Page 1

Technical Data Manual

VITOTRONIC 100

Digital boiler control unit

for modulating temperature heating systems

Vitotronic 100

Model KW10B, Part No. 7834 238

Digital boiler control

With outdoor reset control

For heating systems with one modulating temperature

heating circuit (without mixing valve)

With analog boiler water temperature display

Integrated pump connections

Viessmann quick-connect plug-in system

OpenTherm functionality

5604 122 v1.0 07/2011

Certified as a component

part for Viessmann boilers

Page 2

Product Information

Vitotronic 100, KW10B Technical Data

The benefits at a glance:

digital boiler control

space heating circuit controlled by room thermostat

and outdoor reset logic

single-stage or two-stage boiler control

(depending on burner)

integrated diagnostic system

built-in boiler low temperature protection

short assembly time and start-up due to diagnostic

and wire terminals

digital boiler control:

- for single-boiler systems

- outdoor reset control

- for heating circuits without mixing valves

- for single-stage or two-stage burner

- with analog temperature display

- with integrated diagnostic system

Standard equipment:

Vitotronic 100, Model KW10B with;

adjustable fixed high limit

power supply cord

outdoor temperature sensor

boiler temperature sensor

DHW temperature sensor

120VAC boiler pump and DHW pump outputs

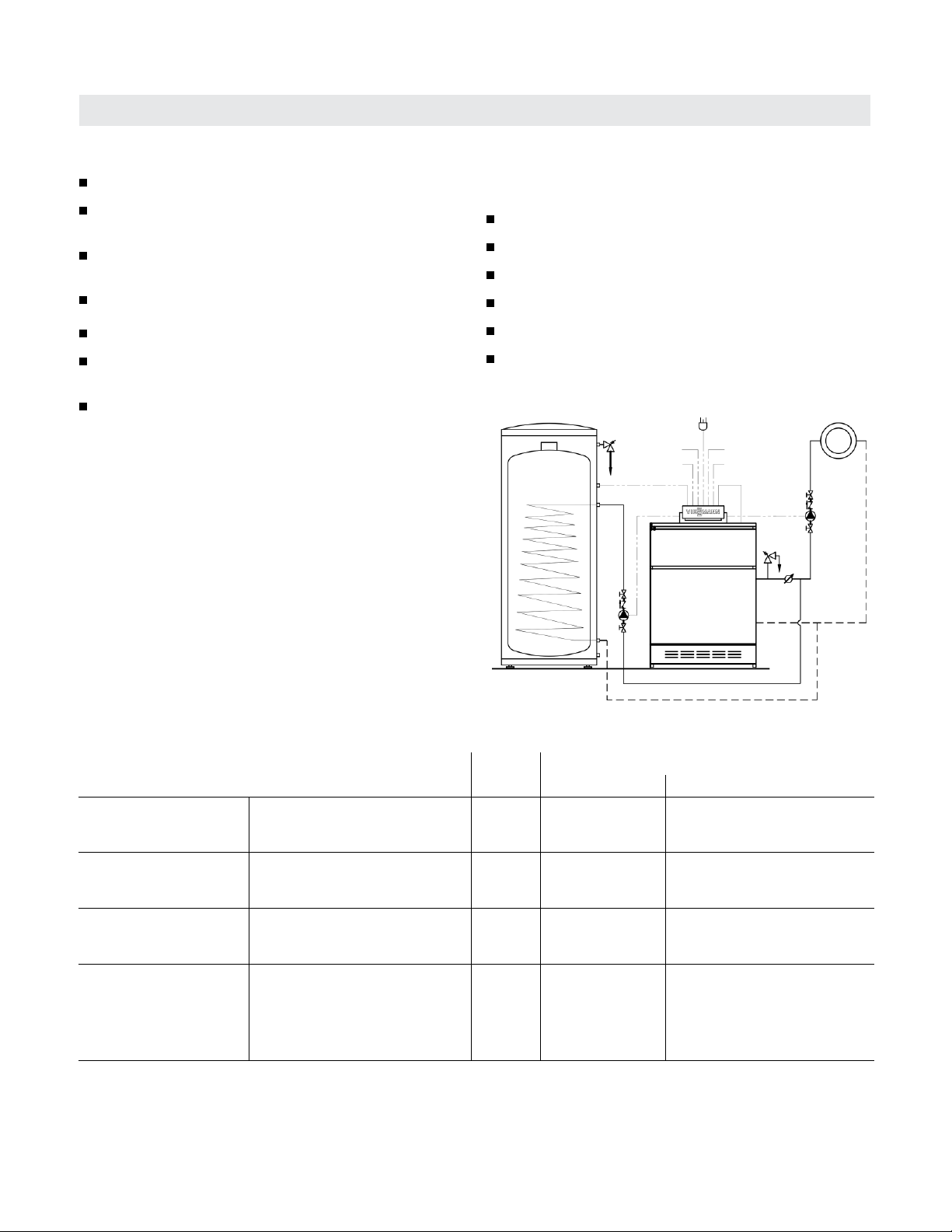

Application

In conjunction with the following Viessmann boiler

Boiler Model and Series

Oil-fired hot water

heating boiler with

power burner

Oil-/Gas-fired hot water

heating boiler with

power burner

Atmospheric gas-/

propane-fired hot water

heating boiler

Atmospheric gas-fired

hot water heating boiler

2

Vitorond 100 Oil 104º F (40º C)

Vitola 200 Oil/Gas

Vitogas 050, RS Series (single-/

two-stage)

Vitogas 100, GS1 Series,

up to 240 MBH/70 kW

Vitogas 100, GS10 Series,

up to 380 MBH/111 kW

Fuel Minimum boiler water temperature

without low limit with low limit (average temp.)

x

Gas 120º F (49º C)

Gas

Gas

104º F (40º C)

120º F (49º C)

5604 122 v1.0

Page 3

Vitotronic 100, KW10B Technical Data

Structure and Operation

Functionality Overview

- outdoor reset functionality with the ability to connect

to room thermostat demand type connection

- reset curve adjustments with rotary dial settings as

well as WWSD adjustments

- integrated DHW control and pump output adjustable

set point with rotary dial settings

- operational DHW settings with DIP switch settings;

- DHW priority

- DHW post purge time

- relay test functionality

pumps: DHW and boiler

burner: 1st and 2nd stage

alarm output

- LON addressing with rotary dial settings

- multi-boiler operation when used in conjunction with

Vitocontrol-S MW1 cascade control

- minimum boiler protection

- two stage burner operation

- compiled fault output (dry contact) and LED indicators

- 0-10VDC BMS set point control

Options

With optional OT thermostat via digital two wire

communication, providing local or remote user interface

- DHW set point adjustment and time scheduling

- outdoor reset adjustment and time scheduling

- slope, daytime/night time settings

- boiler status and temperature displayed on thermostat

- can be installed within living space or adjacent to boiler

Modular structure

The control unit consists of:

System ON/OFF switch, analog temperature display and

override switch.

- adjustable high limit (type RAK 51.1/3382, Mfg. Etheco

or type TR 97.55180.251, Mfg. EGO)

- fixed high limit (type RAK 75.4/3412, Mfg. Etheco

or type STW 56.10525.400, Mfg. EGO)

- electronic circuit board with power supply and

integrated outdoor reset function

- integrated diagnostic system (power, burner call and

fault indicators)

Boiler-specific functions

The Vitotronic 100 control unit controls the boiler

temperature according to heat demand input (room

thermostat connections) or the calculated outdoor reset

set point.

Boiler water temperature is limited through the adjustable

aquastat. Minimum boiler water temperature protection is

achieved with the built-in pump aquastat and the outdoor

reset control.

Electronic boiler control

- single boiler systems

- heating circuits without mixing valves

- single and two stage burners

- anolog temperature display

With optional LON communication module

- communications to Vitotronic 050, HK1M mixing valve

controls

- communications to Vitocontrol-S, MW1 cascade control

- enables connection with extension output module

- BACnet communications utilizing Versatronik 505,

BACIP

5604 122 v1.0

3

Page 4

Structure and Operation (continued)

Heating curve

BOILER TEMPERATURE

Vitotronic 100, KW10B Technical Data

OUTDOOR TEMPERATUIRE

Technical data

Power: 120 VAC, 1 Phase, 60 Hz, 15A pre-fuse

Burner switching capacity: 120 VAC, 2.5A (full load)

Room thermostat: 24 VAC

Anticipator setting: 0.1 A

Fixed high limit: 230° F (110° C) max. (fixed)

Adjustable high limit: 167° F to 239° F max.

(75° C to 115° C) max. (adjustable)

Boiler & DHW Pump output: 120 VAC, 1 Phase, 60 Hz,

3A (full load)

Outdoor temperature sensor: 5k Ohms at 77° F (25° C)

max. wire length up to

95 ft. (35 m)

Boiler temperature sensor: 10K

DHW temperature sensor: 10K

Main fuse: 6.3A

Main pump output fuse: 6.25A

Certification: CSA certified in conjunction with Viessmann

boilers

4

5604 122 v1.0

Page 5

Vitotronic 100, KW10B Technical Data

Features

Function Description KW10B KK10 KW10 KK10LON

120VAC Power connection Control Power

Boiler Pump 120V output for boiler pump

DHW Pump 120V output for DHW pump

Burner connection Harness connection for burner

Low Water Cut-off Powers LWCO device

Outdoor Temperature Sensor 5K ohm sensor

Boiler Temperature Sensor 10K ohm sensor

DHW Temperature Sensor 10K ohm sensor

TT Stage 1 Call for heat first stage

TT Stage 2 Call for heat second stage

OpenTherm Communication OT connection for OT enabled room

thermostat/device

Fault Output Compiled Fault Indication Dry Contact

0-10VDC Input/Ext Demand Coded function either 0-10VDC or

external demand

Lon Communications Daisy-chained LON connection when

optional LON board installed

Override Switch Mounted on face of control

Diagnostic LED Sensor Flash Flash based on sensor issue

Power Switch

Pump Aquastat min. temp. control

Electronic minimum temperature control

External pump module

Integrated pump boiler and DHW pump

connection

Relay Test

Selectable boiler pump operation based

on TT demand or continuous operation

Electronic DHW set point control

DHW Priority Override Timer With TT demands only

Front Panel mounted AHL and FHL

Front panel mounted analog

temperature gauge

All relays with sockets with locking tabs

Field replaceable motherboard no hardwired PCB connections

Second Stage Second stage burner demand*

5604 122 v1.0

5

Page 6

Vitotronic 100, KW10B Technical Data

Connections

Function Connection Description

120VAC power connection 40 control power

Boiler pump 20 120VAC output for boiler pump

DHW pump 21 120VAC output for DHW pump

Burner connection 41 harness connection for burner

Second stage 191 second stage burner demand

Low water cut-off LWCO powers LWCO device

Outdoor temperature sensor 1 5K ohm sensor

Boiler temperature sensor 3 10K ohm sensor

DHW temperature sensor 5 10K ohm sensor

TT stage 1 call for heat first stage

TT stage 2 call for heat second stage

OpenTherm communication OT OT connection for OT enabled room thermostat/device

Fault output AL Compiled fault indication

0-10VDC input/ext demand A1 coded function either 0-10VDC or external demand

LON communications C1/C2 Daisy-chained LON connection when optional LON board installed

Terminal connections

- screw-type connection

- RAST-5 quick connects

- Low voltage sensor and communication screw type

connections

6

5604 122 v1.0

Page 7

Vitotronic 100, KW10B Technical Data

Accessories

Boiler water / DHW temperature sensor

Cable length: 5.2 ft. (1.6 m), ready to plug in.

Maximum ambient temperature

- at operation: (in rooms and installation sites with

normal ambient conditions) 32 to 104 ºF (0 to 40 ºC)

- when storing or transporting:

-4 to +149 ºF (-20 to +65 ºC)

Minimum boiler temperature protection and freeze-up

- controlled by electronic boiler temperature sensor

- DIP switch enabled/disabled

Outdoor temperature sensor

Installation site: North or northwest side of building

6.6 to 8.2 ft. (2 to 2.5 m) above ground,

for multi-storey buildings mount sensor

on upper half of second storey.

Connection: 2-wire cable, cable length 1000 ft. (300 m)

with a wire size of min. AWG 16 copper.

The cable to the outdoor sensor must not be laid near line

voltage wiring (120/240 V).

Maximum ambient temperature at operation, when storing

or transporting:- 40 to +158 ºF (- 40 to +70 ºC)

5604 122 v1.0

7

Page 8

Vitotronic 100, KW10B Technical Data

Quick Reference

°C °F

-40 -40

-35 -31

-25 -13

-20 -4

-18 0

-16 +3

-14 +7

-12 +10

-10 +14

-9 +16

-8 +18

-7 +19

-6 +21

-5 +23

-4 +25

-3 +27

-2 +28

-1 +30

0 +32

+1 +34

+2 +36

+3 +37

+4 +39

+5 +41

+6 +43

+7 +45

+8 +46

+9 +48

+10 +50

+12 +54

+14 +57

+16 +61

+18 +64

+20 +68

+25 +77

+30 +86

+35 +95

+40 +104

+50 +122

+60 +140

+70 +158

+80 +176

+90 +194

+100 +212

+110 +230

Printed on environmentally friendly

(recycled and recyclable) paper.

Technical information subject to change without notice.

Viessmann Manufacturing Company (U.S.) Inc.

45 Access Road

Warwick, Rhode Island · 02886 · USA

1-800-288-0667 · Fax (401) 732-0590

www.viessmann-us.com · info@viessmann-us.com

Viessmann Manufacturing Company Inc.

750 McMurray Road

Waterloo, Ontario · N2V 2G5 · Canada

1-800-387-7373 · Fax (519) 885-0887

www.viessmann.ca · info@viessmann.ca

5604 122 v1.0

Loading...

Loading...