Page 1

Operating Instructions

Lock fitting

ARV60.CB4 up to 64 bar

Level and Pressure

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Safety information ................................................................. 3

2 Mounting

2.1 Mounting procedure ............................................................ 4

3 Technical data

3.1 Technical data....................................................................... 6

3.2 Dimensions ........................................................................... 7

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 Lock fitting ARV60.CB4 up to 64 bar

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the operating instructions and come with the Ex approved instruments.

Page 3

Product description

1 Product description

The lock fitting ARV60.CB4 is a pressure-tight

clamping connection with G 1 A, G1½A or 1

NPT, 1½ NPT thread and can be used together with a level sensor in tube version

(e.g. VEGASWING 63). The tube extension of

the sensor must have a diameter of 21.3 mm

(DIN 2463/2462 D4-T3).

The wetted parts of the lock fitting are either

manufactured of steel 1.4435 (316L) or

Hastelloy C22 (2.4602).

The compression screw of the lock fitting

ARV60.CB4 radially squeezes a graphite

package consisting of four rings, which then

presses axially against the tube of the sensor. When properly mounted, a tight seal is

formed by the graphite package. The lock

fitting bracket secures the compression

screw and the clamp against unauthorised or

inadvertent loosening.

The lock fitting has the following approvals:

- tested by TÜV Rheinland acc. to

DruckbehV

- Zone 0 (ElexV) in combustible substances

of Ex group IIB up to max. 6 bar

-WHG

Note

If the lock fitting has to be removed for service or control purposes, you have to make

sure that the vessel is unpressurised. Switch

the power supply of the sensor off and remove all connection cables. Loosen the

mounting boss (6) with a spanner (SW 46).

Now you can remove the sensor together

with the lock fitting. It is therefore not necessary to readjust the switching point and the

lock fitting must not be completely disassembled.

1.1 Safety information

• Dismount the lock fitting only in

unpressurised condition.

• Only use suitable graphite packing rings

(article no. 2.26486). Make sure that the

graphite packing rings are not damaged.

Damaged rings do not ensure tightness. If

you are not sure, use new rings.

• Exclusively use approved hexagon socket

head screws DIN 912 M6 x 25 made of A470 acc. to AD regulation W2. The respective spring rings B6 must be made of A4

acc. to DIN 7980.

• Before screwing in, lubricate the thread of

the mounting boss, as well as the thread

and the head of the screws with a suitable

lubricant. The lubricant must be suitable for

the material combination 1.4435/1.4435

(stainless steel/stainless steel) or 2.4602/

2.4602 (Hastelloy/Hastelloy) and for a

temperature range of -50°C up to +250°C,

e.g. Varybond type NSS-16/7. The threads

come factory-treated with a suitable lubricant.

Lock fitting ARV60.CB4 up to 64 bar 3

Page 4

2 Mounting

Mounting

2.1 Mounting procedure

The numbers in brackets relate to the diagrams on the following pages.

• Loosen the holding screw (5) and remove

the lock fitting bracket (3).

• Unscrew the pressure screw (10) from the

mounting boss.

• Screw the mounting boss (6) with a resistant seal ring into the thread of your vessel

and tighten the mounting boss (6) with the

hexagon (SW 46).

• Now unpack the new laminated and graphite packing rings. The graphite packing

rings (8) have a plain cylindrical surface;

laminated packing rings (7) can be easily

recognised by their rougher cylindrical

surface and the laminated structure.

Make sure that the graphite packing rings

are not damaged. Damaged rings do not

ensure tightness. If you are not sure, use

new rings (article no. 2.26486).

• First of all, place one of the two laminated

packing rings (7) into the mounting boss

(6). Then place the two graphite packing

rings (8) on top, followed by the second

laminated packing ring (7).

• Place the metal compression ring (9) onto

the stack of packing rings.

• Screw the compression screw (10) with a

few turns from the top into the mounting

boss (6).

• Carefully remove grease, oil and dirt from

the extension tube of the sensor and the

surfaces of the clamp (11) and the compression screw (10) and insert the sensor

into the lock fitting. Move the tube to the

desired position and hold it firmly.

• Make sure that the sensor is in the correct

position (height). Please note that with the

height adjustment of the sensor, you also

determine the switching point.

• Tighten the compression screw (10) with a

torque of 80 ±10 Nm.

• Turn the compression screw (10) clockwise

until the hexagon surfaces of the compression screw (10) and the mounting boss (6)

are aligned (max. 1/6 turn).

• Tighten the screws (2) alternately with

uniform torque. Make sure that the gap

between clamp and compression screw is

in parallel. Fasten the screws up to a

torque of 7 ±2 Nm. The clamp (11) is

thereby pressed against the tube, fixing

the tube of the sensor in this position.

• Fasten the lock fitting bracket (3) with the

holding screw (5) and the spring ring (4)

laterally against the mounting boss (6).

This secures the compression screw and

the clamp screws against unintentional

loosening.

4 Lock fitting ARV60.CB4 up to 64 bar

Page 5

Mounting

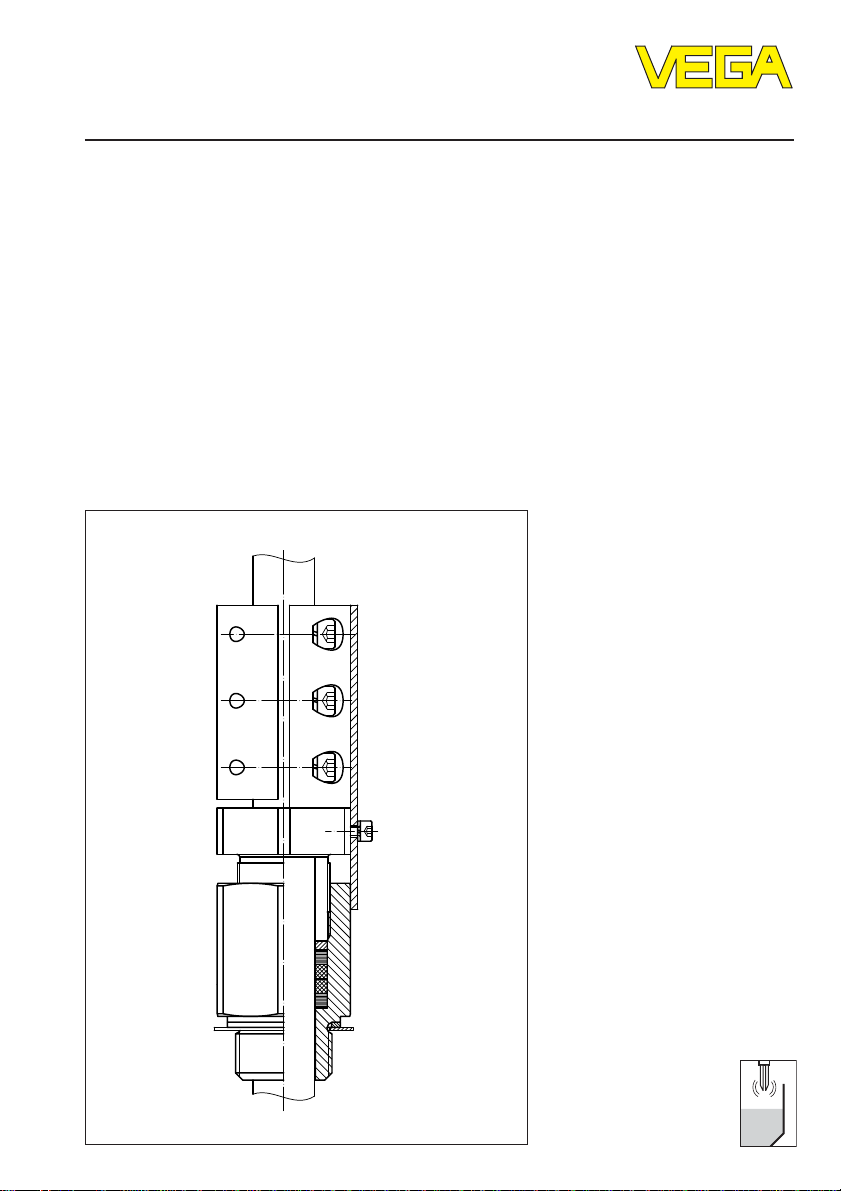

ARV60.CB4 (64 bar)

11

10

1

2

3

4

9

5

7

8

8

7

6

1 Spring ring B6

2 Screw M6 x 25

3 Lock fitting bracket

4 Spring ring B4

5 Holding screw M4 x 10

6 Mounting boss

7 Laminated packing ring

8 Graphite packing ring

9 Compression ring

10 Compression screw

11 C la m p

Lock fitting ARV60.CB4 up to 64 bar 5

Article no. 2.26648

Page 6

Technical data

3 T echnical data

3.1 Tec hnical data ARV60.CB4

Thread size (mounting boss) G 1 A, G1½ A or 1 NPT, 1½ NPT

Tube diameter of the sensor ø 21.3 mm (DIN 2463/2462 D4-T3)

Material steel 1.4435 (316L) or Hastelloy C22 (2.4602)

Screws (2) hexagon socket screws DIN 912 M6 x 25

Holding screw (5) hexagon socket screws DIN 7964 M4 x 10

Product temperature -50°C … +250°C

Operating pressure

- ARV60.CA4… 64 bar

Tor qu e

- screws (2) 7 ±2 Nm

- compression screw (10) 80 ±10 Nm

Approvals:

material A4-70 acc. to AD regulation W2

accessory spring rings (1) B6

material A4 acc. to DIN 7980

material A4-70; accessory spring ring (4) B4

material A4 acc. to DIN 7980

note the nominal pressure of the sensor. The

lowest permissible operating pressure is valid.

DruckbehV

The TÜV Rheinland has tested the lock fitting ARV60.CB4 and approved it acc. to DruckbehV.

Ex, WHG

The lock fitting ARV60.CB4 in conjunction with suitable VEGA sensors (e.g. VEGASWING 63)

is approved acc. to WHG or for Ex-Zone 0. Note the corresponding certificates of the sensors.

6 Lock fitting ARV60.CB4 up to 64 bar

Page 7

Technical data

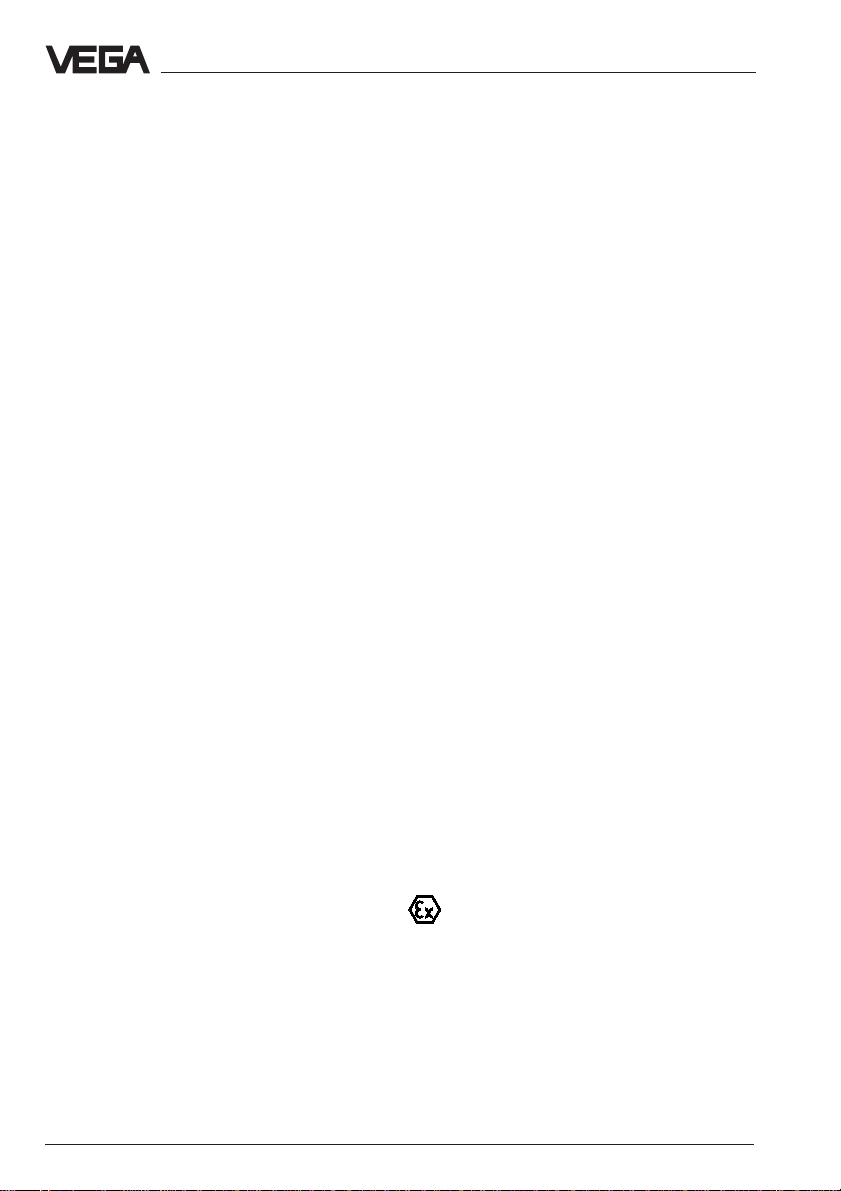

3.2 Dimensions

ø 21,3

SW 46

ca. 164

68

20

G1A, G1½A

1 NPT, 1½ NPT

ARV60.CB4 (64 bar)

Lock fitting ARV60.CB4 up to 64 bar 7

Page 8

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (07836) 50-0

Fax (07836) 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application, practical

use and operating conditions of the sensors and processing systems correspond to the latest information at the time of printing.

Technical data to subject to alterations

26320-EN-030715

Loading...

Loading...