Vertiv Liebert DM Series User Manual

Liebert DM S

eries

Precision Air Conditioner

User Manual

Copyright by Vertiv Co. Ltd.

The content in this document is subject to change without notice. All rights, including rights of

translation, reproduced by printing, copying or similar methods, and even of parts, are reserved.

Violators will be liable for damages. All rights, including rights deriving from patent license or

registration of a utility model or design, are reserved. No part of this document may be

reproduced or transmitted in any form or by any means without the prior written consent of

Vertiv Co. Ltd.

Notice

The purchased products, services, and features are stipulated by the contract made between

Vertiv Co., and the customer. All or part of the products, services, and features described in this

document may not be within the purchasing scope or the usage scope. Unless otherwise

specified in the contract, all statements, information, and recommendations in this document are

provided "AS IS" without warranties, guarantees or representations of any kind, either express or

implied. The information in this document is subject to change without notice. Every effort has

been made in the preparation of this document to ensure the accuracy of the contents, but all

statements, information, and recommendations in this document do not constitute a warranty of

any kind, express or implied.

Vertiv Co., Ltd.

• China

Website: www.vertivco.com.

E-mail:

Customer service hotline:

• Asia Pacific

Homepage: www.vertivco.com.

E-mail:

For Technical Support, users may contact the nearest Vertiv Co. local sales office or service

center.

support@Vertivco.com.

4008876510

overseas.support@Vertivco.com

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

Purpose of the Document

Situation

Description

The Warning/Danger/Caution note

degradation, or interruption in service.

The Note section indicates additional and

This document applies to the Liebert DM series of precision air conditioners and cooling solutions

which maintain an optimal environmental control mainly for testing laboratories, data center rooms

and similar technological ecosystems at minimal operating costs.

This document explains the product description, installation measures, operational workflow,

maintenance, and detailed aspects from the user perspective. The figures used in this document

are for reference only.

Please read this manual carefully before installing, maintaining, and troubleshooting, especially

the warning information in the manual

Styling used in this Guide

The styles used in the manual will be defined as mentioned in the following table:

indicates a hazardous or potentially

Warning/Danger/Caution

harmful situation that can result in death

or injury. It also indicates instructions that

need to be adhered to, failing which may

result in danger and safety issues thereby

having an adverse effect on the reliability

of the device and security. Even for

practices not related to physical injury, the

content under the Warning heading is

used for precautions which need to be

taken which, otherwise, could result in

equipment damage, performance

Note

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

useful information including tips and

tweaks. It also calls attention to best

practices and industry-best protocols that

are standardized and help make maximum

utilization of the resources at hand.

Helpful information related to the

mainstream stuff also comes under the

Note heading helping the users get to

grips with the definitions, concepts, and

terminologies used in the manual.

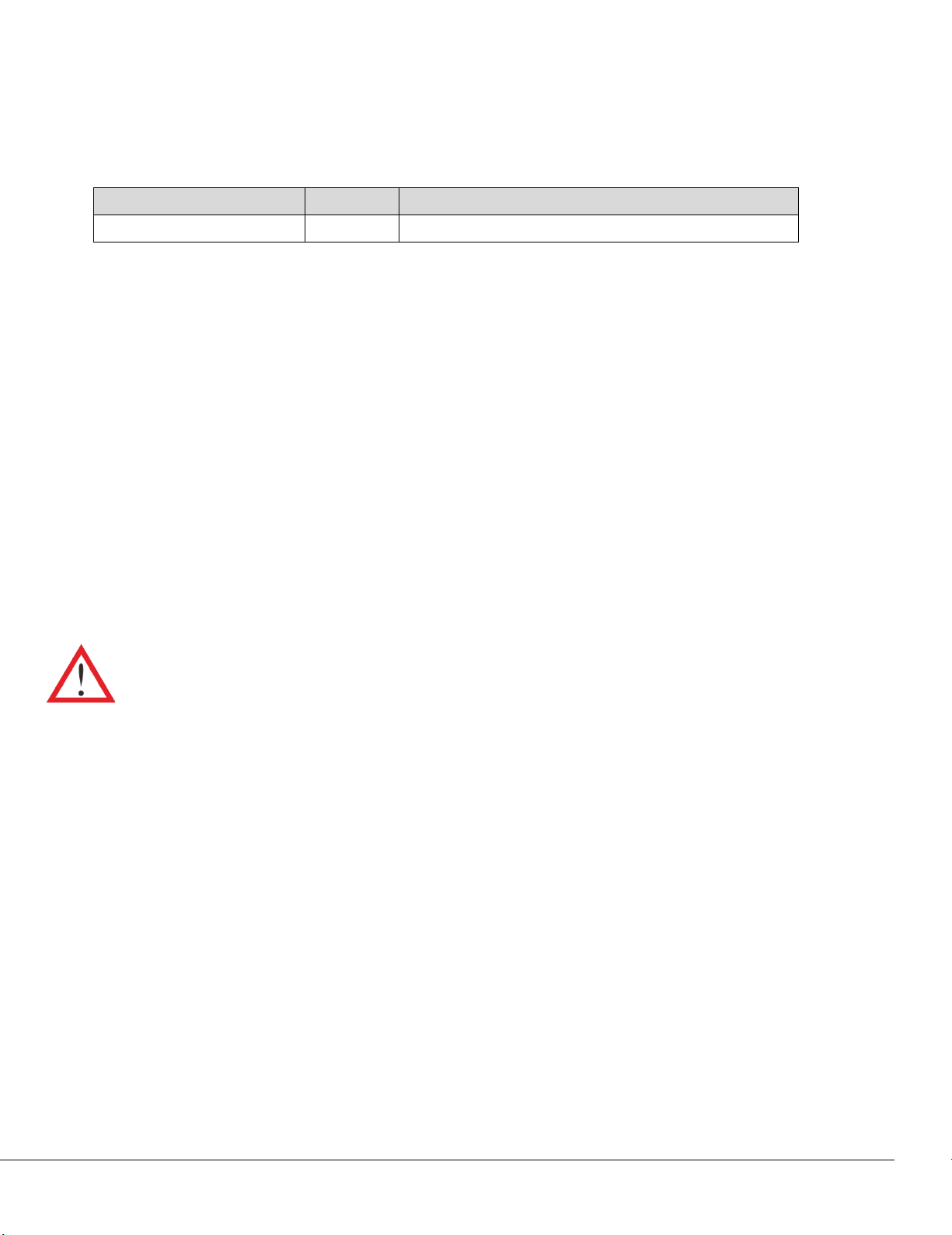

Version History

Issue

Revision

Changes

1

1.0

-------

afety Precautions and Measures

S

The important safety precautions and measures that should be followed during the installation and

maintenance of the Liebert DM models are described in the following sections.

Read the manual prior to installation and operation of the unit. Only qualified personnel should

move, install, or service this equipment.

The user reads and takes into account all the precautions, compliance, and safety measures before

working on the equipment. The unit control must be used exclusively for the purpose which it is

intended for; the manufacturer takes no liability for incorrect use or a modification to the unit

control.

Adhere to all the Warnings and Cautionary measures included in the manual.

Please read this manual carefully before installing, maintaining and troubleshooting; especially the

Warning/ Danger/ Caution information in the User Guide. Apart from the User Guide, also pay

attention to the warning labels on the unit and its components.

This manual is retained for the entire service life of the machine. The user must read all the

precautions, danger, warnings, and cautionary measures mentioned in the manual prior to

carrying out any operations on the machine. Each machine is equipped with an electric

insulation which allows the users to work in safe conditions. The main switch is positioned on

the electrical panel cover; Open the right door to access it. Before any maintenance operation,

switch off the machine with this electronic insulation device in order to eliminate risks such as

electrical shocks, burns, automatic restarting, moving parts, and remote control. The panel key,

supplied along with the unit, must be kept by the personnel responsible for the maintenance.

The protective covers can be removed after the electric power has been cut off by opening

the main switch.

In the following section, take a look at the various cautionary measures and warnings that need to be read

carefully prior to installing or operating the system.

Disconnect the local and remote power supplies prior to working with the unit.

Prior to the installation process, read all the instructions, verify if all the parts are in place, and check the

nameplate to ensure that the voltage matches the utility power that is available for that unit.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

The controller doesn’t isolate power from the unit even in the Off mode. Moreover, some internal

components require and receive power even during the Off mode.

If the unit door is open while the fans are operating, the airflow may result in abrupt slamming of the door

resulting in injury. Another aspect is the presence of small objects in the fans bay which may result in object

ejection during the fan start-up and there is a probable risk of being hit by these objects leading to grievous

injury as well as causing equipment damage.

The unit contains fluids and gasses under high pressure. Therefore, the pressure should be relieved

before working with the piping.

Various components such as compressors, refrigerant discharge lines, and humidifiers are extremely hot

during the unit operation. Therefore, allow sufficient time for the unit to cool down before working with the

unit cabinet. Handle the unit with extreme caution and wear safety equipment such as protective gloves,

safety shoes, and arm protection while working with the hot compressors, discharge lines, and reheats.

There is a risk of leaking water that can cause damage to the equipment as well as the building. There

should be an effective water drain connection and facilities. Installation should be precise. Implementation

of the application and service practices should be suitable and fault-free. Not complying with these norms

will result in water leakage from the unit. Water leakage can result in massive damage and loss of critical

equipment in the hosting ecosystem. Therefore, care should be taken to ensure that the unit must not be

located directly above any equipment that could sustain damage due to water and excessive moisture.

Using a leak detection system for unit and system supply lines are recommended by Vertiv Co.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

TABLE OF CONTENTS

PART I - GENERAL INFORMATION

1 Introduction ......................................................................................................................................................................................... 2

1.1 Model Nomenclature....................................................................................................................................................... 3

1.2 Basic Performance Parameters .............................................................................................................................. 3

1.3 Product Description ........................................................................................................................................................ 4

1.3.1 Compressor ......................................................................................................................................................... 5

1.3.2 Evaporator ........................................................................................................................................................... 6

1.3.3 Thermal expansion valve (TXV) ......................................................................................................... 6

1.3.4 Micro-processing Controller.................................................................................................................. 7

1.3.5 Strainer .................................................................................................................................................................. 7

1.3.6 Filter ......................................................................................................................................................................... 8

1.3.7 Centrifugal Fan................................................................................................................................................. 8

1.3.8 Condenser ........................................................................................................................................................... 8

1.3.9 Sight Glass .......................................................................................................................................................... 9

1.3.10 Infrared Humidifier ..................................................................................................................................... 9

1.4 Optional Components ................................................................................................................................................ 10

1.4.1 Electric Heater ............................................................................................................................................. 10

1.4.2 Remote Monitor ........................................................................................................................................... 10

1.4.3 Energy-Saving Card ...................................................................................................................................11

1.4.4 Power SPD..........................................................................................................................................................11

1.5 Working Conditions................................................................................................................................... 11

1.5.1 Operating Environment ............................................................................................................................ 12

1.5.2 Storage Environment ................................................................................................................................ 13

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

1.5.3 Refrigerant Charging Requirement ................................................................................................ 13

PART II - INSTALLATION

2 Installation .......................................................................................................................................................................................... 15

2.1 Pre-Installation ................................................................................................................................................................. 15

2.1.1 Transportation and Movement ........................................................................................................... 15

2.1.2 Unpacking..........................................................................................................................................................16

2.1.3 Inspection .......................................................................................................................................................... 17

2.2 Installation Preparation (Site Preparation) ................................................................................................. 17

2.2.1 Equipment Room Requirement.......................................................................................................... 17

2.2.2 Installation Space requirements .......................................................................................................18

2.2.3 Installation Tools.........................................................................................................................................20

2.3 Mechanical Installation .............................................................................................................................................. 21

2.3.1 System arrangement during installation..................................................................................... 21

2.3.2 System Installation Mode ..................................................................................................................... 23

2.3.3 Product Dimensions ................................................................................................................................. 24

2.3.4 Outdoor unit ................................................................................................................................................... 25

2.3.5 Indoor Unit Installation ........................................................................................................................... 26

2.3.6 Outdoor Unit Installation ...................................................................................................................... 27

2.3.7 Procedure ......................................................................................................................................................... 27

2.3.8 Piping for AC Unit ...................................................................................................................................... 29

2.3.9 Installation Notes Of Connector ..................................................................................................... 30

2.3.10 Required Pipe Connections............................................................................................................... 31

2.3.11 Connecting Refrigerant Pipe ............................................................................................................. 31

2.3.12 Pipe connector position ...................................................................................................................... 33

2.3.13 Connecting discharge pipe ............................................................................................................... 34

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

2.3.14 Connecting liquid pipe ......................................................................................................................... 34

2.3.15 Connecting Drain Pipe Of Indoor Unit ...................................................................................... 35

2.3.16 Connecting Humidifier Water Supply Pipe (If Applicable) ........................................ 35

2.3.17 Removing Transportation Fastener And Vibration Absorber ................................. 35

2.3.18 Adding Refrigerant For Long Pipe System ........................................................................... 36

2.3.19 Check List ...................................................................................................................................................... 37

2.4 Electrical Installation .................................................................................................................................................. 38

2.4.1 On-site Wire connections ..................................................................................................................... 38

2.4.2 Installation Notes ....................................................................................................................................... 38

2.4.3 Connecting Power Cable Of Indoor Unit ................................................................................... 39

2.4.4 Connecting Power Cable Of Outdoor Unit ............................................................................. 40

2.4.5 Connecting Control Terminals ......................................................................................................... 41

2.4.6 Connecting Monitoring Port Cable ............................................................................................... 45

2.4.7 Connecting Energy-Saving Card .................................................................................................... 45

2.4.8 Checklist ........................................................................................................................................................... 47

PART III - SYSTEM OPERATION & GENERAL MAINTENANCE

3 System Operation ......................................................................................................................................................................... 51

3.1 Start-Up Inspection ....................................................................................................................................................... 51

3.2 Micro-Processing Controller................................................................................................................................. 52

3.2.1 Features ............................................................................................................................................................. 52

3.2.2 Appearance ..................................................................................................................................................... 52

3.2.3 LCD Screen ..................................................................................................................................................... 53

3.2.4 Control Buttons ........................................................................................................................................... 53

3.2.5 Control Buttons Operation Example ............................................................................................ 54

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

3.2.6 ON Screen ........................................................................................................................................................ 55

3.2.7 Language Screen ........................................................................................................................................ 55

3.2.8 Normal Screen .............................................................................................................................................. 56

3.2.9 Password Screen ........................................................................................................................................ 56

3.3 Function Testing ........................................................................................................................................................... 57

3.3.1 Cooling ................................................................................................................................................................ 57

3.3.2 Heating............................................................................................................................................................... 58

3.3.3 Humidifying .................................................................................................................................................... 58

3.3.4 Dehumidifying .............................................................................................................................................. 58

3.3.5 Checking Refrigerant Charge Capacity of Low-Temp Outdoor .............................. 58

3.4 Micro-Processing Controller Menu Options ............................................................................................. 59

3.4.1 Main Menu........................................................................................................................................................ 59

3.4.2 Alarm Menu ................................................................................................................................................... 60

3.4.3 Set Points ......................................................................................................................................................... 63

3.4.4 System Status............................................................................................................................................... 63

3.4.5 System Menu .................................................................................................................................................66

3.4.6 Help Menu ....................................................................................................................................................... 67

3.4.7 Display Set .......................................................................................................................................................68

4 General Maintenance ................................................................................................................................................................69

4.1 Electric Inspection ........................................................................................................................................................ 70

4.2 Indoor Unit Maintenance ........................................................................................................................................ 70

4.2.1 Filter ...................................................................................................................................................................... 70

4.2.2 Fan ......................................................................................................................................................................... 72

4.2.3 Drain Pipe......................................................................................................................................................... 72

4.2.4 Heater ................................................................................................................................................................. 72

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

4.2.5 Humidifier ........................................................................................................................................................ 72

4.2.6 Power SPD ....................................................................................................................................................... 74

4.2.7 Thermal Expansion Valve..................................................................................................................... 76

4.2.8 High-Pressure Switch And Low-Pressure Switch ............................................................. 76

4.2.9 Compressor .................................................................................................................................................... 77

4.3 Outdoor Unit Maintenance .................................................................................................................................... 78

4.3.1 Refrigeration System................................................................................................................................ 78

4.3.2 Air-Cooled Condenser ............................................................................................................................ 78

4.3.3 Low-Temperature Unit Of Low-Temp Outdoor Unit ....................................................... 78

4.4 Maintenance Inspection Checklist .................................................................................................................. 79

4.5 Troubleshooting .............................................................................................................................................................81

APPENDIX 1 - Crcuit Diagrams .................................................................................................................................... 86

APPENDIX 2 Menu Structure ...................................................................................................................................... 87

APPENDIX 3 Parameter Setting Table................................................................................................................... 88

APPENDIX 4 - RDU-Cooling AC Single-Unit Manager Software Introduction ............................91

APPENDIX 5 - Hazardous Substances List........................................................................................................94

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual

PART I

GENERAL INFORMATION

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 1

1 Introduction

The Liebert DM series is the next generation series of small air conditioners that provide precise

environmental control. The Liebert DM models are the latest in the long line of modern enterprisegrade products from the Liebert family. Incorporating the high standards associated with the Liebert

name, the DM series utilizes the latest technology, system components, and a streamlined

manufacturing process.

Liebert DM air conditioners are products that are specifically created and designed for cooling the

electrical devices. It is applicable to equipment rooms, computer rooms, and similar ecosystems

which call for a high degree of accuracy and precision in maintaining the ambient temperature. It

addresses the needs and challenges associated with such applications and setups. It caters to

sensitive applications which need a suitable environment for optimal performance. Therefore, care

should be taken while testing these sensitive products or maintaining a favorable environment for

mission critical equipment, as even a slight deviation may lead to inaccurate results. Precision Air

Conditioning must not only keep room conditions within a specific range but also must have the

precision to react quickly to a drastic change in heat load and prevent wide temperature fluctuations.

The DM air cooled AC unit is packed with features such as high reliability, high sensible heat ratio,

and large airflow. The unit is an air-cooled single cooling system and configured with DC Speed

Regulation back- inclined centrifugal fan.

Packed with a host of features, it lowers the sound emissions significantly and thereby reduces the

noise pollution. It is a top-notch system that adheres to the standard in Precision Air Cooling in

terms of energy-efficiency, space requirements, and reliability.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 2

Figure 1-1 shows the appearance of various models in the Liebert DM series:

Figure 1-1

1.1 Model Nomenclature

The model nomenclature of the Liebert DM AC is shown in Figure 1-2:

Figure 1-1

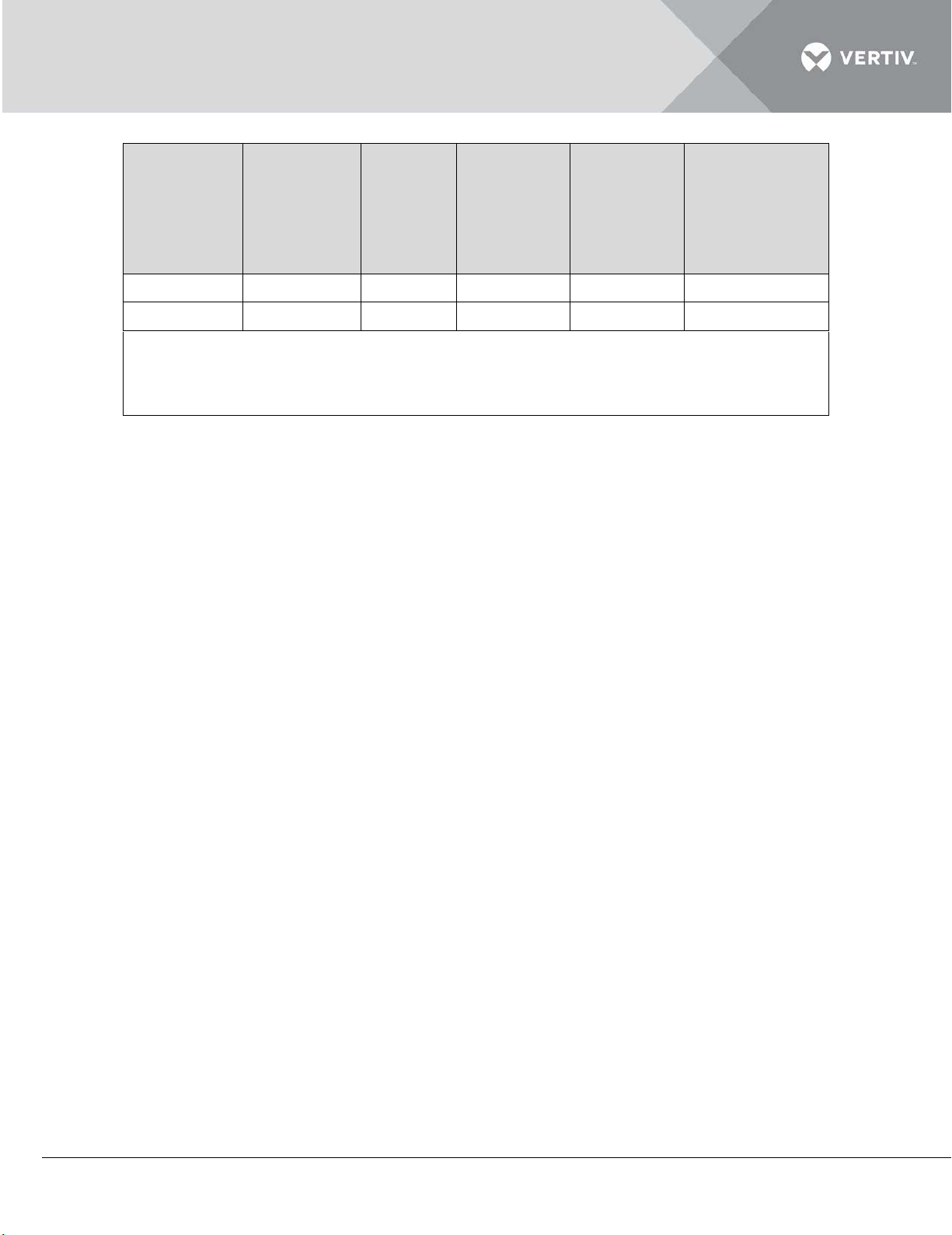

1.2 Basic Performance Parameters

The basic performance parameters of the Liebert DM AC are given in Table within

Listing 1.1.

Listing 1.1

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 3

Model

Nominal

cooling

capacity

(kW)

Power

(kW)

Annual

energy

efficiency

ratio

Heating

capacity

[1]

(kW)

Humidification

capacity

[2]

(kg/h)

DME07M**5

6.85

2.36

2.9

3.2

1.5

DME12M**5

11.9

4.1

2.9

3.2

1.5

Note:

[1]: The heating capacity is only for the models with heating function;

[2]: The humidification capacity is only for the models with humidification function

1.3 Product Description

The Liebert DM AC unit is a comprehensive system that includes all the main functions fundamental to

precision cooling units such as cooling, humidification, dehumidification, re-heating, air filtration,

condensation management, temperature and humidity control, alarm functions and compatibility with

data communications. Liebert DM AC is designed to comply with mission-critical requirements and

ensure that servers are maintained at the correct temperature and humidity levels.

Figure 1-3 shows the various components and their respective locations:

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 4

Figure 1-2

Item

Description

Item

Description

1

Heater

2

Evaporator

3

Centrifugal Fan

4

Compressor

5

Infrared Humidifier

6

Microcontroller Display

7

Filter

Listing 1.2

In the following sections, take a look at the list of components used in the Liebert DM AC series.

1.3.1 Compressor

The Liebert DM AC series models comprise of a scroll compressor which has a host of promising

features such as low operating noise, less vibration and high reliability. Its compactness, smooth

compression with scroll operation and high energy efficiency ratio makes it an ideal compressor to

bank on for the DM series.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 5

Figure 1-3 shows the image of a compressor.

Figure 1-4

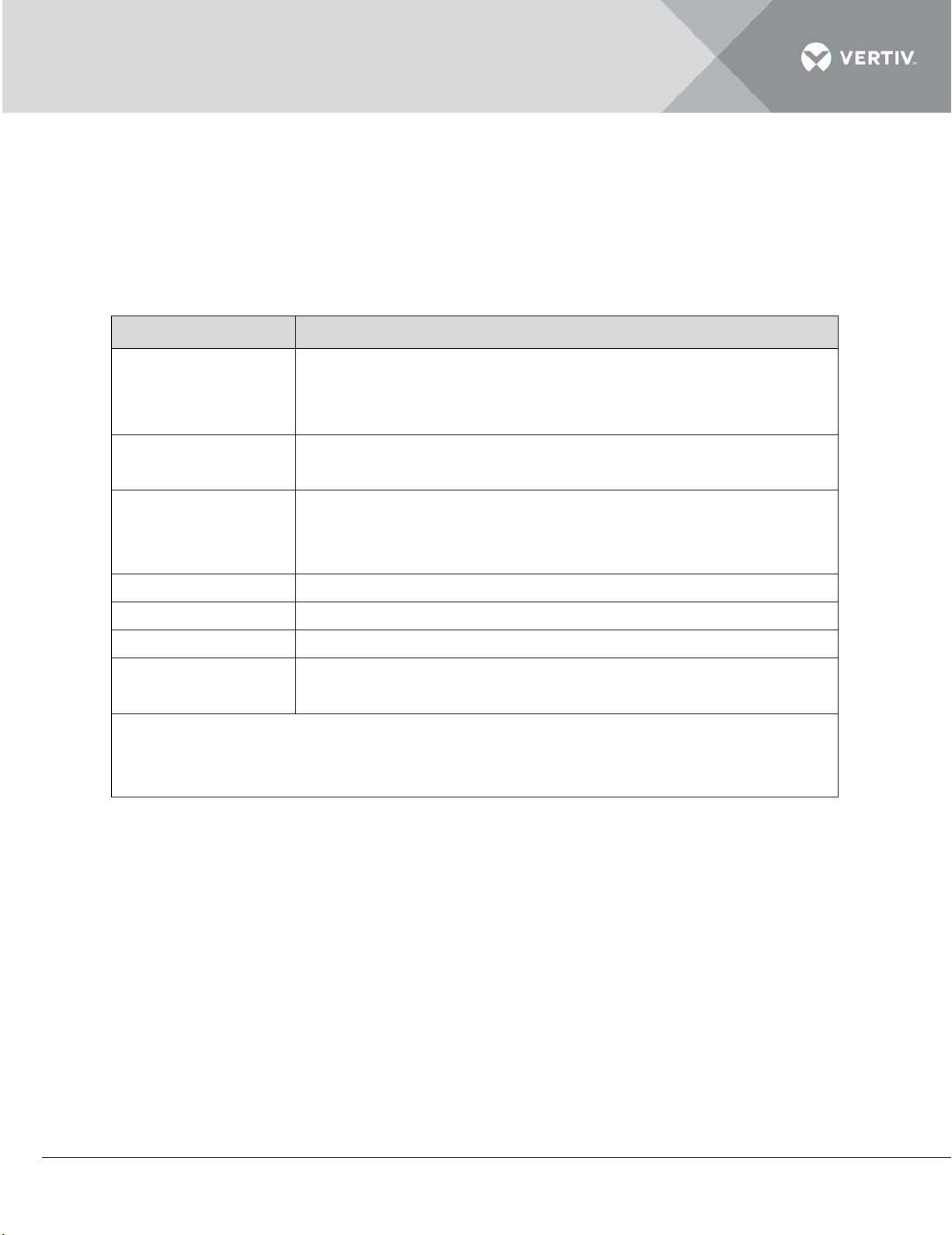

1.3.2 Evaporator

Heat exchanger design and appropriate air distributions are important factors that determine optimum

performance. The Evaporator used in the Liebert DM AC models consists of a fin-tube heat exchanger

for higher efficiency. The sophisticated design of the distributor ensures that the refrigerant is

distributed evenly in each loop, thereby improving the effectiveness of the heat exchanger.

Figure 1-5 shows the image of an Evaporator.

Figure 1-5

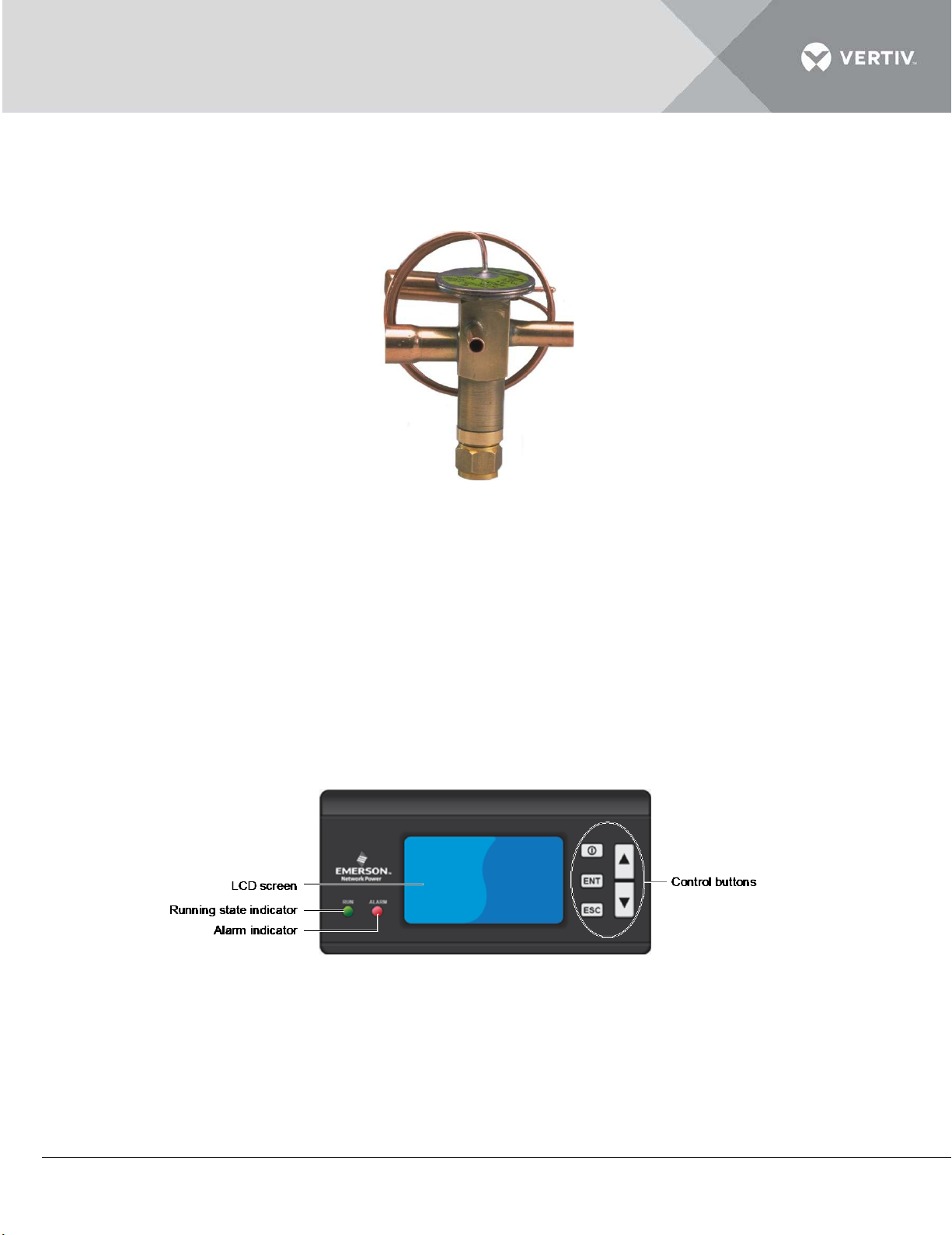

1.3.3 Thermal expansion valve (TXV)

The thermal expansion valve controls the amount of refrigerant flow into the evaporator thereby

controlling the superheat at the outlet of the evaporator. Liebert DM consists of a thermal expansion

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 6

valve with external equalizer type. It collects temperature and pressure signals at the same time to

accurately regulate the refrigerant flow.

Figure 1-5 depicts the image for the TXV:

Figure 1-6

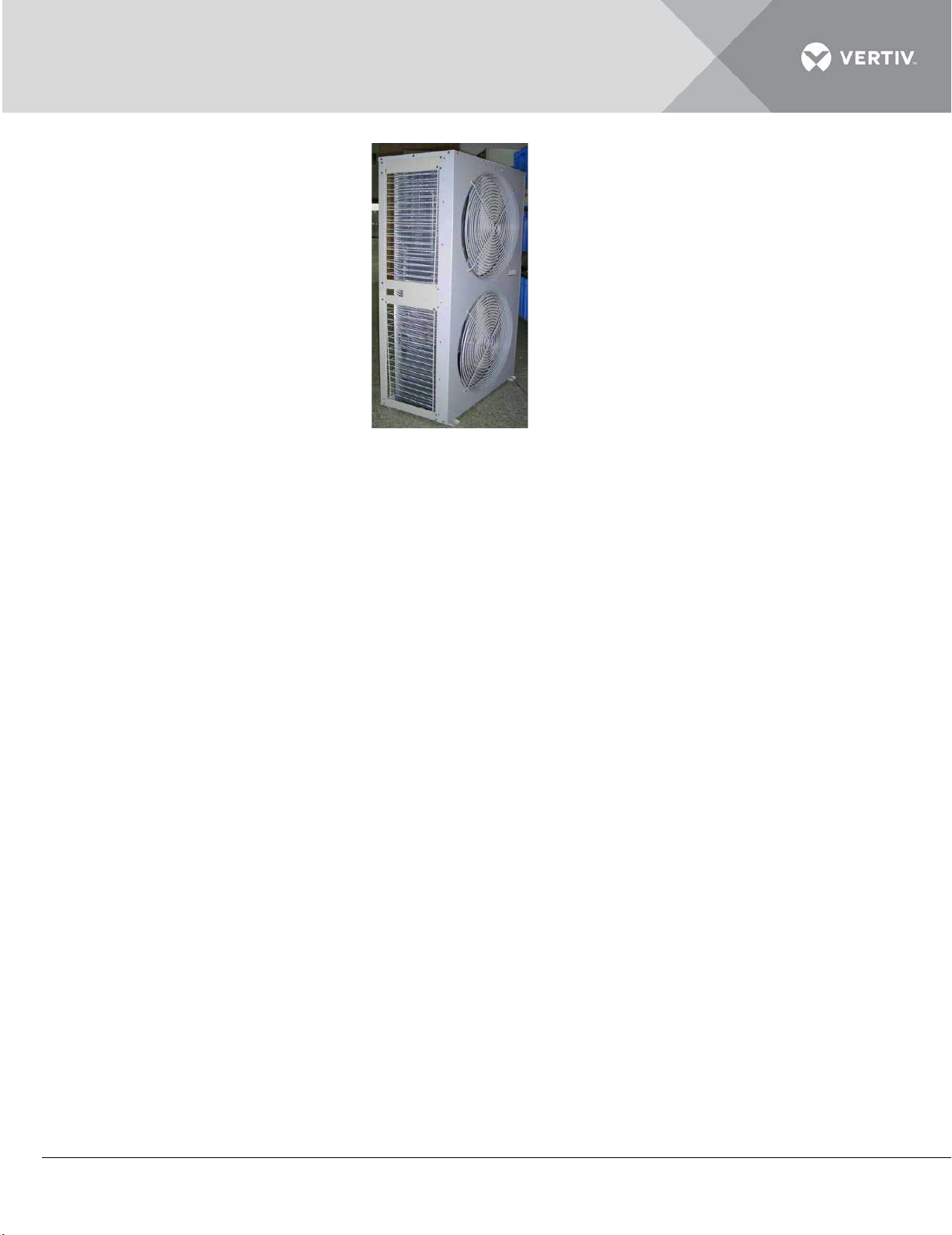

1.3.4 Micro-processing Controller

The Controller adheres to the latest and highly advanced PID regulation technology. It provides a

simple operation user interface with multi-level password protection, self-recovery upon power failure,

high-voltage & low-voltage protection, phase loss protection, automatic phase-sequence switching

upon anti-phase and rotate speed control of the outdoor fan. The expert-level fault diagnoses system

can automatically display current fault information to facilitate equipment maintenance by

maintenance personnel.

Figure 1-7 depicts the panel of the Microcontroller:

Figure 1-7

1.3.5 Strainer

The Strainer filters the impurities generated during long-term system operation and ensures normal

system operation.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 7

1.3.6 Filter

Moisture can have an adverse effect on the operation and life of a system in the refrigeration cycle.

To counter that effect, Filter-driers are used to filter out particles, and remove and hold moisture to

prevent it from circulating through the system. The Liebert DM AC consists of nylon filter material

with big mesh. The filter features compact structure and easy maintenance. It can be washed

repeatedly.

1.3.7 Centrifugal Fan

Centrifugal fans are rigid and strong metal fans. Its axial flow blades help in reducing the noise. The

single-phase motor with high performance is customized based on the power grid of base stations, so

it can work over a wide voltage range with high reliability. It features large airflow, long blowing

distance, direct driving and easy maintenance.

Figure 1-8 depicts the image for the Centrifugal Fan:

Figure 1-8

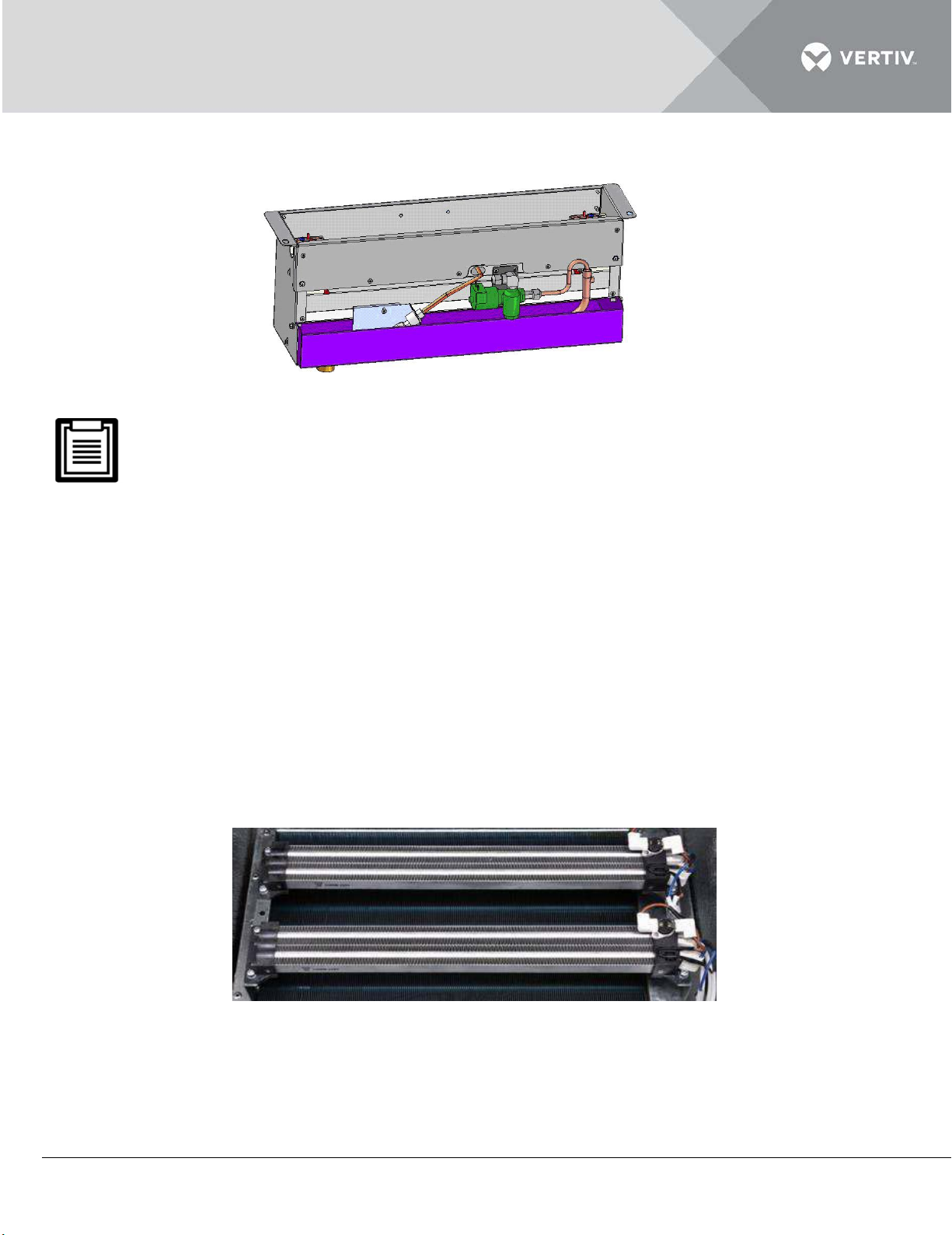

1.3.8 Condenser

The Liebert range of air-cooled condensers offers many advantages, including sharp design, antirust

aluminum cabinets, low sound levels, and reliable operations over a wide range of ambient conditions.

Figure 1-9 depicts the image of a condenser:

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 8

Figure 1-9

1.3.9 Sight Glass

The sight glass is a utility for observing the refrigerant state; specifically the moisture content of the

system. If the moisture content exceeds the levels of defined standards the color changes, thereby,

indicating irregularity in the moisture content.

1.3.10 Infrared Humidifier

The infrared humidifier consists of infrared humidifier lamp, water injection valve, humidifying water

dish, temperature alarm protection devices and water level alarm device.

The infrared humidifier in the Liebert DM series provides quicker and more responsive operation

which is quite important for mission-critical applications. These humidifiers reduce the dependency of

water quality and simultaneously achieve full capacity in quick time using almost any water quality.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 9

Figure 1-10 depicts the image of a Humidifier.

Figure 1-10 Humidifier

1. The electrode humidifier should be installed and tested at the factory.

2. The Liebert DM AC can control the ambient humidity only after a humidifier is installed.

1.4 Optional Components

1.4.1 Electric Heater

T

he PTC electric heaters are used as they have lower running temperatures thereby ensuring

operational safety. PTC heaters are less susceptible to overheating and therefore, are long lasting

due to less wear. Lower maintenance and smooth functioning make it an important utility in Liebert DM

AC models.

Figure 1-11 shows an image of the Electric Heater:

igure 1-11

F

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 10

1.4.2 Remote Monitor

The Liebert DM AC communicates with the host computer through a configured RS485 port and

receives the control of the host software. Select and configure a monitoring card to realize different

monitoring functions. For the descriptions of the host monitoring software RDU-Cooling developed by

Vertiv Co., Refer to Appendix 4 RDU-Cooling Air-Conditioner Single-Unit Manager Software

Introduction.

1.4.3 Energy-Saving Card

The Liebert DM AC can monitor the maximum room temperature with the energy-saving card

located outside the unit cabinet. The card is placed in position with high heat load and temperature.

Up to four cards can be used for an AC unit. When the temperatures measured by all energy-saving

cards are lower than the set-point in ‘Sleep Mod’ and the only indoor fan is running; if the ‘Sleep Mod’

is set to ‘ENAB’, the AC unit will turn off the indoor fan and enter the sleep mode for saving the

energy.

1.4.4 Power SPD

T

he power SPD is used for the second level (C level) lightning over-voltage protection of the AC

power. It can be easily maintained and provides status indicating and alarm function.

1.5 Working Conditions

In

this section, take a look at the environmental conditions including the Operating and Storage

environment.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 11

1.5.1 Operating Environment

The table in Listing 1.3 defines the Operating environment parameters including the Ambient

Temperature, Protection level, Altitude, and Voltage range.

Listing 1.3

Item Requirements

The maximum equivalent horizontal distance between the

Installation position

indoor unit and outdoor unit

Vertical distance ΔH

[2]

[1]

: 50m;

: -5m ≤ ΔH ≤ 20m

Installation mode

Indoor unit: vertical mode, mounting base ≥ 150mm;

outdoor unit: horizontal airflow mode

Indoor: 0°C ~ 40°C

Ambient

Outdoor: standard model, -15°C ~ +45°C; Low-Temp model, -

temperature

34°C ~ +45°C

Ambient humidity 30%RH ~ 80%RH

Protection level Outdoor unit: IPX4

Altitude < 1000m. Derating is required when the altitude exceeds 1000m

Operation voltage

range

380V (-15% ~ +15%), settable according to different

environments, the tolerance is 3%

Note: [1]: For the equivalent lengths of parts, refer to Listing 2.5

[2]: The value is positive if the outdoor unit is installed above the indoor unit; negative

if the indoor unit is installed above the outdoor unit

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 12

1.5.2 Storage Environment

Item

Requirement

Storage environment

Indoor, clean (without dust)

Ambient humidity

5%RH ~ 85%RH

Ambient temperature

-40°C ~ +70°C

Total transportation and storage time should not exceed

Brand

Logo

Note

The DU PONT refrigerant adapts

The following table defines the Storage Environment parameters including the ambient humidity,

ambient temperature, and storage time conditions.

Listing 1.4

Storage time

six months. Otherwise, the performance needs to be recalibrated

Another essential aspect is the quality and the make of the refrigerant oil. Adding poor quality oil,

counterfeit oil, or oil for a different model will damage the system. The quality issue due to the wrong

refrigerant oil will result in the voiding of warranty.

1.5.3 Refrigerant Charging Requirement

The low quality or counterfeit refrigerant will damage the system severely. Please use the refrigerant

approved by Vertiv Co., Ltd. For the system abnormality or damage caused by using other brands of

refrigerant, Refer the table in listing 1.5 for the refrigerant brands approved by Vertiv Co., Ltd.

Listing 1.5

DU PONT

custom made package

JUHUA

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 13

Part II

INSTALLATION

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 14

2 Installation

2.1 Pre-Installation

Pre-installation contains the following 3 sub-sections, namely –

Transportation and Movement Unpacking Inspection

2.1.1 Transportation and Movement

When transporting the system, Railroad is a preferable choice. However, if railroad transportation is

not possible, then the truck transport option is an optimal choice. One precaution is to choose roads

that do not have too many bumps and if any, avoid it as much as possible.

It is recommended that equipment like an electric forklift is utilized for these heavy duty systems.

Move the equipment to a location which is in the vicinity of the installation site.

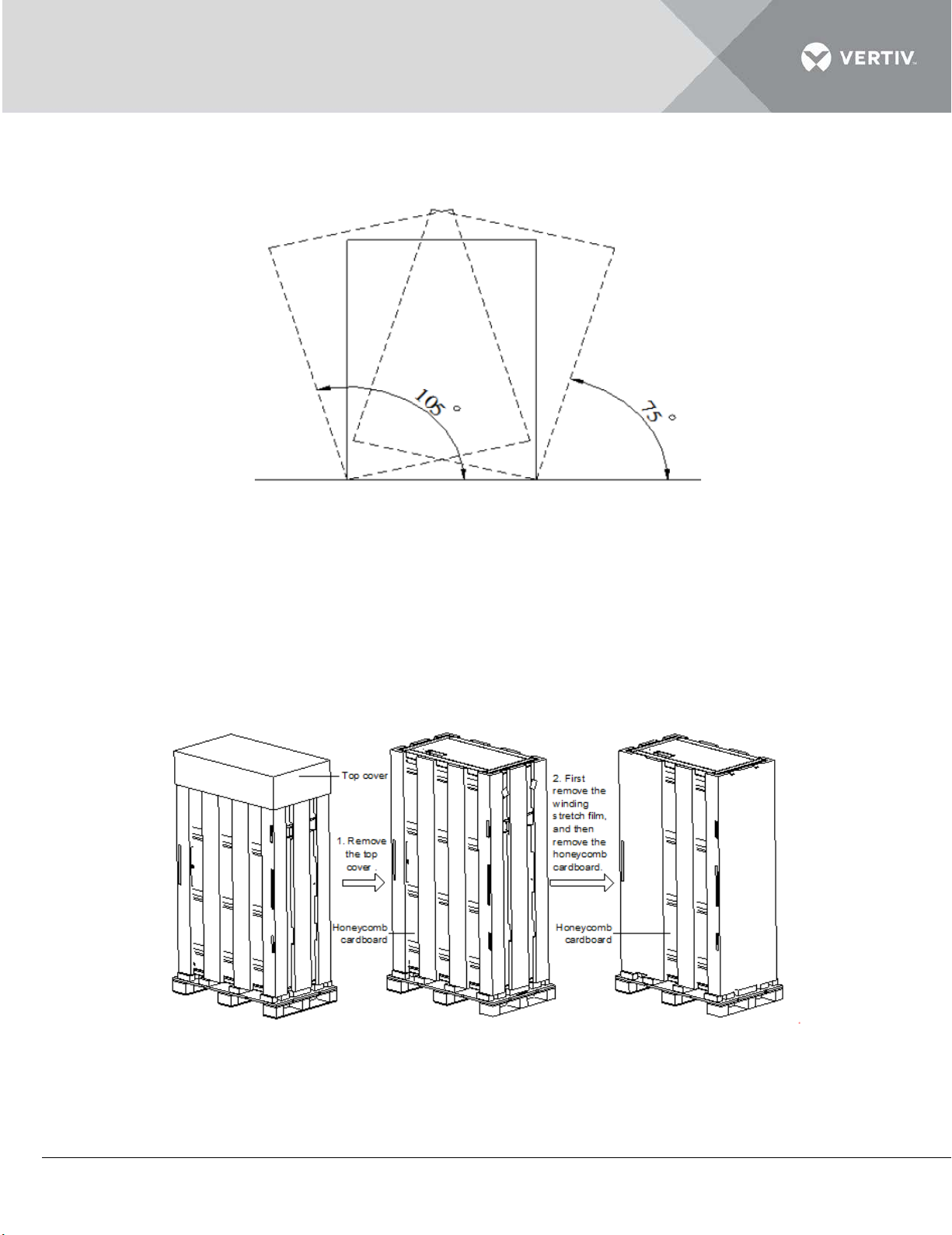

If an electric forklift is used, insert the tines of the forklift below the pallet as displayed in Figure 2-1.

Align the tines with the center of gravity to prevent the equipment from falling over. Figure 2-1

depicts the way the tines of the forklift are inserted below the pallet and in the same image; the

graphic to the right indicates that the tines are aligned with the center of gravity to prevent the

equipment from falling over:

Figure 2-1

In the previous Figure 2-1, the air conditioner is lifted using the forklift truck and is aligned with the

center of gravity. While moving the indoor unit, the obliquity has to be maintained at an angle of 75°

to 105°.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 15

Figure 2-2 depicts the 75° to 105° obliquity that is suitable to move the air conditioning package to the

vicinity of the desired location:

Figure 2-2

2.1.2 Unpacking

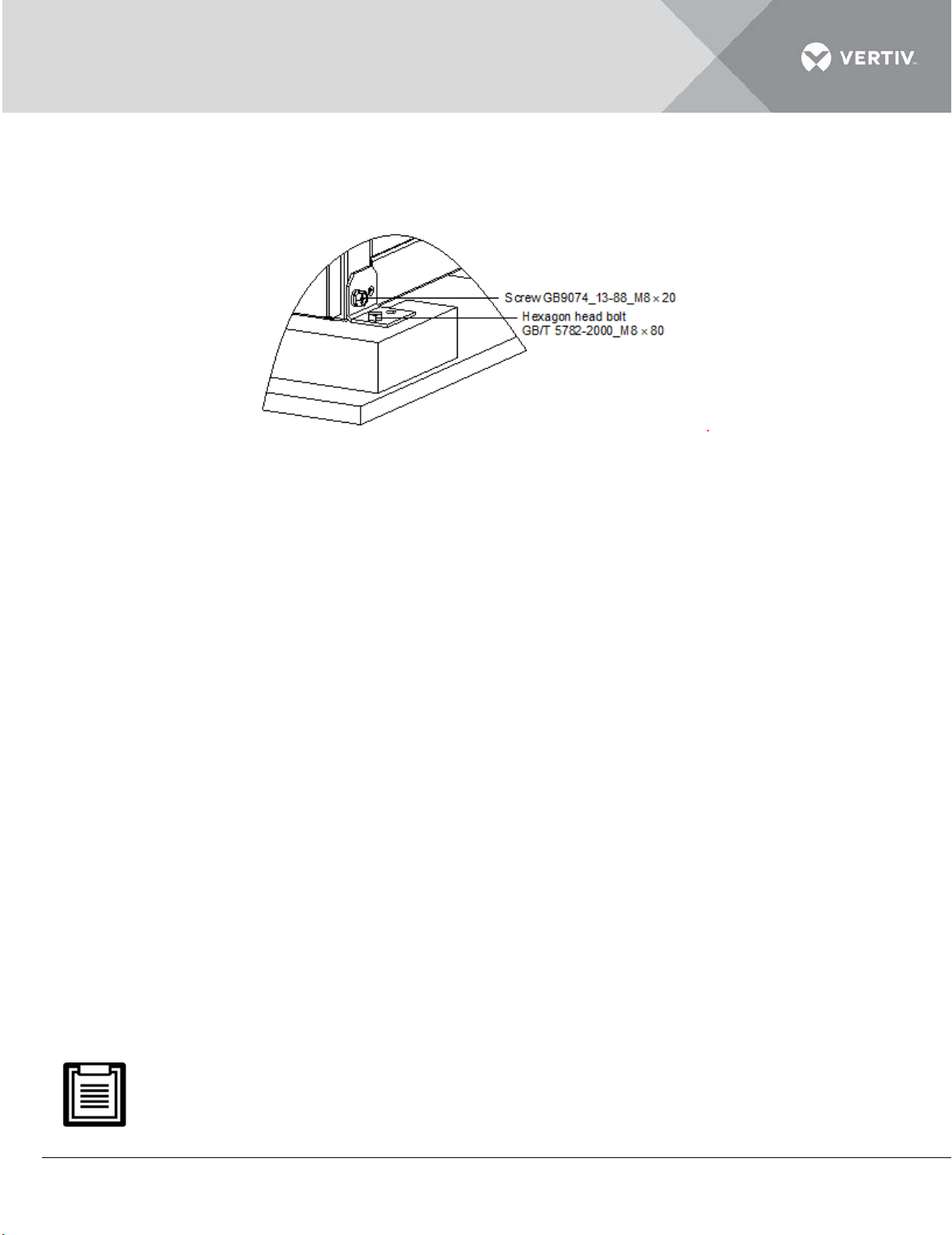

The cabinet uses a honeycomb cardboard and winding stretch film for packaging purposes. Shift the

product to a location closer to the final installation site prior to unpacking the unit.

Initially, remove the top cover and winding stretch film. Next, remove the honeycomb cardboard as

depicted in Figure 2-3.

Figure 2-3

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 16

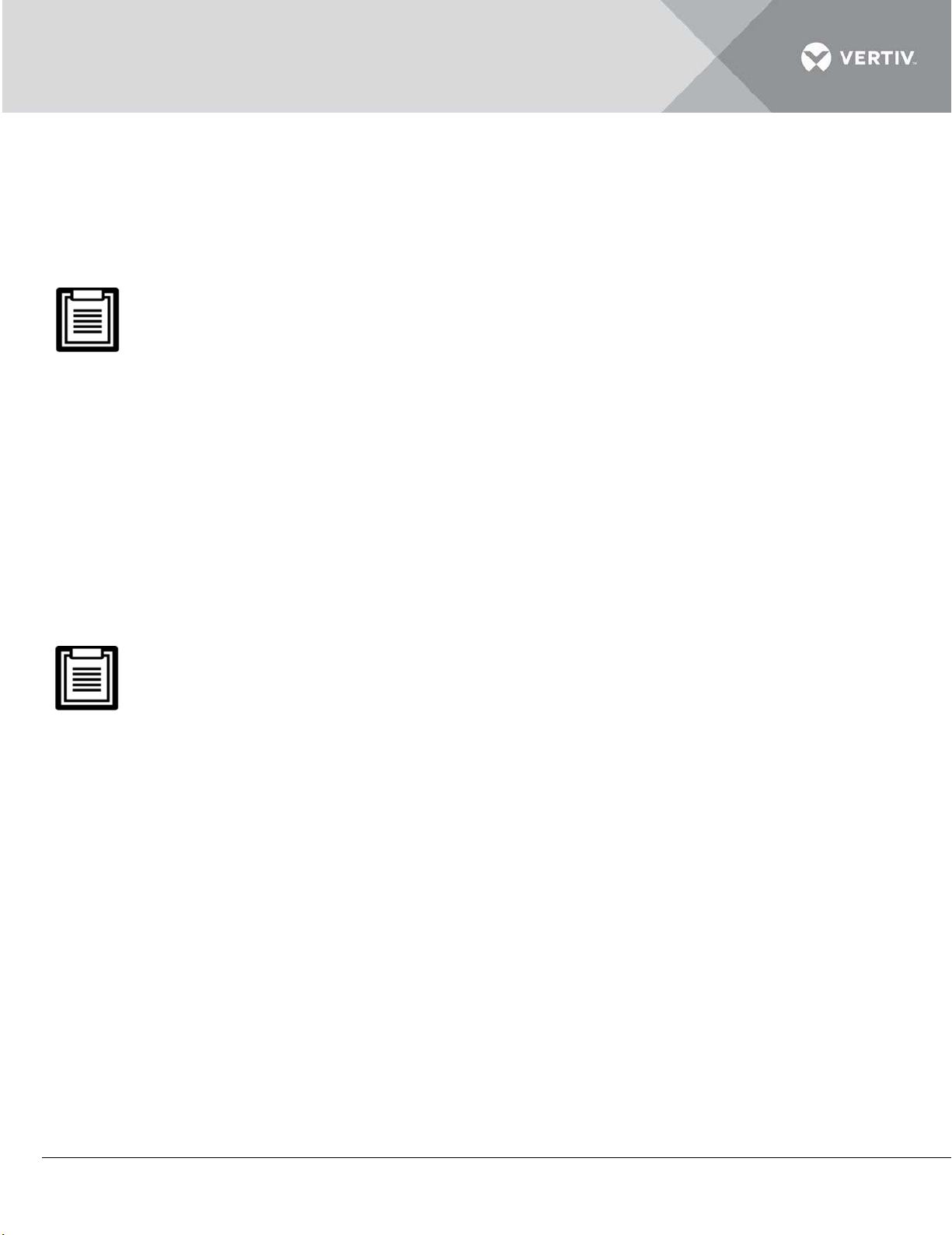

The unit is fixed on the packing pallet with M8*20 and M8*80 screws. Use a 17 mm open-end spanner,

ratchet spanner, or sleeve to remove the screws.

Figure 2-4 to shows the schematic diagram:

Figure 2-4

2.1.3 Inspection

Moving forward, check the system fittings and its components against the packing list to ensure that

everything is in place and the assembly is intact. If any parts or components are missing or damaged,

immediately report to the carrier about the same. If hidden damages are observed, then contact the

local offices of that carrier as well as Vertiv Co., at the earliest.

2.2 Installation Preparation (Site Preparation)

The Liebert DM AC series of air conditioners is streamlined for maintaining a favorable environment

for data centers, computer rooms, and similar ecosystems. Strict adherence to the installation

procedures is mandatory in order to ascertain proper installation of the air conditioner.

2.2.1 Equipment Room Requirement

The equipment room must be prepared to ensure a smooth operation flow and obtain accurate

results. The equipment room must meet the standards for appropriate ventilation and heating. The

design specifications for the air conditioners must be ideal and should match the energy-efficient

design standards.

Following are the requirements for maintaining a favorable room environment prior to installation:

The equipment room should be well insulated and have a sealed damp-proof layer.

The most important elements for maintaining normal environmental control in the conditioned room

are damp proof and heat preservation.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 17

The outside air will add to the loads of heating, cooling, humidifying and dehumidifying of the system. It is

recommended that the inhalation of outside air should be kept below 5% of the total indoor airflow.

All the doors and windows should be properly sealed to minimize the leakage and the seams should be as narrow

as possible.

Vertiv Co. recommends that the site preparation is defined as per the requirements. However, if these

requirements are not met, rectifications must be made on the site so that it complies with the specified

requirements and conditions. However, if the recommended rectifications or modifications are not

implemented, then Vertiv Co. does not guarantee the accuracy and precision of the temperature and

humidity provided by the Liebert DM model. One important aspect to be considered is that the indoor

unit must not be used for the outdoor environment.

2.2.2 Installation Space requirements

Air conditioners in the Liebert DM AC series are advanced precision air cooling units and therefore,

these air conditioners must be installed, preferably in a capacious floor space to ensure its normal

operation.

The Liebert DM AC can generate condensate water. Water leakage can cause damage to other precise

equipment nearby. Do not install the AC units in the vicinity of any precision equipment. The installation

site must provide drainpipes.

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 18

The installation location requirements are given as follows:

Not recommended location

location

Recommended

• Avoid locating the indoor unit in confined areas that affect the airflow pattern, shorten cooling cycles and

result in down-draft and air noise.

• Avoid locating the indoor unit in an alcove or at the extreme end of a long, narrow room.

• Avoid locating multiple indoor units close to each other. This can result in crossing air patterns, uneven

loads and compete for operation.

• Do not install additional devices (such as smoke detectors) over the cabinet for facilitating routine

maintenance.

The following Figure 2-5 depicts the installation location of the indoor unit.

Figure 2-5

Vertiv | Liebert DM Series Precision Air Conditioner | User Manual 19

Loading...

Loading...