Page 1

Total solder points: 187

Difficulty level: beginner 1 2 3 4 5 advanced

Code lock

K6400

d

l

o

e

s

o

h

t

f

o

d

i

r

d

e

G

s

a

f

ILLUSTRATED ASSEMBLY MANUAL H6400IP-2

d

e

n

o

i

h

s

y

e

k

Page 2

Features & Specifications

Features:

More than 3000 codes possible.

State indication by LED.

Pulse or switch output.

Nine digits of which 4 code digits.

Secured against polarity reversal.

Specifications:

Power supply : 9 to 15VDC or 8 to 12VAC.

Relay output : 5A / 220V.

Time limit for code determination : +/- 5sec.

Current consumption :

2

Output OFF : 0,3µ A

Output ON : 40mA

Page 3

Assembly hints

0

.

0

0

0

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project successful. Read them carefully.

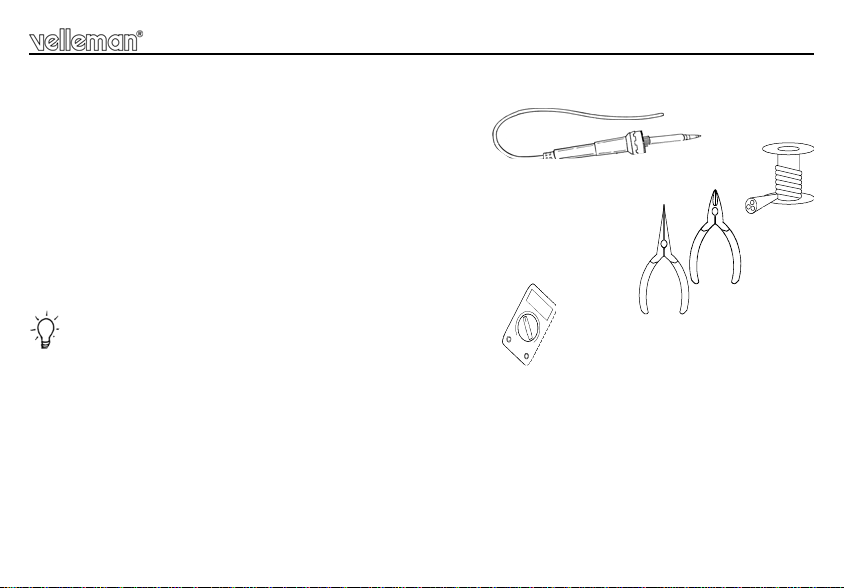

1.1 Make sure you have the right tools:

• A good quality soldering iron (25-40W) with a small tip.

• Wipe it often on a wet sponge or c loth , to kee p it c lean ; th en apply so lder to th e t ip, to g ive it a wet look. This is called ‘ thinning’ and will

protect the tip, an d enab les you t o make good conn ections. When so lder ro lls of f th e tip, it ne eds clean ing.

• Thin raisin-core solder. Do not use any flux or grease.

• A diagonal cutter to trim excess wires. To avoid in jury wh en cutting ex cess leads, ho ld the lead so th ey

cannot fly towards the eyes.

• Needle nose pliers, for bending leads, or to hold components in place.

• Small blade and Phillips screwdrivers. A basic range is fine.

For some projects, a basic multi-meter is required, or might be handy

1.2 Assembly Hints :

⇒ Make sure the skill level matches your experience, to avoid disappointments.

⇒ Follow the instructions carefully. Read and understand the entire step before you perform each operation.

⇒ Perform the assembly in the correct order as stated in this manual

⇒ Position all parts on the PCB (Printed Circuit Board) as shown on the drawings.

⇒ Values on the circuit diagram are subject to changes.

⇒ Values in this assembly guide are correct*

⇒ Use the check-boxes to mark your progress.

⇒ Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for poss ible last m inu te manu al updates, indicated as ‘NOTE’ on a separate leaflet.

3

Page 4

Assembly hints

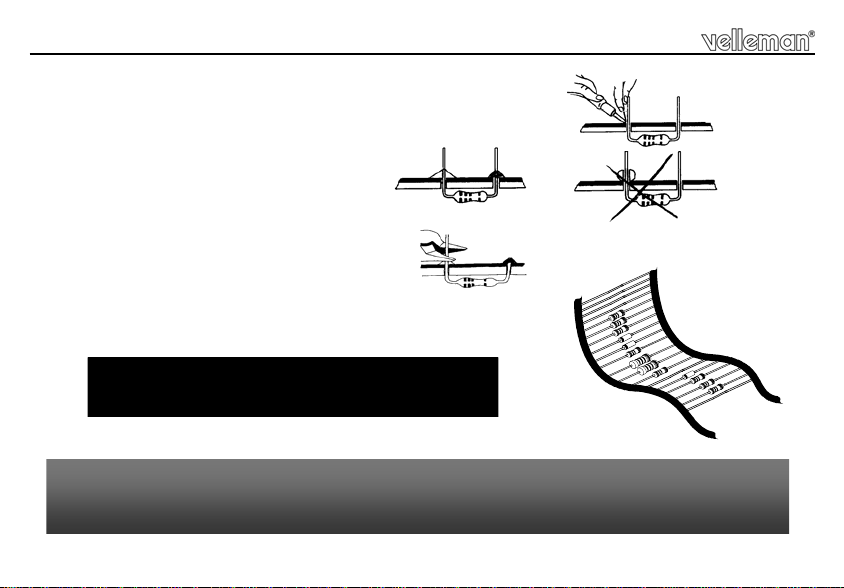

1.3 Soldering Hints :

1- Mount the component against the PCB surface and carefully solder the leads

2- Make sure the solder joints are cone-shaped and shiny

3- Trim excess leads as close as possible to the solder joint

REMOVE THEM FROM THE TAPE ONE AT A TIME !

AXIAL COMPONENTS ARE TAPED IN THE COR-

RECT MOUNTING SEQUENCE !

You will find the colour code for the resistances and the LEDs on our website:

http://www.velleman.be/common/service.aspx

4

Page 5

Assembly of the keyboard module : P6400S

LD1

CATHODE

CODE 1234

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

SW9SW9

SW8

SW7

SW6

SW5

SW4

SW3

SW2

SW1

P6400S

NABDC

Construction

1. Push button

SW1

SW2

SW3

SW4

SW5

2. Led’s. Watch the polarity!

LD1

SW6

SW7

SW8

SW9

3. Determining the code

The four code digits are determined by fitting wire jumpers, see figure 1.0.

Drawing 2 shows the connections for code 1234 as an example.

P6400S

CD BAN

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

SW9 SW9

Fig. 1

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Fig. 2

Attention : the wire jumpers that build the code must be as close

to the pcb as possible, because otherwise they will touch the

aluminium front panel!

The code sequence is determined by connecting the lines A,

respectively B, C and D to the connecting t erminals (keys 1 through 9)

at the inside of the pcb, where line A is the fi rst code, B the second

code and so on. The unused keys (normally 5) are connected to line N.

5

Page 6

Construction

4. Preparation

Fit seven non insulated wires at the solder side of the pcb. These wires will be used later on for through

connection to the master module (see fig. 3.0).

Attention : the wires at the component side must be cut off as close to the pcb as possible.

P6400S

Fig. 3

6

Page 7

Assembly of the Master module : P6400B

Construction

1. Jumpers

J

on/off function of the key lock.

J1

Fit wire jumper J1 in case you intend to use the on/off function of the

key lock. If you don't fit this wire jumper, then, at the input of the code,

the code lock will only generate a pulse (in general this mode is used

with door locks).

"closed" contact or "open" contact .

NC or NO

Fit wire jumper NC if you intend to use the normally "closed" contact

of the relay, or wire jumper NO if you intend to use the normally "open"

contact of the relay.

ATTEN T ION : aft er the rela y has been fitted, t hese wire jum pers are

no longer accessible.

2. Diodes. Watch the polarity!

D1 : 1N4148

D2 : 1N4148

D3 : 1N4148

D4 : 1N4148

D5 : 1N4007

For D2 … D4 :

CATHODE

D...

The side with the mark comes

in the smallest hole marked C !

3. Resistors

R8 : 10 (1 - 0 - 0 - B)

R9 : 220 (2 - 2 - 1 - B)

R10 : 220 (2 - 2 - 1 - B)

R11 : 1K5 (1 - 5 - 2 - B)

R...

7

Page 8

RY...

C...

Construction

PIN 1

1

4. IC sockets, Watch the

position of the notch!

IC1 : 14p

5. Transistor

T1 : BC547B

T2 : BC547B

6. Resistors

R1 : 470K (4 - 7 - 4 - B)

R2 : 47K (4 - 7 - 3 - B)

R3 : 47K (4 - 7 - 3 - B)

R4 : 47K (4 - 7 - 3 - B)

R5 : 10K (1 - 0 - 3 - B)

R6 : 10K (1 - 0 - 3 - B)

R7 : 10K (1 - 0 - 3 - B)

8

7. Electrolytic capacitor.

Watch the polarity !

C1 : 10µ F

C2 : 470µ F

8. Screw connectors

10. IC. Check the position of

the notch!

IC1 : CD4066

J2 : 2p + 2p

9. Relay

R...

RY1 : VR15M121C

Page 9

Final assembly

Final Assembly

CHECK THE WHOLE MOUNTING ONCE

M2 BOLT

M2 NUT

MORE THOROUGHLY AND DON'T

FORGET THE CODE, BECAUSE AFTER

!

THE FOLLOWING ASSEMBLY IT

WON'T BE ACCESSIBLE ANY MORE.

10mm

SPACER

LOCK

WASHER

M2 NUT

P6400B

P6400S

Pass two 2mm bolts through the front panel and

fix th em usi ng a nut.

Then pass a lock washer over the bolts followed by

the keyboard module. Take care that the LED is in the front panel.

ALU FRONT

Fig. 4

Normally, neither the LED nor the push buttons may pass through the front panel. The push buttons

must be flush with the front side.

Pass a 10mm distance tube over the two bolts, followed by the master module. Also take care that the

through connections pass through the master module.

Now fix both modules using two nuts, where after you can solder the through connections (pay attention

to short-circuits).

9

Page 10

Test & usage

Test & usage

Connect a 9 to 15VDC or a 8 to 12VAC to the points V and GND. (V is the plus pole in the case of direct

current).

Put the front panel film next to the keyboard and enter the right code (in the case of a pulse out put this has

to be done within 5 seconds). If everything is going on well, now the relay should close and open again in

case pulse output mode has been selected. If however you have chosen for a constant switch position, then

you can cause the relay to open by entering a digit NOT belonging to the code digits.

Tip: should the opening tim e of the relay (in the case of the pulse output mode) be too short, fit a 22µ F

capacitor instead of C1 to change that time.

Building in

In case you use the key lock outside, it is advisable to mount it sunk, so that no water can soak in. For safety

you better first fix the code lock into the wall where aft er you stick the film to it, so that the fixation screws are

hidden "behind" the film.

Take care that, when sticking the film, the "LED WINDOW" corresponds with the hole in the aluminium.

10

Page 11

Schematic diagram & PCB

Schematic diagram (Control section)

GND

D5

V

1 2 3 4 5 6 7 8 9

C2

NOT USED

CODE A

CODE B

CODE C

CODE D

CODE ABCD

+V

R6

R9

R8

T2

R7

PCB

D1

+

SW3

SW6

SW9

N

B

A

D

C

NABDC

D5

VELLEMAN P6400B'1

C2

11

L

LD1

SW2

+V

R10

ES1

J1

C1

R1

ES2

D2

R2

ES3

+V

D3

R3

D4

R4

LD1

ES4

R11

R5

NC

+V

NO

RY1D1

COM

T1

SW1

VELLEMAN

SW4

P6400S'1

SW7

ABCD+

N

R7 R6

T2

1

R10

J1

C1

SW5

SW8

L

R9

R8

J

IC1

D3D2

CCC

R2R3R4

R1

OUT V GND

J2

RY1

R11

NC NO

D4

T1

R5

Page 12

VELLEMAN Components NV

www.velleman-kit.com

Modifications and typographical errors reserved

© Velleman Components nv.

H6400IP - 2004 - ED2 (rev.1.0)

Legen Heirweg 33

9890 Gavere

Belgium Europe

www.velleman.be

5 410329 291327

Loading...

Loading...