Page 1

Operating Instructions

Housing type 506

Level and Pressure

ESC

%

100

+

-

OK

CONNECT

2

1

on

VEGAMET

514V

on

VEGATRENN

547V Ex

out

in

Page 2

Contents

Safety information ........................................................................ 2

Note Ex-area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 3

1.2 Types and versions ............................................................. 4

1.3 Technical data ....................................................................... 4

1.4 Dimensions ........................................................................... 5

2 Mounting

2.1 General ................................................................................. 6

2.2 Coding with Ex-instruments ................................................ 6

2.3 Transparent cover ............................................................... 6

2.4 Retrofitting of the housing with a power supply unit ......... 6

3 Electrical connection

3.1 Terminal coordination on VEGAMET ................................... 9

3.2 Connection examples ........................................................ 10

Contents

Safety information

The described module must only be installed

and operated as described in these operating

instructions. Please note that other action can

cause damage for which VEGA does not take responsibility.

Note Ex-area

Please note the approval documents attached

(yellow binder), and especially the included

safety data sheet.

2 Housing type 506

Page 3

Product description

1 Product description

1.1 Function and configuration

The housing type 506 is used for single

mounting of a signal conditioning instrument

for VBUS-sensors of series 500 (width 5 TE =

25,4 mm) and, additionally for VEGATRENN

547V Ex or 548V Ex separator also with 5 TEwidth.

The housing can be either screwed directly

to the mounting plate or mounted to a carrier

rail (35 x 15 acc. to EN 50 022).

The housing consists generally of three components:

- Socket with terminals

The connection terminals for the sensors

are located at the bottom and the ones for

the outputs and the power supply on top of

the socket. Therefore, the necessary separation between intrinsically safe and notintrinsically safe circuits in Ex-applications

is ensured. For carrier rail mounting an appropriate adapter is integrated in the socket.

- Upper part of the housing with guide rails

and ventilation slots. Sufficient ventilation is

also ensured when connecting several

housings in series. No external ventilation

necessary.

- The attached bag includes blue Ex-labels

and coded pins.

If you already have a power supply of

20 … 53 V AC or 20 … 72 V DC available,

you can use the housing without power supply unit.

If you only have other supply voltages available, use a housing with integrated power

supply unit.

The power supply unit is suitable for a voltage range of 90 … 250 V AC and DC and

can power the module units.

A later retrofitting of the housing with a power

supply unit is possible.

Note:

The housing type 506 is only designed for

series 500 instruments:

- VEGAMET 514V, 514VD, 515V

- VEGATRENN 547V Ex, 548V Ex

The power supply unit of the housing provides no galvanic isolation from the supply

voltage. Series 500 instruments realise the

galvanic isolation in the signal conditioning

instrument.

The module instruments of the new series

500

- VEGAMET…

- VEGATRENN…

are generally provided for a power supply of

20 … 53 V AC or 20 … 72 V DC.

Housing type 506 3

Page 4

Product description

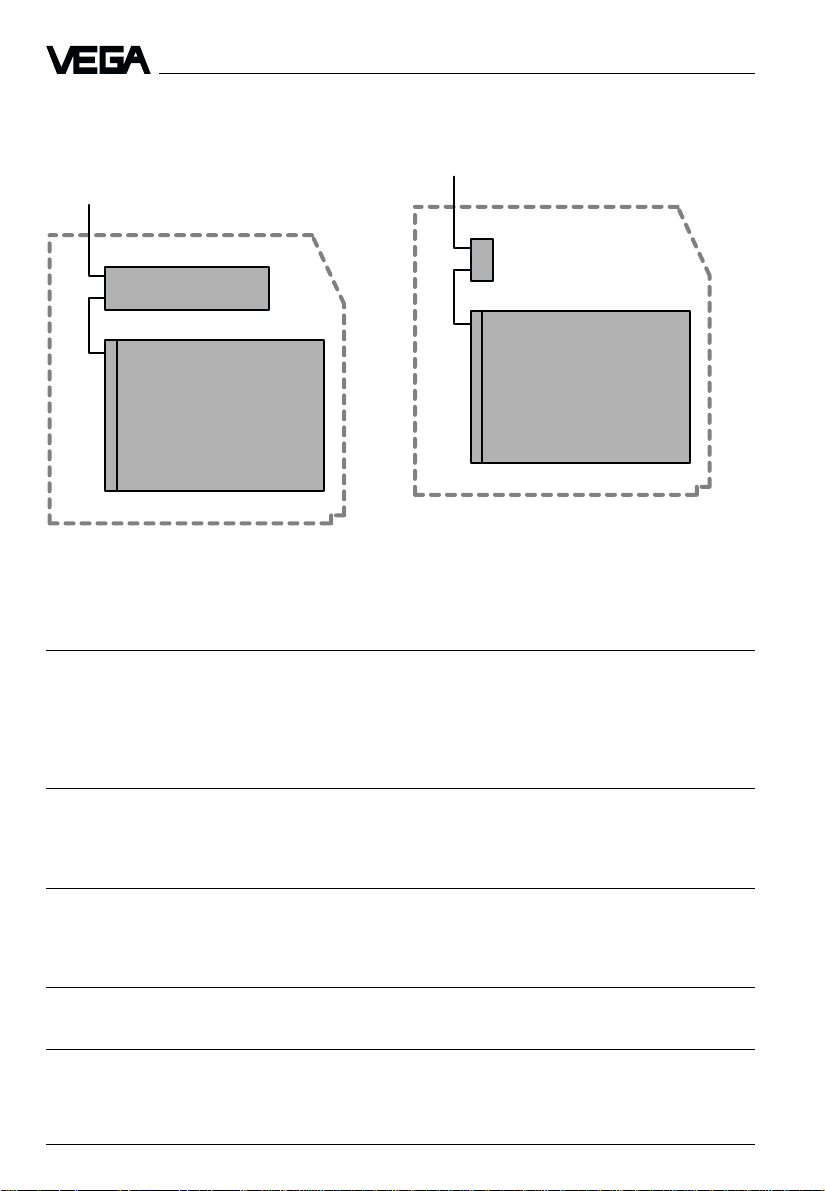

1.2 Types and versions

Housing with power supply unit

90 … 250 V AC

Power supply unit

Signal conditioning instrument

Housing without power supply unit

20 … 53 V AC

20 … 72 V DC

Adapter plug

Signal conditioning instrument

1.3 Technical data

Power supply

Supply voltage 20 … 72 V DC

Supply voltage with

integral power supply unit 90 … 250 V AC galvanically not isolated

20 … 53 V AC

(18 W; 50 VA)

Material

Terminal socket PPE (Noryl) black, self-extinguishing

Upper part of housing PPE (Noryl) grey (RAL 7036),

self-extinguishing

Multipoint connectors

Number 2

Version acc. to DIN 41 612, series F, 48-pole, 3 rows,

d, b, z (partly equipped)

Strip terminal

Cross-section area of conductor max. 2,5 mm

2

Protection classes

Protection IP 20

Protection class II

Overvoltage categories II

4 Housing type 506

Page 5

Product description

Mounting

Carrier rail 35 x 15 acc. to EN 50 022

Mounting plate 3 holes with 4,5 mm ø

3 screws M4 x 12 mm

Mechanical data

Dimensions W x H x D = 62 x 180 x 198 mm

Weight approx. 650 g

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +80°C

CE-conformity

Housing type 505 is manufactured according to the European standard and meets the

protective regulations of EMVG (89/336/EWG) and NSR (73/23/EWG). The conformity has

been judged acc. to the following standards:

EMVG Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

1.4 Dimensions

12

Upper part of

housing

200

Terminal socket

6

Front side

180

VEGAMET VEGASEL

62

ø4,5

Holes

41,5

106,7

19,4

13,7

10,3

Housing type 506 5

Page 6

2 Mounting

2.1 General

The housing type 506 can be screwed directly on a mounting plate (see "Dimensions,

holes") or placed on a carrier rail (35 x 15

acc. to EN 50 022). To do this, it is necessary

to loosen the two screws on the front of the

housing and to remove the upper part of the

housing from the socket.

For placing on carrier rail or loosening from

the carrier rail, unlock the holding strap with a

screwdriver in the lower rectangular opening

of the socket.

Holding strap (orange)

Mounting

2.2 Coding with Ex-instruments

To avoid a not-Ex-instrument being inserted

into the housing instead of the separator, the

right multipoint connector of the housing is

provided with a coded pin (position c23). A

hole is provided in the appropriate position

on the multiple plug of the VEGATRENN 547V

Ex and 548V Ex separators.

2.3 T ransparent cover

The module units can be provided with a

lockable transparent cover to avoid unauthorised adjustment.

The transparent covers are supplied along

with the module units.

2.4 Retrofitting of the housing with a

power supply unit

Please proceed as follows to retrofit a power

Wire the terminals acc. to the connection plan

(see either "3 Electrical connection", or the

operating instructions of the signal conditioning instrument to be installed, or the separator).

The designations of the terminals correspond

to those on the multipoint connector on the

rear of the signal conditioning instrument. The

exceptions are the sensor connection terminals, see "3 Electrical connection".

6 Housing type 506

supply unit:

- First of all make sure that the supply volt-

age is disconnected on the terminal strips

of the socket!

- Loosen the two hold screws on the front of

the housing and remove the upper part of

the housing (the hold screws are only

accessible when there is no module card in

the housing).

- Shift the power supply board into the guide

rails of the upper part of the housing. Note

the position of the connection plug.

Page 7

Mounting

Guide rail

Power supply

board

Connection plug

Terminal strips

Adapter plug

Socket

- Insert the red safety pin through the gaps

of the power supply board and the guide

rail. This fastens the power supply board.

Gap

Safety pin

- Remove the adapter plug from the housing

socket.

- Insert the upper part of the housing into the

socket again, tighten the two screws on the

housing front.

- Now you can connect the supply voltage

for the power supply unit (90 … 250 V AC)

on the terminal strips of the socket.

Housing type 506 7

Page 8

3 Electrical connection

The designations of the terminals are identical

to those on the multiples plugs of the signal

conditioning instruments. Exception: Sensor

terminals.

Module for adapter plug. Remove this

adapter plug when inserting a power

supply board (90 … 250 V AC/DC).

Hole for screwing on a mounting plate

Thread for the housing fastening

Multipoint connector, module for

VEGATRENN 547V Ex or 548V Ex

Multipoint connector, module for

VEGAMET

Ex-coded pin (c23)

Electrical connection

Holding strap for carrier rail mounting

Holes for screwing on mounting plate

Sensor terminals

8 Housing type 506

Page 9

Electrical connection

3.1 Terminal coordination on VEGAMET

VEGAMET 514V 514VD 515V

z6b6d

z10b10d

z12b12d

+ –

d22d

24

+ –

b22b

24

b22b

24

d22d

24

+ –

d16d18d

+ –

b16b18b

+ –

z16z18z

d16d18d

6

10

12

z

22

z

24

z

–

24

z

+

22

20

20

20

Fail safe relay • • •

Level relay 1 • • •

Level relay 2 • • •

Correction signal input 4 • • •

Correction signal input 5 •

DISBUS-output • • •

Current output 1 • • •

Current output 2 • • •

Current output 3 • •

+–

20

Voltage output 1 • • •

+–

b16b18b

20

+–

z16z18z

20

12

34 56 78

+–

+–+–+–

Voltage output 2 • • •

Voltage output 3 • •

with VEGATRENN 547V Ex • • •

1234

Sensor 1

12 34 56 78

+ – + –

Sensor 1

Sensor 2

(only with VEGAMET 515V)

Housing type 506 9

1234

Sensor 2 (only with VEGAMET 515V)

with VEGATRENN 548V Ex • • •

Page 10

Electrical connection

3.2 Connection examples

VEGATRENN 547V Ex

VEGATRENN 547V Ex can power max.

- two Ex-ultrasonic sensors VEGASON

series 80

- two Ex-radar sensors VEGAPULS 81

- a combination of both

via intrinsically safe circuits in four-wire technology and transmit their digital measured

data.

Processing

Sensor

Processing

VEGAMET 514V, 514VD

VEGATRENN 547V Ex

Not-Ex-area

Ex-area

VEGAMET 515V

VEGATRENN 547V Ex

VEGATRENN 548V Ex

VEGATRENN 548V Ex can power max.

- two hydrostatic pressure transmitters

series D84 … D87

- two ultrasonic sensors VEGASON

51V … 53V

- two radar sensors VEGAPULS 51V … 56V

via intrinsically safe circuits in two-wire technology and transmit their digital measured

data.

Processing

Sensor

1

Processing

VEGAMET 515V

VEGATRENN 548V Ex

Not-Ex-area

Ex-area

Sensor

2

VEGAMET 515V

VEGATRENN 548V Ex

Not-Ex-area

Ex-area

Sensor

2

VEGAMET 514V, 514VD

VEGATRENN 548V Ex

Not-Ex-area

Ex-area

Sensor

1

Not-Ex-area

Ex-area

Sensor

2

Sensor

1

Processing

Sensor

10 Housing type 506

Page 11

Notes

Housing type 506 11

Page 12

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@vega-g.de

ISO 9001

The statements on types, application, use and operating conditions of

the sensors and processing systems correspond to the actual

knowledge at the date of printing.

Technical data subject to alteration.

2.23 471 / April ’99

Loading...

Loading...