Page 1

Page 2

Service Manual

AVEA Ventilator Systems

L1524 Rev. C

© 2006 VIASYS

®

Respiratory Care Inc.

Page 3

Service Manual

ii L1524

Page 4

AVEA Ventilator Systems

Revision History

Date Revision Pages Changes

August 2002 Rev. A All Released Engineering Document

Control ECO

July 2003 Rev. B All Add Exception button and

Exception screen to Error Log

screen. Add list of error codes.

Add OVP kits & instructions.

Add Software upgrade

instructions. Add heliox Smart

connector instructions. Add

Compressor upgrade

instructions. Add cart instructions

(both). Add external battery

pack instructions. Add Insp &

Exp transducer Cal instructions.

Add ref to Communications

Protocol. Add unpacking &

setup instructions.

Reorganize chapters, add

chapter 3, add chapter 5 (OVP),

add software upgrade info

(chapter 6), add chapter 9, add

chapter 10, add appendix D.

L1524

iii

Page 5

Service Manual

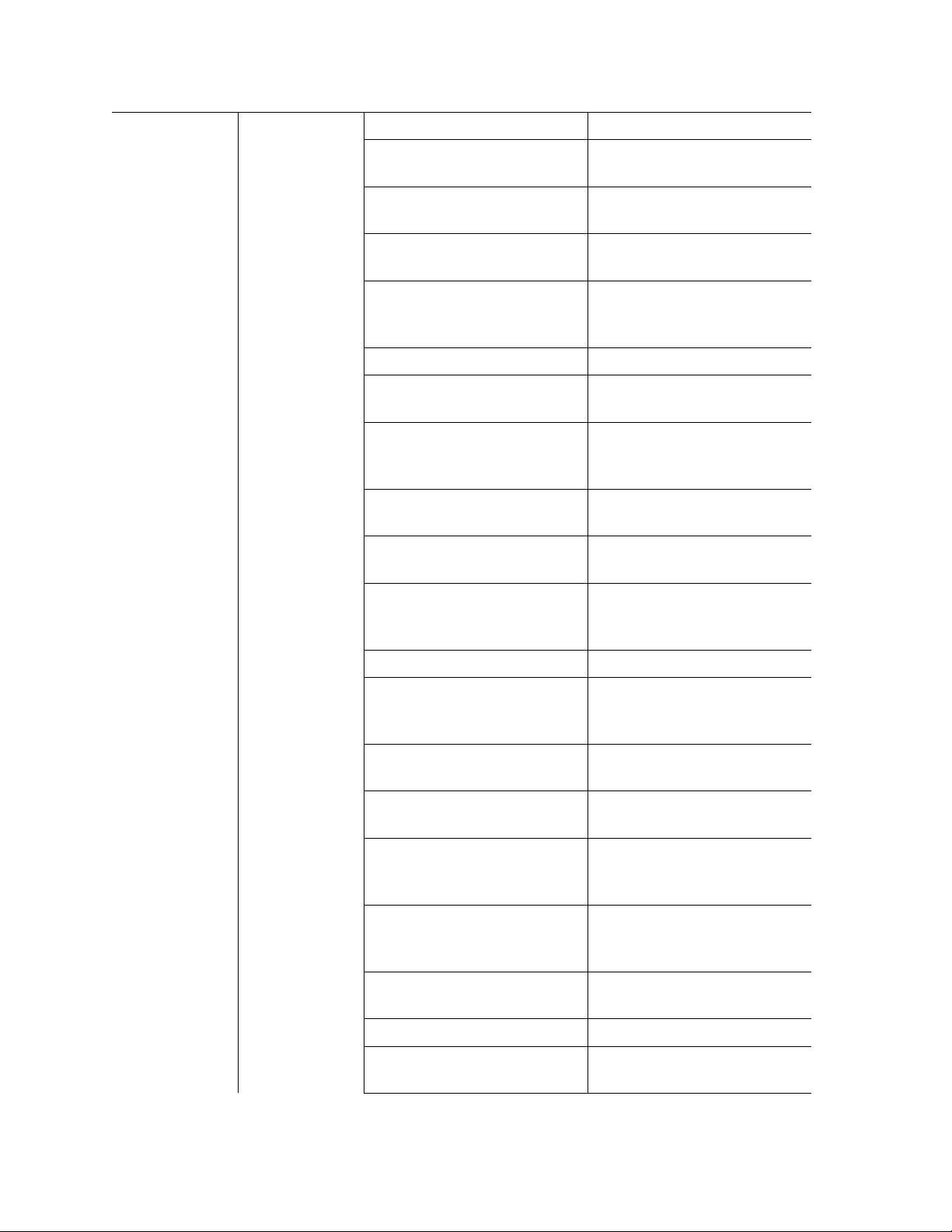

January 2006 Rev. C

Throughout Updated the company name.

vi Added external batteries to the

Limitation of Liability.

1-7 Added symbols for the battery

and for HeOx.

2-1 Updated the General

Description.

2-2 Changed the references of the

Tracheal Catheter and the

Esophageal Balloon.

2-3 Changed “O2 bottle” to “O2 tank.”

2-6 Changed the Monitor MCU

description.

2-9 Updated the description of the

power supply system and the

Transducer / Alarm PCB.

2-12 Updated the description of the

heated expiratory system.

3-1 Updated the standard-stand

carton contents table.

3-8 Updated the procedure for

setting up the Customer

Transport Cart kit.

3-11 – 3-12 Updated figures.

3-14 Added part number references to

“E Cylinder Bracket Assembly

Instructions.”

4-1 Added Pediatric Patient Circuit to

the list of equipment.

4-2 Removed the note regarding the

UIM.

4-3 Replaced the word “arm” with

“neck.” Removed the note

regarding the UIM.

4-4 Added a note regarding the

screws to the Metal Top Cover

section.

4-4 – 4-7 Updated the Gas Delivery

Engine Removal procedure.

4-11 – 4-12 Updated the fuse specifications.

4-15 – 4-16 Updated the Compressor /Scroll

Pump section.

iv L1524

Page 6

AVEA Ventilator Systems

5-4 – 5-7 Updated the Manual Alarms

5-10 Added two steps to the Testing

5-11 Added step 22 to the Membrane

4-16 Changed the part number of the

Enhanced Patient Monitor board.

4-18 – 4-19 Added the fan assembly and

power supply part numbers.

4-22 Added part numbers to step 1 of

the removal procedure.

4-23 Changed step 5 of the

Installation procedure to include

the part number.

5-1 Added references to PSI to the

Setup procedure.

Testing section.

Guidelines section.

Switch test.

5-12 – 513 Op. Verification Checklist

5-16 Updated the Checkout Sheet.

A-58 Replaced figure A-1

A-59 – A-60 Updated the MIB Connection

section.

A-61 Added the Blender Bleed

section.

A-62 Added the Sound Levels section.

A-63 – A-64 Updated the Water Trap section.

A-66 Updated the Message Bar Text

table.

A-69 – A-74 Added the Monitor Ranges and

Accuracies table.

A-75 Added the Sensor Specifications

and Circuit Resistance table.

A-76 Added the Hot Wire Flow Sensor

Specifications table.

A-77 Added the Circuit Resistance

section.

L1524

v

Page 7

Service Manual

Notices

Copyright Notice

Copyright © 2006 VIASYS Respiratory Care Inc.

This work is protected under Title 17 of the U.S. Code and is the sole property of the Company. No part

of this document may be copied or otherwise reproduced, or stored in any electronic informat ion

retrieval system, except as specifically permitted under U.S. Copyright law, without the prior written

consent of the Company. For more information, contact:

USA European Authorized Representative

VIASYS Respiratory Care Inc. VIASYS Healthcare GmbH

22745 Savi Ranch Parkway Leibnizstrasse 7

Yorba Linda, California 92887-4668 97204 Höchberg

U.S.A. Germany

Telephone: 800 231-4645

(1) (714) 283-2228 Telephone: (49) (931) 4972-0

Fax: (1) (714) 283-8471 Fax: (49) (931) 4972-423

www.viasyshealthcare.com

Trademark Notices

AVEA® is a registered trademark of VIASYS Respiratory Care Inc. in the U.S. and some other

countries. All other brand names and product names mentioned in this manual are trademarks,

registered trademarks, or trade names of their respective holders.

EMC Notice

This equipment generates, uses, and can ra diate radio frequency energy. If not installed and use d in

accordance with the instructions in this manual, e lectromagnetic interference may result. The

equipment has been tested and found to comply with the limits set forth in EN60601-1-2 for Medical

Products. These limits provide reasonable protection against electromagnetic interference when

operated in the intended use environments described in this manual.

The ventilator has been tested to conform to the following specifications:

MIL-STD-461D:1993, MIL-STD-462D:1993, EN55011:1991, IEC 1000-4-2:1994, IEC 1000-4-3:1994,

IEC 1000-4-4:1994, IEC 1000-4-5:1994, QUASI-STATIC:1993

This ventilator is also designed and manufacture d to co mply with the safety requirements of IEC 601-1,

IEC 601-2-12, CAN/CSA-C22.2 No. 601.1-M90, and UL 2601-1.

vi L1524

Page 8

AVEA Ventilator Systems

MRI Notice

This equipment contains electromagnetic components whose operation can be affected by intense

electromagnetic fields.

Do not operate the ventilator in an MRI environment or in the vicinity of high-frequency surgical

diathermy equipment, defibrillators, or short-wave therapy equipment. Electromagnetic interference

could disrupt the operation of the ventilator.

Intended Use Notice

The AVEA Ventilators are designed to provide ventilator support for the critical care management of

infant, pediatric or adult patients with compromised lun g fu nction. They are intended to provide

continuous respiratory support in an institutional health care environment. They should only be

operated by properly trained clinical personnel, under the direction of a physician.

Regulatory Notice

Federal law restricts the sale of this device except by or on order of a physician.

IEC Classification

Type of Equipment: Medical Equipment, Class 1 type B

Adult/Pediatric/Infant Lung Ventilator

Declaration of Conformity Notice

This medical equipment complies with the Medical Dev ice Directive, 93/42/EEC, and the following

Technical Standards, to which Conformity is declared:

EN60601-1

EN60601-1-2

ISO 13485

EU Notified Body:

BSI (Reg. No. 0086)

Trade names:

AVEA Ventilator

If you have a question regarding the Declaration of Conformity for this product, please contact VIASYS

Respiratory Care Inc. at the number given in Appendix A.

0086

L1524

vii

Page 9

Service Manual

Warranty

THE AVEA® ventilator systems are warranted to be free from defects in material and workmanship and

to meet the published specifications for TWO (2) years or 16,000 hours, whichever occurs first.

The liability of VIASYS Respiratory Care Inc., (referred to as the Company) under this warranty is

limited to replacing, repairing or issuing credit, at the discretion of the Company, for parts that become

defective or fail to meet published specifications during the warranty period; the Company will not be

liable under this warranty unless (A) the Company is promptly notified in writing by Buyer upon

discovery of defects or failure to meet published specifications; (B) the defective unit or part is returned

to the Company, transportation charges prepaid by Buy er; (C) the defective unit or part is received by

the Company for adjustment no later than four weeks following the last day of the warranty period; and

(D) the Company’s examination of such unit or part shall disclose, to its satisfaction, that such defects

or failures have not been caused by misuse, neglect, improper installation, unauthorized repair,

alteration or accident.

Any authorization of the Company for repair or alteration by the Buyer must be in writing to prevent

voiding the warranty. In no event shall the Company be liable to the Buyer for loss of profits, loss of

use, consequential damage or damages of any kind based upon a claim for breach of warranty, other

than the purchase price of any defective product covered hereunder.

The Company warranties as herein and abov e set forth shall not be enlarged, diminished or affected

by, and no obligation or liability shall arise or grow out of the rendering of technical advice or service by

the Company or its agents in connection with the Buyer's order of the products furnished hereunder.

Limitation of Liabilities

This warranty does not cover normal maintenance suc h as cleaning, adjustment or lubrication and

updating of equipment parts. This warranty shall be voi d a nd shall not apply if the equipment is used

with accessories or parts not manufactured by the Company or authorized for use in writing by the

Company or if the equipment is not maintained in accordance with the prescribed schedule of

maintenance.

The warranty stated above shall extend for a period of TWO (2) years from date of shipment or 16,000

hours of use, whichever occurs first, with the following exceptions:

1. Components for monitoring of physical vari ables such as temperature, pressure, or flow are

warranted for ninety (90) days from date of receipt.

2. Elastomeric components and other parts or components subject to deterioration, over which the

Company has no control, are warranted f or sixty (60) days from date of receipt.

3. Internal batteries are warranted for ninety (90) d ays fro m the date of receipt.

4. External batteries are warranted for one (1) year from th e date of receipt.

The foregoing is in lieu of any warranty, expressed or implied, including, without limitation, any warranty

of merchantability, except as to title, and can be amended only in writing by a duly authorized

representative of the Company.

viii L1524

Page 10

AVEA Ventilator Systems

Contents

Revision History.............................................................................................................iii

Notices............................................................................................................................vi

Warranty........................................................................................................................ viii

Chapter 1 Introduction .............................................................................................1-1

Safety Information......................................................................................................................1-1

Equipment Symbols...................................................................................................................1-4

Chapter 2 Theory of Operation................................................................................2-1

General Description...................................................................................................................2-1

High Level Design......................................................................................................................2-3

Detail Design ..............................................................................................................................2-5

Chapter 3 Installation Instructions..........................................................................3-1

Stand Assembly.........................................................................................................................3-1

Comprehensive Assembly Instructions...................................................................................3-4

Customer Transport Cart Kit P/N 11372...................................................................................3-8

“E” Cylinder Bracket Assembly Instructions.........................................................................3-14

Assembly Instructions for Comprehensive Cart Tank Rack Bracket.................................3-18

AVEA Unpacking Instructions.................................................................................................3-19

SETTING UP THE REAR OF THE VENTILATOR.....................................................................3-22

Medical Gas Connector Kit Installation Instructions ............................................................3-22

Air and Heliox Tethered “Smart” Connector Installation Instructions................................3-25

Heliox “Smart” Connector Installation Instructions (DISS P/N 51000-40918).....................3-27

Chapter 4 Assembly and Disassembly...................................................................4-1

General Instructions and Warnings..........................................................................................4-1

Recommended Tools & Equipment..........................................................................................4-1

Gas Delivery Engine P/N 16222A..............................................................................................4-4

Ventilator wheeled base ..........................................................................................................4-10

Internal Batteries P/N 68339A..................................................................................................4-10

Compressor/Scroll Pump P/N 51000-09750A.........................................................................4-15

Enhanced Patient Monitor (EPM) Board P/N 51000-40848A.................................................4-16

L1524

ix

Page 11

Service Manual

Fan Assembly P/N 51000-40861 .............................................................................................4-18

Power Supply P/N 16388.........................................................................................................4-19

Exhalation Valve P/N 16319 and Exhalation Flow Sensor Assembly P/N 51000-40023......4-22

Exhalation housing P/N 20030.................................................................................................4-22

Heater Assembly P/N 51000-40824..........................................................................................4-24

Microswitch, Top Cover P/N 68294.........................................................................................4-24

EMI Shield..................................................................................................................................4-25

Front Interface Panel P/N 51000-40635...................................................................................4-25

Transition board with harness P/N 16216...............................................................................4-27

Alarm Speaker P/N 51000-40818.............................................................................................4-28

Nebulizer Assembly P/N 51000-40026....................................................................................4-29

Accumulator P/N 51000-40748.................................................................................................4-31

Secondary Alarm Installation (KitP/N 16316)..........................................................................4-32

General Instructions and Warnings........................................................................................4-32

Recommended Tools & Equipment.........................................................................................4-32

Functional testing of the Secondary Alarm Assembly..........................................................4-34

Chapter 5 Operational Verification Procedure (OVP) ........................................... 5-1

Set up.......................................................................................................................................... 5-1

User Verification Tests (UVT) ...................................................................................................5-1

Return Flow Correction to BTPS upon completion of testing......................................................5-10

User Interface Module (UIM) Verification................................................................................5-10

AVEA Assembly and Operational Verification Test Checklist..............................................5-12

Field replacement and test of the AVEA Compressor Assembly.........................................5-12

Checkout Sheet – AVEA Compressor Replacement..............................................................5-16

Power Indicators and Charging Verification...........................................................................5-17

Battery Run Procedure.............................................................................................................5-17

Air/Oxygen Inlet Pressure Verification....................................................................................5-18

Breath Rate Verification...........................................................................................................5-19

Blending Accuracy Verification...............................................................................................5-19

PEEP Verification......................................................................................................................5-19

AVEA Assembly and Operational Verification Test Checklist..............................................5-20

x L1524

Page 12

AVEA Ventilator Systems

Chapter 6 AVEA Software Upgrade.........................................................................6-1

Requirements:............................................................................................................................6-1

Procedure:..................................................................................................................................6-2

Software Install Verification AVEA Ventilators......................................................................6-11

Installation Verification............................................................................................................6-11

Confirmation checks................................................................................................................6-11

Verification and Calibration.....................................................................................................6-12

Test and Access of the Security System ...............................................................................6-12

Chapter 7 Calibration................................................................................................7-1

Screen Calibration Procedure...................................................................................................7-1

Transducer Calibration..............................................................................................................7-4

Calibration setup........................................................................................................................7-5

Flow and Exhalation valve Characterization/Hysteresis Test ..............................................7-18

Exhalation Valve Characterization Test .................................................................................7-19

Hysteresis Test.........................................................................................................................7-20

Exhalation Valve Leak Test.....................................................................................................7-21

Chapter 8 Preventive Maintenance.........................................................................8-1

Replacing the O2 and Air/Heliox filters....................................................................................8-2

Replacing the Compressor Inlet & Outlet filters......................................................................8-4

Replacing the Exhalation Diaphragm P/N 16240.....................................................................8-5

Chapter 9 Troubleshooting......................................................................................9-1

Chapter 10 Parts List.............................................................................................10-1

L1524

xi

Page 13

Service Manual

Appendix A...................................................................................................................A- 1

Contact & Ordering Information...............................................................................................A-1

Diagrams and Schematics........................................................................................................A-2

Specifications ..........................................................................................................................A-55

AVEA Message Bar Text.........................................................................................................A-66

Adjusting Barometric Pressure for Altitude..........................................................................A-68

Monitor Ranges and Accuracies............................................................................................A-69

Sensor Specifications & Circuit Resistance..........................................................................A-75

Hot Wire Flow Sensor Specifications.....................................................................................A-76

Circuit Resistance (per EN794 –1)..........................................................................................A-77

Advanced Pulmonary Mechanics Monitored Parameters....................................................A-78

Glossary...................................................................................................................................A-85

Index .................................................................................................................................1

xii L1524

Page 14

Service Manual AVEA Ventilator Systems

Chapter 1 Introduction

Safety Information

Please review the following safety information prior to operating the ventilator. Attempt ing to

operate the ventilator without fully understanding its features and functions may result in unsafe

operating conditions.

Warnings and Cautions which are general to the use of the ventilator under all circumstances are

included in this section. Some Warnings and Cautions are also inserted within the manual where they

are most meaningful.

Notes are also located throughout the manual to provide additional information related t o specific

features.

If you have a question regarding the installation, set up, operation, or maintenance of the ventilator,

contact VASYS Respiratory Care customer care as shown in Appendix A, Contact & Ordering

Information.

Terms

WARNINGS identify conditions or practices that could result in serious adverse reactions or

CAUTIONS identify conditions or practices that could result in damage to the ventilator or other

NOTES identify supplemental information to h elp you better understand how the ventilator

Warnings

Warnings and Cautions appear throughout this manual where they are relevant. The Warnings and

Cautions listed here apply generally any tim e you work on the ventilator.

• Alarm loudness must be set above ambient sound in order to be heard.

• Due to possible explosion hazard, the ventilator should not be used in the presence of

• An audible alarm indicates an anomalous con dition and should never go unheeded.

• Anti-static or electrically conductive hoses or tubing should not be used within the patient

• If a mechanical or electrical problem is recognized wh ile running the Operational Verification

potential safety hazards.

equipment.

works.

flammable anesthetics.

circuit.

Tests, or while operating the ventilator, the ventilator must be removed from use until the

problem has been identified and resolved.

• The functioning of this equipment may be adversely affected by the operation of other

equipment nearby, such as high frequency surgical (diathermy) equipment, defibrillators,

short-wave therapy equipment, “walkie-talkies,” or cellular phones.

• Water in the air supply can cause malfunction of this equipment.

L1524

1-1

Page 15

Service Manual

• Do not block or restrict the Oxygen bleed port located on the instrument back panel.

Equipment malfunction may result.

• Electric shock hazard – Ensure the ventilator is disconnect ed from the AC power supply before

performing and repairs or maintenance. When you remove any of the ventilator cover panels,

immediately disconnect the internal battery “quick rele ase” connector before working on the

ventilator. If the ventilator has an external battery installed, ensure that the external battery is

unplugged from the rear panel before pr oceeding

• A protective ground connection by way of the grounding conductor in the power cord is

essential for safe operation. Upon loss of protective ground, all conductive parts including

knobs and controls that may appear to be insulated, can render an electric shock. To avoid

electrical shock, plug the power cord into a properly wired receptacle, use only the power cord

supplied with the ventilator, and make sur e the power cord is in good condition.

The following warnings must be read and understood before performing the procedures described in

this manual.

• Under no circumstances should this medical device be operated in the presence of flammable

anesthetics or other volatile materials due to a possi ble explosion hazard.

• Liquid spilled or dripped into the unit may cause damage to the unit or result in an electrical

shock hazard.

• Oxygen vigorously accelerates combustion. To avoid violent ign ition, do not use any gauges,

valves, or other equipment that has been exposed to oil or grease contamination.

• Do not use this device if any alarm/alert function is inoperative. To do so could r esu lt in a

malfunction without warning, possibly resulting in personal injury, including death or property

damage.

• All tubing and fittings used to connect high pressure gas from the source to the test equipment

and from the test equipment to the device being tested must be capable of withstanding a

minimum supply pressure of 100 psi (7.03 kg/cm2). The use of tubing and fittings not capable

of withstanding this pressure could cause the tubin g to rupture, resulting in personal injury or

property damage.

• When verifying the operation of this medical device, do not breathe directly from the machine.

Always use a fresh bacterial filter and test circuit. Failure to do so may constitute a hazard to

the health of the service person.

• If any of the procedures outlined in this document cannot be verified, do not use this device

and refer it to VIASYS Respiratory Care or a VIASYS Respiratory Care authorized service

facility or a VIASYS Respiratory Care trained hospital service technician.

1-2 L1524

Page 16

AVEA Ventilator Systems

Cautions

The following cautions apply any time you work with the ventilator.

• Ensure that the voltage selection and installed fuses are set to match the voltage of the wall

outlet, or damage may result.

• A battery that is fully drained (i.e. void of any charge) may cause damage to the v entilator and

should be replaced.

• All accessory equipment that is connected to the ventilator must comply with

CSA/IEC601/UL2601.

• To avoid damage to the equipment, clean the air filter regularly.

The following cautions apply when cleaning the ventilator or when sterilizing ventilator

accessories.

• Do not sterilize the ventilator. The internal components are not compatible with steri liz ati on

techniques.

• Do not gas sterilize or steam autoclave tubing adapters or connectors in place. The tubing will,

over time, cause poor connection and possible leaks.

• DO NOT submerge the ventilator or pour cleaning liquids over or into the ventilator.

• Do not use MEK, Trichloroethylene or similar solutions as damage to su rface may result. Do

not allow any liquid to spill or drip into the ventilator.

• Circuit boards are subject to damage by static electricity. Do not touch compo nents, circuit, or

connector fingers with hands. Handle only by edges.

L1524

1-3

Page 17

Service Manual

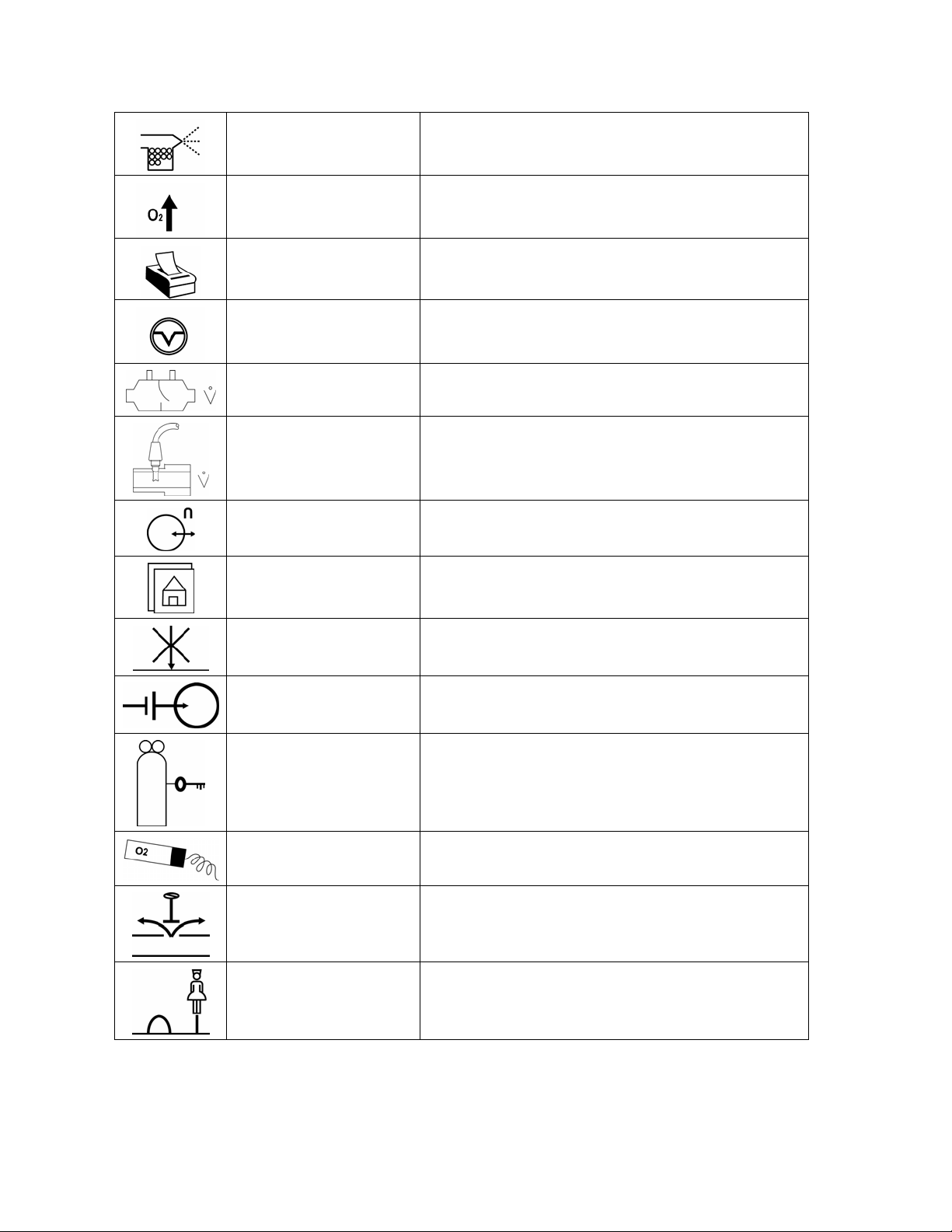

Equipment Symbols

The following symbols may be reference d o n the ventilator or in accompanying documenta t ion

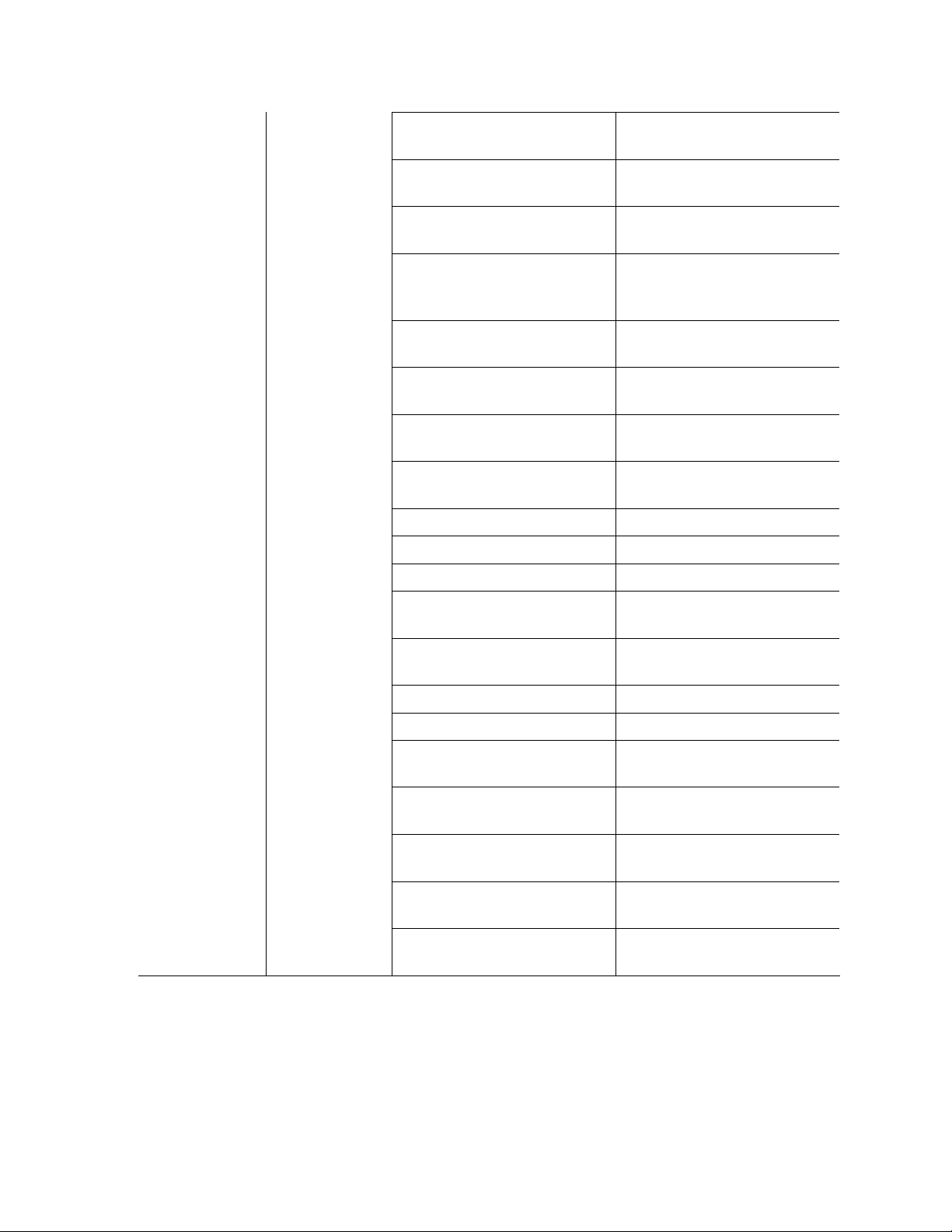

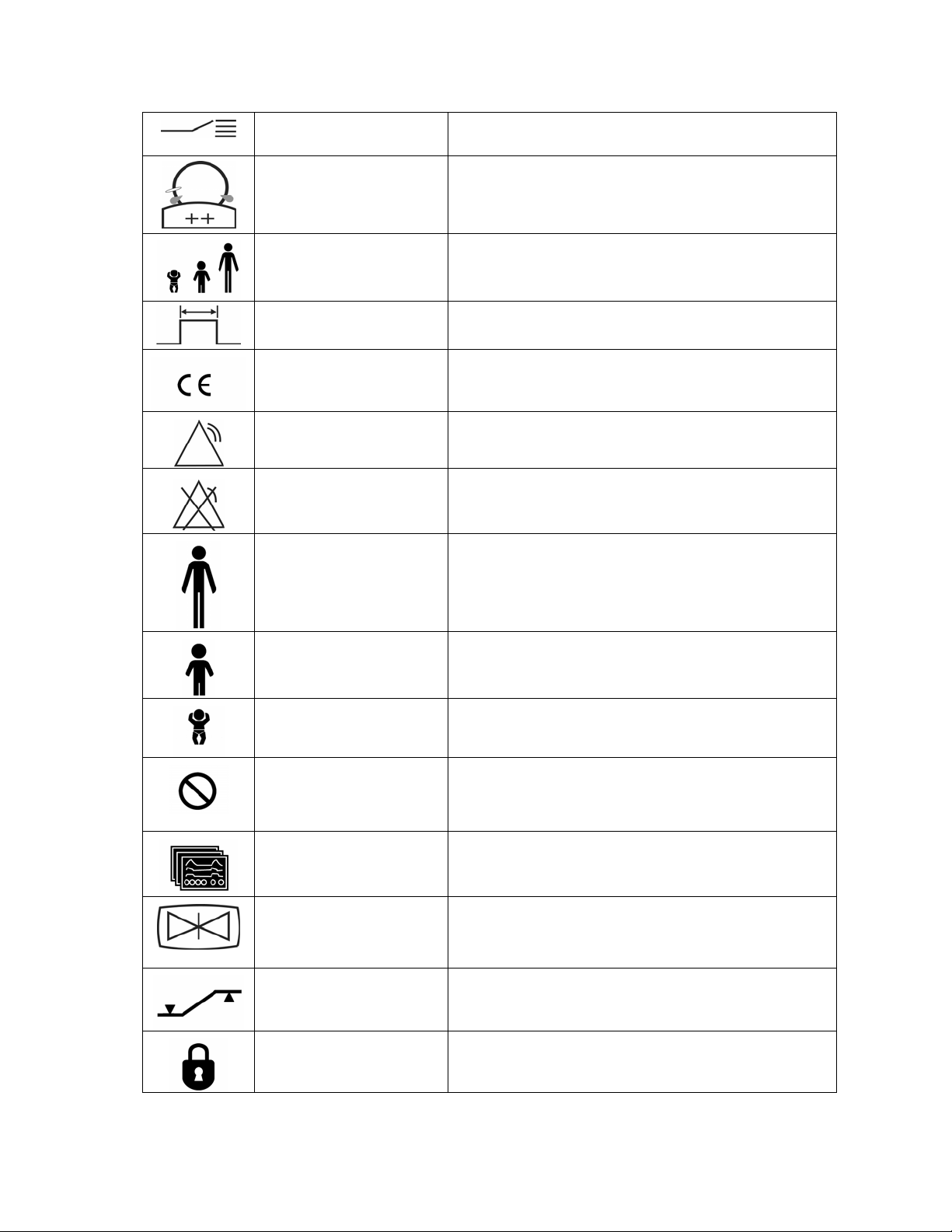

Symbol Source/Compliance Meaning

Symbol #03-02 IEC 60878

Symbol #5016 IEC 60417

Symbol #5034 IEC 60417

Symbol #01-36 IEC 60878

Symbol #5035 IEC 60417

Symbol #01-37 IEC 60878

Symbol #5019 IEC 60417

Symbol #01-20 IEC 60878

Indicates ATTENTION, consult ACCOMPANYING DOCUMENTS

This symbol indicates a FUSE.

This symbol indicates INPUT.

This symbol indicates OUTPUT

This symbol indicates protective EARTH (ground).

This symbol indicates the EQUIPOTENTIAL connection used to

Symbol #5021 IEC 60417

Symbol # 01-24 IEC 60878

connect various parts of the equipment or of a system to the

same potential, not necessarily being the earth (ground) potential

(e.g., for local bonding).

This symbol indicates TYPE B equipment, which indicates

Symbol # 5333 IEC 60417

Symbol #02-03 IEC 60878

Symbol #5032 IEC 60417

Symbol #01-14 IEC 30878

Symbol #5007 IEC 60417

Symbol #01-01 IEC 60878

Symbol #5008 IEC 60417

Symbol #01-02 IEC 60878

equipment that provides a particular degree of protection against

electric shock, particularly with regards to allowable leakage

current and reliability of the protective earth connection.

This symbol is located on the rating plate. It indicates the

equipment is suitable for alternating current.

Indicates ON (Power)

Indicates OFF (Power)

Horizontal return with line feed. Indicates ACCEPT entered

values for a specific field.

Indicates PATIENT EFFORT

ACCEPT

Symbol #0651 ISO 7000

VIASYS Respiratory Care Symbol

VIASYS Respiratory Care symbol

Indicates MANUAL BREATH

VIASYS Respiratory Care Symbol

MAIN SCREEN

Symbol #417 IEC 5102

EVENT READY

1-4 L1524

Page 18

AVEA Ventilator Systems

VIASYS Respiratory Care Symbol

MODE

VIASYS Respiratory Care Symbol

VIASYS Respiratory Care Symbol

VIASYS Respiratory Care Symbol

MDD Directive 93/42/EEC

Symbol #5307 IEC 60417

Symbol #5319 IEC 60417

VIASYS Respiratory Care symbol

ADVANCED SETTINGS

SET-UP for patient Data

SiPAP Duration

CE Mark

ALARM RESET

ALARM SILENCE

ADULT patient

CANCEL

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

Graphical Symbol in general use

internationally for “DO NOT”

VIASYS Respiratory Care symbol

Symbol 5467 IEC 60417

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

PEDIATRIC patient

NEONATAL (Infant) patient

CANCEL, do not accept entered values.

Select DISPLAYED SCREEN function.

FREEZE the current display.

Enable the ALARM LIMITS screen

This symbol indicates a CONTROL LOCK.

L1524

1-5

Page 19

Service Manual

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

NEBULIZER port

Increase OXYGEN

PRINT SCREEN

SUCTION port

VARIABLE ORIFICE FLOW SENSOR connection

HOT WIRE FLOW SENSOR connection

ANALOG IN/OUT connection

Display the MAIN SCREEN

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

VIASYS Respiratory Care symbol

DO NOT BLOCK PORT

EXTERNAL BATTERY connection

Indicates GAS ID port

OXYGEN SENSOR connection

OVERPRESSURE relief

REMOTE NURSE CALL connection

1-6 L1524

Page 20

AVEA Ventilator Systems

VIASYS Respiratory Care symbol

VIASYS Respiratory Care Symbol

VIASYS Respiratory Care Symbol

VIASYS Respiratory Care Symbol

VIASYS Respiratory Care Symbol

VIASYS Respiratory Care Symbol

UNIVERSAL INTERFACE MONITOR connection

This symbol indicates an EXTERNAL BATTERY INPUT

This symbol indicates an INTERNAL BATTERY FUSE

This symbol indicates ALARM LOUDNESS

Operating on Battery Indicator

Operating on Heliox

L1524

1-7

Page 21

Service Manual

1-8 L1524

Page 22

Service Manual AVEA Ventilator Systems

Chapter 2 Theory of Operation

General Description

AVEA is a software driven, servo-controlled ventilator designed to meet the requirements of neonate to

adult patients. The design intent of the device is to provide a high performance software-driven gas

delivery engine, which is capable of providing a full range of volume and pressure ventilation including

dual limb NIPPV. This affords the flexibility of developing new modes of ventilation with no impact to

the basic gas delivery engine. In addition, the device will contain a graphical user interfac e (GUI) that

utilizes a 12.1-inch SVGA color LCD screen with integral touch screen. The GUI will be used to change

settings and operating parameters as well as providing real time waveforms, digital monitors, and

alarms. The device also contains an internal battery that serves as a backup in case of loss of hospital

AC power. The Custom Cart may be equipped with tank holder, external batteries and battery tray for

use of the AVEA during inter-facility transport .

There are three models of AVEA; comprehensive, plus and standard. These are shown in table 2.1

based on the same basic platform. Additional models may be developed in the future by adding or

removing software and/or hardware features to the existing platform.

The AVEA is a fourth generation, servo-controlled, software-driven ventilator. It has a dynamic range of

breathing gas delivery that provides for neonatal through adult patients. Its revolutionary user interfac e

module (UIM) provides maximum flexibility with simple operator interaction. It has a flat panel color

LCD with real time graphic displays and digital monitoring capabilities, a touch screen for eas y

interaction, membrane keys and a dial for changing settings and operating parameters. A precision gas

delivery engine with servo controlled active inhalation and exhalation improves performance over

previous generations.

The AVEA has been designed to function using most commonly available accessories. It is easy to

clean and its design does not allow liquids to pool on the casing, reducing the likelihood of fluid leakage

into the body of the ventilator.

L1524

2-1

Page 23

Service Manual

There are three models of AVEA to choose from: The Comprehensive, Plus, and the Standard. The

following matrix details the standard and optional functions available with eac h model.

Functions & Accessories Standard Plus Comprehensive

Modes

Proximal Hot Wire Flow Sensing

Synchronized Nebulizer

24 Hour Trending

Internal Battery

Full Color Graphics Display

Loops and Waveforms

Standard Cart

Proximal Variable Orifice flow sensing

Proximal Airway Pressure Monitoring

Tracheal Pressure Monitoring

Esophageal Pressure Balloon

Internal Compressor

Heliox Delivery

Optional Functions & Accessories

Custom Cart Option Option Included

External Battery (on custom cart only) Option Option Option

Gas Tank Holder (on either cart) Option Option Option

Internal Compressor Option Option Included

All All All

Heliox Delivery Option Option Included

2-2 L1524

Page 24

AVEA Ventilator Systems

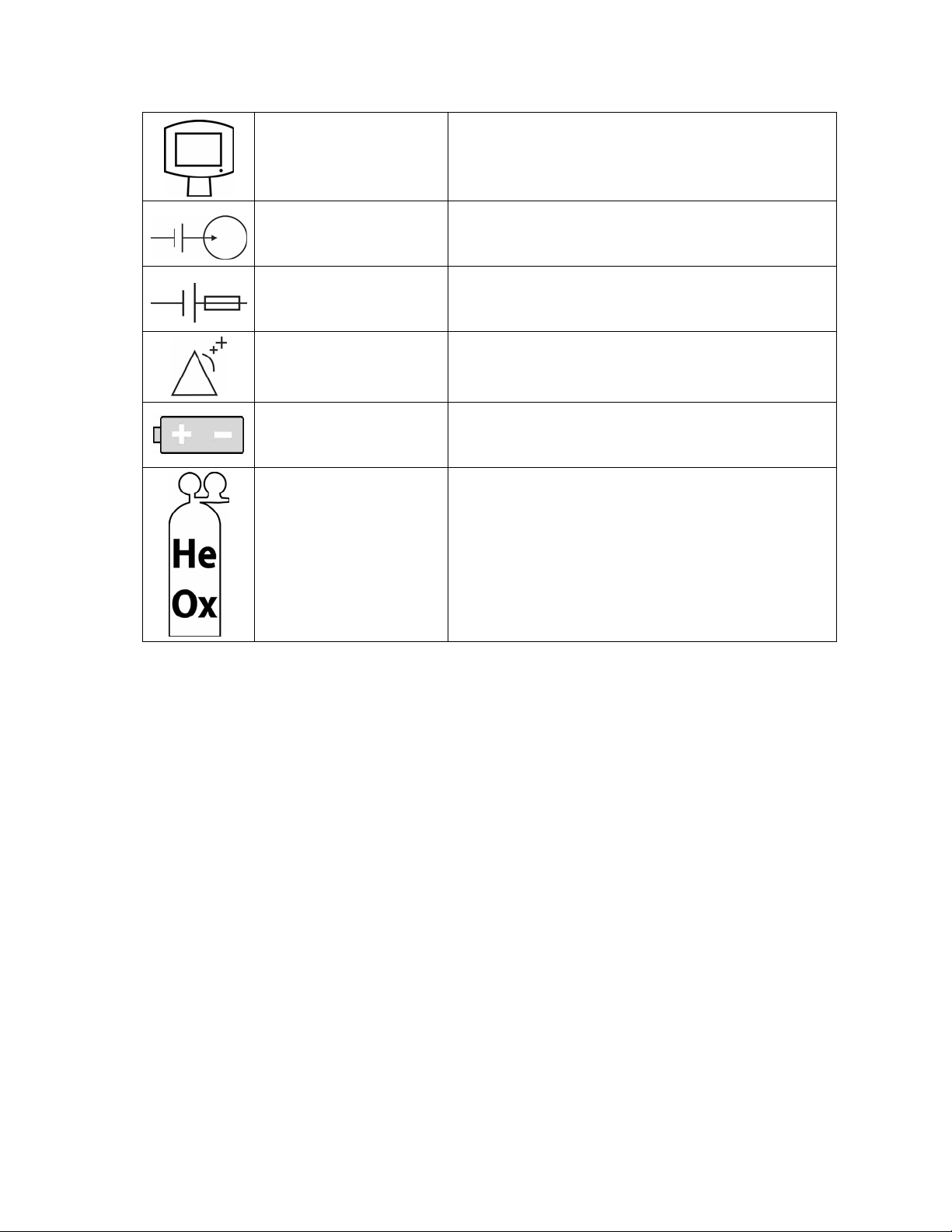

High Level Design

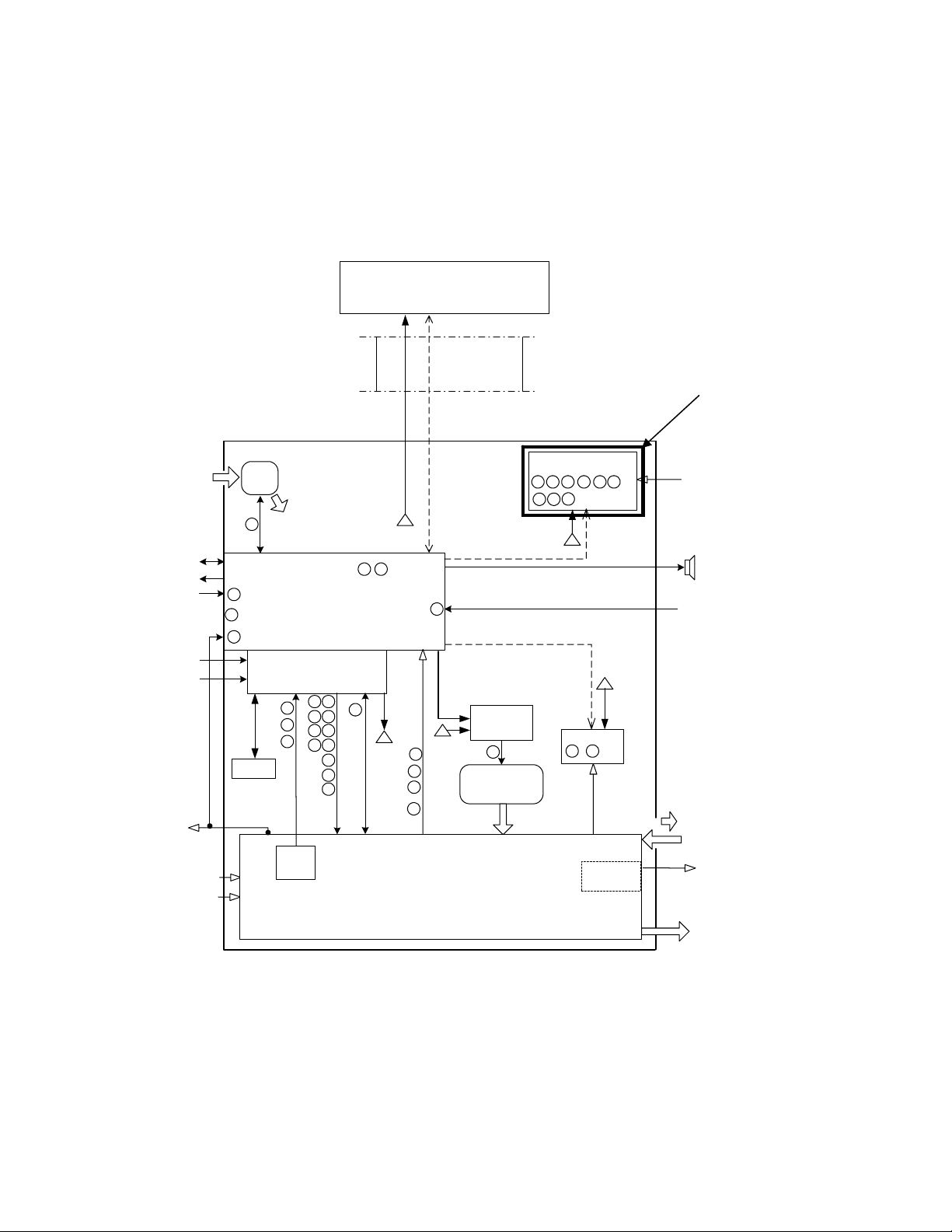

AVEA has been designed with three basic modules, the user interface module (UIM), the pneumatics

module (PM), and the stand (see Figure 1). The UIM contains a graphic al user int erfac e (GUI) which

utilizes a 12.1-inch SVGA color LCD screen with integral touch screen. The UIM also contains a control

PCB that has two microprocessors, control and monitor. The monitor processor manages the GUI,

while the control processor has the real time control system that controls all of the mechanical valves in

the PM. The UIM communicates with the PM via a high-speed serial channel (HSSC). The HSSC also

provides power to the UIM.

The pneumatics module (PM) contains all of the m echanical valves, sensors, analog electronics, power

supply including the internal batteries, and the optional internal compressor. The pneumatics module

takes high-pressure air or 80/20 heliox and oxygen from an external wall source or other high-pressure

source. It filters the gas and blends them through a step per motor controlled blender according to the

front panel settings. It then delivers the appropriate pressure or volume via a high-speed proportional

solenoid with flow sensor feedback. The high-speed control system occurs every 2 msec and is

computed in the control microprocessor in the UIM. The deli vered gas flows to the patient through a

safety valve that has a mechanical over pressure relief valve as well as a sub-ambient valve. The gas is

forced into the patient by closing the servo-controlled voice coil exhalation valve, which is also

controlled by the control microprocessor in the UIM. The patient is a llowed to exhale by the voice coil

exhalation valve, which also maintains baseline pressure or PEEP. The exhaled gas exits the patient

through the expiratory limb of the patient circuit to an inte gral heated expiratory filter to an external flow

sensor and out the exhalation valve to ambient air.

The pneumatics module has several additional capabilities. First it uses either air or 80/20 heliox for an

input gas, and corrects all blending, volume delivery, volume monitoring and alarming, and FiO

monitoring and alarming based on the correct gas density. The system knows what the gas is, by a

patent pending gas ID that identifies the appropr iate inlet DISS fitting with the gas that is being

delivered, which creates an inherently safer system for delivering heliox. The second capability is the

optional back up compressor that is battery backed up for a minimum of 30 minutes by a fully charged

internal battery, which allows for uninterrupted ventilation during a loss of AC power. The third feature is

the ability to monitor volume either at the expiratory limb of the ma chine or at the patient wye. This

allows for more accurate patient monitoring especially in infants while allowi ng the convenience of an

expiratory limb flow sensor protected by a heated filter. Fina lly, the fourth feature is the ability to

measure tracheal and esophageal pressures, which is currently commercially available only on other

VIASYS (Bear/Bird) ventilators.

The stand is used to support the ventilator at an ergonomically correct height. It may contain an optional

external battery for extended use with AC power (custom stand only). It also has an optional O

bracket so that the unit can be used without wal l oxygen during inter-hospital transport. The st and does

not contain active electronic or mechanical components other than the optional external batteries, which

are charged when connected to A/C Power.

2

tank

2

L1524

2-3

Page 25

Service Manual

Printer

User Input

INTERFACE

MODULE

Power

USER

(UIM)

High

Speed

Serial

Channel

(HSSC)

RS232 x 2

MIB

VGA

Air/Heliox

O2 Supply

AC Power

24 VDC

Nurse Call

Analog I/O,

ILV

Ambient Air

Gas ID

O2

sensor

COMPRESSOR

(Optional)

PNEUMATICS MODULE

EXTERNAL BATTERY

(Optional)

Enhanced Pt.

Monitors

(Optional)

Pes

Paux

Faw

Nebulizer

Drive gas

Humidfier

(Optional)

Exhaled Gas

from patient

Exhaust,

Exhaled Flow

Delivered Gas

Patient

CART

Figure 2-3 High End Device Modular Diagram

2-4 L1524

Page 26

AVEA Ventilator Systems

Detail Design

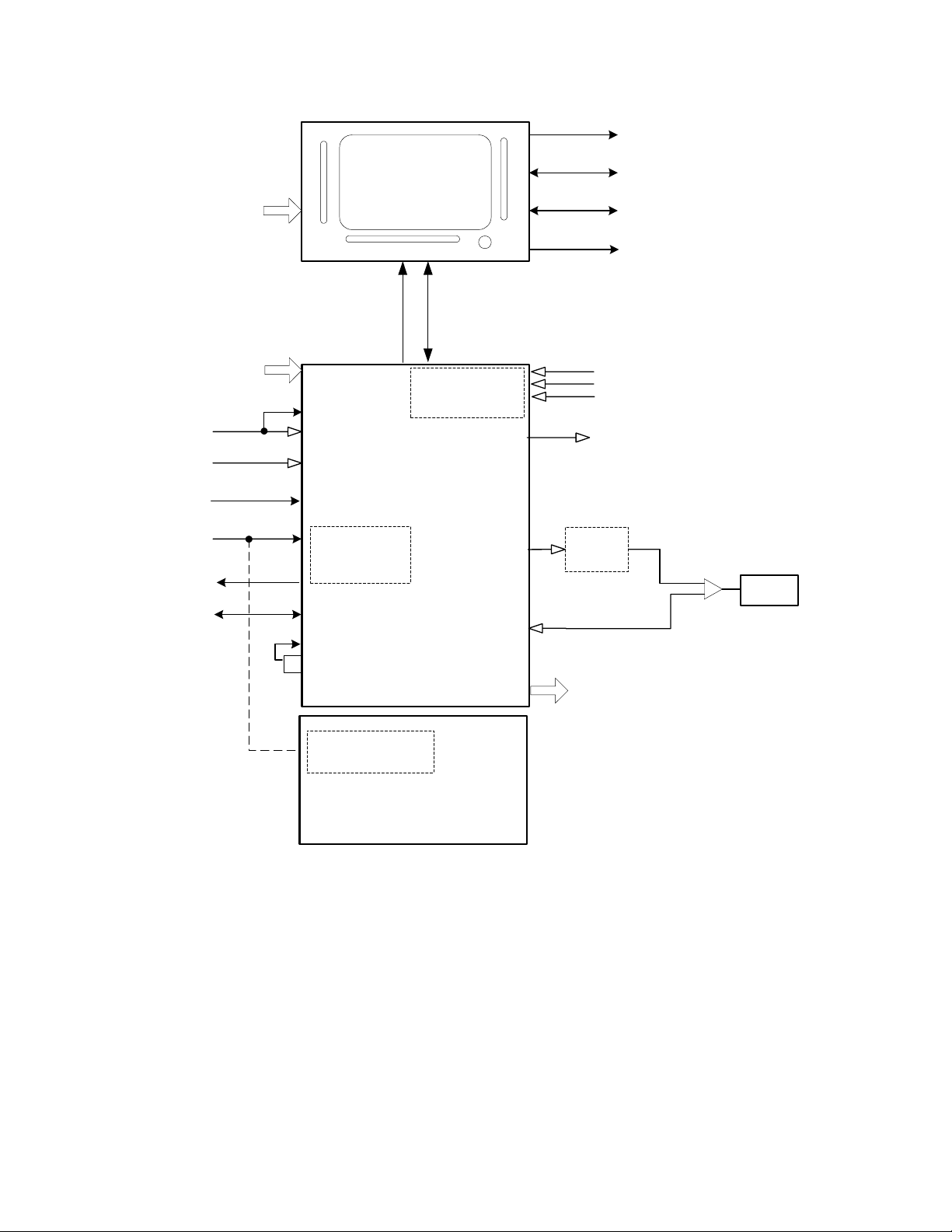

User Interface Module (UIM)

The UIM consists of a 12.1-inch, 800x600 active matrix LCD with an analog resistive touch screen

overlay, a back light inverter, a set of membrane key pan els, an optical encoder, and a Control PCB.

Software and the touch screen provide a set of context sensitive soft keys. The membrane panel

provides a set of hard (permanent) keys for dedicated functions. Selecting the function wit h a soft key

and adjusting the setting using the optical encoder changes a parameter. The parameter is accepted or

canceled by pressing the appropriate membrane key.

LCD & TOUCHSCREEN

(1 & 2)

(3 & 4)

BACK LIGHT AC VOLTAGE

DIGITAL

CONTROL PCB

(7)

DC-DC

CONVERTERS

24VDC

TOUCH

SCREEN

5V

5V, PRN PORT

3.3V, DIG LOGIC

BACK LIGHT INVERTER

HIGH SPEED

(6)

SERIAL

DIGITAL

UNIVERSAL SERIAL BUS (FUTURE)

Figure 2-4 User Interface Design Module Block Diagram

MEMBRANE PANEL WITH

(5)

EMBEDDED LED'S

PRINTER

RS232

RS232

RS232 (MIB)

(CRT)

L1524

2-5

Page 27

Service Manual

The UIM performs all ventilator control functions, gas cal c ulations, monitoring and user interface

functions. The UIM uses a Graphical User Interface (GUI) via the active matrix SVGA LCD and resistive

touch screen to provide system and patient information to the user and to allow the user to modify

ventilator settings. The Control PCB (with two micro-controllers, RAM, ROM and support electronics)

provides all ventilator functions. The Control micr o-controller (MCU) performs all gas calculations;

controls all valves, solenoids, and electronics required to deliver blended gas to the patient. The

Monitor MCU handles all user interface requirements, including updating the active m atrix liquid crystal

display (LCD), monitoring the membrane keypad, analog resistive touch screen, and optical encoder for

activity. The Monitor MCU also performs all the input/output functions of the UIM, including RS-232,

printer, video output, and communication to patient monitors. Communication between the Control and

Monitor MCU’s is accomplished via an 8 bit dual port SRAM. In addition, both MPU's monitor each

other and both are independently capable of activating the fail safe system.

The UIM is self-contained and is tethered to the pneumatics module with a high-speed data and power

cable. All valves are contained in the pneumatics module; the control MCU controls all ventilator

functions via the high-speed serial channel (HSSC). The Monitor MCU provides additional input/output

functions contained in the ventilator. These functions include analog outputs, independent lung

ventilation, and nurse call and are updated by the Monitor MCU via the HSSC.

Liquid Crystal Display

The liquid crystal display (LCD) provides graphical and digital feedback to the clinician. The panel is a

12.1” SVGA, 800x600 pixel, active matrix LCD. The LC D is used to implement the graphical user

interface (GUI). It provides all of the adjustable controls and alarms, as well as displays waveforms,

loops, digital monitors and alarm status in real time.

Touch Screen

The touch screen in conjunction with the LCD provides a set of software configurable soft keys. The

software allows the keys to be context sensitive. The touch screen is a 12.1” analog resistive overlay on

a piece of glass, which is placed over the LCD. It has a resolution of 1024x1024. Physica lly the touch

screen, consists of two opposing transparent resistive layers separated by insulating spacers. Actuation

brings the two opposing layers into electrical contact. The Y coordinate is determ ined by applying a

voltage from top to bottom on the top resistive layer. This creates a voltage gradient across this layer.

The point of contact forms a voltage divider, which is read b y the analog-to-digital converter. The X

coordinate is determined by applying a voltage from left to right on the bottom resistive layer. Again this

creates a voltage gradient and the point of contact forms a divider, which is read with an analog-todigital converter.

Membrane Panel

The membrane panel provides a set of permane nt d edicated keys, which allow the clinician to change

certain ventilator functions. The membrane panel will provide visual status to the clinician via embedded

light emitting diodes (LEDs). The membrane panel consists of membrane switches, which are read by

the monitor CPU. The switches form a matrix of rows and columns. A key closure causes an interrupt to

the monitor CPU, which responds by scanning the key matrix to determine which key has been

pressed.

Light Emitting Diodes (LEDs)

Some of the membrane keys require LED’s to indicate when the key is active. The LED’s are

embedded into the membrane panels.

2-6 L1524

Page 28

AVEA Ventilator Systems

Optical Encoder

The optical encoder allows the clinician to change settings. The setting to be changed is selected by

pressing a soft key on the LCD and then turning the optical encoder to change the value. When the

encoder is rotated two pulse streams ar e generated, phase A and B. When the encoder is turned

clockwise, phase A leads B by 90 degrees. When the direction is counter clockwise, phase B leads A

by 90 degrees. The electronics uses the pha s e information to drive an up-down counter, which is read

by the monitor CPU. The optical encoder is not interrupt-driven and therefore must be polled by the

monitor CPU.

Back Light Inverter

The back light inverter converts 5 VDC into the high frequency AC voltage necessary to power the LCD

back light, which is used to illuminate the LCD.

Control PCB

The control PCB consists of two micro-controllers, the control CPU and the monitor CPU, both of which

are 100 MHz ELAN 410’s. The control and associated circuitry (RAM, ROM, etc) micro controllers

perform all ventilator control functions including the 2 msec closed loop flow control servo and the 2

msec closed loop exhalation valve control servo. The monitor micro-controller manages the GUI and

performs all user input and output including the RS-232 ports, printer port, video out, and MIB port. The

two processors communicate with each other via a dual port RAM. The control processor

communicates with the pneumatics module via a high-speed serial channel (HSSC - 4 Mbits/sec).

Each processor has 8 Mbytes of DRAM, and one Mbyte of flash memory for program storage. In

addition, the monitor circuitry also has a second one Mbyte of flash memory for saving control settings

and trended data for clinical parameters. The control PCB also contains a DC-to-DC converter to

regulate the incoming 24 VDC to the voltages used by the UIM. Finally, the control PCB also contains

all of the circuitry necessary to scan the membrane panels, touch screen, and optical encoder, a s well

as the video controller necessary to drive the SVGA LC D screen.

L1524

2-7

Page 29

Service Manual

Pneumatics Module

The pneumatics module (PM) consists of a power supply system including internal NiMH batteries, a

transducer/ communication/alarm PCB (TCA PCB), the pneumatics, a heated expiratory system, a fan,

an optional internal compressor, a built-in nebulizer system, and an audible alarm. The PM

communicates with the UIM (User Interface Module) via the HSSC described above.

User Interface Module

(UIM)

Ambient

Analog I/O,

ILV

Nurse Call

Gas ID

AC Power

24 VDC

Sensor

O2 supply

Air/Heliox

SHIELDED

CABLE

Air

Fan

29

10

Transducer/Comm./Alarm (TCA)

18

7

PCB

DC

Power

21

9

High

Speed

Serial

Channel

Enhanced Pt.Monitoring (EPM)

PCB (Optional)

14

15

35

1

HSSC

31363417

16

39

1

Future software option.

Faw, Ptr, Pes,

Paw

Alarm

12

HW Flow

HSSC

Power/Driver

PCB

26

1

2

13

Battery

O

2

222027

23

25

24

28

32

33

37

38

1

DC

Power

RPM

Propotional

Voltage

Compr.Driver

1

1

2

3

13

PCB

(optional)

30

Compressor

System

(optional)

Insp. Flow PCB

19

11

1

Exhaust

3 x

Pres.

PCB

PNEUMATICS

Nebulizer

(Optional)

Exhaled Flow

Neb. gas

Patient

Flow

Reference: Pneumatic Schematic P/N 51K-09742 Rev X1

Figure 2-5 Pneumatics Module Block Diagram

2-8 L1524

Page 30

AVEA Ventilator Systems

Power Supply System

The power supply system, consists of a power inlet module, and a medical grade 350-watt power

supply, the power driver PCB, and a set of internal 12 VDC NiMH batteries connected in series. The

power inlet system accepts a standard IEC medical grade power cord and allows the system to be

configured externally for use with 100 to 240 VAC 5 0/60 Hz power. AC power is converted to 34 VDC

by the internal medical grade power supp ly, which is also power factor corrected. The power driver PCB

converts the 34 VDC from the power supply or the 24 VDC from the internal or external batteries to the

appropriate voltages used by the rest of th e system. The power driver PCB also contains the charging

circuit for both the internal and external batteries, as well as the drivers for the flow control, exhalation

valve, and multiple solenoids. The internal 4.5 Ah NiMH batteries can power the entire system including

the internal compressor for 30 minutes, or 2 hours without the compressor. With the external 17 Ah lead

acid batteries combined with the internal battery powers the entire system, including compressor, will

run for 2 hours on batteries, and greater than 8 hours without compressor.

Transducer/Alarm PCB (TCA PCB)

The TCA PCB consists of circuitry for the audible alarm, the wy e hot wire flow sensor, the gas ID, the

inspiratory and expiratory pressure transducers, the source gas pressure transducers, the exhaled flow

sensor, the FiO2 cell, and communications with the UIM. It also contains the nurse call, and analog

input and output.

A 68HC705 micro-controller is used to generate ala r m waveforms for an ASTM F1463-93 compliant

alarm. A super capacitor is used to provide a minimum if 120 seconds of power without wall AC or a

battery.

Analog circuitry is provided to signal condition the wye Hot Wire Flow Sensor signal and a 12 bit ADC is

used to digitize the signal. A Flow Sensor Fail s ignal is provided to allow the Control Process or to

determine when the flow sensor wire is broken. The Flow Sensor EEPROM is SPI bus compatible and

is read at power up and when a Flow Sensor is co nnected.

The air inlet fitting contains a resistor for determining which gas source is connected to the Air inlet, Air

( 5K ohm) or Heliox (10K ohm). The type of gas connected is determined with a resistor divider, one

half of the divider is contained in a connector and the other half is located on the TCA. The resistor

contained in the connector is different for each gas source and therefore produces a different voltage

output from the divider. The output of the divider is read via an ADC.

Inspiratory and expiratory pressure transducers and associated signal conditioning are digitized on the

TCA PCB. The control processor reads the digitized data via the HSSC. The air, oxygen, and blended

gas pressure transducers and associated signal conditioning are on separate PCBs for ease of

mounting. The amplified signals are cabled to the TCA where they are digitized and communicated to

the control processor via the HSSC.

Exhaled flow is measured with a VARFLEX

a variable orifice with pressure taps on either sid e of th e orifice. The TCA uses a low-pressure

pressure transducer and analog circuitry to measure the flow proportional pressure drop across the

orifice.

Integrated circuit temperature sensors are signal conditioned and digitized by the TCA electronics. The

exhalation and ambient temperature sens ors are cabled to the TCA PCB. The output of oxygen cell is

also signal conditioned and digitize d on the TCA.

®

Exhaled Flow Sensor. The VARFLEX® Flow Sensor uses

There are four 10-bit analog output channels on the TCA for pressure, flow, volume, and breath p hase

respectively. They have a full scale of 0 to 5 VDC with 10- bit resolution. In addition, there are 8

programmable analog inputs that can be used to display external signals. They are digiti zed with a 10

bit DAC, and are scalable from 0 to 1VDC, 0 to 5 VDC, an d 0 to 10 VDC.

L1524

2-9

Page 31

Service Manual

Finally, there is a nurse call output that can be configured as either normally open or normally clos ed.

The nurse call shall be activated for all medium and high priority alarms except when al ar m silenc e is

activated.

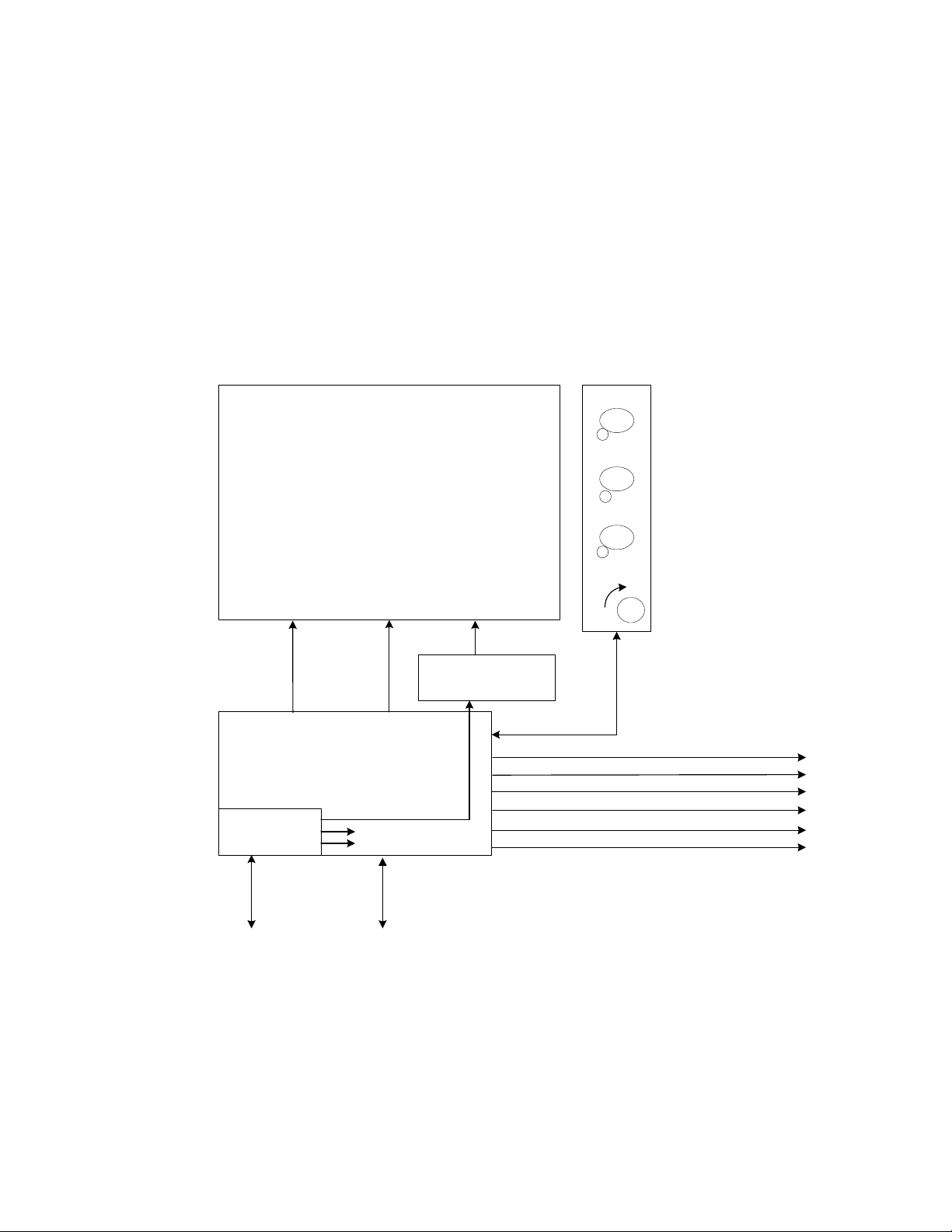

Pneumatics-Gas Delivery Engine

The GDE (Gas Delivery Engine) receives and conditi ons supplied Oxygen, Air, or Heliox from an

external and/or internal (compressor) sources. It then mixes the gas to the concentration required and

delivers the desired flow or pressure to the patient.

The Gas Delivery Engine begins with the Inlet Pneumatics. The Inlet Pneumatics accepts clean O

or Air alternate external gas; it provides extra filtrati on and regulates air and O

gas before entering the

2

Oxygen Blender. The Oxygen Blender mixes the gases to the desired concentration before reaching

the Flow Control Valve. The Flow Control Valve controls the flow rate of the gas mixture to the patient.

Between the Oxygen Blender and Flow Control Valve, the Accumulator System is installed to provide

peak flow capacity. The Flow Sensor provides informati on about the actual inspiratory flow for closed

loop servo control. The gas is then delivered to the patient through the Safety/Relief Valve and Outlet

Manifold.

Compressor

Flow

(Optional)

Air/Heliox

Oxygen

Inlet

Pneumatics

Oxygen

Blender

Accumulator

System

Flow Control

Valve

Flow Sensor

Safety/Relief

Valve &

Manifold

Figure 2-6 Gas Delivery Engine Block Diagram

Inlet System

The Inlet Pneumatics conditions and monitors the air, oxygen, and/or helium-oxygen mix supplies

entering the ventilator. The Inlet Pneumatics has Inlet Filters that remove aerosol and particulate

contaminants from the incoming gas supp lies. The downstream Air Regulator and O

Relay

2

combination is used to provide balanced supply pressure to the gas blending system. The Air

Regulator reduces the air supply pressure to 11.0 PSIG and pilots the O

Relay to track at this same

2

pressure. This system automatically regulates to 9.5 PSIG when the optional internal c ompressor is

being used.

, Air,

2

Patient

Flow

In the event the supply air pressure falls below the acceptable level, the internal compressor will be

activated to automatically supply air to the blender. Without an optional internal compressor, the

Crossover Solenoid opens delivering high-pressure oxygen to the Air Regulator, allowing the Air

Regulator to supply regulated O

simultaneously moves to the 100% O

pressure to pilot the O2 Relay. In addition, the Oxygen Blender

2

position, so that full flow to the patient is maintained.

2

In the event of an oxygen supply pressure drop below a pressure threshold, the Crossover Solen oid

stays closed, the blender moves to 21% O

, and the regulated air pressure provi des 100% air to the

2

blending system.

2-10 L1524

Page 32

AVEA Ventilator Systems

Oxygen Blender

The Blender receives the supply gases from the Inlet Pneumatics System and blends the two gases to

the user-selected value. It consists of three sub-systems, valve, stepper motor, and drive electronics.

The Oxygen Blender PCB provides the electronics needed to control the Oxygen Blender stepper

motor. The stepper motor controls the oxygen blender and is stepped in 1.8-degree increments. The

Blender has a disk, which is positioned during cali bration. One end of the disk will interrupt the optical

interrupter when the valve position is closed an d the other end will only interrupt in case the Blender

goes approximately one full revolution due to loss of position. An EEPROM will be used to store th e

number of steps required to travel from the home position to the full open position of the valve, the PCB

revision, and manufacturing date.

Accumulator

The Accumulator stores blended gas supplied from either regulated wall gas or an optional internal

compressor. The accumulator provides the capability to achieve volume capacity at relatively lo wer

pressure, resulting in lower system power requirements. It stores blended gas during patient exhalatio n

cycles which maximizes system efficiency. The Accumulator gas pressur e cycles between 3 and 11

PSIG depending on the Tidal Volume. The system efficiency is improved because a smaller

compressor can be used to meet Tidal Volume while the accumulator provides the extra gas needed to

meet the patient’s peak flow demand. A 6-L/MIN accumulator ble ed orifice allows gas concentration in

the accumulator to match the oxygen blender setting in a maximum time of 1 minute. A pressure relief

valve will provide protection from pressure exceeding 12 PSIG to the accumulator.

Flow Control System

The Flow Control System provides the desired flow rate of gas to the patient. Real time feedback from

the Flow Sensor through the Control System provid es flow correction in the Flow Control Valve. The

Flow Control System consists of a Proportional Voltage Servo Valve controlled by the real time

measurement (2 ms) of flow through a variable orifice Flow Sensor. The variable orifice effect is

created by a thin circular shaped piece of stainless steel that is mounted from an extended side in the

flow stream. The flow will bend the metal creating a variable orifice. The flow proportional pressure

drop is characterized and used for flow measurement. The Servo Control Electronics/Softwar e

receives and sends the control signals to the Flow Control System Components. Flow Control Valve

adjustments are made for gas temperature, g as density, and backpressure.

Safety/Over Pressure System

The Safety/Pressure Relief Valve prevents over-pressure in the breathing circuit, and provides a

connection between the patient and am bient air during a gas delivery failure from th e Ventilator. A

Check Valve downstream of the Safety/Pressure Relief Valve prevents flow from the patient back into

the Ventilator. Pressure Relief around the Check Valve is accomplished through an orifice installed in

parallel to the Check Valve. The Safety/Relief Valve allows the patient to breathe room air in the event

of a ventilator or power failure. It also acts as an independent relief valve, which limits the maximum

pressure the ventilator can deliver.

L1524

2-11

Page 33

Service Manual

Hour Meter

The Hour Meter provides a means of monitoring the number of hours the ventilator is in use. In addition,

it is used by the ventilator to track compressor hours of operation. A Curtis 201-hour meter is used. The

hour meter is active as long as 5 volts is available. The hour meter outputs a continuous stream of

serial data. The control processor reads the data by synchronizing to the start pulse of the data stream

and then reading each successive bit. The hour meter does not have a visible readout and therefore

must be read by software. The hour meter is hard mounted in the pneumatics module and is cabled to

the TCA PCB.

Heated Expiratory System

The heated expiratory system consists of a heated filter contained in a chamber with a micro-controller

controlled heater, a water collector, an exhalation flow sens or, and a servo-controlled exhalation valve.

The expiratory system is located at the end of the patient circuit; the Exhalation Valve regulates gas

flow out of the patient circuit. Diaphragm position of the voice coil type active Exhalation Valve controls

the exiting gas flow rate and patient circuit press ure with precision. Pressure feedback data is sent to

the Electronic Control Unit continuously, which interprets the data, and based upon current ventilator

settings, signals back to position the Exhalation Valve Diaphragm. Since the ventilator will be used in

neonate, pediatric and adult ranges, the exhal ation servo can be optimized for each circuit type to be

used. The Water Collector and Filter remove contami nates from the gas flow before they reach the

Flow Sensor, Exhalation Valve, or the environment. Als o, warm air exhausts through the Exhalation

System enclosure to the atmosphere. The system incorporates a resettable fuse.

Fan

The expiratory flow sensor determines flow by measuring the pressure difference across a variable

orifice. The variable orifice is created with a thin circular shaped piece of stainless steel th at is mounted

on a hinge in the flow stream from an extended side. As flow increases and decreases the hinged flap

creates the variable orifice effect. The pressure drop across the orifice is measured by a press ure

transducer on the TCA and converted to flow by the software in the control micro-controller.

As stated earlier, the exhalation valve is a voice co il with a diaphragm. The exhalation valve controls

circuit pressure, permits only one-way flow, and provides pressure relief above a set level durin g

inspiration. The exhalation valve is controlled with a closed loop servo contained in the control microcontroller and is updated every 2 msec.

The water collector stores water that condenses in the expiratory limb of th e patient circuit protecting

the filter and exhalation valve system. The water collector consists of a vial and an inlet and outlet

shaped fitting. A male 22 mm outside taper (15mm inside ta per) connector is provided for the patient

circuit connection and a 22 mm female connector is used for the heated filter.

The bacteria filter removes particles from the gas that exceed 0.3µm in size. The excess water drains

into the water collector reducing the risk of contamination of the exhalation valve system. Warm heated

air flows past the outside surface of the filter reducing condensation in the filter. The filter is an off-theshelf purchased part.

A 40 cfm fan runs at all times to keep the internal tem perature of the pneumatics module as close to

ambient as possible. In addition, the fan forces flow out past the expiratory filter. A heater heats the gas

as it exits in order to heat the filter as described above.

2-12 L1524

Page 34

AVEA Ventilator Systems

Compressor System (Optional)

The Compressor System provides 3 to 9.5 PSIG air pressure to the system when wall air is not

available. The Compressor has two opposing machined aluminum involutes that are called Scrolls.

One scroll orbits a fixed scroll forming air pockets that get progressively smaller as they travel from the

outer to inner regions of the involute, compressing the gas. The shaft rotation from a brushless DC

motor powers the orbiting scroll within the fixed scroll through an eccentric shaft. It operates at 800 to

3,000 RPM using about 100 watts at 24 VDC. A Pressure Servo improves power efficiency and noise

by matching ventilator demand with supplied compressed air. While the accumulator is the device

which handles the peak flow demand, the servo o perates the compressor at a level which matches the

minute ventilation of the patient.

Nebulizer System

The Nebulizer system provides a 10 PSIG source of blended gas for an external nebulizer. The gas will

only be delivered during the inspiratory cycle of a breath so that the delivery of nebulized gas will be

synchronized with the patient's breathing. Most manuf actur ers’ ne buliz ers dra w betwee n 4 and 8 L/MIN

at 10 PSIG. The Nebulizer is disabled during use of the optional internal compressor.

Enhanced Patient Monitoring PCB (Optional-EPM)

The Enhanced Patient Monitoring PCB provides Esophageal and Tracheal pressure monitoring and

VARFLEX

transducers for the esophageal pressure, tra cheal pressure, and wye flow sensing. In addition, it

contains a 12-bit serial ADC to convert the pressures to digital data. The TCA provides the chip select

and solenoid control signals. Three solenoids are used to control the evacuation and filling of the

Esophageal Balloon. Two solenoids are used to provide purge flow and auto zeroing of the flow sensor

pressure transducer.

®

wye flow sensing. The EPM PCB contains all of the signal condition as well as the pressure

L1524

2-13

Page 35

Service Manual

2-14 L1524

Page 36

Service Manual AVEA Ventilator Systems

Chapter 3 Installation Instructions

This chapter provides instructions for installing the AVEA ventilator systems.

Stand Assembly

Standard Cart Assembly Instructions (P/N 15986)

Standard stand carton contents

QUANTITY DESCRIPTION

10 each 5/16” screws

10 each 5/16 “ lock washers

2 each 5/16-18” hex nuts

1 each Drag chain and modified washer

2 each

1 each

1 each

2 pieces

1 each

4 each

4 each

Flat washers for pole

7/16 tube bracelet

Top plate assembly

Stand Posts

Pedestal base

End caps

Casters (2 with brake, 2 without brake)

Tools required

1/2“ open end socket

3/16” Allen wrench or driver

1. Remove the contents of carton.

2. Attach the base to the pedestal using the 5/16” screws, washers and nuts as shown in Figure

3.1. The anti-static drag chain may be attached to either screw.

3. Attach the pole to the assembly using the 5/16” screws and washers (refer to Figure 3.1).

L1524

3-1

Page 37

Service Manual

4. Attach the top plate to the pedestal using the 5/16” screws and washers (refer to Figure 3.1).

(5x) 5/16-18 x 1” screw and (4X) 5/16

X 1” screw & washer

Thumbscrew

(2X) 5/16 X 1”

screw, flat washer &

lock washer

Top plate

Pedestal

Pole

Base

Figure 3-1 Assembling the Stand

3-2 L1524

Page 38

AVEA Ventilator Systems

5. Place AVEA Ventilator on top plate, align thumbscrews (4) and lightly start all thumbscrews to

locate AVEA Ventilator (refer to figure 3.2). Fully tighten (4) thumbscrews to secure AVEA

Ventilator.

5/16 X 1” screw and

washer

5/16-18 x 1” screw

5/16 X 1” screw nut and washer

Figure 3-2 Bottom of stand

Anti-static drag chain

5/16-18 x 1” screw

L1524

3-3

Page 39

Service Manual

Comprehensive Assembly Instructions

Refers to P/N 33976

1. Open main carton.

2. Remove the center carton that contains the pedestal, hardware and instructions and open.

3. Remove second carton that contains top plate/pole and set aside.

4. Remove the 4-legged base assembly from carton and set base on the floor as shown in Figure 3-3.

Place pedestal onto the base assemb ly as show in Figure 3-3.

Figure 3-3

5. Using the 1/8” Allen wrench provided install and secure the 4 10/24” x ¾” screws along with the 4

star washers.

3-4 L1524

Page 40

AVEA Ventilator Systems

6. Install collar set screw using the 1/8” Allen as shown in Figure 3-4. Next remove pole from Top

Plate carton install and secure the 1” pole using the collar set screw as shown in Figure 3-4.

Figure 3-4

L1524

3-5

Page 41

Service Manual

7. Remove Top Plate and set Top Plate onto the pedestal and pole as shown in Figure 3-5. Using the

3/32” Allen wrench provided install and secure the 4 counter sink screws as shown in Figure 3-5.

Figure 3-5

3-6 L1524

Page 42

AVEA Ventilator Systems

8. Using the 1/8” Allen secure the setscrew of the upper collar into the 1 ” pole as shown in Figure 3-6.

Figure 3-6

Note

If installing external battery pack, proceed to the next section.

9. Place AVEA Ventilator on top plate, align thumbscrews (4) and lightly start all thumbscrews to

locate AVEA Ventilator. Fully tighten (4) thumbscrews to secure AVEA Ventilator.

L1524

3-7

Page 43

Service Manual

Customer Transport Cart Kit P/N 11372

Note: Before installation, verify that the following parts are in your kit:

Description Quantity Part Number

12V lead acid battery 2 16179

Battery tray, screw (10/32 x 5/16)

X2, washer #10 X 2 & nut 10/32

KEPS

Wire harness 1 16217

Literature 1 L2285

Rack Tank Cart Assembly 1 33978

If any parts are missing contact VIASYS AVEA Customer Service at

800-325-0082 or 760-883-7185.

External Battery Installation

1. Unscrew the (4) thumbscrews securing the base to the ventilator body as shown. Lift the ventilator

body and UIM from the wheeled base.

2. Gently set the ventilator down on a secure flat surface (see note on following page).

3. If attached, remove the Gas Tank holder from the base.

33977

Patient Breathing

Gas Outlet

3-8 L1524

Page 44

AVEA Ventilator Systems

Note

Do not rest the ventilator on the patient breathing gas outlet. Resting the weight of the ventilator on this outlet may

cause damage resulting in leaks at the site.

4. Detach the drop-cable portion from the main battery harness as shown.

L1524

3-9

Page 45

Service Manual

5. Remove the two screws holding the face plate between the rear wheels of the AVEA cart and

detach the faceplate.

6. Thread cable harness through the cart pole.

CAUTION

After the cable has been threaded, inspect the cable for any cuts, abrasions or scaring.

3-10 L1524

Page 46

AVEA Ventilator Systems

7 Place the two batteries into the tray as shown in Photo 1.

Red

Figure 3-7

Orange

Dual Orange

8. Attach harness (P/N 16217) to batteries:

• Connect black wire to negative post (black) on the outer right hand side battery

• Connect the dual orange wire to positive post (red) on the inner right hand side battery

• Feed the single orange and single red wires through the center battery support bracket opening to the

left hand side battery area

• Connect the single orange wire to the negative post (black) on the left hand side battery

• Connect the single red wire (positive) to the positive post (red) on left hand side battery

Black

Black

Dual Orange

Single Orange

Single Red

Figure 3-8

L1524

3-11

Page 47

Service Manual

9. Attach monitor PC board (P/N 16105) and wiring:

• Connect 4 pin male Molex™ to the 4 pin female Molex from the b attery harness

Figure 3-9

3-12 L1524

Page 48

AVEA Ventilator Systems

10. Slowly slide the completed battery and tray assembly onto the mount beneath the AVEA stand making sure

that no wires are kinked or scuffed during assembly. Maintain tension on drop cable from top of cart to prevent

kinking at battery tray. Sufficient cable slack must be availabl e at top of cart to make connection at back of

ventilator.

Battery Tray

Mount

11. Attach the faceplate removed earlier in the instructions to the bottom of the battery tray with the hardware

supplied.

12. Re-attach the ventilator body to the stand making sure the external battery cable lays untwisted in the cable

slot and emerges at the rear of the ventilator.

13. Connect the

external battery cable to the connection labeled EXT BATT on the rear panel of the AVEA.

To Rear of

Ventilator

L1524

3-13

Page 49

Service Manual

14 Plug the AVEA into a grounded AC outlet and apply power to the ventilator.

15. Check that the battery status display on the front panel indicates that the ventilator is connected to External

battery power.

Note

The battery status will indicate red immediately after the external batteries are connected and the unit is powered

up. If the batteries are fully charged, the battery status should indicate green (charged) within one hour of

connection. If the batteries are not fully charged, it may take up to 48 hours to indicate green. Refer to your

operator’s manual for recommended battery charging.

“E” Cylinder Bracket Assembly Instructions

This assembly (P/N 33978) is part of kit, P/N 11372.

Quantity Description

1 each Saddle

1 each Center post wit h Ve lcro cylinder straps

2 each 1/4”-20 counter-sink allen-head screws

4 each 1/4”-20 round-head allen screws

4 each Lock washers

Tools Required for Assembly

1 each 5/32” hex wrench/driver

1 each drill with 17/64” bit

1 each ruler

1 each center punch

3-14 L1524

Page 50

AVEA Ventilator Systems

Standard Stand Tank Rack Bracket Installation

Basic Stand Tank Rack Bracket Installation

1. Install the center post in the tank bracket using tw o flathead 1/4"-20 thread screws to secure.

(Figure 3.10)

Figure 3-10 Basic Stand Assembly

Place assembled tank bracket on short side of “H ” stand legs. (Figure 3.11)

Figure 3-11 Tank brackets

NOTE

If there are pre-drilled holes on the “H” stand, skip to Step 8.

2. Place tape measure under bracket. Slide bracket back 3/4” from the edge of the “H” cross piece.

(Figure 3.12)

Figure 3-12 Plate

L1524

3-15

Page 51

Service Manual

3. Center the bracket on the two legs of the “H”. The bracket shoul d be positioned approximately

11/16” from the outside edge of each leg. Recheck the initial 3/4” dimension measurement (refer

to Figure 3.13).

Figure 3-13 Plate Placement

4. Using a pencil, mark location of tank bracket in ce nter of slotted holes on the bracket.

(Figure 3.14).

Figure 3-14 Hole pattern