Page 1

Operating Instructions

Pressure transmitter with metallic

measuring cell

VEGABAR 87

Slave sensor for electronic differential pressure

Document ID: 45053

Page 2

Contents

Contents

1 About this document

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbolism used ............................................................................................................... 4

2 For your safety

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use ................................................................................................................ 5

2.3 Warning about incorrect use ............................................................................................. 5

2.4 General safety instructions ............................................................................................... 5

2.5 CE conformity ................................................................................................................... 5

2.6 Measuring range - permissible process pressure ............................................................. 6

2.7 Environmental instructions ............................................................................................... 6

3 Product description

3.1 Conguration .................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Packaging, transport and storage ................................................................................... 11

3.4 Accessories and replacement parts ............................................................................... 12

4 Mounting

4.1 General instructions to use the instrument ..................................................................... 13

4.2 Ventilation and pressure compensation .......................................................................... 14

4.3 Combination Master - Slave ........................................................................................... 15

4.4 Dierential pressure measurement ................................................................................ 16

4.5 Interface measurement .................................................................................................. 16

4.6 Density measurement .................................................................................................... 17

4.7 External housing ............................................................................................................ 19

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 20

5.2 Connecting ..................................................................................................................... 20

5.3 Single chamber housing ................................................................................................. 21

5.4 External housing with version IP 68 (25 bar)................................................................... 22

5.5 Connection example ...................................................................................................... 24

6 Set up with the display and adjustment module

6.1 Parameter adjustment - Quick setup .............................................................................. 25

6.2 Parameter adjustment - Extended adjustment................................................................ 28

7 Diagnosis, asset management and service

7.1 Maintenance .................................................................................................................. 38

7.2 Rectify faults ................................................................................................................... 38

7.3 Exchanging the electronics module ................................................................................ 38

7.4 Exchange process assembly with version IP 68 (25 bar) ................................................ 38

7.5 How to proceed in case of repair .................................................................................... 40

8 Dismounting

8.1 Dismounting steps.......................................................................................................... 41

8.2 Disposal ......................................................................................................................... 41

9 Supplement

9.1 Technical data ................................................................................................................ 42

45053-EN-131011

2

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 3

Contents

9.2 Dimensions .................................................................................................................... 47

Safety instructions for Ex areas

Please note the Ex-specic safety information for installation and operation in Ex areas. These safety instructions are part of the operating

instructions manual and come with the Ex-approved instruments.

45053-EN-131011

Editing status: 2013-10-09

VEGABAR 87 • Slave sensor for electronic dierential pressure

3

Page 4

1 About this document

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important instructions for maintenance and fault rectication. Please read this information before putting the instrument into operation and keep this manual

accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained specialist

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

List

•

The dot set in front indicates a list with no implied sequence.

Action

→

This arrow indicates a single action.

1 Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of batteries and accumulators.

45053-EN-131011

4

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 5

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must

be carried out only by trained specialist personnel authorised by the

plant operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

VEGABAR 87 is a slave sensor for electronic dierential pressure

measurement.

You can nd detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly

used according to the specications in the operating instructions

manual as well as possible supplementary instructions.

2.3 Warning about incorrect use

Inappropriate or incorrect use of the instrument can give rise to

application-specic hazards, e.g. vessel overll or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a high-tech instrument requiring the strict observance of standard regulations and guidelines. The user must take note of the safety

instructions in this operating instructions manual, the country-specic

installation standards as well as all prevailing safety regulations and

accident prevention rules.

The instrument must only be operated in a technically awless and

reliable condition. The operator is responsible for trouble-free opera-

tion of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new regulations.

2.5 CE conformity

The device fullls the legal requirements of the applicable EC guidelines. By axing the CE marking, we conrm successful testing of the

product.

You can nd the CE Certicate of Conformity in the download section

of our homepage.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

5

Page 6

2 For your safety

2.6 Measuring range - permissible process pressure

The permissible process pressure is specied on the type label with

"process pressure", see chapter "Conguration". For safety reasons,

this range must not be exceeded. This applies also if a measuring

cell with higher measuring range (order-related) than the permissible

pressure range of the process tting is installed.

2.7 Environmental instructions

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system

with the goal of continuously improving company environmental protection. The environment management system is certied according

to DIN EN ISO 14001.

Please help us fulll this obligation by observing the environmental

instructions in this manual:

Chapter "Packaging, transport and storage"

•

Chapter "Disposal"

•

45053-EN-131011

6

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 7

Type plate

3 Product description

3 Product description

3.1 Conguration

The nameplate contains the most important data for identication and

use of the instrument:

1

2

3

4

5

6

7

8

9

10

Fig. 1: Layout of the type label (example)

1 Instrument type

2 Product code

3 Field for approvals

4 Power supply and signal output, electronics

5 Protection rating

6 Measuring range

7 Permissible process pressure

8 Material, wetted parts

9 Hardware and software version

10 Order number

11 Serial number of the instrument

12 Symbol of the device protection class

13 ID numbers, instrument documentation

14 Reminder to observe the instrument documentation

15 Notied authority for CE marking

16 Approval directive

16

15

14

13

12

11

Serial number

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

The type label contains the serial number of the instrument. With it

you can nd the following data on our homepage:

Product code of the instrument (HTML)

•

Delivery date (HTML)

•

Order-specic instrument features (HTML)

•

Operating instructions at the time of shipment (PDF)

•

Order-specic sensor data for an electronics exchange (XML)

•

Test certicate pressure transmitters (PDF)

•

Go to www.vega.com, "VEGA Tools" and "Serial number search".

As an alternative, you can nd the data via your Smartphone:

Download the smartphone app "VEGA Tools" from the "Apple App

•

Store" or the "Google Play Store"

Scan the Data Matrix code on the type label of the instrument or

•

Enter the serial number manually in the app

•

7

Page 8

3 Product description

Scope of this operating

instructions manual

Scope of delivery

Electronicdierential

pressure measurement

Measured variables

This operating instructions manual applies to the following instrument

versions:

Hardware from 1.0.0

•

Software version from 1.0.0

•

The scope of delivery encompasses:

VEGABAR 87 pressure transmitter

•

Connection cable to the master sensor

•

Cable gland for the master sensor

•

Documentation

•

– this operating instructions manual

– Test certicate measuring accuracy (optional)

– Supplementary instructions manual "Plug connector for con-

tinuously measuring sensors" (optional)

– Ex-specic "Safety instructions" (with Ex versions)

– if necessary, further certicates

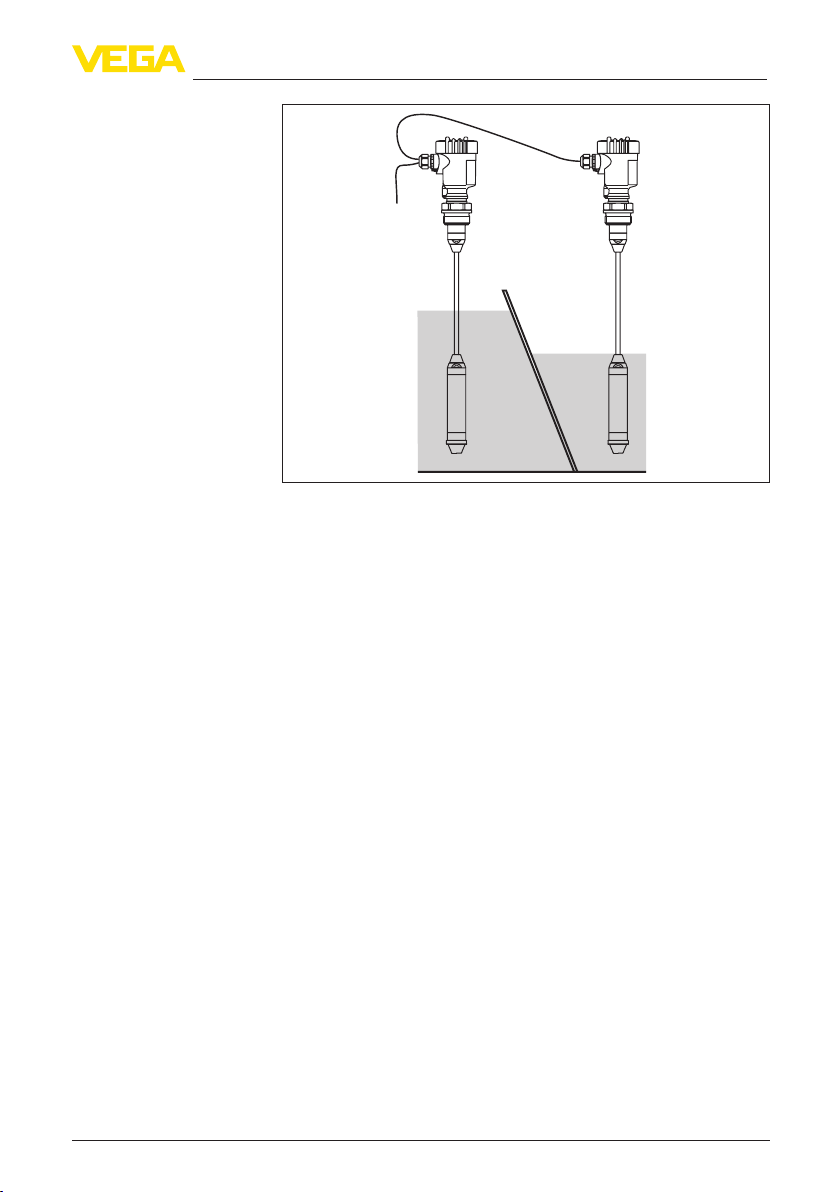

3.2 Principle of operation

The VEGABAR 87 slave sensor is combined with a sensor from the

VEGABAR 80 series for electronic dierential pressure measurement.

The sensors are connected via a screened four-wire cable. The

measured value from the slave sensor is read in and factored into the

calculations. Parameter adjustment is carried out through the master

sensor.

The dierential pressure measurement is suitable for the measurement of the following process variables:

Level

•

Flow

•

Dierential pressure

•

Density

•

Interface

•

45053-EN-131011

8

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 9

3 Product description

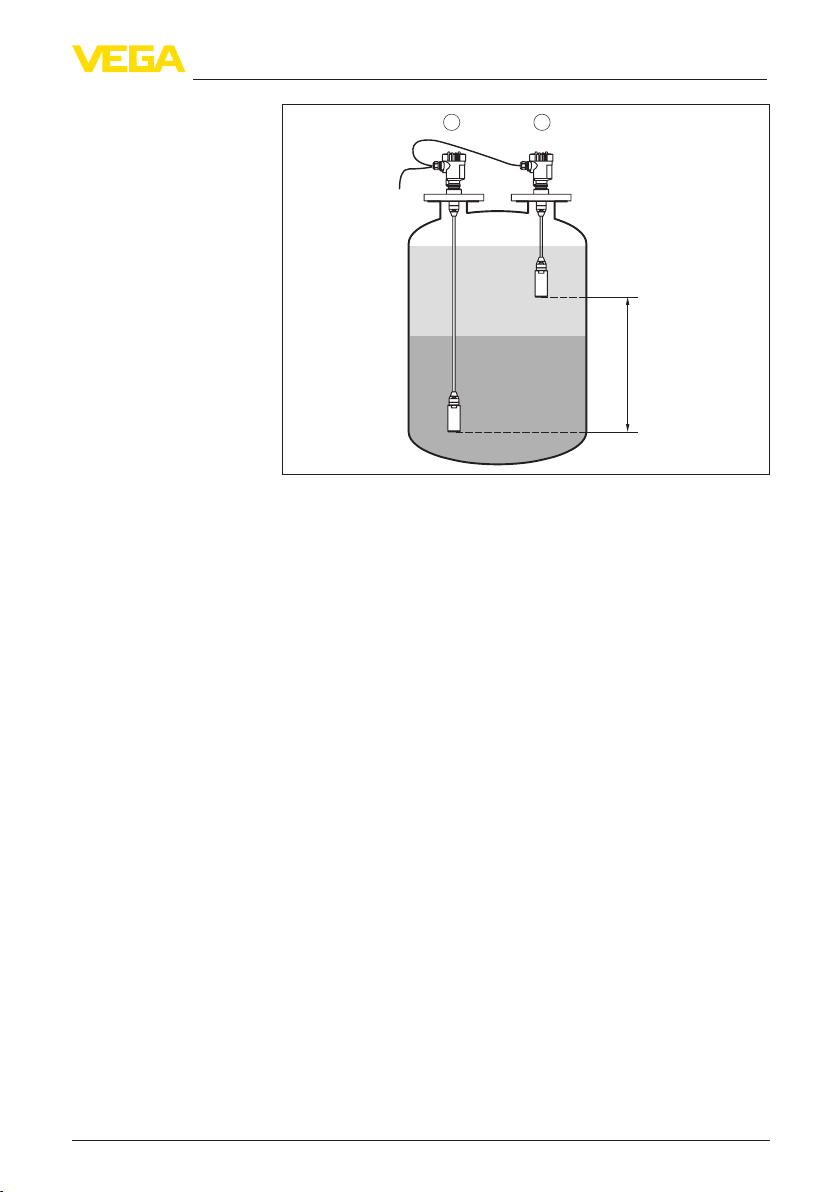

Fig. 2: Electronic level dierence measurement through Master/Slave combination

Application area

The VEGABAR 87 is a pressure transmitter for pressure and level

measurements of liquids with higher temperatures in the chemical,

food processing and pharmaceutical industry.

Measured products

Measured products are liquids.

Depending on the instrument version and the measurement setup,

the measured products can be also viscous.

Measuring system

The process pressure acts on the sensor element via the stainless

steel diaphragm and an internal transmission liquid. The process

pressure causes a resistance change which is converted into a corresponding output signal and outputted as measured value.

The METEC® measuring cell is the measuring unit. It consists of

the ceramic-capacitive CERTEC® measuring cell and a special,

temperature-compensated isolating system.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

9

Page 10

3 Product description

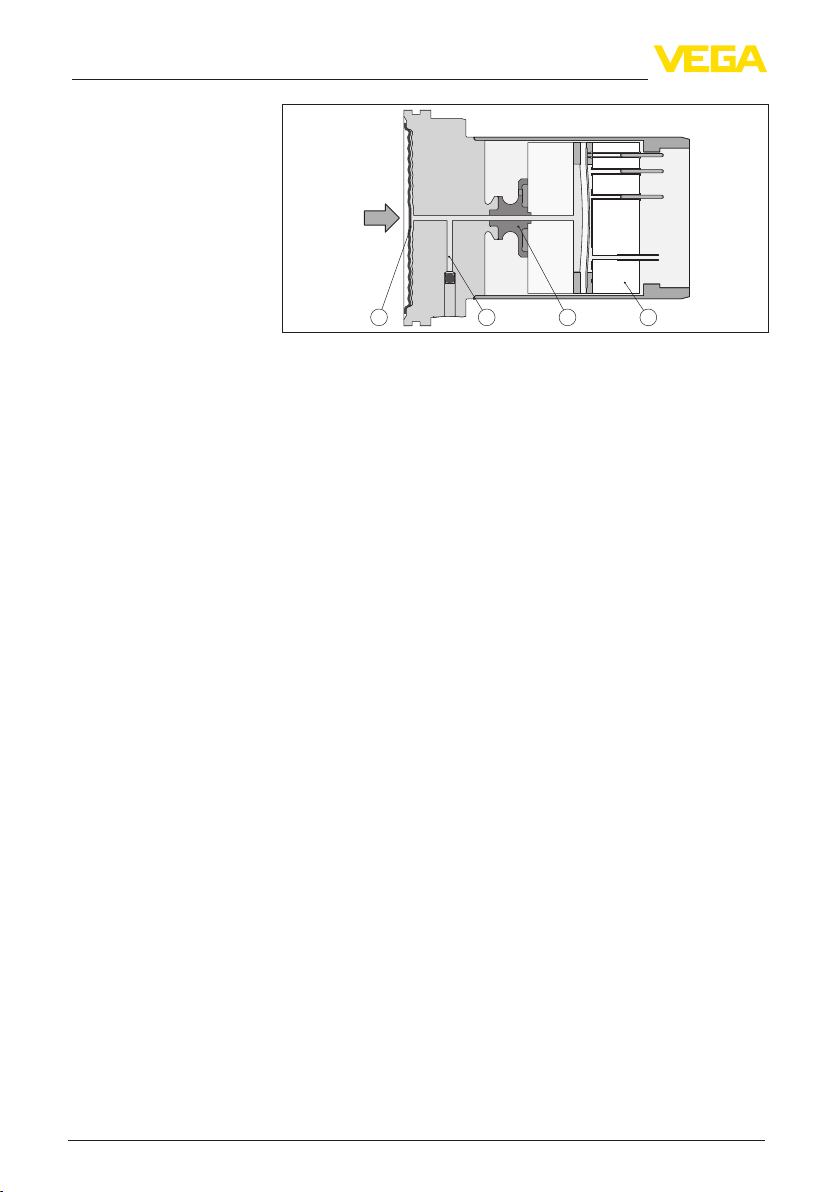

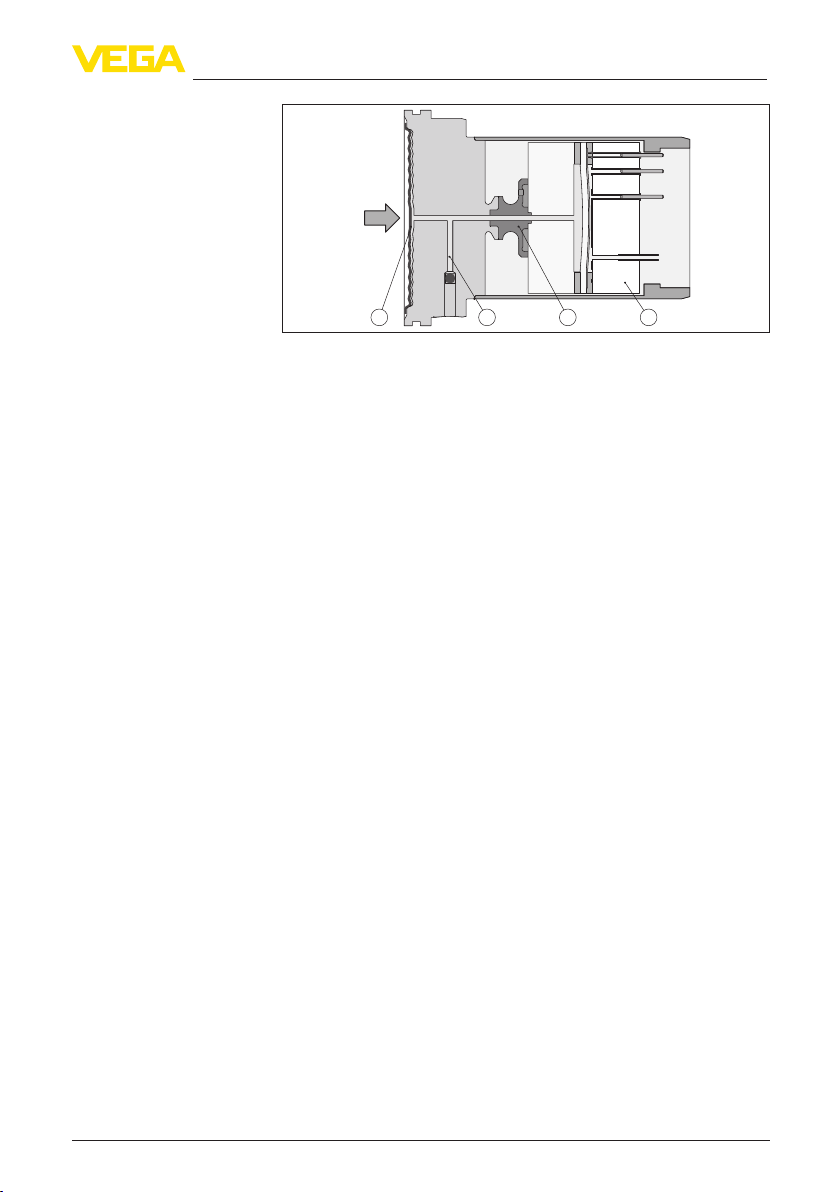

4321

Fig. 3: Conguration of the METEC® measuring cell with VEGABAR 87

1 Process diaphragm

2 Isolating liquid

3 FeNi adapter

4 CERTEC® measuring cell

Pressure types

Measuring system

The measuring cell design depends on the selected pressure type.

Relative pressure: the measuring cell is open to atmosphere. The

ambient pressure is detected in the measuring cell and compensated.

It thus has no inuence on the measured value.

Absolute pressure: the measuring cell is evacuated and encapsulated. The ambient pressure is not compensated and does hence

inuence the measured value.

Relative pressure, climate-compensated: the measuring cell is

evacuated and encapsulated. The ambient pressure is detected

through a reference sensor in the electronics and compensated. It

thus has no inuence on the measured value.

The process pressure acts on the sensor element via the stainless

steel diaphragm and an internal transmission liquid. The process

pressure causes a resistance change which is converted into a corresponding output signal and outputted as measured value.

The METEC® measuring cell is the measuring unit. It consists of

the ceramic-capacitive CERTEC® measuring cell and a special,

temperature-compensated isolating system.

45053-EN-131011

10

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 11

Packaging

3 Product description

4321

Fig. 4: Conguration of the METEC® measuring cell with VEGABAR 87

1 Process diaphragm

2 Isolating liquid

3 FeNi adapter

4 CERTEC® measuring cell

3.3 Packaging, transport and storage

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

based on ISO 4180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE

foil is also used. Dispose of the packaging material via specialised

recycling companies.

Transport

Transport inspection

Storage

Storage and transport

temperature

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

Transport must be carried out in due consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or concealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

Not in the open

•

Dry and dust free

•

Not exposed to corrosive media

•

Protected against solar radiation

•

Avoiding mechanical shock and vibration

•

Storage and transport temperature see chapter "Supplement -

•

Technical data - Ambient conditions"

Relative humidity 20 … 85 %

•

11

Page 12

3 Product description

Protective cap

3.4 Accessories and replacement parts

The protective cover protects the sensor housing against soiling and

intense heat from solar radiation.

You will nd additional information in the supplementary instructions

manual "Protective cover" (Document-ID 34296).

Flanges

Welded socket

Electronics module

Screwed anges are available in dierent versions according to the

following standards: DIN 2501, EN 1092-1, BS 10, ANSI B 16.5,

JIS B 2210-1984, GOST 12821-80.

You can nd additional information in the supplementary instructions

manual "Flanges according to DIN-EN-ASME-JIS" (Document-ID

31088).

Welded sockets are used to connect the sensors to the process.

You can nd further information in the supplementary instructions

"Welded socket VEGABAR series 80" (Document-ID 45082).

The electronics module VEGABAR series 80 is a replacement part

for pressure transmitters of VEGABAR series 80. There is a dierent

version available for each type of signal output.

You can nd further information in the operating instructions "Elec-

tronics module VEGABAR series 80" (Document-ID 45054).

12

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 13

Suitability for the process

conditions

4 Mounting

4 Mounting

4.1 General instructions to use the instrument

Make sure that all parts of the instrument exposed to the process are

suitable for the existing process conditions.

These are mainly:

Active measuring component

•

Process tting

•

Process seal

•

Process conditions are particularly:

Process pressure

•

Process temperature

•

Chemical properties of the medium

•

Abrasion and mechanical inuences

•

You can nd the specications of the process conditions in chapter

"Technical data" as well as on the nameplate.

Protection against moisture

Screwing in

Vibrations

Temperature limits

Protect your instrument further through the following measures

against moisture penetration:

Use the recommended cable (see chapter "Connecting to power

•

supply")

Tighten the cable gland

•

Loop the connection cable downward in front of the cable gland

•

This applies particularly to:

Outdoor mounting

•

Installations in areas where high humidity is expected (e.g. through

•

cleaning processes)

Installations on cooled or heated vessels

•

On instruments with process tting thread, the hexagon must be tightened with a suitable screwdriver. Wrench size see chapter "Dimen-

sions".

Warning:

The housing must not be used to screw the instrument in! Applying

tightening force can damage internal parts of the housing.

In case of strong vibrations at the mounting location, the instrument

version with external housing should be used. See chapter "External

housing".

Higher process temperatures often mean also higher ambient

temperatures. Make sure that the upper temperature limits stated in

chapter "Technical data" for the environment of the electronics hous-

ing and connection cable are not exceeded.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

13

Page 14

4 Mounting

Filter elements

2

1

Fig. 5: Temperature ranges

1 Process temperature

2 Ambient temperature

4.2 Ventilation and pressure compensation

Ventilation and pressure compensation are carried out with VEGABAR 87 via a lter element. It is air permeable and moisture-

blocking.

Caution:

The lter element causes a time-delayed pressure compensation.

When quickly opening/closing the housing cover, the measured value

can change for approx. 5 s by up to 15 mbar.

For eective ventilation, the lter element must always be free of

buildup.

Caution:

Do not use a high-pressure cleaner. The lter element could be damaged, which would allow moisture into the housing.

The following paragraphs describe how the lter element is arranged

in the dierent instrument versions.

Instruments in non-Ex

and Ex-ia version

14

The lter element is mounted into the electronics housing. It has the

following functions:

Ventilation electronics housing

•

Atmospheric pressure compensation (with relative pressure meas-

•

uring ranges)

VEGABAR 87 • Slave sensor for electronic dierential pressure

45053-EN-131011

Page 15

4 Mounting

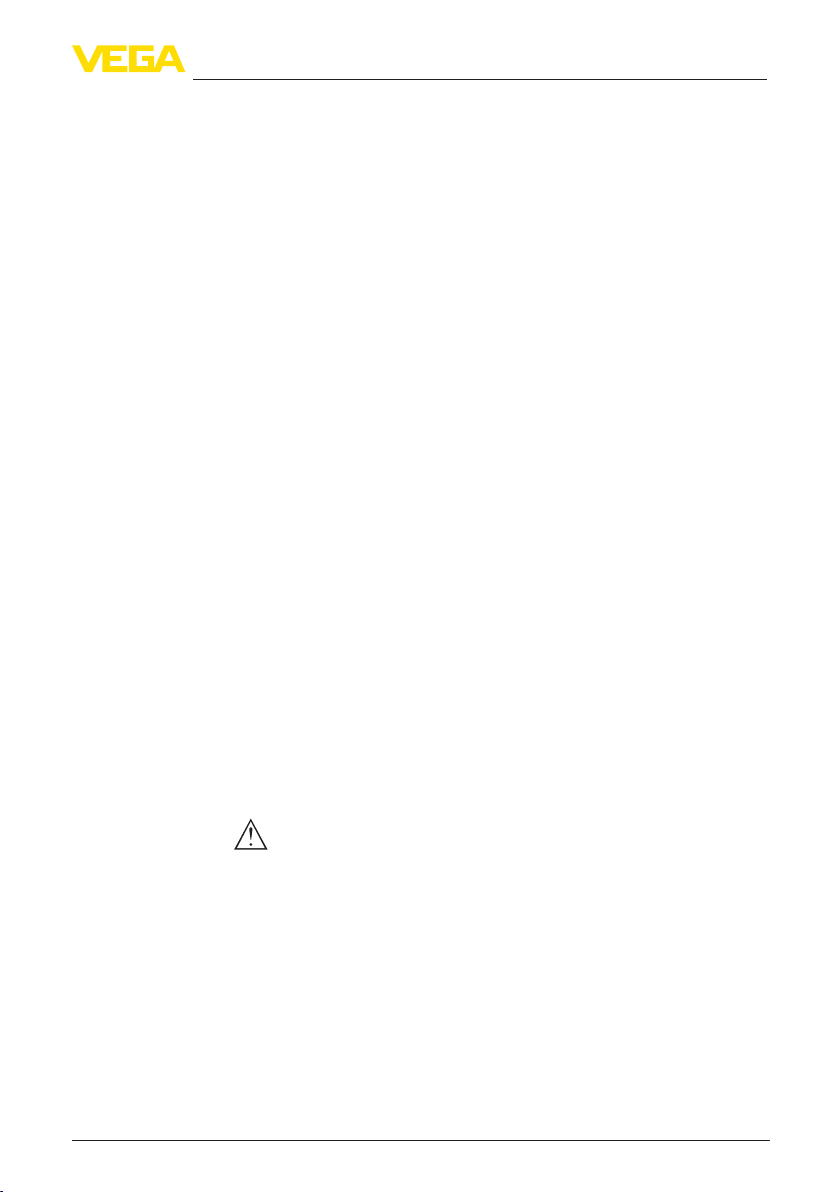

4 4 4

1 2 3

Fig. 6: Position of the lter element - non-Ex, Ex-ia version

1 Housing plastic, stainless steel precision casting

2 Housing aluminium

3 Housing stainless steel, electropolished

4 Filter element

With the following instruments a blind plug is installed instead of the

lter element:

Instruments in protection IP 66/IP 68 (1 bar) - ventilation via capil-

•

laries in x connected cable

Instruments with absolut pressure

•

Instruments in IP 69K

version

The lter element is mounted into the electronics housing. It has the

following functions:

Ventilation electronics housing

•

Atmospheric pressure compensation (with relative pressure meas-

•

uring ranges)

1

Fig. 7: Position of the lter element - IP 69K version

1 Filter element

Instruments with absolute pressure have a blind plug mounted

instead of the lter element.

4.3 Combination Master - Slave

In principle, any sensor combination within the VEGABAR 80 series is

allowed. The following requirements must be fullled:

Conguration, Master sensor suitable for electronic dierential

•

pressure

Pressure type is identical for both sensors, i.e. relative pressure/

•

relative pressure or absolute pressure/absolute pressure

The master sensor must always measure the higher pressure

•

Measurement setup as shown in the following chapters

•

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

15

Page 16

4 Mounting

Measurement setup

4.4 Dierentialpressuremeasurement

With the Master/Slave combination, a gauge dierent measurement

can be realized.

Measurement setup

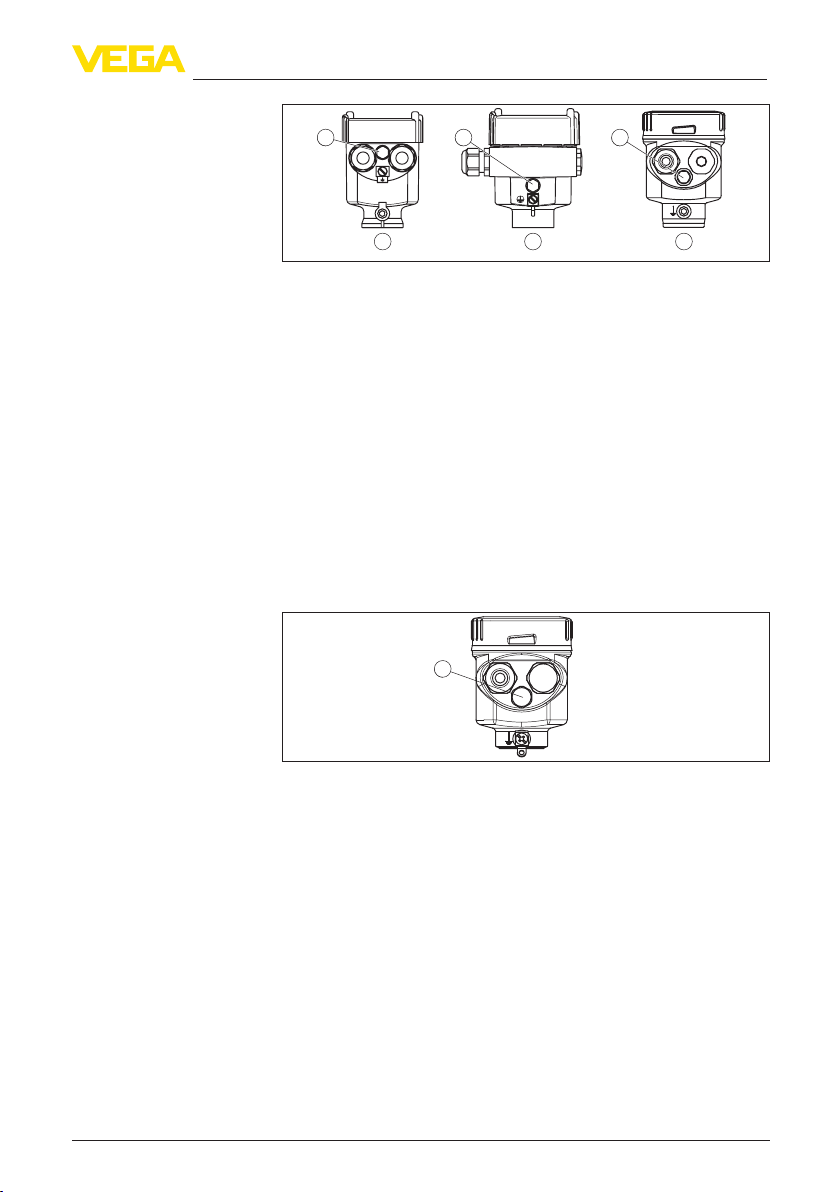

1

Fig. 8: Measurement setup with a level dierence measurement

2

3

4.5 Interface measurement

With the Master/Slave combination also an interface measurement

can be realised.

Requirements for a functioning measurement are:

Vessel with changing level

•

Products with steady densities

•

Interface always between the measurement points

•

Total level always above the upper measurement point

•

16

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 17

4 Mounting

Measurement setup

1

Fig. 9: Measurement setup with interface measurement, h = distance between

the two measuring points

1 VEGABAR 87

2 VEGABAR 87 - Slave sensor

The interface measurement is possible in open as well as in closed

vessels.

2

0,8

1,0

h

4.6 Density measurement

With the Master/Slave combination also a density measurement can

be realised.

Requirements for a functioning measurement are:

Vessel with changing level

•

Product with consistent density

•

Distance between the measurement points as large as possible

•

Level always above the upper measuring point

•

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

17

Page 18

4 Mounting

1

Fig. 10: Measurement setup with density measurement, h = distance between

the two measuring points

1 VEGABAR 87

2 VEGABAR 87 - Slave sensor

2

h

Density measurement is possible in open as well as in closed vessels. Small changes in the density cause only small changes in the

measured dierential pressure. So a suitable measuring range has to

be selected.

18

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 19

Conguration

Mounting

4 Mounting

4.7 External housing

1

2

3

4

Fig. 11: Arrangement measurement loop, external housing

1 Vessel

2 Sensor

3 Connection cable sensor - external housing

4 External housing

5 Signal cable

1. Mark the holes according to the following drilling template

2. Fasten wall mounting plate with 4 screws

90 mm

(3.54")

70 mm

(2.76")

3mm

(0.12")

8 mm

(0.32")

(3.66")

(4.33")

93 mm

110 mm

Fig. 12: Drilling template - wall mounting plate

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

R 3,5 mm

(0.14")

19

Page 20

5 Connecting to power supply

Safety instructions

5 Connecting to power supply

5.1 Preparing the connection

Always keep in mind the following safety instructions:

Connect only in the complete absence of line voltage

•

If overvoltage surges are expected, overvoltage arresters should

•

be installed

Voltage supply

Cable gland ½ NPT

Connection technology

Connection procedure

The voltage supply and the signal transmission are carried out via the

four-wire, screened connection cable from the master sensor.

You can nd the data for this signal circuit in chapter "Technical data".

With plastic housing, the NPT cable gland or the Conduit steel tube

must be screwed without grease into the threaded insert.

Max. torque for all housings see chapter "Technical data".

5.2 Connecting

The voltage supply and signal output are connected via the spring-

loaded terminals in the housing.

The connection to the display and adjustment module or to the interface adapter is carried out via contact pins in the housing.

Information:

The terminal block is pluggable and can be removed from the

electronics. To do this, lift the terminal block with a small screwdriver

and pull it out. When reinserting the terminal block, you should hear it

snap in.

Proceed as follows:

1. Unscrew the housing cover

2. If a display and adjustment module is installed, remove it by turning it slightly to the left.

3. Loosen compression nut of the cable entry

4. Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) of insulation from the ends of the individual wires

5. Insert the cable into the sensor through the cable entry

20

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 21

5 Connecting to power supply

Fig. 13: Connection steps 5 and 6

6. Insert the wire ends into the terminals according to the wiring plan

Information:

Solid cores as well as exible cores with wire end sleeves are inserted directly into the terminal openings. In case of exible cores without

end sleeves, press the terminal from above with a small screwdriver;

the terminal opening is freed. When the screwdriver is released, the

terminal closes again.

You can nd further information on the max. wire cross-section under

"Technical data/Electromechanical data"

7. Check the hold of the wires in the terminals by lightly pulling on

them

8. Connect the screen to the internal ground terminal, connect the

outer ground terminal to potential equalisation

9. Tighten the compression nut of the cable entry. The seal ring must

completely encircle the cable

10. Reinsert the display and adjustment module, if one was installed

11. Screw the housing cover back on

The electrical connection is hence nished.

5.3 Single chamber housing

The following illustration applies to the non-Ex, Ex-ia and Ex-d ver-

sion.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

21

Page 22

5 Connecting to power supply

Electronics and connection compartment

Master

Overview

5678

4

1

2

Fig. 14: Wiring plan VEGABAR 87 Slave sensor

1 To the sensor

2 Ground terminal for connection of the cable screen

1)

5.4 External housing with version IP 68 (25 bar)

22

Fig. 15: VEGABAR 87 in IP 68 version 25 bar, non-Ex and axial cable outlet,

external housing

1)

Connect screen here. Connect ground terminal on the outside of the housing

to ground as prescribed. The two terminals are galvanically connected.

VEGABAR 87 • Slave sensor for electronic dierential pressure

45053-EN-131011

Page 23

5

2

( )

+

(-)

6

8

A

Electronics and connection compartment for

power supply

Terminal compartment,

housing socket

5 Connecting to power supply

1

4...20m

1

2

3

Fig. 16: Electronics and connection compartment

1 Electronics module

2 Cable gland for voltage supply

3 Cable gland for connection cable, transmitter

45053-EN-131011

1234

5

Fig. 17: Connection of the sensor in the housing base

1 Yellow

2 White

3 Red

4 Black

5 Shielding

6 Breather capillaries

VEGABAR 87 • Slave sensor for electronic dierential pressure

2

341

6

23

Page 24

5 Connecting to power supply

Electronics and connection compartment

Master

Connection example,

slave sensor

5678

4

1

2

Fig. 18: Wiring plan VEGABAR 87 Slave sensor

1 To the sensor

2 Ground terminal for connection of the cable screen

2)

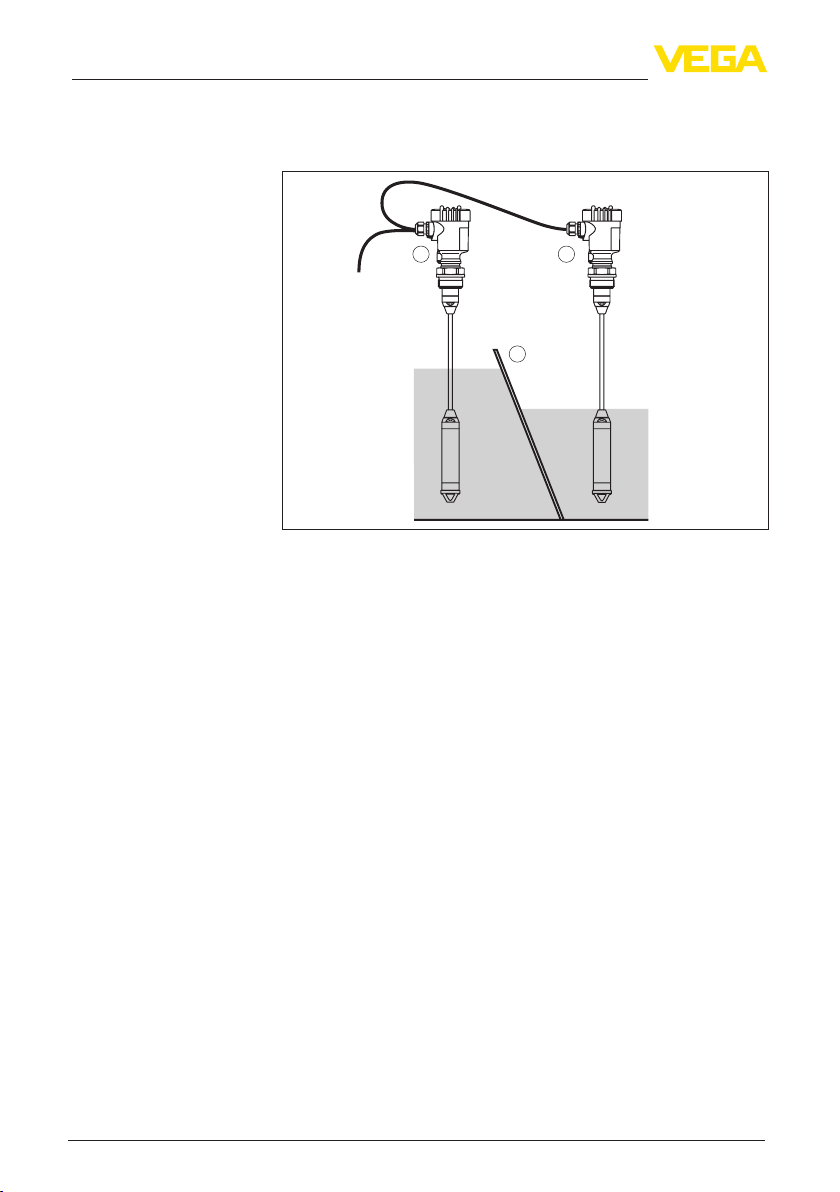

5.5 Connection example

4...20mA

( )

+

(-)

1

2

5

678

3

4

1

Fig. 19: Connection example VEGABAR 87 slave sensor

1 VEGABAR 87

2 VEGABAR 87 slave sensor

3 Connection cable

4 Supply and signal circuit VEGABAR 87

The connection between VEGABAR 87 and the VEGABAR 87 slave

sensor is made with a standard cable according to the chart:

VEGABAR 87 Slave sensor

Terminal 5 Terminal 5

Terminal 6 Terminal 6

Terminal 7 Terminal 7

Terminal 8 Terminal 8

5678

4

2

24

2)

Connect screen here. Connect ground terminal on the outside of the housing

to ground as prescribed. The two terminals are galvanically connected.

VEGABAR 87 • Slave sensor for electronic dierential pressure

45053-EN-131011

Page 25

Presettings

6 Set up with the display and adjustment module

6 Set up with the display and adjustment

module

6.1 Parameter adjustment - Quick setup

To quickly and easily adapt the sensor to the application, select

the menu item "Quick setup" in the start graphic on the display and

adjustment module.

Carry out the following steps in the sequence specied below. The

presettings apply to all applications.

You can nd "Extended adjustment" in the next sub-chapter.

1. Measurement loop name

In the rst menu item you assign a suitable measurement loop name.

Permitted are names with max. 19 characters.

2. Application

In this menu item you activate/deactivate the slave sensor for electronic dierential pressure and select the application.

Note:

It is absolutely necessary to activate the slave sensor in advance to

have the applications displayed in the electronic dierential pressure

measurement menus.

3. Units

In this menu item you determine the adjustment and temperature

units of the instrument. Depending on the selected application in the

menu item "Application", dierent adjustment units are available.

Quick setup - Level measurement

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

4. Unit, static pressure

In this menu item, you determine the unit of the static, i.e. superimposed pressure.

5. Position correction

In this menu item you compensate the inuence of the installation

position of the instrument (oset) to the measured value.

6. Min. adjustment

In this menu item you carry out the min. adjustment for level.

Enter the percentage value and the corresponding pressure value for

the min. level.

7. Max. adjustment

In this menu item you carry out the max. adjustment for level.

25

Page 26

6 Set up with the display and adjustment module

Enter the percentage value and the corresponding pressure value for

the max. level.

The quick setup for level measurement is nished.

Quick setup - Flow measurement

4. Position correction

In this menu item you compensate the inuence of the installation

position of the instrument (oset) to the measured value.

5. Min. adjustment

In this menu item you carry out the min. adjustment for ow.

Enter the percentage value and the corresponding pressure value for

the min. ow.

6. Max. adjustment

In this menu item you carry out the max. adjustment for ow.

Enter the percentage value and the corresponding pressure value for

the max. ow.

7. Linearization

In this menu item, you select the characterics of the output signal.

Quicksetup-Dierential

pressure measurement

26

The quick setup for ow measurement is nished.

4. Unit, static pressure

In this menu item, you determine the unit of the static, i.e. superimposed pressure.

5. Position correction

In this menu item you compensate the inuence of the installation

position of the instrument (oset) to the measured value.

6. zero adjustment

In this menu item you carry out the zero adjustment for the dierential

pressure.

Enter the respective pressure value for 0 %.

7. span adjustment

In this menu item you carry out the span adjustment for the dierential

pressure

Enter the respective pressure value for 100 %.

VEGABAR 87 • Slave sensor for electronic dierential pressure

45053-EN-131011

Page 27

Quick setup - Density

measurement

Quick setup - Interface

measurement

6 Set up with the display and adjustment module

The quick setup for dierential pressure measurement is nished.

4. Unit, static pressure

In this menu item, you determine the unit of the static, i.e. superimposed pressure.

5. Position correction

In this menu item you compensate the inuence of the installation

position of the instrument (oset) to the measured value.

6. Distance

In this menu item, you enter the installation distance between master

and slave sensor.

7. Min. adjustment

In this menu item you carry out the min. adjustment for density.

Enter the percentage value and the corresponding density value for

the min. density.

8. Max. adjustment

In this menu item you carry out the max. adjustment for density.

Enter the percentage value and the corresponding density value for

the max. density.

The quick setup for density measurement is nished.

4. Unit, static pressure

In this menu item, you determine the unit of the static, i.e. superimposed pressure.

5. Position correction

In this menu item you compensate the inuence of the installation

position of the instrument (oset) to the measured value.

6. Distance

In this menu item, you enter the installation distance between master

and slave sensor.

7. Min. adjustment

In this menu item, you carry out the adjustment for the min. height of

the interface.

Enter the percentage value and the corresponding height of the

interface.

8. Max. adjustment

In this menu item, you carry out the adjustment for the max. height of

the interface.

Enter the percentage value and the corresponding height of the

interface.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

27

Page 28

6 Set up with the display and adjustment module

The quick setup for interface measurement is nished.

6.2 Parameter adjustment - Extended adjustment

For technically demanding measurement loops you can carry out

extended settings in "Extended adjustment".

Main menu

The main menu is divided into ve sections with the following functions:

Setup: Settings, e.g., for measurement loop name, application, units,

position correction, adjustment, signal output

Display: Settings, e.g., for language, measured value display, lighting

Diagnosis: Information, e.g. on instrument status, pointer, measure-

ment reliability, simulation

Additional adjustments: PIN, date/time, reset, copy function

Info: Instrument name, hardware and software version, date of manu-

facture, sensor features

In the main menu item "Setup", the individual submenu items should

be selected one after the other and provided with the correct parameter values.

The following submenu points are available:

In the following section, the menu items from the menu "Setup" for

electronic dierential pressure measurement are described in detail.

Depending on the selected application, dierent sections are relevant.

Information:

Further menu items of the menu "Setup" as well as the complete

menus "Display", "Diagnosis", "Additional adjustments" and "Info"

are described in the operating instructions of the respective master

sensor.

45053-EN-131011

Setup - Application

28

In this menu item you activate/deactivate the slave sensor for electronic dierential pressure and select the application.

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 29

6 Set up with the display and adjustment module

The following applications are available:

Level

•

Flow

•

Dierential pressure

•

Density

•

Interface

•

Note:

It is absolutely necessary to activate the slave sensor in advance to

have the applications displayed in the electronic dierential pressure

measurement menus.

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

Setup - Units

Setup - Position correction

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

In this menu item, you determine the units for the "Min. adjustment/

zero" and "Max. adjustment/span" as well as the static pressure.

If the level should be adjusted in a height unit, the density of the medium must also be entered later during the adjustment.

In addition, the unit for the measuring cell and electronics temperature

is determined in the menu item "Peak values".

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

Particularly with chemical seal systems, the installation position of

the instrument can shift the measured value (oset). The position

correction compensates this oset. Hence the actual measured value

is accepted automatically. With relative pressure measuring cells also

a manual oset can be carried out. With a master/slave combination,

the position correction is carried out for both sensors.

If the actual measured value should be taken over as correction value

during automatic position correction, this value must not be inuenced by product coverage or static pressure.

With the manual position correction, the oset value can be determined by the user. Select for this purpose the function "Edit" and

enter the requested value.

29

Page 30

6 Set up with the display and adjustment module

Save your settings with [OK] and move with [ESC] and [->] to the

next menu item.

After the position correction is carried out, the actual measured value

is corrected to 0. The corrective value appears with an inverse sign as

oset value in the display.

The position correction can be repeated as often as necessary. How-

ever, if the sum of the corrective values exceeds 20 % of the nominal

measuring range, then no position correction is possible.

Parameterization example

VEGABAR 87 always measures pressure independently of the process variable selected in the menu item "Application". To output the

selected process variable correctly, an allocation to 0 % and 100 % of

the output signal must be carried out (adjustment).

With the application "Interface" the hydrostatic pressure at min. and

max. height of the interface is entered for adjustment. See the follow-

ing example:

100%

2

0,8

1,0

Fig. 20: Parameter adjustment example "Min./max. adjustment, interface

measurement"

1 Min. interface = 0 % correspond to 0.0 mbar

2 Max. interface = 100 % correspond to 490.5 mbar

3 VEGABAR 87

4 VEGABAR 87 - Slave sensor

")

2 m

(78.74

h

0%

1

If these values are not known, an adjustment with interface layers of

for example 10 % and 90 % is also possible. By means of these settings, the layer of the actual interface is then calculated.

The real product level during the adjustment is not important,

because the adjustment is always carried out without changing the

product level. These settings can be made ahead of time without the

instrument having to be installed.

45053-EN-131011

30

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 31

6 Set up with the display and adjustment module

Note:

If the adjustment ranges are exceeded, the entered value will not be

accepted. Editing can be interrupted with [ESC] or corrected to a

value within the adjustment ranges.

Setup - Min. adjustment

Level

Setup - Max. adjustment

Level

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Adjustment", then "Min.

adjustment" and conrm with [OK].

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value (e.g. 10 %) with [+] and save

with [OK]. The cursor jumps now to the pressure value.

4. Enter the pressure value corresponding to the min. level (e.g.

0 mbar).

5. Save settings with [OK] and move with [ESC] and [->] to the max.

adjustment.

The min. adjustment is nished.

For an adjustment with lling, simply enter the actual measured value

indicated at the bottom of the display.

Proceed as follows:

1. Select with [->] the menu item "Max. adjustment" and conrm

with [OK].

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value (e.g. 90 %) with [+] and save

with [OK]. The cursor jumps now to the pressure value.

4. Enter the pressure value for the full vessel (e.g. 900 mbar) corresponding to the percentage value.

5. Save settings with [OK]

The max. adjustment is nished.

For an adjustment with lling, simply enter the actual measured value

indicated at the bottom of the display.

Setup - Min. adjustment,

ow

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Min. adjustment" and conrm

with [OK].

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

31

Page 32

6 Set up with the display and adjustment module

2. Edit the mbar value with [OK] and set the cursor to the requested

position with [->].

3. Set the requested mbar value with [+] and store with [OK].

4. Change with [ESC] and [->] to the span adjustment

The min. adjustment is nished.

For an adjustment with pressure, simply enter the actual measured

value indicated at the bottom of the display.

Setup - Max. adjustment,

ow

Setup - zero adjustment,

dierentialpressure

Proceed as follows:

1. Select with [->] the menu item "Max. adjustment" and conrm

with [OK].

2. Edit the mbar value with [OK] and set the cursor to the requested

position with [->].

3. Set the requested mbar value with [+] and store with [OK].

The max. adjustment is nished.

For an adjustment with pressure, simply enter the actual measured

value indicated at the bottom of the display.

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "zero adjustment" and conrm

with [OK].

2. Edit the mbar value with [OK] and set the cursor to the requested

position with [->].

3. Set the requested mbar value with [+] and store with [OK].

4. Change with [ESC] and [->] to the span adjustment

The zero adjustment is nished.

Information:

The zero adjustment shifts the value of the span adjustment. The

span, i.e. the dierence between these values, however, remains

unchanged.

For an adjustment with pressure, simply enter the actual measured

value indicated at the bottom of the display.

45053-EN-131011

32

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 33

6 Set up with the display and adjustment module

Setup - span adjustment,

dierentialpressure

Setup - Distance, density

Proceed as follows:

1. Select with [->] the menu item "Span adjustment" and conrm

with [OK].

2. Edit the mbar value with [OK] and set the cursor to the requested

position with [->].

3. Set the requested mbar value with [+] and store with [OK].

The span adjustment is nished.

For an adjustment with pressure, simply enter the actual measured

value indicated at the bottom of the display.

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Distance" and conrm with

[OK].

2. Edit the sensor distance with [OK] and set the cursor to the

requested position with [->].

3. Set the requested distance with [+] and store with [OK].

The adjustment of the distance is hence nished.

Setup - Min. adjustment,

density

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Min. adjustment" and conrm

with [OK].

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the density value.

4. Enter the min. distance suitable for the percentage value.

5. Save settings with [OK] and move with [ESC] and [->] to the max.

adjustment.

The min. adjustment for density is nished.

Setup - Max. adjustment,

Proceed as follows:

density

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

33

Page 34

6 Set up with the display and adjustment module

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Max. adjustment" and con-

rm with [OK].

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the density value.

4. Enter the max. density value matching the percentage value.

The max. adjustment for density is nished.

Setup - Min. adjustment Interface

Setup - Max. adjustment Interface

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Min. adjustment" and conrm

with [OK].

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the height value.

4. Enter the min. height of the interface suitable for the percentage

value.

5. Save settings with [OK] and move with [ESC] and [->] to the max.

adjustment.

The min. adjustment, interface is hence nished.

Proceed as follows:

1. Select the menu item "Setup" with [->] and conrm with [OK].

Now select with [->] the menu item "Max. adjustment" and con-

rm with [OK].

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value with [+] and save with [OK].

The cursor jumps now to the height value.

4. Enter the max. height of the interface matching the percentage

value.

The max. adjustment for interface is nished.

45053-EN-131011

34

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 35

6 Set up with the display and adjustment module

Additional adjustments

- Reset

With a reset, certain parameter adjustments carried out by the user

are reset.

The following reset functions are available:

Delivery status: Restoring the parameter settings at the time of

shipment from the factory incl. the order-specic settings. A user-programmable linearization curve as well as the measured value memory

will be deleted.

Basic settings: Resetting the parameter settings incl. special

parameters to the default values of the respective instrument. A user

programmable linearization curve as well as the measured value

memory is deleted.

The following table shows the default values of the instrument. De-

pending on the instrument version or application, all menu items may

not be available or some may be dierently assigned:

Reset - Setup

Menu item Parameter Default value

Measurement

loop name

Application Slave for elec-

tronic dierential

pressure

Application No reset

Units Unit of measure-

ment

Static pressure bar

Position correction

Adjustment Distance (with

density and interface)

Zero/Min. adjustment

Span/Max. adjustment

Damping Integration time 0.0 s

Linearization Linear

Sensor

No reset

mbar (with nominal measuring range

≤400 mbar)

bar (with nominal measuring rang-

es ≥1 bar)

0.00 bar

1.00 m

0.00 bar

0.00 %

Nominal measuring range in bar

100.00 %

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

35

Page 36

6 Set up with the display and adjustment module

Menu item Parameter Default value

Current output Current output -

Lock adjustment Last setting

Reset - Display

Menu item Default value

Menu language Order-specic

Displayed value 1 Current output in %

Displayed value 2 Measuring cell temperature in °C

Backlight Switched o

Reset - Diagnosis

Menu item Parameter Default value

Sensor status -

Peak value Pressure Actual measured value

Simulation -

Mode

Current output Min./Max.

Temperature Actual temperature values from meas-

Output characteristics

4 … 20 mA

Reaction when malfunction occurs

≤ 3.6 mA

3.8 mA

20.5 mA

uring cell, electronics

36

Reset - Additional settings

Menu item Parameter Default value

PIN 0000

Date/Time Actual date/Actual time

Copy instrument

settings

Special parameters

Scaling Scaling size Volume in l

Scaling format 0 % corresponds to 0 l

Current output

HART mode Address 0

Current output - Size Lin. percent - Level

Current output - adjustment 0 … 100 % correspond to

-

No reset

100 % corresponds to 0 l

4 … 20 mA

VEGABAR 87 • Slave sensor for electronic dierential pressure

45053-EN-131011

Page 37

6 Set up with the display and adjustment module

Menu item Parameter Default value

Eective

pressure

transmitter

Unit m3/s

Adjustment 0.00 % correspond to 0.00

m3/s

100.00 %, 1 m3/s

Setup - Characteristics

values,eectivepressure

transmitter

In this menu item, the units for the eective pressure transmitter are

determined as well as the selection of mass or volume ow.

Furthermore the adjustment for the volume or mass ow rate at 0 % or

100 % is carried out.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

37

Page 38

7 Diagnosis, asset management and service

7 Diagnosis, asset management and service

7.1 Maintenance

Maintenance

Reaction when malfunctions occur

If the instrument is used properly, no special maintenance is required

in normal operation.

In some applications, product buildup on the diaphragm can inuence

the measuring result. Depending on the sensor and application, take

precautions to ensure that heavy buildup, and especially a hardening

thereof, is avoided.

7.2 Rectify faults

The operator of the system is responsible for taking suitable measures to rectify faults.

Procedure for fault recti-

cation

Reaction after fault recti-

cation

24 hour service hotline

The rst measures are:

Evaluation of fault messages, for example via the display and

•

adjustment module

Checking the output signal

•

Treatment of measurement errors

•

Further comprehensive diagnostics options are available with a PC

with PACTware and the suitable DTM. In many cases, the reasons can

be determined in this way and faults rectied.

Depending on the reason for the fault and the measures taken, the

steps described in chapter "Setup" must be carried out again or must

be checked for plausibility and completeness.

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is also available outside normal working hours, seven

days a week around the clock.

Since we oer this service worldwide, the support is provided in

English. The service itself is free of charge, the only costs involved are

the normal call charges.

7.3 Exchanging the electronics module

In case of a defect, the user can replace the electronics module with

another one of identical type.

In Ex applications, only instruments and electronics modules with appropriate Ex approval may be used.

If there is no electronics module available on site, one can be ordered

from the agency serving you.

7.4 Exchange process assembly with version

IP 68 (25 bar)

With version IP 68 (25 bar), the user can exchange the process assembly on site. Connection cable and external housing can be kept.

45053-EN-131011

38

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 39

7 Diagnosis, asset management and service

Required tools:

Hexagon socket wrench, size 2

•

Caution:

The exchange may only be carried out in the complete absence of

line voltage.

In Ex applications, only a replacement part with appropriate Ex approval may be used.

Proceed as follows when carrying out the exchange:

1. Losen the xing screw with the hexagon socket wrench

2. Carefully detach the cable assembly from the process assembly

53

4

2

1

Fig. 21: VEGABAR 87 in IP 68 version, 25 bar and lateral cable outlet, external

housing

1 Process assembly

2 Plug connector

3 Cable assembly

4 Connection cable

5 External housing

3. Loosen the plug connector

4. Mount the new process assembly on the measuring point

5. Plug the connector back in

6. Mount the cable assembly on the process assembly and turn it to

the desired position

7. Tighten the xing screw with the hexagon socket wrench

The exchange is nished.

If there is no replacement part available on site, one can be ordered

from the agency serving you.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

39

Page 40

7 Diagnosis, asset management and service

The necessary serial number can be found on the type label of the

instrument or on the delivery note.

7.5 How to proceed in case of repair

You can nd a repair form as well as detailed information on how to

proceed under www.vega.com/downloads and "Forms and certi-

cates".

By doing this you help us carry out the repair quickly and without having to call back for needed information.

If a repair is necessary, please proceed as follows:

Print and ll out one form per instrument

•

Clean the instrument and pack it damage-proof

•

Attach the completed form and, if need be, also a safety data

•

sheet outside on the packaging

Please contact the agency serving you to get the address for

•

the return shipment. You can nd the agency on our home page

www.vega.com.

40

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 41

8 Dismounting

8 Dismounting

8.1 Dismounting steps

Warning:

Before dismounting, be aware of dangerous process conditions such

as e.g. pressure in the vessel or pipeline, high temperatures, corrosive or toxic products etc.

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

8.2 Disposal

The instrument consists of materials which can be recycled by specialised recycling companies. We use recyclable materials and have

designed the parts to be easily separable.

Correct disposal avoids negative eects on humans and the environ-

ment and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/EG and

the respective national laws. Pass the instrument directly on to a specialised recycling company and do not use the municipal collecting

points. These may be used only for privately used products according

to the WEEE directive.

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

41

Page 42

9 Supplement

9 Supplement

9.1 Technical data

Materials and weights

Materials, wetted parts

Process tting 316L

Transmitter 316L

Suspension cable FEP

Seal, suspension cable FKM, FEP

Connection tube 316L

Diaphragm Hastelloy C276

Protective cap PFA

Seal for process tting (in the scope of delivery)

Ʋ Thread G1½ (DIN 3852-A) Klingersil C-4400

Ʋ Threaded tting Klingersil C-4400

Materials, non-wetted parts

Isolating liquid Essomarcal (med. white oil, FDA-approved)

Straining clamp 1.4301

Threaded tting 316L

Electronics housing Plastic PBT (polyester), Alu die-casting powder-coated,

External housing plastic PBT (Polyester), 316L

Socket, wall mounting plate external

housing

Seal between base and wall mounting

plate

Seal, housing cover NBR (stainless steel housing), silicone (Alu/plastic hous-

Inspection window in housing cover for

display and adjustment module

Ground terminal 316Ti/316L

Connection cable between transmitter

and external electronics housing with

IP 68 (25 bar) version

Type label support on connection cable PE hard

Connection cable with IP 68 (1 bar)

version

Connection cable, master and slave

sensor

Weights

Basic weight 0.7 kg (1.543 lbs)

Suspension cable 0.1 kg/m (0.07 lbs/ft)

Connection tube 1.5 kg/m (1 lbs/ft)

316L

plastic PBT (Polyester), 316L

EPDM (xed connected)

ing)

Polycarbonate (UL-746-C listed)

PE, PUR

PE

PE, PUR

45053-EN-131011

42

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 43

9 Supplement

Straining clamp 0.2 kg (0.441 lbs)

Threaded tting 0.4 kg (0.882 lbs)

Input variable

Adjustment

Adjustment range of the min./max. adjustment relating to the nominal measuring range:

Ʋ Percentage value -10 … 110 %

Ʋ Pressure value -20 … 120 %

Adjustment range of the zero/span adjustment relating to the nominal measuring range:

Ʋ zero -20 … +95 %

Ʋ span -120 … +120 %

3)

Ʋ Dierence between zero and span max. 120 % of the nominal range

Recommended max. turn down 20 : 1 (no limitation)

Nominal measuring ranges and overload capability in bar/kPa

The specications are only an overview and refer to the measuring cell. Limitations due to the

material and version of the process tting as well as the selected pressure type are possible. The

specications on the nameplate apply.

Nominal range Overload capacity, max.

pressure

Gauge pressure

0 … +0.1 bar/0 … +10 kPa +15 bar/+1500 kPa -0.2 bar/-20 kPa

0 … +0.4 bar/0 … +40 kPa +30 bar/+3000 kPa -0.8 bar/-80 kPa

0 … +1 bar/0 … +100 kPa +35 bar/+3500 kPa -1 bar/-100 kPa

0 … +2.5 bar/0 … +250 kPa +50 bar/+5000 kPa -1 bar/-100 kPa

0 … +10 bar/0 … +1000 kPa +90 bar/+9000 kPa -1 bar/-100 kPa

0 … +25 bar/0 … +2500 kPa +130 bar/+13000 kPa -1 bar/-100 kPa

Absolute pressure

0 … 1 bar/0 … 100 kPa 35 bar/3500 kPa 0 bar abs.

0 … 2.5 bar/0 … 250 kPa 50 bar/5000 kPa 0 bar abs.

0 … 10 bar/0 … 1000 kPa 90 bar/9000 kPa 0 bar abs.

0 … 25 bar/0 … 2500 kPa 130 bar/13000 kPa 0 bar abs.

Overload capacity, min. pressure

Nominal measuring ranges and overload capacity in psi

The specications are only an overview and refer to the measuring cell. Limitations due to the

material and version of the process tting as well as the selected pressure type are possible. The

specications on the nameplate apply.

Nominal range Overload capacity, max.

Gauge pressure

0 … +1.5 psig +225 psig -2.901 psig

3)

Values less than -1 bar cannot be set.

45053-EN-131011

pressure

Overload capacity, min. pressure

VEGABAR 87 • Slave sensor for electronic dierential pressure

43

Page 44

9 Supplement

Nominal range Overload capacity, max.

pressure

0 … +5 psig +435 psig -11.60 psig

0 … +15 psig +510 psig -14.51 psig

0 … +30 psig +725 psig -14.51 psig

0 … +150 psig +1300 psig -14.51 psig

0 … +300 psig +1900 psig -14.51 psig

Absolute pressure

0 … 15 psi 510 psi 0 psi

0 … 30 psi 725 psi 0 psi

0 … 150 psi 1300 psi 0 psi

0 … 300 psi 1900 psi 0 psi

Overload capacity, min. pressure

Reference conditions and actuating variables (according to DIN EN 60770-1)

Reference conditions according to DIN EN 61298-1

Ʋ Temperature +15 … +25 °C (+59 … +77 °F)

Ʋ Relative humidity 45 … 75 %

Ʋ Air pressure 860 … 1060 mbar/86 … 106 kPa (12.5 … 15.4 psig)

Determination of characteristics Limit point adjustment according to IEC 61298-2

Characterstic curve Linear

Reference installation position upright, diaphragm points downward

Inuence of the installation position < 0.2 mbar/20 Pa (0.003 psig)

Deviation (according to IEC 60770)

Specications refer to the set span. Turn down (TD) is the ratio: nominal measuring range/set span.

Accuracy class Non-linearity, hysteresis and re-

peatability with TD 1 : 1 up to 5 : 1

0.1 % < 0.1 % < 0.02 % x TD

Non-linearity, hysteresis and repeatability with 5 : 1

Inuenceoftheproductorambienttemperature

Thermal change zero signal and output span

Turn down (TD) is the relation nominal measuring range/adjusted span.

Ceramic/Metal measuring cell - Standard

Medium or ambient temperature T

-40 … 0 °C (-40 … +32 °F) < {0.15 % + 0.015 %/K x (-T)} x {0.5+0.5 x TD}

0 … 40 °C (+32 … +104 °F) < {0.0075 %/K x (T - 20 °C)} x {0.5+0.5 x TD}

40 … 100 °C (+104 … +212 °F) < {0.15 % } x {0.5+0.5 x TD}

100 … 120 °C (+212 … +248 °F) < {0.15 % + 0.005 %/K x (T - 100 °C)} x {0.5+0.5 x TD}

Ceramic/Metal measuring cell - climate-compensated

Compensated temperature range 0 … +100 °C (+32 … +212 °F)

44

VEGABAR 87 • Slave sensor for electronic dierential pressure

45053-EN-131011

Page 45

9 Supplement

Non-compensated temperature range -40 … 0 °C (-40 … +32 °F), -100 … 130 °C

(212 … +276 °F)

Nominal measuring range in bar/

kPa

0 … 10 bar/0 … 1000 kPa 0 … 150 psig

0 … 25 bar/0 … 2500 kPa 0 … 350 psig

0 … 1 bar/0 … 100 kPa 0 … 15 psig

0 … 2.5 bar/0 … 250 kPa 0 … 35 psig

0 … 0.4 bar/0 … 40 kPa 0 … 6 psig < {0.15 % + 0.4 x

Nominal measuring

range in psig

In the compensated

temperature range

< {0.05 % + 0.1 x

(0.5+0.5 x TD)}

< {0.1 % + 0.2 x

(0.5+0.5 x TD)}

(0.5+0.5 x TD)}

In the non-compensated temperature

range

< {0.1 % + 0.15 x

(0.5+0.5 x TD)}

< {0.1 % + 0.3 x

(0.5+0.5 x TD)}

< {0.15 % + 0.6 x

(0.5+0.5 x TD)}

Long-term stability (according to DIN 16086 and IEC 60770-1)

Specications refer to the set span. Turn down (TD) is the ratio: nominal measuring range/set span.

Long-term drift of the zero signal

Time period All measuring ranges Measuring range

One year < 0.05 % x TD < 0.1 % x TD

Five years < 0.1 % x TD < 0.2 % x TD

Ten years < 0.2 % x TD < 0.4 % x TD

0 … +0.025 bar/0 … +2.5 kPa

Long-term drift of the zero signal - Version climate-compensated

Nominal measuring range in bar/kPa Nominal measuring range

in psig

0 … 10 bar/0 … 1000 kPa 0 … 150 psig

0 … 25 bar/0 … 2500 kPa 0 … 350 psig

0 … 1 bar/0 … 100 kPa 0 … 15 psig

0 … 2.5 bar/0 … 250 kPa 0 … 35 psig

0 … 0.4 bar/0 … 40 kPa 0 … 6 psig < (1 % x TD)/year

Long-term drift of the zero signal

< (0.1 % x TD)/year

< (0.25 % x TD)/year

Process conditions

Product temperature

Ʋ Suspension cable -12 … +100 °C (+10 … +212 °F)

Ʋ Connection tube -12 … +100 °C (+10 … +212 °F)

Mechanical stress, depending on the instrument version

Vibration resistance

Ʋ Suspension cable 4 g at 5 … 200 Hz according to EN 60068-2-6 (vibration

with resonance)

Ʋ Connection tube 1 g (with lengths > 0.5 m (1.64 ft), the tube must be sup-

ported in addition)

Shock resistance 100 g, 6 ms according to EN 60068-2-27 (mechanical

shock)

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

45

Page 46

9 Supplement

Ambient conditions

Version Ambient temperature Storage and transport temper-

Version with connection tube -40 … +80 °C (-40 … +176 °F) -60 … +80 °C (-76 … +176 °F)

Version with suspension cable FEP -20 … +80 °C (-4 … +176 °F) -20 … +80 °C (-4 … +176 °F)

Version IP 68 (1 bar) with connection cable PE

-20 … +60 °C (-4 … +140 °F) -20 … +60 °C (-4 … +140 °F)

ature

Electromechanical data - version IP 66/IP 67 and IP 66/IP 68; 0.2 bar

Options of the cable entry

Ʋ Cable diameter (options) 5 … 9 mm (0.20 … 0.35 in)

6 … 12 mm (0.24 … 0.47 in)

10 … 14 mm (0.39 … 0.55 in)

Ʋ Cable entry ½ NPT

Ʋ Blind plug M20 x 1.5; ½ NPT

Ʋ Closing cap M20 x 1.5; ½ NPT

Plug options

Ʋ Signal circuit Plug M12 x 1, according to ISO 4400, Harting HAN,

7/8" FF

Ʋ Indication circuit M12 x 1 plug

Wire cross-section (spring-loaded terminals)

Ʋ Massive wire, cord 0.2 … 2.5 mm² (AWG 24 … 14)

Ʋ Stranded wire with end sleeve 0.2 … 1.5 mm² (AWG 24 … 16)

Electromechanical data - version IP 68 (25 bar)

Connection cable between IP 68 instrument and external housing

Ʋ Conguration four wires, one suspension wire, one breather capillary,

screen braiding, metal foil, mantle

Ʋ Wire cross-section 0.5 mm² (AWG 20)

Ʋ Wire resistance < 0.036 Ω/m (0.011 Ω/ft)

Ʋ Standard length 5 m (16.40 ft)

Ʋ Max. length 180 m (590.5 ft)

Ʋ Min. bending radius at 25 °C/77 °F 25 mm (0.985 in)

Ʋ Diameter approx. 8 mm (0.315 in)

Ʋ Colour Blue

Cable entry/plug

4)

Ʋ External housing – 1 x cable gland M20 x 1.5 (cable: ø 5 … 9 mm), 1 x

blind plug M20 x 1.5

or:

– 1␣x plug (depending on the version), 1␣x blind stopper

M20␣x␣1.5

4)

Depending on the version M12 x 1, according to ISO 4400, Harting, 7/8" FF.

46

VEGABAR 87 • Slave sensor for electronic dierential pressure

45053-EN-131011

Page 47

9 Supplement

Spring-loaded terminals for wire cross-

2.5 mm² (AWG 14)

section up to

Voltage supply, interface to the master sensor

Voltage supply Through the master sensor

Data transmission digital (I²C-Bus)

Conguration, connection cable 4-wire, screened

Cable length max. 25 m

Potential connections in the instrument

Electronics Not non-oating

Ground terminal Galvanically connected with the process tting

Electrical protective measures

Housing material Version IP-protection class NEMA protection

Plastic Single chamber IP 66/IP 67 NEMA 4X/6P

Aluminium Single chamber IP 66/IP 68 (0.2 bar)

IP 68 (1 bar)

Stainless steel, electro-

polished

Stainless steel, investment

casting

Stainless steel Transmitter for external

Single chamber

Single chamber

Single chamber IP 66/IP 68 (0.2 bar)

housing

IP 66/IP 68 (0.2 bar)

IP 69K

IP 68 (1 bar)

IP 68 (25 bar) -

NEMA 4X/6P

-

NEMA 4X/6P

-

NEMA 4X/6P

NEMA 4X

Overvoltage category III

Protection class II

Approvals

Instruments with approvals can have dierent technical data depending on the version.

For that reason the associated approval documents of these instruments must be carefully noted.

They are part of the delivery or can be downloaded under www.vega.com and "VEGA Tools" as

well as under "Downloads" and "Approvals".

9.2 Dimensions

The following dimensional drawings represent only an extract of the possible versions. Detailed

dimensional drawings can be downloaded at www.vega.com under "Downloads" and "Drawings".

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

47

Page 48

9 Supplement

Housing

~ 69 mm

M20x1,5/

½ NPT

~ 69 mm

(2.72")

(2.72")

ø 79 mm

(3.11")

1

ø 79 mm

(3.11")

(4.41")

112 mm

M20x1,5/

½ NPT

~ 59 mm

~ 116 mm

(4.57")

(2.3")

ø 86 mm

(3.39")

2

ø 80 mm

(3.15")

M20x1,5

(4.57")

116 mm

M20x1,5/

½ NPT

~ 59 mm

(2.32")

ø 80 mm

(3.15")

3

(4.41")

112 mm

M20x1,5/

½ NPT

(4.61")

117 mm

M20x1,5/

4

½ NPT

5

(4.1")

104 mm

Fig. 22: Housing versions in protection IP 66/IP 67 and IP 66/IP 68 (0.2 bar)

1 Plastic housing

2 Aluminium housing

3 Stainless steel housing, electropolished

4 Stainless steel housing, precision casting

5 Stainless steel housing, electropolished IP 69K

45053-EN-131011

48

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 49

External housing with IP 68 version

82 mm

(3.23")

41,6 mm

(3.15")

80 mm

(1.64")

9 Supplement

1

(4.25")

108 mm

41,6 mm

(1.64")

2

Fig. 23: VEGABAR 87, IP 68 version with external housing

1 Lateral cable outlet

2 Axial cable outlet

3 Plastic version

4 Stainless steel version

5 Seal 2 mm (0.079 in) - only with 3A approval

3

~ 66 mm

(2.60")

4

110 mm x 90 mm

110 mm x 90 mm

(4.33" x 3.54")

(4.33" x 3.54")

(2.32")

59 mm

(2.01")

51 mm

5

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

49

Page 50

9 Supplement

VEGABAR 87

48-52 mm

(1.89" -

2.05")

175 mm

L

197 mm

52 mm

(6.89")

ø 8 mm

(0.32")

(7.76")

SW 30 mm

(1.18")

22 mm

(0.87")

(1.52")

38,5 mm

(2.05")

L

G1 ½ /

1½ NPT

(0.55")

14 mm

(0.79")

20 mm

L

SW 46 mm

(1.81")

G1 ½ /

1½ NPT

G1 ½ /

1½ NPT

(0.87")

22 mm

L

ø 29 mm

(1.14")

ø 40 mm

(1.58")

1 2 3 4

Fig. 24: VEGABAR 87, standard ttings

1 Straining clamp

2 Threaded tting

3 Thread G1½

4 Thread 1½ NPT

5 Lock tting

50

45053-EN-131011

VEGABAR 87 • Slave sensor for electronic dierential pressure

Page 51

VEGABAR87,angeconnection

d2

9 Supplement

(2.01")

51 mm

D

ø 8 mm

L

(6.97")

177 mm

(0.32")

ø 40 mm

(1.58")

Fig. 25: VEGABAR 87, ange connection

1 Flanges according to DIN 2501

2 Flanges according to ANSI B16.5

f

b

d4

k