Page 1

Operating Instructions

VEGABAR 15

Level and Pressure

p

Page 2

Contents

Safety information ........................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 3

1.2 Measuring ranges ............................................................... 3

1.3 Technical data ....................................................................... 4

1.4 Dimensions ........................................................................... 6

2 Mounting

2.1 Mechanical connection ........................................................ 7

2.2 Electrical connection ............................................................ 7

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGABAR 15

Page 3

Product description

1 Product description

1.1 Function and configuration

VEGABAR 15 is a process pressure transmitter with a piezoresistive sensor element for

pressure measurement of gas, steam or

liquids between 1 bar and 600 bar (relative

pressure). For use in dense, non-uniform and

cristallizing products, a version with flush

diaphragm is available. A standardised

4 … 20 mA current signal is available as

output signal.

1.2 Measuring ranges

Nominal meas. range Max. test pressure

Gauge pressure ranges

0 ... 1.0 bar/ 0 ... 100 kPa 2 bar / 200 kPa

0…1.6 bar / 0…160 kPa 8 bar / 800 kPa

0…2.5 bar / 0…250 kPa 8 bar / 800 kPa

0…4.0 bar / 0…400 kPa 8 bar / 800 kPa

0…6.0 bar / 0…600 kPa 20 bar / 2 000 kPa

0…10.0 bar / 0…1 000 kPa 20 bar / 2 000 kPa

0…16.0 bar / 0…1 600 kPa 50 bar / 5 000 kPa

0…25.0 bar / 0…2 500 kPa 50 bar / 5 000 kPa

0…40.0 bar / 0…4 000 kPa 80 bar / 8 000 kPa

0…60.0 bar / 0…6 000 kPa 200 bar / 20 000 kPa

0…100 bar / 0…10 000 kPa 200 bar / 20 000 kPa

0…160 bar / 0…16 000 kPa 320 bar / 32 000 kPa

0…250 bar / 0…25 000 kPa 600 bar / 60 000 kPa

0…400 bar / 0…40 000 kPa 600 bar / 60 000 kPa

0…600 bar / 0…60 000 kPa 900 bar / 90 000 kPa

with flush version

with flush version

with flush version

with flush version

with flush version

with flush version

with flush version

VEGABAR 15 3

Page 4

Product description

1.3 Technical data

Power supply

Supply voltage 10 … 30 V DC

Permissible residual ripple USS £ 1 V

Max. permissible load depending on the supply voltage

Output signal

The analogue 4 … 20 mA output signal (measuring signal) is transmitted together with the

power supply via one two-wire cable.

Range 3.5 … 23 mA

Current limitation approx. 28 mA

Accuracy1)(typical values under reference conditions, all statements relate to the nominal

measuring range)

Determination of characteristics limit point adjustment acc. to DIN 16 086

Characteristics linear

Deviation in characteristics

- inner sensor element < 0.3 %

- flush version < 0.2 %

Hysteresis < 0.1 %

Repeatability < 0.1 %

Average temperature coefficient of the

zero signal

2)

Long-term drift of the zero signal < 0.25 % per year

Calibration position upright, diaphragm points downwards

Vibration resistance mechanical vibrations with 4 g and

(see load diagram)

1000

500

in Ohm

Ltotal

0

Load R

10

15 20 25 30

Supply voltage UH in Volt

< 0.2 %/10 K

5 … 100 Hz, tested acc. to the regulations of

German Lloyd GL-characteristics 2

Characteristics

Delay time (0 … 63 %) < 4 ms

Ambient conditions

Ambient temperature -40°C … +85°C

Storage and transport temperature -50°C … +85°C

Product temperature -40°C … +100°C

4 VEGABAR 15

Page 5

Product description

Protective measures

Protection

1)

IP 65

Protection class III

Overvoltage category III

Connection

Cable entry Pg 9 (DIN 43 650)

Materials, wetted parts

Process connection stainless steel 1.4404

Diaphragm

- internal sensor element stainless steel 1.4404

- flush version stainless steel 1.4401

Materials, non-wetted parts

Housing

- internal sensor element stainless steel 1.4404

- flush version stainless steel 1.4301

Connection plug PA

Weight

VEGABAR 15 approx. 300 g

CE conformity

VEGABAR 15 process pressure transmitters meet the protective regulations of EMC

(89/336/EWG) and NSR (73/23/EWG). Conformity has been judged acc. to the following

standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

1)

Similar to DIN 16 086, reference conditions acc. to IEC 770: Temperature 15°C … 35°C; rel. moisture

45 % … 75 %; pressure 860 mbar … 1060 mbar/86 kPa … 106 kPa

2)

In compensated temperature range from 0°C … +80°C, reference temperature 20°C.

3)

Maintaining the housing protection requires the use of a seal that correctly fits the cable in the cable entry.

If the supplied seal does not fit, a suitable seal must be provided by the customer.

VEGABAR 15 5

Page 6

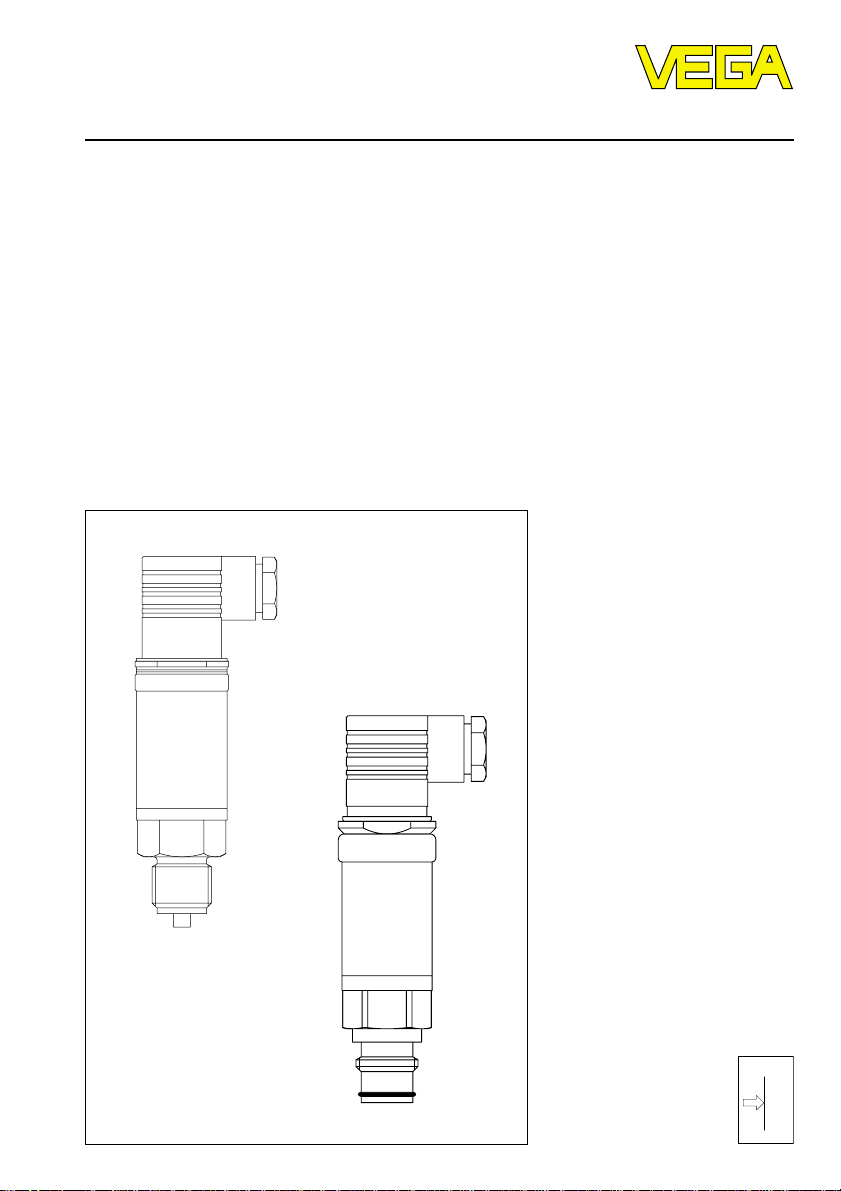

1.4 Dimensions

with internal sensor element with flush sensor element

Product description

131

38,5

G 1/2 A

ø 33

50

Pg 9

131

SW 27

38 57 36

20,5

50

42

20

5

PG 9

SW 27

ø 6

G ½ A

ø 35

6 VEGABAR 15

Page 7

Mounting

2 Mounting

2.1 Mechanical connection

A seal correctly fitting the connection must be

used for mounting. This seal must be provided by the customer.

2.2 Electrical connection

1

3

2

+-

+

U

B

-

R

L

Note:

The wire cross-section must be 4.5 … 7 mm

to ensure the seal effect of the cable entry.

VEGABAR 15 7

Page 8

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach/Germany

Phone +49 (0) 7836 50-0

Fax +49 (0) 7836 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application, practical

use and operating conditions of the sensors and processing systems correspond to the latest information at the time of printing.

Technical data subject to alterations

2.21 696 / November 2000

Loading...

Loading...