Page 1

Operating Instructions

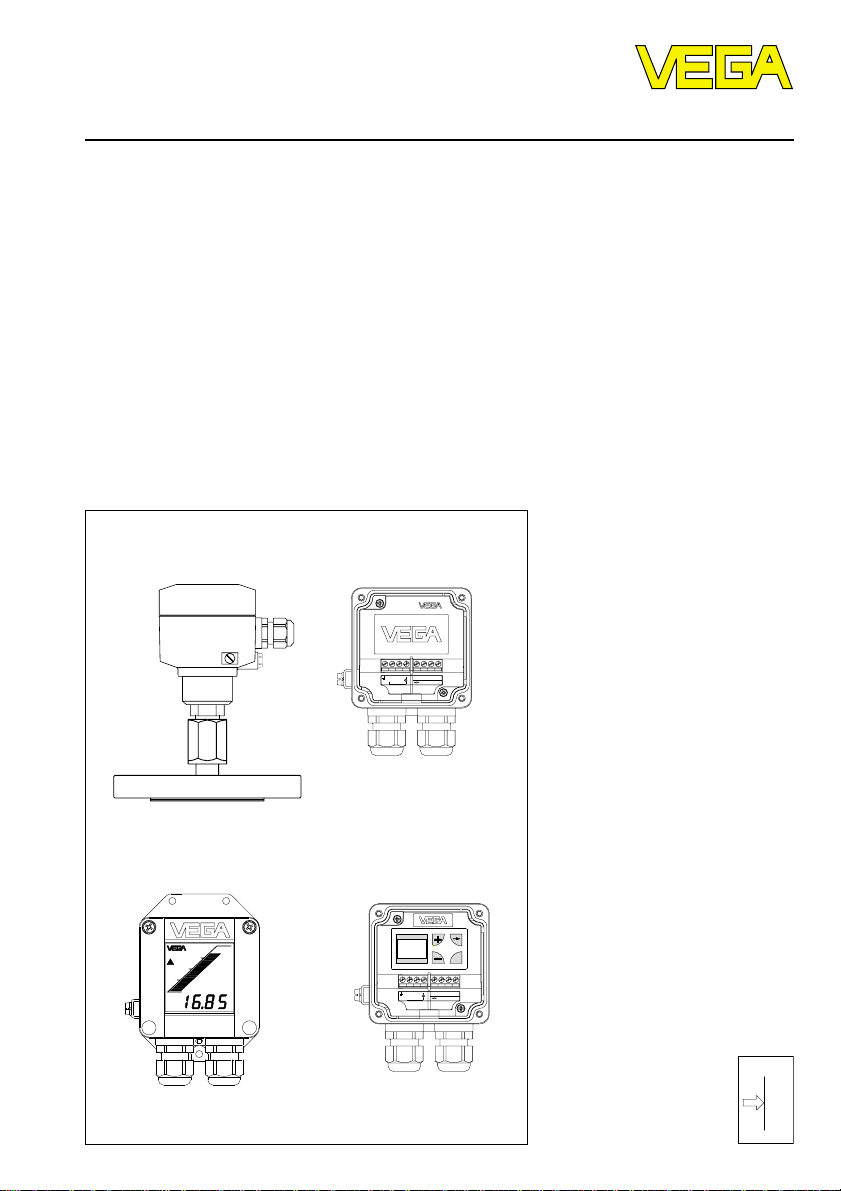

VEGABAR 21

87654321

+ -

-

DISPLAY

4 ¼ 20 mA

+

VEGADIS 10

12 ¼ 36 V DC E12

Level and Pressure

+ 4 … 20 mA

12 … 36 V DC E12

+

DISPLAY

VEGADIS 10

OK

87654321

p

Page 2

Safety information

Safety information

The described module must only be installed

and operated as described in these operating

instructions. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 VEGABAR 21

Note Ex-area

Please note the approval documents attached

(yellow binder), and especially the included

safety data sheet.

Page 3

Contents

Contents

Safety information ........................................................................ 2

Note Ex-area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Self-monitoring ..................................................................... 4

1.3 Technical data ....................................................................... 5

1.4 Approvals and certificates ................................................ 10

1.5 Dimensions ......................................................................... 10

2 Mounting................................................................................... 13

3 Electrical connection

3.1 Connection information ...................................................... 13

3.2 Connection plan ................................................................. 14

3.3 Connection examples ........................................................ 15

4 Set-up

4.1 Adjustment of the basic functions .................................... 16

4.2 Menu-guided adjustment with additional functions ......... 17

4.5 Indicating module ............................................................... 22

5 Diagnosis

5.1 Maintenance ....................................................................... 23

5.2 Failure removal ................................................................... 23

6 Instrument modification

6.1 Interchanging adjustment modules .................................. 25

7 Measurement with isolating systems ................................. 26

VEGABAR 21 3

Page 4

1 Product description

Product description

1.1 Function and configuration

VEGABAR 21 is an efficient pressure transmitter with isolating system for process pressure measurement and hydrostatic level

measurement. The hydrostatic pressure of

the medium acts on the separating diaphragm of the isolating system and is transferred via the isolating liquid to a ceramiccapacitive measuring cell CERTEC®. The

pressure on this measuring cell effects a

capacitance change within the measuring

cell. This capacitance change is detected by

an ASIC (Application specific integrated

circuit) and converted by an integral oscillator with microcomputer into a pressure proportional signal. The exact, digital processing

of measured data with highest resolution

ensures perfect technical data.

Isolating systems are used to protect the

measuring cell against aggressive products

and high temperatures. Due to the suitable

selection of isolating liquid and diaphragm

material, systems with a temperature resistance up to 400°C are possible.

The oscillator is powered by a separate

VEGA-signal conditioning instrument, a stabilised power supply unit or a DCS (active

input). After the adjustment, a standardised

current signal 4 … 20 mA is available which

can be displayed (e.g. in DCS-systems) or

further processed.

1.2 Self-monitoring

Important electronics components are

checked on their function and internal parameters such as sensor value, temperature and

operating voltage are monitored to increase

the reliability.

VEGABAR 21 with ceramic CERTEC®-measuring cell offers the advantage of a continuous self-monitoring. Measuring and reference

capacitance of the measuring cell are in a

defined relation over the complete measuring

range. Each deviation from these data is a

reliable indicator for a malfunction of the

measuring cell.

If during these routines failures or malfunctions are detected, a fault signal is triggered

via the 4 … 20 mA-output (current jump to

3,6 mA or 22 mA).

Two versions are available for adjustment:

- adjustment module directly on VEGABAR

- adjustment module in external housing

(VEGADIS 10)

4 VEGABAR 21

Page 5

Product description

1.3 Technical data

Mechanical data

Materials, wetted parts

Process connection stainless steel 1.4571

Diaphragm stainless steel 1.4571, Hastelloy C276 or B2,

Extension stainless steel 1.4571

Materials, non-wetted parts

Housing high resistance plastic PBT (Polyester)

Earth terminal stainless steel 1.4305

Window of the indicating module Lexan

Weight

VEGABAR approx. 0,8 … 8 kg

Adjustment and indicating elements

Adjustment of the basic functions 2 keys, 1 rotating switch

Menu-guided adjustment with

additional function

- adjustment elements 4 keys

- indicating elements DOT-Matrix display, 3 lines with 7 figures each

Indicating module LC-display with

Monel 400, Tantalum, PTFE-foil on 1.4571

(dependent on the isolating system)

- bargraph (20 segments)

- digital value (4-digit)

- tendency indicators for raising or falling

values

Electrical data

Connection

Cable entry M20 x 1,5 (for cable-ø 5 … 9 mm)

Screw terminals for cross-section area of conductor up to

Protective measures

Protection

1)

Protection class III

Overvoltage category III

1)

For maintaining the housing protection, the use of the suitable seal for the cable in the Pg is necessary. If

the used seal does not fit with the cable, it should be replaced by a suitable one.

VEGABAR 21 5

2,5 mm

IP 65

2

Page 6

Product description

Supply and signal circuit

Supply voltage 12 … 36 V DC

Permissible residual ripple USS £ 1 V

Output signal

- range 3,8 … 20,5 mA

- resolution 6 µA

Current limitation 22 mA

Fault signal 22 mA (3,6 mA)

Integration time 0 … 10 s adjustable

Average delay time 70 ms

Connection line 2-wire

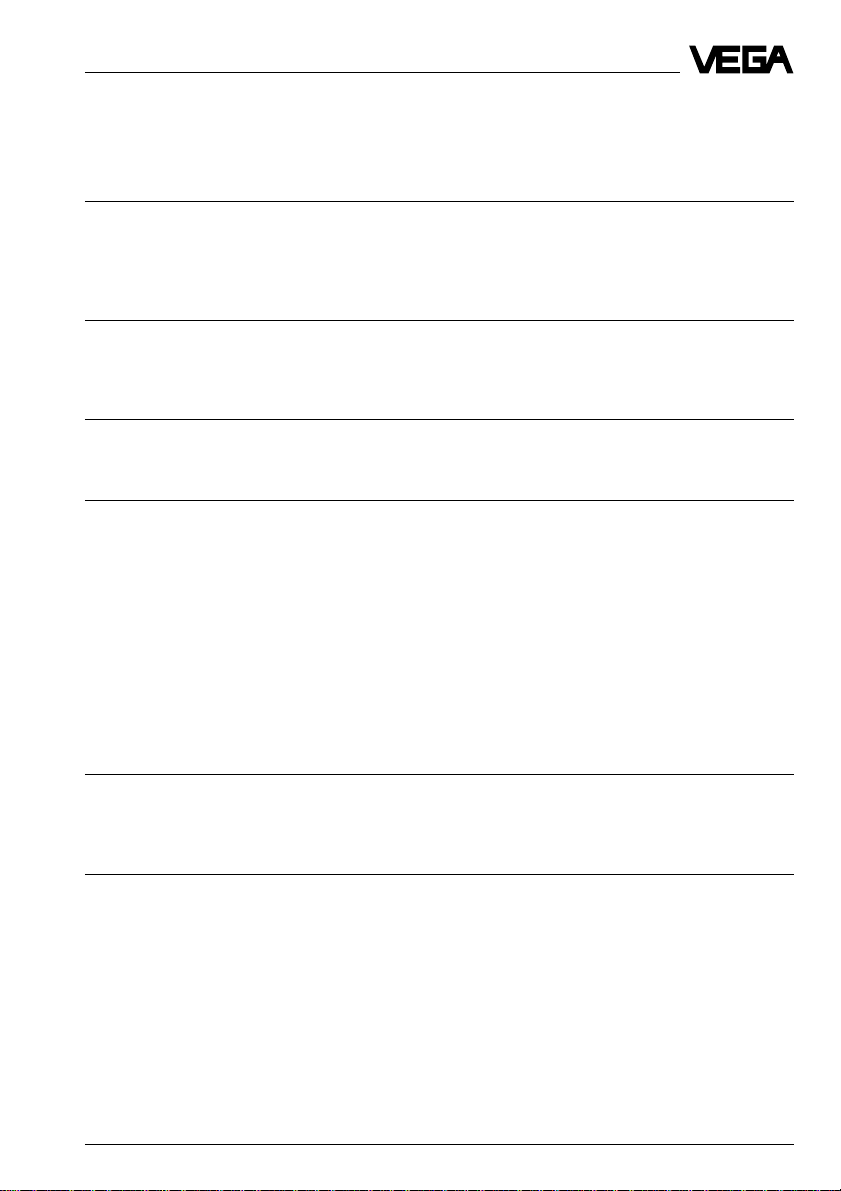

Max. permissible load dependent on the supply voltage

(see load diagram)

1000

750

in Ohm

total

500

250

Load RL

0

12

18 24 30 36

Voltage of the external energy UH in Volts

Indicating and adjustment circuit

For connection to VEGADIS 10 and/or the indicating module

Data transmission digitally

Connection line 4-wire

Max. line length 25 m

Adjustment ranges

Zero -20 % … +95 % adjustable of nominal range

Span 3,3 % … 120 % adjustable of nominal range

Recommended turn down:

- accuracy class 0,25 up to 1 : 5

- accuracy class 0,1 up to 1 : 10

6 VEGABAR 21

Page 7

Product description

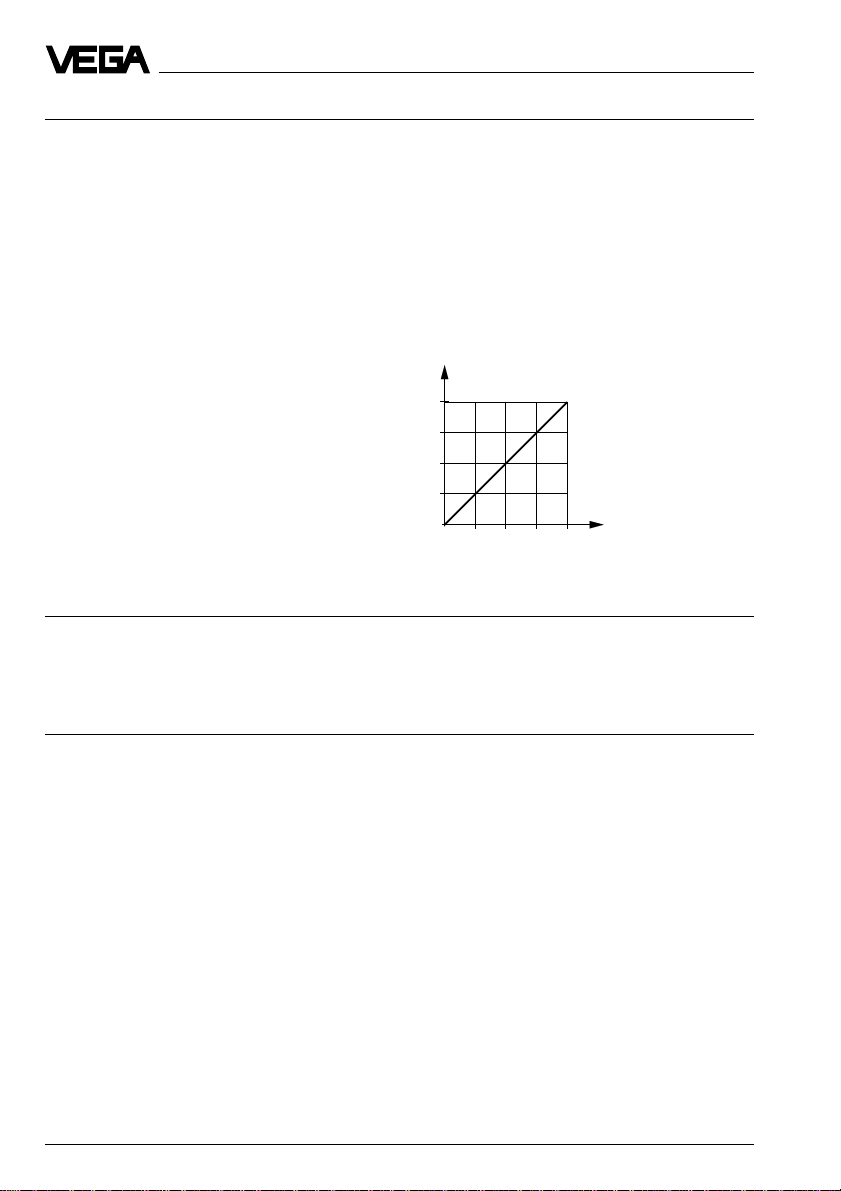

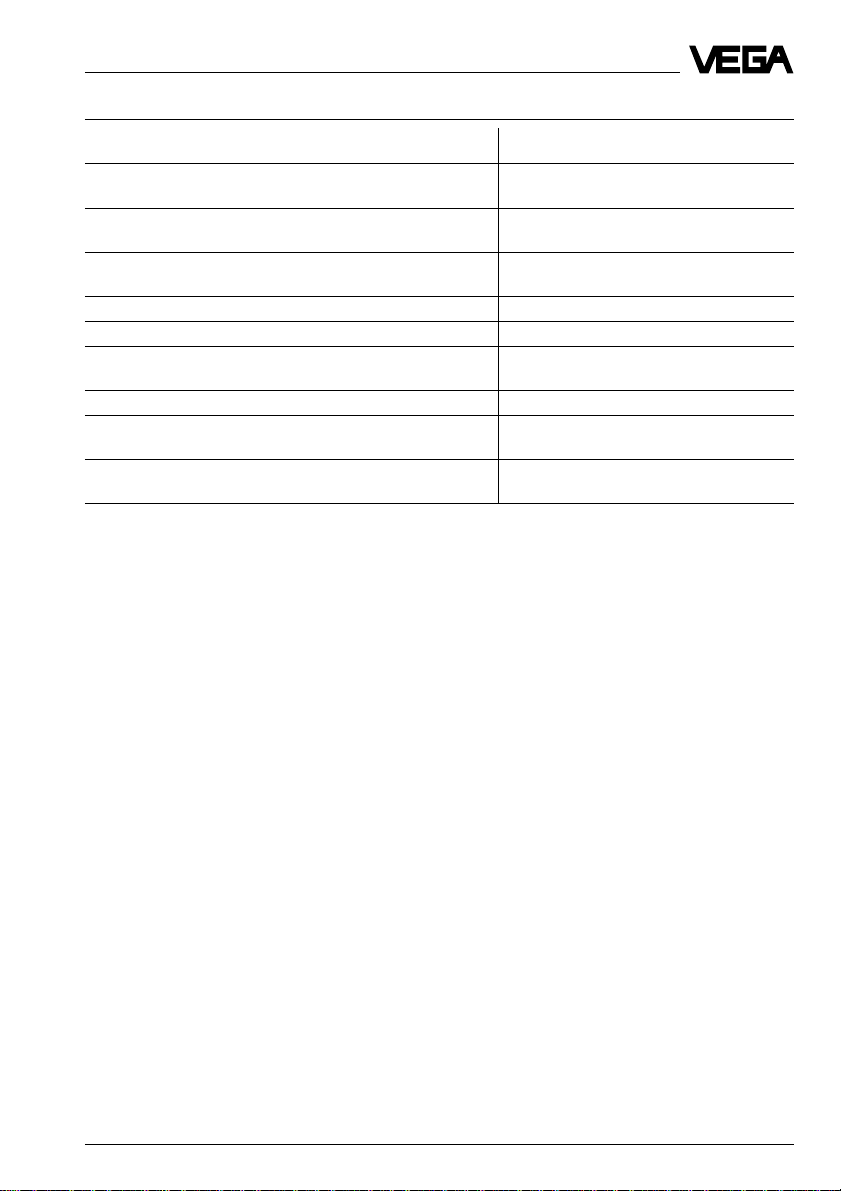

Measuring ranges

Nominal measuring Gauge pressure Low pressure

range resistance

1)

resistance

Relative pressure

0 … 0,4 bar 20 bar -0,4 bar

0 … 1,0 bar 25 bar -1,0 bar

0 … 2,5 bar 35 bar -1,0 bar

0 … 5,0 bar 45 bar -1,0 bar

0 … 10,0 bar 60 bar -1,0 bar

0 … 20,0 bar 90 bar -1,0 bar

0 … 40,0 bar 140 bar -1,0 bar

0 … 60,0 bar 200 bar -1,0 bar

-0,05 … 0,05 bar 10 bar -0,1 bar

-0,1 … +0,1 bar 15 bar -0,2 bar

-0,2 … +0,2 bar 20 bar -0,4 bar

-0,5 … +0,5 bar 25 bar -1,0 bar

-1,0 … +0,0 bar 25 bar -1,0 bar

-1,0 … +1,5 bar 35 bar -1,0 bar

-1,0 … +4,0 bar 45 bar -1,0 bar

-1,0 … +10,0 bar 60 bar -1,0 bar

-1,0 … +20,0 bar 90 bar -1,0 bar

-1,0 … +40,0 bar 140 bar -1,0 bar

-1,0 … +60,0 bar 200 bar -1,0 bar

Absolute pressure

0 … 1,0 bar 25 bar

0 … 2,5 bar 35 bar

0 … 5,0 bar 45 bar

0 … 10,0 bar 60 bar

0 … 20,0 bar 90 bar

0 … 40,0 bar 140 bar

0 … 60,0 bar 200 bar

1)

Note the nominal pressure of the process connection!

VEGABAR 21 7

Page 8

Accuracy (similar to DIN 16 086, DIN V 19 259 - 1 and IEC 770)

Influence of the ambient temperature

Average temperature coefficient

of the zero signal

- accuracy class 0,25 < 0,15 %/10 K

- accuracy class 0,1 < 0,05 %/10 K

1) 2)

Product description

Long-term stability

Long-term drift of the zero signal

1) 3)

< 0,1 % (meas. cell, without considering the

isolating system)

Deviation

Reference conditions (acc. to IEC 770)

- temperature 15°C … 35°C

- rel. humidity 45 % … 75 %

- air pressure 860 mbar … 1060 mbar

Determination of characteristics limit point adjustment acc. to DIN 16 086

Characteristics linear

Deviation in characteristics

1)

- accuracy class 0,25 < 0,25 %

- accuracy class 0,1 < 0,1 %

Hysteresis

Repeatability

1)

1)

< 0,02 %

< 0,02 %

Other actuating variables

Calibration position standing, diaphragm points downwards

Vibration resistance mechanical vibrations with 4 g and

5 … 100 Hz, tested acc. to the regulations of

German Lloyd GL-characteristics 2

Operating conditions

Ambient conditions

Ambient temperature -40°C … +85°C

- indication module -20°C … +70°C

Storage and transport temperature -40°C … +85°C

Medium temperature -40°C … +100°C

Medium temperature, abhängig von

Druckmittlerflüssigkeit Temperature

- silicone oil -40°C … +130°C / -40°C … +130°C

- silicone oil and cooling element -40°C … +200°C / -40°C … +130°C

- silicone oil and capillaries 1 m -40°C … +200°C / -40°C … +130°C

- vegetable oil -10°C … +130°C / -10°C … +130°C

- vegetalble oil and cooling element -10°C … +250°C / -10°C … +130°C

- high temperature oil a. cooling element -10°C … +400°C / -10°C … +200°C

- high temperature oil and capillaries 1 m -10°C … +400°C / -10°C … +200°C

1)

Relating to the nominal range.

2)

In the compensated temperature range of 0°C … +80°C, reference temperature 20°C. Without isolating

diaphragm, capillaries, cooling element (see influence of the ambient temperature).

3)

Acc. to IEC 770, item 6.1.2 relating to the nominal range.

4)

At pabs < 1 bar (vacuum range ) the isolating liquid boils already at low temperatures.

8 VEGABAR 21

p

> 1 bar / p

abs

4) < 1 bar

abs

Page 9

Product description

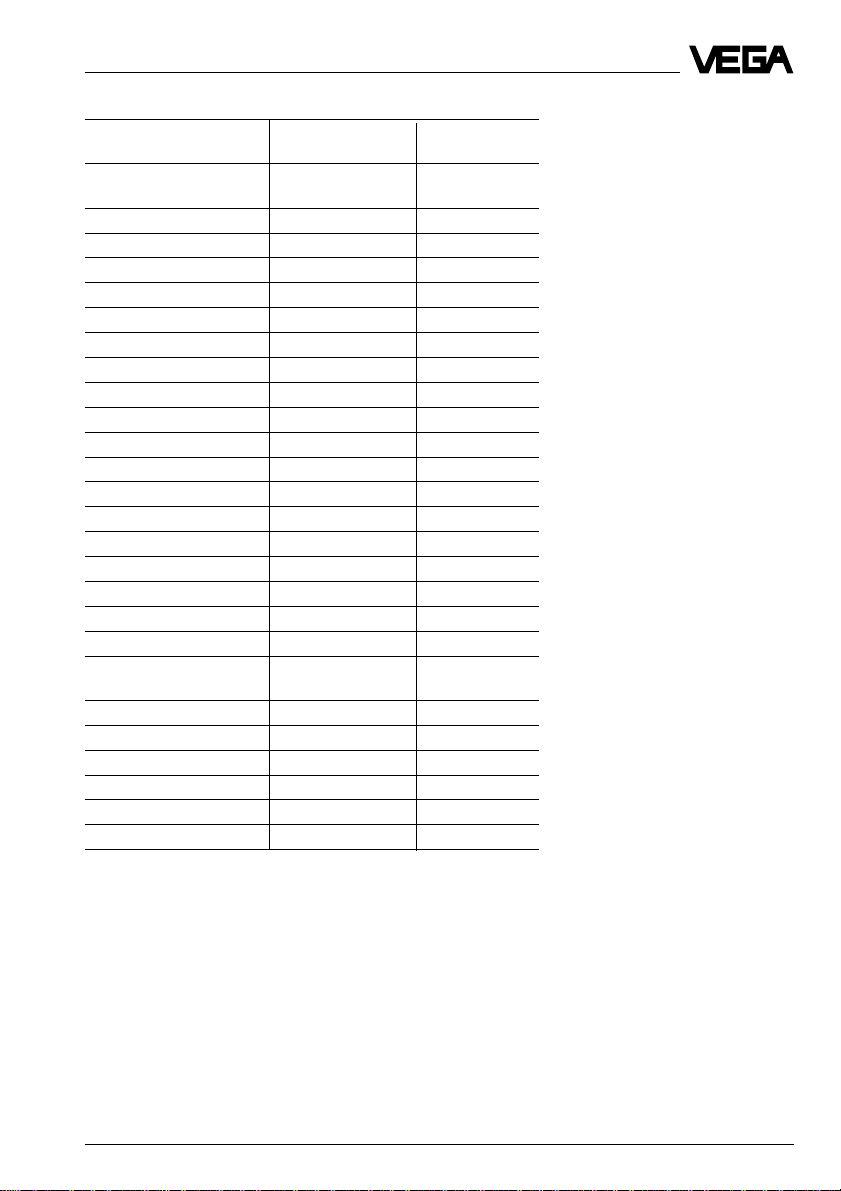

Zusätzlicher Temperatureinfluß durch Druckmittler

Process connection Temperature coefficient

[mbar/10 K]

FA Flange DN 25 PN 40 acc. to DIN 2501,

seal surface acc. to DIN 2526 Form D 1,8

FB Flange DN 40 PN 40 acc. to DIN 2501,

seal surface acc. to DIN 2526 Form D 1,0

FC Flange DN 50 PN 40 acc. to DIN 2501,

seal surface acc. to DIN 2526 Form D 2,0

FE Flange DN 50 PN 40 with ext. 100 mm 1,9

FG Flange DN 50 PN 40 with ext. 200 mm 2,1

FH Flange DN 80 PN 40 acc. to DIN 2501,

seal surface acc. to DIN 2526 Form D 0,4

FK Flange DN 80 PN 40 with ext. 100 mm 0,5

FN Flange DN 1" 300 lbs acc. to ANSI B 16.5,

seal surface RF 1,8

FO Flange DN 2" 600 lbs acc. to ANSI B 16.5,

seal surface RF 2,0

- by cooling elements,

dependent on diaphragm-ø 0,1 … 1,5 mbar/10 K

- by 1 m capillary line

dependent on diaphragm-ø 0,1 … 15 mbar/10 K

VEGABAR 21 9

Page 10

Product description

1.4 Approvals and certificates

Approvals

Ex Zone 2

StEx Zone 10

Ship approval

CENELEC EEx ia IIC

ATEX II 1G EEx ia IIC and WHG

ATEX II 1G EEX ia IIC and ship approval

If for certain applications the use of approved instruments is required, the appropriate legal

documents (test reports, test certificates and conformity certificates) have to be noted.

These are supplied with the appropriate instrument.

CE-conformity

VEGABAR 21 corresponds to the requirements of EMC (89/336/EWG) and NSR

(73/23/EWG). The conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

NAMUR-regulations

The NAMUR-regulations NE 21, May 1993 are met.

1.5 Dimensions

Housings

without indication module with indication module

85

~76

72

M20x1,5

Earth connection

10 VEGABAR 21

82

Breather facility

Page 11

Product description

Process connections

Capillaries 1 m (TK = 15)

Cooling element (TK = 4,5)

Standard

100

d2

51

FA, FB, FC

FH

FN, FO

d4

k

D

D = outer flange diameter

b = flange thickness

k = diameter of hole circle

d2= diameter of holes

d4= seal ledge diameter

d5= extension diameter

f = seal ledge strength

RL= extension length

dM= diaphragm diameter

Standard

83

51

f

b

L

R

d5

FE, FG, FK

Flange connection acc. to DIN 2501, seal ledge acc. to DIN 2526 form D

Order Flange Holes Seal ledge Extension

code Size D b k No. d2d4fRLd

d

5

M

FA DN 25 / PN 40 115 22 85 4 14 68 2 –– –– ––

FB DN 40 / PN 40 150 18 110 4 18 88 3 –– –– ––

FC DN 50 / PN 40 165 20 125 4 18 102 3 –– –– ––

FE 100 48,3 47

FG 200 48,3 47

FH DN 80 / PN 40 200 24 160 8 18 138 3 –– –– ––

FK 100 76 72

Flange connection acc. to ANSI B 16.5, seal ledge RF

FN DN 1" / 300 lbs 125 22 89 4 20 51 2

FO DN 2" / 600 lbs 165 32 127 8 20 92 6,4

VEGABAR 21 11

Page 12

Product description

Tube isolating diaphragms for mounting

between flanges with connection acc. to

DIN 2501

Order DN PN D Mb

code

RC 50 6 … 400 95 54,5

Tube isolating diaphragms with connection acc.

to DIN 11 851

Order DN PN G1 L2 D2 d6 g m

code

RF 50 25 Rd78x1/6 156 70 68,5 11 18

Tube isolating diaphragms with Clampconnection

Order DN PN L D d D1 D2 Mb

code

RH 2" 40 156 64 56,3 56 75 48

60

D

Mb

g

d6

d

D

Mb

L2

D2

L

D2

D1

12 VEGABAR 21

Page 13

Mounting, electrical connection

2 Mounting

VEGABAR can be mounted in any position.

The cable entries have to point downwards to

avoid humidity ingress. For this purpose the

housing can be rotated by 330° against the

mounting part.

For mounting, a seal must be used corresponding to the connection. This seal is either

supplied with VEGABAR or must be provided

by the customer.

Compensation of the atmospheric

pressure

The atmospheric pressure of instruments

used for overpressure measurements is

compensated via a breather facility integrated in the housing.

3 Electrical connection

3.1 Connection information

The electronics in VEGABAR 21 requires a

power supply of 12 … 36 V DC. It is pro-

vided in two-wire technology, i.e. supply

voltage and current signal are led to the

terminals via the same two-wire connection

cable.

This external energy is provided via a separate power supply unit:

- power supply unit, e.g. VEGASTAB 690

- processing unit with integral DC-current

source (e.g. active DCS-input)

- VEGAMET or VEGADIS 371

Observe that the external energy source is

reliably separated from the mains circuits

acc. to DIN VDE 0106, part 101. The above

mentioned VEGA-instruments meet this requirement and protection class III is therefore

ensured.

The external energy source must supply a

terminal voltage of at least 12 V to the transmitter. The actual terminal voltage on the

transmitter depends on the following factors:

- output voltage of the external energy

source under nominal load.

- Electrical resistors of the connected instruments in the circuit (see connected instruments, load resistor).

Note the following instructions for electrical

connection:

- The connection must be made acc. to the

specific installation standards (e.g. in Germany according to the VDE-regulations).

- The terminal voltage must not exceed 36 V

to avoid damage of the electronics.

- The electrical connection is provided with a

reverse polarity protection.

- The wiring between VEGABAR and power

supply can be made with standard twowire cable.

VEGABAR 21 13

Page 14

Electrical connection

- If strong electromagnetic interferences

have to be expected, screened cable is

recommended. The screening should be

earthed at one side of the sensor.

- If overvoltages are expected, we recommend the installation of VEGA-overvoltage

arresters.

- In the PG a seal must be used which fits to

the cable.

3.2 Connection plan

Note:

A current meter for local control of the output current can be connected to terminals 1 and 3.

This measurement can be made during operation without interrupting the supply line.

VEGABAR

VEGABAR (with or without indication)

Current meter for local

control

1)

Earth

1

876532

rd wt vio or

–+

Supply voltage

12 … 36 V DC

4 … 20 mA

1)

If screened cable is used, the screen must be connected in the terminal box on one side to earth and the

earth terminal must be earthed outside on the housing according to the prescription. Both terminals are

connected in the housing.

14 VEGABAR 21

Page 15

Electrical connection

3.3 Connection examples

Supply via power supply unit

The processing is made by an indicating instrument.

Current meter for local

control

+ – –

1 2 3

Terminals

VEGABAR

Supply via a DCS with active input circuit

The processing is made via a DCS with active input circuit.

Current meter for local

control

analogue / digital indicating instrument

Power supply unit

–

~

+

+ – –

1 2 3

Terminals VEGABAR

DCS

–

+

DCS

VEGABAR 21 15

Page 16

4 Set-up

Set-up

The electrical connection as well as the setup can be facilitated by mounting the cover

or indicating module short-term laterally or

displaced to the bottom on VEGABAR.

VEGABAR

+ 4 ¼ 20 mA

12 ¼ 36 V DC E12

OK

87654321

-

DISPLAY

+

VEGADIS 10

Tighten screws moderately

Indicating module

4.1 Adjustment of the basic

functions

Adjustment elements

Rotating switch: Choose the

requested function

Key +: Change

OPERATE

t

i

ZERO

SPAN

value (raising)

Adjustment

For adjustment of zero and span, a current

meter must be connected to terminals 1 and

3. The measured value is identical with the

output current.

1 Adjustment of zero

(e.g. process pressure zero or empty

vessel)

• Set rotating switch to zero

• By pushing the “+“ and “–“-keys simultane-

ously, the current jumps directly to 4 mA or

adjusting by pushing the “+“ and “–“-keys

a current of 4 mA

Adjustment range of zero:

-20 % … +95 % of the nominal measuring

range

2 Adjustment of span

(e.g. process pressure or vessel level

maximum)

• Set rotating switch to span

• By pushing the “+“ and “–“-keys simultane-

ously, the current jumps directly to 20 mA

or adjusting by pushing the “+“ and “–“-

keys a current of 20 mA

Adjustment range of span:

3,3 % … 120 % of the nominal measuring

range

Key –: Change

value (falling)

Note:

- A modification of zero does not influence

the span.

Adjustment system

• Select the requested function with the rotating switch.

• Change the value with keys “+“- and “–“.

• Reset rotating switch to OPERATE, the

- It is also possible to adjust currents for

part fillings or part pressures, e.g. 8 mA for

25 % and 16 mA for 75 %. VEGABAR calculates automatically the current values for

0 % or 100 % (only possible with ³ 3,3 %).

adjusted values are transferred to the

EEPROM-memory. They remain there even

in case of voltage loss.

16 VEGABAR 21

Page 17

Set-up

Integration time

An integration time ti of 0 … 10 s can be adjusted for damping of pressure shocks.

Procedure

• Set rotating switch to t

• By pushing the “-“-key 10-times, ensure

i

first of all that the integration time is set to

0 s

• For every 1 s requested integration time,

push the “+“-key once

The integration time is the time required by

the current output signal to reach 90 % of the

actual level after a step change of the process pressure.

4.2 Menu-guided adjustment with

additional functions

The adjustment with the multiple function

module is menu orientated and is made via

the four keys in conjunction with the clear text

indication. The jump from the measured value

indication to the main menu is made with the

“OK“-key. Use the “®“-key to change from

one menu point to the other within the menu.

Branching

A branching is indicated with the symbol ▼

and enables a jump to the below menu with

the “OK“-key. In this menu you can find parameters which are linked (possibly in other

submenus).

Parameters have no ▲ or ▼symbol. The

value of the parameters can be modified with

the “+“ and “–“-keys or chosen from the list.

When these buttons are pushed once, the

value flashes first. When pushing again, the

value is modified. The modified value can be

saved with the “OK“-key. Push the “®“-key to

interrupt the input (without storing the modification).

Certain parameters can only be indicated

and their values cannot be modified.

Reset

A reset is marked with the symbol ▲ and

enables with the “OK“-key a jump to the

above menu.

Automatic reset to measured value indication

is triggered 60 minutes after having pushed

a key for the last time.

Adjustment elements

Indication of:

- measured value

- functions in menu

Jump to the below menu

with OK-key

D Reset to the above menu

with OK-key

VEGABAR 21 17

Dependent on the parameter, change value (raising)

or choose from list

+

OPERATE

3.00

mbar

Dependent on the parameter, change value (falling)

or choose from list

fi

OK

–

Choose menu point or interrupt input

Acc. to the menu point, save the

adjusted value or change the menu

stage

Page 18

Menu plan

Set-up

Operate

0,2

mbar

Ad-

just-

ment

Adjust

with

press.

Measured value

indication

Calcu-

lation

ti

1

s

Adust

without

press

Unit

0,0

mbar

psi

kPa

Output

Unit

0,0

mbar

psi

kPa

%

Scal.

mA

Current

output

4-20mA

20-4mA

Scaling

indica-

tion

0%=

0

Fault

signal

22mA

Escape

3,6mA

Escape

The scaling can only be carried out, when in the

menu point "Unit“ the option „scal“ had been chosen

before.

100%=

1000

Decimal

point

888,8

Escape

Escape

For pressure transmitters with a measuring range ³ 1 bar the

unit bar can be selected instead of mbar.

Offset

correc-

tion

Offset

corr.

OK?

Zero

0,0

mbar

Span

100,0

mbar

Only with pressure transmitters for

relative pressure measurement

Escape

Simula-

tion

Sim.

xx,x

mbar

Sensor

unpres-

surized?

Zero

4,000

mA

Span

4,000

mA

Escape

18 VEGABAR 21

Page 19

Set-up

Addi-

tional

functiion

Sensor

data

Escape

Lan-

guage

Lan-

guage

English

Reset

Reset

OK ?

Escape

Deutsch

Franc.

Ital.

Español

Herst.

Date

49.98

1)

By pushing the “+“ and “–“-keys simultaneously,

P min

1)

-0,3

mbar

Reset

Now!

OK ?

P max

150

mbar

1) 1) 1)

Temp.

30,7

°C

the min. and max. values can be reset to the

actual value.

T min

23,5

°C

T max

36,2

°C

Diagno-

stic no.

- - -

Escape

In white letters you see the parameters

which can be modified with the “+“ or

“–“-key and saved with the “OK“-key.

The sensor and measured value

information which cannot be modified

in these positions are in itallic print.

List

These options can be chosen with the

“+“ or “–“-key and saved with the

“OK“-key.

Adjust

with

press.

Escape

Use the arrow key, to move in

the menu plan to the right.

In menu points with these

symbols you can move with the

“OK“-key to the bottom or top.

Span

100,0

mbar

Lan-

guage

English

Deutsch

Franc.

Ital.

Español

VEGABAR 21 19

Page 20

Set-up

Adjustment by considering the actual

pressure (life-adjustment)

The life-adjustment comprises two steps:

1 Adjustment of zero

2 Adjustment of span

The appropriate output current is displayed

via the DOT-matrix.

1 Adjustment of zero

(e.g. process pressure zero or vessel

empty)

Set with the “+“ or “–“-key the cur-

Zero

4,000

rent value to 4,000 mA. Then push

mA

the “OK“-key.

2 Adjustment of span

(e.g. process pressure or vessel level max.)

Set with the “+“ or “–“-key the cur-

Span

20,000

rent value to 20,000 mA. Then push

mA

the “OK“-key.

Note:

- A modification of zero does not influence

the adjusted span.

- For standard adjustment of zero/span “+“

and “–“ are pushed simultaneously. The

value jumps directly to 4 mA/20 mA.

- In case of a high turn down generally the

“+“ and “-“-key should be pushed simultaneously due to the resolution.

- When pushing the “+“ or “–“-keys individually, the output current remains at the last

value, only after storing with the “OK“-key it

takes the adjusted value.

- It is also possible to adjust currents for

part fillings or part pressures, e.g. 8 mA for

25 % and 16 mA for 75 %. Then VEGABAR

calculates automatically the current values

for 0 % or 100 % (only possible with

>3,3 %).

Adjustment without considering the

actual pressure (dry adjustment)

The adjustment without pressure comprises

four steps:

1 Enquiry of the unit in which the adjustment

should be carried out

2 Offset correction

3 Adjustment of zero

4 Adjustment of span

The offset correction (only with overpressure)

defines the reference basis for the measurement. It can be carried out:

- before or after the adjustment of zero and

span

- before or after installation of VEGABAR.

VEGABAR must be unpressurised when the

offset correction is carried out!

The adjustment without pressure can be

carried out assembled or unassembled (e.g.

workroom). An actually available pressure

has no meaning for the adjustment.

1 Enquiry of the unit

Choose with the “+“ or “–“-key the

Adjust

without

2 Adjustment of zero

mbar

4 Adjustment of span

Span

100,0

mbar

unit. Save the selected unit with the

press.

“OK“-key.

Unit

0,0

mbar

psi

kPa

Adjust zero with the “+“ or “–“-key

Zero

0,0

and save with the “OK“-key.

Adjust span with the “+“ or “–“-key

and save with the “OK“-key.

20 VEGABAR 21

Page 21

Set-up

Note:

- A modification of zero does not influence

the adjusted span.

- By pushing the “+“ and “–“-keys the output

current remains on the last value, after

saving with the “OK“-key, the output current takes the adjusted value.

Processing

Adjustment of the integration time

ti

For damping of pressure shocks an

1

integration time ti of 0 s … 10 s can

s

With the “OK“-key the adjusted value can be

saved.

Selection of the unit

Scaling

be adjusted with the “+“ or “–“-key.

In the measured value indication

Unit

0,0

the actually measured pressure is

mbar

displayed on the DOT-matrix. The

psi

appropriate unit can be chosen out

kPa

of a list with the “+“ or “–“-key and

%

the “OK“-key. When choosing the

scal.

mA

unit “Scal.“ the following menu

points are available.

The bar graph relates to the adjusted measuring range and change proportionally to the

current output. Digital values < –10 % or

> 110 % are displayed as flashing figure.

By scaling user specific figures as 4-digit

digital values are coordinated on the indicating module to the values 4 mA or 20 mA of

the current output.

Outputs

Current output/Selection of the characteristics

The current output provides the actually

measured pressure as analogue current

signal 4 … 20 mA relating to the adjustment.

Current

4-20mA

20-4mA

Fault signal

If during the continuous self-monitoring failures, damages or interferences in the measuring cell or the electronics are detected,

the fault signal is triggered via the current

output.

The characteristics can also be

output

inverted, i.e. adjusted to 20 ... 4 mA

with the “+“ or “–“-key and the

“OK“-key.

In operating condition the actually measured

pressure is displayed on the indicating module as 4-digit digital value.

Scaling

indica-

tion

0%=

100%=

0

1000

Decimal

point

888,8

Escape

Simulation

Simula-

With the “+“ or “–“-key and the

Fautl

signal

“OK“-key you choose if the failure

22mA

current should be 22 mA or

3,6mA

3,6 mA.

To check the outputs of VEGABAR

and connected components, you

tion

can adjust with the “+“ or “–“-key an

individual pressure or %-value. The

Sim.

adjusted value flashes with acti-

xx,x

vated simulation. With the “OK“-key

mbar

the simulation can be finished.

VEGABAR 21 21

Page 22

Set-up

Additional functions

Important sensor data can be indicated via

DOT-matrix for information and diagnosis

purposes:

- manufacturing date

- pointer function (p

- pointer function (p

- actual temperature value (Temp)

- pointer function (T

- pointer function (T

- diagnosis number

Addi-

tional

function

Sensor

data

Herst.

P min

Date

49.98

1)

The min. and max.-values can be set to the actual

value by pushing the “+“ and “–“-keys simultaneously.

P max

-0,3

mbar

1)

1) 1) 1)

Language

150

mbar

min

max

min

max

Temp.

30,7

)

)

)

)

T max

T min

23,5

°C

°C

36,2

°C

Diagno-

stic no.

- - -

Reset

The reset function deletes the ad-

Reset

justed values and resets the parameters to the data of the factory setting. The adjustment data

Reset

correspond again to the nominal

OK ?

measuring range.

Reset

Now!

OK ?

4.5 Indicating module

Digital value

- 4 digits and decimal point

- with single range and basic function module fixed indication range in bar

- the multiple function module can be individually scaled.

The connection is made acc. to the scheme in

section “Electrical connection“.

Tendency

indication

As factory setting VEGABAR is

Lan-

adjusted to the order language.

guage

Bargraph

With the “+“ or “–“-key and the

“OK“-key the languages German,

English, Italian or Spanish can be

Lan-

guage

English

Deutsch

Franc.

Ital.

Español

22 VEGABAR 21

chosen.

Digital value

Page 23

Diagnosis

5 Diagnosis

5.1 Maintenance

VEGABAR process pressure transmitters are

maintenance free.

5.2 Failure removal

Fault signals

With selftest and continuous self-monitoring

VEGABAR offers high reliability. If however

interferences occur, the diagnosis of VEGABAR distinguishes between atypical process

conditions and faults in the VEGABAR.

Atypical process conditions

Exceeding or decreasing of the measuring

range limits (fault signal extinguishes when

the value is again in the measuring range).

Failure in VEGABAR

Failure in the electronics, interferences or

damages in the measuring cell.

The below table assists in the processing of

fault signals.

Reason Fault signal via

Clear de- “OPERATE Bargraph 0 %

creasing or ???? or 100 % Current

exceeding bar“ Digital value value

of the flashes 3,6 mA

measuring or

range 22 mA

Overload Bargraph 0 %

range of the or 100 %, digital

measuring value: four flashing

cell segments “- - - -”

Failure in all segments

VEGABAR flash

DOT-matrix Bargraph Current

Digital indication output

On instruments with menu-guided adjustment

with additional functions, possible reasons

are displayed in the menu point “Diagnosis

no.“ in case of failure.

Diagnosis no. Meaning

1 No frequency from C/f-converter

2 Frequency signal of the capacitor

outside the limit values

3 Frequency signal of the reference

capacitor outside the limit values

4 Frequency signal temperature outside

the limit values

7 Communication to EEPROM interfered

9 Error in CRC-check sum EEPROM

Fault finding

If the indicated value does not correspond to

the level in the vessel or to the process pressure, the following measures have to be

carried out:

- check the pressure compensation (only

with overpressure measuring ranges)

- check the electrical connection.

Checking pressure compensation

Open the housing of VEGABAR. The measured value should not change. However if the

indicated value changes, compensation of

the atmospheric pressure is not ensured and

the measured value will be affected. Check

the breather facility on the VEGABAR-housing.

VEGABAR 21 23

Page 24

Checking the electrical components

Diagnosis

–+

1 2 3

mA

–

Voltage

V

Current meter for

local control

Current

mA

External

energy source

–

~

+

Voltage

- the terminal voltage on VEGABAR must be

at least 12 V DC

Current

Current value Condition

3,8 … 20,5 mA standard range for output current

0 mA signal line open circuit

3,6 mA oscillator or pressure sensor ele-

22 mA short-circuit in the signal line,

ment defect

oscillator or pressure sensor element defect

24 VEGABAR 21

Page 25

Instrument modification

6 Instrument modification

6.1 Interchanging adjustment

modules

Indication

module

Module for

basic

functions

Module for

menu-guided

adjustment

VEGABAR

Module

without

adjustment

Exchange of the adjustment module

Removal of the adjustment module

1 Separate VEGABAR from the power

supply

2 Loosen the screws on the cover of

VEGABAR or VEGADIS 10

3 Loosen connection line from the terminals

4 Loosen screws of the adjustment cover

5 Remove adjustment cover and plug con-

nection

Insertion of an adjustment module

6 Plug the connection of the new adjust-

ment cover to the plug-in socket of the

oscillator

7 Fasten new adjustment cover

8 Fasten connection lines to terminals

9 Close cover of VEGABAR or VEGADIS 10

10 Connect VEGABAR to power supply

Retrofitting of an indicating module

1 Separate VEGABAR from power supply

2 Loosen screws on cover of VEGABAR or

VEGADIS 10

3 Remove cover

4 Connect indicating module via the four

lines to the screw terminals (note “3.2

Connection plan“)

The modular construction of VEGABAR enables to retrofit, interchange or remove adjustment modules and the indicating module. A

retrofitting can be e.g. necessary when a

Note:

Step 4 is facilitated when the indicating module is temporarily (carefully) mounted with two

screws.

VEGABAR with factory setting should be

adapted to modified measurement conditions. Already saved data (e.g. adjustment

values) are not saved in the adjustment module but in an EEPROM of the oscillator and a

5 Place indicating module in the correct

position on VEGABAR or VEGADIS 10

6 Tighten screws of the cover

7 Connect VEGABAR to power supply

new adjustment is therefore not necessary.

The connection of the modules is made:

- on the adjustment module via a 4-pole plug

connection

- on the indicating module via screw terminals.

VEGABAR 21 25

Page 26

7 Measurement with isolating systems

Measurement with isolating systems

Application limits

Isolating systems extend the temperature

and product application range of pressure

transmitters considerably. Therefore check in

addition that the complete measurement loop

suits the temperature. If due to the temperature conditions, a high ambient temperature

can be caused on the instrument, the use of

a cooling element or a capillary will be necessary.

The max. permissible gauge pressure on the

separating diaphragm should not exceed a

value of -500 mbar. Should higher low pressure values be expected, please contact us

respectively.

Error treatment

The influence of an isolating system is directly

determined by the temperature of the isolating liquid in front of the measuring cell. The

temperature coefficient Tk (see „1.5 Technical

data“) is valid for silicone oil. It reduces with

water-glycerine to 50 % of the values.

The total temperature error results in the sum

of Tk

Pressure transmitter

Tk

= Tk

tot

Example:

You use an isolating system with a Tk of

2,7 mbar/10 K (acc. to „1.5 Technical data“).

Your pressure transmitter has a measuring

range of 0 … 1 bar and a Tk of 0,05 %/10 K

(acc. to technical data). This corresponds to

a Tk of 0,5 mbar/10 K.

Tk

=

total

= 2,7 mbar/10 K + 0,5 mbar/10 K

= 3,2 mbar/10 K

We recommend the use of a process pressure transmitter with the max. available accuracy level to keep the total error within the

limits.

and Tk

Isolating diaphragm

Isolating diaphragm

+ Tk

Pressure transmitter

:

26 VEGABAR 21

Page 27

Notes

VEGABAR 21 27

Page 28

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@vega-g.de

ISO 9001

The statements on types, application, use and operating conditions

of the sensors and processing systems correspond to the actual

knowledge at the date of printing.

Technical data subject to alteration.

2.23 421 / Oct. ’99

Loading...

Loading...