Page 1

Verizon 4G LTE

Network Extender for Enterprise

Installation Manual

Network Systems

Samsung Telecommunications America

Document Version 1.1

December 2014

VSR 1.2

Page 2

© 2014 SAMSUNG Electronics Co. Ltd.

All Rights Reserved. No part of this document may be photocopied, reproduced, stored in a retrieval

system, or transmitted, in any form or by any means whether, electronic, mechanical, or otherwise

without the prior written permission of SAMSUNG Electronics Co., Ltd.

No warranty of accuracy is given concerning the contents of the information contained in this

publication. To the extent permitted by law no liability (including liability to any person by reason of

negligence) will be accepted by SAMSUNG Electronics Co., Ltd., its subsidiaries or employees for

any direct or indirect loss or damage caused by omissions from or inaccuracies in this document.

SAMSUNG Electronics Co., Ltd. reserves the right to change details in this publication without

notice.

This manual should be read and used as a guideline for properly installing and/or operating the

product.

This manual may be changed for system improvement, standardization and other technical

reasons without prior notice.

Updated manuals are available at:

http://www.verizonwireless.com/

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 ii

©Samsung

Page 3

Contents

Contents

Preface vi

Relevance ........................................................................................................................................ vi

Conventions in this Document ........................................................................................................ vi

Revision History ............................................................................................................................... vi

Organization of This Document ..................................................................................................... vii

Related Documentation ................................................................................................................. vii

Personal and Product Safety .......................................................................................................... vii

Chapter 1 Installing the System 11

Installing the 4G LTE Network Extender......................................................................................... 11

Foundation Work ........................................................................................................................... 12

Unpacking and Transporting .......................................................................................................... 16

Fixing the 4G LTE Network Extender .............................................................................................. 18

Chapter 2 Connecting the Cables 24

Workflow for Cabling ..................................................................................................................... 24

Cabling ............................................................................................................................................ 30

GPS Requirements.......................................................................................................................... 32

Power Cabling ................................................................................................................................ 34

External Interface Connection ....................................................................................................... 37

Appendix A Before Installation 40

System Configuration ..................................................................................................................... 41

Specifications ................................................................................................................................. 43

Cautions for Installation ................................................................................................................. 46

Pre-survey ...................................................................................................................................... 47

Installation Tools ............................................................................................................................ 48

Appendix B Optional GPS Antenna Installation 50

GPS Antenna System Configuration ............................................................................................... 50

Signal Interference ......................................................................................................................... 62

GPS Antenna Installation................................................................................................................ 64

Grounding the Optional GPS Arrestor ............................................................................................ 70

Appendix C Installing the Feeder Cable 72

Cautions When Installing Feeder Cable ......................................................................................... 72

Appendix D Connector Assembly 75

RJ-45 (Shield Type) ......................................................................................................................... 75

RJ-45 (Normal Type) ....................................................................................................................... 77

N type-male (LMR-400) .................................................................................................................. 77

TNC-male (LMR-400) ...................................................................................................................... 80

Appendix E Standard Torque 83

Appendix F Acronyms 84

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 iii

©Samsung

Page 4

Contents

List of Figures

Figure 1. Procedure to Install the System ..................................................................................................... 11

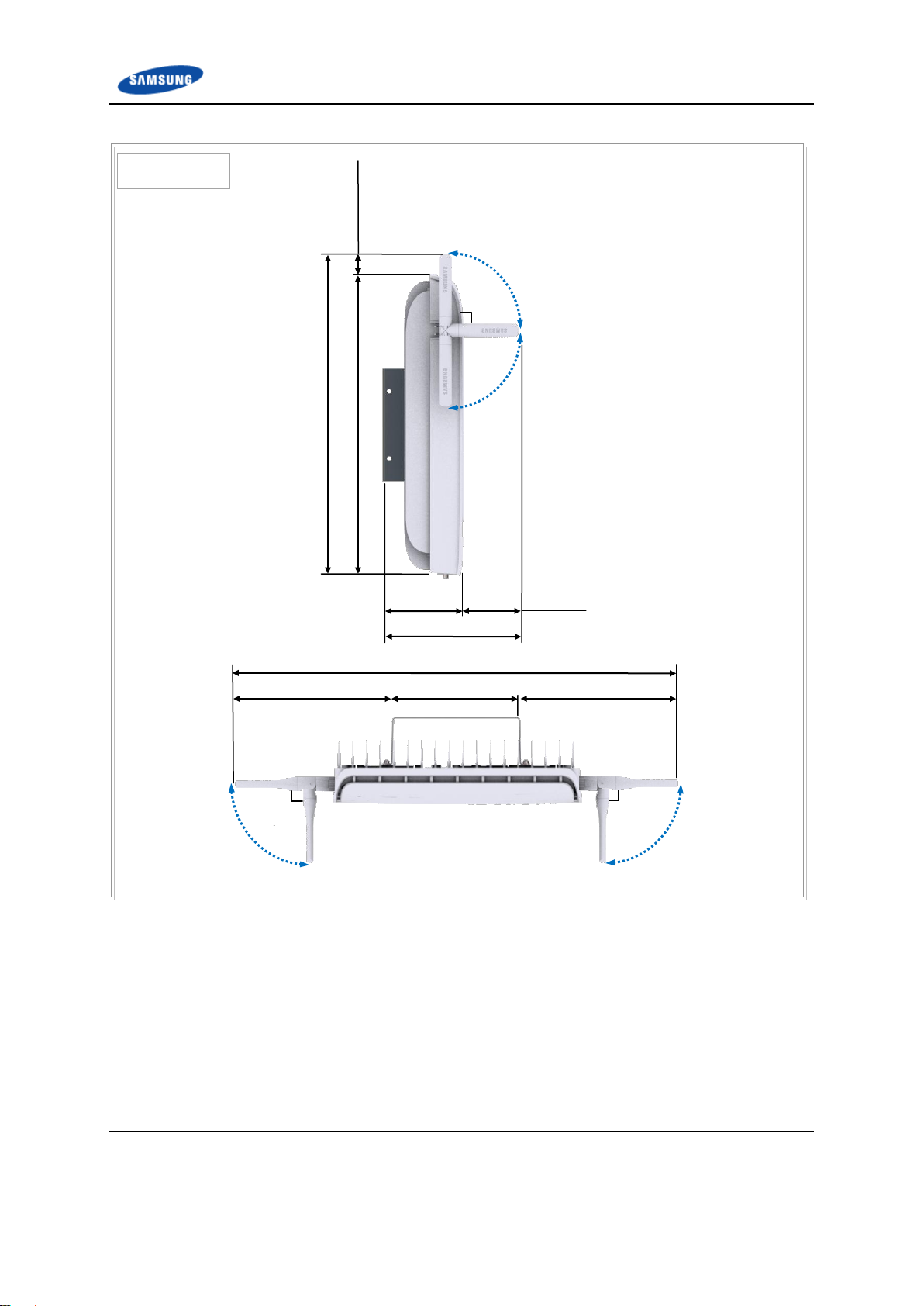

Figure 2. 4G LTE Network Extender Dimensions ........................................................................................... 13

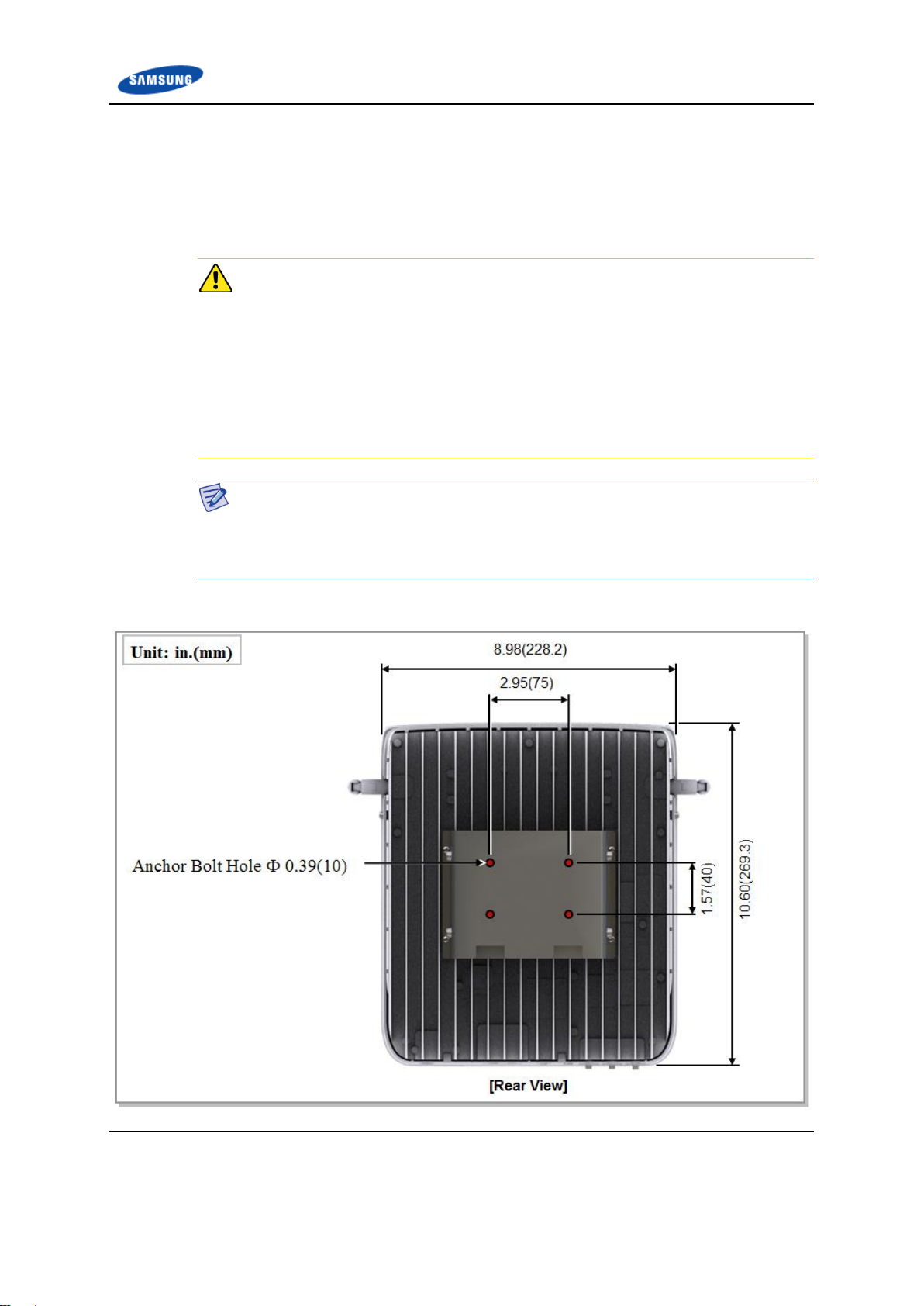

Figure 3. System Marking - Wall Type ........................................................................................................... 14

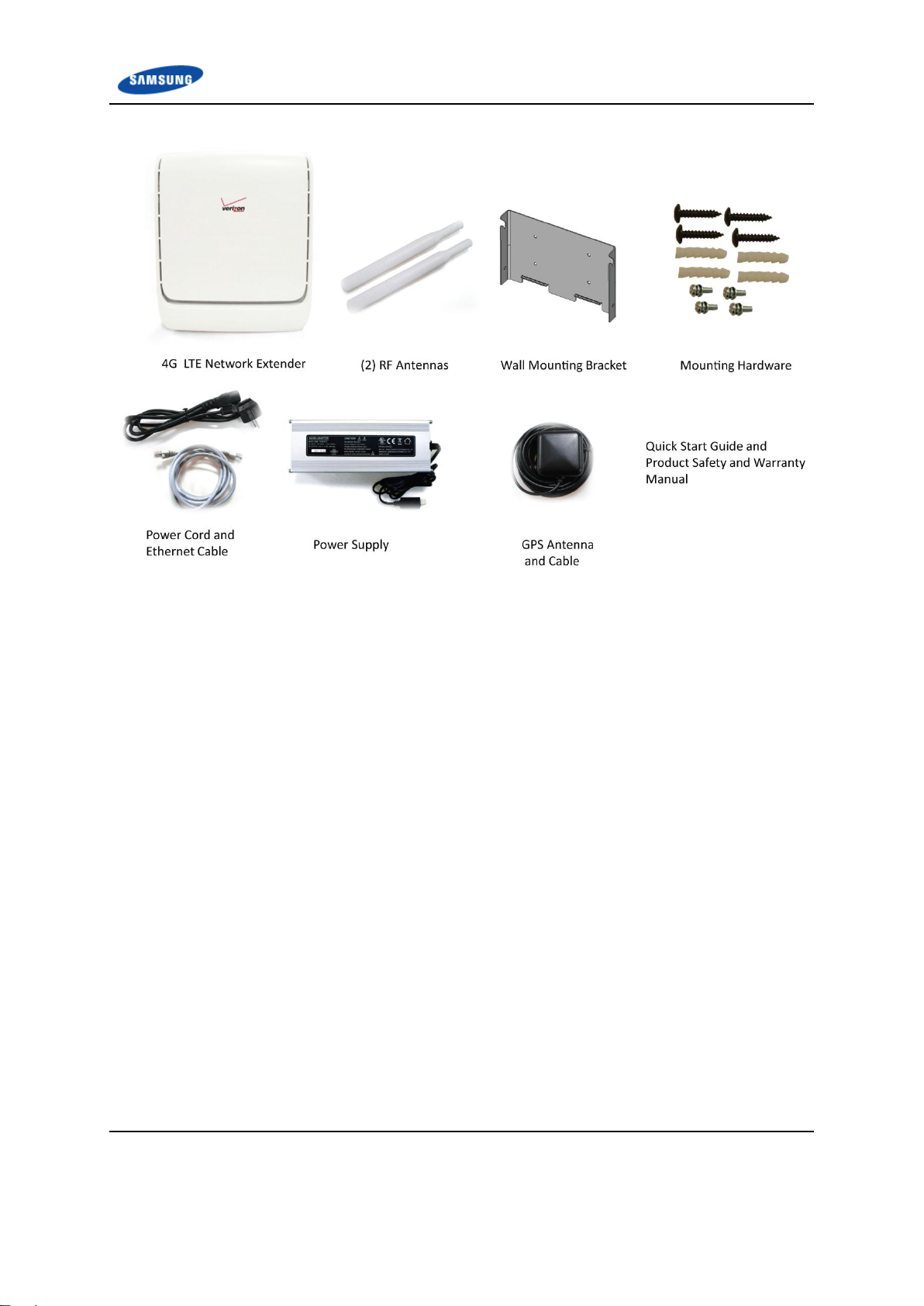

Figure 4. Package Contents ........................................................................................................................... 17

Figure 5. Fixing the Wall Mounting Bracket (1)............................................................................................. 18

Figure 6. Fixing the Wall Mounting Bracket (2)............................................................................................. 19

Figure 7. Fixing the 4G LTE Network Extender (1) ........................................................................................ 20

Figure 8. Fixing the 4G LTE Network Extender (2) ........................................................................................ 21

Figure 9. Fixing the 4G LTE Network Extender (3) ........................................................................................ 22

Figure 10. Fixing 4G LTE Network Extender on the Ceiling or Flat Surface ..................................................... 23

Figure 11. Workflow for System Cabling ......................................................................................................... 24

Figure 12. Detailed Cabling Procedure ............................................................................................................ 25

Figure 13. Cabling Diagram ............................................................................................................................. 30

Figure 14. Elevation Mask and Satellites......................................................................................................... 32

Figure 15. Power Equipment Diagram ............................................................................................................ 34

Figure 16. AC/DC Adaptor ............................................................................................................................... 34

Figure 17. Power Cable Connection ................................................................................................................ 36

Figure 18. Backhaul Cable Connection ............................................................................................................ 38

Figure 19. 4G LTE Network Extender Configuration ....................................................................................... 41

Figure 20. 4G LTE Network Extender External Interface Structure ................................................................. 42

Figure 21. Example of a Common GPS Antenna System Configuration .......................................................... 50

Figure 22. GPS Cable Configuration Case #1 ................................................................................................... 54

Figure 23. GPS Cable Configuration Case #2 ................................................................................................... 55

Figure 24. 4G LTE Network Extender GPS Arrestor Cable Connection Case #1 .............................................. 57

Figure 25. 4G LTE Network Extender GPS Arrestor Cable Connection Case #2 .............................................. 58

Figure 26. 4G LTE Network Extender GPS Arrestor Cable Connection Details ................................................ 59

Figure 27. GPS Arrestor GPS Antenna Cable Connection Detail ..................................................................... 60

Figure 28. GPS Antenna Installation................................................................................................................ 61

Figure 29. GPS Antenna Installation (Wall) ..................................................................................................... 65

Figure 30. GPS Antenna Installation (Floor) .................................................................................................... 66

Figure 31. Fixing GPS Bulkhead ....................................................................................................................... 68

Figure 32. Fixing the GPS Arrestor .................................................................................................................. 69

Figure 33. Connection of the GPS Arrestor Ground Cable .............................................................................. 71

Figure 34. Assembling the RJ-45 Connector (Shield Type) (1) ........................................................................ 75

Figure 35. Assembling the RJ-45 Connector (Shield Type) (2) ........................................................................ 76

Figure 36. Assembling the RJ-45 Connector (Normal Type) ........................................................................... 77

Figure 37. N type-male Connector Assembling (1) ......................................................................................... 78

Figure 38. N type-male Connector Assembling (2) ......................................................................................... 79

Figure 39. TNC-male Connector Assembling (1) ............................................................................................. 80

Figure 40. TNC-male Connector Assembling (2) ............................................................................................. 81

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 iv

©Samsung

Page 5

Contents

List of Tables

Table 1. Recommended Distances for 4G LTE Network Extender Installation ............................................ 12

Table 2. Anchor Bolt Drill Bits and Hole Depth ............................................................................................ 15

Table 3. Fixing the Wall Mounting Bracket - Parts and Tools ...................................................................... 18

Table 4. Fixing the 4G LTE Network Extender - Parts and Tools .................................................................. 20

Table 5. Recommended Minimum Allowed Cable Bend Radius .................................................................. 26

Table 6. 4G LTE Network Extender Connection Cable ................................................................................. 31

Table 7. Power Cable Connection ................................................................................................................ 34

Table 8. Backhaul Cable Pin Map ................................................................................................................. 37

Table 9. GPS Cable Connection .................................................................................................................... 39

Table 10. Key Specifications ........................................................................................................................... 43

Table 11. Input Power .................................................................................................................................... 44

Table 12. Power Specifications ...................................................................................................................... 44

Table 13. Dimensions and Weight ................................................................................................................. 44

Table 14. GPSR Specifications ........................................................................................................................ 44

Table 15. IEEE1588v2 Specifications .............................................................................................................. 44

Table 16. Ambient Specifications ................................................................................................................... 45

Table 17. Basic Installation Tools ................................................................................................................... 48

Table 18. GPS Antenna System Configuration ............................................................................................... 50

Table 19. GPS Cable Connection .................................................................................................................... 51

Table 20. Identification Tag of GPS Cable ...................................................................................................... 53

Table 21. Optional GPS Bulkhead Fixing Parts and Tools ............................................................................... 67

Table 22. GPS Arrestor Fixing Parts and Tools ............................................................................................... 69

Table 23. Grounding the GPS Arrestor (MGB GPS Arrestor) .......................................................................... 70

Table 24. Curvature Radius of Feeder Cable for Outdoor ............................................................................. 73

Table 25. Curvature Radius of Feeder Cable for Indoor (Based on LS Feeder Line) ...................................... 73

Table 26. Connector Connection Torque Value ............................................................................................. 74

Table 27. Standard Torque Value for Tightening Bolts .................................................................................. 83

Table 28. Brass Bolts Torque Value................................................................................................................ 83

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 v

©Samsung

Page 6

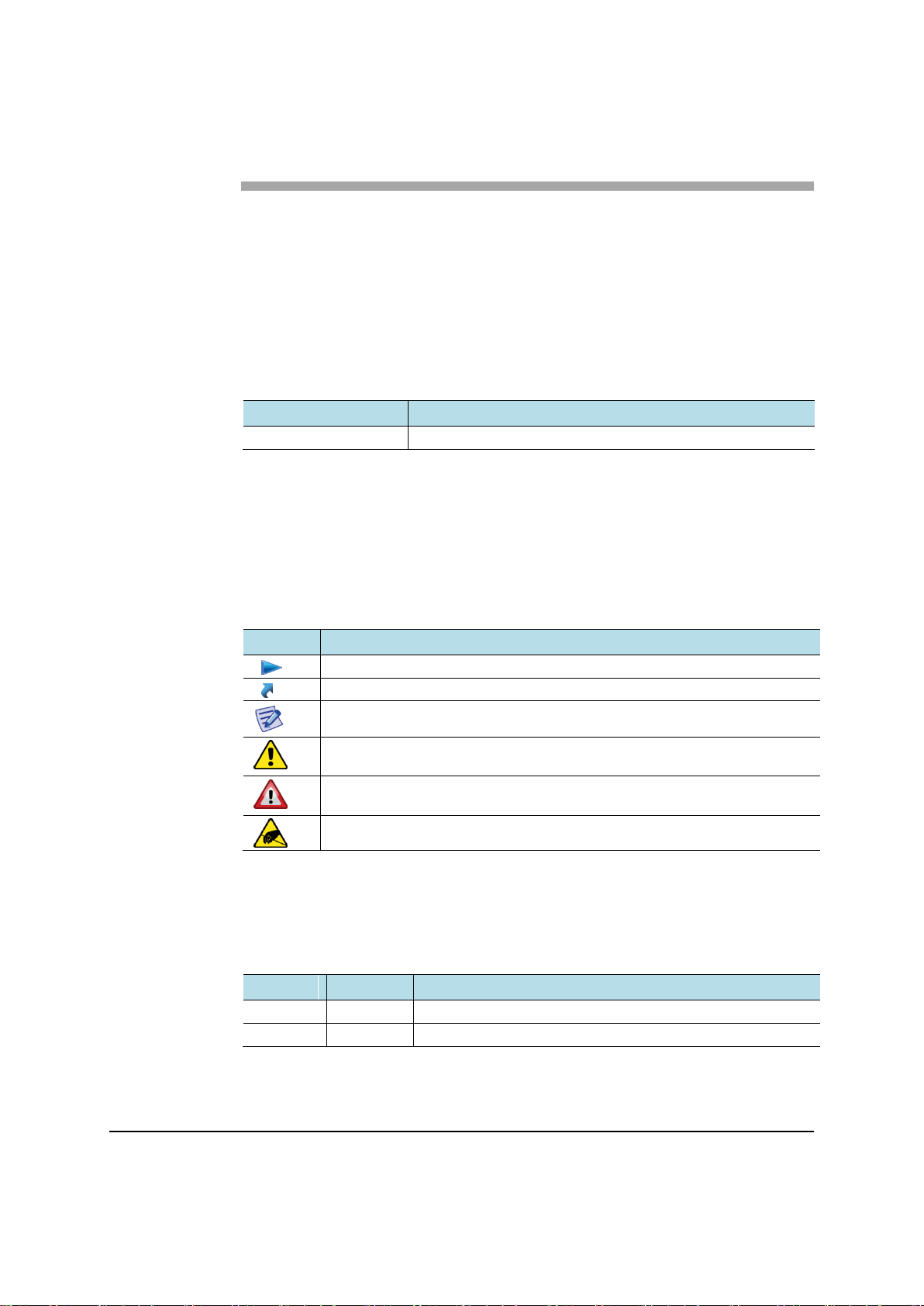

Model

Release

SLS-BU102

VSR 1.2

Symbol

Description

Indicates a task.

Indicates a shortcut or an alternative method.

Provides additional information.

Provides information or instructions that you should follow to avoid service

failure or damage to equipment.

Provides information or instructions that you should follow to avoid personal

injury or fatality.

Provides antistatic precautions that you should observe.

Version

Date

Description

1.0

10/31/2014

First Version

1.1

12/22/2014

Content Reduction

Preface

This manual describes how to install the Verizon 4G LTE Network Extender for

Enterprise and cable connection specifications.

Relevance

This manual applies to the following products/software.

Conventions in this Document

Samsung Networks product documentation uses the following conventions.

Symbols

Revision History

The following table lists all versions of this document.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 vi

©Samsung

Page 7

Preface

Section

Title

Description

Chapter 1

Installing the System

Describes the procedures required to

perform the installation.

Chapter 2

Connecting the Cables

Describes the procedures and checks

required to connect the system.

Appendix A

Before Installation

Describes the procedures and checks

required prior to installation.

Appendix B

Optional GPS Antenna

Installation

Describes the procedures required to

install a GPS antenna system.

Appendix C

Installing the Feeder Cable

Describes the specifications and

cautions required to install a feeder

cable.

Appendix D

Connector Assembly

Describes the procedures required to

assemble connectors.

Appendix E

Pressure Terminal Assembly

Describes the procedures required to

assemble a pressure terminal.

Appendix F

Standard Torque

Provides the standard torque values.

Appendix G

Acronyms

List of terms.

Organization of This Document

Related Documentation

Verizon 4G LTE Network Extender for Enterprise Quick Start Guide

Verizon 4G LTE Network Extender for Enterprise Product, Safety and

Warranty

Verizon 4G LTE Network Extender for Enterprise User Guide

Personal and Product Safety

This product safety information includes U.S. directives that you must follow.

All applicable OSHA regulations and standards shall be followed.

The installation, maintenance, or removal of telecommunications equipment

requires qualified, experienced personnel. Samsung installation instructions are

written for such installation personnel.

Site Safety

Site construction shall be design-approved and certified by engineers who have

valid and up-to-date P.E. license approval with the National Society of

Professional Engineers.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 vii

©Samsung

Page 8

Materials

Electrical

Preface

Workers shall evaluate site safety as per all applicable safety ordinances and

requirements including, but not limited to OSHA, NFPA 70, and applicable

building code requirements prior to, during, and after completion. Workers shall

not conduct product work until and unless the site is in full safety compliance with

associated regulatory requirements.

Workers shall use only approved materials that comply with applicable safety and

environmental requirements. All materials shall be deployed in accordance with all

applicable safety requirements, and according to manufacturer instruction.

Workers shall not install any materials that are intrinsically unsafe, or have

shipping, handling, or installation instructions that are intrinsically unsafe.

This product contains hazardous energy levels as defined by UL 60950. Care must

be taken as injury to personnel or damage to the equipment could result from

mistakes. Maintenance should only be carried out by approved workers who have

adequate training and understanding, and are familiar with the required procedures

and instructions.

In addition to all applicable safety requirements, workers shall abide by the latest

edition of NFPA 70 national electrical code. Certified and licensed Electricians

and Power Limited Technicians shall perform electrical work as required by

applicable regulatory requirements.

All structural materials shall be grounded, and all input and outputs shall have

built-in isolation from the network as per NFPA 70 standards and client-approved

standards. All connectivity and input and output hardware ports that connect to

external power sources shall be designed and installed to meet national safety and

regulatory requirements.

Shipping, Transport, and Manual Handling

Worker shall assure they understand and abide by all associated regulatory and

standards instruction applicable to shipping, transport and handling of product,

including but not limited to OSHA and all associated Samsung documentation for

product shipping, transport, and manual handling requirements.

Worker shall assure adequate and approved shipping, transport, and handling

procedures are utilized to maintain safety.

Installation

Installation shall be carried out by trained and competent workers observing all

applicable safety rules and regulations at all times.

Workers shall read, and understand the latest published installation documentation,

and make sure all required workers, tools, and materials are approved and present

prior to beginning any defined work task.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 viii

©Samsung

Page 9

Preface

Workers shall also abide by the latest published installation documentation for

general work procedures and guidance materials.

All relevant safety measures must be taken to ensure that equipment is not

connected to live power and transmission sources during installation. Equipment

must be correctly installed in order to meet the relevant safety standards and

approval conditions.

Maintenance

Maintenance shall be carried out by trained and competent workers while

observing all applicable safety rules and regulations at all times. Equipment covers

shall not be removed while live power and/or transmission is connected unless

specifically directed by a Samsung published work instruction and as determined

safe by all associated safety rules and regulations.

Environment

The product must be operated in an environment within the specified relative

humidity and ambient temperature ranges.

Keep all liquids away from the equipment, as accidental spillage can cause severe

damage.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 ix

©Samsung

Page 10

Preface

Grounding

To comply with ANSI/NFPA70 and UL 60950, equipment must be connected to a

safety grounding point via a permanent connection. Grounding points are located

on the product for this purpose. Always connect the ground cable as per the latest

published instructions before fitting other cables. The product must remain

grounded continuously unless all system and power connections are removed.

If equipment is grounded through a cabinet or rack, make sure it is done so

properly according to the latest published installation instructions.

.

AC System

Single pole /neutral fusing

Disconnect AC power, before servicing.

RF Cable Installation

Circuit Breaker

Installation shall be in accordance with the applicable parts of Chapter 8 of

ANSI/NFPA 70.

Branch circuit protection

The power system must be equipped with external branch circuit protection that

complies with NEC requirement and have a rating maximum of 20A.

(Use UL-listed circuit breaker.)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 x

©Samsung

Page 11

Chapter 1 Installing the

System

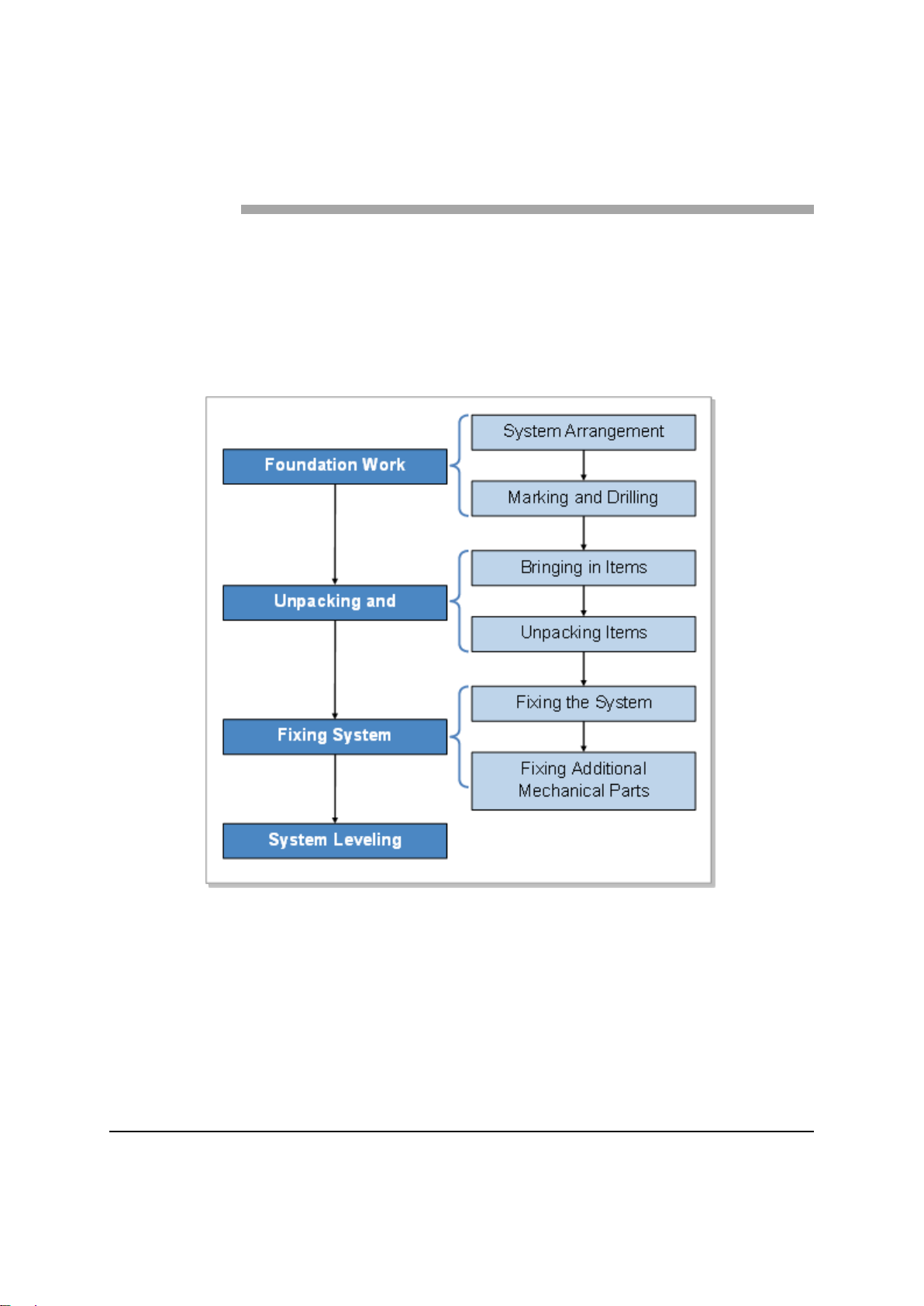

Installing the 4G LTE Network Extender

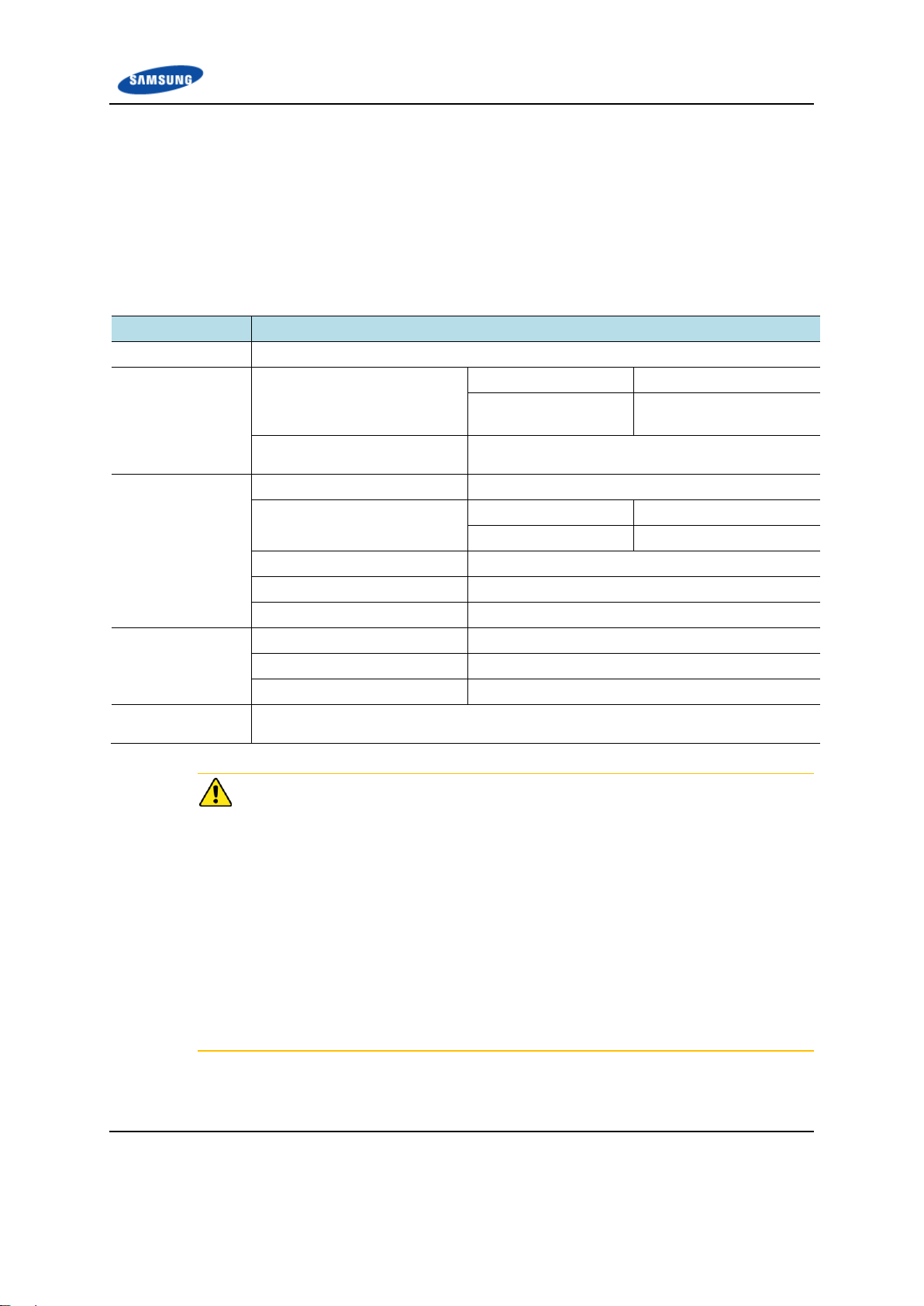

The procedure to install the 4G LTE Network Extender is shown in the following

figure.

Figure 1. Procedure to Install the System

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 11

©Samsung

Page 12

Appendix A Before Installation

Category

Recommended Distance

Top

19.69 in. (500 mm) or more

Front

19.69 in. (500 mm) or more

Sides

7.87 in. (200 mm) or more

Foundation Work

System Arrangement

A minimum distance must be secured around the 4G LTE Network Extender, in

each direction for installation and maintenance.

Table 1. Recommended Distances for 4G LTE Network Extender Installation

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 12

©Samsung

Page 13

Appendix A Before Installation

≒ 11.5(292.5)

3(75.2)

2(50.2)

10.6(269.3)

≒ 4.9(125.4)

0.89(22.5)

90

90

4.6(116)

5.8(147)

5.8(147)

≒ 16.2(410.6)

[Top View]

[Left View]

90

Unit: in (mm)

Figure 2. 4G LTE Network Extender Dimensions

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 13

©Samsung

Page 14

Appendix A Before Installation

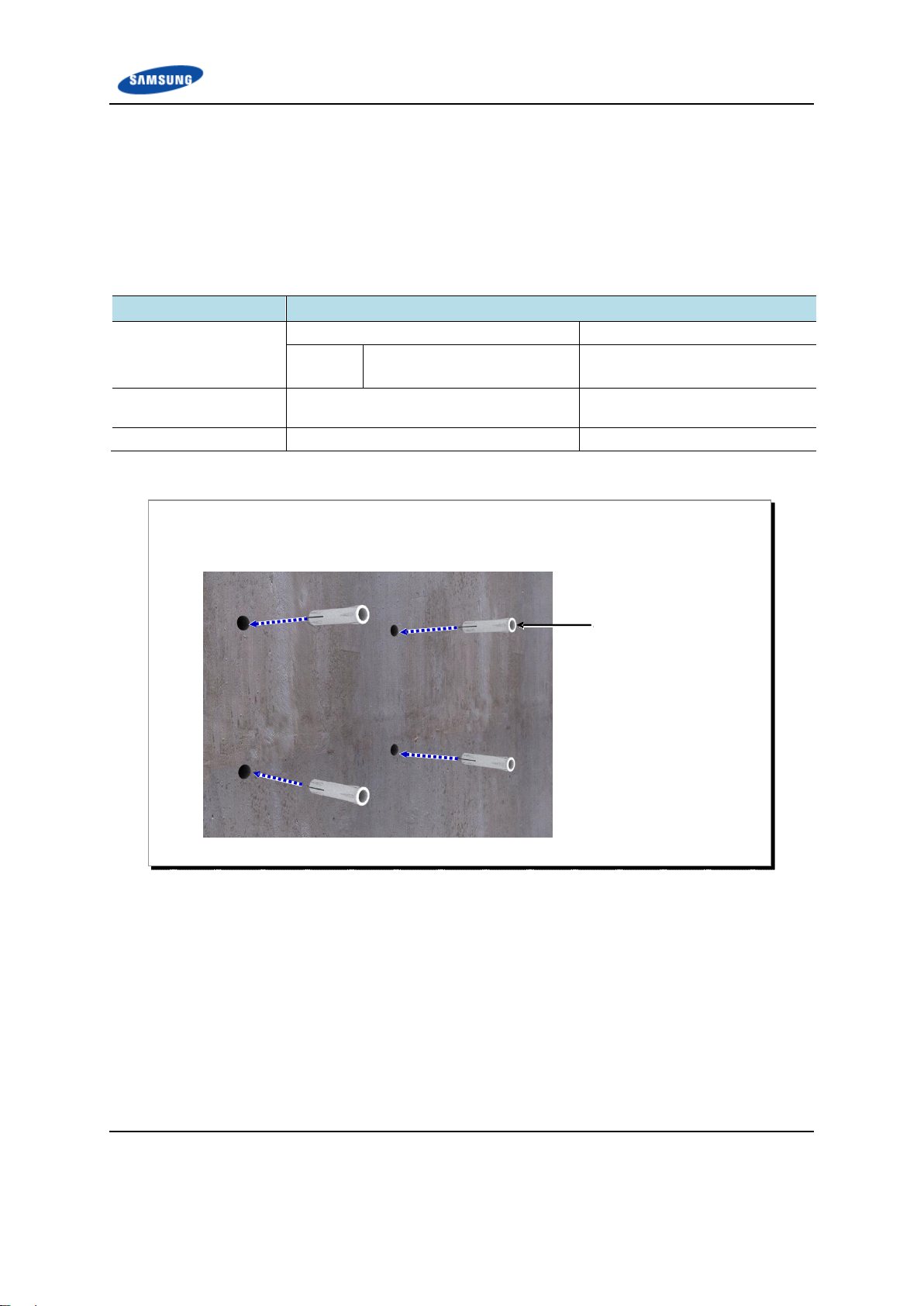

Marking and Drilling

Marking

Before placing the system, mark the position where the system will be installed

and also the positions where anchor bolts will be fixed using an ink line or a pen.

Check Marking (Horizontal/Vertical) When Mounting the System on Wall

If you do the drilling or anchoring on a wall, ensure the positions are marked as

horizontal or vertical, as only a limited range of tuning is allowed for leveling after

the system is mounted.

To mount the system on a wall, perform the leveling test by referring to the

System Leveling section to check that positions are marked to be horizontal or

vertical before drilling. If the result shows that they are not horizontal or vertical,

modify the marking positions.

Marking Using the System

When the device position is determined, place the mounting bracket on the surface

and then mark the positions where anchor bolts will be fixed using a pen. This will

reduce marking error.

Figure 3. System Marking - Wall Type

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 14

©Samsung

Page 15

Appendix A Before Installation

Category

Anchor Bolt

Drill Bits

Hole Depth

Wall Type

M4

0.24 in. (6 mm)

1.18 in. (30 mm)

Drilling

When marking is completed, drill holes for anchor bolts.

Table 2. Anchor Bolt Drill Bits and Hole Depth

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 15

©Samsung

Page 16

Appendix A Before Installation

Unpacking and Transporting

This section describes the work to unpack cabinets and other components, and

transport them to the place to be installed.

Bringing in Items

Bring in items, taking care of the following:

Use a lift or cart to prevent accidents. However, if multiple systems must be

carried by people, make sure that there are enough people to carry the system

safely.

Before moving the systems, check the storage place and remove obstacles in

advance.

While moving the systems, avoid potential damage caused by physical shock,

dust, moisture, or static electricity.

Unpacking Items

The procedure to unpack items is as follows:

1 The items should be packed until they reach the installation place.

2 The items are classified in accordance with each job specification and stored in

a place that does not interfere with the working area.

3 Unpacked systems should be installed immediately. If not installed

immediately, the systems should be stored in the installation place temporarily.

4 Unpack the inner packaging after each system is placed on its installation

location.

5 Dispose of packing waste it in accordance with local laws.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 16

©Samsung

Page 17

Appendix A Before Installation

Figure 4. Package Contents

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 17

©Samsung

Page 18

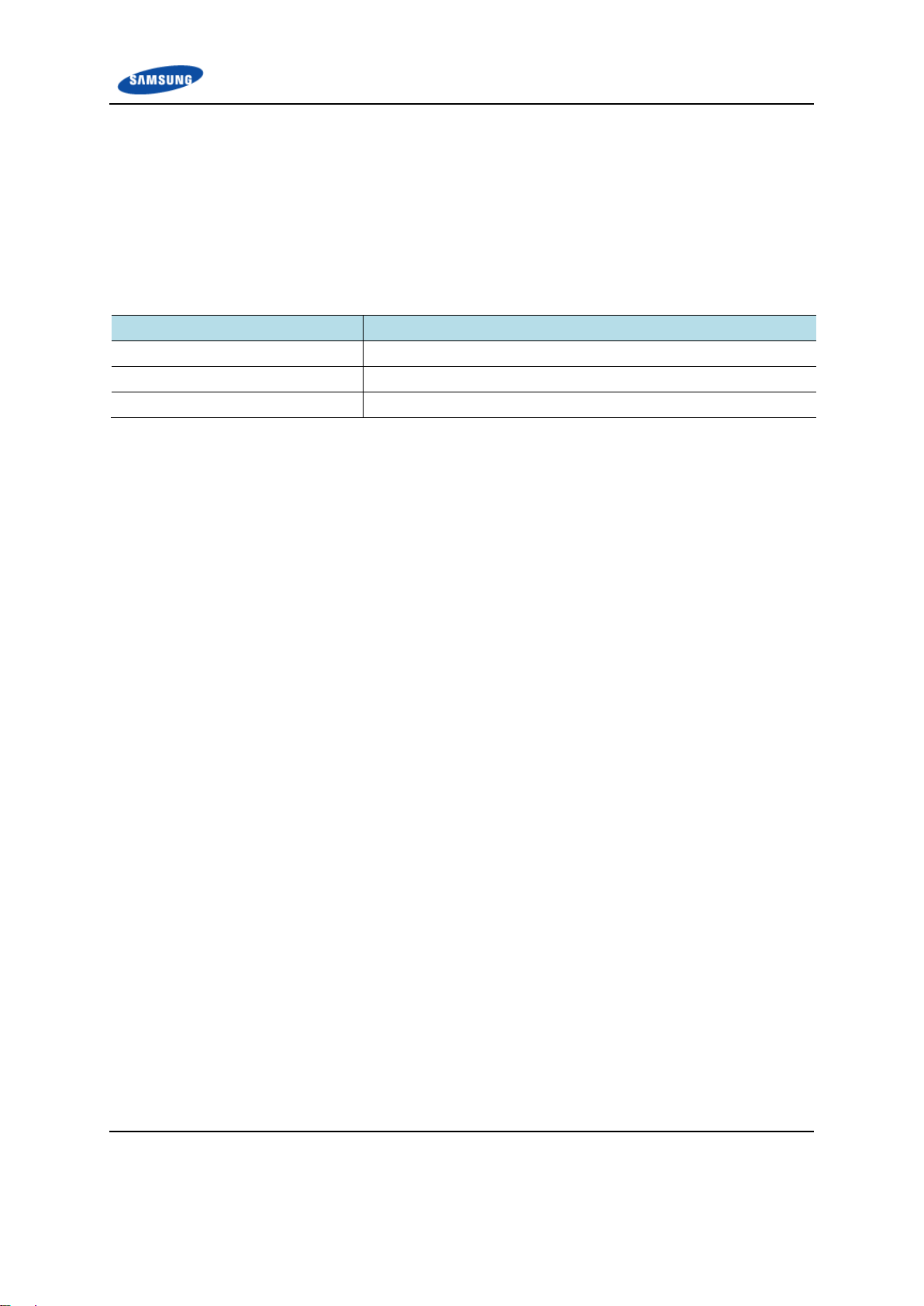

Appendix A Before Installation

Classification

Description

Parts

Wall Mounting Bracket

1 EA

Fastener

M4 x 20L TH Tapping Screw

M6 x 30L Plastic Anchor

4 EA

4 EA

Recommended Torque

Value [ft.lb. (kgf.cm)]

M4 Tapping Screw

0.69~1.03 (9.5~14.3)

Working Tools

Drill, Hammer, Torque Wrench, Level

Working Tools

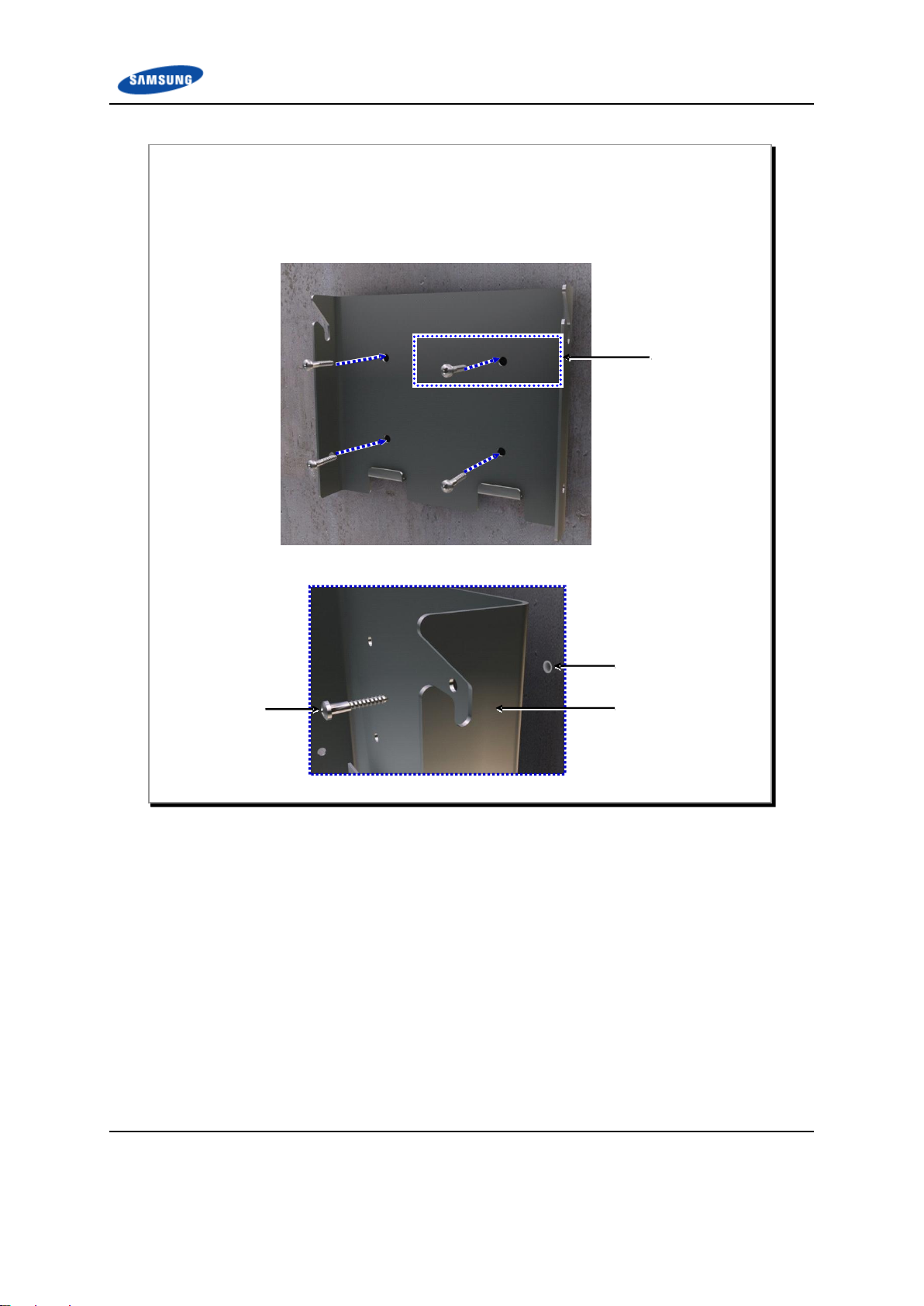

1 Fix the M6 plastic anchors to the holes marked and drilled on the wall.

Plastic

Anchor

Fixing the 4G LTE Network Extender

Fixing the Wall Mounting Bracket

The procedure for fixing the wall mounting bracket is as follows.

Table 3. Fixing the Wall Mounting Bracket - Parts and Tools

Figure 5. Fixing the Wall Mounting Bracket (1)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 18

©Samsung

Page 19

Appendix A Before Installation

‘A’

Detail

‘A’

Tapping

Screw

Wall Mounting

Bracket

Plastic Anchor

2 Place the wall mounting bracket along with the fixed M6 plastic anchors.

3 Securely fix the wall mounting bracket using four tapping screws in the holes.

Figure 6. Fixing the Wall Mounting Bracket (2)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 19

©Samsung

Page 20

Appendix A Before Installation

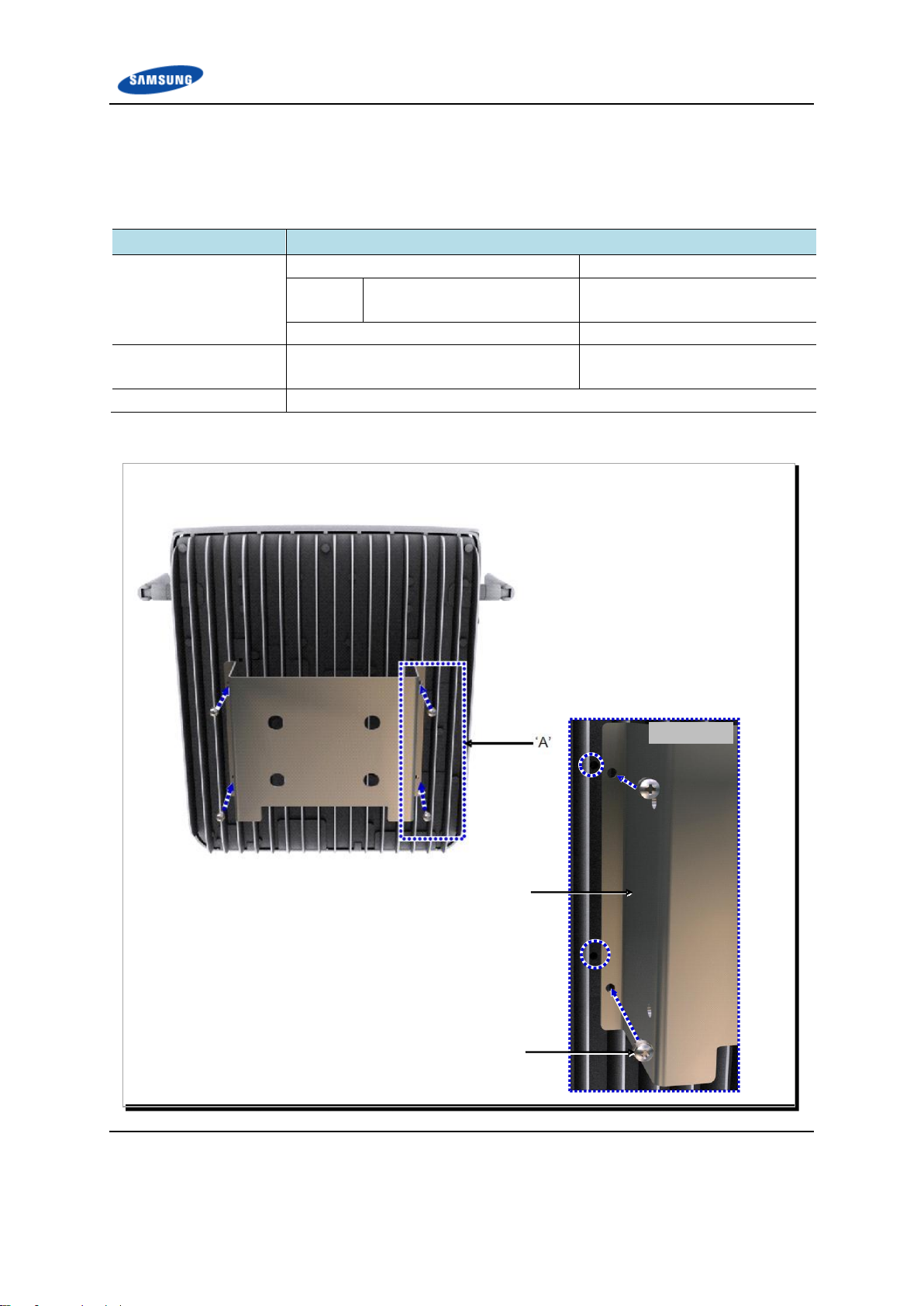

Classification

Description

Parts

Unit Mounting Bracket

1 EA

Fastener

M3 × 8L SEMS

M4 × 10L SEMS

4 EA

4 EA

Bakelite(5T)

2 EA

Recommended Torque

Value [ft.lb. (kgf.cm)]

M3 SEMS

M4 SEMS

0.29~0.44(4.08~6.12)

0.69~1.03(9.52~14.28)

Working Tools

Torque Driver

Detail

‘A’

1 Fix the unit mounting bracket to the four holes on the rear side of the 4G LTE Network Extender if not

preassembled.

M3 SEMS

Unit Mounting

Bracket

Fixing the 4G LTE Network Extender

The procedure for fixing the 4G LTE Network Extender is as follows.

Table 4. Fixing the 4G LTE Network Extender - Parts and Tools

Figure 7. Fixing the 4G LTE Network Extender (1)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 20

©Samsung

Page 21

Appendix A Before Installation

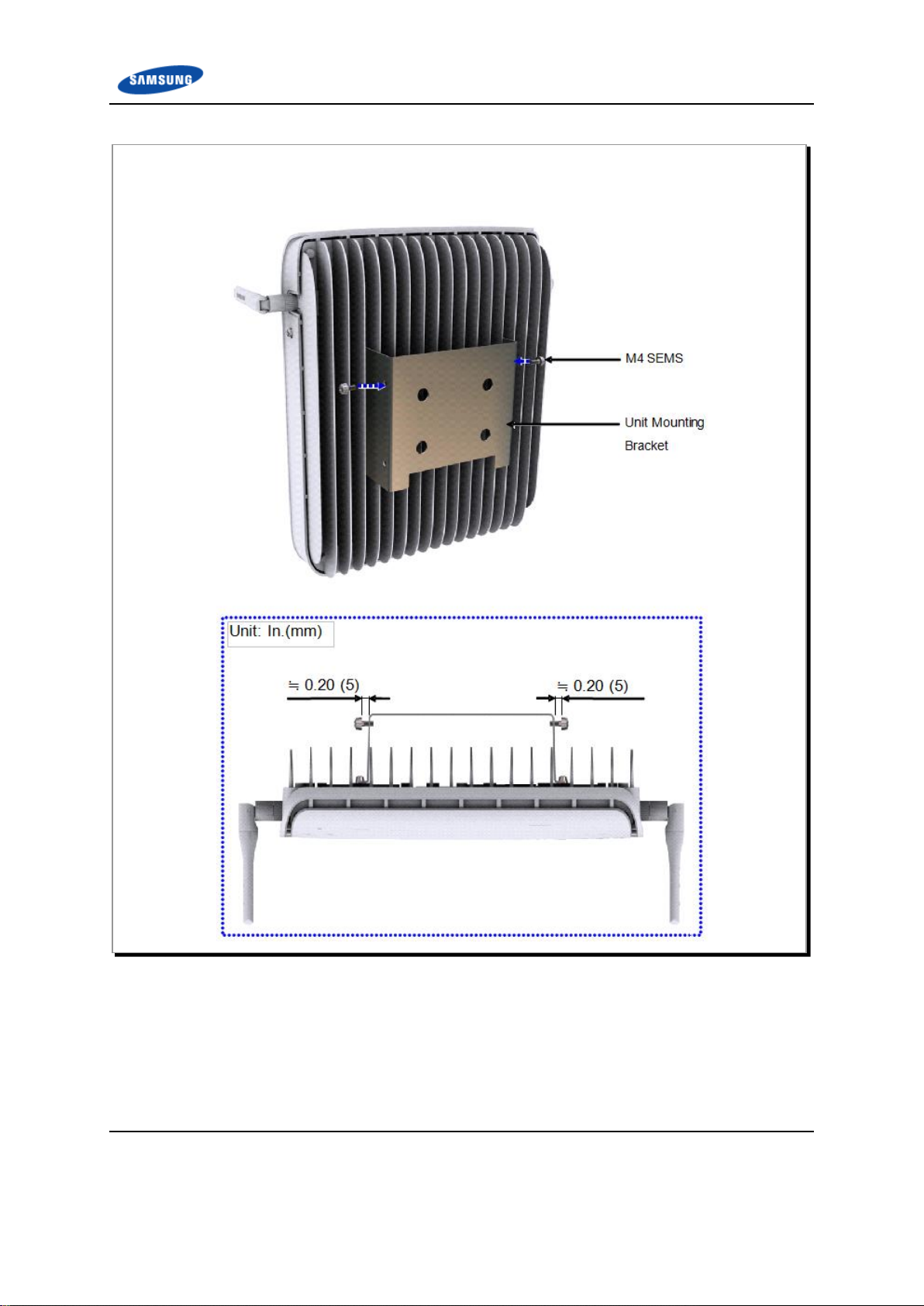

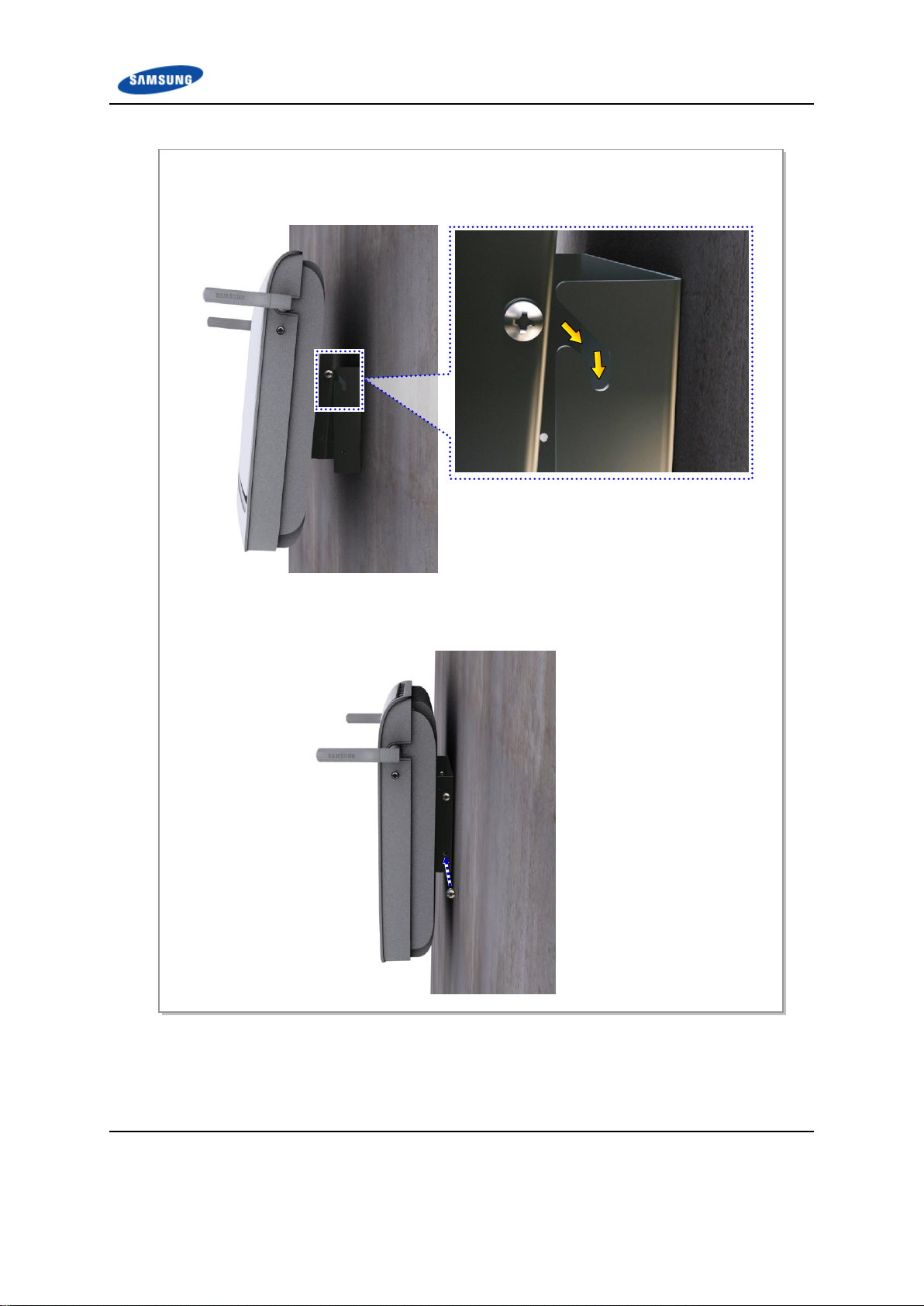

2 Fix the M4 SEMS temporarily to the fixing holes at the top left and right sides of the unit mounting

bracket, leaving about 0.20 in. (5 mm) clearance between the M4 SEMS and the unit mounting bracket.

Figure 8. Fixing the 4G LTE Network Extender (2)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 21

©Samsung

Page 22

Appendix A Before Installation

3 Hang the SEMS, fixed on the top left and right sides of the unit mounting bracket, over the

top groove of the wall mounting bracket.

4 Fix the fasteners to the rest of the fixing holes.

5 Firmly fix the fasteners that were temporarily fixed to the top left and right sides of the 4G

LTE Network Extender.

Figure 9. Fixing the 4G LTE Network Extender (3)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 22

©Samsung

Page 23

Appendix A Before Installation

[Floor]

[Wall]

[Ceiling]

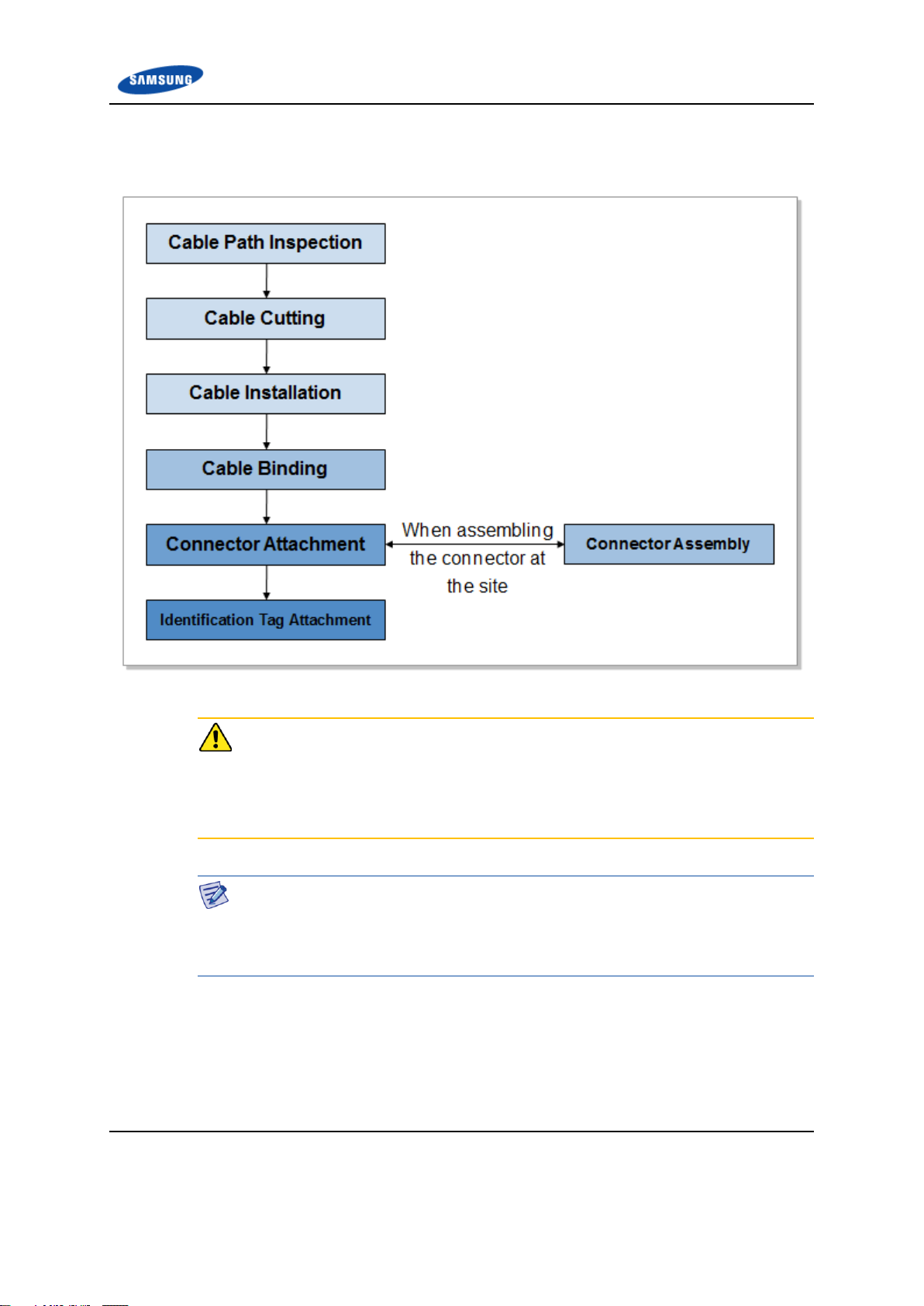

Fixing the 4G LTE Network Extender on the Ceiling or Flat Surface

The procedures for fixing the system on the ceiling or a flat surface are the same as

fixing the system on the wall.

Figure 10. Fixing 4G LTE Network Extender on the Ceiling or Flat Surface

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 23

©Samsung

Page 24

Appendix A Before Installation

Grounding

Power Cabling

GPS Arrestor Grounding

External Interface

Connection

Backhaul Cable

GPS Cable Connection

Chapter 2 Connecting the

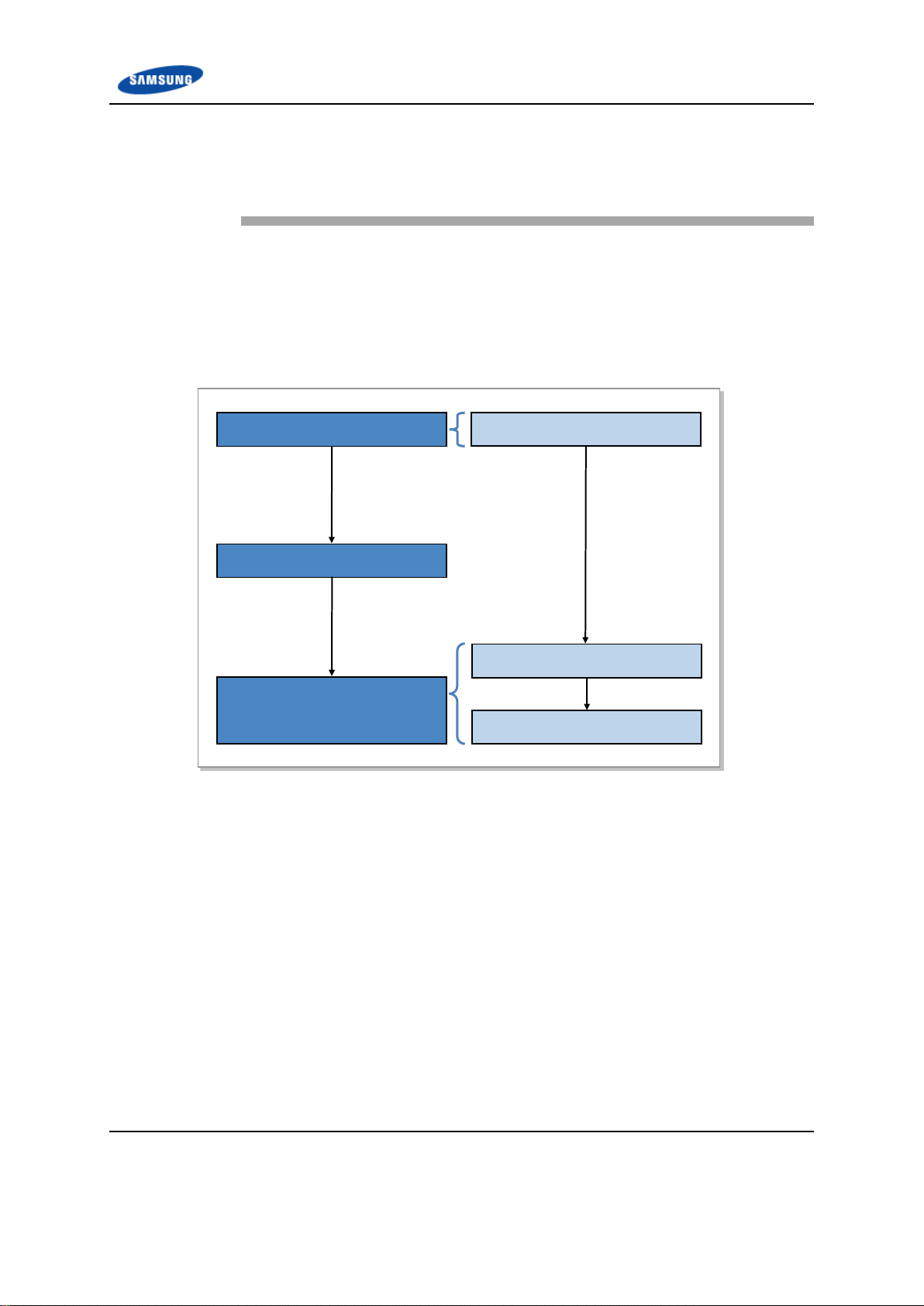

Workflow for Cabling

The cable workflow for the system is as follows.

Figure 11. Workflow for System Cabling

Cables

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 24

©Samsung

Page 25

Appendix A Before Installation

The detailed procedure for cabling is as follows.

Figure 12. Detailed Cabling Procedure

Considerations when Cutting the Cable after Installation

When cutting the cable after installation, make sure that the connector is

disconnected. Installation of the cable with the connector connected to the system

may cause contact failure or damage to the connector assembled to the system and

the cable due to cable tension or the operator’s mistakes.

Cabling Workflow

The sequence of cable cutting and installation of the cable workflow can be

changed depending on the field situation such as ‘cutting after installing’ or

‘installing after cutting’.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 25

©Samsung

Page 26

Appendix A Before Installation

No

Type

Allowed Cable Bend Radius

Remark

1

F-GV/F-CV/FR-8

Eight times of the cable

external diameter

0.6/1 KV Cable

2

Optic Cable

20 times of the cable

external diameter

-

Cable Path Inspection

Follow these guidelines when inspecting the cabling path:

A minimum cable length must be selected, provided that it does not affect the

cable installation and maintenance.

The cable must be placed in a location where it will not be damaged by

external factors (such as power line, flooding, and footpaths).

In areas where the cable may be damaged by external factors (such as cable

tray, ducts, and flexible pipe), ensure that measures are taken to prevent

damage to the cable.

Cable Cutting

Measure the exact distance, carefully checking the route, and cut the cable using a

cutting tool.

Follow these guidelines when cutting the cable:

Cut the cable to the length determined in the Cable Path Inspection step.

Use a dedicated cable cutting tool.

Cut the cable at right angles.

Be careful to keep the cable away from any moisture, iron, lead, dust or other

foreign material when cutting.

Remove any foreign material attached to the cable using solvent and a brush.

Cable Installation

Cable installation involves running the cable along the cabling path to the target

connector of the system or an auxiliary device after the cable path inspection and

cable cutting have been completed.

Follow these guidelines when installing a cable:

Be careful not to damage the cable.

Always use the maximum curvature radius possible, and make sure that the

minimum curvature radius specification is complied with.

If the cable needs to be protected, use a PVC channel, spiral sleeve, flexible

pipe, or cable tray.

Table 5. Recommended Minimum Allowed Cable Bend Radius

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 26

©Samsung

Page 27

Appendix A Before Installation

No

Type

Allowed Cable Bend Radius

Remark

3

UTP/FTP/S-FTP Cable

Four times of the cable

external diameter

PVC/LSZH,

4 Pair

4

1/2 in. Feeder Line(Indoor)

1.26 in. (32 mm)

RFS, LS

5

1/2 in. Feeder Line(Outdoor)

4.92 in. (125 mm)

RFS, LS

6

7/8 in. Feeder Line(Outdoor)

9.84 in. (250 mm)

RFS, LS

7

1-1/4 in. Feeder

Line(Outdoor)

14.96 in. (380 mm)

RFS, LS

8

1-5/8 in. Feeder

Line(Outdoor)

19.69 in. (500 mm)

RFS, LS

9

LMR-400

1 in. (25.4 mm)

Installation

4 in. (101.6 mm)

Repeated

10

RG-316D

0.59 in. (15 mm)

-

※ If the allowed cable bend radius is specified by the manufacturer, comply with the bend radius specified.

Cable Binding

Cable binding involves fixing and arranging an installed cable using binding

thread, cable ties, binding wire, and ram clamps.

Follow these guidelines when binding a cable:

Be careful not to damage the cable during binding.

Use appropriate cable binding tools according to the target location (indoor or

outdoor) and the use of the cable (such as power supply cable, optical cable, or

feeder line).

Do not let the cutting section of a cable tie, binding line, and so on be exposed

to the outside. This may cause damage to cables or personal injury. Make sure

that the cutting sections of the cables are not exposed to the outside.

Trim the cable binding cord at a 50 mm distance from its knob and insert it

into the knot so that the knot does not loosen.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 27

©Samsung

Page 28

Appendix A Before Installation

Connector Attachment

Connector attachment involves assembling a connector to an installed cable or to a

device on the site.

Follow these guidelines when attaching a connector:

Make sure you are fully aware of the connector assembly method before

assembling a connector. Assemble the connector in accordance with its pin

map.

Each connector has a hook to prevent its core positions from being changed.

Check the corresponding grooves before connecting a connector to another

connector.

Use a heat shrink tube at a connector connection for cables that are installed

outdoors, such as feeder lines, to prevent water leakage and corrosion from

occurring at the part exposed to the outside.

Connect each cable of the connector assembly in a straight line.

Be careful when connecting a cable so that contact failure does not occur at a

connector connection due to tension.

Identification Tag Attachment

Identification tag attachment involves attaching a marker cable tie, nameplate, and

label to both ends of a cable (connections to a connector) to identify its use and

cabling path.

Marker Cable Tie

On the marker cable tie, a label can be attached. The

appearance and specification may differ depending

on the type and manufacturer.

Follow these guidelines when attaching an identification tag:

When installing a cable outdoors, use relief engraving and coated labels to

prevent the markings from being erased.

Since the form and attachment method for identification tags are different for

each provider, consult with the provider before attaching them.

Connecting Ground Cable

When connecting the cables, always connect the ground cable first. If a person

comes in contact the equipment, connects a cable, or performs maintenance

without connecting the ground cable, the system can be damaged or someone may

be injured due to static electricity and/or short circuit.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 28

©Samsung

Page 29

Appendix A Before Installation

Finishing the System I/O Ports and Cable Inlet

To prevent foreign substances, outdoor air and moisture from entering the system

I/O ports (power, external interface, and so on) and cable inlet, finish it as follows:

- Unused inlets

Use finishing materials including dust cap and rubber packing.

- Cable-installed inlet

After cable installation, block any space in the inlet with dust covers.

Cable Installation Checklist

When installing, take care not to overlap or tangle the cables; also, consider future

expansion. Install the DC power cable and data transmission cable away from the

AC power cable to prevent electromagnetic induction.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 29

©Samsung

Page 30

Appendix A Before Installation

Cabling

The cabling diagram of the 4G LTE Network Extender is as follows.

Figure 13. Cabling Diagram

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 30

©Samsung

Page 31

Appendix A Before Installation

From

To

Cable

MGB

Optional GPS Arrestor

1 GPS Arrestor Ground Cable

AWG8, F-GV 6 mm2 × 1C

AC Distributor

AC/DC Adaptor

2 Power Cable-1

Power Cable Assembly-1

AC/DC Adaptor

4G LTE Network Extender

3 Power Cable-2

Power Cable Assembly-2

4G LTE Network

Extender

Switch or Router

4 Backhaul Cable

S-FTP Cat.5e or Cat.6, 4 Pair #24

328 ft.(100m) or less

GPS Antenna

5 GPS Cable-1

RG-316D(9.8 ft./3 m or less)

GPS Arrestor

Optional GPS Antenna

6 GPS Cable-2

LMR-400 [Extension cable from RG316D to GPS Arrestor when the length

of GPS cable-1 is over 9.8 ft.(3m)]

Table 6. 4G LTE Network Extender Connection Cable

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 31

©Samsung

Page 32

Appendix A Before Installation

GPS Requirements

Installation Requirements for the GPS Antenna

The GPS antenna must be installed in a location where it has the maximum

amount of open sky. The ideal position is one where there are no obstacles that

interfere with the antenna within 10 degrees or more of the horizon (the elevation

angle). This allows the GPS receiver to select the best combination or distribution

of GPS satellites that gives optimal performance.

Figure 14. Elevation Mask and Satellites

For good signal strength, you do not have to place the GPS antenna on a high pole

or building, which is often required for RF and microwaves reception.

Any place where there are no obstacles blocking the GPS antenna from the sky

and where it is protected from the outdoor elements is suitable. In this case, you

can even install it on the floor.

However, you can prevent the GPS antenna from malfunctioning by installing it in

a place where it does not receive reflected satellite signals. As multi-path

interference greatly affects the accuracy of the GPS receiver, it is better to

minimize reflected satellite signals entering through the top of the GPS antenna.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 32

©Samsung

Page 33

Appendix A Before Installation

Therefore, the GPS antenna installation location must meet the following three

guidelines:

1 A location that can avoid the effects of many obstacles and buildings that

interfere with GPS reception and cause multi-path interference.

2 A location that can avoid RF signal interference. Keep clear from other RF

antennas as well as steel-framed structures or microwave signals.

3 In outdoor applications, a location as low as possible and within a coverage

area of a lightning rod to avoid damage from lightning.

Considerations for Elevation Mask

Considering the elevation mask, make the GPS antenna take the signals received at

a valid elevation angle only.

Countermeasures for External Interference and Multi-Path Influences

If a GPS antenna is influenced by external interference signals or multi-path

interference at a certain place, it is best to reinstall the antenna at another place.

GPS Antenna Sharing

To ensure the GPS receiver works properly, it is recommended that you install one

GPS antenna per GPS receiver. It is also recommended that you use a GPSspecific splitter only if absolutely necessary.

Installing the GPS Antenna

The signals from a GPS satellite have a very low level (-130 dBm). Therefore, the

GPS receiving antenna should be installed in a place where it can receive signals

in direct line of sight, limiting the number of walls and floors as possible.

To receive as many satellite signals as possible, it is important to ensure there is

maximum open sky. The visual field angle must be 360 degrees, and there must

be 160 degrees or more above the horizon. If there are too many obstacles within

the horizon, it decreases the performance and functionality of the GPS receiver.

The GPS satellites are distributed so that eight of them can always be tracked from

any one place across the world, as long as there are no obstacles in the horizon.

For the GPS receiver to operate according to our needs, there must be three GPS

satellites with a healthy status for first fix (that is, there is no obstacle directly

between it and the GPS antenna). If the position hold operation has been

completed, the GPS receiver can perform its operations suitably if at least one

satellite can be tracked continually.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 33

©Samsung

Page 34

Appendix A Before Installation

Classification

Description

Cable

AC Distribution~AC/DC Adaptor

Cable

Connector

AC/DC Adaptor~4G LTE Network

Extender Power Input Terminal

Power Cable Assembly-1 (120/240 V AC)

4G LTE Network Extender

Power Cable Assembly-2 (12 V DC)

Connector

AC/DC Adaptor

Tyco 4P/1-770968-1. Equivalent

Power Cabling

The power supply is configured as follows.

Figure 15. Power Equipment Diagram

Figure 16. AC/DC Adaptor

Table 7. Power Cable Connection

Adaptor Installation Environment

Because the adaptor is not waterproof, you should consider the installation

environment. The adaptor can be damaged due to electrical short-circuit from

water.

The adaptor must be installed in an open space for proper heat dissipation.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 34

©Samsung

Page 35

Appendix A Before Installation

Spacing between AC/DC Adaptor and 4G LTE Network Extender

The AC/DC adaptor’s power cable length for the 4G LTE Network Extender is

4.92 ft. (1.5 m). The AC/DC adaptor should be installed where the cable length

does not exceed 4.92 ft. (1.5 m) for installation and connection to the 4G LTE

Network Extender.

Proper Circuit Breaker

To ensure a stable power supply, a slow blow (low speed operation) type circuit

breaker must be installed in the power cable connecting the AC power supply (or

power distributor) to the 4G LTE Network Extender. (Circuit breaker’s capacity: 5

A). After installing the circuit breaker, attach a tag showing the connected

system’s name to the breaker to prevent misuse.

Shutdown the Power Supply

The isolation procedure to turn the system power off is as follows:

In order to shut down the power supply to the entire system, the main power

switch on the AC power distribution should be turned off.

If the system needs to be shielded from the main power supply for service

purposes, the switches on the relevant circuit breakers (for example, those on

the AC power distribution or applied to building installation) must be turned

off.

If the system needs to be operated independently, the following (power) isolation

may be provided by unplugging the power supply cord or main plug.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 35

©Samsung

Page 36

Appendix A Before Installation

Power Connector

Power Port

‘

Power Cable

Power Cable Assembly-2

D

e

t

a

i

l

‘

A

’

AC/DC

Adaptor

[AC Distribution]

Power Cable Assembly-1

[4G LTE NE]

1 Install and connect the power cable assembly-1 from the AC distributor to the AC/DC

adaptor.

2 Install the power cable assembly-2 of the AC/DC adaptor to the power input port of the 4G

LTE Network Extender. Then, connect the connector to the 4G LTE NE power input port.

Figure 17. Power Cable Connection

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 36

©Samsung

Page 37

Appendix A Before Installation

Classification

Description

Installation Section

Switch or Router~4G LTE NE Backhaul Port

Cable

S-FTP Cat.5e or Cat.6, 4Pair #24, 328.1 ft.(100 m) or less

Connector

Switch or Router

RJ-45

4G LTE Network Extender

Pin No.

10 Base-T/100 Base-TX

1000 Base-T

Color

Pair No.

1

Output signal positive

BI Data 0 positive

Orange/White

2

2

Output signal negative

BI Data 0 negative

Orange

2

3

Input signal positive

BI Data 1 positive

Green/White

3

4 - BI Data 2 positive

Blue

1

5 - BI Data 2 negative

Blue/White

1

6

Input signal negative

BI Data 1 negative

Green

3

7 - BI Data 3 positive

Brown/White

4

8 - BI Data 3 negative

Brown

4

External Interface Connection

Backhaul Cable Connection

Follow the steps below to connect the backhaul cable.

Table 8. Backhaul Cable Pin Map

Check when Assembling Cable Connector

The table above is based on the connectors on the system side, so it is necessary to

check the pin connection positions when connecting to the connectors on the cable

side.

Assembling the RJ-45 Connector

To see how to assemble an RJ-45 connector to a cable, refer to Appendix C,

Connector Assembly.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 37

©Samsung

Page 38

Appendix A Before Installation

1 Install the backhaul cable from the switch (or router) to the B/H port of the 4G LTE Network

Extender.

2 Assemble the RJ-45 connectors and connector caps at both ends of the installed backhaul

cable.

3 Connect the assembled connectors to the B/H port of the 4G LTE Network Extender and

switch (or router).

‘

[4G LTE Network

Extender]

[Switch or Router]

Backhaul Cable

D

RJ-45 Connector

B/H (Backhaul) Port

Backhaul Cable

Figure 18. Backhaul Cable Connection

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 38

©Samsung

Page 39

Appendix A Before Installation

Classification

Description

Installation Section

4G LTE Network Extender to GPS Arrestor* to GPS Antenna

Cable

4G LTE Network Extender to

GPS Antenna

9.84 ft (3 m) or less

RG-316D

More than 9.84 ft (3 m)

RG-316D (9.84 ft or less)

+LMR-400

GPS Arrestor to GPS Antenna

(or Line Amplifier)

LMR-400

Connector

4G LTE Network Extender

SMA-Male

Connection part between RG316D and LMR-400*

RG-316D

N Type-Male

LMR-400

N Type-Female

GPS Arrestor*

N Type-Male

Line Amplifier*

N Type-Male

GPS Antenna

TNC-Male

Recommended

Torque Value

SMA-Male

0.18 ft.lb. (2.5 kgf.cm)

N Type-Male

1.45 ft.lb. (20 kgf.cm)

TNC-Male

0.65 ft.lb. (9 kgf.cm)

Working Tools

Cable Cutter, Wire Stripper, Nipper, Torque Wrench, Spanner, Knife, Soldering Iron,

Lead

* Optional Accessories

GPS Cable Connection

The following table lists the GPRS cable connector type and torque values.

Table 9. GPS Cable Connection

Installing GPS Line Amplifiers

The allowed length of a cable is limited according to the GPS cable configuration.

You must compensate for the signal loss by installing a line amplifier if the cable

exceeds the length allowed. Because the required number of line amplifiers and

installation method may vary depending on the extended length of the LMR-400

cable and line amplifier specifications, you must refer to the installation

instructions provided with the line amplifier.

In addition, you must install the line amplifier within 32.8 ft (10 m) from the GPS

antenna. The line amplifier is required when the total length of LMR-400 cable is

longer than 328.08 ft (100 m). See Appendix A for details.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 39

©Samsung

Page 40

Appendix A Before Installation

Appendix A Before

Installation

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 40

©Samsung

Page 41

Appendix A Before Installation

10.60 (269.3)

Unit: in. (mm)

[Right View]

[Left View]

[Bottom

[Rear View]

[Top View]

2.17(55.2)

0.79(20)

8.98 (228.2)

[Front View]

11.2 (285.6)

System Configuration

4G LTE Network Extender Configuration

The 4G LTE Network Extender dimensions are as follows.

Figure 19. 4G LTE Network Extender Configuration

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 41

©Samsung

Page 42

Appendix A Before Installation

1PPS Verizon

Use only

RESET

LMT

RF

Antenna

RF

Antenna

GPS

10 M Verizon

use only

B/H (Backhaul)

PWR (Power)

[Bottom View]

4G LTE Network Extender External Interface

The 4G LTE Network Extender external interface structure is as follows.

Figure 20. 4G LTE Network Extender External Interface Structure

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 42

©Samsung

Page 43

Appendix A Before Installation

Item

Specification

Operating Frequency

(selective)

Band 4 (UL: 1710~1755MHz, DL:2110~2155MHz) or

Band 13 (UL:777~787MHz, DL: 746~756MHz)

Channel Bandwidth

5/10MHz

Capacity

1Carrier/Omni

Antenna Configuration

2Tx/2Rx

RF Output Power

250mW/Path (Total 500mW)

Active UE

42 Active UE (=RRC connected UE)

Backhaul Interface

100Base-TX/1000Base-T (RJ45)

Synchronization (selective)

AGPS or IEEE1588v2

Holdover

GPS 24 hours, IEEE1588v2 48 hours

Operational temperature

0 ~ 50°C

Humidity

8~95% (Non-condensing, not to exceed 30g/m3 absolute humidity)

EMC/Safety/Dust Rating

FCC Part 15 / UL 60950 / IP5X

Cooling

Convection cooling

O&M protocol

TR-069

Security

IPsec

Installation

Wall, Floor, Ceiling and 19 inch Rack mounting

Volume

Volume: 3. 39 Liters

Power Supply (selective)

AC 105 – 125 VAC @ 60 Hz (± 5% of the Input Voltage) with external

adaptor or High power PoE.

Power consumption

45W with AC adapter / 51W with High Power PoE

Specifications

Key Specifications

The key specifications of the 4G LTE Network Extender are as follows.

Table 10. Key Specifications

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 43

©Samsung

Page 44

Appendix A Before Installation

Item

Specification

4G LTE Network Extender

External AC adapter (100~254 V AC)

Power Consumption

POE

AC Adaptor

TYP

38W

34W

MAX

42W

38W

Item

Specification

Size (W×D×H) [in. (mm)]

8.98 (228.2) × 2.17 (55.2) × 10.60 (269.3)

Weight [lb (kg)]

5.29 (2.4kg)

Item

Specification

Received Signal from GPS

GPS L1 Signal

Accuracy/Stability

±0.05 ppm (frequency)

Cold Start (no AGPS)

-148dBm

Warm Start (w/ AGPS)

-152dBm

Tracking

-162dBm

Item

Specification

Clock Source

1588 Grand Master

Input Power

The power specifications of the 4G LTE Network Extender are as follows.

Table 11. Input Power

Table 12. Power Specifications

Dimensions and Weight

The dimensions and weight of the 4G LTE Network Extender are as follows.

Table 13. Dimensions and Weight

GPSR Specifications

The specifications of the 4G LTE Network Extender’s GPS receiver (GPSR) are as

follows.

Table 14. GPSR Specifications

IEEE1588v2 Specifications

The IEEE1588v2 specifications for the 4G LTE Network Extender are as follows.

Table 15. IEEE1588v2 Specifications

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 44

©Samsung

Page 45

Appendix A Before Installation

Item

Specification

Accuracy/Stability

±0.05 ppm (frequency)

Packet delay variation (PDV)

<125μs

Item

Specification

Temperature

0~50 °C (32~122 ℉)

Storage Temperature

-40~70 °C (-40~158 ℉)

Humidity

5~90 % RH

Storage Humidity

5~95 % (RH)

Altitude

60~1,800 m @ 50°C

1,800~4,000 m @ 40°C

Earthquake

Richter magnitude 7.0~8.3 (Zone 4, Telcordia GR-63 CORE)

Sound Pressure Level

45 dBA or below; 3.28 ft (1.0 m) distance from the product surface

Dust Rating

IEC60529, IP2X

EMC

FCC Part 15

Fire Test

UL 2043

Ambient Specifications

The ambient specifications for the 4G LTE Network Extender are as follows.

Table 16. Ambient Specifications

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 45

©Samsung

Page 46

Appendix A Before Installation

Cautions for Installation

Observe the following safety instructions when installing the 4G LTE Network

Extender.

Before Installing

Post warning signs in areas where high-voltage cables are installed.

Post ‘off limit’ signs in areas where accidents are most expected.

With guardrails or fences, block open areas such as connecting parts, roof, and

scaffold.

While Installing

The system power must be cut off before installing.

Power Switch Off

Make sure the power switch of the power supply is off when installing the system.

Installing the system with the power switch on may cause system damage or fatal

human injury when cables are not correctly connected.

Wearing Protective Gloves and Glasses

The workers should wear protective gloves and glasses because they can be

injured by the debris generated when drilling holes on walls or ceilings.

Do Not Wear Metal Things such as Watch, Ring, Etc.

Do not let an electric short circuit occur due to metal objects such as a watch or

ring.

Worker Injury

Avoid applying excessive force when installing the power cable in narrow areas.

Adjacent equipment and walls may cause accidental injury.

Do not Work by Yourself

A worker must not work alone during any key process.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 46

©Samsung

Page 47

Appendix A Before Installation

Finishing the Cable Inlet

To prevent foreign substances, outdoor air and moisture from entering the cable

inlet (including the cable gland and conduit), finish it as follows:

- Unused inlet

Use the finishing materials including dust cap and rubber packing.

- Cable-installed inlet

After cable installation, block any space in the inlet with tape, compressed

sponge, rubber packing, and silicon.

After Installing

Cover the cable holes drilled on the floor with a solid cover.

Remove any debris produced during the work and clean up the installation site.

Cautions while Cleaning the Unit

Make sure that the worker does not damage the installed cables while cleaning the

unit.

Cautions while Cleaning Power Supply

While cleaning the power supply device, take caution that the device does not

come in contact with alien bodies that may cause power failure.

Cautions while System Operation

Because the system heat sink may become hot, avoid physical contact.

Pre-survey

To enable seamless construction, the installer and the service provider should

perform a preconstruction inspection to examine and analyze the following items:

Examination of the conformance and the economic efficiency of the place that

Status of external interfaces

Power capacity and wiring status

Possibility of system extension

Review if the place has the enough space for operation and maintenance.

the system is transported or installed

If there is a need for improvement or an issue, the installer and the service provider

must discuss measures to resolve any issue that arises.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 47

©Samsung

Page 48

Appendix A Before Installation

No.

Name

Specification

Remarks

1

Screw Driver Set

No.0~+No.3 (M2.6~M6 ‘+’ Driver)

1.0~60 kgf.cm

2

Torque Wrench Set

M6~M12

10~30 kgf.cm, 100~500 kgf.cm, Replaceable head

3

Drill/Bit Set

0.24~0.67 in. (6~17 mm)

4

Heating Gun

122~572 ℉ (50~300 °C)

5

Power Extension Cable

98.42 ft (30 m)

6

Tape Measure

16.4 ft/164 ft (5 m/50 m)

7

Cable Cutter

325 mm

8

Silicon Gun/Silicon

Normal/Gray & Colorless

9

Hummer Set

Still/Rubber/PVC

Installation Tools

The basic tools for installation are listed in the following table. Additional tools

required for each site need to be identified and prepared during a site survey before

starting the installation.

Precautions When Using the Installation Tools

The required installation tools may vary depending on the conditions at the site.

In addition to the basic tools, a protractor, compass, GPS receiver, ladder, safety

equipment, cleaning tools, and so on should also be prepared in consideration of

the site conditions.

Table 17. Basic Installation Tools

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 48

©Samsung

Page 49

Appendix A Before Installation

No.

Name

Specification

Remarks

10

Spanner

0.75 in., 0.94 in., 1.42 in.

(19 mm, 24 mm, 36 mm)

11

Wire Stripper

0.24~0.94 in.

(6 mm~24 mm)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 49

©Samsung

Page 50

Appendix B Optional GPS Antenna Installation

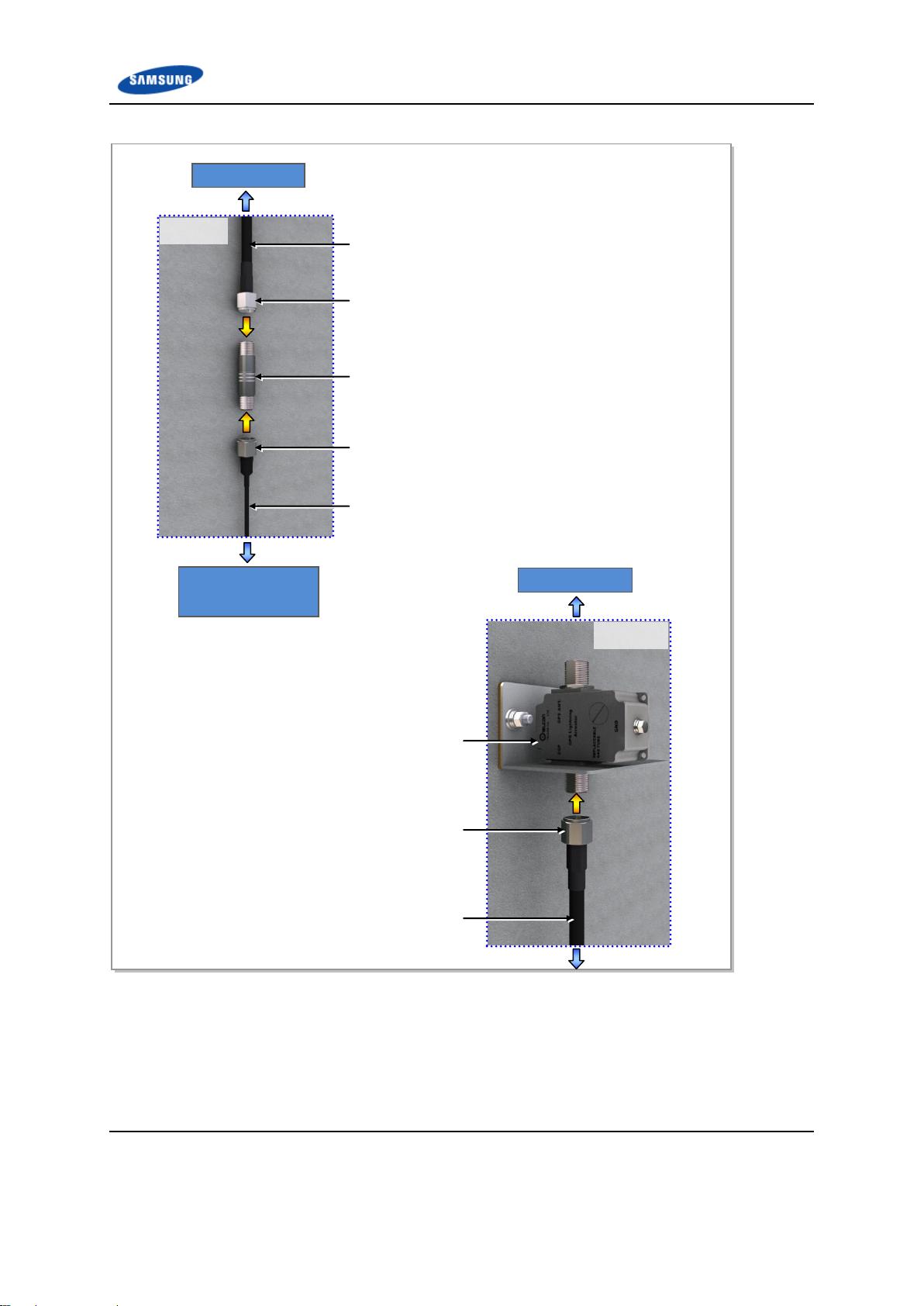

Category

Description

GPS Antenna

Device receiving a signal from a GPS satellite

GPS Line Amplifier (Option)

Device amplifying the GPS signal received from the GPS antenna (used to

compensate the GPS signal loss caused by GPS antenna, GPS arrestor, cable

and connector)

GPS (Lightning) Arrestor

Device protecting people or system from lightning

System

GPS Antenna

GPS

GPS Cable (LMR-400)

GPS Cable (RG-316D)

Line Amplifier

Appendix B Optional GPS

Antenna

Installation

GPS Antenna System Configuration

A GPS antenna system requiring outdoor installation or longer cable runs is

configured as shown below.

Table 18. GPS Antenna System Configuration

Figure 21. Example of a Common GPS Antenna System Configuration

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 50

©Samsung

Page 51

Appendix B Optional GPS Antenna Installation

Classification

Description

Installation Section

4G LTE Network Extender GPS Arrestor GPS Antenna

Cable

4G LTE Network Extender GPS

Arrestor

9.84 ft (3 m) or less

RG-316D

More than 9.84 ft (3 m)

RG-316D (9.84 ft or less)

+LMR-400

GPS Arrestor GPS Antenna (or

Line Amplifier)

LMR-400

Connector

4G LTE Network Extender

SMA-Male

Connection part between RG316D and LMR-400

RG-316D

N Type-Male

LMR-400

N Type-Female

GPS Arrestor

N Type-Male

Line Amplifier

N Type-Male

GPS Antenna

TNC-Male

Recommended

Torque Value

SMA-Male

0.18 ft.lb. (2.5 kgf.cm)

N Type-Male

1.45 ft.lb. (20 kgf.cm)

TNC-Male

0.65 ft.lb. (9 kgf.cm)

Working Tools

Cable Cutter, Wire Stripper, Nipper, Torque Wrench, Spanner, Knife, Soldering Iron,

Lead

To satisfy the GPS specifications and operate the GPS antenna in a stable manner,

the following GPS antenna configuration and installation requirements must be

met.

GPS Antenna

Follow the steps below to connect the GPS cable.

Table 19. GPS Cable Connection

Installing GPS Line Amplifiers

The allowed length of a cable is limited according to the GPS cable configuration.

You must compensate for the signal loss by installing a line amplifier if the cable

exceeds the length allowed. Because the required number of line amplifiers and

installation method may vary depending on the extended length of the LMR-400

cable and line amplifier specifications, you must refer to the installation

instructions provided with the line amplifier.

In addition, you must install the line amplifier within 32.8 ft (10 m) from the GPS

antenna.

Line Amplifier Usage Guideline for GPS Cable Configuration

When the total length of the LMR-400 cable is longer than 328.08 ft (100 m)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 51

©Samsung

Page 52

Appendix B Optional GPS Antenna Installation

Installing the Antenna

When you install the antenna, the antenna must be within the protective angle

(left/right side 45° each from the central axis) to prevent the antenna from

lightning damage.

Installing GPS Antenna

When installing the GPS antenna, you must check the antenna installation location,

restriction and installing method in Appendix A.

Checking the Specifications of Antenna/Arrestor/Line Amplifier Connector

Depending on the supplier or manufacturer of the antenna/arrestor/line amplifier,

the connector type may be different. Also, the detail specifications of a connector

may be different depending on the cable type even for the same connector type.

Therefore, check the detailed specifications of a connector before preparing parts.

For example, N Type-Male: N-Type-Male connector for CNT-400, N-Type-Male

connector for RG-316D

Specification of GPS Line Amplifier

The GPS line amplifier specification is ‘Symmetricom-58529A’ or equivalent.

(http://www.symmetricom.com/products/gps-solutions/accessories/58529A-GPSLine-Amplifier-with-L1-Bandpass-Filter/)

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 52

©Samsung

Page 53

Appendix B Optional GPS Antenna Installation

Classification

Description

Installation position

Attach the identification tag to the ends of the GPS antenna and arrestor.

Materials

Aluminum coated by vinyl identification tags are recommended.

Fixing method

Fix the GPS cable to the two holes on the identification tag with the black cable tie.

Identification method

The markings must be prevented from being erased by using relief engraving or

coated labels.

[Identification Tag Example]

1. CABLE NAME: Cable name

2. LENGTH: Cable length (m)

3. USE: Cable usage purpose

GPS Antenna Specifications

For the GPS antenna, ACE technology GA-1575 or equivalent must be used.

(http://www.aceteq.com/)

GPS Cable Identification Tag Installation

Attach the identification tape specified in the following table to the GPS cable.

Table 20. Identification Tag of GPS Cable

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 53

©Samsung

Page 54

Appendix B Optional GPS Antenna Installation

[4G LTE NE]

GPS Cable (LMR-400)

[Line Amplifier]

GPS Cable (LMR-400)

GPS Arrestor ~ GPS Antenna

Without Amplifier: Max. 328. ft. (100 m) /

With Amplifier (1EA): Max. 656.2 ft. (200 m)

Amplifier ~ GPS Antenna

Max. 32.8 ft. (10 m)

[GPS Antenna]

[GPS Arrestor]

GPS Cable (RG-316D)

4G LTE NE ~ Arrestor

9.8 ft. (3 m) or less

GPS Cable Configuration (Case #1)

The configuration of the GPS cable is shown in the following figure.

Figure 22. GPS Cable Configuration Case #1

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 54

©Samsung

Page 55

Appendix B Optional GPS Antenna Installation

Adaptor ~ GPS Antenna

Without Amplifier: Max. 328. ft. (100 m) / With Amplifier (1EA): Max. 656.2 ft. (200 m)

Amplifier ~ GPS Antenna

Max. 32.8 ft. (10 m)

[GPS Antenna]

[4G LTE NE]

GPS Cable (LMR-400)

[Line Amplifier]

GPS Cable

(LMR-400)

[GPS Arrestor]

GPS Cable (RG-316D)

[

Adapt

o

r]

GPS Cable (LMR-400)

4GLTENE~Arrestor

9.8 ft. (3 m) or less

GPS Cable Configuration (Case #2)

Figure 23. GPS Cable Configuration Case #2

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 55

©Samsung

Page 56

Appendix B Optional GPS Antenna Installation

GPS Cable Length

The length of the GPS cable is limited for each section as shown below.

1. 4G LTE Network Extender GPS arrestor: 9.84 ft (3 m) or less

If the distance between the 4G LTE Network Extender and the GPS arrestor is

longer than 9.84 ft. (3 m), use the straight adapter for extension. Connect the RG316D cable up to 9.84 ft. (3 m) to the straight adapter and then extend the

connection to the GPS arrestor using the LMR-400 cable.

2. RG-316D~GPS arrestor GPS antenna (LMR-400 cable installation section)

- Total length of the LMR-400 cable: 328.08 ft. (100 m) or less

- If the total length of the LMR-400 cable is longer than 328.08 ft. (100 m),

compensate the loss by installing a line amplifier.

Because the required number of line amplifiers and installation method may vary

depending on the extended length of the LMR-400 cable and line amplifier

specifications, you must refer to the installation instructions provided with the line

amplifier. In addition, you must install the line amplifier within 32.8 ft. (10 m)

from the GPS antenna.

For example, when using a line amplifier (Symmetricom-58529A) × 1 EA →

Total length of the LMR-400 cable: 656.17 ft. (200 m) or less

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 56

©Samsung

Page 57

Appendix B Optional GPS Antenna Installation

Detail ‘A’

SMA Male Connector

GPS Cable

(RG-316D)

‘A’

‘B’

[GPS Arrestor]

[GPS Antenna]

[4G LTE NE]

GPS Cable

(RG-316D)

GPS Cable

(LMR-400)

Detail ‘B’

N Type-Male Connector

GPS Arrestor

4G LTE NE

GPS Arrestor

1 Install the GPS cable from the GPS antenna port of the 4G LTE Network Extender to

GPS arrestor.

2 Connect the assembled connectors of the cable to the GPS antenna port.

o RG-316D Cable: SMA Male 4G LTE Network Extender), N Type-Male (GPS Arrestor)

o LMR-400 Cable: N Type-Male (GPS Arrestor EQP)

GPS Antenna

4G LTE NE

4G LTE Network Extender GPS Arrestor Cable Connection (Case #1)

Follow the steps below to connect the GPS cable from the 4G LTE Network

Extender to the GPS arrestor.

Figure 24. 4G LTE Network Extender GPS Arrestor Cable Connection Case #1

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 57

©Samsung

Page 58

Appendix B Optional GPS Antenna Installation

Detail ‘A’

SMA Male Connector

GPS Cable (RG-316D)

‘A’

‘C-

1’

[GPS Arrestor]

[GPS

Antenna]

[4G LTE NE]

GPS Cable

(RG-316D)

GPS Cable

(LMR-400)

4G LTE NE

‘B’

[Adaptor]

GPS Cable

(LMR-400)

1 Install the GPS cable from the GPS antenna port of the 4G LTE Network Extender to GPS

arrestor.

2 Connect the assembled connectors of the cable to the GPS antenna port.

o RG-316D Cable: SMA Male (4G LTE Network Extender), N Type-Male (Straight Adaptor)

o LMR-400 Cable: N Type-Male (GPS Arrestor EQP)

‘D’

‘C-

2’

GPS Arrestor

4G LTE Network Extender GPS Arrestor Cable Connection (Case #2)

Figure 25. 4G LTE Network Extender GPS Arrestor Cable Connection Case #2

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 58

©Samsung

Page 59

Appendix B Optional GPS Antenna Installation

Detail ‘B’

GPS Cable (RG-316D)

N Type-Male Connector

Straight Adaptor

N Type-Male Connector

GPS Cable (LMR-400)

Detail ‘C-

GPS Arrestor

N Type-Male Connector

GPS Cable (LMR-400)

GPS Arrestor

GPS Antenna

4G LTE Network

Extender

Figure 26. 4G LTE Network Extender GPS Arrestor Cable Connection Details

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 59

©Samsung

Page 60

Appendix B Optional GPS Antenna Installation

Detail ‘C-2’

GPS Arrestor

N Type-Male Connector

GPS Cable (LMR-400)

GPS Cable (LMR-400)

GPS Antenna

Clamp

Clamp fixing Screw

Bakelite

GPS Antenna Fixing Pipe

TNC Male Connector

Heat Shrink Tube

Heat Shrink Tube (Jelly Type)

Detail ‘D’

1 Install the GPS cable from the GPS ANT. port of the GPS arrestor to the GPS antenna.

2 Connect the assembled connectors of the GPS cable (LMR-400) to the GPS arrestor and

antenna port.

LMR-400 Cable: N Type-Male (GPS Arrestor EQP)

TNC Type-Male (GPS Antenna)

GPS Antenna

Straight Adaptor

Figure 27. GPS Arrestor GPS Antenna Cable Connection Detail

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 60

©Samsung

Page 61

Appendix B Optional GPS Antenna Installation

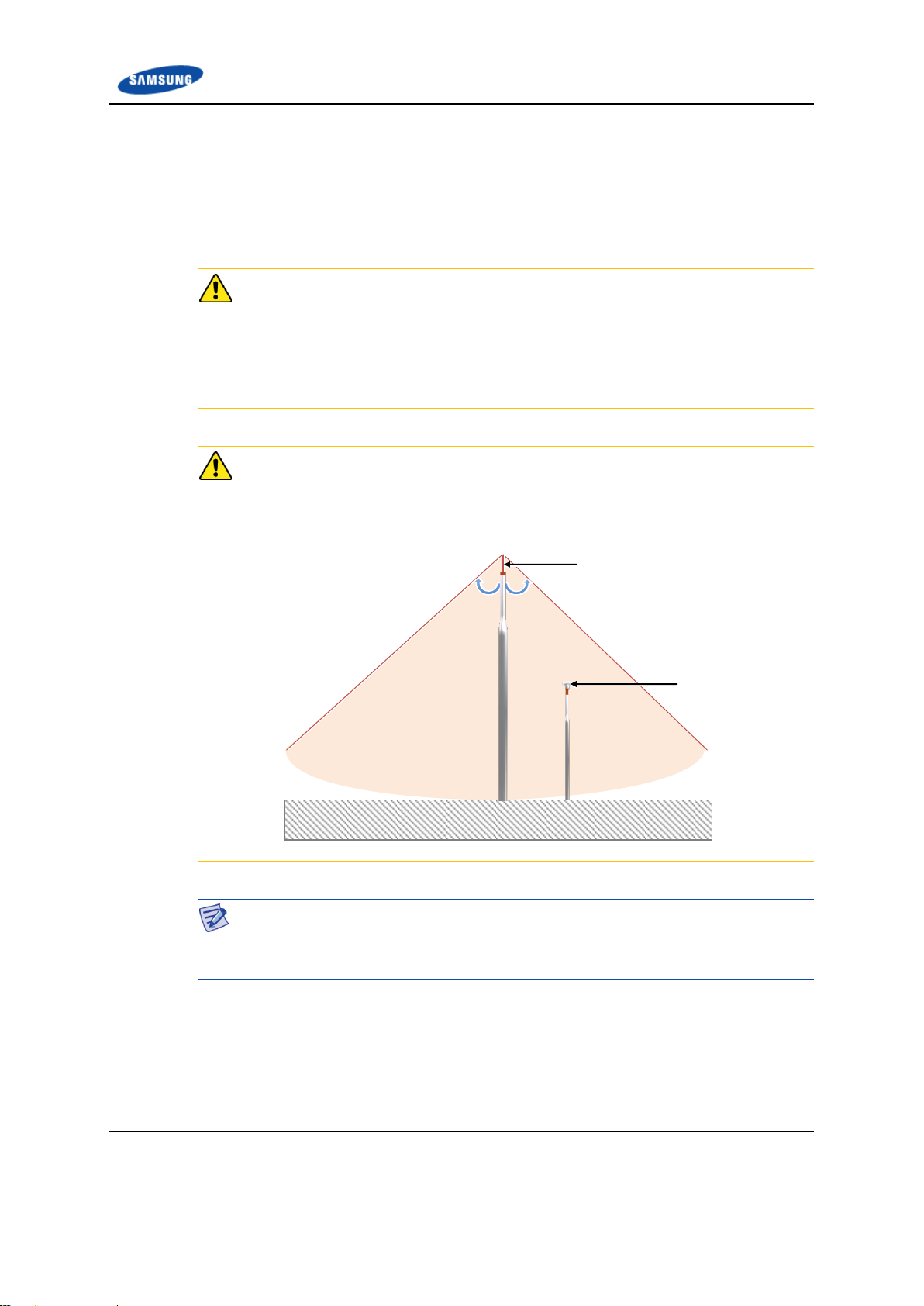

GPS Satellite Tracking and Position Hold

The survey of an object’s position using GPS satellites is based on triangulation.

Three satellites are enough to survey the position of an object by triangulation.

However, to calculate the correct time deviation, a total of four satellites are

required.

Usually, the GPS antenna is installed in a high place, such as on a roof. It must be

installed away from protruding objects, such as trees or buildings. In addition, it

must be positioned away from any obstacle that covers part of the airspace around

the horizon of the building where it is installed.

If it is impossible to ensure a completely open airspace, you should install the GPS

antenna facing the equator providing a maximum view of the Southern sky

(Northern sky in the Southern hemisphere).

Furthermore, when installing the GPS antenna using a steel cylinder structure

shared by other RF antennas, it must be separated by more than 1 m from that steel

structure.

Figure 28. GPS Antenna Installation

Lightening Arrestor

A lightning arrestor is required when there is a danger of lightning striking a cable

or related part. The lightning arrestor must be installed in a place where the

antenna cable or set of combined cables enters a building or station, or a place

inside the building or station. The purpose of this is to protect the people and

equipment inside the building or station.

If struck directly by lightning, the lightning arrestor, antenna, or cable must be

replaced. Furthermore, you must inspect the lightening arrestor periodically, and

replace the antenna and cable periodically to ensure protection if lightning occurs

frequently at the site.

The lightning arrestor must be well grounded so that it can transmit a large current

quickly.

Verizon 4G LTE Network Extender for Enterprise Installation Manual v1.0 61