Vinten Radamec AutoCam Multicontroller II User Manual

Multicontroller II

AutoCam™ Controller

Operation, Installation

And Maintenance

(pn AB-300100 for sn 82xxxx0010 - 082699)

i

Multicontroller II

Safety

IMPORTANT!: Read the Safety Section starting on page 1-2

before installing or using this equipment, or attempting any

adjustment or repair. This safety triangle is used in the manual to

indicate important information. Readthis information carefully to

avoid the risk of personal injury, injury to others, or damage to the equipment.

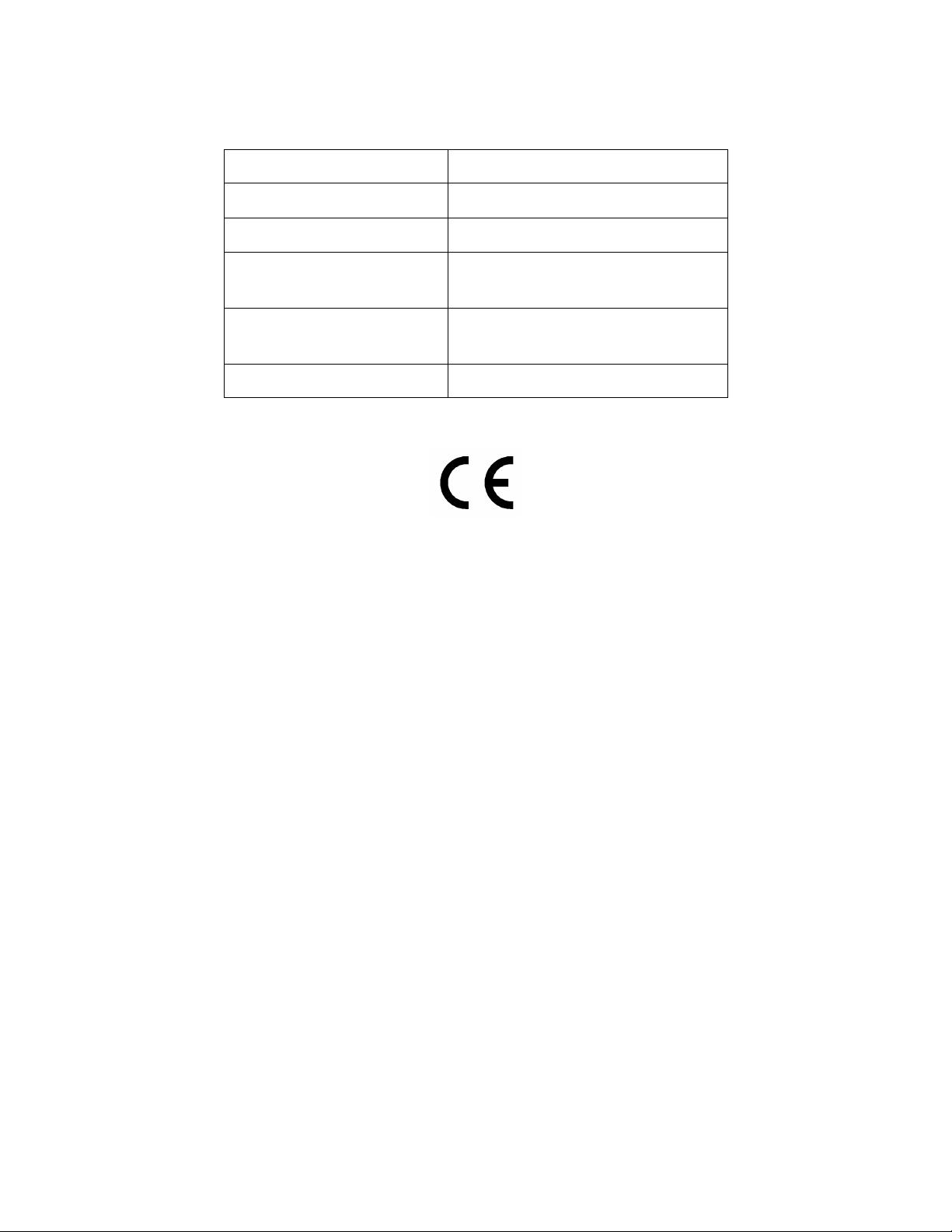

Warning Labels

Various colored safety labels are attached to the AutoCam equipment to alert you to

hazardous situations. The labels and their meaning are described below.

DANGER (with a red background) indicates an imminently

hazardous situation which, if not avoided, will result in death or serious injury.

WARNING (with an orange background) indicates a poten-

tially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION(withayellowbackground) indicates a potentially

hazardous situation which, if not avoided, may result in minor or moderate

injury.

CAUTION(with a yellow background, but without the Safety

Alert symbol) indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

ii

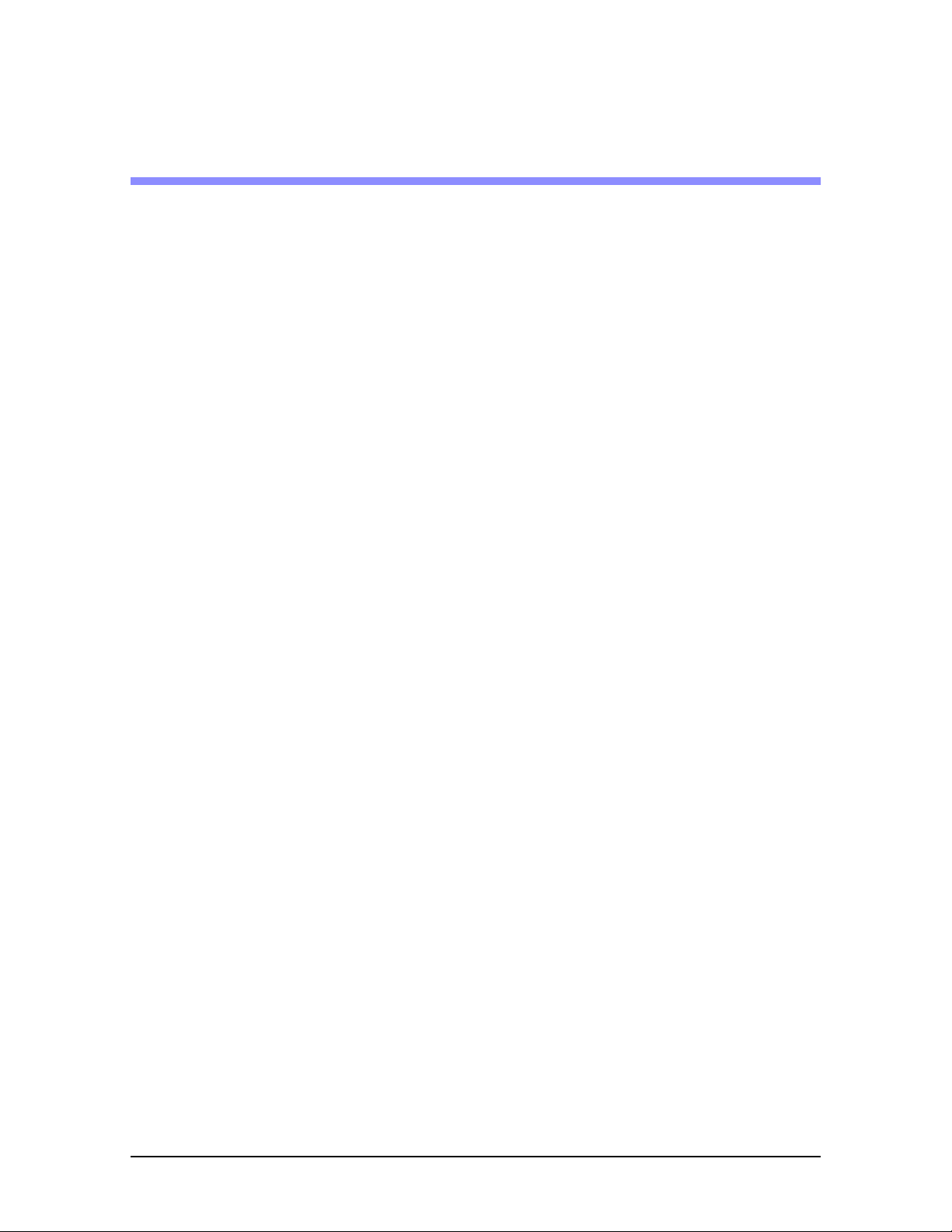

Critical Data For Multicontroller II

Mass (Weight) 11.0 lb (5.0 kg)

Maximum Load Not applicable

Maximum Pressure Not applicable

Input Voltage 100-250 VAC

47-63 Hz

Input Current 0.9 A at 110 V

0.45 A at 220 V

Date Of Manufacture 1999

iii

Technical Support

If you are based in North, South or Central America and need technical support on

the AutoCam system, contact Vinten Inc. at:

709 Executive Blvd.

Valley Cottage, NY 10989

USA

Phone:1-888 4 VINTEN (1-888-484-6836) - Toll free in the U.S.A.

+1 845-268-0100

Fax:+1 845-268-0113

Or, if you are based outside of North, South or Central America, contact Vinten

Broadcast Limited at:

West er n Wa y

Bury St. Edmunds

Suffolk IP33 3TB

ENGLAND

Phone: +44 (0) 284 752121

Fax: +44 (0) 284 750560

iv

Warranty

Vinten, Incorporated (Vinten) warrants that its equipment shall be free of defects in

material and workmanship for a period of twelve (12) months from the first date of

installation, but no more than eighteen (18) months from date of shipment, and is

extended only to the original purchaser. Vinten, at its option, will repair or replace

defective components. Warranty covers only those defects that occur when the equipment is used in the manner described in the Operation, Installation, and Service manual. Vinten’s liability is limited to parts, material, and labor necessary to repair or

replace equipment manufactured by Vinten. Any and all consequential damages are

excluded. Consumable supplies and normal wear items are the customer’s responsibility and are not covered by this warranty.

The warranty is in effect only when equipment is operated, adjusted, and maintained

in the manner described in the appropriate Operation, Installation, and Service manual. Modifications, service by non-authorized service personnel, failure to provide

proper maintenance, and abuse and misuse of the equipment will void the warranty.

Repairs not covered by this warranty will be billed for parts, labor, and expenses at

the rates in effect at the time of service.

Warranty service and repair will normally be performed at the Vinten factory in Valley Cottage, New York, but may, at the discretion of Vinten, be performed on the customer site. It is the customer’s responsibility to contact Vinten and obtain

authorization prior to returning equipment for warranty service. Returned equipment

must include a Return Material Authorization (RMA) number, and a failure report

describing the nature of the failure or complaint as well as the customer’s name,

address, and a contact name and phone number.

v

Copyright

The Vinten Inc. AutoCam User Manual is copyrighted with all rights reserved. Under

the copyright law, this manual may not be copied, in whole or in part, without written

consent from Vinten Inc.

© 1998, 1999 by Vinten Inc.

Disclosure Statement - AutoCam System

This document contains information proprietary to Vinten Inc. Except by written

authorization from Vinten Inc., the information contained in this document shall not,

in whole or in part, be disclosed to third parties, reproduced for any purpose, or used

except for evaluation, operation and maintenance of equipment supplied by Vinten

Inc. or Vinten Broadcast.

Manual Outline

This manual covers the installation, operation and maintenance of the AutoCam Multicontroller II. See Chapter 1 for a detailed description of the contents of this manual.

Product Serial Numbers

Vinten AutoCam products are marked with unique serial numbers that include a 2

digit product identifier, a 4 digit serial number and a 2 character revision code. The

format is AABBBBXXCD where:

AA Product Identifier - 82 for the MultiController II

BBBB Serial number

XX Reserved for future use - currently 00

C Primaryrevisionstatus-0,1,2,3etc.

D Secondary revision status - 0, A, B, C etc.

This manual is applicable to products that have serial numbers 82xxxx0010 where

xxxx may be any 4 digit number.

AutoCamTM,VintenInc.TMand Lubricated Friction (LFTM) are trademarks of

Vinten Inc. or Vinten Broadcast Limited.

Specifications and features are subject to change without prior notice.

(082699)

vi

Table Of Contents

Multicontroller II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Critical Data For Multicontroller II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Disclosure Statement - AutoCam System . . . . . . . . . . . . . . . . . . . . . . vi

Manual Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Product Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1 Safety & Introduction

Safety Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Very Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Customer Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Safe Working Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Safe Operating Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Warning Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Heads Can Start Unexpectedly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Power Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Pinch Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Sharp Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Manual Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

Typical System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

Data Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

Pan and Tilt Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

Tally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

Switcher Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

2 Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

The Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Mains Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

PTZ Joystick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Lens Focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Display Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

vii

Table Of Contents

Shot Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

On Shot LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Numeric Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Range Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Alt Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Framing Shots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Joystick Sense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Pan And Tilt Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Creating, Saving & Recalling Shots . . . . . . . . . . . . . . . . . . . . . . 2–8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Creating Shots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Recalling Shots And Making Transitions . . . . . . . . . . . . . . . . . . . . . . 2–9

Time 2–9

Move and Jump Transitions 2–9

Stopping A Move Or Jump 2–10

Trimming And Resaving A Shot 2–10

Multiple Moves 2–10

Exploring Moves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

Air-Time Philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Trimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Cueing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Command Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Turning Functions On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Function Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

3 Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

MultiController II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Tabletop Dimensions 3–4

Recessed Mounting 3–5

Grounding For CE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Electrical Installation And Interconnection . . . . . . . . . . . . . . . 3–8

Data Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–9

PS-4 Supply 3–9

PS-1 Supply 3–10

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

viii

Table Of Contents

Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

Tally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

Command Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–12

Powering And Configuring The System . . . . . . . . . . . . . . . . . . 3–14

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–14

Power Up Sequence 3–14

Head Type Cofiguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–16

Proportional/Fixed Speed 3–16

HS-102 3–16

HS-105 3–16

HS-2010 3–16

Configuring The Controller 3–17

Controller Range Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–18

Pan Limits 3–18

Tilt Limits 3–19

Joystick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–20

Joystick Centering 3–20

Joystick Speed 3–20

Joystick Deadband 3–20

4 Maintenance And Repair

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Electronics Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Service Philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

ix

Table Of Contents

This page left blank intentionally.

x

1 Safety & Introduction

User Manual 1-1

Multicontroller II Safety & Introduction

Safety Issues

Safety issues including important warnings, risks and related topics are covered

in this section of the manual. It is very important that this information be available to all personnel who will work on or near the Autocam equipment.

Very Important Information

1. To avoid personal injury, always exercise caution when working in the

vicinity of energized heads as they can start to move without any warning.

2. Unless it is impossible, you should always de-energize the head before

working on any part of the head, the camera/lens, or any associated equip-

ment.

Customer Responsibility

It is the customer’s responsibility to ensure that the workplace is safe. Make sure

that you comply with local safety requirements for owning and operating

robotic equipment. In normal operation, the remote controlled heads and payloads in an Autocam system can move suddenly and without warning. Since

audible warnings are out of the question in normal television applications, it is

recommended that only trained personnel be allowed to work in the active areas

where the remote controlled heads and payloads are located. As part of the training, personnel must be made aware of the hazards of working in a robot environment, including the specific hazards listed below. The forces are sufficient to

cause personal injury, or injury to others and therefore, caution is essential.

Safe Working Environment

Each of the remote control heads should be within the view of the operator of

the Autocam system at the Multicontroller II. Before and during remote operation, the operator must verify visually that the active area is clear. If personnel

are too close to one of the heads that is about to move, the operator can prevent

the motion from starting, or stop the motion after it has started.

If the direct line of sight is obstructed in your installation, it is recommended

that one or more viewing cameras are installed to cover the active areas and

allow the operator to view t he entire workspace at all times.

Safe Operating Zone

The safe operating zone for personnel is a minimum of 3 feet (1m) outside of the

footprint of the pan/tilt head. In most installations, the teleprompter (if installed)

is the piece of equipment mounted on the head that protrudes the furthest

beyond the base of the head. The footprint must take into account the overhang

of the teleprompter and/or other payload equipment as the head pans around.

If your operating practices require personnel to work less than 3 feet (1m) outside the footprint of the pan/tilt head, you must make sure that they are trained

and are aware of the hazards of working in a robot environment, including the

1-2 User Manual

Multicontroller II Safety & Introduction

specific hazards listed below. The forces are sufficient to cause personal injury,

or injury to others and therefore, caution is essential.

Warning Signs

Warning signs should be displayed prominently in the workplace as a reminder

to trained personnel, and a primary warning to untrained personnel and visitors.

A typical sign might read:

WARNING:

Robotic Heads & Cameras

Move Suddenly Without Warning

Heads Can Start Unexpectedly

The hazards associated with robotic camera systems are only slightly different

than those associated with operating a camera under conventional manual control. The speeds and camera weights are similar. The main difference is that

with automation, the operator is normally not near the cameras, and it is more

difficult to verify that the area is clear. For personnel working on or near the

equipment, they must be aware that the equipment can start moving unexpectedly.

All personnel should be trained and aware of the hazards of robotic heads, and

the fact that they can move at any time. They must be trained on how far the

heads and payloads can move, the speeds involved, and the need to stay back an

appropriate distance.

Most adjustments to the camera and head, such as tilt balancing and camera

video, should be made with the system de-energized. However, if adjustments

are absolutely necessary while the head is powered, they should only be made

by trained technical personnel familiar with the AutoCam robotics system. They

must understand that the camera can move unexpectedly at any time, and must

position themselves so that any motion would not cause them personal harm.

When the robotic heads move, the speeds involved are fairly slow. However, the

equipment is still capable of generating sufficient force to cause injury. Therefore, it essential that you exercise caution. In particular, be aware that the teleprompter is usually the fastest swinging element.

Any failure of the system could possibly cause one or more axes to move on

their own, but the speeds and forces should not be noticeably greater than those

encountered during normal use.

User Manual 1-3

Multicontroller II Safety & Introduction

Power Switches

For an emergency power down, make sure that all personnel are aware of the

location of the power switch on the power supplies (and heads if they have separate power switches).

Pinch Points

Particular care should be exercised around possible points where you could get

pinched, such as the tilt cradle. Here, the forces can be somewhat greater, due to

the short lever arm.

Sharp Edges

If the lens, teleprompter or other camera attachments have sharp edges that

could cause injury, make sure they are padded or protected.

1-4 User Manual

Multicontroller II Safety & Introduction

This page left blank intentionally.

User Manual 1-5

Multicontroller II Safety & Introduction

Manual Outline

Chapter 1 This chapter covers important safety issues

and gives an overview of the Multicontroller

II and the AutoCam system.

Chapter 2 Step by step instructions for operating the

Multicontroller II.

Chapter 3 Step by step instructions for installing and

configuring the Multicontroller II and associated equipment.

Chapter 4 Technical information including routine

maintenance, circuit descriptions, calibration, schematics and parts lists.

1-6 User Manual

Multicontroller II Safety & Introduction

This page left blank intentionally.

User Manual 1-7

Multicontroller II Safety & Introduction

Introduction

The Vinten Multicontroller II is a mid scale six head controller that combines

many of the latest features and performance enhancements from the top of the

line AutoCam systems while retaining the popular Multicontroller control panel

format. The Multicontroller II is ideally suited for most medium scale legislative

and broadcast applications such as city halls, compact studios and remote

trucks.

1-8 User Manual

Multicontroller II Safety & Introduction

Features

• Controls up to six AutoCam heads of mixed type and payload

from the HS-102P up to the HS-2010MH

• Stores 99 shots per head

• Control panel operation is easy to learn - head status is visible at a

glance

• Six kinematic co-processors allow unlimited simultaneous moves

• Software profiles all axes in Jumps as well as Moves

• On air confidence is enhanced by “on air” and “on stick” LED

indicators and automatic jump lockout

• Local clip settings and LED indicators prevent pan/tilt joystick

overrun

• Move times calibrated to 0.1 second accuracy

• Joystick speed can be constant or can track zoom angle

• Controls video router for automatic monitor switching (optional)

• Status indicators show condition of remotely controlled lighting,

heaters, wipers etc.

• Compact design available for flush mounting in a desk or in a

table top case

• Preprinted shot cards

• CE compliant design

User Manual 1-9

Loading...

Loading...