Page 1

Supple

mentary instructions

Float for oil/water

for VEGACAP 63

detection

Document ID:

31595

Capacitive

Page 2

1 Conte

nts

Conten

1 About this document

2 For your safety

3 Product description

4 Mounting

5 Connect the sensor

6 Setup

7 Maintenance

ts

1.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Environmental instructions. . . . . . . . . . . . . . . . . . . . .

3.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Storage and transport . . . . . . . . . . . . . . . . . . . . . . .

4.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Preparing the connection . . . . . . . . . . . . . . . . . . . . .

5.2 Connection procedure. . . . . . . . . . . . . . . . . . . . . . . .

6.1 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Instrument repair . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3

3

4

4

4

5

5

6

7

8

8

9

11

8 Dismounting

8.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Supplement

9.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Float

12

12

13

14

31595-EN-100604

for oil/water detection • for VEGACAP 63

Page 3

out this document

1 Ab

1 Abou

t this document

1.1 Function

This supplementary manual, together with the attached operating

instructions manual, has all the information you need for quick setup

and safe operation. Please read this manual before you start setup.

1.2 Target group

This operating instructions manual is directed to trained qualified

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Inform

ation, tip, note

This symbol indicates helpful additional information.

Cauti

on: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

applications

Ex

This symbol indicates special instructions for Ex applications.

31595-EN-100604

Float

l List

The dot set in front indicates a list with no implied sequence.

à Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

for oil/water detection • for VEGACAP 63 3

Page 4

2 For

your safety

or your safety

2 F

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

The float for oil/water detection is part of a sensor. It is used for

detection of light liquids on water.

2.3 Environmental instructions

Protection of the environment is one of our most important duties. That

is why we have introduced an environment management system with

the goal of continuously improving company environmental protection.

The environment management system is certified according to DIN

EN ISO 14001.

Please help us fulfil this obligation by observing the environmental

instructions in this manual:

l Chapter "Storage and transport"

l Chapter "Disposal"

4 Float

31595-EN-100604

for oil/water detection • for VEGACAP 63

Page 5

1

2

3

6

4 5

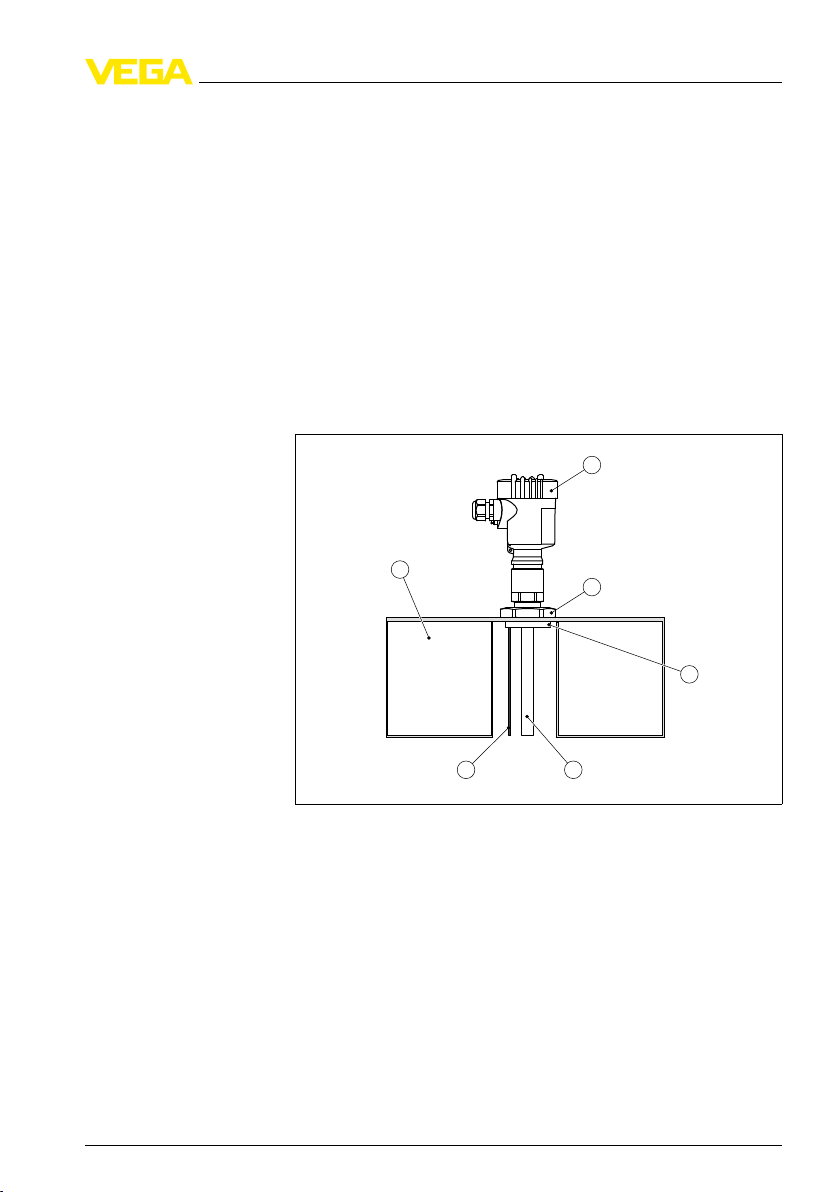

3 Produc

t description

Scope of delivery

Constituent parts

3 Produc

t description

3.1 Structure

The scope of delivery encompasses:

l Floating body for a point level sensor

l Nut G1½ (plastic)

l Adapter with pin

l Ground rod

l Documentation

- This supplementary operating instructions

The instrument version "Point level sensor with float" consists of a float

and the point level sensor.

Application area

31595-EN-100604

for oil/water detection • for VEGACAP 63 5

Float

Fig. 1: Components

1 Probe (mounted in the centre)

2 Nut (plastic)

3 Adapter (316L) with pin

4 Electrode

5 Ground electrode (screwed into the adapter)

6 Float

3.2 Principle of operation

of the float probe

The float is suitable for the following plics

l VEGACAP 63

®

sensors:

Page 6

1

2

4

3

3 P roduc

t description

Functional principle

The probe detects non-conductive light liquids (< 1 kg/dm³) on water,

e.g. in water or oil separating basins.

Fig. 2: Measuring

1 Cable holder for relief

2 Inlet - Water/Oil mixture

3 Oil layer

4 Water

system for oil/water detection

The measuring system floats on the water and due to the own weight

the electrode of the probe immerses up to a certain depth.

If there is e.g. oil on the water surface, the measuring system floats.

The immersion depth of the electrode in water reduces. Hence the

capacitance of the probe changes. The capacitance change is

converted into a switching command.

An oil layer can be already detected from a thickness of 4 mm.

3.3 Storage and transport

Packaging

Storage and transport

temperature

6 Float

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also used. Dispose of the packaging material via specialised

recycling companies.

l Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

31595-EN-100604

for oil/water detection • for VEGACAP 63

Page 7

4 M

ounting

Guidance

4 Moun

ting

4.1 General instructions

To prevent the float from touching the vessel wall, it can be guided

vertically.

Use two thin vertical rods or two vertically strained wires at a distance

of 306 mm (12 in) which you lead through the holes in the float plate.

Connection cable

Product movements

Static charges

31595-EN-100604

for oil/water detection • for VEGACAP 63 7

Float

Fig. 3: Guidance

The connection cable can influence the float position of the measuring

system and therefore adulterate the measuring result.

If possible, use a light, flexible connection cable and fasten the cable

with a cable holder. In case of considerable height differences of the

float, you should use a light helix cable.

Product movements can influence the measurement. In this case, use

a signal conditioning instrument with adjustable damping to avoid

fluctuations of the measured value.

There is a danger of static charging on the plastic floating body.

Avoid friction

No dry cleaning

Do not mount in areas with flowing, non-conductive products

of the float

Page 8

5 Conn

ect the sensor

5 Conn

ect the sensor

5.1 Preparing the connection

Follow the instructions in the operating instructions manual of the

sensor.

Th

e connection cable can influence the floating position of the

measuring system. For this reason, use a light, flexible connection

cable and fasten the cable on a cable holder.

5.2 Connection procedure

The electrical connection is described in the operating instructions of

the sensor.

8 Float

31595-EN-100604

for oil/water detection • for VEGACAP 63

Page 9

0 10

5

521

on

1 2 43

5 6 7 8

9 10 11 12 13 14

on

min.

!

VEGATOR 621EX

0 10

5

1

2

6 Setup

6 Setup

6.1 Setup

is carried out according to the operating instructions manual of

Setup

the respective sensor.

Make sure that the measuring system is in the water for setup.

Ti

p:

If setup is not possible in the original vessel, then fill a suitable vessel

(ø approx. 400 mm, height approx. 150 mm) with water and place the

measuring system with float inside the vessel. The measuring result

can be transferred to the original vessel.

Proceed as follows:

1 Connect probe and signal conditioning instrument

2 Switch on power supply

3 Turn the A/B switch on the signal conditioning instrument to

position B

The relay deenergizes if an oil layer is detected (safe condition)

31595-EN-100604

Float

Fig. 4: Suitable

1 Potentiometer

2 Relay control lamp

signal conditioning instruments

4 Set potentiometer (1) to 0. The relay control lamp (2) lights.

5 Turn t he potentiometer (1) slowly clockwise until the relay control

lamp (2) extinguishes.

for oil/water detection • for VEGACAP 63 9

6 Turn the potentiometer (1) very slowly anticlockwise until the relay

control lamp (2) lights.

Page 10

A

C

1

2

B

6 Setup

e the measuring system is set very sensitively. An of oil layer

Henc

of 3 - 4 mm is sufficient to switch the relay.

Information:

To make the measuring system less sensitive, you have to turn the

potentiometer anticlockwise.

The more the potentiometer is turned back, the higher the light liquid

layer has to be to switch the relay.

We recommend connecting the level switch in such a way that the

switching circuit is open when there is a level signal, line break or

failure (safe condition).

An open switch symbol corresponds hence in the following drawing to

the detection of a liquid.

Fig. 5: Switching

A No liquid present

B Water

C Oil layer on water

1 Liquid level water

2 Liquid level oil > 4 mm (> 0.157 in)

status of the measuring system

10 Float

31595-EN-100604

for oil/water detection • for VEGACAP 63

Page 11

7 M

aintenance

7 Maint

enance

7.1 Instrument repair

If a repair of the instrument is necessary, please proceed as follows:

You can download a return form (23 KB) from our Internet homepage

www.vega.com

form".

By doing this you help us carry out the repair quickly and without

having to call back for needed information.

l Print and fill out one form per instrument

l Clean the instrument and pack it damage-proof

l Attach the completed form and probably a safety data sheet to the

instrument

l Send the instrument to the address of the agency serving you. In

Germany, send it to the company headquarters in Schiltach.

under: "Downloads - Forms and certificates - Repair

31595-EN-100604

Float

for oil/water detection • for VEGACAP 63 11

Page 12

8 Dismoun

ting

8 Dismou

nting

8.1 Dismounting steps

Note chapter "Mounting" and carry out the described steps in reverse

order.

8.2 Disposal

The instrument consists of materials which can be recycled by

specialised recycling companies. We have purposely designed the

electronic modules to be easily separable. Mark the instrument as

scrap and dispose of it according to national government regulations

(e.g. in Germany according to electronic scrap ordinance).

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

12 Float

31595-EN-100604

for oil/water detection • for VEGACAP 63

Page 13

9 Sup

plement

9 Supp

lement

9.1 Technical data

Technical data

Following you find all data deviating from the standard instrument. All other technical data are

specified in the operating instruction of the respective sensor.

General data

Material 316L corresponds to 1.4404 or 1.4435

Materials, wetted parts

- Float PVC

- Nut PPH

- Adapter 316L

- Ground rod 316L

Weights

- Float approx. 2400 g (85 oz)

Suitable point level sensor - VEGACAP 63

- Order length L - Point level sensor 160 mm

- Housing material Plastic

- Electronics version Two-wire electronics (Z)

- Process fitting G ¾ A

Suitable signal conditioning instruments

VEGATOR 521, 621

Process conditions

Process temperature -30 … +60 °C (-22 … +140 °F)

Approvals

The floating body can be used in Ex area zone 1 (ATEX II 2G).

There is a danger of static charging on the plastic floating body.

- Avoid friction

- No dry cleaning

- Do not mount in areas with flowing,

non-conductive products

31595-EN-100604

for oil/water detection • for VEGACAP 63 13

Float

Page 14

5 mm

(0.2")

80 mm

(3.15")

ø 350 mm

(13.78")

306 mm

(12.05")

L

ø 49 mm

(1.93")

ø 27 mm

(1.06")

100 mm

(3.94")

62,5 mm

(2.46")

ø 49 mm

(1.93")

150 mm

(5.91")

ø 25 mm

(0.98")

ø 25 mm

(0.98")

9 Suppl

9.2 D

ement

imensions

Measuring system for oil/water detection

Fig. 6: Measuring

L Order length of the VEGACAP 63 level sensor (L = 160 mm)

system for oil/water detection with VEGACAP 63 point level sensor

14 Float

31595-EN-100604

for oil/water detection • for VEGACAP 63

Page 15

9 Sup

plement

31595-EN-100604

Float

for oil/water detection • for VEGACAP 63 15

Page 16

VEGA Grieshaber KG

ISO 9001

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

Printing date:

statements concerning scope of delivery, application,

All

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2010

Subject to change without prior notice 31595-EN-100604

Loading...

Loading...