Fusion FHR-35

Robotic Pan and Tilt Head

Installation and Configuration Guide

Fusion FHR-35 Robotic Pan and Tilt Head

Part No. V4096-0001

www.vintenradamec.com

Original Instructions: English

Copyright © 2013

All rights reserved throughout the world. No part of this document may be

stored in a retrieval system, transmitted, copied or reproduced in any way,

including, but not limited to, photocopy, photograph, magnetic or other record

without the prior agreement and permission in writing of the Vitec Group plc.

Disclaimer

The information contained in this manual is believed to be correct at the time

of printing. Vitec Videocom Ltd. reserves the right to make changes to the

information or specifications without obligation to notify any person of such

revision or changes. Changes will be incorporated in new versions of the

publication.

We are making every effort to ensure that our manuals are updated on a

regular basis to reflect changes to product specifications and features. Should

this manual not contain information on the core functionality of your product,

please let us know. You may be able to access the latest revision of this

manual from our website.

Vitec Videocom

functionality without notification.

Trademarks

All product trademarks and registered trademarks are the property of the

Vitec Group plc.

All other trademarks and registered trademarks are the property of their

respective companies.

Published by:

Vitec Videocom

Supports Technical Publications Dept.

William Vinten Building

Western Way

Bury St Edmunds

Suffolk IP33 3TB

E-mail: technical.publications@vitecgroup.com

Ltd. reserves the right to make changes to product design and

FHR-35 Robotic Pan and Tilt Head

Safety and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Components and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Box Contents and Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting Supports and Adaptors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cable Management Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing the Camera Cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setting the Pan and Tilt Mechanical Hard Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setting the Tilt Mechanical Hard Stops

Setting the Pan Mechanical Hard Stops

Ceiling Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wall Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pozi Loc Tripod Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HD Tripod Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Locking/Unlocking the Camera Cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mounting the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Balancing the Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cable Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Powering Up

ICE Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ICE Tool Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Using ICE Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting the Zero Position and Soft Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Soft Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

General Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Contents

Installation and Configuration Guide

1

FHR-35 Pan and Tilt HeadRobotic

Safety and Warnings

For your personal safety, read these instructions. Do not

operate the product if you do not understand how to use it

safely. Save these instructions for future reference.

Follow all warnings and instructions marked on the

product and in this manual. Safety warnings are

Installation and Configuration Guide

included in this manual. These safety instructions must

be followed to avoid possible personal injury and

damage to the product.

WARNING! Do not install this product onto a bracket,

support or other equipment that is not designed to

support the weight of the product and its payload. All

supports must comply with local government

regulations.

WARNING! The fitting of non-approved parts and

accessories, or the carrying out of non-approved

alterations or servicing can be dangerous and could

affect the safety of the product. It may also invalidate

the terms and conditions of the product warranty.

WARNING!

be fully trained and adhere to correct manual handling

techniques. It is the responsibility of the individual and

the local organisation to enforce safe working practices

at all times.

WARNING! Risk of personal injury or injury to others. All

personnel must be fully trained and adhere to local

health and safety laws and guidelines. It is the

responsibility of the local organisation to enforce safe

working practices at all times.

CAUTION! This product is designed for robotic use only

and is operated remotely. Do not attempt to manually

operate this product.

Risk of personal injury. All personnel must

2

Electrical Connection

WARNING! This product must be connected to a

power supply of the same voltage (V) and current (A)

as indicated on the product and described in the

specification section of this manual. To reduce the

risk of electric shock, do not remove the covers. No

user-servicable parts inside. Refer all servicing to

qualified service personnel.

WARNING! The IEC connector is the primary

disconnect device and must be accessible both during

and after installation of the product.

WARNING! Inspect the AC cable regularly for signs of

wear or damage. If the AC cable is damaged, the

product must be returned to Vinten Radamec for repair.

Basic Electrical Insulation (Class 1 equipment)

WARNING! This product is Class 1 equipment. For

safe operation this equipment must be connected to

a power supply that has a protective earth connection

(US: ground).

Ventilation and Overheating

CAUTION! Slots and openings are intended for

ventilation purposes to ensure reliable operation of

the product and protect it from overheating. Do not

block or cover any slots and openings.

Cleaning and Maintenance

CAUTION! Do not use solvent or oil-based cleaners,

abrasives or wire brushes to remove accumulations

of dirt as these damage the protective surfaces. To

clean mechanical surfaces, use only detergent-based

cleaners.

FHR-35 Pan and Tilt HeadRobotic

Safety and Warnings

CAUTION! Do not use oil or grease on any exposed

part of the product. This is unnecessary and traps dirt

which acts as an abrasive.

CAUTION! Risk of damage to equipment. Do not lift or

carry the head by the top cover.

Intended Use

This product is designed for use within television studios to

support and balance a camera together with ancillary

equipment weighing up to 16 kg (35 lb). Camera operators can

remotely control camera zoom and focus and movements about

the pan and tilt axes using Vinten Radamec control systems.

Safe Working Environment

In normal operation, remote controlled equipment can

move suddenly and without warning. Since audible warnings

are not suitable for use within the studio environment, it is

recommended that only trained personnel be allowed to work in

the active areas where remote controlled heads and pedestals

are located.

Personnel should be made aware of the potential hazards of

working in a robotic environment. To avoid personal injury,

personnel should always exercise caution when working in the

vicinity of robotic equipment. The forces are sufficient to cause

personal injury or injury to others and therefore caution is

essential.

Safe Operating Zone

The safe operating zone for personnel is a minimum of 1 m

(3 ft) outside of the footprint of the pan and tilt head. In most

installations, the teleprompter (if installed) is mounted on to the

head and protrudes the furthest beyond the base of the head.

The footprint must take into account the overhang of the

teleprompter and/or other payload equipment as the head

moves about the pan axis.

Personnel need to be trained and aware of how far the head

and pedestal can move, the speeds involved and the need to

stay clear of robotic equipment at all times.

Warning Signs

Warning signs should be displayed prominently in the

workplace alerting personnel that robotic equipment is in use

and may move suddenly without warning.

If personnel are working on robotic or associated equipment,

ensure a warning sign is placed at the controller (control panel)

to alert operators that work is being carried out.

Safety Notes for Operators

Each remote controlled head and/or pedestal in the system

should remain within the view of the operator at all times. Do

not operate a head and/or pedestal if it cannot be seen.

Before and during remote operation, the operator must verify

visually that the active area is clear of hazards and personnel. If

personnel are too close to a head or pedestal that is about to

move, the operator should prevent the motion from starting or

stop the motion after it has started.

Operators must familiarise themselves with the working

footprint of the robotic head, including all associated equipment

(lens, zoom and focus controls, viewfinder, prompter, etc.), to

prevent inadvertent collisions or injury to personnel.

Installation and Configuration Guide

3

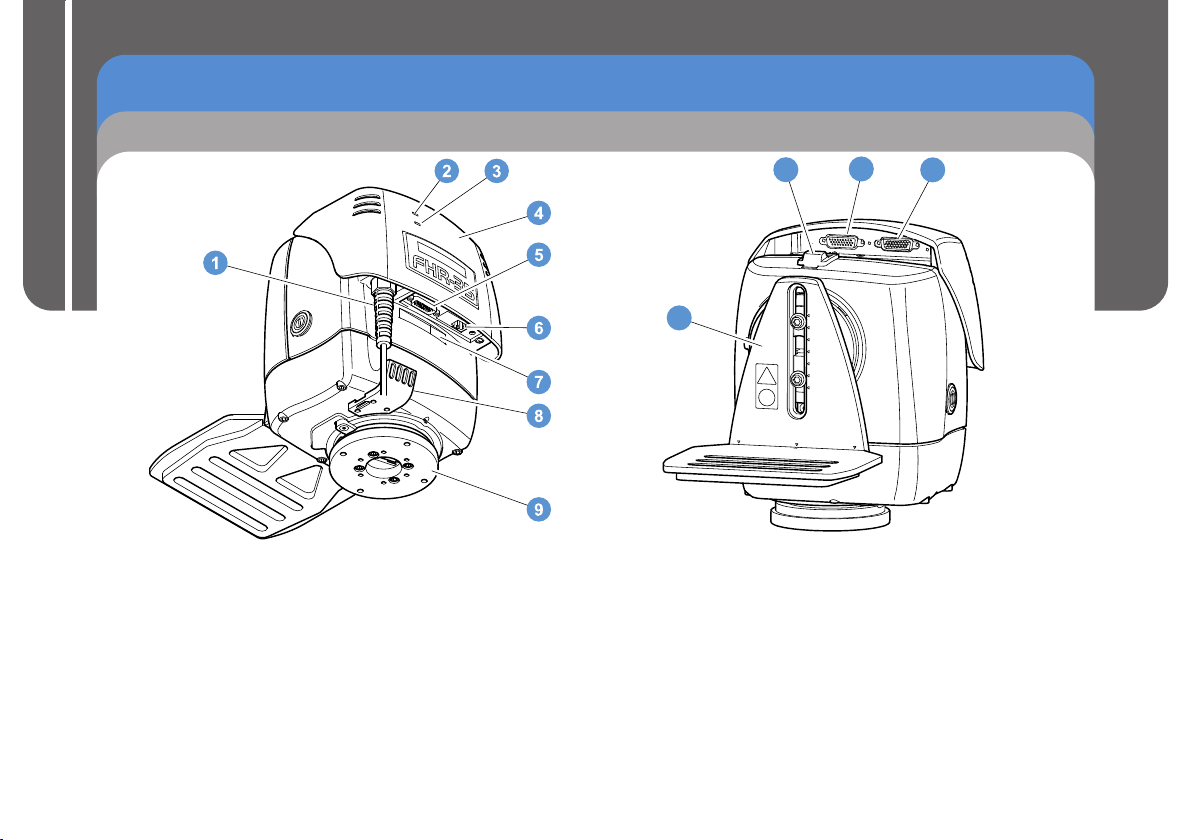

FHR-35 Pan and Tilt HeadRobotic

Components and Connections

Front View

Installation and Configuration Guide

1 . . . . . . . . . . . . . . . . . . . . . .

2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 . . . . . . . . . . . . . . . . . . . . . . . . .

9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mounting plate

Power cable

Cable management bracket

with IEC connector

Genlock LED

Service port

Ethernet port

Network ID label

Data LED

Top cover

Rear View

11

10

10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Camera cradle

11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tilt lock

12 . . . . . . . . . . . . . . . . . . . . . . . . . General purpose connector

13 . . . . . . . . . . . . . . . . . . . . . . . . . . . Lens interface connector

12

13

4

FHR-35 Pan and Tilt HeadRobotic

Installation

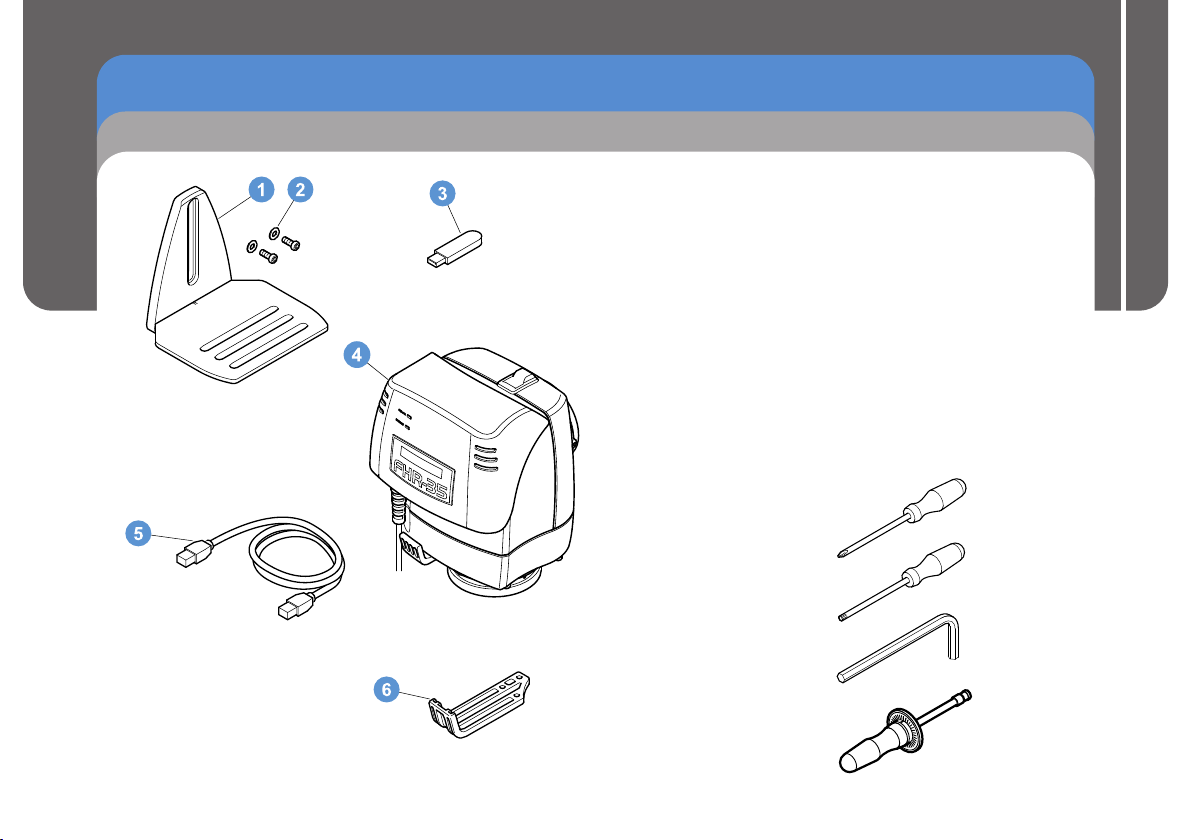

Box Contents and Tools Required

1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Camera cradle

2. . . . . . . . . . . . . . . . . . . . . . . . . . Cradle screws and washers

3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . USB stick

4 . . . . . . . . . . . . . . . . . . . . . FHR-35 Robotic pan and tilt head

5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 . . . . . . . . . . . . . . . . . . . . . Large cable management bracket

NI . . . . . . . . . . . . . . . . . .

NI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Quick Setup Guide

NI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cable ties x5

NI . . . . . 10-32 U x .625 in. pan head screws and washers x6

NI . . . . . . . . . . . . . M6 x 16 cap head screws and washers x4

NI . . . . . . . 3/8" BSW x 3/4" cap head screws and washers x2

NI = Not Illustrated

Tools required

®

Pozidriv PZ-1 screwdriver

®

Torx T10 screwdriver

Installation and Configuration Guide

Ethernet cable

Installation and Configuration Guide

4 mm Allen key

5 mm Allen key

5/16" Allen key

5/32" Allen key

Torque screwdriver

5

FHR-35 Pan and Tilt HeadRobotic

NO.

MOUNTING

SUPPORT OR

ADAPTOR

PART NO.

MOUNT

OPTION

1

VMA plate

AM-VMA-105

HD tripod

2

Wall mounting

bracket

AM-WBKT-102

Wall

3

Ceiling mounting

bracket

AM-CEIL-102

Ceiling

4

Adaptor with

Quickfix groove

V4096-1013

Pozi Loc tripod

HD tripod

5

Quickfix adaptor

3490-3

HD tripod

6

Radamec

adaptor column

196-728-0044

Ceiling

Pozi Loc tripod

7

150 mm bowl

adaptor

3104-3

Pozi Loc tripod

8

Quickfix 150 mm

bowl adaptor

3143-3

Pozi Loc tripod

Installation

Mounting Supports and Adaptors

Installation and Configuration Guide

6

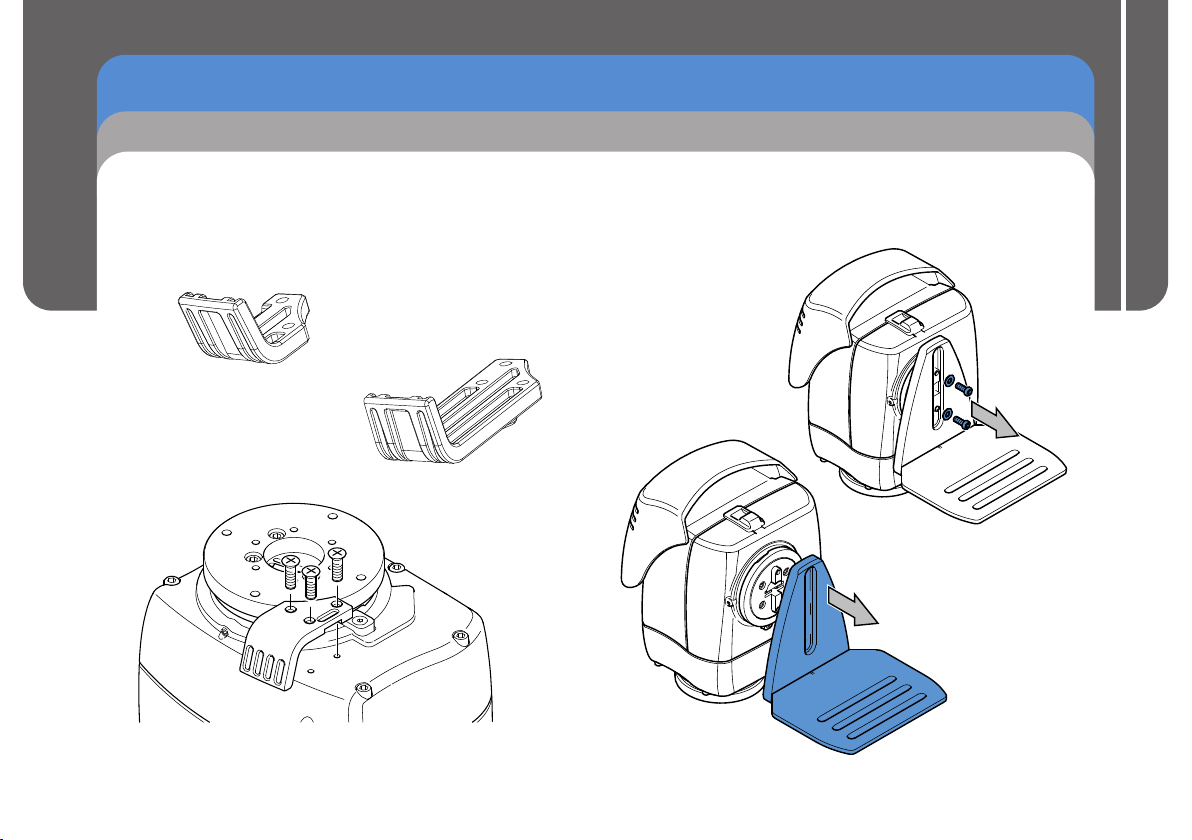

FHR-35 Pan and Tilt HeadRobotic

Installation

Cable Management Brackets

The FHR-35 is supplied with a cable management bracket fitted

to the base. Camera and head connecting cables can be neatly

secured to the bracket providing strain relief for the connectors.

Depending on the camera and head setup, the larger cable

management bracket can be fitted.

V4096-2075

Supplied fitted

to the head

V4096-2082

Removing the Camera Cradle

The first step in installing the head is to set the mechanical

hard stops to limit the movement of the head about the pan and

tilt axes. To set these limits, the camera cradle must be

removed.

Using a 4 mm Allen

1.

key,

remove the two

screws and washers

securing the camera

cradle.

2. Pull the camera

cradle away from

the mounting

tilt

plate.

Installation and Configuration Guide

7

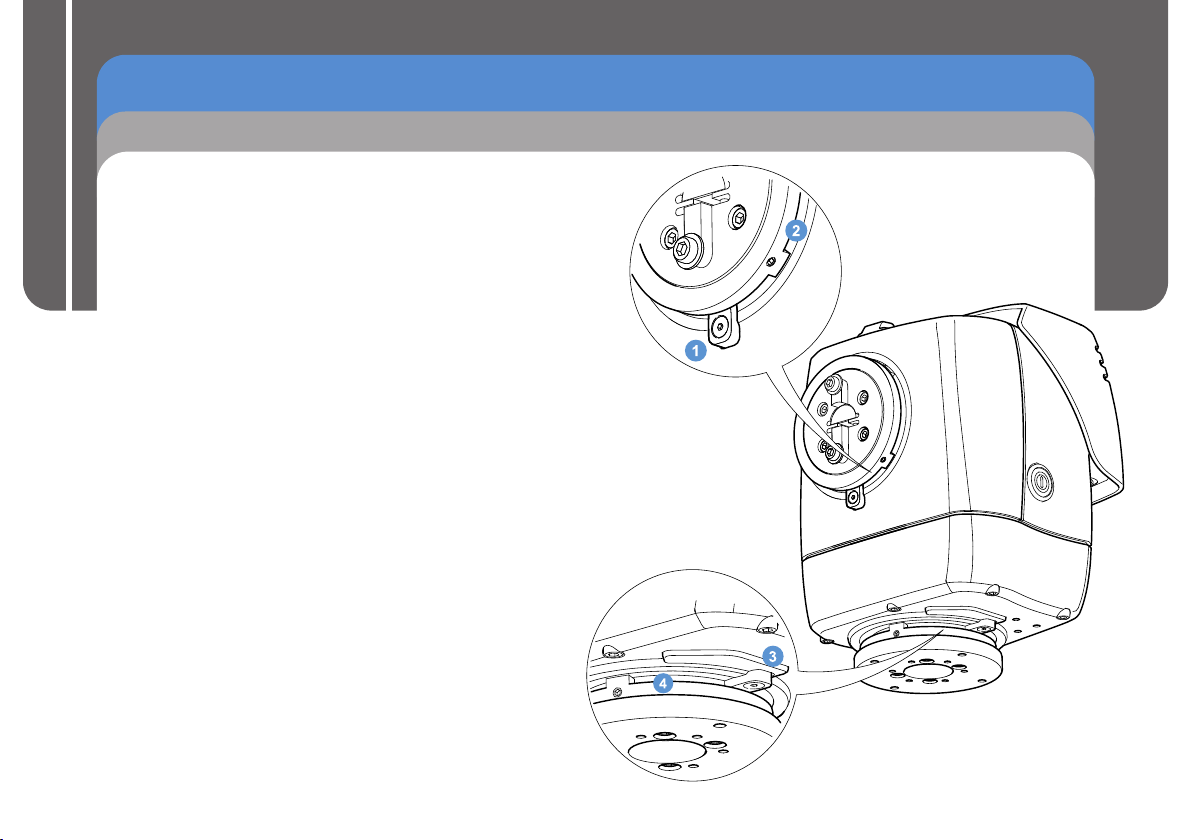

FHR-35 Pan and Tilt HeadRobotic

Installation

Setting the Pan and Tilt Mechanical Hard Stops

The FHR-35 is fitted with adjustable

that safely restrict the range of movement about the pan and

tilt axes. The pan and tilt mountings have a fixed stop and

two adjustable stop rings that are locked at the required

maximum and minimum limits of movement.

Installation and Configuration Guide

Setting the pan and tilt mechanical hard stops ensures that:

- The head and payload cannot collide with any fixed objects

within the working robotic footprint of the head.

- The payload will not collide with the head or the mounting

bracket or support.

- Undesirable areas of the studio are kept out of shot.

When the mechanical hard stops are locked in position, the

head will not be able to drive beyond them. However, the

head is still able to drive and collide into the mechanical

hard stops. To prevent this, soft limits are programmed into

the head at points within the range of the mechanical hard

stops. This eliminates the risk of constant collision with the

mechanical hard stops, and also restricts the head’s

movement range further whenever necessary. See the

section Setting the Zero Position and Soft Limits for

more details.

mechanical hard stops

1.......................

2.......................

3......................

4......................

Tilt fixed stop

Tilt stop rings

Pan fixed stop

Pan stop rings

8

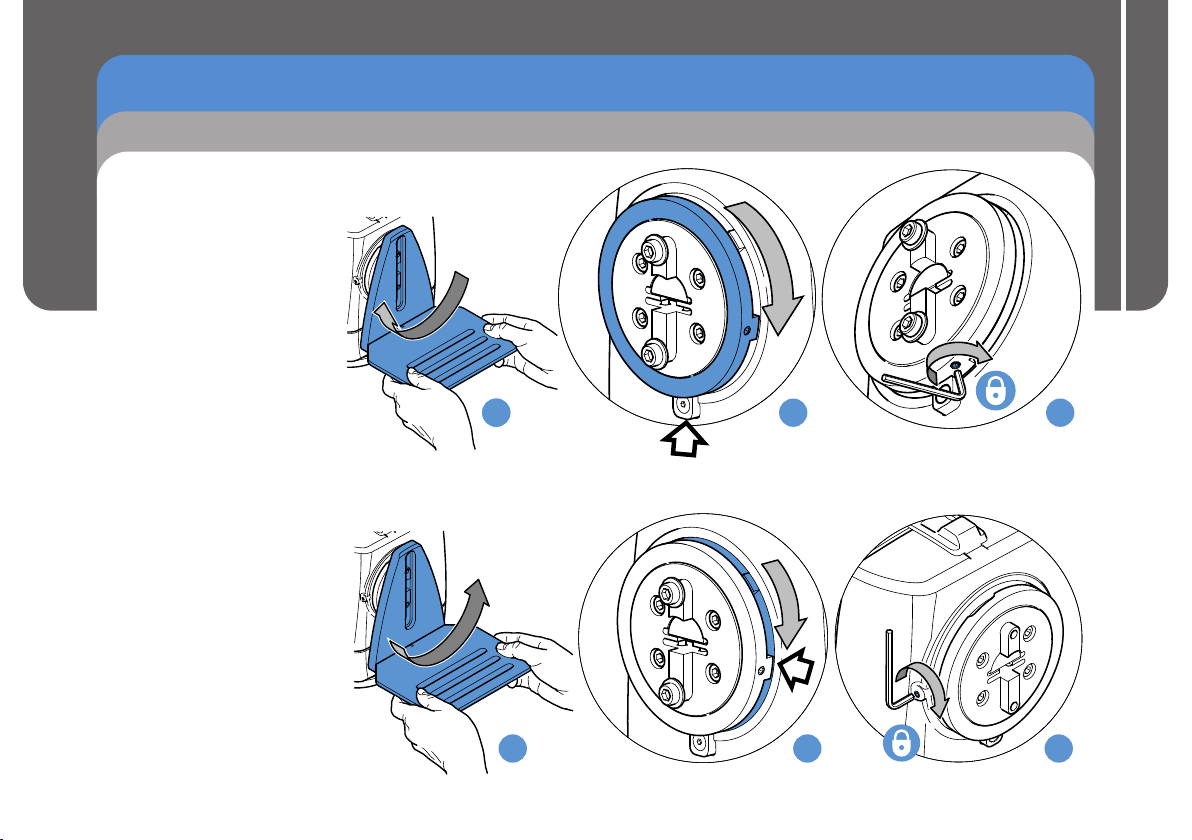

1.(a) Place the camera cradle

over the tilt mounting.

Move the tilt mounting in

a clockwise direction to

the required maximum

limit of movement.

(b) Remove the camera

cradle. Move the large

outer ring clockwise until

it rests on the fixed stop.

(c) Secure the grub screw

into position using a

2.5 mm Allen key. Tighten

the screw to a minimum

of 1.5 Nm (13.3 lbf-in.).

2.(a) Place the camera cradle

over the tilt mounting.

Move the tilt mounting in a

counterclockwise direction

to the required minimum

limit of movement.

(b) Remove the camera

cradle. Move the inner ring

clockwise until it rests on

the large outer ring stop.

(c) Secure the grub screw into

position using a 2.5 mm

Allen key. Tighten the

screw to a minimum of

1.5 Nm (13.3 lbf-in.).

FHR-35 Pan and Tilt HeadRobotic

Installation

Setting the Tilt Mechanical Hard Stops

Installation and Configuration Guide

a

a

a

b

b

c

c

9

FHR-35 Pan and Tilt HeadRobotic

Installation

Setting the Pan Mechanical Hard Stops

3.(a) Move the pan mounting

in a counterclockwise

direction to the required

minimum limit of

movement.

Installation and Configuration Guide

10

(b) Move the large outer ring

counterclockwise until it

rests on the fixed stop.

(c) Secure the grub screw

into position using a

2.5 mm Allen key. Tighten

the screw to a minimum

of 1.5 Nm (13.3 lbf-in.).

4.(a) Move the pan mounting

in a clockwise direction

to the required

maximum limit of

movement.

(b) Move the inner ring

counterclockwise until it

rests on the outer ring

stop.

(c) Secure the grub screw

into position using a

2.5 mm Allen key.

Tighten the screw to a

minimum of 1.5 Nm

(13.3 lbf-in.).

FHR-35 Robotic Pan and Tilt Head

a

a

b

b

c

c

FHR-35 Pan and Tilt HeadRobotic

Installation

Ceiling Mounting

The FHR-35 can be mounted to the ceiling using either a

column mount (part no. 196-728-0044) or a bracket (part no.

AM-CEIL-102). When mounting the head to a ceiling support,

the camera cradle must be inverted.

1. Refit the camera cradle to the tilt

mounting in an inverted orientation.

Using a 4 mm Allen key, secure in

position using the two screws and

washers.

2. Mount the head to the ceiling bracket or column.

Radamec Adaptor Column

(196-728-0044)

Using a 5 mm Allen key, attach

the head to the column mounting

using the four M6 cap head

screws and washers provided.

Ceiling Mounting Bracket

(AM-CEIL- )102

Using a 5/16" Allen key,

ttach the head to the ceiling

a

mounting bracket

six 10-32 cap head screws

and washers provided.

Installation and Configuration Guide

using the

11

FHR-35 Pan and Tilt HeadRobotic

Installation

Wall Mounting

The FHR-35 can be mounted to a wall using the wall mounting

bracket (part no. 196-728-0044). When mounting the head to

the wall, the cradle is fitted to the head in the standard position.

Installation and Configuration Guide

12

1. Fit the camera cradle to the tilt

mounting in the standard

positioning. Using a 4 mm

Allen key, secure in position

using the two screws and

washers.

User Guide

2. Using a 5/16" Allen key,

attach the head to the

wall mounting bracket

using the six 10-32 cap

head screws and

washers provided.

FHR-35 Pan and Tilt HeadRobotic

Pozi Loc Tripod Mounting Options

Installation

The FHR-35 can be mounted onto the following Pozi Loc tripods:

- Vinten two-stage aluminium EFP Pozi Loc tripod (part no. V4086-0001).

- Vinten two-stage carbon fibre EFP Pozi Loc tripod (part no. 3881-3).

When mounting the head to the tripod, the cradle is fitted to the head in

the standard position.

1. Fit the camera cradle to the tilt

mounting in the standard positioning.

Using a 4 mm Allen key, secure in

position using the two screws and

washers.

2. Mount the head to the Pozi Loc tripod using

one of the following three mounting options.

Radamec Adaptor Column

(196-728-0044)

Using a 5 mm Allen key, attach

the Radamec adaptor column

to the head using the four M6

screws and washers provided.

Mount onto the tripod using the

150 mm bowl adaptor.

Installation and Configuration Guide

13

FHR-35 Pan and Tilt HeadRobotic

Installation

Pozi Loc Tripod Mounting Options

Adaptor with Quickfix

Groove (V4096-1013)

Using a 5 mm Allen key, attach the

adaptor with Quickfix groove to the head

using the four M6 screws and washers

Installation and Configuration Guide

provided. Mount onto the tripod using

either the 150 mm bowl adaptor or the

Quickfix 150 mm bowl adaptor.

3104-3

150 mm bowl

adaptor

V4096-1013 Adaptor with

Quickfix groove

3143-3

bowl adaptor

Quickfix 150 mm

14

FHR-35 Pan and Tilt HeadRobotic

HD Tripod Mounting Options

Installation

The FHR-35 can be mounted onto the following heavy-duty

(HD) tripods:

- Vinten HDT-1 single-stage tripod (part no. 3901-3).

- Vinten HDT-2 two-stage tripod (part no. 3902-3).

When mounting the head to the tripod, the cradle is fitted to the

head in the standard position.

1. Fit the camera cradle to the tilt

mounting in the standard

positioning. Using a 4 mm Allen

key, secure in position using the

two screws and washers.

2. Mount the head to the HD tripod using one of

the following three mounting options.

Radamec Adaptor Column

(196-728-0044)

Using a 5 mm Allen key, attach the Radamec adaptor

column to the head using the four M6 screws and washers

provided. Attach the head and column onto the tripod

using the four bolts retained underneath the tripod mount.

Installation and Configuration Guide

15

FHR-35 Pan and Tilt HeadRobotic

Installation

HD Tripod Mounting Options

VMA Plate (AM-VMA-105)

Using a 5/16" Allen key, attach the

VMA plate to the head using the

six 10-32 screws provided. The

head can then be directly

Installation and Configuration Guide

mounted on the tripod.

Adaptor with Quickfix Groove (V4096-1013)

Using a 5 mm Allen key, attach the

adaptor with Quickfix groove to the

head using the four M6 screws and

washers provided. Mount onto the

tripod with a Quickfix adaptor.

16

FHR-35 Pan and Tilt HeadRobotic

Installation

Locking/Unlocking the Camera Cradle

Before installing or adjusting the camera or payload, the tilt lock

must be engaged. The tilt lock the camera

cradle in the horizontal position, to provide a stable platform

when making adjustments. The tilt lock is operated by a slider

button located on the top of the head.

Slide button back to

disengage tilt lock

Unlocked

Note: The tilt lock only operates when

the camera cradle is in the

horizontal position.

mechanism holds

Slide button forward

to engage tilt lock

Locked

1. Using a 4 mm Allen

key, loosen the two

screws securing the

camera cradle

enough to slide the

camera cradle to its

lowest position.

Secure in position

using the two screws.

Mounting the Camera

Installation and Configuration Guide

2. Carefully position

the camera onto

the cradle. Align the

mounting holes in

the bottom of the

camera with one of

the slots on the

cradle. Fit the two

screws and tighten

to secure the

camera in position.

17

FHR-35 Pan and Tilt HeadRobotic

Installation

Balancing the Head

The FHR-35 is designed to allow the camera and payload to

swing about its own Centre of Gravity (C of G), as opposed to

balancing with the use of springs or cams. The camera and

payload are mounted onto the camera cradle so the resulting

C of G aligns with the tilt-axis pivot point, providing true

balance.

Installation and Configuration Guide

When the head is correctly balanced, the robotic drives will

need the minimum amount of effort to move the head. A

correctly balanced head and payload can be set to any tilt

position and the head will maintain that position ‘hands off’.

Setting the Fore/Aft Balance

Ensure that the head and camera cradle are level before

balancing. The camera and payload should be fitted on the

cradle so that the load is balanced. This can be achieved by

moving the camera forwards (Fore) or backwards (Aft) on the

cradle.

CAUTION! Risk of damage to equipment. Be prepared

to prevent the camera and cradle from falling away

suddenly.

1. Engage the tilt lock. Loosen the bolts securing the camera to

the cradle just enough to be able to slide the camera and

payload backwards and forwards.

2. Hold and steady the camera cradle, and disengage the tilt

lock. Carefully release the camera cradle and observe how it

moves and where it stops.

If the camera cradle stops in a horizontal position (camera

pointing directly forward) the balance is correct.

If the camera cradle tilts forward (points downwards) then the

camera must be moved towards the rear of the head (aft).

18

FHR-35 Pan and Tilt HeadRobotic

Installation

Balancing the Head

If the camera cradle tilts backwards (points upward) then the

camera must be moved towards the front of the head (fore).

3. Reposition the camera as required on the camera cradle and

secure in position. The horizontal balance is correct when

the camera cradle comes to rest in a horizontal position.

4. Tighten the bolts securing the camera to the cradle and

recheck the horizontal balance. Readjust if necessary.

Note: If the camera has to be moved too far fore or aft to

balance the head, you can remove the camera cradle

base plate and refit it, using two screws, 50 mm further

in the required direction.

Adjusting the Centre of Gravity (C of G)

CAUTION! Risk of damage to equipment. Be prepared

to prevent the camera and camera cradle from falling

away suddenly.

Installation and Configuration Guide

1. Tilt the camera approximately 30° upward and release it.

If the camera stays in the same position when released, the

payload is properly balanced with the C of G on the tilt axis.

If the camera continues to move upwards after releasing the

camera cradle, the payload is mounted too high—lower the

camera cradle.

19

FHR-35 Pan and Tilt HeadRobotic

Installation

Balancing the Head

If the camera moves back towards the horizontal position when

released, the payload is mounted too low—raise the camera

cradle.

Installation and Configuration Guide

2. Tilt the camera cradle through positive and negative angles

of travel, checking that the head remains at the angle of tilt it

is set to, unsupported.

If the camera cradle angle falls or rises, repeat the alignment

procedure until balance is achieved.

3. After adjusting the C of G height it may be necessary to

check that the fore and aft balance remains satisfactory.

Readjust the position of the camera horizontally on the

camera cradle as required.

4. After balancing, exercise the head through both axes to

confirm that it operates smoothly.

Electrical Connections

CAUTION! Connect the head to the power source using

the attached power cable only. Ethernet cables must be

rated at Cat5e with screened RJ45 connectors.

WARNING! The IEC connector is the primary

disconnect device and must be accessible both during

and after installation of the product.

1. Connect the lens interface

cable to the lens interface

connector on the FHR-35.

2. Connect the

power cable

and the

Ethernet cable.

20

FHR-35 Pan and Tilt HeadRobotic

Installation

Cable Management

To ensure a safe and tidy installation, all of the cables connected

to the head can be secured neatly using the cable management

bracket. Depending on the type of head mounting, the cables can

also be secured to the tripod leg or mounting bracket using the

cable ties provided.

CAUTION! Leave sufficient slack in the cables between

the fixed mounting and the head for free and full range

of movement.

CAUTION! Cables must be secured to the cable

management bracket when head is mounted to a tripod.

Ceiling mounted

Powering Up

WARNING! Ensure that all personnel are clear from

the robotic equipment before powering up.

CAUTION! Disengage tilt lock before powering up.

Before powering up the head, ensure that all external cable

connections have been secured correctly.

To power up, press the power button located on the side of the

head. The head will not move when powered up, but zoom and

focus servos on the camera will take up their default positions

on analogue lenses.

The LEDs located at the rear of the head, indicate that data

communications (green LED) and a genlock signal (amber

LED) is present.

If the LEDs do not illuminate on power up, refer to the

Troubleshooting section of this manual.

Installation and Configuration Guide

Tripod or wall mount

21

FHR-35 Pan and Tilt HeadRobotic

ICE Tool

ICE Tool Installation

The USB stick provided with the FHR-35 contains a software

utility called ICE Tool. When installed onto a controller

, ICE Tool can be used to change configuration settings in

laptop

the head and setup the soft limits.

Installation and Configuration Guide

CAUTION! Risk of product damage. Soft limits must be

set inside the range set for the hard limits.

Installing ICE Tool

ICE Tool can be installed and run on either the Windows XP or

Windows 7 operating systems.

®

1. Insert the USB stick into the PC and view the contents.

2. Double-click on the ICE Tool Windows Installer icon to

launch ICE Tool Wizard Setup.

3. Click Next and tick to accept the license agreement.

4. Click Next and select a location for the program to install to

(the default location Program Files\Vinten Radamec\Ice

Tool\ is recommended).

5. Click Next for the software to automatically install.

6. Click Finish to exit the Install Wizard.

PC or

®

Using ICE Tool

1. To run the configuration software:

a) Double-click the ICE Tool icon to display the login

dialog box.

b) Select Customer Mode from the drop-down menu and

click Continue to display the ICE Tool window.

ICE Tool Login

Select User Mode

Customer Mode

Continue

Exit

2. Add the FHR-35 to the System tree:

a) Expand the Available Hosts tree

structure.

b) Expand the FHR35 folder, to list all

the available heads.

c) Double-click the Host ID of the

required head to load it onto the

System tree.

22

FHR-35 Pan and Tilt HeadRobotic

ICE Tool

Using ICE Tool

3. Display the Configuration window for the required head:

a) Expand the System tree structure.

b) Expand the FHR35 folder, to list all added heads.

c) Expand the Host ID of the required head.

d) Double-click the Head component to open the

Configuration window for the selected FHR-35 head.

Setting the Zero Position and Soft Limits

In the Configuration window, the zero point position and the

soft limits can be set or changed. The head can be manually

moved to the required minimum and maximum positions and

the values stored by the software. (in degrees)

If the head is mounted in an inaccessible location, such as

ceiling or wall mounted, where manually moving the head is not

possible, the pan and tilt position values can be entered into the

pan and tilt fields.

Setting the Zero Position

Setting a zero reference position before setting the soft limits

will make the configuration of the head easier. The zero

reference position for the tilt axis is, by default, when the

camera cradle is in the horizontal position (tilt lock engaged).

1. Manually move the head about the pan and tilt axes to

approximately the mid- points within the set hard limits.

range

2. Click the Set Zero button to store this position as zero

degrees in pan and tilt.

3. Click Apply to .send and store the settings in the head

Installation and Configuration Guide

23

FHR-35 Pan and Tilt HeadRobotic

ICE Tool

Soft Limits

Setting the pan and tilt soft limits

CAUTION! Risk of product damage. Soft limits must be

set inside the range set for the hard limits.

Installation and Configuration Guide

There are two methods for setting the soft limits, depending on

the accessibility of the mounting installation.

Accessible (or Manual) Mounting

1.

Move the pan mechanism to the required minimum

and click the Set Min button to store the value.

2. Move the pan mechanism to the required maximum position

and click the Set Max button.

epeat steps 1 and 2 to set the tilt axis minimum and

3.

R

maximum limits.

4.

Click Apply to send and store the settings in the head.

Inaccessible Mounting (Wall or Ceiling)

Enter a minimum

1.

Limits boxes and click the Set Min button to store the value.

Enter a maximum

2. soft limit value in the pan and tilt Max

Limits boxes and click the Set Max button.

Click Apply to send and store the settings in the head.

3.

soft limit value in the pan and tilt Min

position

Setting the zoom and focus soft limits

Minimum and maximum soft limits can also be set for the lens

focus and zoom. Units represent 0–100% of the full range for

each setting.

1. Set the lens to the required minimum zoom setting and click

the Set Min button to store the value.

2. Set the lens to the required maximum zoom setting and click

the Set Max button to store the value.

3. Repeat steps 1 and 2 to set limits for the focus.

4. Click Apply to send and store the settings in the head.

24

Configuration Settings

Key settings can also be changed in the Configuration

window:

Normalise Invert Axes

Select if the head is mounted upside down from

the ceiling. Pan and tilt axes are reversed to

give standard control on an inverted mount.

Enable Zoom Proportional

Select to enable the speed of pan and tilt

movement to be proportional to the zoom angle

(zoomed in slower and zoomed out faster).

Axes Invert

Pan Tilt

Zoom

Focus

Selecting a checkbox reverses

the direction of the axis when

controlled using a joystick.

FHR-35 Pan and Tilt HeadRobotic

ICE Tool

Installation and Configuration Guide

Lens Type

Select the applicable lens type

option from the drop-down menu.

25

FHR-35 Pan and Tilt HeadRobotic

Maintenance

Regular Checks

Routine Use

During use, check the following:

Once a month check the balance of the camera and

Ÿ

Installation and Configuration Guide

payload and adjust if necessary.

No further routine maintenance is required.

Cleaning

WARNING! Disconnect and isolate the product

from the power supply before cleaning.

We encourage regular cleaning of the product. During normal

use the only cleaning required should be a regular wipe over

with a lint-free cloth. External electrical connection ports should

only be cleaned with a vacuum cleaner.

Cover the head when not in use. Dirt accumulated during

storage or periods of non-use may be removed with a vacuum

cleaner.

26

Fault

Check

Action

Power supplied, but the camera cradle is

not moving.

Check that the tilt lock is disengaged.

See Locking/unlocking the Camera

Cradle

Head not operating.

Check that the power switch is ON.

See Powering up

Ensure that the power and Ethernet

cables are connected and secure.

See Electrical Connections

Check mains power supply to head.

Check that power is being supplied from

the pedestal, height drive or studio

supply.

Camera and payload moving too far on

the pan and/or tilt axis.

Check the setting of the hard and soft

limits.

See Setting the Pan and Tilt Hard

Limit Stops

and

Setting Pan and Tilt Soft Limits

Intermittent or no communications

Check Ethernet cable.

Check the Ethernet cable is CAT5E FTP.

If possible, try using another Ethernet

cable.

FHR-35 Pan and Tilt HeadRobotic

Troubleshooting

Installation and Configuration Guide

27

FHR-35 Pan and Tilt HeadRobotic

General Notices

Parts List

Mounting supports and adaptors

Vinten 4-bolt adaptor (with Quickfix® groove) . . . . V4096-1013

VMA plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AM-VMA-105

Radamec adaptor column 196-728-0044

Installation and Configuration Guide

Autocam ceiling mounting bracket. . . . . . . . . . . . . AM-CEIL-102

Autocam wall mounting bracket . . . . . . . . . . . . . AM-WBKT-102

Vinten 4-bolt to 150 mm bowl adaptor . . . . . . . . . . . . . . . 3104-3

Vinten Quickfix 150 mm bowl adaptor . . . . . . . . . . . . . . 3143-3

Vinten HD Quickfix adaptor . . . . . . . . . . . . . . . . . . . . . . 3490-3

Vinten two-stage aluminium EFP Pozi Loc tripod V4086-0001

Vinten two-stage carbon fibre EFP Pozi Loc tripod 3881-3

Vinten HDT-1 single-stage tripod 3901-3

Vinten HDT-2 two-stage tripod 3902-3

®

. . . . . . . . . . . . . . . . . .

®

User-replaceable parts

Mounting kit

(incl. cable management brackets) . . . . . . . . . . . . . V4096-1905

. .

. . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Specification

Physical data

Weight (with cradle) . . . . . . . . . . . . . . . . . . . . . . . . . 8 kg (18 lb)

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247.4 mm (9.7 in.)

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323.5 mm (12.7 in.)

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193.5 mm (7.6 in.)

Maximum payload . . . . . . . . . . . . . . . . . . . . . . . . . 16 kg (35 lb)

Operating data

Operating temperature range . . 0°C to +50°C (+32°F to +122°F)

Motor noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Minimal

Tilt range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±90°

Pan range, max. (with mechanical end stops set) . . . . . . . 319°

Angular velocity (max) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60°/s

Angular acceleration (typical) . . . . . . . . . . . . . . . . . . . . . . 60°/s

Angular acceleration (peak) . . . . . . . . . . . . . . . . . . . . . . 120°/s

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 arcseconds

Robotic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full

Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . None

Electrical data

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100W

Power input . . . . . . . . . . . Autoranging 100–240V AC, 50/60 Hz

2

2

28

FHR-35 Pan and Tilt HeadRobotic

General Notices

Compliance

Declaration of Conformity

Vitec Videocom

has been manufactured in accordance with BS EN

ISO 9001:2008 and is in compliance with the

essential requirements and other relevant provisions

of the Machinery Directive 2006/42/EC. A copy of the

Declaration of Conformity is available upon request.

Waste of Electrical and Electronic Equipment (WEEE)

Directive (2002/96/EC)

This symbol marked on the product or its packing

indicates that this product must not be disposed of

with general household waste. In some countries or

European Community regions, separate collection

systems have been set up to handle the recycling of

electrical and electronic waste products. By ensuring

this product is disposed of correctly you will help

prevent potentially negative consequences for the environment

and human health. The recycling of materials helps conserve

natural resources.

In countries outside the EU:

Dispose of this product at a collection point for the recycling of

electrical and electronic equipment according to your local

government regulations.

Visit our website for information on how to safely dispose of this

product and its packaging.

Limited declares that this product

RoHS Compliance Statement

Vitec Videocom Limited is compliant with the European Union

Directive 2002/95/EC (RoHS) that restricts the use of

hazardous substances in Electrical and Electronic Equipment.

The Restrictions of Hazardous Substances (RoHS directive).

Pollution Degree 2

This equipment is designed for operation in Pollution Degree 2

environments.

Installation and Configuration Guide

29

FHR-35 Pan and Tilt HeadRobotic

Pin No.

Description

Pin No.

Description

1

Not connected

14

Not connected

2

Aux GND

15

CCU TXD422

3

Aux +12V

16

CCU TXD232

4

Aux +12V

17

Not connected

5

Not connected

18

GP I/O 1

6

CCU RXD422

19

GND

7

CCU RXD232

20

Aux GND

8

GP I/O 3

21

Aux +12V

9

GP I/O 0

22

Not connected

10

GND23CCU TXD422

11

Aux GND

24

CCU RXD422

12

Aux GND

25

Not connected

13

Aux +12V

26

GP I/O 2

General Notices

Compliance

FCC Notice

This product complies with the limits for a Class B digital

Installation and Configuration Guide

device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful

interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may

cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one

or more of the following measures:

Ÿ Reorient or relocate the receiving antenna

Ÿ Increase separation between the equipment and receiver

Ÿ Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected

Ÿ Consult the dealer or an experienced radio/television

technician for assistance.

FCC Warning

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to

operate the equipment.

FCC Declaration of Conformity

This product complies with Part 15 of the FCC Rules,

Operation is subject to the following two conditions:

(1) This product may not cause harmful interference.

(2) This product must accept any interference received,

including interference that may cause undesired

operations.

FHR-35

V4096-0001

General Purpose Connector

The General Purpose Connector can be used to connect a

Camera Control Unit (CCU) or for switching and powering other

camera accessories. The pin outs of the connector are given in

the following table.

CAUTION: Total power drawn from the 12V pins of this

connector must NOT exceed 30W.

30

FHR-35 Pan and Tilt HeadRobotic

End User License Agreement

General Notices

IMPORTANT PLEASE READ THE TERMS AND CONDITIONS

OF THIS LICENSE AGREEMENT CAREFULLY BEFORE

CONTINUING WITH THIS PROGRAM INSTALL:

Vitec Videocom

legal agreement between you (either an individual or a single

entity) and Ltd for the Ltd

software product(s) identified above which may include

associated software components, media, printed materials, and

‘online’ or electronic documentation (‘SOFTWARE PRODUCT’).

By installing, copying, or otherwise using the SOFTWARE

PRODUCT, you agree to be bound by the terms of this EULA.

This license agreement represents the entire agreement

concerning the program between you and Ltd,

(referred to as ‘licenser’), and it supersedes any prior proposal,

representation, or understanding between the parties. If you do

not agree to the terms of this EULA, do not install or use the

SOFTWARE PRODUCT. The SOFTWARE PRODUCT is

protected by copyright laws and international copyright treaties,

as well as other intellectual property laws and treaties. The

SOFTWARE PRODUCT is licensed, not sold.

1. GRANT OF LICENSE.

The SOFTWARE PRODUCT is licensed as follows:

to install and use copies of the SOFTWARE PRODUCT on your

computer running a validly licensed copy of the operating

system for which the SOFTWARE PRODUCT was designed

[e.g. Windows 95, Windows NT, Windows 98, Windows 2000,

Windows 2003, Windows XP, Windows ME, Windows Vista].

Ltd End-User License Agreement (‘EULA’) is a

Vitec Videocom Vitec Videocom

Vitec Videocom

Vitec Videocom(a) Installation and Use. Ltd grants you the right

b) Backup Copies. You may also make copies of the

SOFTWARE PRODUCT as may be necessary for backup and

archival purposes.

2. DESCRIPTION OF OTHER RIGHTS AND LIMITATIONS.

(a) Maintenance of Copyright Notices. You must not remove or

alter any copyright notices on any and all copies of the

SOFTWARE PRODUCT.

(b) Distribution. You may not distribute registered copies of the

SOFTWARE PRODUCT to third parties.

(c) Prohibition on Reverse Engineering, Decompilation, and

Disassembly. You may not reverse engineer, decompile, or

disassemble the SOFTWARE PRODUCT, except and only to

the extent that such activity is expressly permitted by applicable

law notwithstanding this limitation.

d) Rental. You may not rent, lease, or lend the SOFTWARE

PRODUCT.

(e) Support Services. Ltd may provide you with

support services related to the SOFTWARE PRODUCT

(“Support Services”). Any supplemental software code provided

to you as part of the Support Services shall be considered part

of the SOFTWARE PRODUCT and subject to the terms and

conditions of this EULA.

(f) Compliance with Applicable Laws.You must comply with all

applicable laws regarding use of the SOFTWARE PRODUCT.

Vitec Videocom

Installation and Configuration Guide

31

FHR-35 Pan and Tilt HeadRobotic

General Notices

End User License Agreement

3. TERMINATION

Without prejudice to any other rights, Vitec Videocom Ltd may

terminate this EULA if you fail to comply with the terms and

conditions of this EULA. In such event, you must destroy all

copies of the SOFTWARE PRODUCT in your possession.

Installation and Configuration Guide

4. COPYRIGHT

All title, including but not limited to copyrights, in and to the

SOFTWARE PRODUCT and any copies thereof are owned by

Vitec Videocom Ltd or its suppliers. All title and intellectual

property rights in and to the content which may be accessed

through use of the SOFTWARE PRODUCT is the property of

the respective content owner and may be protected by

applicable copyright or other intellectual property laws and

treaties. This EULA grants you no rights to use such content. All

rights not expressly granted are reserved by Vitec Videocom

Ltd.

5. NO WARRANTIES

Vitec Videocom Ltd expressly disclaims any warranty for the

SOFTWARE PRODUCT. The SOFTWARE PRODUCT is

provided ‘As Is’ without any express or implied warranty of any

kind, including but not limited to any warranties of

merchantability, noninfringement, or fitness of a particular

purpose. Vitec Videocom Ltd does not warrant or assume

responsibility for the accuracy or completeness of any

information, text, graphics, links or other items contained within

the SOFTWARE PRODUCT.

Vitec Videocom Ltd makes no warranties respecting any harm

that may be caused by the transmission of a computer virus,

worm, time bomb, logic bomb, or other such computer program.

Vitec Videocom Ltd further expressly disclaims any warranty or

representation to Authorized Users or to any third party.

6. LIMITATION OF LIABILITY

In no event shall Ltd be liable for any damages

(including, without limitation, lost profits, business interruption,

or lost information) rising out of ‘Authorized Users’ use of or

inability to use the SOFTWARE PRODUCT, even if

Videocom

damages. In no event will Ltd be liable for loss

of data or for indirect, special, incidental, consequential

(including lost profit), or other damages based in contract, tort

or otherwise. Ltd shall have no liability with

respect to the content of the SOFTWARE PRODUCT or any

part thereof, including but not limited to errors or omissions

contained therein, libel, infringements of rights of publicity,

privacy, trademark rights, business interruption, personal injury,

loss of privacy, moral rights or the disclosure of confidential

information.

Vitec Videocom

Vitec

Ltd has been advised of the possibility of such

Vitec Videocom

Vitec Videocom

32

Publication No. V4096-4980/4

Vinten Radamec

A Vitec Group brand

Loading...

Loading...