Page 1

Safety Manual

VEGABAR series 80

Two-wire 4 … 20 mA/HART

and Secondary sensors

With SIL qualication

Document ID: 48369

Page 2

Contents

Contents

1 Document language ................................................................................................................ 3

2 Scope ........................................................................................................................................ 4

2.1 Instrument version ............................................................................................................ 4

2.2 Application area ............................................................................................................... 4

2.3 SIL conformity .................................................................................................................. 5

3 Planning .................................................................................................................................... 6

3.1 Safety function ................................................................................................................. 6

3.2 Safe state ......................................................................................................................... 6

3.3 Prerequisites for operation ............................................................................................... 6

4 Safety-related characteristics................................................................................................. 7

4.1 Characteristics acc. to IEC 61508 for process pressure measurement or hydrostatic level

measurement ................................................................................................................... 7

4.2 Characteristics acc. to IEC 61508 for applications with Secondary sensor ...................... 8

4.3 Characteristics acc. to ISO 13849-1 for process pressure measurement or hydrostatic

level measurement ......................................................................................................... 10

4.4 Characteristics acc. to ISO 13849-1 for applications with Secondary sensor ................. 11

4.5 Supplementary information ............................................................................................ 12

5 Setup ....................................................................................................................................... 13

5.1 General information ........................................................................................................ 13

5.2 Instrument parameter adjustment ................................................................................... 13

6 Diagnostics and servicing .................................................................................................... 15

6.1 Behaviour in case of failure ............................................................................................ 15

6.2 Repair ............................................................................................................................ 15

7 Proof test ................................................................................................................................ 16

7.1 General information ........................................................................................................ 16

7.2 Test 1: Without checking the process variable ................................................................ 16

7.3 Test 2: With check of the process variable ...................................................................... 17

8 Appendix A: Test report ......................................................................................................... 18

9 AppendixB:Termdenitions ................................................................................................ 19

10 Supplement C: SIL conformity .............................................................................................. 20

48369-EN-210114

Editing status: 2020-12-18

2

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 3

1 Document language

1 Document language

DE Das vorliegende Safety Manual für Funktionale Sicherheit ist verfügbar in den Sprachen

EN The current Safety Manual for Functional Safety is available in German, English, French and

FR Le présent Safety Manual de sécurité fonctionnelle est disponible dans les langues suivantes:

RU Данное руководство по функциональной безопасности Safety Manual имеется на

Deutsch, Englisch, Französisch und Russisch.

Russian language.

allemand, anglais, français et russe.

немецком, английском, французском и русском языках.

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

3

Page 4

2 Scope

2 Scope

2.1 Instrument version

This safety manual applies to pressure transmitters

VEGABAR 81, 82, 83, 86, 87

VEGABAR 81, 82, 83, 86, 87 Secondary-Sensor

Electronics types:

Two-wire 4 … 20 mA/HART with SIL qualication

•

Two-wire 4 … 20 mA/HART with SIL qualication and supplemen-

•

tary electronics "Additional current output 4 … 20 mA"

Secondary electronics for electronic dierential pressure with SIL

•

qualication

Valid versions:

from HW Ver 1.0.0

•

from SW Ver 1.0.0

•

Secondary electronics from HW Ver 1.0.0

•

The climate-compensated versions are excluded from safety-relevant

applications!

2.2 Application area

The pressure transmitter can be used in a safety-related system

according to IEC 61508 in the modes low demand mode or high de-

mand mode for the measurement of the following process variables:

Process pressure measurement

•

Hydrostatic level measurement

•

With Secondary sensor:

Dierential pressure measurement

•

Flow measurement

•

Density measurement

•

Interface measurement

•

Due to the systematic capability SC3 this is possible up to:

SIL2 in single-channel architecture

•

SIL3 in multiple channel architecture

•

The following interface can be used to output the measured value:

Current output: 4 … 20 mA

•

The following interfaces are only permitted for parameter adjustment

and for informative use:

HART

•

Display and adjustment module PLICSCOM (also via Bluetooth)

•

VEGACONNECT (also via Bluetooth)

•

Current output II

•

1)

48369-EN-210114

1)

Only with instrument version with supplementary electronics "Additional cur-

rent output 4 … 20 mA".

4

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 5

2 Scope

2.3 SIL conformity

The SIL conrmity was judged and certied independently by TÜV

Rheinland according to IEC 61508:2010 (Ed.2) (verication docu-

ments see " Supplement").

The certicate is valid for the entire service life of all instruments that

were sold before the certicate expired!

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

5

Page 6

3 Planning

Safety function

3 Planning

3.1 Safety function

The transmitter generates on its current output a signal between

3.8 mA and 20.5 mA corresponding to the process variable. This

analogue signal is fed to a connected processing system to monitor

the following conditions:

Exceeding a dened limit value of the process variable

•

Falling below a dened limit value of the process variable

•

Monitoring of a dened range of the process variable

•

Safety tolerance

Safe state

Fault signals in case of

malfunction

Instructions and restrictions

For the design of the safety function, the following aspects must be

taken into account with regard to the tolerances:

Due to undetected failures in the range between 3.8 mA and

•

20.5 mA, an incorrect output signal can be generated which deviates from the real measured value by up to 2 %

Due to the special application conditions, increased measurement

•

deviations can be caused (see Technical data in the operating

instructions)

3.2 Safe state

The safe state of the current output depends on the safety function

and the characteristics set on the sensor.

Characteristics

4 … 20 mA Output current ≥ Switching

20 … 4 mA Output current ≤ Switching

Possible fault currents:

≤ 3.6 mA ("fail low")

•

> 21 mA ("fail high")

•

Monitoring upper limit val-ueMonitoring lower limit value

point

point

Output current ≤ Switching

point

Output current ≥ Switching

point

3.3 Prerequisites for operation

The measuring system should be used appropriately taking pres-

•

sure, temperature, density and chemical properties of the medium

into account. The application-specic limits must be observed.

The specications according to the operating instructions manual,

•

particularly the current load on the output circuits, must be kept

within the specied limits

Existing communication interfaces (e. g. HART, USB) are not used

•

for transmission of the safety-relevant measured value

The instructions in chapter " Safety-related characteristics", para-

•

graph " Supplementary information" must be noted

All parts of the measuring chain must correspond to the planned "

•

Safety Integrity Level (SIL)"

48369-EN-210114

6

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 7

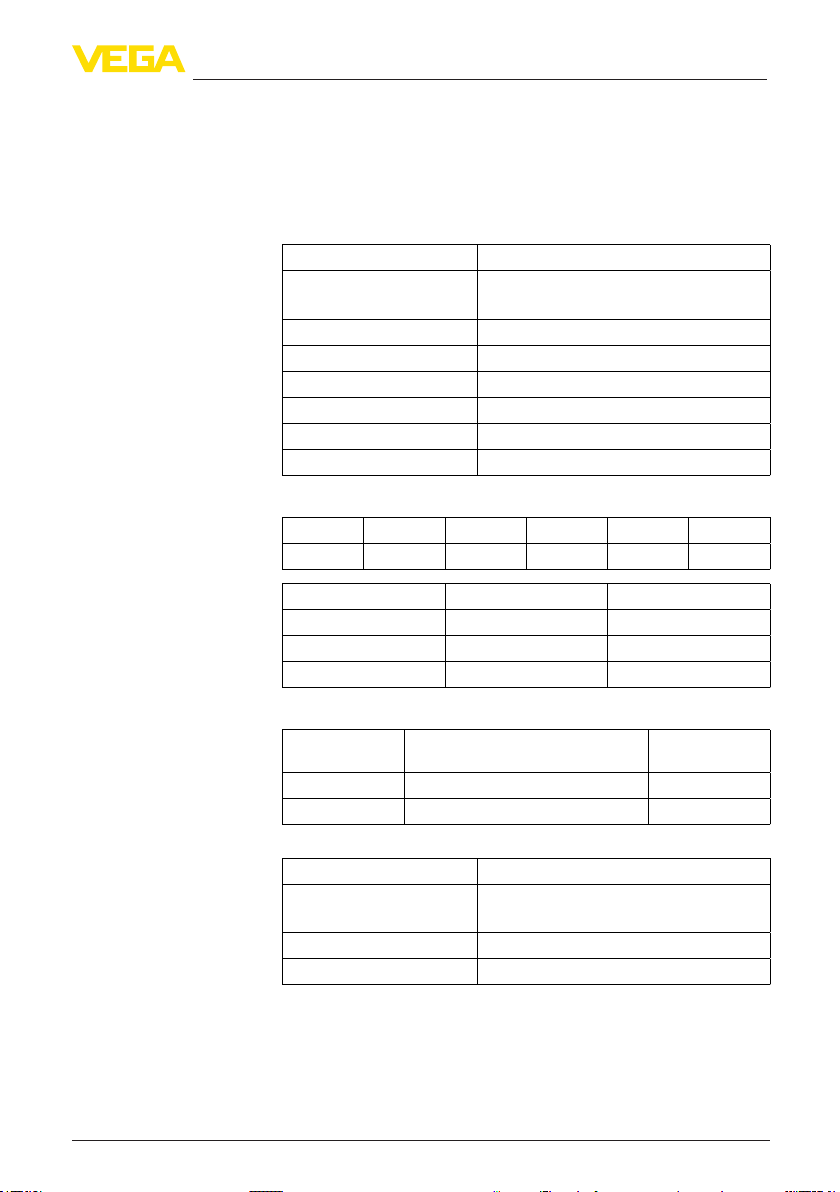

VEGABAR 82, 83, 86, 87

4 Safety-related characteristics

4 Safety-related characteristics

4.1 Characteristics acc. to IEC 61508 for process pressure measurement or hydrostatic level measurement

Parameter Value

Safety Integrity Level SIL2 in single-channel architecture

SIL3 in multiple channel architecture 2)

Hardware fault tolerance HFT = 0

Instrument type Type B

Mode Low demand mode, High demand mode

SFF > 90 %

MTBF 3) 0.50 x 106 h (57 years)

Diagnostic test interval 4) < 30 min

Failure rates

λ

S

0 FIT 1121 FIT 44 FIT 9 FIT 59 FIT 34 FIT

λ

DD

λ

DU

λ

H

λ

L

λ

AD

PFD

AVG

PFD

AVG

PFD

AVG

PFH 0.044 x 10-6 1/h

Proof Test Coverag (PTC)

Test type 5)

Test 1 21 FIT 52 %

Test 2 2 FIT 95 %

VEGABAR 81

Parameter Value

Safety Integrity Level SIL2 in single-channel architecture

Hardware fault tolerance HFT = 0

Instrument type Type B

2)

Homogeneous redundancy possible, because systematic capability SC3.

3)

Including errors outside the safety function.

4)

Time during which all internal diagnoses are carried out at least once.

5)

See section "Proof test".

6)

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Homogeneous redundancy possible, because systematic capability SC3.

0.037 x 10

0.054 x 10

0.106 x 10

-2

-2

-2

(T1 = 1 year)

(T1 = 2 years)

(T1 = 5 years)

Remaining failure rate of dangerous undetected failures

SIL3 in multiple channel architecture 6)

PTC

7

Page 8

4 Safety-related characteristics

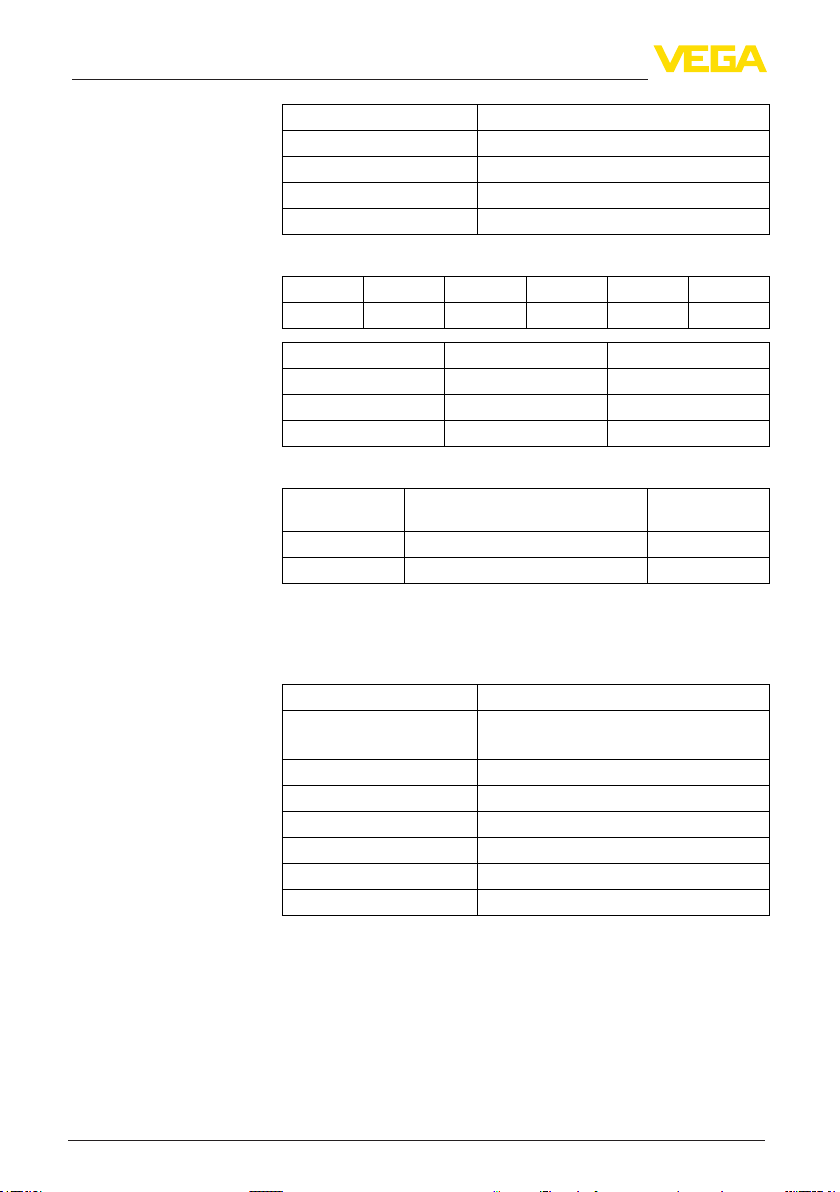

Parameter Value

Mode Low demand mode, High demand mode

SFF > 90 %

MTBF 7) 0.57 x 106 h (65 years)

Diagnostic test interval 8) < 30 min

Failure rates

λ

S

0 FIT 981 FIT 77 FIT 9 FIT 59 FIT 34 FIT

λ

DD

λ

DU

λ

H

λ

L

λ

AD

Device combination consisting of VEGABAR 82,

83, 86 or 87

PFD

PFD

PFD

AVG

AVG

AVG

0.065 x 10

0.096 x 10

0.188 x 10

-2

-2

-2

(T1 = 1 year)

(T1 = 2 years)

(T1 = 5 years)

PFH 0.077 x 10-6 1/h

Proof Test Coverag (PTC)

Test type 9)

Test 1 56 FIT 28 %

Test 2 2 FIT 97 %

Remaining failure rate of dangerous undetected failures

PTC

4.2 Characteristics acc. to IEC 61508 for applications with Secondary sensor

Parameter Value

Safety Integrity Level SIL2 in single-channel architecture

SIL3 in multiple channel architecture

Hardware fault tolerance HFT = 0

Instrument type Type B

Mode Low demand mode, High demand mode

SFF > 90 %

11)

MTBF

0.39 x 106 h (44 years)

Diagnostic test interval

12)

< 30 min

10)

48369-EN-210114

7)

Including errors outside the safety function.

8)

Time during which all internal diagnoses are carried out at least once.

9)

See section "Proof test".

10)

Homogeneous redundancy possible, because systematic capability SC3.

11)

Including errors outside the safety function.

12)

Time during which all internal diagnoses are carried out at least once.

8

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 9

4 Safety-related characteristics

Failure rates

λ

S

0 FIT 1406 FIT 63 FIT 9 FIT 59 FIT 34 FIT

λ

DD

λ

DU

λ

H

λ

L

λ

AD

Device combination consisting of a VEGABAR 81

and a VEGABAR 82, 83,

86 or 87

PFD

PFD

PFD

AVG

AVG

AVG

0.054 x 10

0.079 x 10

0.154 x 10

-2

-2

-2

(T1 = 1 year)

(T1 = 2 years)

(T1 = 5 years)

PFH 0.063 x 10-6 1/h

Proof Test Coverag (PTC)

Remaining failure rate of danger-

Test type

13)

ous undetected failures

PTC

Test 1 40 FIT 36 %

Test 2 3 FIT 95 %

Parameter Value

Safety Integrity Level SIL2 in single-channel architecture

SIL3 in multiple channel architecture

Hardware fault tolerance HFT = 0

Instrument type Type B

Mode Low demand mode, High demand mode

SFF > 90 %

15)

MTBF

0.43 x 106 h (50 years)

Diagnostic test interval

16)

< 30 min

Failure rates

λ

S

0 FIT 1266 FIT 97 FIT 9 FIT 59 FIT 34 FIT

λ

DD

λ

DU

λ

H

λ

L

14)

λ

AD

PFD

AVG

PFD

AVG

PFD

AVG

PFH 0.097 x 10-6 1/h

13)

See section "Proof test".

14)

Homogeneous redundancy possible, because systematic capability SC3.

15)

Including errors outside the safety function.

16)

48369-EN-210114

Time during which all internal diagnoses are carried out at least once.

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

0.082 x 10

0.120 x 10

0.235 x 10

-2

-2

-2

(T1 = 1 year)

(T1 = 2 years)

(T1 = 5 years)

9

Page 10

4 Safety-related characteristics

Device combination consisting of VEGABAR 81

Proof Test Coverag (PTC)

Remaining failure rate of danger-

Test type

17)

ous undetected failures

PTC

Test 1 75 FIT 22 %

Test 2 3 FIT 97 %

Parameter Value

Safety Integrity Level SIL2 in single-channel architecture

SIL3 in multiple channel architecture

Hardware fault tolerance HFT = 0

Instrument type Type B

Mode Low demand mode, High demand mode

SFF > 90 %

19)

MTBF

0.49 x 106 h (56 years)

Diagnostic test interval

20)

< 30 min

Failure rates

λ

S

0 FIT 1124 FIT 132 FIT 9 FIT 59 FIT 34 FIT

λ

DD

λ

DU

λ

H

λ

L

18)

λ

AD

10

PFD

PFD

PFD

AVG

AVG

AVG

0.111 x 10

0.163 x 10

0.320 x 10

-2

-2

-2

(T1 = 1 year)

(T1 = 2 years)

(T1 = 5 years)

PFH 0.132 x 10-6 1/h

Proof Test Coverag (PTC)

Remaining failure rate of danger-

Test type

21)

ous undetected failures

PTC

Test 1 110 FIT 16 %

Test 2 4 FIT 97 %

4.3 Characteristics acc. to ISO 13849-1 for process pressure measurement or hydrostatic level measurement

The transmitter has been manufactured and veried using principles

that demonstrate its suitability and reliability for safety-related applications. It can therefore be considered a " proven component" according

to DIN EN ISO 13849-1.

17)

See section "Proof test".

18)

Homogeneous redundancy possible, because systematic capability SC3.

19)

Including errors outside the safety function.

20)

Time during which all internal diagnoses are carried out at least once.

21)

See section "Proof test".

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

48369-EN-210114

Page 11

4 Safety-related characteristics

VEGABAR 82, 83, 86, 87

VEGABAR 81

Device combination consisting of VEGABAR 82,

83, 86 or 87

Device combination consisting of a VEGABAR 81

and a VEGABAR 82, 83,

86 or 87

Device combination consisting of VEGABAR 81

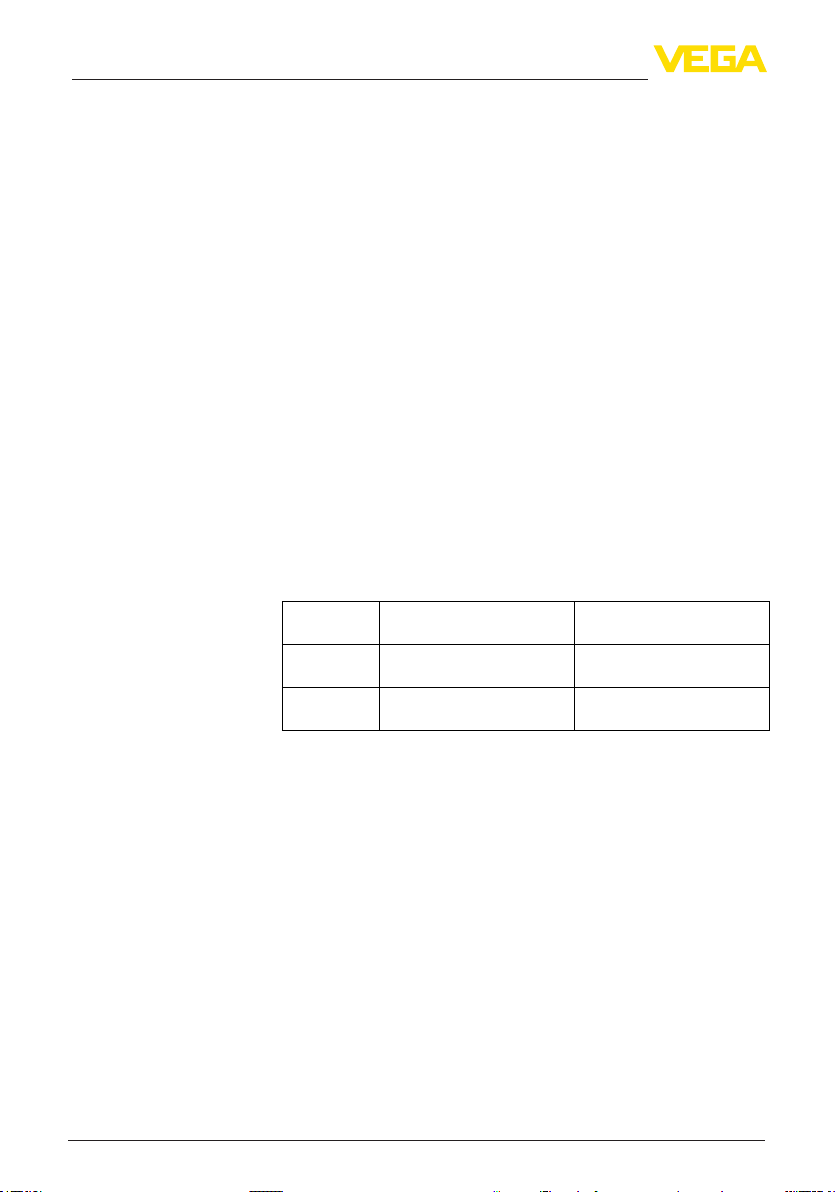

Derived from the safety-related characteristics, the following gures

result according to ISO 13849-1 (safety of machinery):

Parameter Value

MTTFd 90 years

DC 97 %

Performance Level 4.35 x 10-8 1/h

Parameter Value

MTTFd 98 years

DC 93 %

Performance Level 7.75 x 10-8 1/h

22)

4.4 Characteristics acc. to ISO 13849-1 for applications with Secondary sensor

The transmitter has been manufactured and veried using principles

that demonstrate its suitability and reliability for safety-related applications. It can therefore be considered a " proven component" according

to DIN EN ISO 13849-1.

Derived from the safety-related characteristics, the following gures

result according to ISO 13849-1 (safety of machinery):

Parameter Value

MTTFd 73 years

DC 96 %

Performance Level 6.33 x 10-8 1/h

Parameter Value

MTTFd 78 years

DC 93 %

Performance Level 9.72 x 10-8 1/h

Parameter Value

MTTFd 84 years

DC 90 %

Performance Level 1.32 x 10-7 1/h

23)

22)

ISO 13849-1 was not part of the certication of the instrument.

23)

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

ISO 13849-1 was not part of the certication of the instrument.

11

Page 12

4 Safety-related characteristics

PTC × λDU × T1

2

(1 – PTC) × λDU × LT

2

Determination of the

failure rates

Assumptions of the

FMEDA

4.5 Supplementary information

The failure rates of the instruments were determined by an FMEDA

according to IEC 61508. The calculations are based on failure rates of

the components according to SN 29500:

All gures refer to an average ambient temperature of 40 °C (104 °F)

during the operating time. For higher temperatures, the values should

be corrected:

Continuous application temperature > 50 °C (122 °F) by factor 1.3

•

Continuous application temperature > 60 °C (140 °F) by factor 2.5

•

Similar factors apply if frequent temperature uctations are expected.

The failure rates are constant. Take note of the useful service life of

•

the components according to IEC 61508-2.

Multiple failures are not taken into account

•

Wear on mechanical parts is not taken into account

•

Failure rates of external power supplies are not taken into account

•

The environmental conditions correspond to an average industrial

•

environment

Calculation of PFD

Boundary conditions re-

latingtotheconguration

of the processing unit

Multiple channel architecture

AVG

The values for PFD

1oo1 architecture:

PFDAVG = + λDD x MTTR +

Parameters used:

T1 = Proof Test Interval

•

PTC = 90 %

•

LT = 10 years

•

MTTR = 8 h

•

A connected control and processing unit must have the following

properties:

The failure signals of the measuring system are judged according

•

to the idle current principle

" fail low" and " fail high" signals are interpreted as a failure, where-

•

upon the safe state must be taken on

If this is not the case, the respective percentages of the failure rates

must be assigned to the dangerous failures and the values stated in

chapter Safety-related characteristics“ redetermined!

Due to the systematic capability SC3, this instrument can also be

used in multiple channel systems up to SIL3, also with a homogene-

ously redundant conguration.

The safety-related characteristics must be calculated especially for

the selected structure of the measuring chain using the stated failure

rates. In doing this, a suitable Common Cause Factor (CCF) must be

considered (see IEC 61508-6, appendix D).

specied above were calculated as follows for a

AVG

48369-EN-210114

12

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 13

Mounting and installation

Tools

5 Setup

5 Setup

5.1 General information

Take note of the mounting and installation instructions in the operating

instructions manual.

Setup must be carried out under process conditions.

5.2 Instrument parameter adjustment

The following adjustment units are permitted for parameterization of

the safety function:

Display and adjustment module

•

The DTM suitable for VEGABAR 80 in conjunction with an adjust-

•

ment software according to the FDT/DTM standard, e. g. PACTware

The device description EDD suitable for VEGABAR 80

•

The parameter adjustment is described in the operating instructions

manual.

Wireless connection is also possible with existing Bluetooth function.

The documentation of the device settings is only possible with the full

version of the DTM Collection.

Safety-relevant parameters

Safe parameterization

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

For protection against unwanted or unauthorzed adjustment, the set

parameters must be protected against unauthorized access. For this

reason, the instrument is shipped in locked condition. The PIN in

delivery status is "0000".

The default values of the parameters are listed in the operating

instructions. When shipped with customer-specic parameter settings, the instrument is accompanied by a list of the values diering

from the default values.

By means of the serial number this list can also be downloaded at "

www.vega.com", " Instrument search (serial number)".

To avoid or detect possible errors during parameter adjustment for

unsafe operating environments, a verication procedure is used that

allows the safety-relevant parameters to be checked.

Parameter adjustment proceeds according to the following steps:

Unlock adjustment

•

Change parameters

•

Lock adjustment and verify modied parameters

•

The exact process is described in the operating instructions.

Wireless connection is also possible with existing Bluetooth function.

The instrument is shipped in locked condition!

For verication, all modied, safety-relevant and non safety-relevant

parameters are shown.

13

Page 14

5 Setup

The verication texts are displayed either in German or, when any

other menu language is used, in English.

Unsafe device

status

Instrument reset

Warning:

When adjustment is unlocked, the safety function must be considered

as unreliable. This applies until the parameters are veried and the

adjustment is locked again. If the parameter adjustment process is

not carried out completely, the device statuses described in the operating instructions must be taken into consideration.

If necessary, you must take other measures to maintain the safety

function.

Warning:

In case a reset to " Delivery status" or " Basic setting" is carried out,

all safety-relevant parameters must be checked or set anew.

14

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 15

Internal diagnosis

6 Diagnostics and servicing

6 Diagnostics and servicing

6.1 Behaviour in case of failure

The instrument permanently monitored by an internal diagnostic

system. If a malfunction is detected, a fault signal will be output on the

safety-relevant output (see section " Safe status").

The diagnosis interval is specied in chapter " Safety-related characteristics".

Error messages in case

of malfunction

Electronics exchange

Software update

A fault message coded according to the type of fault is output. The

fault messages are listed in the operating instructions.

If failures are detected, the entire measuring system must be shut

down and the process held in a safe state by other measures.

The occurrence of a failure must be reported to the manufacturer

(including a description of the fault and whether it is a dangerous,

undetected failure). The device must be returned to the manufacturer

for examination.

6.2 Repair

The procedure is described in the operating instructions manual. Note

the instructions for parameter adjustment and setup.

The procedure is described in the operating instructions manual. Note

the instructions for parameter adjustment and setup.

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

15

Page 16

7 Proof test

Objective

Preparation

Unsafe device

status

7 Proof test

7.1 General information

To identify possible dangerous, undetected failures, the safety function must be checked by a proof test at adequate intervals. It is the

user's responsibility to choose the type of testing. The time intervals

are determined by the selected PFD

characteristics").

For documentation of these tests, the test protocol in the appendix

can be used.

If one of the tests proves negative, the entire measuring system must

be switched out of service and the process held in a safe state by

means of other measures.

In a multiple channel architecture this applies separately to each

channel.

Determine safety function (mode, switching points)

•

If necessary, remove the instruments from the safety chain and

•

maintain the safety function by other means

Provide an approved adjustment unit

•

Warning:

During the function test, the safety function must be treated as unreli-

able. Take into account that the function test inuences downstream

connected devices.

If necessary, you must take other measures to maintain the safety

function.

After the function test, the status specied for the safety function must

be restored.

(see chapter " Safety-related

AVG

Conditions

Procedure

Expected result

16

7.2 Test 1: Without checking the process variable

Instrument can remain in installed condition

•

Output signal corresponds to the assigned process variable

•

Device status in the menu Diagnosis: " OK"

•

1. Carry out a re-start (separate the test item at least 10 seconds

from mains voltage)

2. Simulate upper fault current > 21 mA and check current output

(test line resistor)

3. Simulate lower fault current ≤ 3.6 mA and check current output

(test quiescent currents)

Note

Test 1 detects no failures in the probably used Secondary sensor!

Step 1: Output signal corresponds to the assigned process variable

and the device status in the menu Diagnosis is " OK"

Step 2: Output signal corresponds to > 21 mA

Step 3: Output signal corresponds to ≤ 3.6 mA

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

48369-EN-210114

Page 17

7 Proof test

Proof Test Coverage

Conditions

Procedure

Expected result

See Safety-related characteristics

7.3 Test 2: With check of the process variable

Instrument can remain in installed condition

•

Output signal corresponds to the assigned process variable

•

Device status in the menu Diagnosis: " OK"

•

1. Carry out a re-start (separate the test item at least 10 seconds

from mains voltage)

2. Simulate upper fault current > 21 mA and check current output

(test line resistor)

3. Simulate lower fault current ≤ 3.6 mA and check current output

(test quiescent currents)

4. Reference pressure measurement at 0 % - 50 % - 90 … 100 %

of the adjusted measuring range in use (4 mA - 12 mA 18,4 … 20 mA)

5. If necessary, sensor calibration through service log-in and subse-

quent reference pressure measurement as under point 4

Note

When a Secondary sensor is used, also this sensor must be checked

with a reference pressure measurement acc. to point 4!

Step 1: Output signal corresponds to the assigned process variable

and the device status in the menu Diagnosis is " OK"

Step 2: Output signal corresponds to > 21 mA

Step 3: Output signal corresponds to ≤ 3.6 mA

Step 4 and 5: Output signal corresponds to the reference pressure

Proof Test Coverage

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

See Safety-related characteristics

17

Page 18

8 Appendix A: Test report

8 Appendix A: Test report

Identication

Company/Tester

Plant/Instrument TAG

Meas. loop TAG

Instrument type/Order code

Instrument serial number

Date, setup

Date of the last proof test

Test reason/Test scope

Setup without checking the process variable

Setup with check of the process variable

Proof test without checking the process variable

Proof test with check of the process variable

Mode

Monitoring of an upper limit value

Monitoring a lower limit value

Range monitoring

Adjusted parameters of the safety function are documented

Ye s

No

Test result (if necessary)

Test point Process variable

Value 1

Value 2

Value 3

Value 4

Value 5

Conrmation

Date: Signature:

24)

Expected measured

value

24)

e.g.: limit level, level, interface, pressure, ow, density

18

Real value Test result

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 19

Abbreviations

9 Appendix B: Term denitions

9 AppendixB:Termdenitions

SIL Safety Integrity Level (SIL1, SIL2, SIL3, SIL4)

SC Systematic Capability (SC1, SC2, SC3, SC4)

HFT Hardware Fault Tolerance

SFF Safe Failure Fraction

PFD

PFH Average frequency of a dangerous failure per hour (Ed.2)

FMEDA Failure Mode, Eects and Diagnostics Analysis

FIT Failure In Time (1 FIT = 1 failure/109 h)

λ

λ

λ

λ

λ

λ

λ

λ

λ

DC Diagnostic Coverage

PTC Proof Test Coverage (Diagnostic coverage for manual proof tests)

T1 Proof Test Interval

LT Useful Life Time

MTBF Mean Time Between Failure = MTTF + MTTR

MTTF Mean Time To Failure

MTTR IEC 61508, Ed1: Mean Time To Repair

MTTFdMean Time To dangerous Failure (ISO 13849-1)

PL Performance Level (ISO 13849-1)

Average Probability of dangerous Failure on Demand

AVG

Rate for safe detected failure

SD

Rate for safe undetected failure

SU

λS = λSD + λ

S

Rate for dangerous detected failure

DD

Rate for dangerous undetected failure

DU

Rate for failure, who causes a high output current (> 21 mA)

H

Rate for failure, who causes a low output current (≤ 3.6 mA)

L

Rate for diagnostic failure (detected)

AD

Rate for diagnostic failure (undetected)

AU

SU

IEC 61508, Ed2: Mean Time To Restoration

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

19

Page 20

10 Supplement C: SIL conformity

10 Supplement C: SIL conformity

20

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 21

10 Supplement C: SIL conformity

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

21

Page 22

10 Supplement C: SIL conformity

22

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

Page 23

Notes

48369-EN-210114

VEGABAR series 80 • Two-wire 4 … 20 mA/HART

23

Page 24

Printing date:

All statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the information

available at the time of printing.

Subject to change without prior notice

© VEGA Grieshaber KG, Schiltach/Germany 2021

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info.de@vega.com

www.vega.com

48369-EN-210114

Loading...

Loading...