Fusion FPR-210

Manual and Robotic Pedestal

+

Fusion FPR-210 Pedestal

+

Operators Guide

Part Nos. V3952-0005

www.vintenradamec.com

Publication Part No. V3952-4987

Published by

Vitec Videocom Ltd

Supports Technical Publications Department

Western Way, Bury St Edmunds

Suffolk

IP33 3TB

United Kingdom

Email: technical.publications@vitecgroup.com

Copyright © 2014

All rights reserved.

Original Instructions: English

All rights reserved throughout the world. No part of this

document may be stored in a retrieval system, transmitted,

copied or reproduced in any way, including, but not limited

to, photocopy, photograph, magnetic or other record

without the prior agreement and permission in writing of

the Vitec Group plc.

Trademark acknowledgements

All product trademarks and registered trademarks are the

property of The Vitec Group Plc.

All other trademarks and registered trademarks are the

property of their respective companies.

Disclaimer

The information contained in this manual is believed to be

correct at the time of printing. Vitec Videocom Ltd reserves

the right to make changes to the information or specifications

without obligation to notify any person of such revision or

changes. Changes will be incorporated in new versions of the

publication.

We are making every effort to ensure that our manuals are

updated on a regular basis to reflect changes to product

specifications and features. Should this manual not contain

information on the core functionality of your product, please let

us know. You may be able to access the latest revision of this

manual from our website.

Vitec Videocom Ltd. Reserves the right to make changes to

product design and functionality without notification.

Operators guide

Contents

Page

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Components and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction and description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Column. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Steering mechanism checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fitting the load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressurising the pedestal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Height control box installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parking brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cable clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cable guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using the column lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Switching on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operating the Pedestal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Movement indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Emergency stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Collision detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Referencing the studio datum position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Transportation and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Routine checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fuse replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Main assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Transport fixings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1

Fusion FPR-210+ pedestal

Safety instructions

Important information on the safe

installation and operation of this product.

Read this information before operating the

product. For your personal safety, read

these instructions. Do not operate the

product if you do not understand how to

use it safely. Save these instructions for

future reference.

Warning Symbols Used in

these Instructions

Safety cautions are included in these

instructions. These safety instructions must be

followed to avoid possible personal injury and

avoid possible damage to the product

WARNING!

Where there is a risk of personal

injury or injury to others, comments

appear supported by the warning

triangle symbol. Where there is a

risk of damage to the product,

associated equipment, process or

surroundings, comments appear

supported by the word ‘Caution’.

ELECTRIC SHOCK

Where there is a risk of electric

shock, comments appear supported

by the hazardous voltage warning

triangle.

WARNING!

130 kg/286.6 lb LIFTING AID

REQUIRED. Use a lifting hoist

capable of safely lifting the product.

The product is intended for use by television

camera operators, trained to use Vinten

Radamec robotic equipment. Do not use this

product for any other purpose other than that

specified in this usage statement.

Electrical Connection

CAUTION! This product must be

connected to a power supply of the

same voltage (V) and current (A) as

indicated on the product. Refer to

the Technical Specifications for the

product.

CAUTION! We recommend that you

use the power supply cable supplied

with the product.

CAUTION! Always use a fuse of the

correct type and rating for the

product. Refer to the Technical

Specifications for the product.

CAUTION! Using alternative power

sources will invalidate the system

EMC liability.

Basic Electrical Insulation

(Class 1 equipment)

WARNING! This product is Class 1

equipment. For safe operation this

equipment must be connected to a

power supply that has a protective

earth connection (US: ground).

Intended Use

This product is designed for use within

television studios to support a payload

weighing up to 95 kg (210 lb). The total

payload must not be exceeded. The FPR210+ pedestal can be moved manually or

remotely to allow operators to control their

movements and positioning around the

studio.

2

Operators guide

Mounting and Installation

WARNING! Always ensure that all

power and auxiliary communications

cables are routed so that they do not

present any danger to personnel.

Take care when routing cables in

areas where robotic equipment is in

use.

Water, Moisture and Dust

WARNING! Protect the product from

water, moisture and dust. The

presence of electricity near water

can be dangerous.

Operating Environment

CAUTION! The product should not

be used outside the operating

temperature limits. Refer to the

product Technical Specifications for

the operating limits for the product.

Cleaning

WARNING! Risk of electric shock.

Always disconnect and isolate the

product from the power supply

before cleaning.

CAUTION! Do not use solvent or oilbased cleaners, abrasives or wire

brushes. Only use detergent-based

cleaners.

Safety when working with

Robotic Equipment

In normal operation remote-controlled

equipment can move suddenly and without

warning. Since audible warnings are not

suitable for use within the studio environment,

it is recommended that only trained personnel

be allowed to work in the active areas where

remote-controlled heads and pedestals are

located. The safe operating zone is a

minimum of 1 m (3 ft).

Safety Notes for Operators

Operators must familiarise themselves with

the working footprint of the robotic head,

including all associated equipment (lens,

zoom and focus controls, viewfinder,

prompter, etc.) to prevent inadvertent

collisions or injury to personnel.

If personnel are too close to a head or

pedestal that is about to move, the operator

should prevent the motion from starting or stop

the motion if it has started.

We strongly recommend that the operator

verifies visually that the active area is clear of

hazards and personnel, both before and

during remote operation.

Maintenance

WARNING! The fitting of non-

approved parts and accessories, or

the carrying out of non-approved

alterations or servicing can be

dangerous and could affect the

safety of the product. It may also

invalidate the terms and conditions

of the product warranty.

3

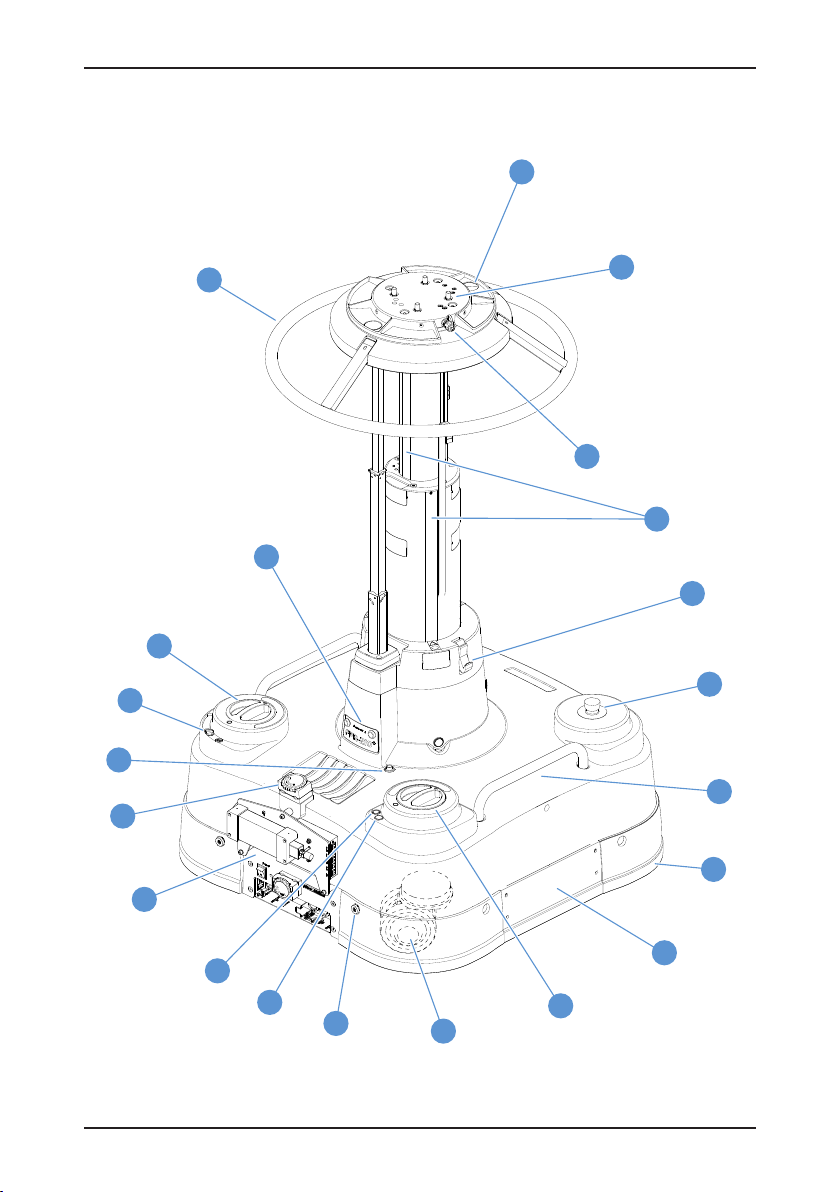

Fusion FPR-210+ pedestal

Components and connectors

1

17

16

18

19

21

2

3

4

20

5

6

7

8

15

14

13

12

Fig. 1 Fusion FP-210+ Pedestal (South East view)

11

10

9

4

Operators guide

[1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressure gauge

[2] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Head mounting plate

[3] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Schrader valve and cap

[4] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Column bearing strip (3 per stage)

[5] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Column lock

[6] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Emergency stop button

[7] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lifting handles

[8] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bumper strip/collision detection

[9] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Alignment sensor/wheel access panel

[10] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic/manual steering mode knob

[11] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Double castor wheels (non-driven, 2 off)

[12] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cable guard lowering buttons

[13] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bumper manual reset

[14] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bumper sensitivity potentiometer

[15] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power box and ICE interface

[16] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cable clamps

[17] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Height control socket

[18] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Parking brake slider

[19] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CRAB/STEER mode changeover knob

[20] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Height adjustment buttons

[21] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Steering ring

5

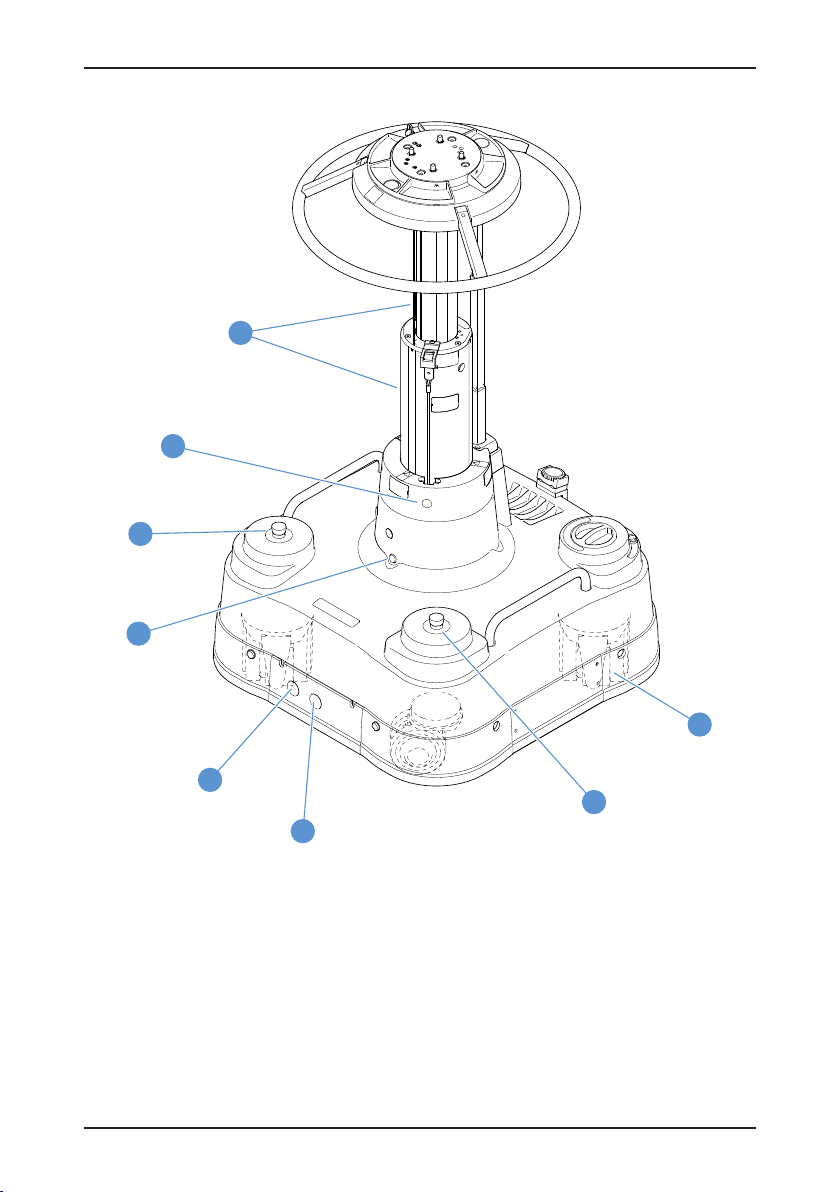

Fusion FPR-210+ pedestal

27

26

6

25

22

24

6

23

Fig. 2 Fusion FP-210+ Pedestal (North West view)

6

Operators guide

[22] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Driven double-wheel sets (2 off)

[23] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . USB configuration port (with cover plug)

[24] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Servo configuration port (with cover plug)

[25] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pedestal movement indicator (3 off)

[26] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Blanking cover (do not remove)

[27] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Moving column

7

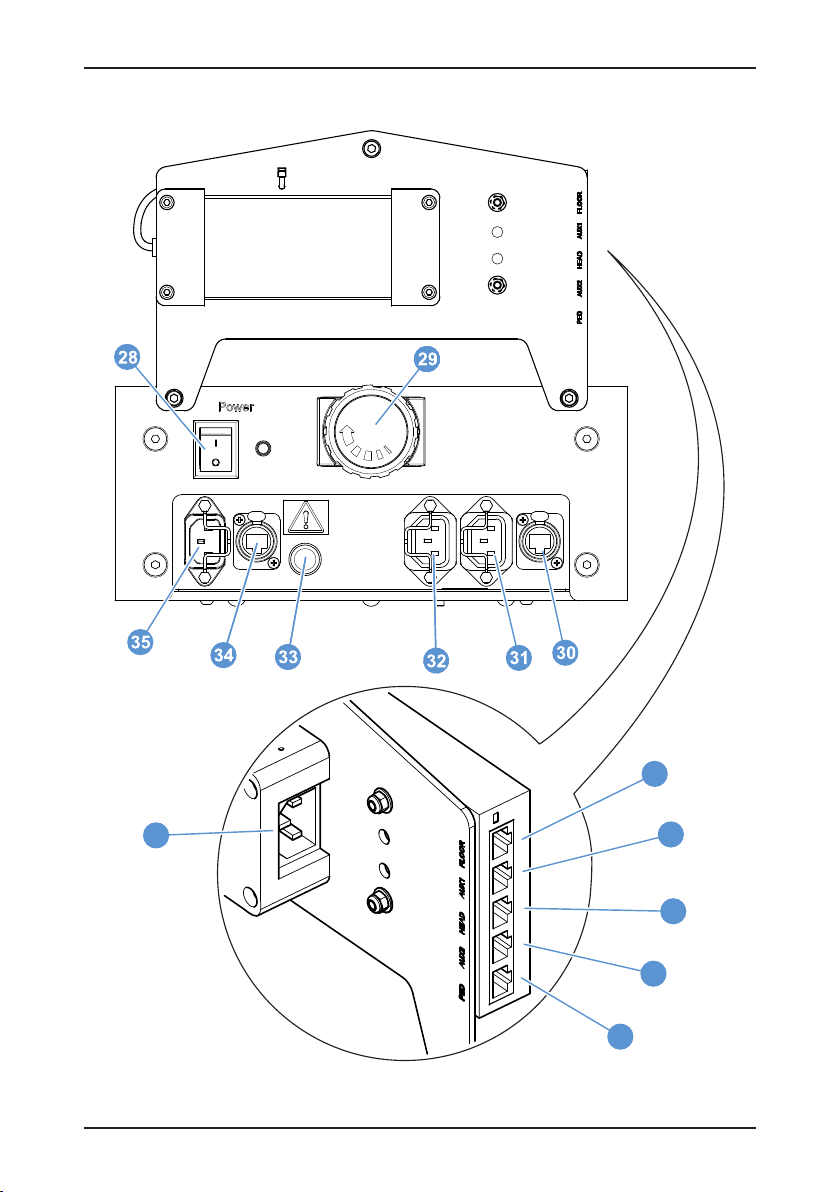

Fusion FPR-210+ pedestal

36

41

Fig. 3 Fusion VR Power Box and ICE Interface Connectors

37

38

39

40

8

Operators guide

[28] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power ON/OFF switch

[29] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cable clamp

[30] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ethernet port (auxiliary)

[31] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power output socket 90–240V, 100 W (Head)

[32] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power output socket 90–240V, 50 W (Aux)

[33] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuse

[34] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ethernet port (ICE interface)

[35] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power socket (mains)

[36] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ICE Ethernet IN port (from floor cable)

[37] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ICE Ethernet primary auxiliary port

[38] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ICE Ethernet head port

[39] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ICE Ethernet secondary auxiliary port

[40] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ICE Ethernet pedestal port

[41] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power supply inlet socket

9

Fusion FPR-210+ pedestal

Introduction and description

This Operators Guide describes how to set up and operate the Fusion FPR-210

The FPR-210+ pedestal has been designed for integration with the Fusion FH/R-145 pan and tilt

heads and Vinten Radamec Control Systems (VRC) using the Intelligent Control Engineering

(ICE) system.

Each product within the Fusion FPR-210+ range of pedestals comprises a central two-stage,

telescopic column mounted in a moveable base. The base of the FPR-210+ pedestals are

motorised.

The pedestals can be operated manually by a camera operator within the studio or remotely

operated in robotic mode from a Fusion control system. The pedestals have a maximum payload

capacity of 95 kg (210 lb).

+.

Column

The telescopic column [27] is pressurised from an external pressure source. Controls on the

column comprise a column lock [5], which locks the column in the fully-depressed position, and

height adjustment buttons [20], which adjust the column height when in manual mode only. The

pedestal is provided with a standard four-bolt mounting interface [2].

Base

The base is carried on four sets of wheels [11, 22], two of which are driven and two freewheeling, mounted on a flexible chassis to accommodate uneven floors. A height-adjustable

cable guard is provided, which can be lowered by depressing the cable guard buttons [12]

located near each corner of the base. The guard can then be raised in predefined increments

as required. Emergency stop buttons [6], lifting handles [7] and a wheel brake slider [18] are

provided on the upper surface of the base. Rotary knobs allow the operator to switch between

conventional and crab steering [19] and manual and robotic operation [10].

The cable clamps [16, 29], main power switch [28] and both power [31, 32, 35] and data

connections [30, 34] can all be found on the South side (rear) of the base, with a USB

configuration port [23] located on the North side (front) of the base. The bumper strip [8] running

around the pedestal base contains collision detection sensors which arrest movement on

contact with an obstacle.

10

Operators guide

Installation

Unpacking

WARNING! 130kg/286.6 lb LIFTING AID REQUIRED. Use a lifting hoist capable

of safely lifting the product.

WARNING!

1. DO NOT lift the pedestal by the steering ring—use the lifting handles on

top of the pedestal base.

2. DO NOT release the column lock, if the pedestal pressure exceeds 4 bar

(60 psi) without a balancing load mounted. Reduce pressure as

necessary using the Schrader valve cap.

Unpack the pedestal ensuring that all transport packing and retaining fixings are removed,

including the Velcro strap (part no. 3320-268) securing the column lock.

Steering mechanism checks

1. Rotate the CRAB/STEER knob [19] counter-clockwise to select CRAB (x4 wheels)

and turn the steering ring [21], until CRAB mode engages. Check that the pedestal

“crabs” correctly, freely moving as directed by the steering ring without any rotation

of the pedestal base (see Fig. 1).

2. Rotate the CRAB/STEER knob [19] clockwise to select STEER (x1 wheel) and turn

the steering ring [21], until it locks in position and STEER mode engages. Check that

the pedestal turns freely, rotated by the locked steering ring.

Fitting the load

The pedestal is fitted with a standard Vinten four-bolt mounting plate [2] for direct mounting of

Fusion FH/R-145 pan and tilt heads or for use with a Quickfix adaptor. The mounting bolts are

captive in the pedestal and the bolt heads are accessible from the underside of the mounting

plate when the column is fully extended (see Fig. 1).

11

Fusion FPR-210+ pedestal

Directly mounting a Fusion head to the pedestal

WARNING!

1. DO NOT release the column lock, if the pedestal pressure exceeds 4 bar

(60 psi) without a balancing load installed. Reduce as necessary, using the

Schrader valve cap.

2. DO NOT lean over the pedestal. A pressurised pedestal could rise rapidly

when the column lock is released. ALWAYS restrain the column by hand

pressure on the pedestal base.

3. ONLY authorised service personnel are permitted to disengage the

robotic height drive cable when increasing/decreasing the pedestal

pressure or changing the payload.

CAUTION! Do not reduce pedestal pressure below 3.5 bar (50 psi). This ensures

that the elevating mechanism remains in tension, preventing damage to the

pedestal.

To fit the pan and tilt head and payload, proceed as follows:

1. Rotate the steering ring [21] so that the pressure gauge [1] is visible through the

viewing window.

2. Push down on the steering ring [21] (A) against residual pressure and release the

column lock [5] (B). Allow the column to extend under hand restraint.

A

Fig. 4 Column Lock Release

3. Fit the pan and tilt head to the four-hole mounting plate [2] and tighten the bolts

supplied with the head securely using a flat-bladed screwdriver or a spanner of the

correct size. A Vinten spanner (part no. J551-001) is available for this purpose.

4. Set the column lock [5] to the ON position (see Using the column lock on page 21)

and lower the moving column under hand restraint until the column lock engages.

5. Fit the camera and accessories. Ensure that all equipment (incl. pan bars,

prompters, lenses, etc.) has been securely fitted. Attaching equipment at a later

stage can affect the pedestal balance.

B

12

Operators guide

6. Push down on the steering ring [21] against residual pressure and release the

column lock [5]. Allow the column to extend under hand restraint.

Mounting a Quickfix® adaptor

In situations where heads are often interchanged on pedestals and tripods, it is recommended

that a Vinten heavy-duty Quickfix adaptor (part no. 3490-3) is used. The adaptor provides an

easier and quicker method of mounting and removing heads from a pedestal or tripod. Mount

the adaptor onto the pedestal or tripod mounting plate and secure into position following the

installation instructions in the Operators Guide supplied with the adaptor (part no. 3490-8).

Fig. 5 Quickfix Adaptor

The Quickfix adaptor has a safety latch mechanism that is used to secure the head into position

on the Quickfix base.

Safety button

and clip

UNLOCKED

Fig. 6 Safety Latch Mechanism

Red safety latch

LOCKED

13

Fusion FPR-210+ pedestal

Pressurising the pedestal

WARNING! DO NOT pressurise the pedestal beyond the maximum safe

working pressure indicated by the leading edge of the red sector on the gauge.

CAUTION! This pedestal must be pressurised with nitrogen or clean, dry air only

to prevent internal corrosion.

CAUTION! Do not reduce pedestal pressure below 3.5 bar (50 psi). This ensures

that the elevating mechanism remains in tension, preventing damage to the

pedestal.

The pedestal may be pressurised from an external pressure source (see page 15) or by using a

portable pump (see page 15).

A correctly pressurised pedestal will balance its payload—allowing movement over the full onshot stroke of the moving column with minimum effort—and maintain its position when the

steering ring is released.

Ascertain the payload to be fitted to the pedestal (payload = pan and tilt head, camera, lens and

any other ancillary equipment). Referring to the balance graph, mark the payload on the

horizontal axis, then strike a vertical line from the load figure to the balance line. At the

intersecting point strike a horizontal line to the vertical axis and read off the required pressure.

14

220

200

180

160

140

120

100

psi

80

Fusion FPR-210 Pedestals Balance Graph

Maximum payload 95 kg (210 lb)

bar

16

14

12

10

8

6

60

4

40

2

20

0

0

010203040 50 60 70 80 90

20

0

+

MAX

kg

100

220

80

60

40

100

120

140

160

180

200

lb

Fig. 7 Balance Graph

Operators guide

Pressurising from an external pressure source

WARNING! DO NOT exceed 4 bar (60 psi) without a balancing load installed.

WARNING! DO NOT adjust the pressure relief valve. Personal injury and

pedestal damage may occur.

A pressure-reducing valve must be fitted between the gas cylinder and the outlet connection of

the hose. The maximum pressure on the outlet side of the reducing valve must not exceed

18.9 bar (275 psi)

To pressurise the pedestal from an external pressure source, proceed as follows:

1. Rotate the steering ring [21], so that the pressure gauge [1] is visible through the

window.

2. Remove the Schrader valve cap [3] and connect the charging line from the pressure

source.

3. Turn on the pressure supply and slowly increase the pedestal pressure until it is

equal to the calculated pressure plotted on the balance graph.

4. Increase the pedestal pressure by a further 1.5 bar (20 psi). Do not exceed the

maximum working pressure indicated by the leading edge of the red sector on the

gauge [1].

5. Disconnect the charging line, and refit the Schrader valve cap [3].

NOTE: The Schrader valve cap forms a primary pressure seal. Always replace

the cap and secure.

Pressurising the pedestal using a portable pump

A portable pump (part no. 3357-21) is available to pressurise the pedestal manually. To

pressurise the pedestal using a pump, proceed as follows:

1. Rotate the steering ring [21] so that the pressure gauge [1] is visible through the

window.

2. Remove the Schrader valve cap [3].

3. Set up the pump following the manufacturer’s instructions. Connect the hose to the

charging valve on the pedestal.

4. Using full, steady strokes increase the pedestal pressure until it is equal to the

calculated pressure plotted on the balance graph.

5. Increase the pedestal pressure by a further 1.5 bar (20 psi). Do not exceed the

maximum working pressure indicated by the leading edge of the red sector on the

gauge [1].

15

Fusion FPR-210+ pedestal

6. Disconnect the hose from the pedestal charging valve, and refit the Schrader valve

cap [3]. Remove the pump.

NOTE: The Schrader valve cap forms a primary pressure seal. Always replace

the cap and secure.

Electrical connections

WARNING! It is recommended to use a residual current device (RCD) to protect

personnel should the power cable become damaged.

WARNING!

1. DO NOT plug moving devices into the auxiliary (Aux ) power port.

2. This port cannot be switched off at the pedestal and is not affected by an

emergency stop. Devices plugged into the auxiliary port must have an

independent isolator switch.

All of the pedestal’s main external ports are located on the power box at the South side of the

base (see Fig. 1 and Fig. 3). Additional system configuration ports are located on the control box

at the North side of the base (see Fig. 2).

Power sockets

External mains power is connected to the power input connector [35].

The pedestal also has two power output sockets [31, 32].

• The Head power output socket [31] supplies power to a Fusion head (for more

information consult the relevant Operators Guide). This socket is controlled by the

pedestal, it is switched [28], fused and isolated on activation of an emergency stop.

16

Operators guide

• The auxiliary (Aux) power output socket [32] is protected by a system fuse, but is

permanently live and intended to power the ICE interface.

Fig. 8 ICE Interface Power Connection

USB configuration port

The USB port [23] is located beneath a protective cover on the North side of the base. This port

allows external connection to a pedestal configuration software tool.

Servo configuration port

The servo configuration port [24] is located beneath a protective cover beside the USB port [23]

and allows trained service engineers to configure servo motor settings.

17

Fusion FPR-210+ pedestal

ICE Interface Ethernet Connections

The following ICE Ethernet connections are made to the ICE interface.

18

Control system

ICE head

Fig. 9 ICE Interface Ethernet Connections

Operators guide

Height control box installation

If the optional accessory height control box (V3952-1910) is to be installed, proceed as follows:

1. Using the cable tie provided, install the height control box onto a pan bar or the

pedestal steering ring (convenient location for the operator).

Fig. 10 Height control box installation

2. Connect the supplied link cable to the height control box.

Fig. 11 Link cable connection

19

Fusion FPR-210+ pedestal

3. Connect the other end of the cable into the height control socket [17] near the side

of the pedestal column

Fig. 12 Pedestal height control socket

Operation

Parking brake

CAUTION! Do not apply the brake while the pedestal is in motion. The pedestal

may become unstable and the brake may be damaged.

The pedestal base is provided with a parking brake [18] on one wheel. The brake is not designed

to slow the pedestal while in motion (see Fig. 1).

Rotate the slider [18] counter-clockwise to engage the brake or clockwise to release it.

Cable clamp

A cable clamp is provided on the base [16] and the power box [29] at the South side of the

pedestal (see Fig. 1 and Fig. 3).

20

Operators guide

Cable guard

CAUTION! Cable guards should be set to the minimum height possible, to

prevent the pedestal damaging studio power and data cables.

The height-adjustable cable guard is lowered by depressing the recessed cable guard buttons

[12]. These buttons are located on the side of the base, near each wheel. When lowered, the

cable guard can be raised in predefined increments as required (see Fig. 1).

Using the column lock

WARNING!

1. DO NOT release the column lock, if the pedestal pressure exceeds 4 bar

(60 psi) without a balancing load installed. Reduce as necessary using

the Schrader valve cap.

2. DO NOT lean over the pedestal. An over-pressurised pedestal may rise

rapidly when the column lock is released, causing personal injury.

CAUTION! Do not reduce pedestal pressure below 3.5 bar (50 psi). This ensures

that the elevating mechanism remains in tension, preventing damage to the

pedestal.

The column lock [5] locks the column in the fully depressed position (see Fig. 1 and Fig. 13).

A

Fig. 13 Column Lock Operation

A. To release the column lock, push down on the steering ring [21] against residual

pressure and rotate the column lock catch [5] downward into the OFF position.

B. To engage the column lock, rotate the column lock catch [5] upward into the vertical

position. Fully depress the column [27] until the lock engages.

B

21

Fusion FPR-210+ pedestal

Height adjustment

WARNING!

1. ALWAYS collapse the moving column and engage the column lock, when

wheeling the pedestal across uneven/sloping surfaces between shots

with the full payload fitted, to prevent loss of stability (toppling hazard!).

2. Take care not to trap fingers under the steering hub or between column

elements while the pedestal height is being reduced.

The column has an on-shot stroke of 770 mm (30 in.). When the automatic/manual steering knob

[10] is set to the MAN position, the column extension position can be moved by using the height

adjustment buttons on the pedestal column, or from the optional accessory height control box

(V3952-1910) (see Fig. 1 and Fig. 14).

22

Fig. 14 Height Adjustment Buttons

Operators guide

Steering

Directional manual control of the pedestal is achieved by turning the steering ring [21]. The

steering system is geared, so that the skid wheels turn by the same amount as the steering ring.

This ensures, for example, that when the pedestal is set to CRAB, turning the steering ring by

90° will also cause the pedestal to change direction by 90° (see Fig. 1).

The pedestal has a changeover mechanism to switch between STEER and CRAB mode.

Rotating the knob [19] counter-clockwise selects CRAB mode and rotating it clockwise selects

STEER mode. Although the CRAB/STEER knob [19] can be switched with the pedestal wheels

in any position, the changeover will not occur until the steering ring [21] is rotated, allowing the

mechanism to engage.

Refer to Steering mechanism checks on page 11 for details.

Switching on

When the complete system is ready, ensure that all external cable connections are complete,

observe the steering mode knob setting [10] and turn on the power switch [28]. The pedestal will

not suddenly move when switched on (see Fig. 1 and Fig. 3).

Operating the Pedestal

WARNING!

1. Display prominent warning signs in studios alerting personnel that

robotic equipment is present and may move without warning.

2. Only operate the pedestal remotely if you are able to see it, to avoid

obstacles and collision hazards.

3. Only operate the pedestal on stable studio floor surfaces.

DO NOT operate the pedestal near floor edges over which the pedestal

may fall, as this can cause personal injury and/or damage the equipment.

CAUTION! Ensure that the pedestal load is balanced before driving the column

remotely, to prevent damage to the drive system.

The pedestal robotic control is independently selected for vertical (Z) column movement and

horizontal (X and Y) pedestal movement.

NOTE: Movement indicators will flash to warn when the pedestal moves across the floor.

Automatic height mode is always engaged when operating the pedestal.

Selecting/deselecting robotic steering

To engage robotic steering mode on the pedestal, rotate the steering mode knob [10] fully

counter-clockwise to the AUTO position and set the changeover knob to CRAB.

NOTE: When automatic steering mode is selected, the steering ring rotates freely and

cannot be used for manual steering.

23

Fusion FPR-210+ pedestal

To select manual pedestal movement/steering on the pedestal, rotate the steering mode knob

[10] clockwise to the MAN position and rotate the steering ring [21] to re-engage the pedestal

wheels.

Movement indicators

The movement indicators [25] will flash to warn when the pedestal moves across the floor. The

indicators also flash when the camera unit is initialised by the control system, to confirm the

correct unit has been selected. Consult the relevant Vinten Radamec Control System Operators

Guide for further information (see Fig. 2).

Emergency stops

CAUTION! Power is not disconnected from the auxiliary (Aux) power socket.

If the EMERGENCY STOP button [6] is pressed, power to the pedestal is immediately cut and

a moving pedestal will come to a halt. This loss of power will also affect any device plugged into

the Head power socket [29], such as the Fusion pan and tilt head (see Fig. 1 and Fig. 3).

To reset the emergency stop mechanism, twist and lift the STOP button [6]. Power will be reinstated immediately, but the pedestal will need re-initialising from the control system. Consult

the relevant Vinten Radamec Control System Operators Guide for more information on reinitialising the pedestal.

Collision detection

If the pedestal collides with an obstacle when in robotic mode, sensors contained in the bumper

strip [10] immediately halt the pedestal (see Fig. 1 and Fig. 15).

Adjusting bumper sensitivity

Collision detection excludes the area of the power box on the South side of the pedestal as

show. Bumper sensitivity can be adjusted for the bumper strip [8] using the bumper sensitivity

potentiometer [14].

NOTE: Bumper sensitivity at the control box/alignment sensor is factory set and cannot be

adjusted.

24

Operators guide

Bumper sensitivity at the

control box/alignment sensor

is factory set.

Collision

detection area

Fig. 15 Collision Detection Area

To adjust the bumper sensitivity, proceed as follows:

1. Ensure that the pedestal is fully prepared with the payload correctly fitted and

balanced. Power up the pedestal.

2. Check the sensitivity of the bumper sensors by tapping the bumper lightly. The

bumper manual reset [13] illuminates when the sensors have detected a collision.

3. To change the sensitivity of the bumper, remove the plastic cap covering the

bumper sensitivity potentiometer [14] and using a small screwdriver adjust the

potentiometer. Turning the potentiometer clockwise increases bumper sensitivity

and turning the potentiometer counter-clockwise will decrease bumper sensitivity.

4. Repeat steps 2 and 3 until the correct adjustment is made.

5. To commence operation of the pedestal, press the bumper manual reset [13] on the

pedestal and then re-initialise the pedestal from the control panel.

Consult the relevant Vinten Radamec Control System Operators Guide for more information on

re-initialising the pedestal.

Referencing the studio datum position

To maintain positional accuracy for the pedestal within the studio, it is necessary to periodically

reference the absolute datum—a target permanently fixed to the studio floor. For instructions on

how to reference the studio datum, consult the relevant VRC Operators Guide.

25

Fusion FPR-210+ pedestal

Transportation and storage

WARNING! 130kg/286.6 lb LIFTING AID REQUIRED. Use a lifting hoist capable

of safely lifting the product.

WARNING! DO NOT lift the pedestal by the steering ring—use the lifting

handles only.

CAUTION! Do not reduce pedestal pressure below 3.5 bar (50 psi). This ensures

that the elevating mechanism remains in tension, preventing damage to the

pedestal.

Local, national or international regulations may apply to the transport and storage of pressurised

pedestals.

To prepare the pedestal or height drive for transportation and storage (see Fig. 1 and Fig. 2)

proceed as follows:

1. Apply the parking brake by rotating the slider [18] counter-clockwise.

2. Set the column lock [5] to the ON position (see Using the column lock on page 21)

and lower the moving column under hand restraint until the column lock engages.

3. Using the Schrader valve cap [3], reduce pedestal pressure to 4 bar (60 psi).

4. Remove the camera and ancillary equipment.

5. Push down on the steering ring [21] against residual pressure and release the

column lock [5] allowing the column to extend under hand restraint (see Using the

column lock on page 21).

6. Undo the four mounting bolts and remove the pan and tilt head.

7. To avoid dust or abrasive particles collecting on moving components, set the column

to minimum height and re-engage the column lock.

8. Fit the Velcro strap to secure the column lock in place.

9. Select manual pedestal movement/steering by rotating the steering mode knob [10]

clockwise to the MAN position and rotating the steering ring [21] to re-engage the

pedestal wheels.

26

NOTE: Reduce pedestal pressure to the minimum operating pressure (3.5 bar/

50 psi) prior to transport or storage.

Operators guide

Maintenance

General

This pedestal is robustly made to high engineering standards and little attention is required to

maintain serviceability. Attention to the following points will ensure a long and useful service life

with minimum need for repair.

Routine checks

During use, check the following:

1. Check the balance of the pedestal. Refer to the section Pressurising the pedestal

on page 14 if rebalancing is required.

2. Check the data communication with the control panel. Refit cables, if necessary.

3. Check for radial or side play in the moving column.

4. Check for height drive case damage or wear.

Adjustments

If excessive radial or side play is apparent in the moving column, wheel alignment is poor or any

other defect is apparent, contact Vinten Radamec or your Vinten Radamec local distributor.

Adjustments and repairs should only be carried out by a trained and competent service engineer.

Cleaning

CAUTION!

1. Do NOT use oil or grease on any exposed part of the column. This is

unnecessary and traps dirt which acts as an abrasive.

2. Do NOT use solvent- or oil-based cleaners, abrasives or wire brushes to

remove accumulations of dirt as these damage the protective surfaces. To

clean mechanical surfaces, use only detergent-based cleaners.

During normal studio use, the only cleaning required should be a regular wipe over with a

lint-free cloth. Dirt accumulated during storage or periods of disuse may be removed with a

vacuum cleaner (see Fig. 1 and Fig. 16).

Particular attention should be paid to the bearing strips [4] on each stage of the column, the

wheels [11] and datum reference sensors [9.2].

Accessing the wheels and datum reference sensors

To gain access to the wheels [11] and the pedestal datum reference sensors [9.2], it is

necessary to remove the two access panels [9] on opposite sides of the pedestal base, below

the lifting handles [7].

To remove these panels, proceed as follows:

27

Fusion FPR-210+ pedestal

1. Switch OFF power to the pedestal [34] and disconnect the power lead [32].

2. Unscrew the four fixing screws [9.1] and lift off the panel [9] to expose the internal

mechanisms.

[9.2]

[9.1]

Fig. 16 Accessing Wheels and Datum Reference Sensors

[9]

Fuse replacement

WARNING! Risk of electric shock. Always disconnect and isolate the product

from the power supply before replacing the fuse.

To replace the power box fuse (see Fig. 3), proceed as follows:

1. Ensure that the power supply has been disconnected and isolated from the

pedestal.

2. Rotate the fuse holder [33] counter-clockwise and remove from the power box [15].

3. Remove the defective fuse from the fuse holder [33] and replace with a serviceable

fuse. Refer to Electrical data on page 30 for correct fuse rating.

4. Install the fuse holder [35] into its housing on the power box [15], push and rotate

clock-wise to secure.

28

Operators guide

Parts list

The following list includes the main assemblies, upgrade kits and optional accessories. For

further information regarding repair or spare parts, contact Vinten Radamec or your local Vinten

Radamec distributor.

Main assemblies

FPR-210+ manual and robotic pedestal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V3952-0005

Transport fixings

Velcro strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3320-268

Optional accessories

Portable pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3357-21

Vinten spanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J551-001

®

Quickfix

Height control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V3952-1910

Cables

Contact Vinten Radamec or your local distributor for information about our range of studio floor

cables, camera lens cables (for use with the Fusion heads) and a Head communication cable

(to allow direct connection to a Fusion pedestal or height drive).

adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3490-3

Technical data

Data characteristics that only apply to some of the equipment covered in this Operators Guide

are clearly marked in the following list.

Physical data

Payload capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 kg (210 lb)

Pedestal weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 kg (286.6 lb)

Height drive weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 kg (286.6 lb)

Min. height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .660 mm (26 in.)

Max. height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1430 mm (56.3 in.)

Ground clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (0.75 in.)

Doorway tracking width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 mm (31.5 in.)

Wheel diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 mm (6.3 in.)

Steering ring diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .635 mm (25 in.)

Degrees of freedom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 DOF (X/Y/Z)

29

Fusion FPR-210+ pedestal

Pedestal base movement data

Max. floor speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 mm/s (11.8 in./s)

Min. floor speed setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 mm/s (1 in./s)

Pedestal travel accuracy . . . . . . . . . . . . . . . . . . . . . . . .0.5% of total floor run (subject to floor)

Repeatability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X,Y = ±1.5% (e.g. ±100 mm after running a

36 m triangular test pattern)

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .X,Y = <1 mm

Column movement data

On-shot stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 770 mm (30.3 in.)

Max. working pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.6 bar (255 psi)

Max. relief valve pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.9 bar (275 psi)

Max. column speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 mm/s (5.9 in./s)

Min. column speed setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 mm/s (0.4 in./s)

Height drive accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.75 mm (±0.03 in.)

Repeatability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Z = ±0.5 mm

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Z = <1 mm

Environmental data

Temperature range (operation). . . . . . . . . . . . . . . . . . . . . . . . .0°C to +40°C (+32°F to +104°F)

Electrical data

Power consumption (peak). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750 W

Power consumption (average) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 W

Supply V (mains) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Autoranging 90–240V, 50/60 Hz AC

Power output socket (Head). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90–240V (supply V), 100 W

Power output socket (Aux) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90–240V (supply V), 50 W

Power box fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A/120V, 4A/240V

30

Technical specifications are

subject to change without notice.

Operators guide

Declaration of conformity

Vitec Videocom Limited declares that this product has been manufactured in accordance with

BS EN ISO 9001:2008 and is in compliance with the essential requirements and other relevant

provisions of the Machinery Directive 2006/42/EC. A copy of the Declaration of Conformity is

available upon request.

Environmental considerations

ROHS Compliance Statement

Vitec Videocom Limited is compliant with the European Union Directive 2002/95/EC Restrictions

of Hazardous Substances (RoHS) that restricts the use of hazardous substances in Electrical

and Electronic Equipment.

European Union Waste of Electrical and Electronic

Equipment (WEEE) Directive (2002/96/EC)

This symbol marked on the product or its packing indicates that this product must not be

disposed of with general household waste. In some countries or European Community regions,

separate collection systems have been set up to handle the recycling of electrical and electronic

waste products. By ensuring this product is disposed of correctly you will help prevent potentially

negative consequences for the environment and human health. The recycling of materials helps

conserve natural resources.

Visit our website for information on how to safely dispose of this product and its packaging.

In countries outside the EU:

Dispose of this product at a collection point for the recycling of electrical and electronic

equipment according to your local government regulations.

31

Vinten Radamec

A Vitec Group brand

Publication part no. V3952-4987/3

Loading...

Loading...