Page 1

Supplementary instructions

External housing

For pressure transmitter VEGABAR

Document ID: 31087

Page 2

Contents

Contents

1 About this document

1.1 Function ........................................................................................................................... 3

1.2 Target group ..................................................................................................................... 3

1.3 Symbolism used ............................................................................................................... 3

2 For your safety

2.1 Authorised personnel ....................................................................................................... 4

2.2 Appropriate use ................................................................................................................ 4

2.3 Environmental instructions ............................................................................................... 4

3 Product description

3.1 Conguration .................................................................................................................... 5

3.2 Principle of operation........................................................................................................ 5

3.3 Storage and transport....................................................................................................... 5

4 Mounting

4.1 Mounting preparations ..................................................................................................... 7

4.2 Exchange of the electronics module ................................................................................. 7

4.3 Mounting steps, external housing ..................................................................................... 8

5 Connect the sensor to the external housing

5.1 Preparing the connection ............................................................................................... 10

5.2 Connection procedure .................................................................................................... 10

5.3 Wiring plan ..................................................................................................................... 11

6 Setup

6.1 Setup .............................................................................................................................. 14

7 Maintenance

7.1 Instrument repair ............................................................................................................ 15

8 Dismounting

8.1 Dismounting steps.......................................................................................................... 16

8.2 Disposal ......................................................................................................................... 16

9 Supplement

9.1 Technical data ................................................................................................................ 17

9.2 Dimensions .................................................................................................................... 18

31087-EN-130322

Safety instructions for Ex areas

PleasenotetheEx-specicsafetyinformationforinstallationandoperation in Ex areas. These safety instructions are part of the operating

instructions manual and come with the Ex-approved instruments.

Editing status: 2013-03-11

2

External housing • For pressure transmitter VEGABAR

Page 3

1 About this document

1 About this document

1.1 Function

This supplementary manual, together with the attached operating

instructions manual, has all the information you need for quick setup

and safe operation. Please read this manual before you start setup.

1.2 Target group

This operating instructions manual is directed to trained specialist

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

List

•

The dot set in front indicates a list with no implied sequence.

Action

→

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

31087-EN-130322

External housing • For pressure transmitter VEGABAR

3

Page 4

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must

be carried out only by trained specialist personnel authorised by the

plant operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

The external housing is a replacement part for a pressure transmitter

VEGABAR series 50 and 60 in IP 68 (25 bar) version.

2.3 Environmental instructions

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system

with the goal of continuously improving company environmental pro-

tection.Theenvironmentmanagementsystemiscertiedaccording

to DIN EN ISO 14001.

Pleasehelpusfulllthisobligationbyobservingtheenvironmental

instructions in this manual:

Chapter "Storage and transport"

•

Chapter "Disposal"

•

31087-EN-130322

4

External housing • For pressure transmitter VEGABAR

Page 5

Scope of delivery

3 Product description

3.1 Conguration

The scope of delivery encompasses:

External housing

•

Documentation

•

– this operating instructions manual

3 Product description

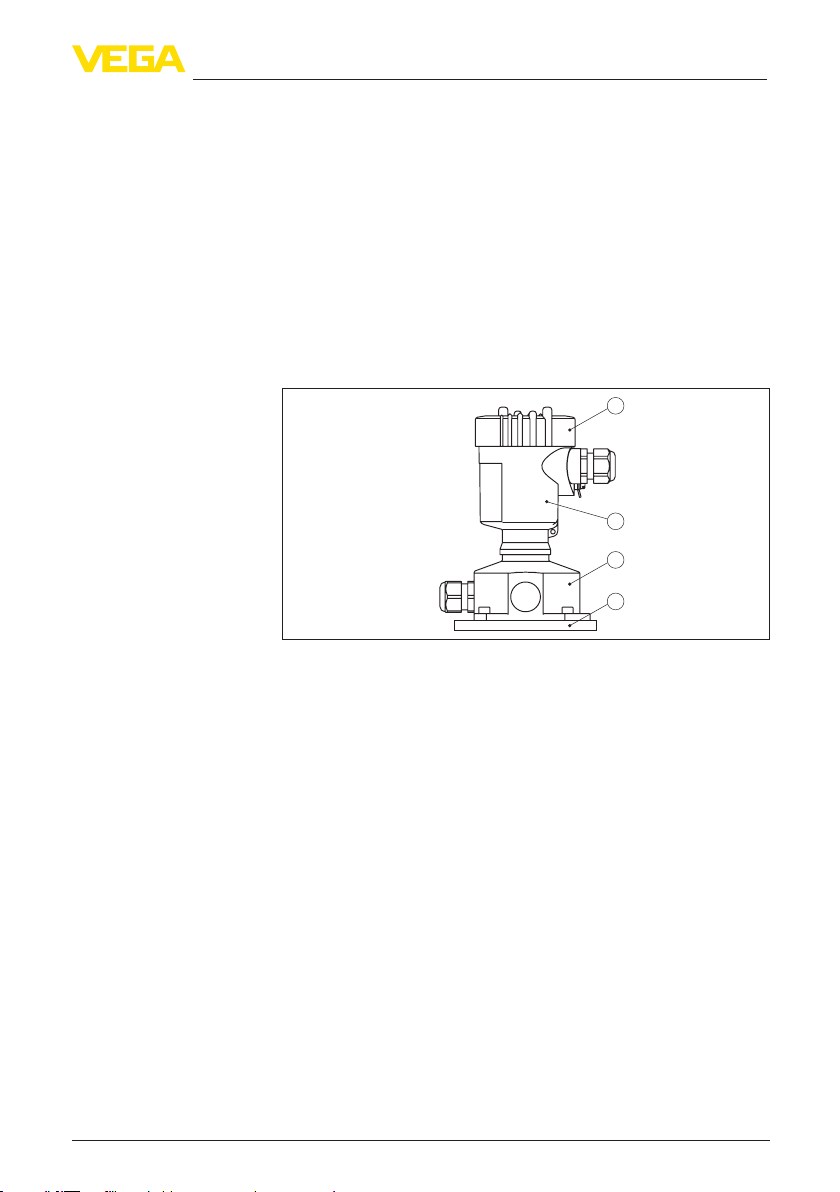

Constituent parts

Application area

The external housing consists of the components electronics housing

and base. Both components are available in plastic or stainless steel.

Dependingontheorderspecication,thescrew-oncoverofthe

electronics housing is available with or without inspection window for

the display and adjustment module.

1

2

3

4

Fig. 1: Components of the external housing for VEGABAR - plastic version

1 Screw-on cover

2 Electronics housing

3 Socket

4 Wall mounting plate

3.2 Principle of operation

The external housing is suitable for the following pressure transmitters

in IP 68 (25 bar) version:

VEGABAR 51, 52, 53, 54, 55

•

VEGABAR 66, 67

•

3.3 Storage and transport

Packaging

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

based on ISO 4180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE

foil is also used. Dispose of the packaging material via specialised

recycling companies.

•

31087-EN-130322

External housing • For pressure transmitter VEGABAR

5

Page 6

3 Product description

Storage and transport

temperature

Storage and transport temperature see chapter "Supplement -

•

Technical data - Ambient conditions"

Relative humidity 20 … 85 %

•

31087-EN-130322

6

External housing • For pressure transmitter VEGABAR

Page 7

Tools

4 Mounting

4 Mounting

4.1 Mounting preparations

The following tools are required for mounting the external housing.

Plastic housing:

Allen wrench size 4

•

Fork wrench, wrench size 19

•

Stainless steel housing:

Fork wrench, wrench size 8

•

Fork wrench, wrench size 19

•

4.2 Exchange of the electronics module

The electronics module is located in the electronics compartment.

The below illustration shows the position of the electronics compartment in an external housing.

1

Fig. 2: Single chamber housing

1 Position of the electronics compartment

Dismounting the electronics module

31087-EN-130322

External housing • For pressure transmitter VEGABAR

Proceed as follows to remove the electronics module from the existing

housing:

1. Switchopowersupply

2. Unscrew housing cover of the electronics compartment

3. Disconnect the connection cables according to the operating

instructions manual of the respective sensor

4. Loosen the two holding screws with a screwdriver (Torx size T 10

or slotted screwdriver size 4)

7

Page 8

4 Mounting

1

2

Fig. 3: Loosen the holding screws of the electronics module

1 Electronics module

2 Screws (2 pcs.)

5. Pull the electronics out by holding the opening levers.

Mounting the electronics

module

To dismount the electronics module from the new housing, proceed

as follows:

1. Insert the electronics module carefully into the new housing.

Information:

The electronics module is connected via a plug. Make sure that the

plug is in the correct position. The marking notch must be in position

"18.00 h".

1

Fig. 4: Plug position in the base of the external housing

1 Notch

2. Screw in and tighten the two screws with the screwdriver.

3. Screw the housing cover back on

Theexchangeoftheelectronicsmoduleisnished.

As a rule, an exchange of electronics must be documented internally

when Ex applications are involved.

31087-EN-130322

Wall mounting - External

housing

8

4.3 Mounting steps, external housing

1. Mark the holes according to the following drilling template

External housing • For pressure transmitter VEGABAR

Page 9

4 Mounting

2. Depending on the mounting surface, fasten the wall mounting

plate with 4 screws

90 mm (3.54")

70 mm (2.76")

3mm

(0.12")

R 3,5 mm

(0.14")

93 mm (3.66")

110 mm (4.33")

Fig. 5: Hole pattern - wall mounting plate (external housing)

8 mm

(0.32")

Tip:

Mount the wall mounting plate in such a way that the cable gland of

the base points downward. Rain and condensation water can thus

draino.

The base of stainless steel can be displaced in 90° increments on the

wall mounting plate, the base of plastic by 180°.

Turn the cable gland of the electronics housing downward. The housing can be turned by 330° without the use of any tools.

Warning:

With the plastic housing, the four screws of the base may only be

screwedinhandtight.Exceedingthemax.torquespeciedinchapter

"Technical data" can damage the wall mounting plate.

31087-EN-130322

External housing • For pressure transmitter VEGABAR

9

Page 10

5 Connect the sensor to the external housing

5 Connect the sensor to the external

housing

5.1 Preparing the connection

Follow the instructions in the operating instructions manual of the

sensor.

5.2 Connection procedure

Proceed as follows to connect the external housing:

1. Loosen the four screws on the base with a hexagon key or fork

wrench

2. Remove the mounting plate from the base

1

3

2

Fig. 6: Removing the mounting plate on the base

1 Screws

2 Wall mounting plate

3 Cable gland

3. Loop the connection cable through the cable entry on the housing

Tip:

With plastic housing, the cable gland can be mounted in three positions each displaced by 90°. Simply exchange the cable gland against

theblindpluginthettingthreadedhole.

Note:

Depending on the delivery date of the sensor, the connection cable

maybeequippedwiththreeorfourwires.Takenoteofthedierent

assignments of the terminals in the housing base in "Wiring plan".

4. With four-wire sensor, remove the bridge between terminal 4 and

1)

1)

base

the ground terminal, see "Wiring plan".

The connection cable comes pre-assembled. If necessary, shorten it to the

requested length, cut the breather capillaries clean. Remove approx. 5 cm of

the cable mantle, strip approx. 1 cm insulation from the ends of the individual

wires. After shortening the cable, fasten the type plate with support back on

the cable.

31087-EN-130322

10

External housing • For pressure transmitter VEGABAR

Page 11

Overview - VEGABAR

series 50

5 Connect the sensor to the external housing

5. Connect the wire ends as described in chapter "Connection plan".

Take note of the numbering.

6. Connect the screen to the internal ground terminal, connect the

outer ground terminal to potential equalisation

7. Tighten the compression nut of the cable entry. The seal ring must

completely encircle the cable

8. Attach the mounting plate again and tighten the screws

The electrical connection of the sensor to the external housing is

nished.

Youndtheelectricalconnectionoftheelectronicsmoduleinchapter

"Wiring plan" or in the operating instructions manual of the respetive

sensor.

5.3 Wiring plan

Fig. 7: External housing in conjunction with VEGABAR 51, 52, 53, 54, 55

31087-EN-130322

External housing • For pressure transmitter VEGABAR

11

Page 12

5 Connect the sensor to the external housing

Overview - VEGABAR

series 60

Fig. 8: External housing in conjunction with VEGABAR 66, 67

Terminal compartment

12

1234

2

341

6

5

Fig. 9: Connection of the sensor in the housing base

1 Brown

2 Blue

3 Yellow

4 White

5 Shielding

6 Breather capillaries

External housing • For pressure transmitter VEGABAR

31087-EN-130322

Page 13

Wiring plan external

electronics

5 Connect the sensor to the external housing

12 5 678

1

Fig. 10: Wiring plan, electronics

1 Voltage supply

Display

I2C

31087-EN-130322

External housing • For pressure transmitter VEGABAR

13

Page 14

6 Setup

6 Setup

6.1 Setup

Setup is carried out according to the operating instructions manual of

the respective sensor.

14

31087-EN-130322

External housing • For pressure transmitter VEGABAR

Page 15

7 Maintenance

7 Maintenance

7.1 Instrument repair

If an instrument repair is necessary, please proceed as follows:

You can download a return form (23 KB) from our Internet homepage

www.vega.com under: "Downloads - Forms and certicates - Repair

form".

By doing this you help us carry out the repair quickly and without having to call back for needed information.

Printandlloutoneformperinstrument

•

Clean the instrument and pack it damage-proof

•

Attach the completed form and possibly also a safety data sheet to

•

the instrument

Send the instrument to the address of the agency serving you. In

•

Germany, send it to the company headquarters in Schiltach.

31087-EN-130322

External housing • For pressure transmitter VEGABAR

15

Page 16

8 Dismounting

8 Dismounting

8.1 Dismounting steps

Take note of chapters "Mounting" and "Connect sensor to the external

housing" and carry out the listed steps in reverse order.

8.2 Disposal

The instrument consists of materials which can be recycled by

specialised recycling companies. We have purposely designed the

electronic modules to be easily separable. Mark the instrument as

scrap and dispose of it according to national government regulations

(e.g. in Germany according to electronic scrap ordinance).

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

16

31087-EN-130322

External housing • For pressure transmitter VEGABAR

Page 17

9 Supplement

9 Supplement

9.1 Technical data

General data

Material 316L corresponds to 1.4404 or 1.4435

Materials, non-wetted parts

Ʋ Electronics housing plastic PBT (Polyester), 316L

Ʋ Socket plastic PBT (Polyester), 316L

Ʋ Wall mounting plate plastic PBT (Polyester), 316L

Ʋ Seal between base and wall mounting

plate

Ʋ Seal between housing and housing

cover

Ʋ Ground terminal 316L

Torque of base screws for plastic housing

max.

Weight approx. 0.7 … 2.0 kg (1.543 … 4.409 lbs), depending on housing

Process conditions

Ambient, storage and transport temperature

Ʋ without display and adjustment

module

Ʋ With display and adjustment module -20 … +70 °C (-4 … +158 °F)

TPE(xedconnected)

Silicone (plastic housing), NBR (stainless steel housing)

5 Nm (3.688 lbf ft)

material

-40 … +80 °C (-40 … +176 °F)

Electromechanical data

Options of the cable entry

Ʋ Cable gland M20 x 1.5 (cable: ø 5 … 9 mm)

Ʋ Cable entry ½ NPT

Ʋ Blind plug M20 x 1.5; ½ NPT

Ʋ Closing cap M20 x 1.5; ½ NPT

Wire cross-section (spring-loaded

up to 2.5 mm² (AWG 14)

terminals)

Electrical protective measures

Protection, depending on housing version

Ʋ Plastic housing IP 66/IP 67

Ʋ Stainless steel housing IP 66/IP 68 (0.2 bar)

2)

The prerequisites for maintaining the protection rating are a suitable cable as well as correct mounting.

31087-EN-130322

2)

External housing • For pressure transmitter VEGABAR

17

Page 18

9 Supplement

9.2 Dimensions

Electronics housing

69 mm (2.72 ")

ø77 mm (3.03")

~ 59 mm

(2.32")

ø 80 mm

(3.15")

M20x1,5/

½ NPT

112 mm (4.41")

M20x1,5/

1

½ NPT

2

112 mm (4.41")

Fig. 11: Electronics housing (with integrated display and adjustment module the housing is 9 mm/0.35 in higher)

1 Plastic housing

2 Stainless steel housing

External housing with sensor in IP 68 (25 bar) version

65 mm

(2.68")

42mm

(2.68")

68 mm

(1.65")

1

(3.62")

92 mm

40mm

(1.57")

2

Fig. 12: External housing - Plastic version

1 Lateral cable outlet

2 Axial cable outlet

110 mm x 90 mm (4.33" x 3.54")

~ 66 mm (2.60")

59 mm (2.32")

18

31087-EN-130322

External housing • For pressure transmitter VEGABAR

Page 19

68 mm

(2.68")

42mm

(1.65")

1

68 mm

(2.68")

9 Supplement

51 mm (2.01")

(3.62")

92 mm

40mm

(1.57")

2

Fig. 13: External housing - Stainless steel version

1 Lateral cable outlet

2 Axial cable outlet

3 Seal 2 mm (0.079 in)

110 mm x 90 mm (4.33" x 3.54")

3

31087-EN-130322

External housing • For pressure transmitter VEGABAR

19

Page 20

Printing date:

All statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the information

available at the time of printing.

Subject to change without prior notice

© VEGA Grieshaber KG, Schiltach/Germany 2013

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info.de@vega.com

www.vega.com

31087-EN-130322

Loading...

Loading...