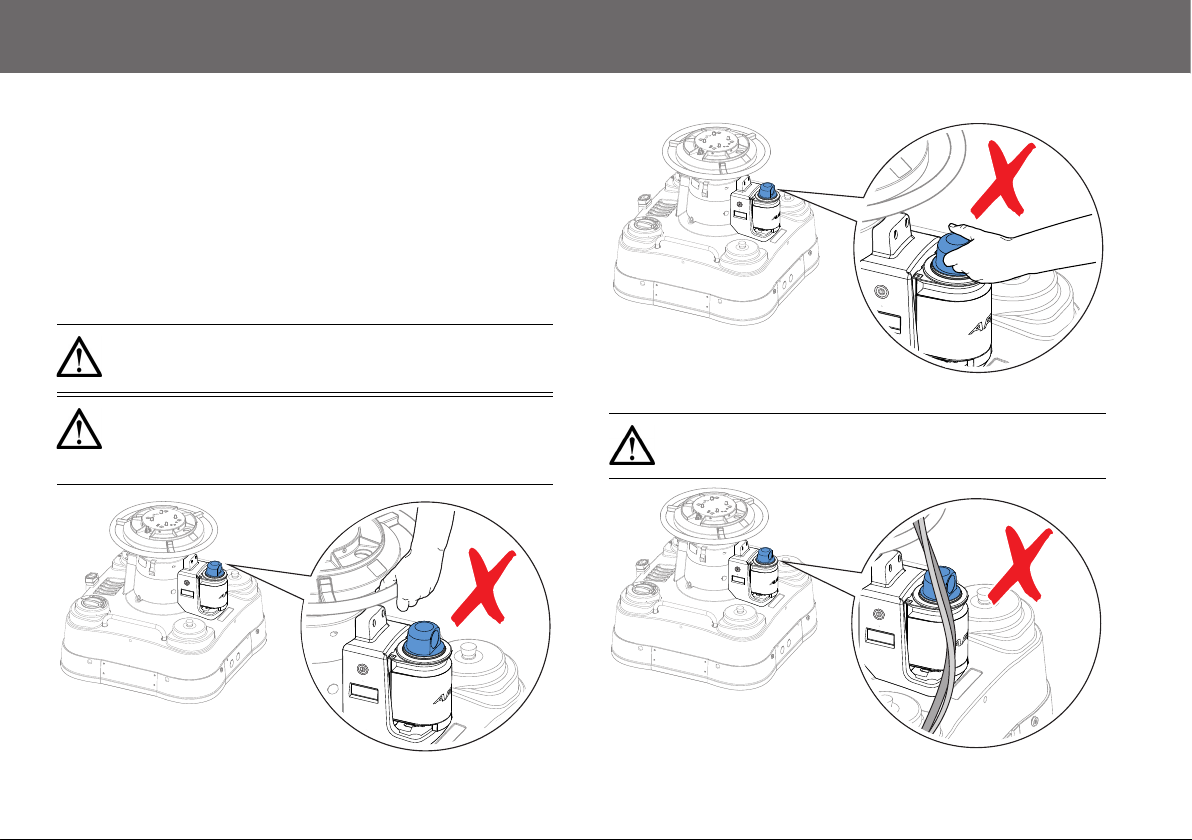

APS Scanner Safety

The laser scanner rotates at a rate of eight revolutions per second and

therefore the following safety points must be adhered to:

WARNING! Risk of personal injury. Do not hold the steering

ring in the proximity of the laser scanner when the pedestal

column is in a lowered position.

WARNING! Risk of personal injury or injury to others. Do

not attempt to touch the laser scanner on the APS scanner

unit while it is in motion. Warn other personnel and visitors

in the studio to the potential risk.

CAUTION! Risk of product damage. Do not route cables or

place objects near the rotating laser scanner head.

6

Installation

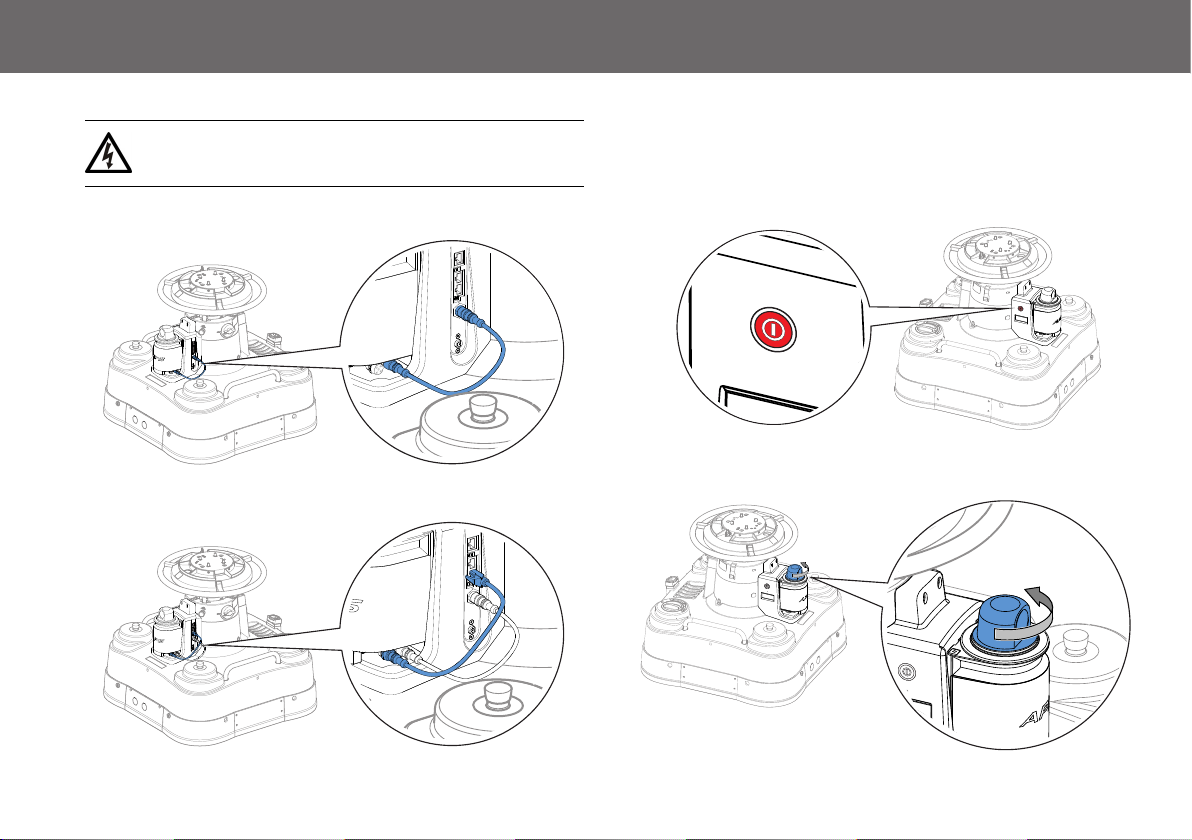

Electrical Connections

WARNING! Disconnect power from the pedestal before

attempting any electrical connections.

Power Interconnection

Data Interconnection

Powering Up

Before powering up the APS scanner, ensure that all external cable

connections are secured correctly. The pedestal must also be powered

up.

1. To power up, operate the on/off push button switch.

2. The power switch and LCD display will illuminate and the laser

scanner head will rotate.

7

Configuration

Configuring the APS Scanner

Before the APS system is fully operational, reflective targets must be

correctly installed into the studio environment and the APS scanner

must be configured to work with them. For configuration purposes, the

APS scanner has a built in user interface which is accessed by

connecting up a computer with compatible network settings running a

web browser such as Internet Explorer.

Reflective Target Installation

The APS scanner will only function in a studio with APS reflective

targets installed. For more information on the correct installation and

use of the APS reflective targets, refer to the APS Reflective Targets

Installation Guide, publication part No. V4109-4981.

The APS Scanner User Interface

The network settings of the computer must be changed for successful

connectivity with the APS scanner. The procedure for changing the

settings differs between Windows XP and Windows 7.

Changing the Network Settings Using Windows XP

1. From the Windows Start menu navigate to Control Panel >

Network Connections to open the Network Connections

window.

2. Right-click on the Local Area Connection icon and select

Properties from the menu.

3. Scroll down and select Internet Protocol (TCP/IP) and click the

Properties button.

4. The Internet Protocol (TCP/IP) Properties window opens.

a) Make a note of any current configuration settings in this

window so that they can be restored when required.

b) Click to select the Use the following IP address option.

c) Enter 192.168.1.5 (or an address appropriate for the device or

system) into the IP address field.

d) Press the Tab key to automatically populate the Subnet mask

field.

5. Click Ok to save the changes and exit the window.

6. Click Close to exit the Local Area Connection Properties

window.

8

Configuration

Changing the Network Settings Using Windows 7

1. From the Windows Start menu click to select Control Panel.

2. Click to select Network and Internet.

3. Click to select Network and Sharing Center.

4. Click on Change adaptor settings.

5. Right-click on the active local area connection and select

Properties from the menu.

6. The Local Area Connection Properties window opens. Click to

select Internet Protocol Version 4 (TCP/IPv4).

7. Click the Properties button.

8. The Internet Protocol Version 4 (TCP/IPv4) Properties window

opens.

a) Make a note of any current configuration settings displayed,

so that they can be restored when required.

b) Click to select the Use the following IP address option.

c) Enter 192.168.1.5 (or an address appropriate for the device or

system) into the IP address field.

d) Press the Tab key to automatically populate the Subnet mask

field.

9. Click Ok to save the changes and exit the window.

10. Click Ok again to exit the Local Area Connection Properties

window.

9

Configuration

Creating a Landmark Map

The APS user interface is used to scan the locations of the reflective

targets in the studio to create a landmark map. This map is then stored

by the APS scanner and used to provide accurate pedestal positional

data anywhere on the studio floor.

Starting Up

1.

Connect the configured computer to a spare network port on the

APS scanner using an Ethernet cable.

3. Power up the APS unit.

The LCD display will

initially show a boot up

screen and then change to

the main display screen.

Positional values are

displayed with a # symbol

indicating that mapping is

required.

4. Launch the web browser and type http://192.168.1.70 in the

address bar.

5. The user interface

home page opens, with

information displayed

about the firmware and

hardware versions of

the APS scanner unit.

Links to the other main

pages of the user

interface are also

provided here.

2. Power up the pedestal. If the pedestal has previously been used

and has pre-stored shots referenced to a floor target, perform the

standard floor targeting procedure.

10

Configuration

Target Type Selection

Before a landmark map can be created, the type of reflective targets

used in the studio installation must be programmed into the APS

scanner.

1. From the home page, click to select Landmark Detection from

the row of page links above the information table.

2. On the landmark detection page, select the reflector type being

used in the studio:

Select if the

studio is using

the wall mounted

flat reflectors

Select if the

studio is using

the cylindrical

bollard reflectors

The size of the

installed reflectors can

be change if required

(default sizes are 76

mm diameter for the

bollard and 75 mm

width for the flat

targets)

settings2

Click to store any

changes to the

target settings

Landmark Map Scanning

1.

Click to select the Landmark Mapping link.

2. Check that the option Replace in current layer is selected.

3. Click the Map Landmarks button to begin the scanning process.

4. When the scan has been completed, the landmark mapping page

updates with the following information:

The position of

the pedestal

The number of

scans performed

to create the

landmark map

The number of landmarks

(reflective targets) detected

during the mapping process

11

Configuration

5. Click the Save

Landmark Map to store

the scanned information.

A confirmation page

opens.

6. This returns the APS scanner unit to normal operation. The LCD

display will now show the following information:

The current position

of the pedestal

X: 1120.7

Y: 1905.5

Q: -12.697

Mode: Nav

Current mode is

navigation mode

layer

dev

lmark

: 0

: 2

: 6

The number of landmarks

(reflective targets)

currently visible to the

APS scanner unit

Adding Additional Targets to a Landmark Map

Additional reflective target locations can be added to the current

landmark map at any time. Common scenarios for this requirement are:

• Additional reflective targets have been installed in the studio

• Previously obscured reflective targets have come into view of the

APS scanner at the current pedestal location in the studio

• Additional previously unmapped reflective targets have come into

view at a different position in the studio

The APS scanner can be instructed to scan for previously unmapped

targets and add them to the current landmark map.

1. Click to select the Landmark Mapping link from any page in the

APS user interface.

2. On the landmark mapping page, tick to select Negative Mapping

and Append to current layer.

3. Click the Map Landmarks button. The APS scanner unit will only

scan for previously undetected targets. When the scan is

complete:

Click to store the new

targets to the current

landmark map

The number of new

targets detected

12

Configuration

Adding Additional Landmark Maps

Additional landmark maps can be scanned and stored in the APS

scanner. This is useful if the APS pedestal is used in several different

studios. Any additional landmark maps are stored as different layers in

the memory of the APS scanner and can be recalled at any time. The

APS scanner can store up to 320 layers.

Creating a New Layer

1. On the landmark mapping page, change the Layer from the

default value of 0 to a number between 1 and 319.

2. Follow the procedure described in the section Landmark Map

Scanning on page 11 to scan and store a new landmark map to

the new layer number.

3. The LCD display also

indicates the new layer

number and number of

landmarks (targets) currently

detected.

Managing Layers

To change between stored layers:

X: 1040.5

Y: 1720.4

Q: -10.265

Mode: Nav

layer

dev

lmark

: 1

: 3

: 4

1. Click to select the Positioning link from any page in the APS user

interface.

2. On the positioning page change the Current Layer field number to

the layer required and click Save.

Replacing a Landmark Map

The currently selected landmark map can be completely replaced. This

can be particularly useful if many of the installed reflective targets in the

studio have been moved.

1. On the scanner mode page, click the Standby Mode button and

then click to select the Landmark Mapping link.

2. On the landmark mapping page select Replace in current layer.

3. Check that Negative Mapping is not selected.

4. Click the Map Landmarks button. The APS scanner unit will

create a new landmark map using all the available reflective

targets.

5. Click the Save Landmark Map button to overwrite all previous

mapping data stored on the selected layer.

13

Configuration

Advanced Settings

CAUTION! Only competent trained personnel should make

changes to setup options or parameters using the APS user

interface. Changing these settings could affect the reliability

of the system.

The APS user interface can be used to configure advanced system

settings to enhance performance and positional accuracy in an

installed location. Adjusting the default settings can also help the

operator if problems are being experienced during basic operation.

If the APS system is performing accurately and

consistently, there is no need to change any default

Note

Defaults

Landmark Settings

The following parameters used by the APS scanner when scanning for

reflective targets in the landmark map can be changed:

Action Radius - The APS scanner can detect targets between a

minimum distance of 0.5 m and a maximum distance of 70 m from the

laser scanner head. However, in some installations it may not be

desirable or necessary to detect targets in such a large field of view, so

the range can be reduced to suit the studio size.

N closest reflectors - This parameter limits the number of targets the

APS scanner uses during scanning, starting with the closest targets

first. This can help to improve accuracy because only the closest

settings.

To restore the APS scanner to the factory default settings,

see Default Settings on page 17 in the Troubleshooting

section.

targets in the map will be scanned. The default setting is 0, which is a

special case allowing all available targets to be detected. A minimum

detection of three targets is required for the APS scanner to produce

positional information.

Reflector Threshold - This parameter changes the sensitivity of the

APS scanner when detecting targets. If the APS scanner is interpreting

other reflective surfaces in the studio as targets, the threshold

percentage can be increased to help minimise the effect of false

readings on system performance.

1. Click to select the Landmark Detection link from any page in the

APS user interface.

2. On the landmark detection page the following detection

parameters can be adjusted:

Increase the

minimum, or

decrease the

maximum field

values. The APS

scanner will then

only detect

targets within the

reduced range

Set a value to limit

the number of

targets the

scanner will detect

(closest only)

Adjust the percentage

to change the sensitivity

of the scanner

settings2

Click to store any

changes to the

detection settings

14

Configuration

Position Settings

The following positioning settings that the APS system uses during

normal operation can be changed:

Sliding Mean Depth - This setting relates to the number of scans

(rotations) performed by the APS scanner to detect the positions of

mapped targets. The default setting is one scan, however if this is set

to a multiple number the target data results collected from each scan is

averaged out. Increasing the number of scans can help to improve

target detection if scanning errors often occur due to other moving

objects in the studio.

The APS scanner performs eight scans (rotations) per

Note

Radius of landmark detection window - This parameter affects the

APS scanner’s ability to accurately resolve precise target locations.

The default is set to a radius of 300 mm. This means that the APS

system will assume that a true landmark position has been resolved if

a reflective object has been detected within 300 mm of a known target

position in the landmark map. If two targets appear very close together

due to a particular angular line of sight, or there is a known reflective

object other than a true reflective target close by, the window radius

could be reduced. This would have the effect of narrowing the focus for

target detection and help to separate close reflective objects in problem

scenarios, thus improving positional accuracy.

Note

second.

The radius of the landmark detection window can be set

independently at the minimum and maximum ranges of the

detection field.

1. Click to select the Positioning link from any page in the APS user

interface.

2. On the positioning page the following parameters can be adjusted:

Increase the number

of scans made to

detect targets

Increase or decrease

the detection window

at both ends of the

scanning range

Click to store any

changes to the

positioning settings

15

Maintenance

Routine Maintenance

The APS scanner requires minimal routine maintenance, apart from

checking the connections and overall operation periodically.

Routine Checks

During use, check the following:

• Check cables for signs of wear or damage. Replace as necessary

• Check that all cables are connected properly

WARNING! Risk of electric shock. Always check cables

for signs of damage. Damaged cables can cause personal

injury and/or damage the equipment.

Cleaning

WARNING! Risk of electric shock. Always disconnect and

isolate the product from the power supply before cleaning.

APS Scanner

During normal use the only cleaning required should be a regular wipe

over with a dry, lint-free cloth. Dirt accumulated during storage or

periods of disuse may be removed with a vacuum cleaner. Particular

attention should be paid to all connection ports.

Laser Scanner Window

CAUTION! Potential performance reduction due to

contamination of the window in the laser scanner. The

window must be regularly cleaned as described.

WARNING! Switch off the APS scanner before cleaning the

laser read head window.

Static charges cause dust particles to be attracted to the window of the

laser scanner.

To clean the window, proceed as follows:

1

Use a clean and soft brush to remove dust particles

from the window.

16

2

Carefully wipe the window using a clean and damp

lens cloth.

Troubleshooting

Default Settings

The following table lists the factory default setting values for the APS scanner.

Landmark Detection Default Value Positioning Default Value

Cylindrical Reflector Size 76 mm Reflector Threshold 50%

Flat Reflector Size 75 mm Sliding Mean Depth 1

Action Radius (Min) 500 mm Radius of landmark detection window at (distLow) 300 mm at 500 mm distance

Action Radius (Max) 70000 mm Radius of landmark detection window at (distHigh) 300 mm at 70000 mm distance

N closest reflectors 0

APS Scanner Function

Fault Check Comments

The APS scanner is switched on,

but the power switch and LCD

display are not illuminated and the

laser scanner head is not rotating.

The pedestal is not maintaining

consistent and accurate absolute

positioning during normal

operation.

Check that all the interconnections on the APS scanner are

secure.

Check that the Fusion pedestal is connected to the power source

supply and switched on.

Check that the APS scanner has a clear view of the reflective

target positions (no obstructions) and they are in the correct

installation positions.

The APS scanner needs contact with at least three reflective

targets.

Repeat the landmark map scan procedure, appending any new

or moved reflective targets to the current landmark map.

See Electrical Connections on

page 7.

See the APS Reflective Targets

Installation Guide, publication part

No. V4109-4981.

See Adding Additional Targets to a

Landmark Map on page 12.

17

Troubleshooting

Fault Check Comments

The pedestal is no longer

maintaining consistent and

accurate absolute positioning.

The APS scanner is not updating

or displaying pedestal positional

information.

Check the laser scanner window for dust

contamination and clean as necessary.

Check the laser scanner window for possible

damage (scratches, cracks or fracture).

Check that the APS scanner is set to navigation

mode.

Check that the APS scanner is set to the correct

layer number for the current studio location.

LCD Display Messages

If the APS scanner detects a problem or fault during use, it is shown on the LCD display.

Display Fault/Check Comments

Communication or power problem with the APS scanner.

Check all interconnections and that the pedestal is

powered up.

Communication has not been established between the

APS scanner and the pedestal. Check that the pedestal is

powered up and working with the control system.

See Laser Scanner Window on page 16.

If the window is damaged it may need to be replaced.

Contact Vinten Radamec customer support.

On the scanner mode page, click on the Navigation

Mode button to return the APS system to normal

operation.

See Managing Layers on page 13.

See Electrical Connections on page 7.

18

Troubleshooting

.

Display Fault/Check Comments

Pedestal positional information not displayed. The APS

scanner requires the landmark mapping procedure to be

carried out.

The APS scanner has not booted correctly. Try power

cycling the scanner and the pedestal.

The APS scanner has not located the memory card, or

the memory card is incorrectly formatted.

See Landmark Map Scanning on page 11.

If the problem persists, contact Vinten Radamec.

Contact Vinten Radamec.

19

General Notices

Technical Specification

Dimensions

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.7 Kg (8.2 lb)

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257 mm (10.1 in.)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177 mm (7.0 in.)

Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211 mm (8.3 in.)

Power

DC power input . . . . . . . . 24V DC (supplied directly from the pedestal)

Environmental

Temperature range (operation) . . . . . . . 0°C to +40°C (32°F to +104°F)

Pedestal Accuracy

X/Y accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±25 mm

Angular accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.1°

Laser Scanner Specification

Laser light wavelength . . . . . . . . . . . . . . . . 905 nm, infrared, eye safe

Laser Compliance

• Complies with laser class 1 in accordance with IEC 60825-1

• Complies with 21 CFR 1040.10 and CFR1040.11 except for

deviations pursuant to laser notice No.50 dated June 24th, 2007

FCC Certification

APS Scanner Unit

V4109-0001

V4109-0002

FCC Notice

This product complies with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio or

television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected

• Consult the dealer or an experienced radio/television technician

for assistance

FCC Warning

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate

the equipment.

20

General Notices

FCC Declaration of Conformity

This product complies with Part 15 of the FCC Rules, Operation is

subject to the following two conditions:

1.This product may not cause harmful interference.

2.This product must accept any interference received, including

interference that may cause undesired operations.

Declaration of Conformity

Vitec Videocom Limited declares that this product has been

manufactured in accordance with BS EN ISO 9001:2008 and is in

compliance with the essential requirements and other relevant

provisions of the Machinery Directive 2006/42/EC. A copy of the

Declaration of Conformity is available upon request.

Environmental Considerations

ROHS Compliance Statement

Vitec Videocom Limited is compliant with the European Union Directive

2002/95/EC Restrictions of Hazardous Substances (RoHS) that

restricts the use of hazardous substances in Electrical and Electronic

Equipment.

European Union Waste Electrical and Electronic

Equipment (WEEE) Directive (2002/96/EC)

This symbol marked on the product or its packing indicates that this

product must not be disposed of with general household waste. In

some countries or European Community regions, separate collection

systems have been set up to handle the recycling of electrical and

electronic waste products. By ensuring this product is disposed of

correctly you will help prevent potentially negative consequences for

the environment and human health. The recycling of materials helps

conserve natural resources.

Visit our website for information on how to safely dispose of this product

and its packaging.

In Countries Outside the EU:

Dispose of this product at a collection point for the recycling of electrical

and electronic equipment according to your local government

regulations.

Pollution Statement

This equipment is designed for operation in Pollution Degree 2

environments.

21

VAVinten Radamec

itec Group brand

Publication part No. V4109-4980/1

Loading...

Loading...