Vertiv Liebert 10 User Manual

Liebert® 10 Fan Drycooler/Fluid

Cooler™

Including Quiet-Line Models, 120 to 150 Tons, 50 & 60 Hz

User Manual

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this manual to see if the issue can be resolved by following outlined procedures. Visit https://www.VertivCo.com/en-us/support/ for additional assistance.

TABLE OF CONTENTS

1 Introduction |

1 |

1.1 System Description and Standard Features |

1 |

1.2 Optional Features |

1 |

2 Product Performance Data & Selection |

5 |

2.1 Standard Data |

5 |

2.2 Typical Application |

7 |

2.3 Engineering Data, Calculations and Selection Procedure |

8 |

2.4 Selection Example |

11 |

3 Installation |

13 |

3.1 Location Considerations |

13 |

3.2 Site Preparation |

15 |

3.3 Equipment Inspection Upon Delivery |

16 |

3.4 Lifting and Handling the Drycooler |

16 |

3.4.1 Unit Weight |

17 |

3.5 Piping Connections |

17 |

3.5.1 Expansion Tanks, Fluid Relief Valves and Other Devices |

18 |

3.6 Filling Instructions |

22 |

3.6.1 Preparing the System for Filling |

22 |

3.6.2 Glycol Solutions |

22 |

3.6.3 Filling the System |

23 |

3.7 Electrical Connections |

24 |

3.7.1 Line Voltage |

24 |

3.7.2 LowVoltage Control Wiring |

25 |

3.8 Checklist for Completing Installation |

26 |

4 Operation |

29 |

4.1 Initial Startup Procedure |

29 |

4.1.1 Control Setpoints |

29 |

4.1.2 Current-Sensing Relays |

30 |

4.1.3 Cold Weather Operation |

31 |

5 System Maintenance |

33 |

5.1 General Procedures |

33 |

5.2 Special Procedures |

34 |

5.2.1 Drycooler Cleaning |

34 |

5.2.2 Maintenance Inspection Checklist |

35 |

6 Troubleshooting |

37 |

Vertiv | Liebert®10-fanDrycooler User Manual| |

i |

Vertiv | Liebert®10-fanDrycooler User Manual| |

ii |

Important Safety Instructions - Save These Instructions

This manual contains important safety instructions that should be followed during the installation and maintenance of the Liebert® 10 Fan Drycooler™. Read this manual thoroughly before attempting to install or operate this unit.

Only properly trained and qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions and installation, operating and safety instructions on the unit and in this manual. Followall operating and user instructions.

WARNING! Arc flash and electric shock hazard. Disconnect allelectric powersupplies and wear protective equipment perNFPA 70E before working within electric controlenclosure. Failure to complycan cause serious injuryordeath.

WARNING! Arc flash and electric shock hazard. Disconnect allelectric powersupplies and wear protective equipment perNFPA 70E before working within electric controlenclosure. Failure to complycan cause serious injuryordeath.

Customermust provide earth ground to unit, perNEC, CECand localcodes, as applicable.

Before proceeding with installation, read allinstructions, verifythat allthe parts are included and check the nameplate to be sure the voltage matches available utilitypower.

The line side of the disconnect switch on the front of the unit contains live high-voltage.

The onlywayto ensure that there is NO voltage inside the unit is to installand open a remote disconnect switch. Referto unit electricalschematic.

Follow alllocalcodes.

WARNING! Risk of high-speed moving parts. Can cause injuryordeath.

WARNING! Risk of high-speed moving parts. Can cause injuryordeath.

Disconnect alllocaland remote electric powersupplies before working in the unit.

Do not operate this unit with anyorallcabinet panels and/orblowerguards removed.

CAUTION: Risk of contact with hot surfaces. Can cause injury.

CAUTION: Risk of contact with hot surfaces. Can cause injury.

The blowermotors maybecome extremelyhot during unit operation. Allow sufficient time for themto coolbefore working within the unit cabinet. Use extreme caution and wearprotective gloves and armprotection when working on ornearhot blowermotors.

CAUTION: Risk of sharp edges, splinters and exposed fasteners. Can cause injury.

CAUTION: Risk of sharp edges, splinters and exposed fasteners. Can cause injury.

Onlyproperlytrained and qualified personnelwearing appropriate safetyheadgear, gloves, shoes and glasses should attempt to move the unit, lift it, remove packaging orprepare the unit forinstallation.

Vertiv | Liebert®10-fanDrycooler User Manual| |

iii |

NOTICE

Risk of clogged or leaking coolant fluid lines. Can cause equipment and building damage.

Improper installation, application and service practices can result in coolant fluid leakage from the unit that can result in severe property damage.

Vertiv™ recommends installing leak detection equipment for unit and supply lines.

NOTICE

Risk of a leaking coil due to freezing and/or corrosion. Can cause equipment and building damage.

Cooling coils and piping systems that are connected to open cooling towers or other open water/glycol systems are at high risk for freezing and premature corrosion. Fluids in these systems must contain the proper antifreeze and inhibitors to prevent freezing and premature coil corrosion. The water or water/glycol solution must be analyzed by a competent water treatment specialist before startup to establish the inhibitor requirement. The water or water/glycol solution must be analyzed every six months to determine the pattern of inhibitor depletion. The complexity of water-caused problems and their correction makes it important to obtain the advice of a water treatment specialist and followa regularly scheduled maintenance program.

NOTICE

Risk of damage from forklift. Can cause unit damage.

Keep tines of the forklift level and at a height suitable to fit belowthe skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Can cause unit damage.

Keep the Liebert 10-Fan Drycooler upright and protected from freezing temperatures and contact damage.

Vertiv | Liebert®10-fanDrycooler User Manual| |

iv |

1 INTRODUCTION

1.1 System Description and Standard Features

The Liebert® 10 Fan Drycooler/Fluid Cooler™ is designed for maximum heat rejection with minimum footprint and to be used with glycol solutions for large-site installations. It has a nominal range of 150 tons of heat rejection and is ideal for rejecting the heat of multiple evaporator units. Standard features include:

•Three different coil circuits: 068 (half), 136 (full), 272 (double). Each coil circuit is designed for a range of specific flowrates based on the particular application.

•Coil constructed of copper tubes in a staggered pattern expanded into continuous corrugated aluminum fins. The fins have full depth fin collars completely covering the copper tubes which are connected to heavy-wall type L headers. Inlet coil connector tubes pass through relieved holes in the tube sheet for maximum resistance to piping strain and vibration. Coil maximum operating pressure is 150 PSIG (1035 kPa).

•Wire guards constructed of coated wire, in 1"x 4"pattern, mounted to protect the exposed vertical coil surface.

•Current sensing relays are provided with customer connection to monitor change in motor current to detect possible motor/fan failure.

•Choice of either 60 or 50Hzmodels as well as a Liebert Quiet-Line™ 60Hz; comes from the factory completely assembled and pre-wired. Units are available in 208, 230, 460 and 575V, 3- phase, 60Hz, and 380/415V, 3-phase, 50Hz.

•Locking disconnect switch and fan cycling control.

•Unit frame of heavy galvanized steel for strength and corrosion resistance, divided internally into individual fan sections by full-width baffles to prevent fan reverse windmilling when not energized.

1.2Optional Features

Quiet-Line

The Liebert Quiet-Line 10 Fan Drycooler includes the same features as the standard Liebert10 Fan Drycooler, except that it has 8-pole motors in lieu of 6-pole motors for lower sound levels as well as reduced airflowand capacity. This option is not available on 50Hzunits.

Aluminum Grilles

Aluminum grilles are used for unit aesthetic and general mechanical security purposes. The aluminum grilles extend from the base of the unit and protect the exposed coil sides.

Coil Fin Options

Pre-Coated Fin Stock provides pre-coated coil fins for added protection in corrosive environments.

PhenolicCoated Coil provides a baked phenolic coated coil for added protection in corrosive environments.

CopperFin/CopperTubeCoil provides coil constructed of copper fins and copper tubes.

Vertiv | Liebert®10-fanDrycooler User Manual| |

1 |

Enclosed Motor Option

TEAO motors are totally enclosed and are used in industrial applications. They are not available for Liebert Quiet-Line, or 575V models.

Ancillary Items

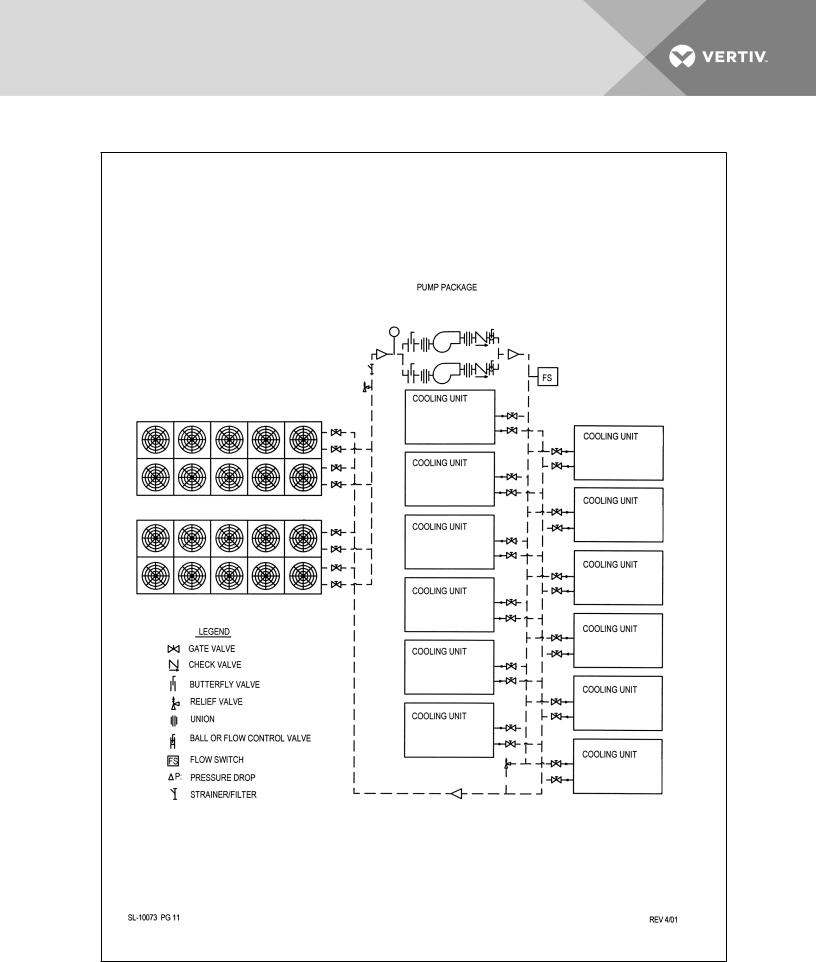

Tanks for fluid expansion, pumps, pump control panels, flowswitches, shut off valves and relief valves should also be considered for the site/installation. Since these items are custom-sized per application, please consult with your sales representative for selection.

Vertiv | Liebert®10-fanDrycooler User Manual| |

2 |

Figure 1.1 Typicalapplication

Vertiv | Liebert®10-fanDrycooler User Manual| |

3 |

Refer to Typical piping diagram on page 19 for a detailed installation diagram.

Vertiv | Liebert®10-fanDrycooler User Manual| |

4 |

2 PRODUCT PERFORMANCE DATA & SELECTION

2.1 Standard Data

Vertiv | Liebert®10-fanDrycooler User Manual| |

5 |

Table 2.1 |

DrycoolerPerformance Data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

TotalHeat |

|

Flow |

|

|

|

|

|

Pressure |

|

|

|

|

|

No. & |

|

No. & |

|

|

|

|

|

|

|

|

|

Internal |

|

|

Shipping |

|||

|

|

|

Rejection* @25°F |

|

|

|

|

|

|

|

|

|

No. of |

|

Size of |

|

Size of |

|

No. |

|

Air Flow |

|

|

Sound |

|

|

|

||||||||

Model |

|

|

Rate |

|

|

|

|

|

Drop |

|

|

|

|

|

|

|

|

|

|

Volume |

|

|

Weight |

|

|

||||||||||

Hz |

(13.9°C)ITD |

|

|

|

|

|

|

|

|

|

Internal |

|

Connec- |

|

Connec- |

|

of |

|

|

|

|

|

|

|

|

|

|

|

|||||||

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Circuits |

|

tions |

|

tions |

|

Fans |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

Btu/h |

|

kW |

|

gpm |

|

lps |

|

Ft ofWater |

|

kPa |

|

|

|

(inlet) |

|

(outlet) |

|

|

|

cfm |

cmh |

|

dBA** |

|

Gal |

L |

|

Lbs |

|

Kg |

||

|

|

|

1,172,000 |

|

343 |

|

136 |

|

8.6 |

|

27.2 |

|

81.2 |

|

68 |

|

2@2.625 |

|

2@2.625 |

|

10 |

|

74160 |

|

126000 |

|

65 |

|

92.8 |

|

351 |

|

5100 |

|

2313 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 |

|

60 |

1,447,000 |

424 |

272 |

17.2 |

15.8 |

47.1 |

136 |

2@4.125 |

2@4.125 |

10 |

74160 |

|

126000 |

65 |

92.8 |

|

351 |

5100 |

2313 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

1,579,000 |

|

463 |

|

544 |

|

34.3 |

|

15.1 |

|

45.1 |

|

272 |

|

2@4.125 |

|

2@4.125 |

|

10 |

|

74160 |

|

126000 |

|

65 |

|

92.8 |

|

351 |

|

5100 |

|

2313 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1,287,000 |

377 |

136 |

8.6 |

27.3 |

81.5 |

68 |

2@2.625 |

2@2.625 |

10 |

99030 |

|

168250 |

72 |

92.8 |

|

351 |

5100 |

2313 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

150 |

|

60 |

1,703,000 |

|

499 |

|

272 |

|

17.2 |

|

15.8 |

|

47.1 |

|

136 |

|

2@4.125 |

|

2@4.125 |

|

10 |

|

99030 |

|

168250 |

|

72 |

|

92.8 |

|

351 |

|

5100 |

|

2313 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1,924,000 |

564 |

544 |

34.3 |

15.1 |

45.1 |

272 |

2@4.125 |

2@4.125 |

10 |

99030 |

|

168250 |

72 |

92.8 |

|

351 |

5100 |

2313 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

1,218,000 |

|

357 |

|

136 |

|

8.6 |

|

27.3 |

|

81.5 |

|

68 |

|

2@2.625 |

|

2@2.625 |

|

10 |

|

82450 |

|

140080 |

|

68 |

|

92.8 |

|

351 |

|

5100 |

|

2313 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150 |

|

50 |

1,541,000 |

452 |

272 |

17.2 |

15.8 |

47.1 |

136 |

2@4.125 |

2@4.125 |

10 |

82450 |

|

140080 |

68 |

92.8 |

|

351 |

5100 |

2313 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

1,703,000 |

|

499 |

|

544 |

|

34.3 |

|

15.1 |

|

45.1 |

|

272 |

|

2@4.125 |

|

2@4.125 |

|

10 |

|

82450 |

|

140080 |

|

68 |

|

92.8 |

|

351 |

|

5100 |

|

2313 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Ratings basedonusing40%ethyleneglycol@95°F(35°C) enteringair,120°F(48.9°C) enteringglycol;2gpm (.13l/s) circ.

**Sounddatais for soundpressuremeasured@5ft. (1.5m) height,30ft.(9.1 m) from theunit.

Manual User Drycooler fan-10 Liebert® 6

Table 2.2 DrycoolerPerformance Data perCircuit

|

|

No. of |

FlowRate Range |

|

|

|

|

Model |

Hz |

Internal |

min-max |

|

|

Circuits |

gpm |

|

|

|

Heat Rejectionper ITD* (Btu/h/°F) |

Pressure Drop* (ft ofwater) |

|

|||

FlowRate per Circuit (gpm/circuit) |

FlowRate per Circuit (gpm/circuit) |

||||

1 |

1.5 |

2 |

1 |

1.5 |

2 |

|

|

68 |

68-136 |

29,507 |

39,991 |

46,972 |

8.2 |

16.1 |

27.3 |

|

|

|

|

|

|

|

|

|

|

120 |

60 |

136 |

136-340 |

45,829 |

53,713 |

57,917 |

5 |

9.2 |

23.7 |

|

|

|

|

|

|

|

|

|

|

|

|

272 |

272-544 |

56,201 |

60,785 |

63,153 |

4 |

8.7 |

15.1 |

|

|

|

|

|

|

|

|

|

|

|

|

68 |

68-136 |

30,144 |

42,440 |

51,621 |

8.2 |

16.1 |

27.3 |

|

|

|

|

|

|

|

|

|

|

150 |

60 |

136 |

136-340 |

50,346 |

61,660 |

68,219 |

5 |

9.2 |

23.7 |

|

|

|

|

|

|

|

|

|

|

|

|

272 |

272-544 |

65,785 |

73,118 |

77,019 |

4 |

8.7 |

15.1 |

|

|

|

|

|

|

|

|

|

|

|

|

68 |

68-136 |

29,791 |

41,011 |

48,823 |

8.2 |

16.1 |

27.3 |

|

|

|

|

|

|

|

|

|

|

150 |

50 |

136 |

136-340 |

47,617 |

56,724 |

61,728 |

5 |

9.2 |

23.7 |

|

|

|

|

|

|

|

|

|

|

|

|

272 |

272-544 |

59,756 |

65,257 |

68,146 |

4 |

8.7 |

15.1 |

|

|

|

|

|

|

|

|

|

|

* Datais basedon40%ethyleneglycolsolutionat115°F(46.1°C) averagesolutiontemperatureexpressedinBtu/h.

Table 2.3 DrycoolerPerformance Data perCircuit—Metric

|

|

|

|

Heat Rejectionper ITD* (kW/°C) |

Pressure Drop* (kPa) |

|

||||

Model |

|

No. of |

FlowRate |

|

|

|

|

|

|

|

Hz |

Internal |

Range min-max |

FlowRate per Circuit (lps/circuit) |

FlowRate per Circuit (lps/circuit) |

||||||

No. |

||||||||||

|

Circuits |

lps |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

0.06 |

0.09 |

0.13 |

0.06 |

0.09 |

0.13 |

|

|

|

68 |

6-13 |

23.9 |

29.8 |

32.1 |

24.5 |

48.0 |

81.5 |

|

120 |

60 |

136 |

13-26 |

30.8 |

31.9 |

32.0 |

14.9 |

27.5 |

70.7 |

|

|

|

272 |

26-38 |

30.7 |

30.6 |

30.5 |

11.9 |

26.0 |

45.1 |

|

|

|

68 |

6-13 |

24.9 |

33.1 |

37.5 |

24.5 |

48.0 |

81.5 |

|

150 |

60 |

136 |

13-26 |

36.0 |

39.1 |

39.8 |

14.9 |

27.5 |

70.7 |

|

|

|

272 |

26-38 |

37.9 |

38.4 |

39.0 |

11.9 |

26.0 |

45.1 |

|

|

|

68 |

6-13 |

24.4 |

31.1 |

34.2 |

24.5 |

48.0 |

81.5 |

|

150 |

50 |

136 |

13-26 |

32.8 |

34.6 |

34.7 |

14.9 |

27.5 |

70.7 |

|

|

|

272 |

26-38 |

33.3 |

33.4 |

33.3 |

11.9 |

26.0 |

45.1 |

|

* Datais basedon40%ethyleneglycolsolutionat46.1°C(115°F) averagesolutiontemperatureexpressedinkW. |

|

|

||||||||

2.2 Typical Application

The most popular use for the Liebert® 10 Fan Drycooler™ is at sites with large cooling loads, such as data center/telecom sites where multiple indoor air conditioners are used. See 2.2 abovefor a general outline of suggested quantity of indoor units for each Liebert 10 Fan Drycooler or contact your Vertiv™ representative for custom matchup. See Typical application on page 3.

Vertiv | Liebert®10-fanDrycooler User Manual| |

7 |

Table 2.4 Maximum Liebert evaporatorunits perEvery10Fan Drycooler

Liebert Deluxe |

Liebert |

Maximum |

|

Outdoor |

|

TotalSystem |

Drycooler1 |

|||

Deluxe |

Deluxe |

|

|

|

|

|

|

|||

Model60 Hz |

|

Ambient |

|

|

|

|

|

|||

Unit |

Units/10 Fan |

|

|

|

|

|

|

Model# |

||

(50 Hz) |

|

Rating |

|

gpm |

|

(lps) |

||||

Capacity |

Drycooler |

|

|

|

|

|||||

|

|

|

|

|

|

|||||

|

|

12 |

|

95°F(35°C) |

|

384 |

|

(24.2) |

|

D*N*150**272 |

|

|

|

|

|

|

|||||

110G |

8tons |

|

|

|

|

|

|

|

|

|

9 |

|

100°F(37.8°C) |

288 |

(18.2) |

|

|

||||

(111 G) |

(28.1 kW) |

|

|

D*N*150**136 |

||||||

6 |

|

105°F(40.6°C) |

|

192 |

|

(12.1) |

|

|||

|

|

|

|

|||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

95°F(35°C) |

380 |

(24.0) |

|

D*N*150**272 |

||

116G |

10tons |

7 |

|

100°F(37.8°C) |

|

266 |

|

(16.8) |

|

|

|

|

|

|

|

||||||

(121 G) |

(35.2kW) |

|

|

|

|

D*N*150**136 |

||||

|

|

|

|

|

|

|

|

|||

5 |

|

105°F(40.6°C) |

190 |

(12.0) |

|

|||||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||

|

|

7 |

|

95°F(35°C) |

|

378 |

|

(23.8) |

|

D*N*150**272 |

|

15tons |

|

|

|

|

|

|

|

|

|

192G |

5 |

|

100°F(37.8°C) |

270 |

(17.0) |

|

|

|||

(52.7 kW) |

|

|

D*N*150**136 |

|||||||

|

4 |

|

105°F(40.6°C) |

|

216 |

|

(13.6) |

|

||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

95°F(35°C) |

402 |

(25.4) |

|

D*N*150**272 |

||

240G |

20tons |

4 |

|

100°F(37.8°C) |

|

268 |

|

(16.9) |

|

|

|

|

|

|

|

||||||

(70.3kW) |

|

|

|

|

D*N*150**136 |

|||||

|

|

|

|

|

|

|

|

|

||

|

3 |

|

105°F(40.6°C) |

201 |

(12.7) |

|

||||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||

|

|

4 |

|

95°F(35°C) |

|

312 |

|

(19.7) |

|

D*N*150**272 |

|

30tons |

|

|

|

|

|

|

|

|

|

363G |

3 |

|

100°F(37.8°C) |

234 |

(14.8) |

|

|

|||

(105kW) |

|

|

D*N*150**136 |

|||||||

|

2 |

|

105°F(40.6°C) |

|

156 |

|

(9.8) |

|

||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

1. Ratings basedonusing40%ethyleneglycol@listedoutdoor ambientratingtemperature, 120°F(48.9°C) enteringglycol. Selections arevalidfor standardor TEAOmotors. Consultyour localLiebertrepresentativefor Quiet-Lineselections.

2.3 Engineering Data, Calculations and Selection Procedure

An alternate, detailed procedure is available to calculate values and select the correct the 10 Fan Drycooler(s) for the application. This can be used to assist in selecting drycoolers for applications for ambient conditions that are not standard. Use the following steps.

1.Determine the following items to begin this procedure:

•Design outdoor ambient air temperature, Toa (F or C)

•Fluid FlowRate, VT (gpm or lps)

•% ethylene glycol concentration

•Fluid temperatures at drycooler: Entering, Tef and leaving Tlf(F or C), or

•Total Required Heat Rejection, QRT(Btu/h or kW) and one of the fluid temperatures above

2.Find the following values using these equations and known values above:

•Initial Temperature Difference (ITD) of entering fluid to outdoor design air, ITD = Tef - Toa

•Total Required Heat Rejection, QRT = VT * cv * (Tef - Tlf), wherecv is found in the following table, or

•Leaving fluid temperature, Tlf = Tef - QRT / (VT * cv)wherecv is found in the following table.

3.Find the Average Fluid Temperature, Tf,avg = (Tef + Tlf) / 2

Vertiv | Liebert®10-fanDrycooler User Manual| |

8 |

Loading...

Loading...