Page 1

Ope

rating Instructions

Overvoltage arrester

B61-300 FI

Document ID:

40489

ting

and protective instruments

Separa

Page 2

Contents

Conten

1 About this document

2 For your safety

3 Product description

4 Connecting to power supply

5 Maintenance and fault rectification

ts

1.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . .

2.4 General safety instructions . . . . . . . . . . . . . . . . . . . .

2.5 Safety label on the instrument . . . . . . . . . . . . . . . . . .

2.6 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Safety instructions for Ex areas . . . . . . . . . . . . . . . . .

2.8 Environmental instructions. . . . . . . . . . . . . . . . . . . . .

3.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Packaging, transport and storage . . . . . . . . . . . . . . .

3.4 Installation in switching cabinet . . . . . . . . . . . . . . . . .

3.5 Mounting in housing . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Preparing the connection . . . . . . . . . . . . . . . . . . . . .

4.2 Connection steps for version with housing . . . . . . . . .

4.3 Wiring plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Fault rectification . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Instrument repair . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3

3

4

4

4

4

4

5

5

5

6

6

7

9

11

12

12

13

15

15

15

6 Dismounting

6.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Supplement

7.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing status: 2011-06-01

2 Overvolta

16

16

17

18

40489-EN-110616

ge arrester • B61-300 FI

Page 3

out this document

1 Ab

1 Abou

t this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important

instructions for maintenance and fault rectification. Please read this

information before putting the instrument into operation and keep this

manual accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained qualified

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Inform

ation, tip, note

This symbol indicates helpful additional information.

Cauti

on: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

applications

Ex

This symbol indicates special instructions for Ex applications.

40489-EN-110616

Overv

l List

The dot set in front indicates a list with no implied sequence.

à Action

Th

is arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

oltage arrester • B61-300 FI 3

Page 4

2 For

your safety

or your safety

2 F

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

The B61-300 FI is an overvoltage arrester for sensors and signal

conditioning instruments with mains power supply connected via a

fault-current circuit breaker (FI).

You can find detailed information on the application range in chapter

"Product description".

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a high-tech instrument requiring the strict observance of

standard regulations and guidelines. The user must take note of the

safety instructions in this operating instructions manual, the countryspecific installation standards as well as all prevailing safety

regulations and accident prevention rules.

The instrument must only be operated in a technically flawless and

reliable condition. The operator is responsible for trouble-free

operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new

regulations.

2.5 Safety label on the instrument

The safety approval markings and safety tips on the device must be

observed.

4 Overvolta

40489-EN-110616

ge arrester • B61-300 FI

Page 5

your safety

2 For

E conformity

2.6 C

This device fulfills the legal requirements of the applicable EC

guidelines. By attaching the CE mark, VEGA provides a confirmation

of successful testing. You can find the CE conformity declaration in the

download area of

www.vega.com.

2.7 Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and

operation in Ex areas. These safety instructions are part of the

operating instructions manual and come with the Ex-approved

instruments.

2.8 Environmental instructions

Protection of the environment is one of our most important duties. That

is why we have introduced an environment management system with

the goal of continuously improving company environmental protection.

The environment management system is certified according to DIN

EN ISO 14001.

Please help us fulfil this obligation by observing the environmental

instructions in this manual:

l Chapter "Packaging, transport and storage"

l Chapter "Disposal"

40489-EN-110616

Overv

oltage arrester • B61-300 FI 5

Page 6

Typ B61 - 300 FI

OUT

IN

IP 20

max. 300 V AC/16 A

L1

N

L1

N

4

1

2

3

PE

PE

3 Produc

t description

pe of delivery

Sco

Constituent parts

3 Produc

t description

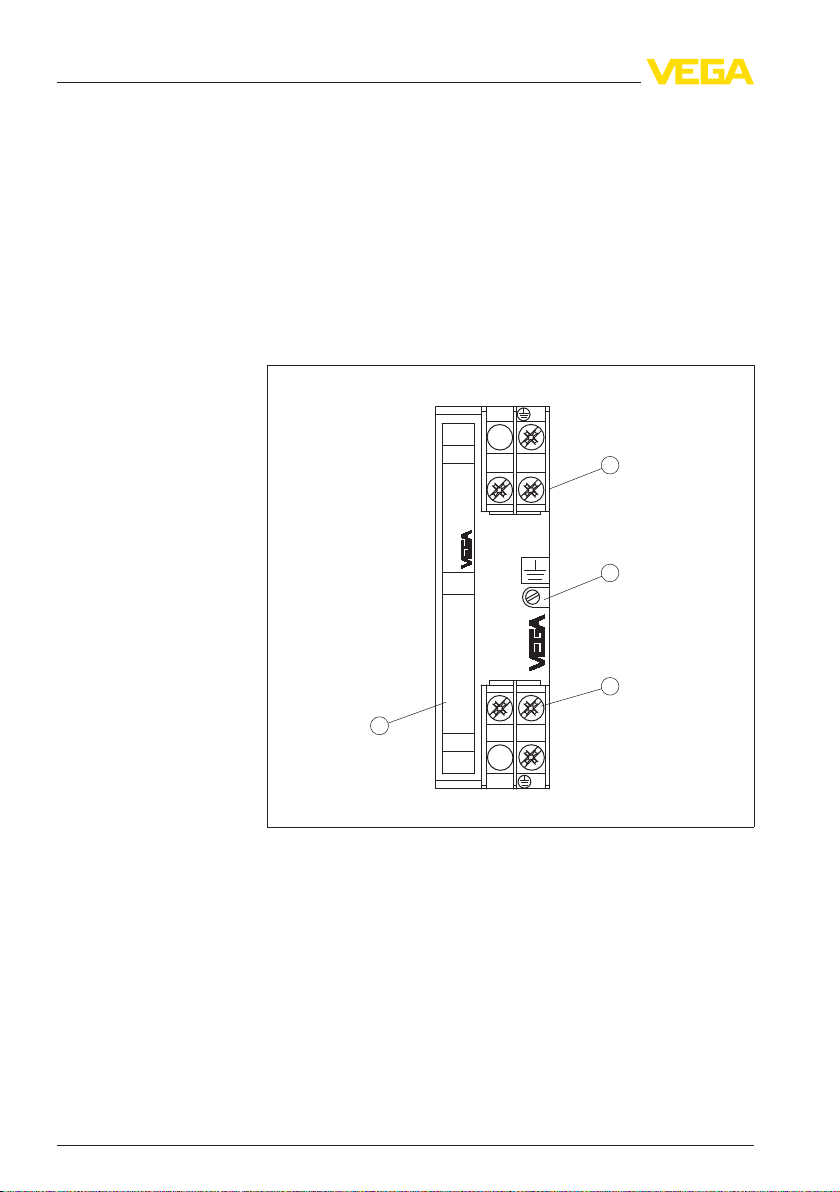

3.1 Structure

The scope of delivery encompasses:

l Overvoltage arrester B61-300 FI

l Documentation

- this operating instructions manual

The following illustration shows the configuration of the overvoltage

arrester B61-300 FI:

Fig. 1: Structure

1 Terminals Out (protected side)

2 Screw for carrier rail fastening

3 Terminals In (unprotected side)

4 Type label

Appli

cation area

3.2 Principle of operation

Voltage surges can be caused by indirect atmospheric discharges

(lightning strokes) or switching operations in the supply network.

Further causes can be inductive or capacitive couplings from other

electrical systems. Voltage peaks (transients) must be expected

especially when long power supply and signal cables are used.

6 Overvolta

of B61-300 FI

40489-EN-110616

ge arrester • B61-300 FI

Page 7

3 Produc

voltage surges can cause damage to sensors and signal

Such

t description

conditioning instruments.

VEGA overvoltage arresters reduce voltage surges on the supply or

signal cables to a safe level. They are designed for mounting on carrier

rail according to EN 50 022/EN 50 035 in the switching cabinet or in a

metal or plastic housing close to the sensor.

Func

tional principle

Packaging

Transport

Transport inspection

Varistors (voltage-dependent resistors) as well as overvoltage arresters (gas arresters) are used as protective elements for voltage

limitation.

As soon as the voltage reaches the response voltage of the protective

element increases, it becomes conductive and dissipates the energy

by briefly bridging the supply cables. When the voltage surge

subsides, the protective element returns to high-impedance status and

has no further influence on the supply circuit.

Due to this protective concept of B61-300 FI without energy dissipation

to ground, a connected fault-current circuit breaker is not triggered.

3.3 Packaging, transport and storage

The device was protected by packaging during transport. Its capacity

to handle normal loads during transport is assured by a test according

to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also used. Dispose of the packaging material via specialised

recycling companies.

Transport must be carried out under consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or

concealed defects must be appropriately dealt with.

Storage

40489-EN-110616

Overv

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

l Not in the open

l Dry and dust free

l Not exposed to corrosive media

l Protected against solar radiation

l Avoiding mechanical shock and vibration

oltage arrester • B61-300 FI 7

Page 8

3 Produc

t description

Storage and transport

temperature

l Storag

e and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

8 Overvolta

40489-EN-110616

ge arrester • B61-300 FI

Page 9

1

1

3 Produc

t description

3.4 Instal

The overvoltage arrester is mounted in the switching cabinet on carrier

rails according to EN 50 022 (DIN rail) or EN 50 035 (C-rail). It is

fastened to the carrier rail with a screw located on its exterior. The

screw is marked with the symbol for functional ground. Depending on

the version, it may be galvanically connected to the ground terminal of

the overvoltage arrester (see circuit diagram in chapter "Wiring plan").

Fig. 2: Mounting

1 Carrier rail

lation in switching cabinet

on carrier rail according to EN 50 022 (DIN rail) 35 x 7.5 mm

40489-EN-110616

Overv

Fig. 3: Mounting

1 Carrier rail

Mounting steps

Proceed as follows:

oltage arrester • B61-300 FI 9

on carrier rail according to EN 50 035 (C-rail) 35 x 7.5 mm

Page 10

OUT

IN

IP 20

1

3 Produc

t description

1 Loos

Fig. 4: Mounting

1 Fixing screw

en fixing screw

on carrier rail

2 Place the overvoltage arrester onto the rail and let it snap in

3 Tighten fixing screw

10 Overvolta

40489-EN-110616

ge arrester • B61-300 FI

Page 11

1

2

4

3

OUT

IN

IP 20

1

2

3

OUT

IN

IP 20

3 Produc

t description

3.5 Mount

ing in housing

The overvoltage arrester is optionally available in a plastic or

aluminium housing. Make sure when mounting that the cable glands

point downward. Thus avoids water ingress.

Fig. 5: Mounting

1 Overvoltage arrester

2 PE terminal

3 Pressure compensation

4 Ground terminal

in Aluminium housing

40489-EN-110616

Overv

Fig. 6: Mounting

1 Overvoltage arrester

2 Pressure compensation

3 Ground terminal

in plastic housing

oltage arrester • B61-300 FI 11

Page 12

ecting to power supply

4 Conn

safety instructions

Note

Take note of sa-

fety instructions

for Ex applications

4 Conn

ecting to power supply

4.1 Preparing the connection

Always keep in mind the following safety instructions:

l Connect only in the complete absence of line voltage

Before starting setup make sure that the power supply corresponds to

the specifications on the type label.

For effective overvoltage protection, the cables between overvoltage

arrester and instrument should be as short as possible.

Dange

r:

Apart from the overvoltage arrester, a separate PE terminal is mounted

on the carrier rail in the aluminium housing. It is galvanically connected

with the carrier rail.

The ground conductor (PE) of the power supply cable must be led to

this PE terminal to reach protection ground for the aluminium housing.

The PE terminal on the overvoltage arrester must be free.

In

hazardous areas you must take note of the respective regulations,

conformity and type approval certificates of the sensors and power

supply units.

4.2 Connection steps for version with housing

Proceed as follows:

1 Loosen screws of the housing cover

2 Push the supply and connection cables through the cable gland

into the housing, strip approx. 1 cm (0.4 in) insulation from the

ends of the wires

3 Connect the wire ends L, N and PE according to chapter "Wiring

plan" to the terminals of the overvoltage arrester

4 With aluminium housing connect the wire end for PE to the green/

yellow PE terminal in the housing

5 Check all cable connections, especially the PE connection, to

make sure they are tightened sufficiently

6 Tighten the compression nuts of the cable glands. The seal ring

must completely encircle the cable

7 Tighten screws of the housing cover

The electrical connection is finished.

40489-EN-110616

12 Overvolta

ge arrester • B61-300 FI

Page 13

1

N

N

L1

L1

2

PE

PE

B61 - 300 FI

OUT

IN

IP 20

max. 300 V AC/16 A

2

4

3

1

L1

N

PE

PE

PE

L1

N

L1

N

ecting to power supply

4 Conn

diagram

Circuit

Wiring plan

4.3 Wir

Fig. 7: Circuit

ing plan

diagram overvoltage arrester B61-300 FI

1 Overvoltage arrester

2 Potential equalisation

Fig. 8: Wiring

plastic housing

plan overvoltage arrester B61-300 FI in the switching cabinet or

1 Mains supply through fault-current circuit breaker (FI)

2 Overvoltage arrester

3 Protected instrument

4 Carrier rail

40489-EN-110616

Overv

oltage arrester • B61-300 FI 13

Page 14

B61 - 300 FI

OUT

IN

IP 20

max. 300 V AC/16 A

PE

PE

L1

N

L1

N

2

3

5

4

1

L1

N

PE

ecting to power supply

4 Conn

Wiring plan with alumi-

housing

nium

Fig. 9: Wiring

plan overvoltage arrester B61-300 FI in aluminium housing

1 Mains supply through fault-current circuit breaker (FI)

2 Overvoltage arrester

3 PE terminal

4 Protected instrument

5 Carrier rail

14 Overvolta

40489-EN-110616

ge arrester • B61-300 FI

Page 15

aintenance and fault rectification

5 M

ction when malfunc-

Rea

occur

tions

Fault rectificat

24 hour service hotline

Reaction after fault rectifi

cation

ion

5 Maint

enance and fault rectification

5.1 Maintenance

If the instrument is used properly, no special maintenance is required

in normal operation.

5.2 Fault rectification

The operator of the system is responsible for taking suitable measures

to rectify faults.

The first measure to be taken is to check the input/output signal as well

as the power supply. In many cases, the causes can be determined

and faults can be quickly rectified.

On-site repair of B61-300 FI is not possible.

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is available to you 7 days a week round-the-clock. Since

we offer this service world-wide, the support is only available in the

English language. The service is free of charge, only the standard

telephone costs will be charged.

Depending on the failure reason and measures taken, the steps

described in chapter "Set up" must be carried out again, if necessary.

40489-EN-110616

Overv

5.3 Instrument repair

If a repair is necessary, please proceed as follows:

You can download a return form (23 KB) from our homepage at

vega.com

By doing this you help us carry out the repair quickly and without

having to call back for needed information.

l Print and fill out one form per instrument

l Clean the instrument and pack it damage-proof

l Attach the completed form and, if need be, also a safety data

l Please ask the agency serving you for the address of your return

oltage arrester • B61-300 FI 15

under: "Downloads - Forms and certificates - Repair form".

sheet outside on the packaging

shipment. You can find the respective agency on our website

www.vega.com

under: "Company - VEGA worldwide"

www.

Page 16

6 Dismoun

ting

6 Dismou

nting

6.1 Dismounting steps

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

6.2 Disposal

The instrument consists of materials which can be recycled by

specialised recycling companies. We use recyclable materials and

have designed the electronics to be easily separable.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/EG and

the respective national laws. Pass the instrument directly on to a

specialised recycling company and do not use the municipal collecting

points. These may be used only for privately used products according

to the WEEE directive.

Correct disposal avoids negative effects on humans and the environment and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

16 Overvolta

40489-EN-110616

ge arrester • B61-300 FI

Page 17

7 Sup

plement

7 Supp

lement

7.1 Technical data

General data

Version Device for carrier rail mounting

Housing material Plastic (PPE)

Weight approx. 175 g (0.385 lbs)

Electrical characteristics

Nominal supply voltage 100 … 300 V AC/DC through fault-current circuit

Max. permissible current 16 A

Internal resistance < 0.01 Ω

Response voltage 500 V

Response time < 10

Nominal leakage current < 10 kA (8/20 µs)

Electromechanical data

Screw terminals for cable cross-section < 2.5 mm² (AWG 14)

Ambient conditions

Ambient temperature -40 … +60 °C (-40 … +140 °F)

Storage and transport temperature -40 … +70 °C (-40 … +158 °F)

Electrical protective measures

Protection rating

- unassembled IP 20

- In Aluminium or plastic housing IP 65

1)

breaker

-6

s

40489-EN-110616

Overv

1)

Reference

temperature 25 °C (77 °F).

oltage arrester • B61-300 FI 17

Page 18

84 mm

(3.31")

52 mm

(2.05")

25 mm

(0.98")

7 Suppl

7.2 D

ement

imensions B61-300 FI

Overvoltage arrester

Fig. 10: Dimensions B61-300 FI

18 Overvolta

40489-EN-110616

ge arrester • B61-300 FI

Page 19

Housing

ø5,5 mm

(0.22")

86 mm

(3.39")

120 mm

(4.72")

160 mm

(6.30")

77 mm

(3.03")

47 mm

(1.85")

50 mm

(1.97")

ø4,5 mm

(0.18")

82 mm

(3.23")

68 mm

(2.68")

72 mm

(2.84")

130 mm

(5.12")

116 mm

(4.57")

M 20 x 1,5

M 20 x 1,5

1

2

7 Sup

plement

Fig. 11: Dimensions B61-300 FI

1 Plastic

2 Aluminium housing

40489-EN-110616

Overv

housing

oltage arrester • B61-300 FI 19

Page 20

VEGA Grieshaber KG

ISO 9001

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

Printing date:

statements concerning scope of delivery, application,

All

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2011

Subject to change without prior notice 40489-EN-110616

Loading...

Loading...