Page 1

VEC-4001K Owner’s Manual Professional Function Generator

INTRODUCTION

This easy-to-build professional grade function generator kit provides precision

sine, square, and triangle waveforms from 1 Hz to 1 MHz in six decade ranges.

Waveform amplitude is continuously adjustable from 0 to 12-Volts peak-topeak. DC offset is adjustable from -6 to +6 VDC. Output impedance is 400

Ohms, with short-circuit output protection. Simple-to-follow step-by-step

instructions guide you through assembly and alignment. Cir cuitry is construct ed

on a rugged professional-quality glass-epoxy PC bo ard with a solder mask and

silk-screened component-placement legend. Your kit uses only high-quality

components througho ut, and it co mes co mplete with a sturd y molded cab ine t and

silk-screened aluminum front panel. AC power adapter included.

TOOLS AND SUPPLIES

Construction Area: Kit construction requires a clean, smooth, and well-lighted

area where you can easily organize and handle small parts without losing them.

An inexpensive sheet of white poster board makes an excellent construction

surface, while providing protection for the underlying table or desk. Diffused

overhead lighting is a plus, and a supplemental high-intensity desk lamp is

especially helpful for close-up work. Safety is always important! Use a suitable

high-temperature stand for your soldering iron, and keep the work area free of

clutter.

Universal Kit-building Tools: No special tools are required to complete this

kit beyond common items normally used for bench construction. We

recommend the following:

! Soldering Iron (grounded-tip and temperature-controlled preferred)

! High-temperature Iron Holder with Cle aning Sponge

! Solder, 60/40 or 37/63 with rosin or "no-clean" flux (.031" dia. is good size)

! Needle Nose Pliers or Surgical Hemostats

! Diagonal Cutters or "Nippy Cutters"

! Solder Sucker (squeeze or vacuum pump type), or Desoldering Braid

! Bright Desk Lamp

! Magnifying Glass

1

Page 2

VEC-4001K Owner’s Manual Professional Function Generator

BEFORE YOU START BUILDING

Experience shows there are four common mistakes builders make. Avoid these,

and your kit will probably work on the first try! Here's what they are:

1. Installing the Wrong Part: It always pays to double-check each step. A 1K

and a 10K resistor may look almost the same, but they may act very

differently in an electronic circuit! Same for capacitors--a device marked

102 (or .001 uF) may have very different operating characteristics from on

marked 103 (or .01uF).

2. Installing Parts Backwards: Always check the polarity of electrolytic

capacitors to make sure the positive (+) lead goes in the (+) hole on the

circuit board. Transistors have a flat side or emitter tab, and ICs have a notch

or dot at one end indicating the correct direction of insertion. Diodes are

polarized with a band to indicate the cathode end. LED polarity is coded by

lead length. Always double-check--especially before applying power to the

circuit!

3. Faulty Solder Connections: Inspect for cold-solder joints and solder

bridges. Cold solder joints happen when you don't fully heat the connection-or when metallic corrosion and oxide contaminate a component lead or pad.

Solder bridges form when a trail of excess solder shorts pads or tracks

together (see Soldering Tips below).

4. Omitting or Misreading a Part: This is easier to do than you might think!

Always double-check to make sure you completed each step in an assembly

sequence.

Soldering Tips: Cleanliness and good heat distribution are the two secrets of

professional soldering. Before you install and solder each part, inspect leads or

pins for oxidation. If the metal surface is dull, sand with fine emery paper until

shiny. Allow the tip of your iron to contact both the lead and pad for about one

second (count "one-thousand-one") before feeding solder to the connection.

Surfaces must become hot enough for solder to flow smoothly. Feed solder to

the opposite side of the lead from your iron tip--solder will wick around the lead

toward the tip, wetting all exposed surfaces. Apply solder sparingly, and do not

touch solder directly to the hot iron tip to promote rapid melting. Keep a damp

sponge handy to wipe your so ldering tip on. This removes excess solde r, and

keeps the tip properly tinned. If the iron is going to sit idling for long periods,

wipe the tip, add some fresh solder, and unplug the iron.

Desoldering Tips: If you make a mistake and need to remove a part, follow

these instructions carefully! First, grasp the component with hemostats or

needle-nose pliers. Heat the pad beneath the lead you intend to extract, and pull

gently. The lead should come out. Repeat for the other lead. Solder may fill in

2

Page 3

VEC-4001K Owner’s Manual Professional Function Generator

behind the lead as you extract it--especially if you are working on a double-sided

board with pla te-through holes. Should this hap pen, try heating the pad again

and inserting a common pin into the hole. Solder won't stick to the pin's

chromium plating. When the pad cools, remove the pin and insert the correct

component. For ICs or multiple-pin parts, use desoldering braid to remove

excess solder before attempting to extract the part. Alternatively, a low-cost

vacuum-bulb or spring-loaded solder sucker may be used. Parts damaged or

severely overheated during extraction should be replaced rather than reinstalled.

Work Habits: Kit construction requires the ability to follow detailed

instructions and, in many cases, to perform new and unfamiliar tasks. To avoid

making needless mistakes, work for short periods when you're fresh and alert.

Recreational construction projects are more informative and more fun when you

take your time. Enjoy!

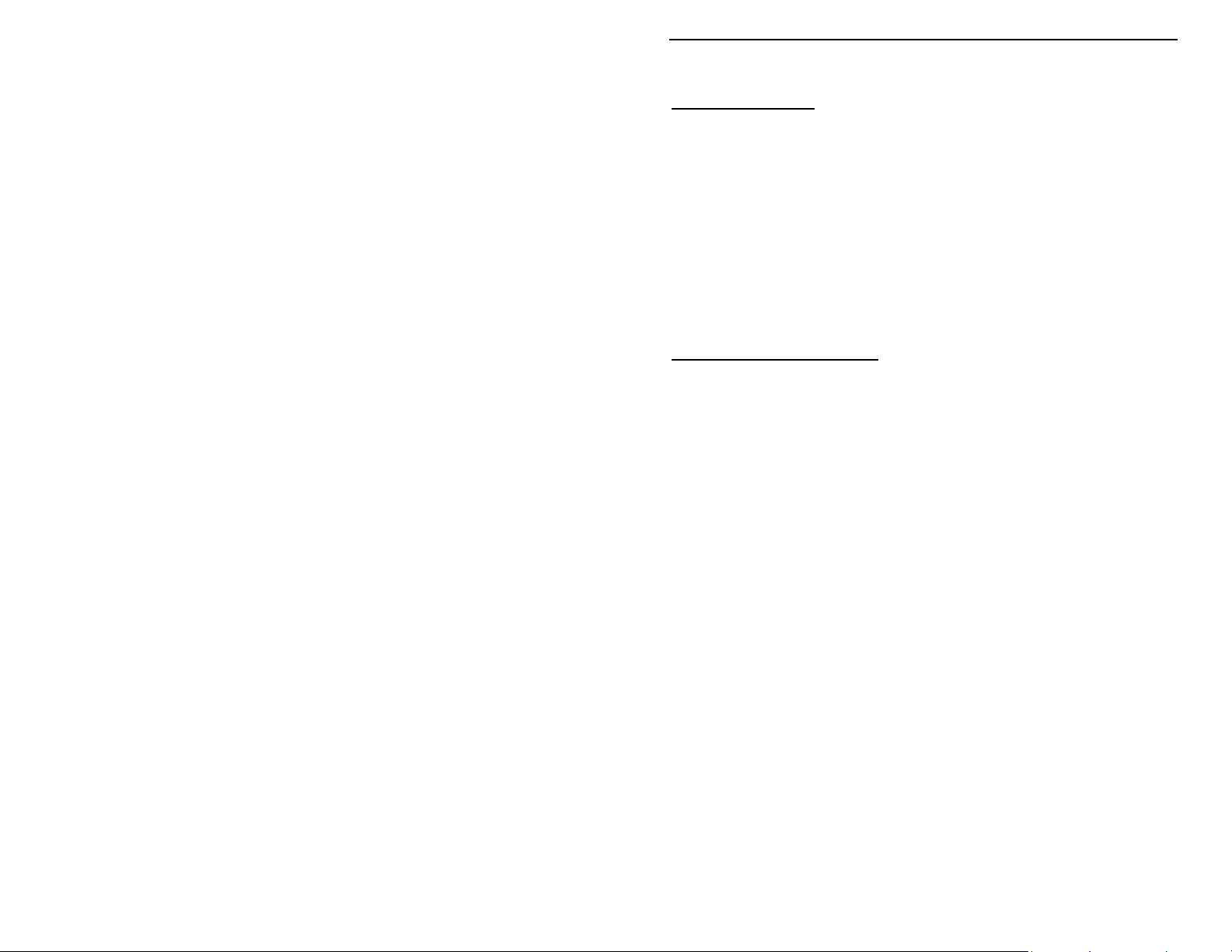

Sorting and Reading Resistors: The electrical value of resistors is indicated by

a color code (shown below). You don't have to memorize this code to work with

resistors, but you do need to understand how it works:

Resistor Color Code

Black = 0 (tens)

1st Digit

2nd Digit

Multiplier

Tolerence

(gold or silver)

When you look at a resistor, check its multiplier code first. Any resistor with a

black multiplier band falls between 10 and 99 ohms in value. Brown designates

a value between 100 and 999 ohms. Red indicates a value from 1000 to 9999

ohms, which is also expressed as 1.0K to 9.9K. An orange multiplier band

designates 10K to 99K, etc. To inventory resistors, first separate them into

groups by multiplier band (make a pile of 10s, 100s, Ks, 10Ks, etc.). Next, sort

each group by specific value (1K, 2.2K, 4.7K, etc). This procedure makes the

inventory easier, and also makes locating specific parts more convenient later on

during construction. Some builders find it especially helpful to arrange resistors

in ascending order along a strip of double-sided tape.

Reading Capacitors: Unlike resistors, capacitors no longer use a color code for

value identification. Instead, the value, or a 3-number code, is printed on the

body.

Brown = 1 (hundreds)

Red = 2 (K)

Orange = 3 (10K)

Yellow = 4 (100K)

Green = 5 (1Meg)

Blue = 6

Violet = 7

Gray = 8

White = 9

Silver = 10%

Gold = 5%

3

Page 4

VEC-4001K Owner’s Manual Professional Function Generator

Value Code

10 pF = 100

100 pF = 101

1000 pF = 102

.001 uF = 102*

.01 uF = 103

.1 uF = 104

As with resistors, it's helpful to sort capacitors by type, and then to arrange them

in ascending order of value. Small-value capacitors are characterized in pF (or

pico-Farads), while larger values are labeled in uF (or micro-Farads). The

transition from pF to uF occurs at 1000 pF (or .001 uF)*. Today, most

monolithic and disc-ceramic capacitors are marked with a three-number code.

The first two digits indicate a numerical value, while the last digit indicates a

multiplier (same as resistors).

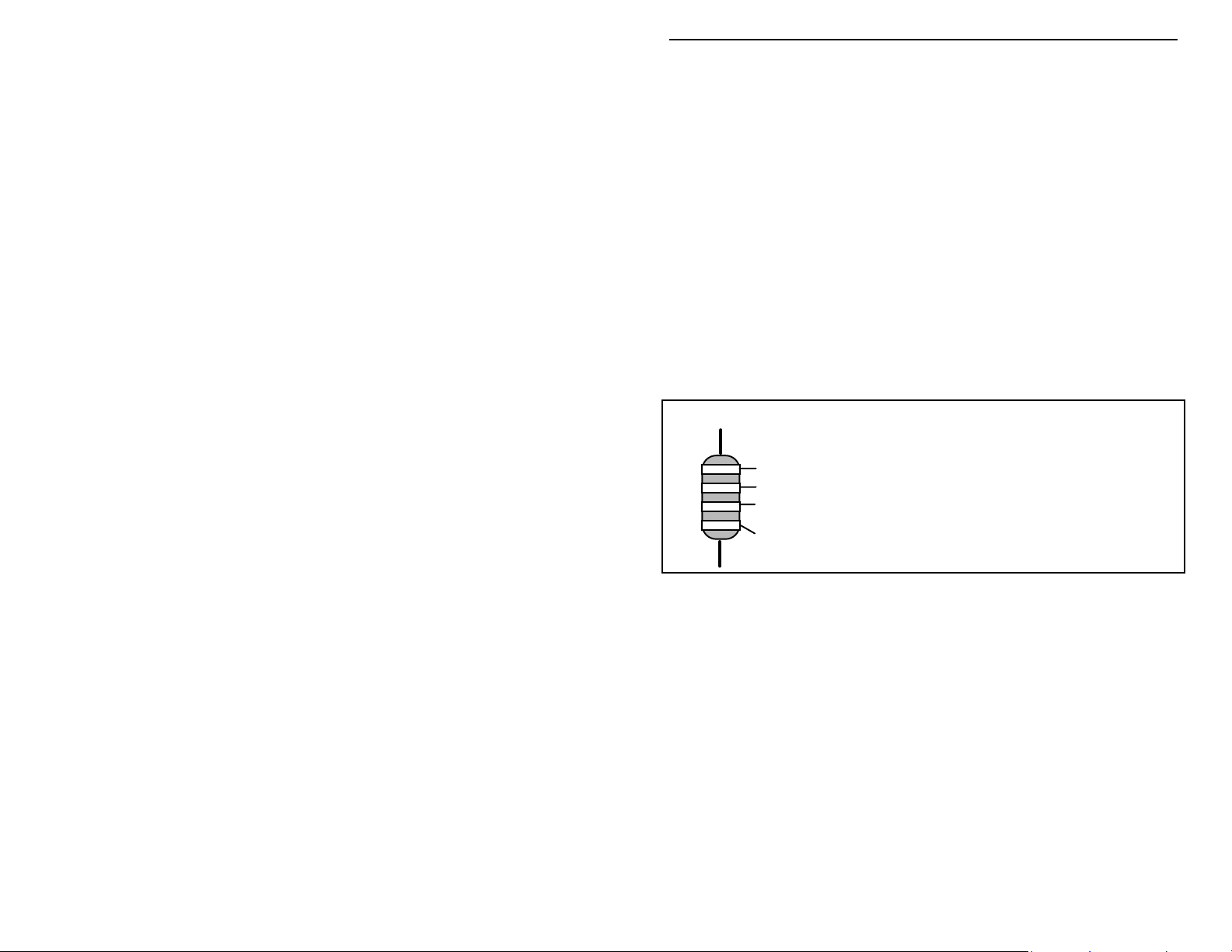

Electrolytic capacitors are always marked in uF. Electrolytics are polarized

devices and must be oriented correctly during installation. If you become

confused by markings on the case, remember the uncut negative lead is slightly

shorter than the positive lead.

Diodes: Diodes are also polarized devices that must be installed correctly.

Always look for the banded--or cathode--end when installing, and follow

instructions carefully.

Multilayer

(270 pF)

271

Ceramic Discs

(.001 uF) (.1 uF)

102

Cathode

104

Electrolytic

1 uF

|

1uF

|

35V

+

-

(shorter Lead)

Diode

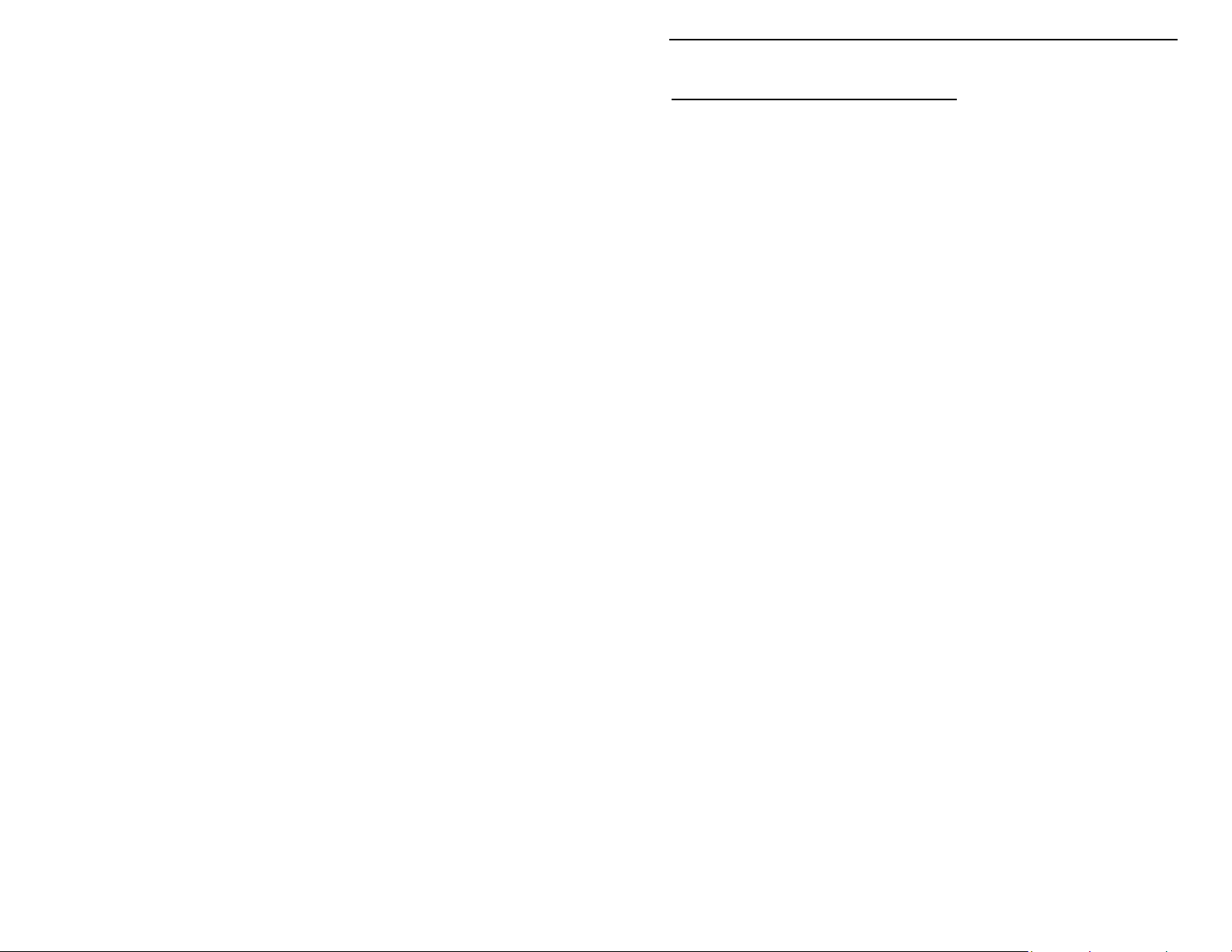

Transistors: If transistors are installed incorrectly, damage may result when

power is applied. Transistors in metal cases have a small tab near the emitter

lead to identify correct positioning. Semiconductors housed in small plastic

cases (TO-92) have an easily-identified flat side to identify mounting orientation.

Many specialized diodes and low-current voltage regulators also use this type

packaging. Larger plastic transistors and voltage regulators use a case backed

with a prominent metal tab to dissipate heat (T-220). Here, orientation is

indicated by the positioning of the cooling tab.

4

LED

Page 5

VEC-4001K Owner’s Manual Professional Function Generator

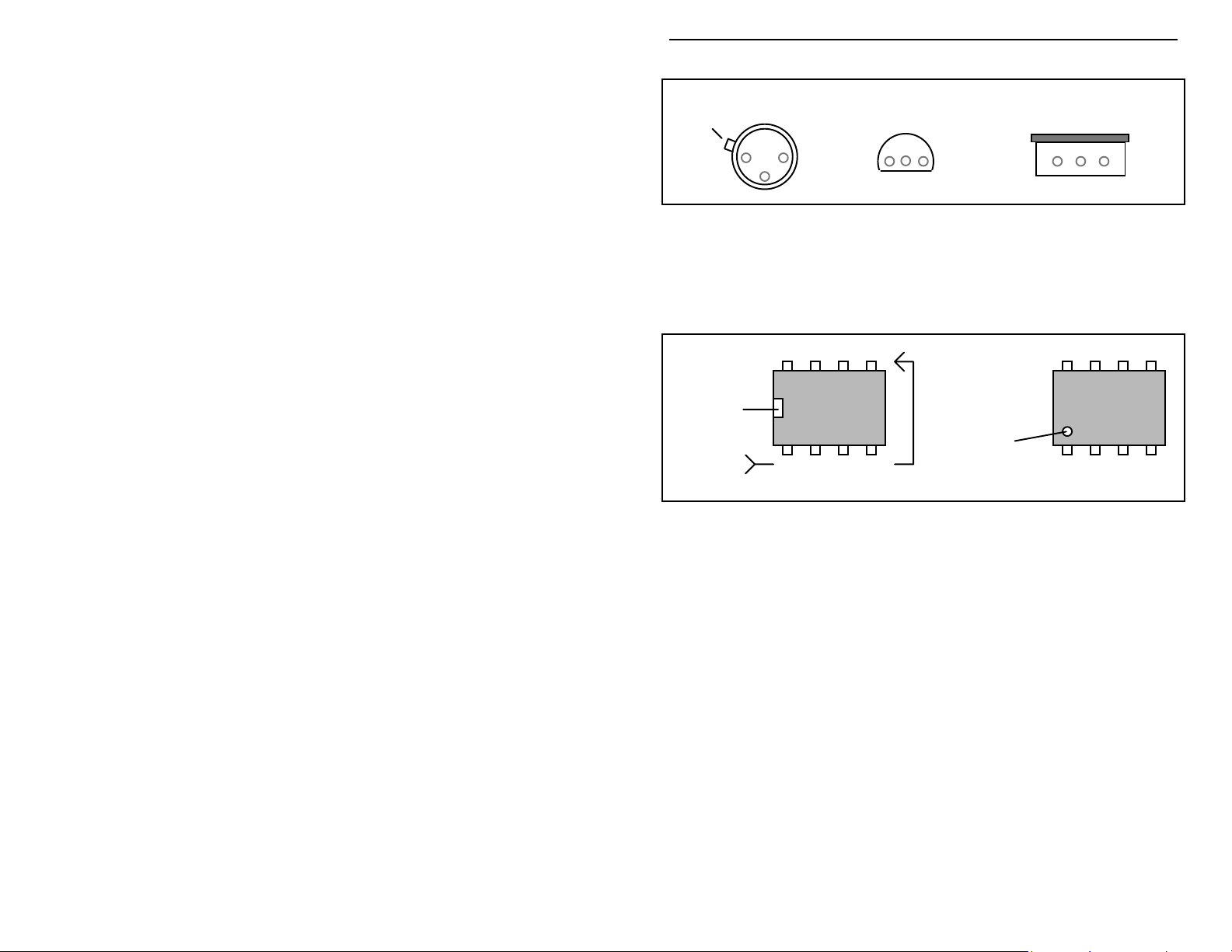

Metal Can Device Plastic Device Tab-cooled Device

Emitter

Flat Side

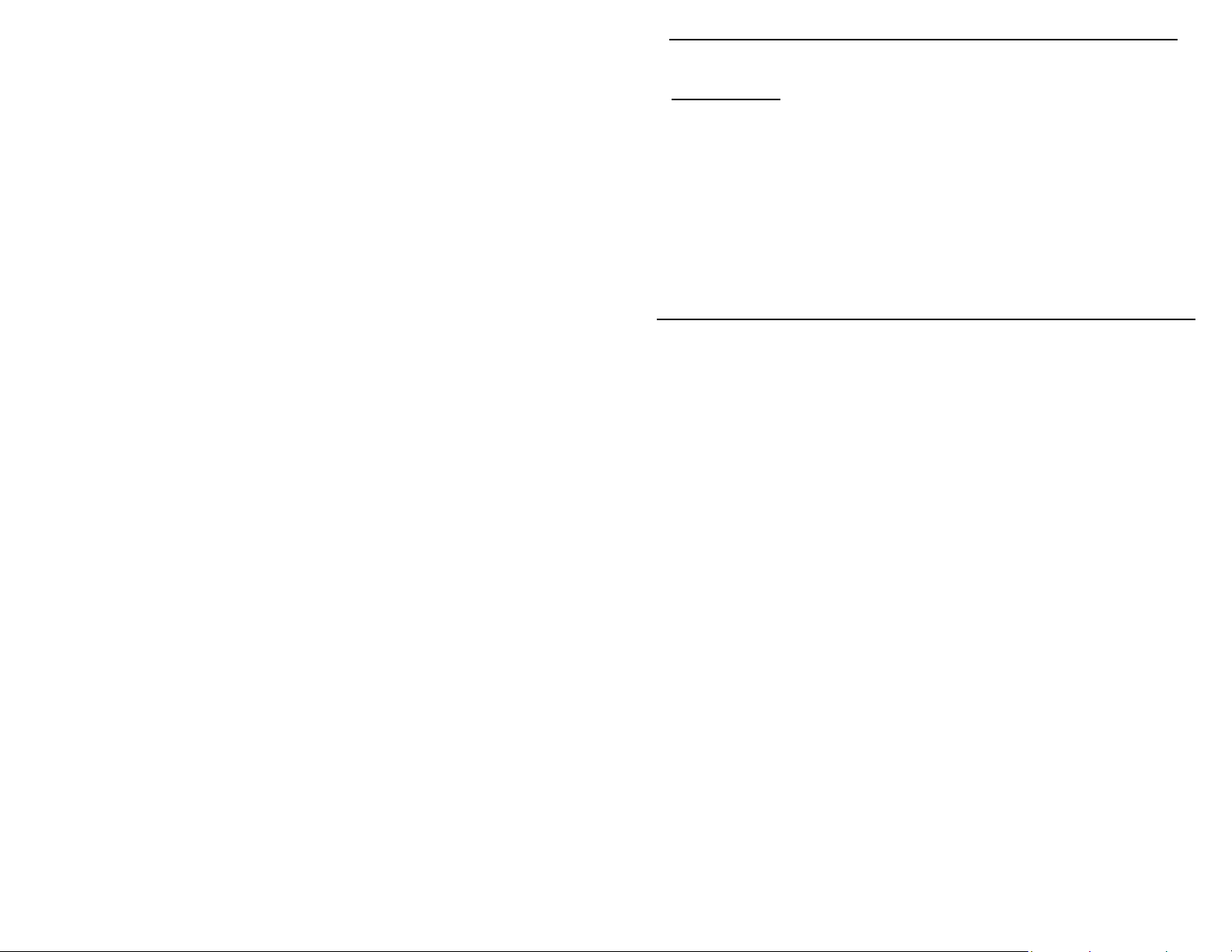

Integrated Circuits: Proper IC positioning is indicated by a dot or square

marking located on one end of the device. A corresponding mark will be silkscreened on the PC board and printed on the kit's parts-placement diagram. To

identify specific IC pin numbers for testing purposes, see the following diagram.

Pin numbers always start at the keyed end of the case and progress counterclockwise around the device, as shown:

8 7 6 5

Installation

Key

Installation

Key

1 2 3 4

Pin Numbers

Metal Tab

5

Page 6

VEC-4001K Owner’s Manual Professional Function Generator

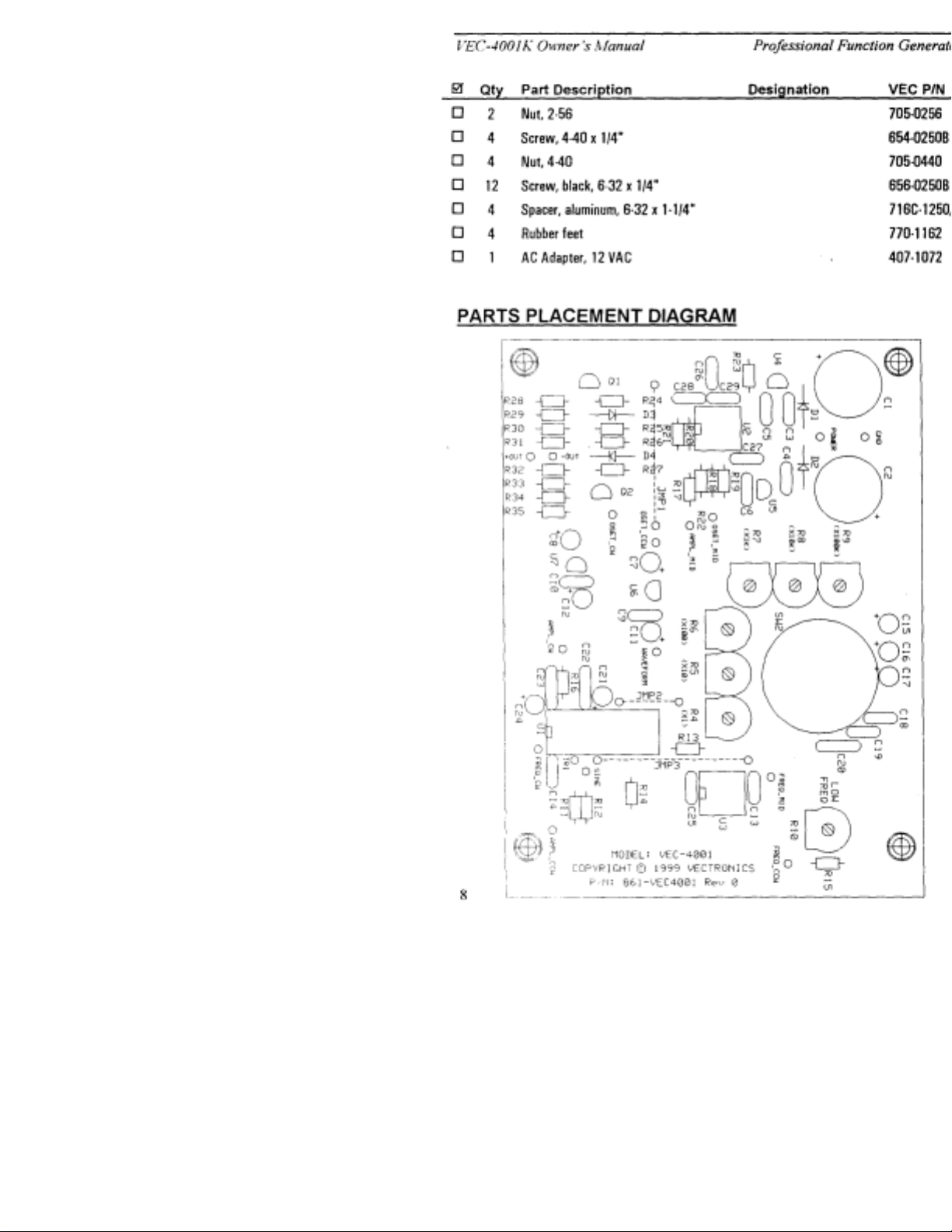

PARTS LIST

Your kit should contain all of the parts listed below. Please identify and

inventory each item on the checklist before you start building. If any parts are

missing or damaged, refer to the manual's warranty section for replacement

instructions. If you can't positively identify an unfamiliar item on the basis of the

information given, set it aside until all other items are checked off. You may

then be able to identify it by process of elimination. Finally, your kit will go

together more smoothly if parts are organized by type and arranged by value

ahead of time. Use this inventory as an opportunity to sort and arrange parts so

you can identify and find them quickly.

""""

Qty Part Description Designation VEC P/N

!

1 51 ohm resistor

(green-brown-black)

!

2 100 ohm resistor

(brown-black-brown)

!

1 680 ohm resistor

(blue-gray-brown)

!

1 1K resistor (brown-

black-red)

!

8 1.6K resistor (brown-

blue-red)

!

1 2K resistor (red-

black-red)

!

2 3K resistor (orange-

black-red)

!

4 12K resistor (brown-

red-orange)

!

2 22K resistor (red-red-

orange)

!

1 24K resistor (red-

yellow-orange)

!

2 27K resistor (red-

violet-orange)

!

1 1K trimpot (102) R10 133-3100

!

6 5K trimpot (502) R4-R9 133-3500

!

3 10K 24-mm

potentiometer (103)

R16 100-1510

R25,R26 100-2100

R15 100-2680

R19 100-3100

R28-R35 100-3160

R17 100-3200

R13,R21 100-330

R11,R12,R14,R

100-4120

20

R24,R27 100-4220

R18 100-4240

R22,R23 100-4270

R1,R2,R3 162-4100-

1

6

Page 7

VEC-4001K Owner’s Manual Professional Function Generator

!

1 680 pF disc ceramic

capacitor (681)

!

2

.001 µF disc ceramic

C20 200-0680-

1

C22,C23 200-1100

capacitor (102)

!

13

.1 µF disc ceramic

capacitor (104)

C3,C4,C5,C6,C

9,C10,C13,C14

200-3100

,C25,C26,

C27,C28,C29

!

1

.0068 µF polyester

C19 230-1680

ceramic capacitor

!

1

.082 µF polyester

C18 230-2820

ceramic capacitor

!

2

1 µF tantalum

capacitor

!

1

1 µF electrolytic

capacitor

""""

Qty Part Description Designation VEC P/N

!

1

10 µF electrolytic

capacitor

!

5

100 µF electrolytic

capacitor

!

2

2200 µF electrolytic

capacitor

!

2 1N4148 switching diode D3,D4 300-4148

!

2 1N4007 rectifier diode D1,D2 300-4007

!

1 2N3904 npn transistor Q1 305-3904

!

1 2N3906 pnp transistor Q2 305-3906

!

1 78L05 voltage

C21,C24 272-4100-

1

C17 270-4100-

2

C16 270-5100-

1

C7,C8,C11,C12

,C15

270-61001

C1,C2 270-7220-

1

U6 307-7805L

regulator IC

!

1 78L12 voltage

U4 307-7812L

regulator IC

!

1 79L05 voltage

U7 307-7905L

regulator IC

!

1 79L12 voltage

U5 307-79L12

regulator IC

!

1 LM318 op-amp U2 324-0318

7

Page 8

VEC-4001K Owner’s Manual Professional Function Generator

!

1 LM358 dual op-amp U3 324-0358

!

1 MAX038CPP function

U1 325-0038

generator IC

!

1 Six-position rotary

SW2 500-1008

switch

!

1 2P2T slide switch SW1 501-1003

!

1 4P4T slide switch SW3 501-1043

!

1 2.1-mm coaxial power

J1 601-6121

jack

!

1 Binding post, red J2 606-0003

!

1 Binding post, black J3 606-0004

!

2 IC socket, 8 pin 625-0008

!

1 IC socket, 20 pin 625-0020

!

1 Switch-style knob 760-0036

!

3 Control knob 760-0033

!

6 6" hook-up wire, black 871-2422-

0600

!

6 6" hook-up wire, red 871-2422-

0600

!

5 6" hook-up wire,

yellow

!

1 PC board, single-sided 861-

871-2444-

0600

VEC4001

!

1 Instruction manual 925-

VEC4001K

!

1 Case, plastic 840-0524

!

1 Faceplate, VEC-4001 804-

VEC4001

!

2 Screw, 2-56 x 3/8" 652-0375

""""

Qty Part Description Designation VEC P/N

!

2 Nut, 2-56 705-0256

!

4 Screw, 4-40 x 1/4" 654-0250B

!

4 Nut, 4-40 705-0440

!

12 Screw, black, 6-32 x

656-0250B

1/4"

8

Page 9

Page 10

VEC-4001K Owner’s Manual Professional Function Generator

STEP-BY-STEP CONSTRUCTION

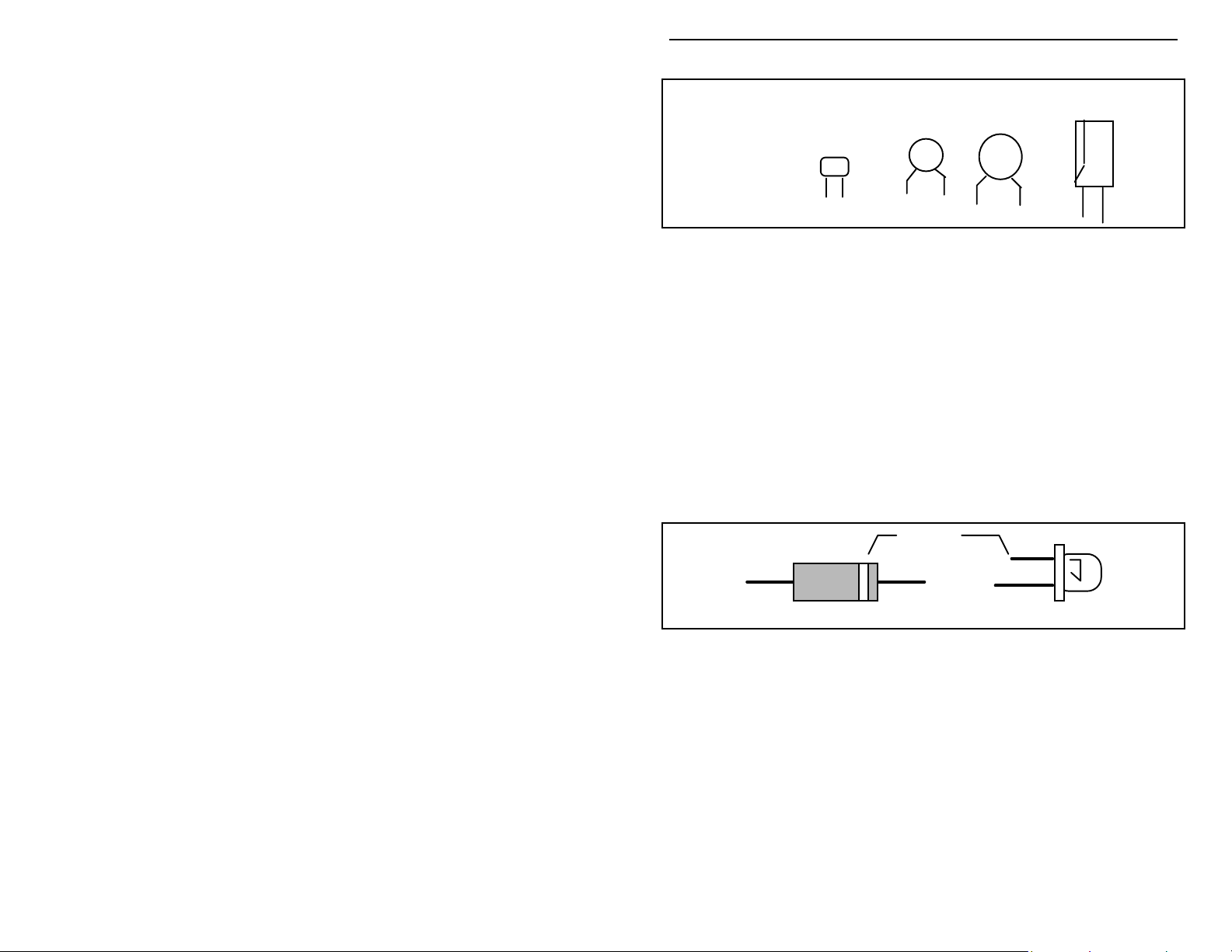

In these instructions, when you see the term install, this means to locate, identify,

and insert the part into its mounting holes on the PC board. T his includes prebending or straightening leads as needed so force is not required to seat the part.

Once a component is mounted, bend each lead over to hold it in place. Use

sharp side-cutters to clip off excess lead length before soldering. Make sure

trimmed leads don't touch other pads and tracks, or a short circuit may result:

Good

Not Good

The term solder means to solder the part's leads in place, and to inspect both (or

all) solder connections for flaws or solder bridges. Nip off excess protruding

leads with a sharp pair of side cutters.

This kit has 25 fixed-value resistors. Mount these now, starting with the smallest

value and moving to the largest. Before mounting each one, carefully bend both

leads close to the resistor body to form right-angles, as shown below:

.4"

! ! 1.#Find a 51 Ohm resistor (green-brown-black). Install at R16 and

solder.

Locate two (2) 100 Ohm resistors (brown-black-brown).

! ! 2.#Install a 100 Ohms at R25 and solder.

! ! 3.#Install a 100 Ohms at R26 and solder.

! ! 4.#Find a 680 Ohm resistor (blue-gray-brown). Install at R15 and

solder.

! ! 5.#Find a 1K resistor (brown-black-red). Install at R19 and solder.

Locate eight (8) 1.6K resistors (brown-blue-red).

! ! 6.#Install a 1.6K at R28 and solder.

! ! 7.#Install a 1.6K at R29 and solder.

! ! 8.#Install a 1.6K at R30 and solder.

10

Page 11

VEC-4001K Owner’s Manual Professional Function Generator

! ! 9.#Install a 1.6K at R31 and solder.

! ! 10.#Install a 1.6K at R32 and solder.

! ! 11.#Install a 1.6K at R33 and solder.

! ! 12.#Install a 1.6K at R34 and solder.

! ! 13.#Install a 1.6K at R35 and solder.

! ! 14.#Find a 2K resistor (red-black-red). Install at R17 and solder.

Locate two (2) 3K resistors (orange-black-red).

! ! 15.#Install a 3K at R13 and solder.

! ! 16.#Install a 3K at R21 and solder.

Locate four (4) 12K resistors (brown-red-orange).

! ! 17.#Install a 12K at R11 and solder.

! ! 18.#Install a 12K at R12 and solder.

! ! 19.#Install a 12K at R14 and solder.

! ! 20.#Install a 12K at R20 and solder.

Locate two (2) 22K resistors (red-red-orange).

! ! 21.#Install a 22K at R24 and solder.

! ! 22.#Install a 22K at R27 and solder.

! ! 23.#Find a 24K resistor (red-yellow-orange). Install at R18 and solder.

Locate two (2) 27K resistors (red-violet-orange).

! ! 24.#Install a 27K at R22 and solder.

! ! 25.#Install a 27K at R23 and solder.

This completes installation of the 25 fixed-value resistors (trimpots and

potentiometers will be installed later). Take a moment to confirm each fixedvalue resistor is positioned in the right location on the PC board.

Next, we’ll install the kit’s diodes. . Diodes are polarized and must be oriented

correctly in order to work. T he banded end of the diode should align with the

single-lined end of the diode symbol on the PC board (see following diagram).

11

Page 12

VEC-4001K Owner’s Manual Professional Function Generator

Locate two (2) 1N4007 diodes.

! ! 26.#Install a 1N4007 at D1 and solder.

! ! 27.#Install a 1N4007 at D2 and solder.

Locate two (2) 1N4148 diodes.

! ! 28.#Install a 1N4148 at D3 and solder.

! ! 29.#Install a 1N4148 at D4 and solder.

Next, we'll install the kit's capacitors--starting with the disc-ceramic types.

! ! 30.#Find a 680 pF disc ceramic capacitor (681). Install at C20 and

solder.

Locate two (2) .001 µF disc ceramic capacitors (102).

! ! 31.#Install a .001 µF at C22 and solder.

! ! 32.#Install a .001 µF at C23 and solder.

Locate thirteen (13) .1 µF disc ceramic capacitors.

! ! 33.#Install a .1 µF at C3 and solder.

! ! 34.#Install a .1 µF at C4 and solder.

! ! 35.#Install a .1 µF at C5 and solder.

! ! 36.#Install a .1 µF at C6 and solder.

! ! 37.#Install a .1 µF at C9 and solder.

! ! 38.#Install a .1 µF at C10 and solder.

! ! 39.#Install a .1 µF at C13 and solder.

! ! 40.#Install a .1 µF at C14 and solder.

! ! 41.#Install a .1 µF at C25 and solder.

! ! 42.#Install a .1 µF at C26 and solder.

! ! 43.#Install a .1 µF at C27 and solder.

! ! 44.#Install a .1 µF at C28 and solder.

! ! 45.#Install a .1 µF at C29 and solder.

! ! 46.#Find the .0068 µF polyester ceramic capacitor (green, marked 682).

Install at C19 and solder.

12

Page 13

VEC-4001K Owner’s Manual Professional Function Generator

! ! 47.#Find the .082 µF polyester ceramic capacitor (green, marked .082).

Install at C18 and solder.

The last group of capacitors in your kit are electrolytic. Electrolytic caps are

polarized and must be installed the correct way in order to work. Each

capacitor's plus (+) mounting hole is marked on both the circuit board and parts

placement diagram. If the markings on the capacitor body are unclear, the plus

(+) lead is always the longer of the two. Most polarized caps you'll install are

aluminum-encased electrolytics. However, your kit also contains two

specialized 1 µF electrolytics called tantalum capacitors. These are small

bulbous parts with a tan-colored dipped-epoxy coating. Do not confuse these

with the 1 µF aluminum type electrolytic also supplied in the kit.

Tantalum Electrolytic Aluminum Electrolytic

+

+

Find the two (2) 1 µF tantalum caps (marked 1 µD). Identify the longer plus

lead (marked +).

! ! 48.#Observing polarity, install a 1 µF tantalum cap at C21.

! ! 49.#Observing polarity, install a 1 µF tantalum cap at C24.

The remaining polarized caps are standard aluminum-case electrolytics.

! ! 50. Locate a 1 µF electrolytic. Observing polarity, install at C17 and

solder.

! ! 51. Locate a 10 µF electrolytic. Observing polarity, install at C16 and

solder.

Find five (5) 100 µF electrolytics. Observing polarity, install as follows:

! ! 52. Install a 100 µF at C7 and solder.

! ! 53. Install a 100 µF at C8 and solder.

! ! 54. Install a 100 µF at C11 and solder.

! ! 55. Install a 100 µF at C12 and solder.

! ! 56. Install a 100 µF at C15 and solder.

Find two (2) 2200 µF electrolytics. Observing polarity:

13

Page 14

VEC-4001K Owner’s Manual Professional Function Generator

! ! 57. Install a 2200 µF at C1 and solder.

! ! 58. Install a 2200 µF at C2 and solder.

This completes installation of all capacitors. Before moving on construction, recheck the polarity of each electrolytic one more time to confirm all are installed

correctly.

The first group of semiconductor include four (4) small ICs and two (2)

transistors. These are all packaged exactly alike. To avoid confusion, read

markings carefully before installing! Like the electrolytic caps, transistors and

ICs must be oriented correctly to work.

Transistors Voltage Regulators

78L05

2N3904

2N3906

78L12

79L05

79L12

! ! 59. Find a 78L05 voltage regulator IC. Install at U6 and solder.

! ! 60. Find a 78L12 voltage regulator IC. Install at U4 and solder.

! ! 61. Find a 79L05 voltage regulator IC. Install at U7 and solder.

! ! 62. Find a 79L12 voltage regulator IC. Install at U5 and solder.

! ! 63. Find a 2N3904 transistor. Install at Q1 and solder.

! ! 64. Find a 2N3906 transistor. Install at Q2 and solder.

The remaining ICs will be installed in sockets. Locate the two (2) eight-pin IC

sockets and one (1) 20-pin socket provided. Identify the notch (or key) at one

end. During installation, each socket will be oriented so that this notch

corresponds to the key on the PC layout.

Key

When installing sockets, make sure all pins enter the mounting holes and appear

on the opposite side of the PC board (it's easy to fold them under the socket).

Also, when soldering, make sure the socket remains flush with the board surface.

14

Page 15

VEC-4001K Owner’s Manual Professional Function Generator

! ! 65. Find a eight-pin IC socket. Orient to U2, install, and solder all 8

pins.

! ! 66. Find a eight-pin IC socket. Orient to U3, install, and solder all 8

pins.

! ! 67. Find a twenty-pin IC socket. Orient to U1. install, and solder all 20

pins.

The ICs will be installed later.

Your kit contains seven (7) calibration trimpots. Locate these now. From this

group, identify the 1K trimpot (marked 1K or 102). This will be installed first.

All others are 5K (marked 5K or 502). Make sure the trimpot body is flush

against the PC board before soldering in place.

! ! 68. Install a 1K trimpot at R10 and solder.

! ! 69. Install a 5K trimpot at R4 and solder.

! ! 70. Install a 5K trimpot at R5 and solder.

! ! 71. Install a 5K trimpot at R6 and solder.

! ! 72. Install a 5K trimpot at R7 and solder.

! ! 73. Install a 5K trimpot at R8 and solder.

! ! 74. Install a 5K trimpot at R9 and solder.

Find the 6-position rotary switch. Orient at SW2, as shown below--noting the

raised "key" next to the shaft.

Switch

Key

The switch must be seated firmly before soldering to ensure shaft alignment with

the front panel.

! ! 75. Install the 6-position rotary switch at SW2 and solder all pins in

place.

Three insulated jumpers are needed to complete PC board assembly. To

prepare, cut hook-up wire to the prescribed length and strip 1/4" of insulation

from both ends. Find a 6" length of yellow hook-up wire and cut as follows:

15

Page 16

VEC-4001K Owner’s Manual Professional Function Generator

! ! 76. Cut to 1 3/4" and prepare jumper. Install at JMP3 and solder.

! ! 77. Cut to 1 3/4" and prepare jumper. Install at JMP1 and solder.

! ! 78. Cut to 1" and prepare jumper. Install at JMP2 and solder.

Finally, locate the remaining three (3) ICs. Each has a round key or a notch at

one end to indicate correct orientation. Before installing, inspect carefully and

confirm all pins are straight. During installation, align pins carefully and insert

slowly to avoid bending or folding. Observing orientation, install as follows:

! ! 79. Install the LM318 op-amp IC at U2.

! ! 80. Install the LM358 op-amp IC at U3.

! ! 81. Install the MAX038CPP function-generator IC at U1.

All components should now be installed on your PC board. Next, you'll install

switches, controls, and jacks on the front panel and wire them to the PC board.

Before starting this procedure, give the PC board a thor ough inspection.

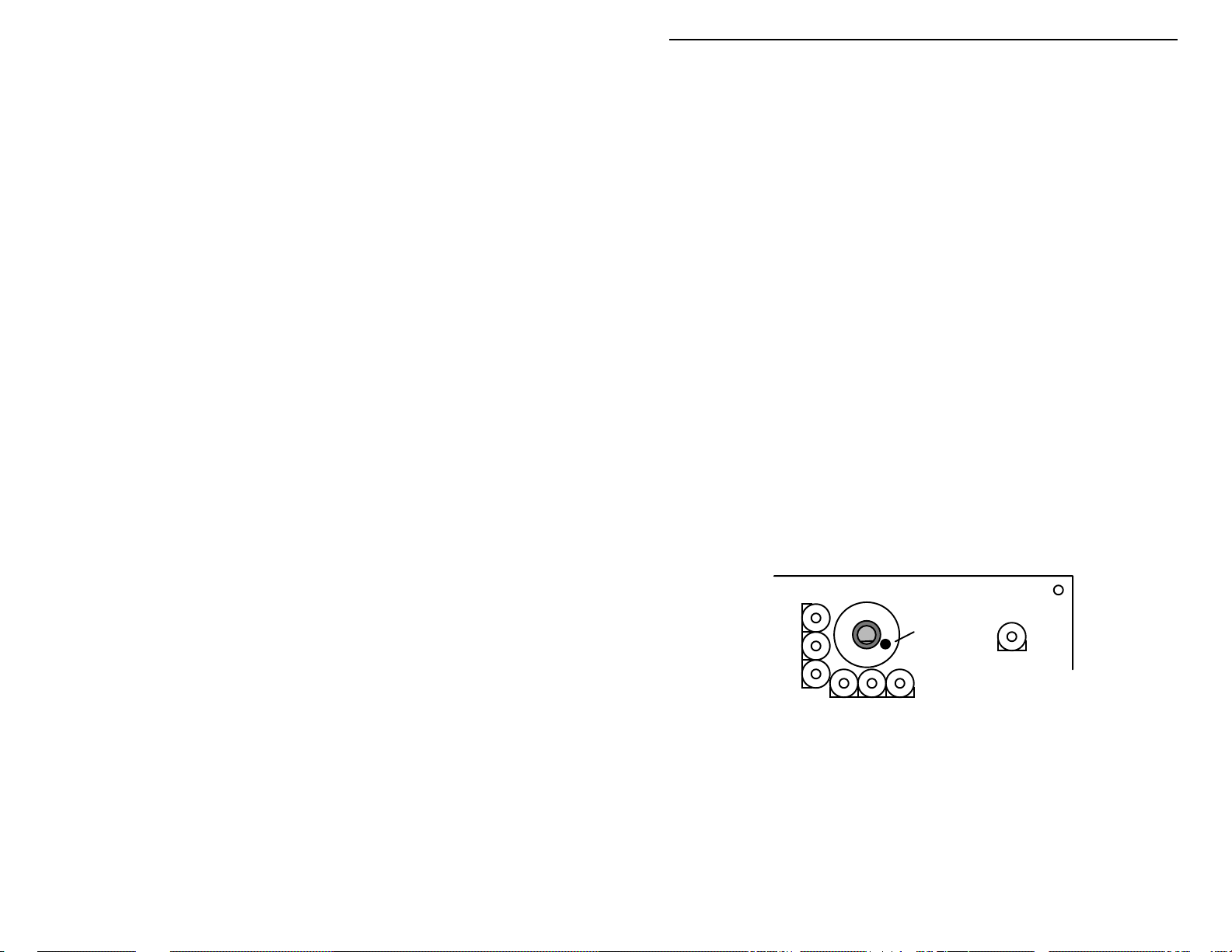

This is the final phase of construction. To begin, position the front panel with

the silk-screened side down, as shown below. Locate the remaining switches,

jacks, and potentiometers. Install as follows:

Black binding post

J3

Red binding post

J2

R3

R2

10K pot

10K pot

R1

Spacer

6-32

Spacer

6-32

4-40

4P3T Switch SW3

2-56

Power Jack

J1

10K pot

2P2T Switch

SW1

4-40

Find two (2) binding posts. When installing, use care not to overtighten--plastic

threads may be damaged by excessive torque.

! ! 82. Install the black binding post at J3.

! ! 83. Install the red binding post at J2.

16

Page 17

VEC-4001K Owner’s Manual Professional Function Generator

Locate three (3) 10K pots (marked B103 or B10K). Using a flat washer and a

nut, install each at the position indicated. Orient with solder terminals to the left

side:

! ! 84. Install a 10K pot at R1.

! ! 85. Install a 10K pot at R2.

! ! 86. Install a 10K pot at R3.

! ! 87. Find the 4P3P slide switch. Using 4-40 hardware, install at SW3.

! ! 88. Find the 2P2T slide switch. Using 4-40 hardware, install at SW1.

! ! 89. Find the 2.1-mm power jack. Position as shown, with the larger

riveted (+) terminal at the bottom. Using 2-56 hardware, install at J1

from the front side of the panel.

Locate four (4) 1-1/4" aluminum spacers. Using 6-32 screws, install on the front

panel at the positions shown:

! ! 90. Install a spacer above J3.

! ! 91. Install a spacer next to J1.

! ! 92. Install a spacer below R1.

! ! 93. Install a spacer above R2.

This concludes mounting of front-panel components. Double-check to make

sure each is positioned correctly. Begin wiring by installing a short jumper

between the power jack and power switch. Find a length of yellow wire and

prepare as follows:

! ! 94. Cut a 1 1/2" length of yellow wire. Remove 1/4" insulation from one

end and 3/8" insulation from the other.

! ! 95. Thread the stripped 3/8" end through the bottom two terminals of

SW1, as shown in the following diagram. Solder to both pins.

! ! 96. Connect the other end to the riveted (+) terminal of power jack J1

and solder (see followingdiagram).

17

Page 18

VEC-4001K Owner’s Manual Professional Function Generator

Color Code

J3 J2

SW3

R3

R2

Red

Yellow

Black

Top or "cl ockwise"

terminal (CW).

Middle or "center"

terminal (CTR)

Bottom or "cou nter-clockwise"

terminal (CCW)

J1

R1

SW1

The remaining wires will be installed one control at a time, and twisted together

for routing to the PC board. To prepare, cut each to the specified length and

remove 1/4" insulation from each end. Wrap tab or lug connections before

soldering (see following diagram):

Tab

Lug

! ! 97. Begin by wiring R1. Cut and prep a set of 6" red, yellow, and black

lead. Find R1 and install as follows:

! ! 98. Attach a red lead to the top (CW) terminal of R1 and solder.

! ! 99. Attach a yellow lead to the center (CTR) terminal of R1 and solder.

! ! 100. Attach a black lead to the bottom (CCW) terminal of R1 and solder.

! ! 101. Twist all three wires together, leaving about 1 1/2" unwound at the

far end.

! ! 102. Cut and prep another set of 6" wires (red, yellow, and black). Find

R2.

! ! 103. Attach a red lead to the top (CW) terminal of R2 and solder.

! ! 104. Attach a yellow lead to the center (CTR) terminal of R2 and solder.

! ! 105. Attach a black lead to the bottom (CCW) terminal of R2 and solder.

! ! 106. Twist all three wires together, leaving about 1 1/2" unwound at the

far end.

18

Page 19

VEC-4001K Owner’s Manual Professional Function Generator

! ! 107. Cut and prep another set of 6" wires (red, yellow, and black). Find

R3.

! ! 108. Attach a red lead to the top (CW) terminal of R3 and solder.

! ! 109. Attach a yellow lead to the center (CTR) terminal of R3 and solder.

! ! 110. Attach a black lead to the bottom (CCW) terminal of R3 and solder.

! ! 111. Twist all three wires together, leaving about 1 1/2" unwound at the

far end.

! ! 112. Cut and prep a 6" red and black lead. Find binding posts J2, J3.

! ! 113. Connect the red wire to J2 and solder.

! ! 114. Connect the black wire to J3 and solder.

! ! 115. Twist together.

! ! 116. Cut and prep a 6" red, yellow, and black lead. Find SW3 and locate

the lower right-hand terminal (see diagram).

! ! 117. Attach a black lead on the bottom right-hand terminal and solder.

! ! 118. Move left one terminal and attach a red lead. Solder.

! ! 119. Move left again, and attach a yellow lead. Solder.

! ! 120. All three leads should be connected on the bottom row. Twist wires

together.

! ! 121. Cut a 6" red and black lead. Remove 1/4" insulation from one end

and 3/8" insulation from the other end on each.

! ! 122. T hread the 3/8" end of the black lead through the two free terminals

on J1. Solder.

! ! 123. Thread the 3/8" end of the red wire through the center terminals o n

SW1. Solder.

! ! 124. Twist both together.

This completes front-panel wiring. Check your work against the wiring pictorial

for errors. The next group of connections will be made on the PC board.

Locate the three-wire harness connected to Frequency control R1. Connect to

the PC board as follows:

! ! 125. Connect R1 red wire to FREQ_CW (near key end of U1).

! ! 126. Connect R1 yellow wire to FREQ_MID (near unkeyed end of U3).

! ! 127. Connect R1 black wire to FREQ_CCW (near R10).

19

Page 20

VEC-4001K Owner’s Manual Professional Function Generator

Locate the three-wire harness connected to Amplitude control R2.

! ! 128. Connect R2 red wire to AMPL_CW (near R16).

! ! 129. Connect R2 yellow wire to AMPL_MID (near R17).

! ! 130. Connect R2 black wire to AMPL_CCW (near R11).

Locate the three-wire harness connected to DC Offset control R3.

! ! 131. Connect R3 red wire to OSET_CW (near Q2).

! ! 132. Connect R3 yellow wire to OSET_MID (near R18).

! ! 133. Connect R3 black wire to OSET_CCW (near end of JMP1).

Locate the three-wire harness connected to Waveform switch SW3.

! ! 134. Connect SW3 red wire to WAVEFORM (near C11).

! ! 135. Connect SW3 yellow wire to TRI (near R11).

! ! 136. Connect SW3 black wire to SINE (near R12).

Locate the two-wire pair connected to On/Off switch SW1 and 12VAC jack J1.

! ! 137. Connect SW1/J1 red wire to POWER (between C1 and C2).

! ! 138. Connect SW1/J1 black wire to GND (same).

Finally, locate the two-wire pair connected to Output binding posts J2, J3.

! ! 139. Connect J2 red wire to +OUT (between R31 and R32).

! ! 140. Connect J3 black wire to -OUT (same).

This concludes wiring of your VEC-4001K Function Generator Kit. Before

moving on to the next section, give your kit a thorough QC (quality control)

inspection. This will help you discover any inadvertent assembly errors that

might prevent the unit from working or cause damage to parts. Follow this

procedure:

1. Compare parts locations with the parts-placement diagram. Was each part

installed where it is supposed to be? Was the correct value used? Start at

one side of the board and work your way across in an organized pattern.

2. Inspect the solder side of the board for cold-solder joins and solder bridges

between tracks or pads. Use a magnifying glass to obtain a clear view of the

track area. If you suspect a solder bridge, hold the board in front of a bright

light for a better view. All joints should be smooth and shiny, indicating

good solder wetting and flow. Resolder any beaded or dull-appearing

connections. Also, check the front-panel jacks, switches, and connectors for

defective solder connections.

20

Page 21

VEC-4001K Owner’s Manual Professional Function Generator

3. Finally, check electrolytic capacitors and diodes for correct polarity. Does

the plus (+) polarity symbol on the part agree with the pictorial and with the

pattern on the PC board? Is the banded end of each diode positioned

correctly? Were all ICs and transistors installed correctly?

Be sure to correct all errors before moving on.

TESTING AND ALIGNMENT

Before applying power and testing, mount the circuit board and install the unit's

control knobs:

! Orient the PC board so the shaft of Multiplier switch SW2 aligns with its

panel opening. Align mounting holes with the aluminum spacers. Secure

the PC board in place using four (4) 6-32 screws.

! Find three (3) 3/4" skirted knobs. Install these on the Frequency, DC Offset,

and Amplitude controls.

!#Find the 3/4" pointer knob. Install on the Multiplier control.

Note

: If you want the pointer knob even with the skirted knobs, simply trim

1/8” off the Multiplier control shaft before installing the pointer knob. This

can be done using large or heavy duty cutters on the plastic shaft.

Power-Up: Your unit is d esigned to run from 12 VAC only and will not work

with conventional 12 VDC power sources. Use only the wall-adapter

transformer supp lied or an equival ent AC source. Before pluggi ng in the power

adapter, position the Generator's On/Off switch to "off".

To check the internal power supply circuitry, connect a DVM to the Output posts

observing (+) and (-) polarity. Set meter for the 10 VDC range. Position DC

Offset and Frequency at 12:00 o'clock. Set Multiplier for 10

2

. Turn Amplitude

fully down (counter-clockwise). Waveform setting isn't important for now.

Apply power by setting the Off/On switch to "on".

1. Rotate DC Offset to the (-) side. The DVM should read a progressively

stronger negative voltage down to -6 volts.

2. Rotate DC Offset toward (+). This should yield a corresponding positive

voltage up to +6 volts.

If you fail to obtain this result, re-check power supply circuitry around U4-U7

and note the orientation of U2 in its socket. Also, check Q1/Q2.

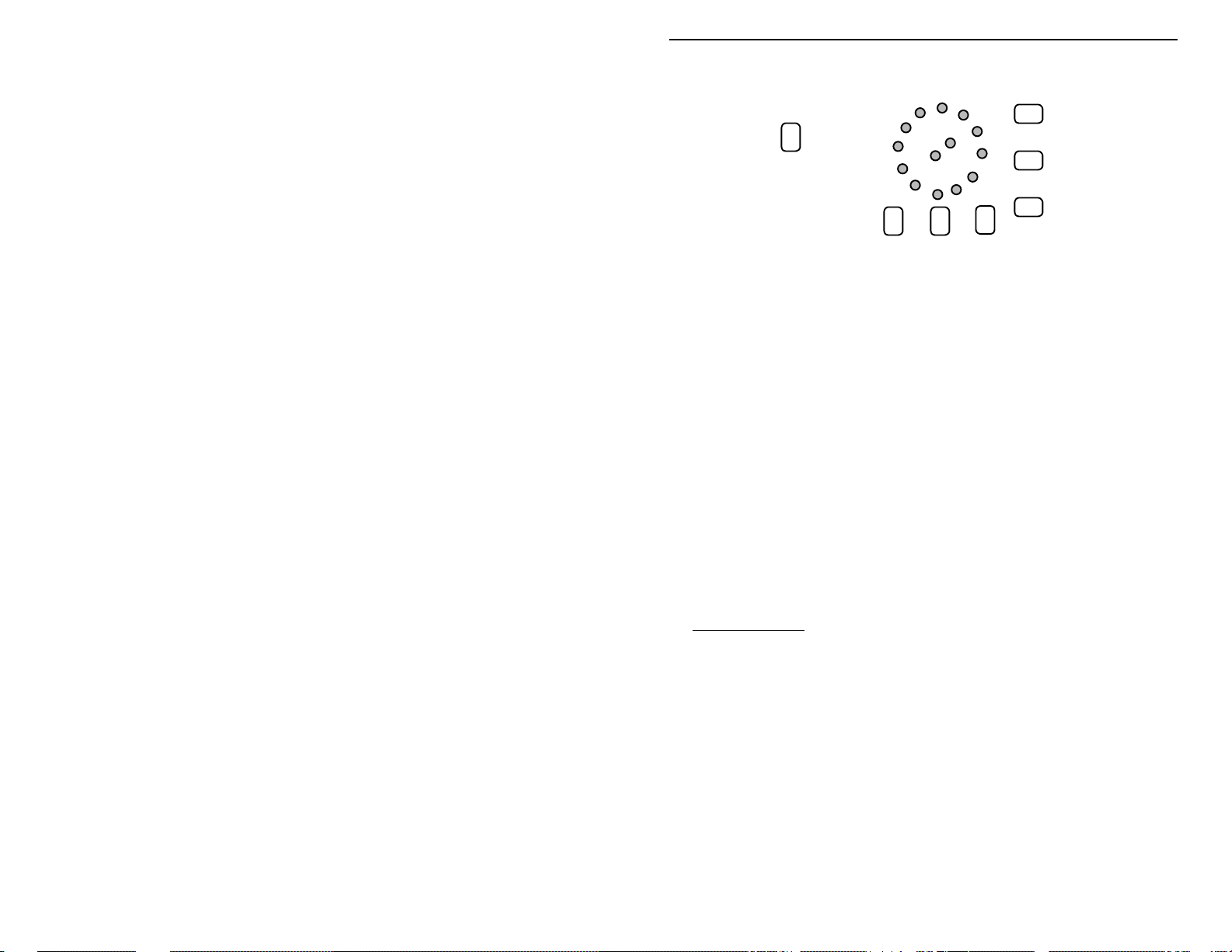

Waveform Check: Before conducting this check, adjust all internal calibration

trimpots (R4-R10) for midscale (12:00). These are all accessible through the

back side of the PC board, as shown.

21

Page 22

VEC-4001K Owner’s Manual Professional Function Generator

0

1

2

3104105

Bottom View

Low Set

R9

R10

R4 R5 R6

10

10

10

R8

R7

10

To check the generator's output signal, set an oscilloscope to measure 10 Vpp

with a 1 mS sweep rate. Connect scope input to Output. Set the generator's DC

Offset, Amplitude, and Frequency for 12:00, and switch Multiplier to 10

2

.

3. Set Waveform for sinewave and check output trace.

4. Set for triangle and check output trace.

5. Set for squarewave and check output trace.

6. Adjust Amplitude up and down observing change.

The generator's peak-to-pea k output should roughly coincide with scale markings

on the Amplitude control. If you fail to obtain the correct waveforms, check

switch wiring and PC-board connections. If amplitude is substantially

inaccurate, check for errors around R2.

Frequency Calibration: You may calibrate your generator using an audio

frequency counter or an oscilloscope with a calibrated sweep. Note that some

wide-range RF counters may not perform well at audio frequencies below 100

kHz.

A. Counter Method

: Connect counter to Output terminals. Set DC Offset and

Amplitude at 12:00. Set Frequency to 10 (CW) and Waveform to square.

1. Set Multiplier to 10

2. Switch Multiplier to 10

3. Switch Multiplier to 10

4. Switch Multiplier to 10

5. Switch Multiplier to 10

6. Switch Multiplier to 10

5

and adjust R9 for 1 MHz output.

4

and adjust R8 for 100 kHz output.

3

and adjust R7 for 10 kHz output.

2

and adjust R6 for 1 kHz output.

1

and adjust R5 for 100 Hz output.

0

and adjust R4 for 10 Hz output.*

7. Set Frequency control to 1 (CCW).

8. Switch Multiplier back to 10

2

and adjust R10 for 100 Hz output.

22

Page 23

VEC-4001K Owner’s Manual Professional Function Generator

* Note that counters designed for RF work may not read 10 Hz or even 100 Hz

with accuracy. If your counter has an input filter, it should be switched "on"

when measuring frequencies in this range.

B. Scope Method #1: Connect a scope with calibrated sweep to Output. Set

DC Offset and Amplitude for 12:00. Set Frequency to 10 (CW) and

Waveform to square. Trimpots will be adjusted to yield period of 5 divisions.

When adjusting the trimpots, make sure the waveform is symmetrical; that is,

the high transition time equals to the low transition time.

1. Set Multiplier to 1 0

5

and set Sweep for .2 µS/div. Adjust R9 for 5 division

period.

4

2. Switch Multiplier to 10

and set Sweep for 2 µS/div. Adjust R8 for 5 division

period.

3

3. Switch Multiplier to 10

and set Sweep for 20 µS/div. Adjust R7 for 5

division period.

4. Switch Multiplier to 10

2

and set Sweep for .2 mS/div. Adjust R6 for 5

division period.

5. Switch Multiplier to 10

1

and set Sweep for 2 mS/div. Adjust R5 for 5

division period.

6. Switch Multiplier to 10

0

and set Sweep for 20 mS/div. Adjust R4 for 5

division period.*

7. Set Frequency control to 1 (CCW).

8. Switch Multiplier back to 10

2

and Sweep for 2 mS/div. Adjust R10 for 5

division period.

* Note the period might be longer than 5 divisions due to component tolerance.

To compromise for this tolerance, adjust for longer than 5-division period

when adjusting trimpot R10 so the frequency ranges will overlapped.

C. Scope Method #2: Connect a scope with calibrated sweep to Output. Set

DC Offset and Amplitude for 12:00. Set Frequency to 10 (CW) and

Waveform to triangle. Trimpots will be adjusted to yield 1 Hz per division.

To ensure accuracy, each waveform peak should align with horizontal

divisions all the way across the screen (see the following diagram).

23

Page 24

VEC-4001K Owner’s Manual Professional Function Generator

1

2

3

4

5

Generator Range

100 1-10 Hz

10-100 Hz

10

100-1000 Hz

10

1 kHz - 10 kHz

10

10 kHz - 100 kHz

10

100 kHz - 1 MHz

10

1. Set Multiplier to 105 and set Sweep for 1 µS. Adjust R9 for 1 Hz/Div.

4

2. Switch Multiplier to 10

3. Switch Multiplier to 10

4. Switch Multiplier to 10

5. Switch Multiplier to 10

6. Switch Multiplier to 10

the entire screen (all 10 divisions).*

7. Set Frequency control to 1 (CCW).

8. Switch Multiplier back to 10

Hz/Div.

* Note 1 Hz might span longer than 10 divisions due to component tolerance. To

compromise for this to lerance, adjust for greater th an one division cycle when

adjusting trimpot R10 so the frequency ranges will overlapped.

and set Sweep for 10 µS. Adjust R8 for 1 Hz/Div.

3

and set Sweep for .1 mS. Adjust R7 for 1 Hz/Div.

2

and set Sweep for 1 mS. Adjust R6 for 1 Hz/Div.

1

and set Sweep for 10 mS. Adjust R5 for 1 Hz/Div.

0

and leave Sweep at 10 mS. Adjust R4 so 1 Hz spans

2

and leave Sweep at 10 mS. Adjust R10 for 1

This concludes calibration. If your generator fails to calibrate properly on one or

more Multiplier settings, check component values in the affected range(s) for

errors.

To complete your unit, install the the front panel (with the pc board attached) to

the plastic enclosure. Use the four (4) remaining 6-32 screws to secure the front

panel to the enclosure. Finally, place the four (4) rubber feet on the botton of the

enclosure. Place one at each corner.

24

Page 25

VEC-4001K Owner’s Manual Professional Function Generator

OPERATING INSTRUCTIONS

Control Functions: See the follwing diagram for control locations:

2

12 VAC

On

Professional Function Generator

1

Off

Power

34

7

Waveform

-+

Output

8

1. Power Adapter: Generator requires 12-VAC adapter (do not use DC types).

2. Power Switch: Turns power on and off.

3. Multiplier: Selects generator freq uency range as a power of 1 0 (1 Hz to 1

MHz).

4. Frequency: Varies frequency from 1 to 10 times the Multiplier setting.

5. Amplitude: Adjusts output amplitude from 0 to 12-volts p-p.

6. DC Offset: Adjusts DC bias on waveform from -6 to +6 VDC.

7. Waveform: Selects square, triangle, or sine waveform output.

8. Output: Bind ing posts provide connection to device under test.

To set for a given output signal, first select the desired increment using the

Frequency control. Then, set the desired Multiplier. For example, a Frequency

setting of 5 and a Multiplier of 10

is calibrated in volts p-p. To obtain low-level signals for AF amplifier testing,

install a 10:1 or 100:1 voltage divider across the output terminals using 1/4-watt

resistors. At low signal levels, the use of a shielded test cable is recommended.

Multiplier Frequency

6

DC Offset Amplitude

2

yields a 500-Hz (5 × 102) signal. Amplitude

5

25

Page 26

VEC-4001K Owner’s Manual Professional Function Generator

IN CASE OF DIFFICULTY

If your VEC-4001K Generator fails to perform to your expectation, please try

these simple steps before seeking outside assistance. If you are still unable to

resolve the problem, technical assistance and repair services are available from

Vectronics (see warrantee for terms and conditions).

Unit won't power up: Check AC adapter. Also, check plug at Generator's

power jack--this must be 2.1-mm type to transfer power. AC wall adapter must

have 12-VAC output (DC adapters won't work). Check cable for breaks, etc.

No Output: Check cable from generator Output to DUT. Check U2 for

damage.

Hum on Output Signal: Open ground on test line. Also, ground loop on

bench. Make sure all test equipment and other power sources are tied to a

common ground.

Low Generator Output: Low-Z load or shorted test cable.

Distortion on Waveform: Low-Z load or short on output of generator. Also,

damage to U2 or incorrect components installed during construction.

If these checks fail to uncover the problem, repeat the "QC" check one more

time. Service records show that, for most malfunctioning kits, outright

component failure is relatively rare. In most cases, the culprit is a misplaced

part, reverse-polarized capacitor or diode, improperly installed transistor, or

faulty solder connection. If, despite your best effort, you cannot solve the

problem, kit repair services are ava ilable through Ve ctronics. See t he warranty

on the inside front cover for complete instructions.

26

Page 27

VEC-4001K Owner’s Manual Professional Function Generator

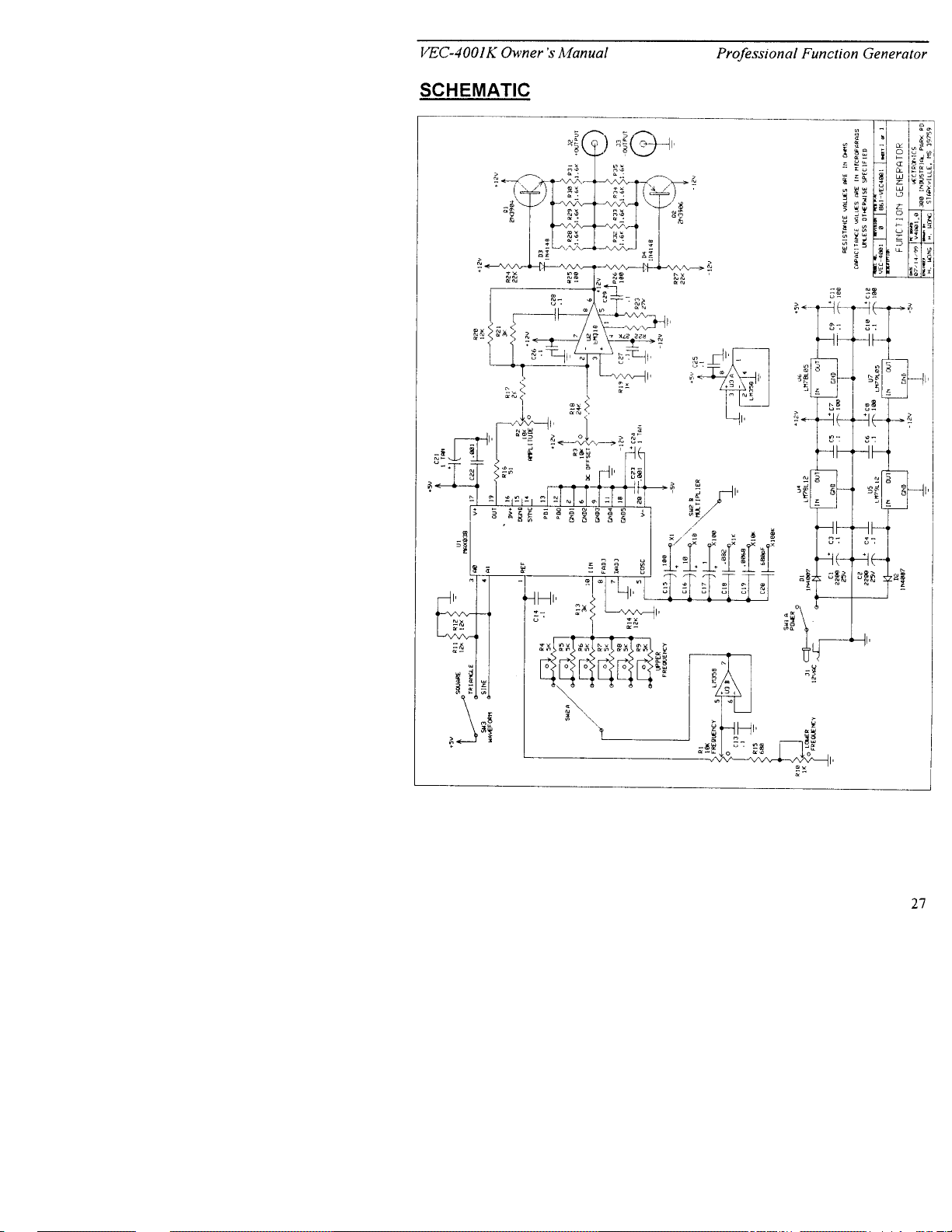

THEORY OF OPERATION AND SPECIFICATIONS

Your generator kit is built around the MAX038CPP, a special-function IC at U1

which provides sinewave, squarewave, and triangle-wave output over a wide

frequency range. Op-amp U2 buffers the generator IC's output signal and

establishes adjustable DC Offset. U3 buffers the IC's VCO reference voltage to

ensure stability. Q1/Q2 provide low-Z output with short-circuit protection. All

source voltages are regulated (U4-U7).

Typical Specifications:

Power Requirements:.......................12 VAC

Frequency Range:............................1 Hz to 1 MHz in six decade ranges

Amplitude Range:............................0 to 12 volts peak-to-peak

DC Offset Range:............................-6 volts to +6 volts

Output Impedance:..........................400 ohms, short-circuit protected

27

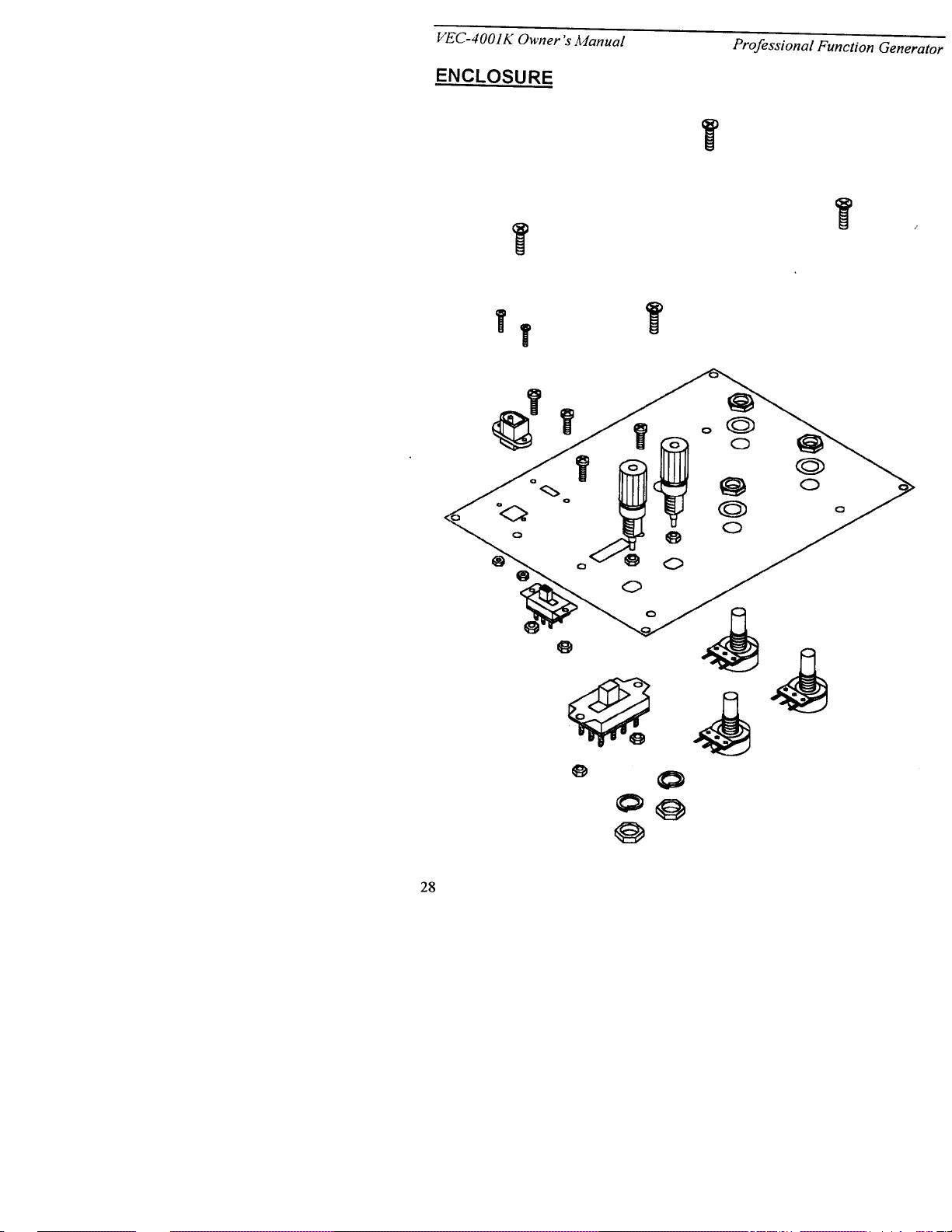

Page 28

Page 29

Page 30

Loading...

Loading...