Page 1

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

INTRODUCTION

General Information: Ever wish you could edit the "dead air time" from tape

recordings of meetings, speeches, interviews, etc? Now you can do it while you

record with the VEC-483K Voice Activated Tape Recorder Switch Kit. With

voice activation, you save money by recording more information on each tape-and you save valuable listening time during playback because every inch of tape

is filled with information. In addition to voice-activating your recorder, the

VEC-483K helps you make better quality recordings because it places a highquality electret microphone near the sound source, and far away from the noisy

tape transport mechanism in your machine.

Circuitry: The VEC-483K has two parts. First, a sensitive electret microphone

picks up sound and sends it to your recorder via the external microphone jack.

Second, a high-gain op-amp samples the microphone signal, amplifies it, and

then detects it--using the detector level to drive a FET switch. This switch, in

turn, activates and pauses your recorder via the remote jack. Sensitivity and

hold-delay are both adjustable to your liking. The unit is internally powered by a

long-lasting 9-volt alkaline battery.

TOOLS AND SUPPLIES

Construction Area: Kit construction requires a clean, smooth, and well-lighted

area where you can easily organize and handle small parts without losing them.

An inexpensive sheet of white poster board makes an excellent construction

surface, while providing protection for the underlying table or desk. Diffused

overhead lighting is a plus, and a supplemental high-intensity desk lamp is

especially helpful for close-up work. Safety is always important! Use a suitable

high-temperature stand for your soldering iron, and keep the work area free of

clutter.

Universal Kit-building Tools: No special tools are required to complete this

kit beyond common items normally used for bench construction. We

recommend the following:

! Soldering Iron (grounded-tip and temperature-controlled preferred)

! High-temperature Iron Holder with Cleaning Sp onge

! Solder, 60/40 or 63/37 with rosin or "no-clean" flux (.031" dia. is good

size).

! Needle Nose Pliers or Surgical Hemostats

! Diagonal Cutters or "Nippy Cutters"

! Solder Sucker (squeeze or vacuum pump type), or Desoldering Braid

1

Page 2

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

! Bright Desk Lamp

! Magnifying Glass

BEFORE YOU START BUILDING

Experience shows there are four common mistakes builders make. Avoid these,

and your kit will probably work on the first try! Here's what they are:

1. Installing the Wrong Part: It always pays to double-check each step. A 1K

and a 10K resistor may look almost the same, but they may act very

differently in an electronic circuit! Same for capacitors--a device marked

102 (or .001 uF) may have very different operating characteristics from one

marked 103 (or .01uF).

2. Installing Parts Backwards: Always check the polarity of electrolytic

capacitors to make sure the positive (+) lead goes in the (+) hole on the

circuit board. ICs have a notch or dot at one end indicating the correct

direction of insertion. Always double-check--especially before applying

power to the circuit!

3. Faulty Solder Connections: Inspect for cold-solder joints and solder

bridges. Cold solder joints happen when you don't fully heat the connection-or when metallic corrosion and oxide contaminate a component lead or pad.

Solder bridges form when a trail of excess solder shorts pads or tracks

together (see solder tips below).

4. Omitting or Misreading a Part: This is easier to do than you might think!

Always double-check to make sure you completed each step in an assembly

sequence.

Soldering Tips: Cleanliness and good heat distribution are the two secrets of

professional soldering. Before you install and solder each part, inspect leads or

pins for oxidation. If the metal surface is dull, sand with fine emery paper until

shiny. Allow the tip of your iron to contact both the lead and pad for about one

second (count "one-thousand-one") before feeding solder to the connection.

Surfaces must become hot enough for solder to flow smoothly. Feed solder to

the opposite side of the lead from your iron tip--solder will wick around the lead

toward the tip, wetting all exposed surfaces. Apply solder sparingly, and do not

touch solder directly to the hot iron tip to promote rapid melting. Keep a damp

sponge handy to wipe your so ldering tip on. This removes excess solde r, and

keeps the tip properly tinned. If the iron is going to sit idling for long periods,

wipe the tip, add some fresh solder, and unplug the iron.

Desoldering Tips: If you make a mistake and need to remove a part, follow

these instructions carefully! First, grasp the component with hemostats or

2

Page 3

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

needle-nose pliers. Heat the pad beneath the lead you intend to extract, and pull

gently. The lead should come out. Repeat for the other lead. Solder may fill in

behind the lead as you extract it--especially if you are working on a double-sided

board with pla te-through holes. Should this hap pen, try heating the pad again

and inserting a common pin into the hole. Solder won't stick to the pin's

chromium plating. When the pad cools, remove the pin and insert the correct

component. For ICs or multiple-pin parts, use desoldering braid to remove

excess solder before attempting to extract the part. Alternatively, a low-cost

vacuum-bulb or spring-loaded solder sucker may be used. Parts damaged or

severely overheated during extraction should be replaced rather than reinstalled.

Work Habits: Kit construction requires the ability to follow detailed

instructions and, in many cases, to perform new and unfamiliar tasks. To avoid

making needless mistakes, work for short periods when you're fresh and alert.

Recreational construction projects are more informative and more fun when you

take your time. Enjoy!

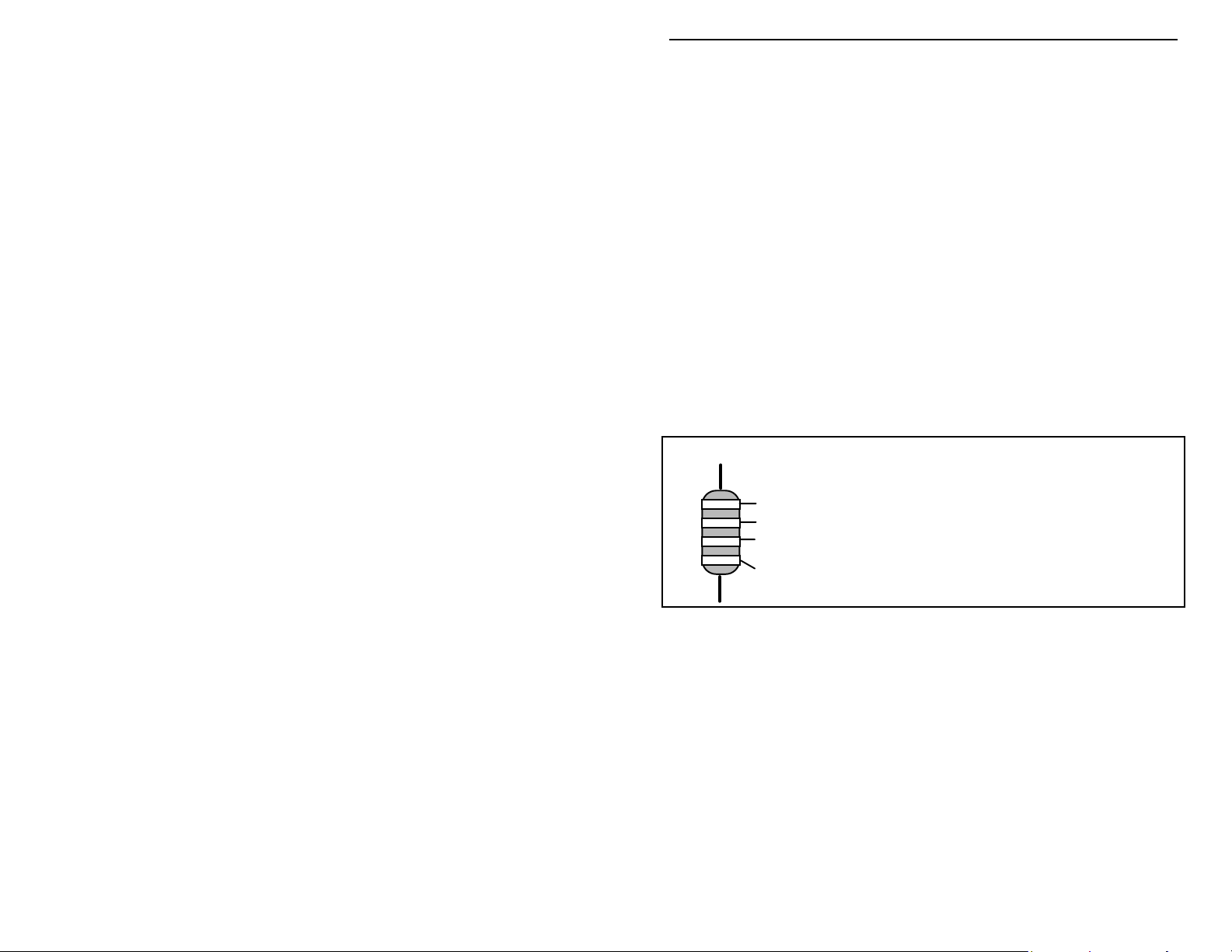

Sorting and Reading Resistors: The electrical value of resistors is indicated by

a color code (shown below). You don't have to memorize this code to work with

resistors, but you do need to understand how it works:

Resistor Color Code

Black = 0 (tens)

1st Digit

2nd Digit

Multiplier

Tolerence

(gold or silver)

When you look at a resistor, check its multiplier code first. Any resistor with a

black multiplier band falls between 10 and 99 ohms in value. Brown designates

a value between 100 and 999 ohms. Red indicates a value from 1000 to 9999

ohms, which is also expressed as 1.0K to 9.9K. An orange multiplier band

designates 10K to 99K, etc. To inventory resistors, first separate them into

groups by multiplier band (make a pile of 10s, 100s, Ks, 10Ks, etc.). Next, sort

each group by specific value (1K, 2.2K, 4.7K, etc). This procedure makes the

inventory easier, and also makes locating specific parts more convenient later on

during construction. Some builders find it especially helpful to arrange resistors

in ascending order along a strip of double-sided tape.

Reading Capacitors: Unlike resistors, capacitors no longer use a color code for

value identification. Instead, the value, or a 3-number code, is printed on the

body.

Brown = 1 (hundreds)

Red = 2 (K)

Orange = 3 (10K)

Yellow = 4 (100K)

Green = 5 (1Meg)

Blue = 6

Violet = 7

Gray = 8

White = 9

Silver = 10%

Gold = 5%

3

Page 4

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

Value Code

10 pF = 100

100 pF = 101

1000 pF = 102

.001 uF = 102*

.01 uF = 103

.1 uF = 104

As with resistors, it's helpful to sort capacitors by type, and then to arrange them

in ascending order of value. Small-value capacitors are characterized in pF (or

pico-Farads), while larger values are labeled in uF (or micro-Farads). The

transition from pF to uF occurs at 1000 pF (or .001 uF)*. Today, most

monolithic and disc-ceramic capacitors are marked with a three-number code.

The first two digits indicate a numerical value, while the last digit indicates a

multiplier (same as resistors).

Electrolytic capacitors are always marked in uF. Electrolytics are polarized

devices and must be oriented correctly during installation. If you become

confused by markings on the case, remember the uncut negative lead is slightly

shorter than the positive lead.

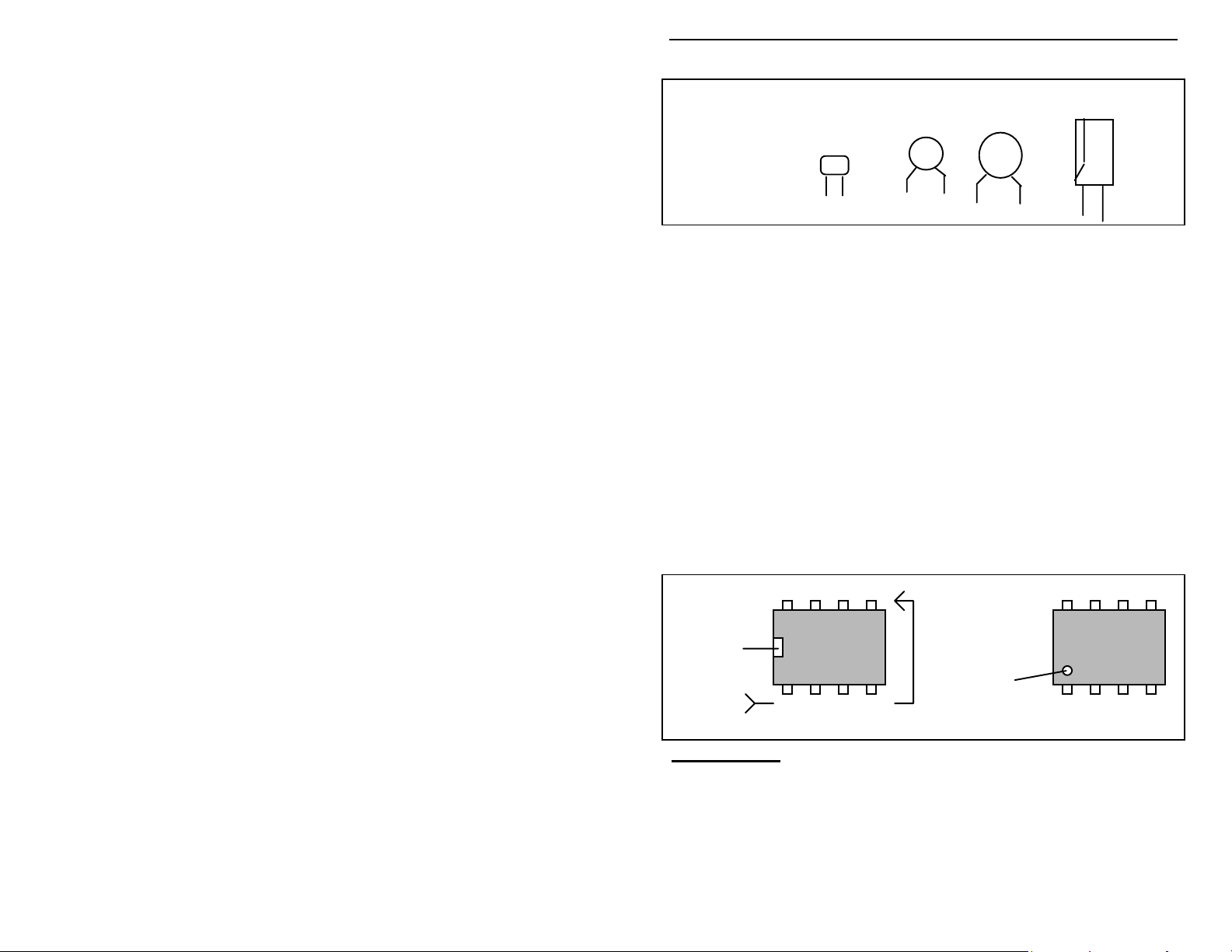

Integrated Circuits: Proper IC positioning is indicated by a dot or square

marking located on one end of the device. A corresponding mark will be silkscreened on the PC board and printed on the kit's parts-placement diagram. To

identify specific IC pin numbers for testing purposes, see the diagram below.

Pin numbers always begin at "1" at the keyed end of the case and progress along

the device, as shown:

Multilayer

(270 pF)

271

Ceramic Discs

(.001 uF) (.1 uF)

102

104

Electrolytic

1 uF

|

1uF

|

35V

+

-

8 7 6 5

Installation

Key

1 2 3 4

Pin Numbers

Installation

Key

PARTS LIST

Your kit should contain all of the parts listed below. Please identify and

inventory each item on the checklist before you start building. If any parts are

missing or damaged, refer to the manual's warranty section for replacement

instructions. If you can't positively identify an unfamiliar item on the basis of the

information given, set it aside until all other items are checked off. You may

4

Page 5

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

then be able to identify it by process of elimination. Finally, your kit will go

together more smoothly if parts are organized by type and arranged by value

ahead of time. Use this inventory as an opportunity to sort and arrange parts so

you can identify and find them quickly.

""""

Qty Part Description Designation VEC P/N

#

2 1K resistor (brown-black-red) R3, R4 100-3100

#

2 10K resistor (brown-black-orange) R1, R2 100-4100

#

1 47K resistor (yellow-violet-orange) R6 100-4470

#

2 500K trimpot R7, R8 133-5500

#

3 1 uF electrolytic capacitor C1, C4, C5 270-4100-2

#

2 10 uF electrolytic capacitor C2, C3 270-5100-1

#

2 1N4148 diode D1, D2 300-4148

#

1 2N7000 plastic FET transistor Q1 305-7000

#

1 LM358 op-amp (8-pin) U1 324-0358

#

1 Microphone element, electret MIC1 410-1092

#

1 2P2T mini power switch SW1 504-2022

#

1 3.5mm stereo jack J1 601-5005

#

1 2.5mm mono jack J2 601-4009

#

1 9V battery snap BAT1 730-3005

#

1 8 pin IC socket for U1 625-0008

#

1 Plastic wire tie 745-2149

#

1 VEC-483 printed circuit board 861-VEC483

#

1 Owner’s Manual 925-VEC483K

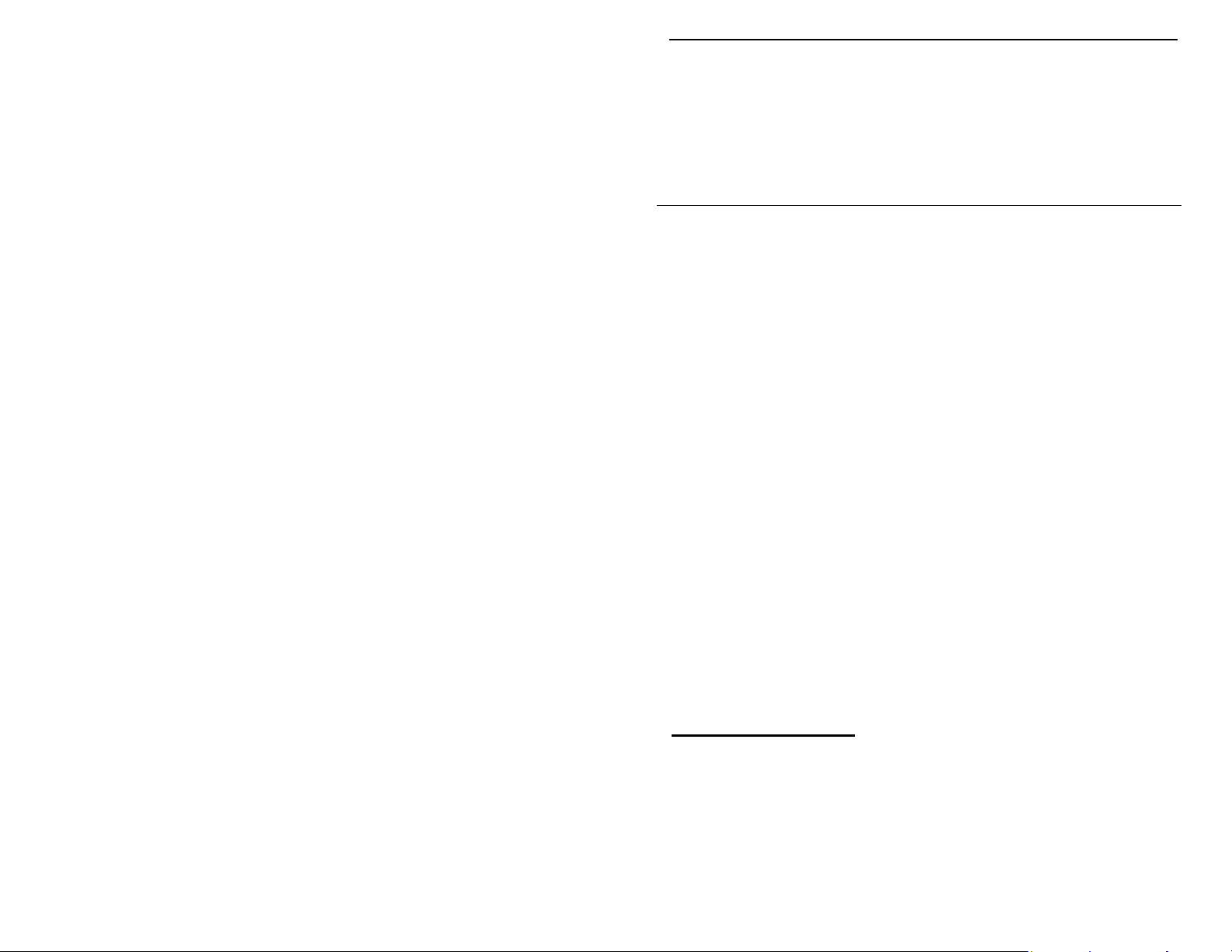

PARTS PLACEMENT

5

Page 6

Page 7

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

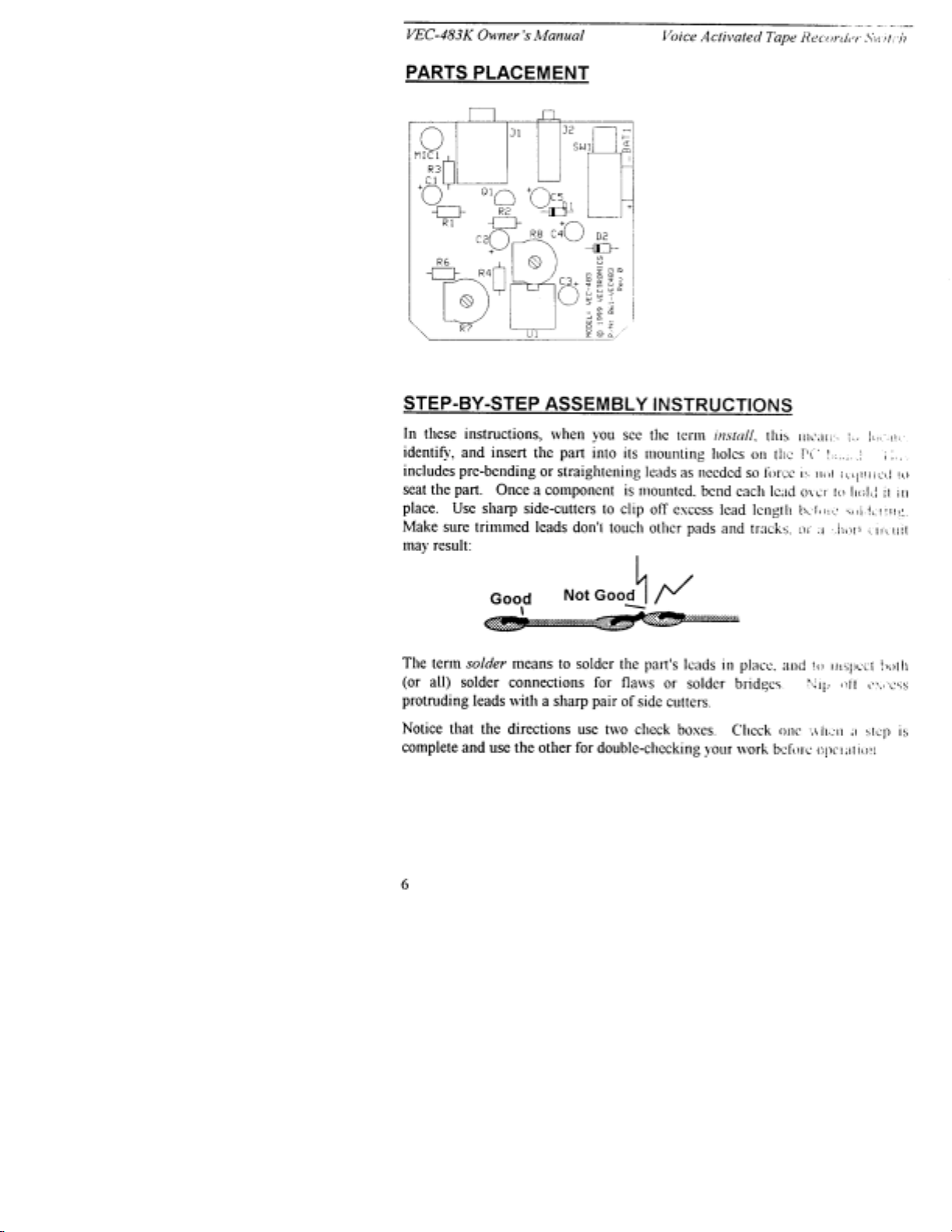

This kit has 5 fixed-value resistors. Mount these now, starting with the smallest

value and moving to the largest. Before mounting each one, carefully bend both

leads close to the resistor body to form right-angles, as shown below:

.4"

Locate two (2) 1K resistors (brown-black-red).

# # 1.$Install 1K at R3 and solder.

# # 2.$Install 1K at R4 and solder.

Locate two (2) 10-K resistors (brown-black-orange).

# # 3.$Install 10 K at R1 and solder.

# # 4.$Install 10 K at R2 and solder.

# # 5.$Find the 47-K resistor (yellow-violet-orange). Install at R6 and solder.

The next two (2) items are 500-K trimpots (black, screw adjustment in the

center, 3 pins). When you install each trimpot, make sure it is seated firmly

against the PC board with all three leads protruding.

# # 6.$Install a 500-K trimpot at R7 and solder.

# # 7.$Install a 500-K trimpot at R8 and solder.

There are five electrolytic capacitors in your kit. Electrolytic caps are

polarized and must be installed the correct way in order to work. Each

capacitor's plus (+) mounting hole is marked on both the circuit board and parts

placement diagram. If the markings on the capacitor body are unclear, the plus

(+) lead is always the longer of the two.

+

Plus Lead

Locate three (3) 1-uF electrolytic capacitors. Observing polarity:

# # 8.$Install 1 uF at C1 and solder.

# # 9.$Install 1 uF at C4 and solder.

7

Page 8

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

# # 10.$Install 1 uF at C5 and solder.

Locate two (2) 10-uF electrolytic capacitors. Observing polarity:

# # 11.$Install 10 uF at C2 and solder.

# # 12.$Install 10 uF at C3 and solder.

Now, find two (2) 1N4148 silicon diodes (glass body). Like capacitors, diodes

are polarized devices that must be installed correctly. Always look for the

banded end when installing--and align this with the banded end shown on the PC

layout.

# # 13.$Install a 1N4148 at D1 and solder.

# # 14.$Install a 1N4148 at D2 and solder.

Locate the 2N7000 plastic transistor. Like the electrolytic caps, transistors must

be oriented correctly to work properly.

2N7000

# # 15.$Install the 2N7000 FET at Q1 and solder.

The ICs in your kit will be installed in a IC socket. Like the IC itself, the socket

is keyed at one end to indicate proper positioning. During installation, orient the

socket so the notch corresponds to the key on the PC layout.

Key

Key

When installing the socket, make sure all pins enter the mounting holes and

appear on the opposite side of the PC board (it's easy to fold one or more under).

8

Page 9

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

Also, when soldering, make sure the socket remains flat against the board

surface.

# # 16.$Find the 8-pin IC socket. Orient to U1, install, and solder all pins.

Next, align the LM358 IC with the socket, matching its key with the socket key.

When you install, press in slowly--making sure all pins go into the socket holes

and none fold over under the device.

# # 17.$Observing the key, install the LM358 at U1.

Your kit co ntains a miniat ure DPDT switch. Some versions r equire install ation

of a plastic clip-on support at the front of the switch body. This piece relieves

stress on the pins and ensures level seating during installation. If your parts kit

contains this piece, install as shown:

# # 18.$Install the DPDT mini power switch at SW1

Locate the 9-V battery snap clip, and note the red+ lead and black- lead.

# # 19.$Install the red lead at BAT1 (+) and solder.

# # 20.$Install the black lead at BAT1 (-) and solder.

Find the oversized hole slightly to the rear of the BAT1 connections. The plastic

tie-wrap supplied with your kit will be installed here to bind the two battery

leads to the PC board. This will help prevent lead breakage later on.

Tie-wrap

+

SW1

-

9

Page 10

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

# # 21.$Locate the tie-wrap and install as shown.

Your kit has two (2) min-phono jacks. The larger of the two is a 3.5 mm stereo

jack, and the smaller is a 2.5 mm mono jack. When installing jacks, make sure

the case sets firmly against the PC board surface before soldering.

# # 22.$Install the 3.5 mm jack (larger) at J1 and solder.

# # 23.$Install the 2.5 mm jack (smaller) at J2 and solder.

Finally, locate the electret condenser microphone element (MIC1) and observe

the leads. One is grounded to the case by a bridge of metal, while the other is

not. The gro und ed le ad must co r re sp ond with the groundp la ne mounting hole on

the PC board.

"Hot" Side

Ground Side

Element

Space element above board

so leads protrude

about .1" through

PC board.

When positioning the mic element, space as far as possible above the surface of

the PC board. Leads should protrude only enough to ensure a good solder

connection.

# # 24.$Observing polarity, install the electret mic element at MIC1 and solder

in place.

This concludes construction of your VEC-483K Voice-Activated Tape Switch.

Before moving on, give your kit a thorough QC (quality control) inspection.

This will help you discover accidental assembly errors that might prevent it from

working properly--or that might cause damage to sensitive parts when you apply

power. Follow this procedure:

1. Compare parts locations with the parts-placement diagram. Was each part

installed where it is supposed to be? Was the correct value used? Start at

one side of the board and work your way across in an organized pattern.

2. Inspect the solder side of the board for cold-solder joints and solder bridges

between tracks or pads. Use a magnifying glass to obtain a clear view of the

track area. If you suspect a solder bridge, hold the board in front of a bright

light for a better view. All joints should be smooth and shiny, indicating

good solder wetting and flow. Resolder any beaded or dull-appearing

connections. Also, check the front-panel jacks, switches, and connectors for

defective solder connections.

3. Finally, check electrolytic capacitors and diodes for correct polarity. Does

the plus (+) polarity symbol on the part agree with the pictorial and with the

10

Page 11

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

pattern on the PC board? Is the banded end of each diode positioned

correctly? Were the IC and transistor installed correctly?

Be sure to correct all errors before continuing.

TESTING AND ALIGNMENT

Before you can test and operate your unit, you'll need two patch cords to connect

the VEC-483K to your recorder. These may be purchased at Radio Shack, or

you may make them up as shown:

3.5 stereo plugs

"External microphone" line to recorder

2.5 mm mono Plugs

"Remote" line to recorder

These mic and switch lines may be any convenient length, but shielded cable

should be used for the microphone cable if it's more than a foot or so long.

Unshielded wire is okay for the remote line. Connect the VEC-483K to your

tape recorder as follows:

VEC-483K

Pwr

J2

Mic

J1

Mic Remote

The PC board has two set-up adjustments. For no w, adjust trimpots R7 and R8

for mid-scale (12:00) using a small screwdriver. Once you're sure the unit is

11

Page 12

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

working properly, you may set these more precisely for your personal

preference.

1. Put SW1 in the Off position (switch button out).

2. Install a fresh 9-volt alkaline battery on the battery snap clip.

3. Press SW1 On (switch button in).

4. Place recorder in "record" mode.

If there's no sound present, the tape transport should not remain on with the

record button is depressed. If it does remain on, check for construction

errors--especially around U1. If not, proceed.

5. Whistle into the microphone.

The tape transport should start rolling. If it doesn't, look for errors around

D1, D2 and Q1.

After a second or so of silence, the tape should shut off again, automatically.

If it doesn't, look for errors around delay control R8. If the tape starts and

stops automatically, your unit is working properly.

Now is a good time to set up the Sensitivity and Delay controls.

Sensitivity: The Sensitivity of your VEC483K is controlled by R7. This sets

the "start-up" threshold for activating the transport. Under noisy conditions,

reducing sensitivity prevents stray background noise from starting the tape

transport. If there's little background noise and a weak sound source, increased

sensitivity is best.

Delay: The Delay (or hold) is controlled by R8. This sets the period of time the

transport stays on after the sound stops. A short delay is best when the sound

source is "up close and personal". A longer delay works best for variable sounds

that may not always be strong eno ugh to hold the switching circuit on.

Once you are satisfied that your unit is operating properly and adjusted to your

needs, you may mount it in the enclosure of your choice. The VEC483KC is

made especially for your unit, and is highly recommended.

OPERATING INSTRUCTIONS

Using Your Recorder Switch: Detailed operating instructions are contained in

the previous section. In general, all you need to do is plug in your unit

(microphone and remote), and turn the MFJ-483K on. If playback sounds

"broken" because the transport drops out during words or phrases, increase

12

Page 13

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

sensitivity (R7) until the recorder remains on. If playback sounds "choppy"

because of constant stopping and starting, increase delay (R8) to add more

natural spacing between words and phrases.

IN CASE OF DIFFICULTY

Before seeking outside assistance, check below for a possible solution:

Does not turn on: Check battery condition, snap clip, and power leads. Also,

make sure lead polarity is correct (red to +, black to GND). Make sure power

switch is "on".

Transport Stays on: Setting of R7 or R8 too high, remote cable shorted.

Transport Won't Start: Setting for R7 or R8 too low, remote cable open.

If these checks fail to uncover the problem, repeat the "QC" check one more

time. Service records show that, for most malfunctioning kits, outright

component failure is relatively rare. In most cases, the culprit is a misplaced

part, reverse-polarized capacitor, improperly installed IC, or a faulty solder

connection. If, despite your best effort, you cannot solve the problem, kit repair

services are available through V ectronics. See the warranty on the inside front

cover for complete instructions.

13

Page 14

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

THEORY OF OPERATION

Electret microphone MIC1 picks up sound and generates an audio signal which

loops through to microphone output jack J1. Along the way a sample of the

audio signal is picked up by U1a, an op-amp configured as a variable gain audio

amplifier. Stage gain is established by Sensitivity control R7. U1's amplified

AF output signal is detected by D1/D2, converted to a dc level, and fed to the

gate of Q1. When sufficient voltage is developed across the detector, FET

switch Q1 conducts and pulls the recorder's "remote" line to ground--providing a

current path for activation of the transport motor. To create the unit's "delay"

function, a RC circuit on the gate of Q1 stores detector voltage and holds the

gate voltage "high" at a decaying rate. The time constant of this circuit is

adjustable by Delay Control R8. Q1 has sufficient current handling capacity to

operate a wide range of small-recorder transport motors.

14

Page 15

Page 16

VEC-483K Owner’s Manual Voice Activated Tape Recorder Switch

ENCLOSURE

To install your Voice-Activated Tape Recorder Switch in the VEC-483KC

matching enclosure follow these instructions (read all instructions before

beginning ... take your time):

1. Find the front panel decal and trim. Be sure to leave excess decal material

around the edges. Put the front panel decal on. T his is done by: a.)

Remove all debris and oil from the face plate. This should be done using a

piece of cloth and alcohol. b.) Remove the crack and peel to expose the

adhesive. c.) Place the decal on the front panel without securing it

completely. d.) Gently rub the alignment circles with your finger--if the

circles are centered in the enclosure holes (also check the corner alignment

marks) secure the decal by rubbing and removing all air bubbles. e.) If the

alignment circles are not centered, adjust the decal accordingly, then secure.

f.) Use a penknife, o r small Exact o

from the adhesive side) and cut out the component holes (cut from the

description side).

2. Now insert the PC board. This must be done by: a.) Insert the front of the

PC board into the metal faceplate with the jacks in their respective holes. b.)

Place the nuts onto the jacks and tighten. Ensure that the switch and the

microphone are aligned properly. c.) Install the red switch cap on the power

switch (SW1).

TM

knife, to cut away the unused edges (cut

3. Slide the face plate in the slots at the end of the bottom portion of the

enclosure. Loop the battery snap through to the battery compartment. Now

place the top portion over the bottom ensuring that the face plate slides into

the slots. Secure the two enclosure portions together with the two mounting

screws.

4. Finally, place a 9V battery into the battery compartment and attach to the

battery snap. Make sure the power switch is off before installing the battery.

16

Page 17

Loading...

Loading...