Page 1

VMB1TSW

Temperature sensor module

for the Velbus system

Page 2

CONTENTS

DESCRIPTION ................................................................................................................................ 3

CHARACTERISTICS ...................................................................................................................... 3

VELBUS CHARACTERISTICS ...................................................................................................... 5

OVERVIEW SENSOR MODULE .................................................................................................... 7

EMBEDDING THE TEMPERATURE SENSOR .............................................................................. 8

EMBEDDING A TEMPERATURE SENSOR TOGETHER WITH A CONTROLLER ...................... 9

OVERVIEW HEATING INSTALLATION ....................................................................................... 10

WIRING ......................................................................................................................................... 11

Connecting the temperature sensor VMB1TS ............................................................................................................ 11

Connecting the temperature controller VMB1TC / VMB1TCW(W) ............................................................................ 11

Relay cabinet wiring ................................................................................................................................................... 12

Terminator .................................................................................................................................................................. 13

Addressing .................................................................................................................................................................. 13

LED INDICATION ......................................................................................................................... 13

Anti-freeze, night, day or comfort mode ..................................................................................................................... 13

Cooling or heating mode ............................................................................................................................................ 14

Air-conditioner or heater active ................................................................................................................................... 14

OPERATION ................................................................................................................................. 15

SETTINGS .................................................................................................................................... 16

Preset range ............................................................................................................................................................... 16

Protecting the circulation pump and/or heating valves ............................................................................................... 16

Time statistics ............................................................................................................................................................. 16

Minimum and maximum temperature ......................................................................................................................... 17

Differential thermostat ................................................................................................................................................ 17

Factory settings .......................................................................................................................................................... 17

CONFIGURING THE OUTPUTS .................................................................................................. 18

REMOTE CONTROL .................................................................................................................... 19

SWITCHING TO ANTI FREEZE MODE THROUGH WINDOW CONTACTS ............................... 20

DIFFERENTIAL THERMOSTAT .................................................................................................. 21

The passage automatically 3° cooler than the office .................................................................................................. 22

Passive cooling of a bedroom .................................................................................................................................... 23

Page 3

DESCRIPTION

The sensor module can be used to measure and send temperatures over the Velbus-system. In combinatio n with a

relay module (VMB4RYNO / VMB4RYLD or VMB1RY) a thermostat can be set-up to control a heating or cooling

installation.

Setting the comfort, day, night or anti-freeze mode can be done via the local pushbutton of with pushbuttons that are

connected to the Velbus. Different sensors can be configured and controlled from a remote location through a

temperature controller (VMB1TC / VMB1TCW) or via a PC interface (VMB1USB, VMB1RS or VMBRSUSB) and the

Velbus link software.

The temperature controller (VMB1TC / VMB1TCW) can also include program instructions to control different sensors.

CHARACTERISTICS

Temperature range of the sensor: -10° to 63.5°C (14° to 146°F)

precision after calibration:

±0.5°C at 25°C

±1°C between -10°C and 63.5°C

Resolution: 0.0625°C

Hysteresis: 0°C to 15.5°C (interval of 0.5°C)

Possibility to automatically send the ambient temperature over the Velbus

Registration of minimum and maximum temperature

Registration on-time of heater/air-conditioner

Thermostat function for cooling or heating

In combination with a second sensor a differential thermostat can be created

Range:

heating function: -32°C to 54°C in steps of 0.5°C (default settings: 5° to 30°)

cooling function: -32°C to 54°C in steps of 0.5°C (default settings: 16° to 36°C)

Relay steering via Velbus for:

heating

fast heating/cooling

heating boiler in day mode

cooling

steering circulation pump

alarm at low temperature

alarm at high temperature

Cycling protection delay on heating and cooling outputs (minimum on/off switching delay): 1 minute defaul t (can be

switched off or set in multiples of minutes via Velbuslink software)

Selectable unjamming function for the circulation pump and/or heating valves (min. 1 minute/day on)

Control:

local pushbutton

remotely via pushbuttons connected to the Velbus

via temperature controller VMB1TC / VMB1TCW

through Velbus program instructions

Local control for switching between:

comfort mode

day mode

night mode

safeguard mode (anti-freeze)

Possibility to prevent (lock) local control

Control through pushbuttons connected to the Velbus to:

set the module to comfort temperature

set the module to day temperature

set the module to night temperature

set the module to safeguard temperature (anti-freeze)

set the thermostat to heating

set the thermostat to cooling

lock the local control

unlock the local control

Heating can be set in anti freeze mode through window contacts conne cted to the Velbus when a window is opened

Feedback to the pushbutton modules to update the LED status

Can be programmed without the aid of a PC

Simple learning process by pressing the desired pushbuttons while in learning mode

Page 4

Storage capacity of 10 different pushbuttons per control function

LED indications for:

thermostat function for cooling

comfort mode

day mode

night mode

heater/air-conditioning status

power supply voltage

receiving/transmitting data over the Velbus

Settings for:

the desired temperature

the desired comfort temperature for heating

the desired day temperature for heating

the desired night temperature for heating

the anti-freeze safeguard temperature

the heating limit (upper limit of the heating preset range)

the desired comfort temperature for cooling

the desired day temperature for cooling

the desired night temperature for cooling

the lower limit of the cooling preset range

the upper limit of the cooling preset range

the hysteresis

calibration of the sensor

the temperature difference for fast heating/cooling or for the differential thermostat

the low temperature alarm (alarm when temperature drops below this value)

the high temperature alarm (alarm when temperature rises above this value)

the duration of temporary mode: from 1 to 65.279 minutes (45 days, 7 hours, 59 minutes)

transmitting the current temperature over the Velbus:

o only when requested

o only when changes occur

o at specific time intervals, selectable between 10 and 255 seconds (4 minutes 15 seconds)

resetting minimum and maximum temperature

the zone (each sensor can belong to a specific zone)

the address of the linked sensor to set up a differential thermostat

cycling protection delay (minimum on/off switching delay)

Change settings through Velbus instructions or via a temperature controller (VMB1TC / VMB1TCW)

Control through a program stored in a temperature controller (VMB1TC / VMB1TCW)

Different modes:

automatic: the sensor module accept all program instructions

temporary manual: program instructions are ignored during a specific period of time

manual: all program instructions are ignored and local control is locked

The learned pushbutton functions and settings are retained when voltage drop-outs occu r

246 possible addresses (setting via rotary switches)

Required power supply: 12 to 18VDC

Consumption when not in use: 12mA

Maximal consumption: 15mA

Dimensions (W x H x D): 43 x 46 x 22mm

Page 5

VELBUS CHARACTERISTICS

2-wire communication for Velbus data and 2 wires for power supply

data transmission: 16.6 Kbit/s

Serial data protocol: CAN (Controller Area Network)

Short circuit proof (towards negative or positive pole of the power supply)

LED indication when receiving or transmitting data over the Velbus

bus error indication: 2 short flashes of the LEDs

auto recovering after 25 seconds when a bus error occurs

The sensor module can be given a designation with a maximum of 16 characters.

The temperature sensor module can transmit following messages:

output status

manual pushbutton status

sensor status

sensor temperature, minimum and maximum temperature

time statistics (heating/air-conditioning on time)

sensor settings

sensor configuration

module type (including zone number and software version)

sensor name

memory content

the communication error counter

The temperature sensor module can transmit following instructions:

change the status of the LED(s) on the pushbutton module

switching off the LED(s) on a pushbutton module

switching on the LED(s) on a pushbutton module

make LED(s) on a pushbutton module flash slowly

make LED(s) on a pushbutton module flash fast

the desired temperature for the linked sensor to create a differential thermostat

The temperature sensor module can receive following messages:

the status of a pushbutton module

The temperature sensor module can receive following instructions:

to set:

the desired temperature

the desired comfort temperature for heating

the desired day temperature for heating

the desired night temperature for heating

the anti-freeze safeguard temperature

the heating limit

the desired comfort temperature for cooling

the desired day temperature for cooling

the desired night temperature for cooling

the lower limit of the cooling preset range

the upper limit of the cooling preset range

the hysteresis

calibration of the sensor

the temperature difference for fast heating/cooling or for the differential thermostat

the temperature difference for fast heating or cooling

the alarm temperatures

the default duration of temporary mode (sleep time)

the zone number

the address of the linked sensor to set up a differential thermostat

to determine:

heating

cooling

local control panel:

lock

unlock

Page 6

memory:

read

(over)write

set the status of the output LED

switching off the indication LED on the pushbutton module(s)

switch unjam function of circulation pump and/or heating valve on or off

output LED handling:

switch off

switch on

flash

flash slowly

flash (very) fast

request:

module type

content of the communication error counter

the sensor temperature (min/max) and setting the time interval for transmitting data

the time statistics

the sensor status

the sensor settings

the sensor configuration

the sensor name

resetting:

minimum temperature

maximum temperature

time statistics

switching to:

comfort mode

day mode

night mode

anti-freeze mode

Page 7

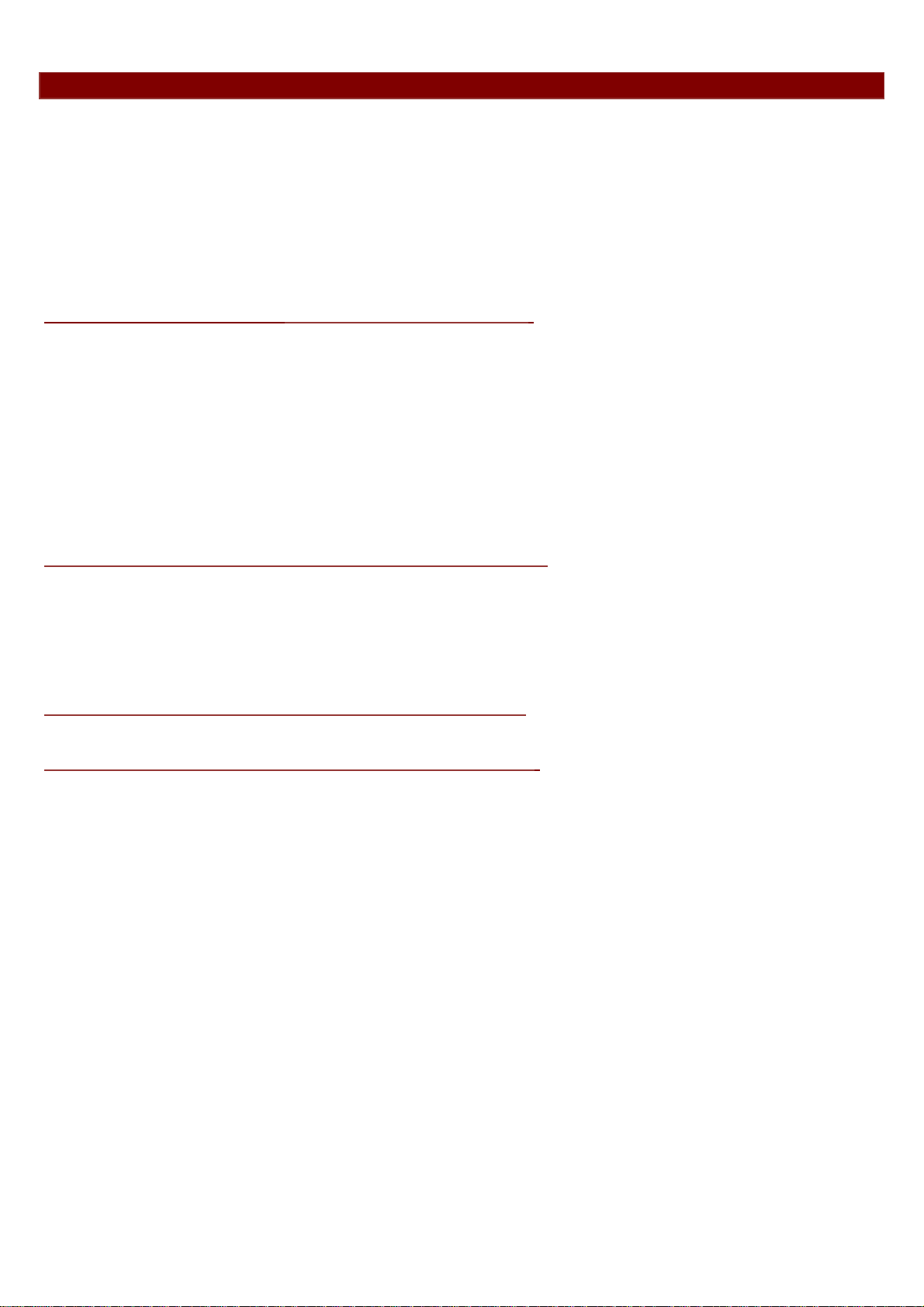

OVERVIEW SENSOR MODULE

9

8

10

LED indication

Cooling mode

1

Comfort mode

2

Day mode

3

Night mode

4

Heating or air-conditioning on

5

Sensor

Temperature sensor

6

Controls

Mode pushbutton

7

8

Terminator

Power supply 12 to 18Vdc

9

Velbus

10

Settings

Wiring

Page 8

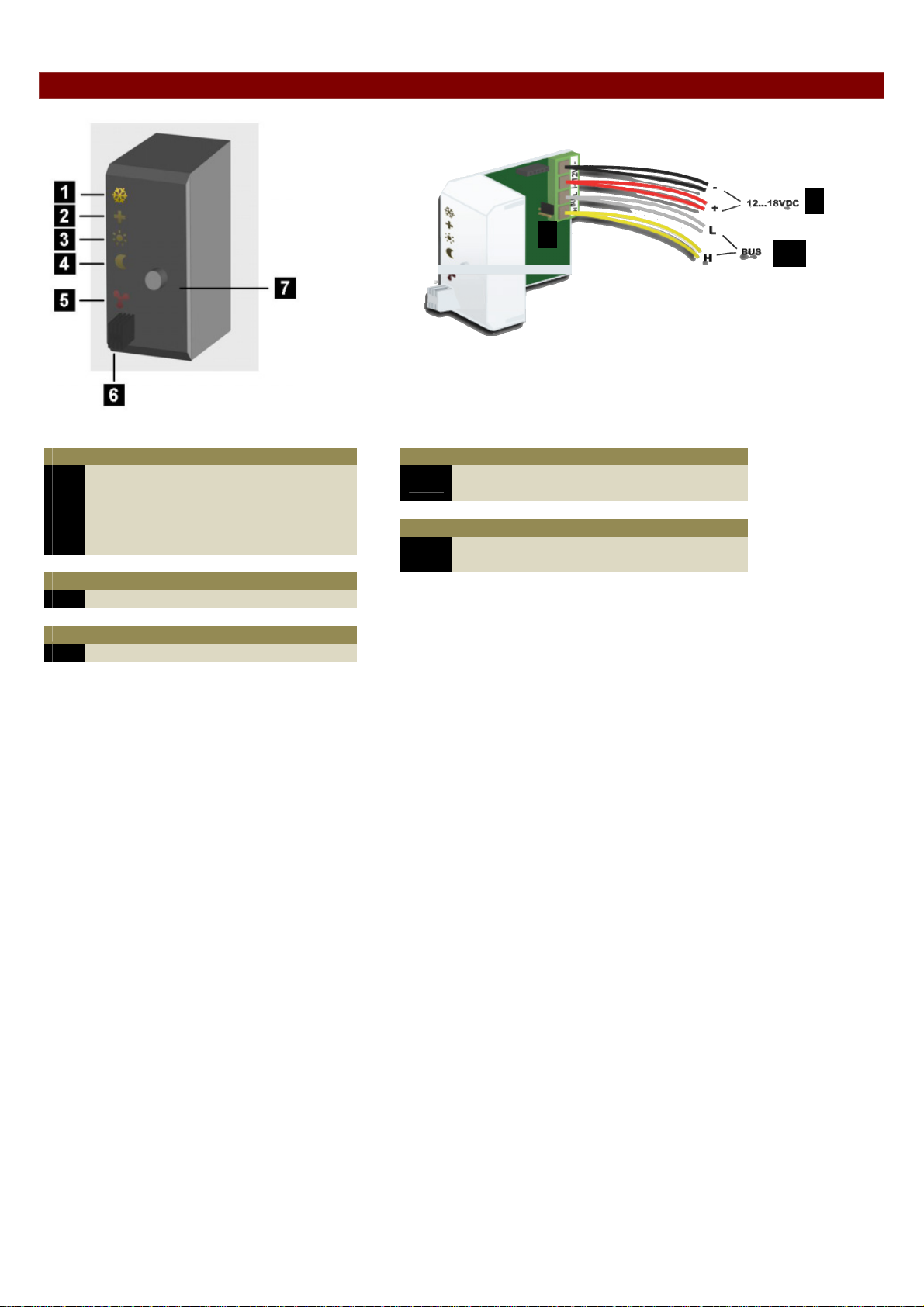

EMBEDDING THE TEMPERATURE SENSOR

The temperature sensor VMB1TSW can be embedded in combination with blank frames VMBFBI and cover plate.

It is possible to use a 2- or 3-module wide frame with cover plate from the BTicino Living series.

The module must be pushed into the build-in frame from the front.

It is also possible to use a 3-module wide frame with cover plate from the BTicino Light or Light Tech series.

The module must be pushed into the build-in frame from the front.

To build the sensor in into a hollow wall, use a hollow wall pattress.

Page 9

EMBEDDING A TEMPERATURE SENSOR TOGETHER WITH A CONTROLLER

The sensor (VMB1TSW) can be embedded together with a controller (VMB1TC / VMB1TCW) in a 4-module wide

frame with cover plate from the BTicino Living series. The module must be pushed into the build-in frame from the

front.

The sensor (VMB1TS) can be build-in together with a controller (VMB1TC / VMB1TCW) in a 4-module wide frame

with cover plate from the BTicino Light of Light Tech series. The module must be pushed into the build-in frame from

the front

To build the controller and sensor in into a hollow wall, use a hollow wall pattress.

Page 10

OVERVIEW HEATING INSTALLATION

A heating installation usually consists of radiators or convectors, a boiler, circulation pump and a collector with valves

for every radiator group. Every room is equipped with a temperature sensor VMB1TSW which is controlled by one or

multiple temperature controllers VMB1TC / VMB1TCW(W). The sensors in turn steer the relay modules VMB4RYNO /

VMB4RYLD (or VMB1RY) that control the valves. As soon as one of the valves is opened, a relay channel can

activate the circulation pump and when one of the sensors is in day or comfort mode, a relay channel can put the

boiler in day mode. When convectors with built-in fan are used, a relay channel can steer this fan in case the room

temperature deviates too much from the desired temperature, e.g. to speed up heating in the morning.

Page 11

WIRING

To interconnect the Velbus modules the use of twisted-pair cable (EIB 2x2x0.8mm2, UTP 8x0.51mm - CAT5 or

equivalent) is recommended.

When a lot of modules (more than 10) are connected to the cable or longer cable lengths (more than 50m) are used, it

is important to use a cable with appropriate diameter (0.5mm² or higher).

Connect the bus to the module (beware of the polarity).

Connect the 12V to 18V direct current to the module (beware of the polarity).

Connecting the temperature sensor VMB1TS

Connecting the temperature controller VMB1TC / VMB1TCW(W)

Page 12

Relay cabinet wiring

Page 13

Terminator

Normally only 2 ‘TERM’ terminators must be used in a complete Velbus installation. Usually this will be on the end

of 2 bus wires (for example in the attic and in the basement.

On all other modules, the terminator must be removed.

Remark:

In case the wiring contains a lot of branches, still a terminator will be set on the end of 2 bus wires (= 2 terminators).

When communication errors occur, an additional terminator can be set as close as possible to one of the two existing

terminators. However, the number of terminators should be limited as more terminators place a heavy load on the bus

(max 3).

Addressing

Every module on the Velbus system must have its own unique address.

The address of the temperature controller VMB1TCW is set via a Velbuslink©

LED INDICATION

Anti-freeze, night, day or comfort mode

In rooms that have a temperature sensor VMB1TS the heating (or air-conditioning) can be set in 4 different modes:

comfort, day, night or anti-freeze. Every mode has its own desired temperature setting. The selected mode is

indicated with LEDs. The sensor module is set to anti-freeze mode when the comfort, day and night mode LEDs are

off. When the comfort, day or night mode LED is flashing, the sensor module is set temporarily (sleep timer) to the

indicated mode and normal program is suspended during that ‘sleep’ time.

Anti-freeze Night Day Comfort

Page 14

Cooling or heating mode

When the temperature sensor is configured to control an air-conditioning system, the frost flower LED (upper LED)

will be lit. Setting the heating or cooling mode can only be done through a temperature controller (VMB1TC /

VMB1TCW) or through the Velbus link program.

Heating mode Cooling mode

Air-conditioner or heater active

When the heater (valve open) or air-conditioner is active, a red LED will be lit.

The red output LED can indicate following error conditions:

Flashing (short on, long off): the heater/cooler should be off but it did not

receive the command from the relays module.

Flashing (short off, long on): the heater/cooler should be on but it did not

receive the command from the relays module.

Fast flashing: configuration of the sensor chip failed.

Note: as long as the error condition exists the output status wil be retransmitted every minute.

Page 15

OPERATION

Pushing the push button repeatedly will switch the module between anti-freeze, night, day or comfort mode

successively.

When the comfort, day or night mode LED is flashing, the sensor module is set temporarily (sleep timer) to the

indicated mode. During this time the program is ignored

When the sleep timer expires, the sensor module will resume the program or in case no program is present will return

to its previous setting.

Remarks:

Anti-freeze mode can not be set temporarily.

Standard time is set through the temperature controller.

Overriding temporary mode can be done by pushing and holding the push button. The LED stops flashing and the

sensor remains in the selected mode until the next program step is executed.

Local operation can be locked or unlocked via a temperature controller VMB1TCW or via the Velbus link program.

When the sensor module is set to manual mode via a temperature controller VMB1TCW or vi a the Velbus link

program, local operation will be locked.

Page 16

SETTINGS

Following parameters can be set via the temperature controller (see manual VMB1TC / VMB1TCW(W)) or via the

Velbus link software:

the zone to which the sensor belongs

the operating mode (heating or cooling)

switching the unjam function of the circulation pump and/or heating valve on or off

the desired comfort temperature for heating

the desired day temperature for heating

the desired night temperature for heating

the anti-freeze safeguard temperature

the heating limit (upper limit of the heating preset range)

the temperature difference for fast heating/cooling or for the differential thermostat

the desired comfort temperature for cooling

the desired day temperature for cooling

the desired night temperature for cooling

the lower limit of the cooling preset range

the upper limit of the cooling preset range

the hysteresis

calibration of the sensor

the alarm temperatures

the duration of temporary mode

the zone number

the low temperature alarm (alarm when temperature drops below this value)

the high temperature alarm (alarm when temperature rises above this value)

the duration of temporary mode: from 1 to 65.279 minutes (45 days, 7 hours, 59 minutes)

transmitting the current temperature over the Velbus:

o only when requested

o only when changes occur

o at specific time intervals, selectable between 10 and 255 seconds (4 minutes 15 seconds)

resetting minimum and maximum temperature

reset time registration for the heater/air-conditioning

locking or unlocking local control

the address of the linked sensor to set up a differential thermostat

sensor name (max. 16 characters)

The cycling protection delay (delay setting is 1 minute) can be modified through the Velbuslink software if the

software version of the sensor module is 0949 or higher (see “Verify software version”).

Preset range

The preset range for the desired temperature can be adjusted by the user.

This is a way to make sure that the heating can never be set higher than a certain value.

Protecting the circulation pump and/or heating valves

When a circulation pump or a valve is not being used for some time, it might get stuck. To avoid this, an unjamming

function can be enabled which activates the pump or opens the valve for at least one minute every day.

Enabling of disabling the unjam function can be done via the temperature controller (VMB1TC / VMB1TCW) or

through the Velbus link software via a PC connected to the Velbus PC interface (VMB1USB, VMB1RS of

VMBRSUSB).

Time statistics

For every mode (comfort, day, night or anti-freeze) the time during which the heating or air-conditioning was one is

stored. These statistics can be recalled or reset via the temperature controller (VMB1TC / VMB1TCW) or through the

Velbus link software via a PC connected to the Velbus PC interface (VMB1USB, VMB1RS of VMBRSUSB).

Page 17

Minimum and maximum temperature

The sensor records the minimum and maximum temperature.

These values can be examined or reset via the temperature controller (VMB1TC / VMB1TCW) or through th e Velbus

link software via a PC connected to the Velbus PC interface (VMB1USB, VMB1RS of VMBRSUSB).

Differential thermostat

Using two sensors a differential thermostat can be created. When the difference in temperature between b oth sensors

reaches a certain value, the relay channel can be activated.

To achieve this, the first sensors must know the address of the second one. The second sensor must than be linked

to a relay channel. The temperature difference value is set on the first sensor.

Factory settings

After receiving this module, following factory default settings are already stored into the sensor:

Description Factory default

Zone number No zone

Differential sensor address None

Operating mode Heating

Unjam heating valve Disabled

Unjam heating valve circulation pump Disabled

Desired comfort temperature for heating 22°C

Desired day temperature for heating 20°C

Desired night temperature for heating 15°C

Anti-freeze safeguard 5°C

Heating limit 30°C

Temperature difference (fast heating/cooling or differential thermostat) 3°C

Calibration factor -2.5°C

Hysteresis 0.5°C

Desired comfort temperature for cooling 21°C

Desired day temperature for cooling 23°C

Desired night temperature for cooling 26°C

Lower limit cooling preset range 16°C

Upper limit cooling preset range 36°C

Low temperature alarm 3°C

High temperature alarm 30°C

Default duration temporary mode (sleep timer) 1 hour

Time interval for automatic transmission temperature Disabled

Local control Unlocked

Cycling protection delay 1 minute

Page 18

CONFIGURING THE OUTPUTS

The sensor module transmit messages over the Velbus when the status of one of its multiple outputs changes. Relay

modules (VMB1RY or VMB4RYNO / VMB4RYLD) can be linked to these Velbus messages to perform following

functions:

steering the heating valve

switching the heating or cooling installation to boost mode when the difference in desired and current temperature

is too big

set the heating boiler in day mode

steering the air-conditioning

steering the circulation pump of the heating installation

generate an alarm when the temperature is too low (heating system down)

generate an alarm when the temperature is too high (a valve does not close anymore)

Every relay channel that is steered by a temperature sensor must be set to momentary (instant) control.

The way to allocate those relay channels is through the use of the Velbus link software via a PC connected to a

Velbus PC interface (VMB1USB, VMB1RS of VMBRSUSB).

Page 19

REMOTE CONTROL

The sensor module can be operated locally, but also remotely via a temperature controller VMB1TC / VMB1TCW(W)

(refer to the manual of the controller).

The sensor module can also be operated remotely by connecting pushbutton s to the Velbus.

Pushbuttons can be defined for:

setting the sensor module mode to comfort

setting the sensor module mode to day

setting the sensor module mode to night

setting the sensor module mode to anti-freeze

setting the sensor module mode to heating

setting the sensor module mode to cooling

lock the local operation of the sensor module

unlock the local operation of the sensor module

For every operating function up to 10 different pushbuttons can be assigned. The easiest way to assign those

pushbuttons is by using the Velbus link software using a PC that is connected to a Velbus PC interface (VMB1USB,

VMB1RS of VMBRSUSB).

Page 20

SWITCHING TO ANTI FREEZE MODE THROUGH WINDOW CONTACTS

The heating can be switched automatically in anti freeze mode as soon as a window featuring window contacts is

opened. The LEDs will switch off on the VMB1TS temperature sensor. The VMB1TC / VMB1TCW(W) temperature

controller displays an anti freeze and key symbol together with a blinking mode LED.

Locatie

Badkamer

- 0m 18

↑

Mode

←

Menu

→

↓

The heating cannot be set into another mode as long as a window remains open. Once all windows closed, the

heating will swith to the initial mode. The used contacts may be of the NO or the NC type, and may be connected to a

VMB8PB push-button interface or a VMB6IN input module. You can connect maximum 10 NO and 10 NC contacts to

the sensor module.

Assign the contacts through Velbuslink software and a PC connected the Velbus interface (VMB1USB, VMB1RS or

VMBRSUSB). The NC contacts (i.e. contacts closed when window is closed) must be connected to the “Normal

closed disable switch” function of the sensor module. The NO contacts (i.e. contacs ope n when the window is closed)

must be connected to the “Normal open disable switch” function of the sensor module.

Page 21

DIFFERENTIAL THERMOSTAT

Using two sensors, a differential thermostat can be created. When the temperature difference between both sensors

crosses a preset value, a relay channel can be activated.

To achieve this, the first sensors must know the address of the second one. The second sensor must than be linked

to a relay channel. The temperature difference value is set on the first sensor.

The settings can be done via a temperature controller VMB1TC / VMB1TCW(W) or via the Velbus link program.

Schematic overview differential thermostat (sensor2 in heating mod e):

SENSOR1

SENSOR2

Set-up:

Differential sensor address =

address sensor2

Temp. Difference ∆t = -10°...10°

t1

Measured temp t1 + ∆t

Schematic overview differential thermostat (sensor2 in coolin g mode):

SENSOR1

Set-up:

Differential sensor address =

address sensor2

Temp. Difference ∆t = -10°...10°

t2

= Desired temperature for sensor2

Remark:

if t1+ ∆t > t

(mode2 = anti-freeze, night, day or comfort)

SENSOR2

t1

Measured temp t1 + ∆t

Refer to some applications of a differential thermostat below.

t2

= Desired temperature for sensor2

Remark: if t1+ ∆t < t

t

(mode2 = anti-freeze, night, day or comfort)

mode2

mode2

Set-up:

heating

heating on when t1+ ∆t > t2

than desired temp. sensor2 = t

Set-up:

cooling

Cooler on when t1+ ∆t < t2

than desired temp. sensor2 =

mode2

mode2

Page 22

The passage automatically 3° cooler than the office

When the sensor module in the office is set to day-mode, the temperature in the passage must be 3° lower than the

office. Is the day temperature of the office is set to 20°C the desired passage temperature will be 17°C.

When the sensor module in the office is set to night-mode, the temperature in the passage must be 3° lower than the

office. Is the night temperature of the office is set to 15°C the desired passage temperature will be 12°C.

Office

Configuration:

The way to configure the system is to use the Velbus link program via a PC connected on the Velbus PC interface

(VMB1USB, VMB1RS of VMBRSUSB).

The configuration is now finished and the differential thermostat is enabled.

Remarks:

Make sure both sensors are in heating mode (frost flower LED on the sensor is off).

The passage temperature can never be higher than the prefe rred setting of its selected mode (anti-freeze, night,

day or comfort).

Passage

Page 23

Passive cooling of a bedroom

During summer time the bedroom is cooled via a fan that extracts air from a cooler room.

Mount a temperature sensor in both rooms. The temperature sensor of the bedroom is set to cooling mode and the

Cooler room

Bedroom

cooling output is linked to a relay channel that controls the fan.

When the temperature in the cooler room is about 3 degrees lower than the bedroom temperature the fan is activated.

Configuration:

The way to configure the system is to use the Velbus link program via a PC connected on the Velbus PC interface

(VMB1USB, VMB1RS of VMBRSUSB).

The configuration is now finished and the differential thermostat is enabled.

Remark:

The cooling will stop when the bedroom temperature reaches the preferred sett ing of its selected mode (anti-freeze,

night, day or comfort).

Page 24

Refer to our website for more information: www.velbus.be

Loading...

Loading...