Page 1

IMPORTANT WARRANTY INFORMATION! PLEASE READ

Return Policy on Kits When Not Purchased Directly From Vectronics: Before continuing

any further with your VEC kit check with your Dealer about their return policy. If your Dealer

allows returns, your kit must be returned before you begin construction.

Return Policy on Kits When Purchased Directly From Vectronics: Your VEC kit may be

returned to the factory in its pre-assembled condition only. The reason for this stipulation is,

once you begin i nsta lli ng a nd sol deri ng pa rt s, you essenti al ly tak e over the rol e of the devic e's

manufacturer . From this point on, neither Vect ronics nor its dea lers can reas onably be held

accountab le for the qua lity or the outcome of your work. Because of this, Vectronics cannot

accept return of any kit-in-progress or completed work as a warranty item for any reason

whatsoever. If you are a new or inexperienced kit b uilder, we urge you to read the manual

carefully a nd determine whether or not you're r eady to tak e on the job. If you wish to c hange

your mind and return your ki t, you may--b ut you must do i t before you begin c ons tr uc ti on, a nd

within ten (10) working days of the time it arrives.

Vectronics Warrants: Your kit contains each item specified in the parts list.

Missing Parts: If you determine, during your pre-construction inventory, that any part is

missing, please contact Vectronics and we'll send the missing item to you free of charge.

However, before you contact Vect ronic s, please look carefully to c onf ir m you haven't misr ea d

the marking on one of the other items provided with the kit. Also, make certain an alternative

part hasn't been substituted for the item you're missing. If a specific part is no longer

available, or if Engineering has determined that an alternative component is more suitable,

Vectronics reserves the right to make substitutions at any time. In most cases, these changes

will be clearly noted in an addendum to the manual.

Defective Parts: Today's electronic parts are physically and electrically resilient, and

defective components a re r a re. However, if you disc over a n it em duri ng your pr e- c onst r uct i on

inventory that's obviously broken or unserviceable, we'll replace it. Just return the part to

Vectronics at the address below accompanied with an explanation. Upon receipt, we'll test it.

If it's defec tive and appear s unused, we'll ship you a new one right away at no charge.

Missing or Defective Parts After You Begin Assembly: Parts and materials lost or

damaged after construction begins are not covered under the terms of this warranty. However,

most parts supplied with VEC kits are relatively inexpensive and Vectronics can replace them

for a reasonable charge. Simply contact the factory with a complete description. We'll

process your order quickly and get you back on trac k.

Factory Repair After You Begin Assembly: Kits-in progress and completed kits are

specifically excluded from coverage by the Vectronics warranty. However, as a service to

customers, tec hnicia ns ar e availa ble t o evaluate a nd repai r malf unctioni ng kits for a minimum

service fee of $18.00 (½ hour rate) plus $7.00 shipping and handling (prices subject to

change). To qualify for repair service, your kit must be fully completed, unmodified, and the

printed circuit board assembled using rosin-core solder. In the event your repair will require

more than an hour to fi x (or $36.00, subject to change), our technicians will contact you in

advance by telephone b efore p erforming t he work. Def ective unit s should b e shipp ed prep aid

to:

Vectronics

1007 HWY 25 South

Starkville, MS 39759

Page 2

When shipping, pack your kit well and include the minimum payment plus shipping and

handling charges ($25.00 total). No work can be performed without pre-payment. Also,

provide a valid UPS return address a nd a day time phone number where you may be reac hed.

Page 3

Table of Contents

Introduction.....................................................................................................1

Tools and Supplies..........................................................................................1

Before You Start Building...............................................................................2

Parts List..........................................................................................................6

Parts Placement Diagram ................................................................................7

Step-By-Step Construction..............................................................................8

PC Board Inspection...............................................................................15

Testing and Alignment ....................................................................................15

Self Test..................................................................................................16

Operating Instructions.....................................................................................18

Special Functions....................................................................................21

Message Memory...................................................................................24

Morse Code Character Set......................................................................26

In Case of Difficulty........................................................................................27

Theory of Operation and Specifications..........................................................28

Circuit Description:................................................................................28

Specifications:........................................................................................28

Schematic........................................................................................................29

Enclosure.........................................................................................................30

Page 4

THIS PAGE INTENTIONALLY LEFT BLANK

Page 5

VEC-221K Instruction Manual CW Memory Keyer Kit

INTRODUCTION

Welcome to the world of effortless CW. With the VEC-221K, you’ll have a

professional sounding fist in no time! Whether you’re a Novice or seasoned

Extra, the VEC-221K CW Memory Keyer Kit has the features you’ve been

waiting for! Novices will appreciate the preset factory defaults for plug-and-play

operation. Extra’s will enjoy the advanced features: weight control from 25 to

75%, iambic A and B operation, auto or semi-auto operation, full dot-and-dash

memories, and immediate front-panel speed control from 3 to 65 WPM. The

VEC-221K uses non-volatile memory to store four messages of about 120

characters each. Because the message memories are non-volatile, it does not

require battery backup to preserve the recorded messages. The built-in sidetone

generator is ideal for CW practice sessions or for radios lacking a CW sidetone.

The sidetone is implemented as a sinewave with 5 ms rise and decay times for

removing harsh key clicks.

The VEC-221K keyer is compatible with any modern transceiver or QRP

transmitter using positive keying. The 50 volt at 100 mA keying permits the use

of many early vintage cathode-keyed transmitters. Its small size and battery

operation are ideal for QRP or Field Day activities! CW has never been so

enjoyable or effortless!

A state-of-the-art PIC16C72 microprocessor is the heart of the keyer! Learn the

basics behind embedded controllers, and how they are revolutionizing the

electronics field. The powerful PIC device permits advanced settings to be

entered from the keyer paddles, using Morse characters! The generously-sized

quality glass-epoxy PC board with silk-screened component legends and soldermasking make assembly a snap. Powered by a common 9-volt transistor radio

battery, the keyer is ready for action whenever you are!

TOOLS AND SUPPLIES

Construction Area:

area where you can easily organize and handle small parts without losing them.

An inexpensive sheet of white poster board makes an excellent construction

surface, while providing protection for the underlying table or desk. Welldiffused overhead lighting is a plus, and a supplemental high-intensity desk lamp

will prove especially helpful for close-up work. Safety is an important

consideration. Be sure to use a suitable high-temperature stand for your

soldering iron, and keep the work area free of combustible clutter.

Universal Kit-building Tools:

additional items to complete, virtually all construction projects require a work

area outfitted with the following tools and supplies:

Kit construction requires a clean, smooth, and well-lighted

Although your particular kit may require

1

Page 6

VEC-221K Instruction Manual CW Memory Keyer Kit

!

30 to 60 Watt Soldering Iron

!

High-temperature Iron Holder with Moist Cleaning Sponge

!

Rosin-core Solder (thin wire-size preferred)

!

Needle Nose Pliers or Surgical Hemostats

!

Diagonal Cutters or "Nippy Cutters"

!

Solder Sucker, Vacuum Pump, or Desoldering Braid

!

Bright Desk Lamp

!

Magnifying Glass

BEFORE YOU START BUILDING

Experience shows there are four common mistakes builders make. Avoid these,

and your kit will probably work on the first try! Here's what they are:

1. Installing the Wrong Part:

and a 10K resistor may look almost the same, but they may act very

differently in an electronic circuit! Same for capacitors--a device marked

102 (or .001 uF) may have very different operating characteristics from one

marked 103 (or .01uF).

2. Installing Parts Backwards:

capacitors to make sure the positive (+) lead goes in the (+) hole on the

circuit board. Transistors have a flat side or emitter tab to help you identify

the correct mounting position. ICs have a notch or dot at one end indicating

the correct direction of insertion. Diodes have a banded end indicating

correct polarity. Always double-check--especially before applying power to

the circuit!

3. Faulty Solder Connections:

bridges. Cold solder joints happen when you don't fully heat the connection-or when metallic corrosion and oxide contaminate a component lead or pad.

Solder bridges form when a trail of excess solder shorts pads or tracks

together (see Soldering Tips below).

4. Omitting or Misreading a Part:

Always double-check to make sure you completed each step in an assembly

sequence.

Soldering Tips:

professional soldering. Before you install and solder each part, inspect leads or

pins for oxidation. If the metal surface is dull, sand with fine emery paper until

shiny. Also, clean the oxidation and excess solder from the soldering iron tip to

ensure maximum heat transfer. Allow the tip of your iron to contact both the

Cleanliness and good heat distribution are the two secrets of

It always pays to double-check each step. A 1K

Always check the polarity of electrolytic

Inspect for cold-solder joints and solder

This is easier to do than you might think!

2

Page 7

VEC-221K Instruction Manual CW Memory Keyer Kit

lead and pad for about one second (count "one-thousand-one") before feeding

solder to the connection. Surfaces must become hot enough for solder to flow

smoothly. Feed solder to the opposite side of the lead from your iron tip--solder

will wick around the lead toward the tip, wetting all exposed surfaces. Apply

solder sparingly, and do not touch solder directly to the hot iron tip to promote

rapid melting.

Desoldering Tips:

these instructions carefully! First, grasp the component with a pair of hemostats

or needle-nose pliers. Heat the pad beneath the lead you intend to extract, and

pull gently. The lead should come out. Repeat for the other lead. Solder may

fill in behind the lead as you extract it--especially if you are working on a

double-sided b o ar d with plat e-thr o ugh hol es. Sho uld this ha pp e n, tr y heat ing the

pad again and inserting a common pin into the hole. Solder won't stick to the

pin's chromium plating. When the pad cools, remove the pin and insert the

correct component. For ICs or multi-pin parts, use desoldering braid to remove

excess solder before attempting to extract the part. Alternatively, a low-cost

vacuum-bulb or spring-loaded solder sucker may be used. Parts damaged or

severely overheated during extraction should be replaced rather than reinstalled.

Work Habits:

instructions and, in many cases, to perform new and unfamiliar tasks. To avoid

making needless mistakes, work for short periods when you're fresh and alert.

Recreational construction projects are more informative and more fun when you

take your time. Enjoy!

Sorting and Reading Resistors:

a color code (shown below). You don't have to memorize this code to work with

resistors, but you do need to understand how it works:

If you make a mistake and need to remove a part, follow

Kit construction requires the ability to follow detailed

The electrical value of resistors is indicated by

Resistor Color Code

1st Digit

2nd Digit

Multiplier

Tolerence

(gold or silver)

Black = 0 (tens)

Brown = 1 (hundreds)

Red = 2 (K)

Orange = 3 (10K)

Yellow = 4 (100K)

Green = 5 (1Meg)

Blue = 6

Violet = 7

Gray = 8

White = 9

Silver = 10%

Gold = 5%

When you look at a resistor, check its multiplier code first. Any resistor with a

black multiplier band falls between 10 and 99 ohms in value. Brown designates

a value between 100 and 999 ohms. Red indicates a value from 1000 to 9999

3

Page 8

VEC-221K Instruction Manual CW Memory Keyer Kit

ohms, which is also expressed as 1.0K to 9.9K. An orange multiplier band

designates 10K to 99K, etc. To sort and inventory resistors, first separate them

into groups by multiplier band (make a pile of 10s, 100s, Ks, 10Ks, etc.). Next,

sort each group by specific value (1K, 2.2K, 4.7K, etc.). This procedure makes

the inventory easier, and also makes locating specific parts more convenient later

on during construction. Some builders find it especially helpful to arrange

resistors in ascending order along a strip of double-sided tape.

Some VEC kits may contain molded chokes which appear, at first glance, similar

to resistors in both shape and band marking. However, a closer look will enable

you to differentiate between the two--chokes are generally larger in diameter and

fatter at the ends than resistors. When doing your inventory, separate out any

chokes and consult the parts list for specific color-code information.

Reading Capacitors:

value identification. Instead, the value, or a 3-number code, is printed on the

body.

Value Code

10 pF = 100

100 pF = 101

1000 pF = 102

.001 uF = 102*

.01 uF = 103

.1 uF = 104

As with resistors, it's helpful to sort capacitors by type, and then to arrange them

in ascending order of value. Small-value capacitors are characterized in pF (or

pico-Farads), while larger values are labeled in uF (or micro-Farads). The

transition from pF to uF occurs at 1000 pF (or .001 uF)*. Today, most

monolithic and disc-ceramic capacitors are marked with a three-number code.

The first two digits indicate a numerical value, while the last digit indicates a

multiplier (same as resistors).

Electrolytic capacitors are always marked in uF. Electrolytics are polarized

devices and must be oriented correctly during installation. If you become

confused by markings on the case, remember the uncut negative lead is slightly

shorter than the positive lead.

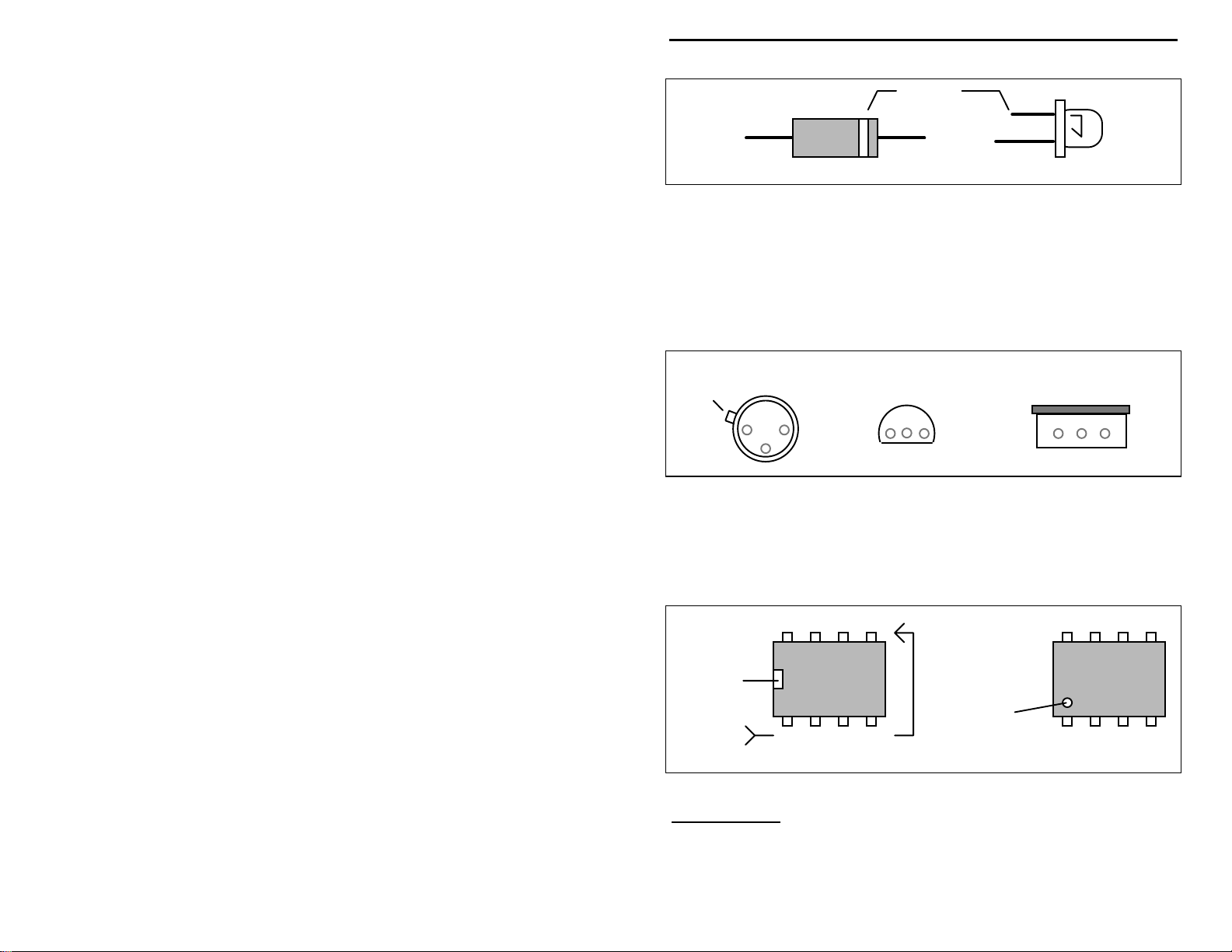

Diodes:

Always look for the banded or cathode end when installing, and follow

instructions carefully.

Diodes are also polarized devices that must be installed correctly.

Unlike resistors, capacitors no longer use a color code for

Electrolytic

1 uF

1uF

|

35V

|

+

-

Multilayer

(270 pF)

271

Ceramic Discs

(.001 uF) (.1 uF)

102

104

4

Page 9

VEC-221K Instruction Manual CW Memory Keyer Kit

Cathode

(shorter Lead)

Diode

Transistors:

power is applied. Transistors in metal cases have a small tab near the emitter

lead to identify correct positioning. Semiconductors housed in small plastic

cases (TO-92) have an easily-identified flat side to identify mounting orientation.

Many specialized diodes and low-current voltage regulators also use this type

packaging. Larger plastic transistors and voltage regulators use a case backed

with a prominent metal tab to dissipate heat (T-220). Here orientation is

indicated by the positioning of the cooling tab.

If transistors are installed incorrectly, damage may result when

LED

Metal Can Device Plastic Device Tab-cooled Device

Emitter

Flat Side

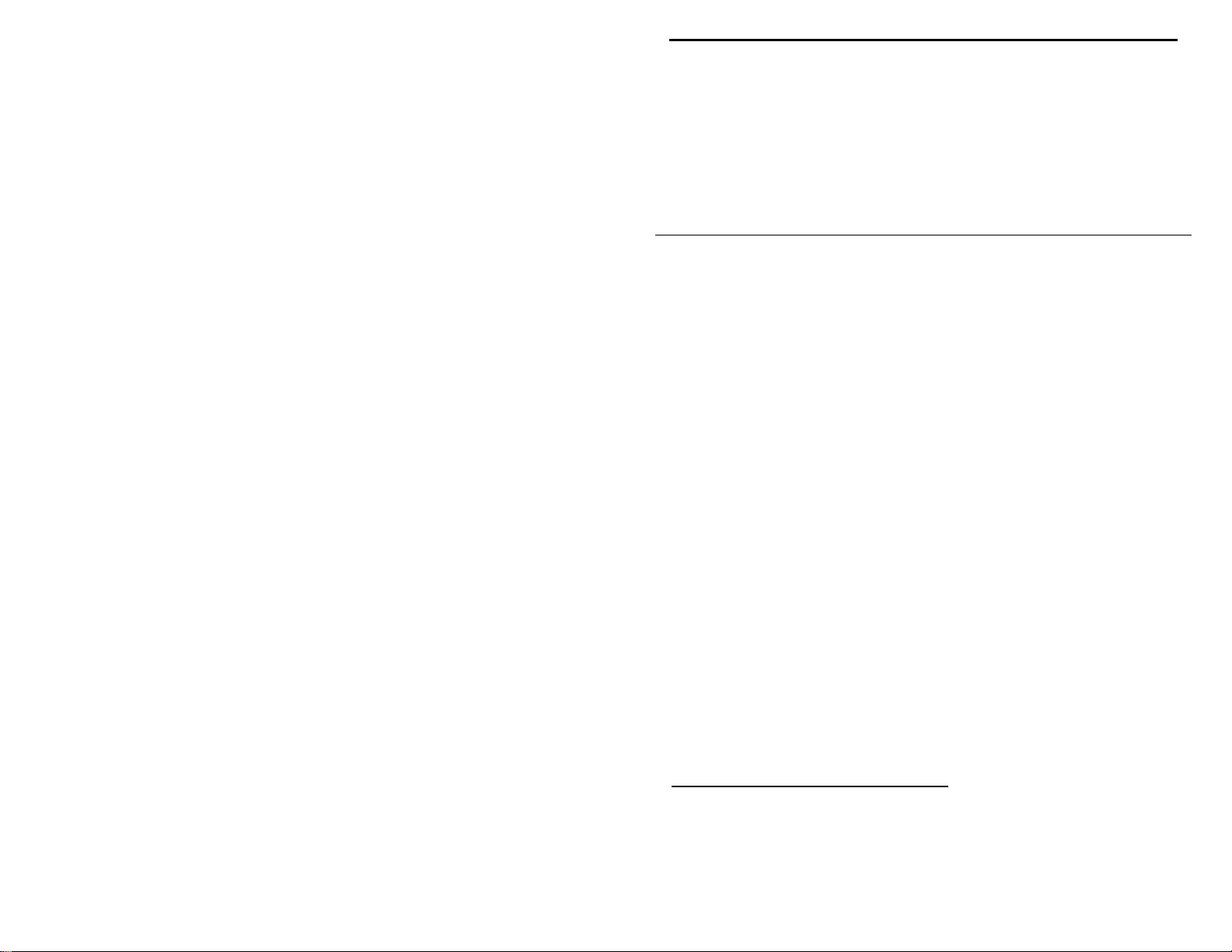

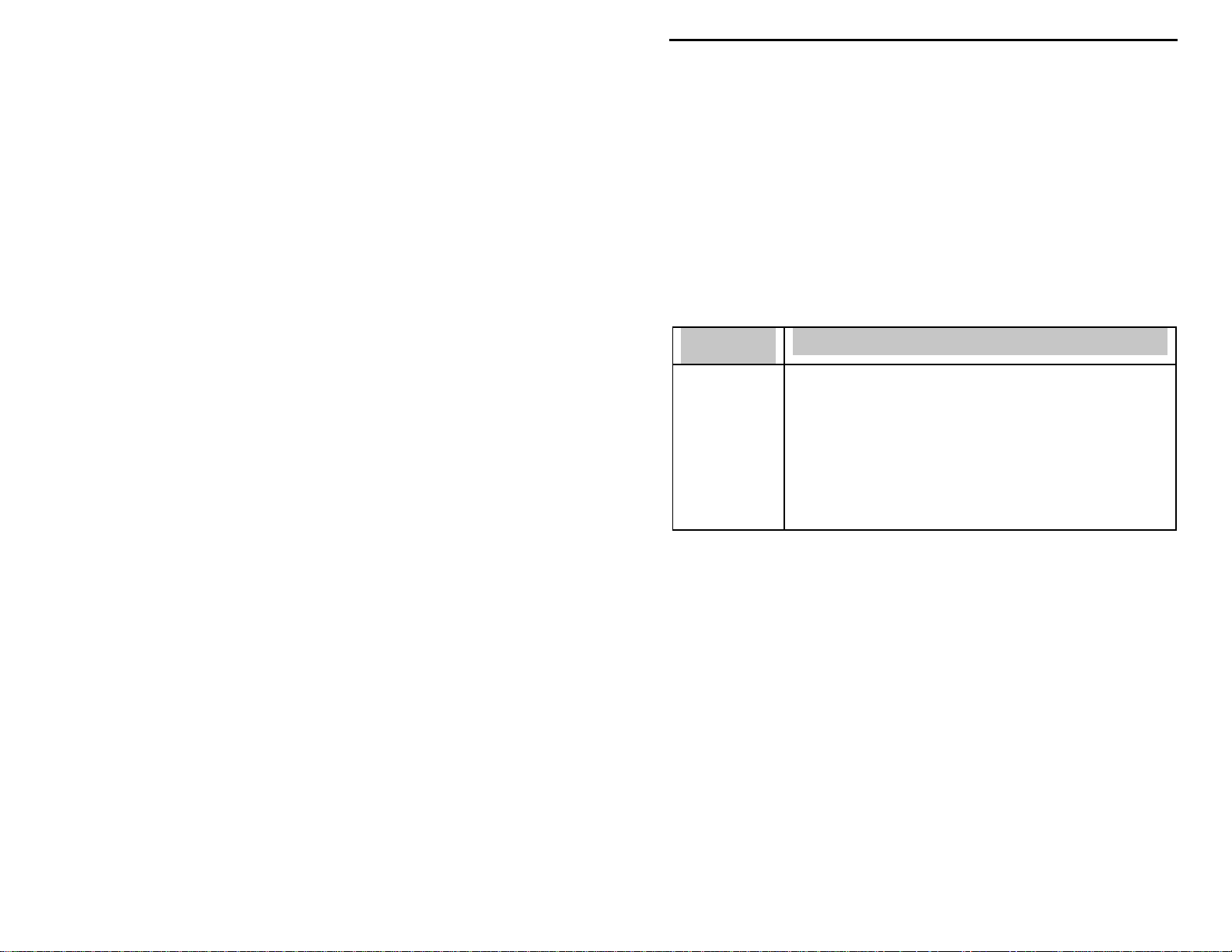

Integrated Circuits:

marking located on one end of the device. A corresponding mark will be silkscreened on the PC board and printed on the kit's parts-placement diagram. To

identify specific IC pin numbers for testing purposes, see the diagram below.

Pin numbers always start at the keyed end of the case and progress counterclockwise around the device, as shown:

Proper IC positioning is indicated by a dot or square

8 7 6 5

Metal Tab

Installation

Key

Installation

Key

1 2 3 4

Pin Numbers

PARTS LIST

Your package kit should c ontain a ll of the p arts li sted be low. Ple ase go through

the parts bag to identify and inventory each item on the checklist before you start

5

Page 10

VEC-221K Instruction Manual CW Memory Keyer Kit

building. If any par ts are missing or damaged, r efer to the warranty section of

this manual for replacement instructions. If you can't positively identify an

unfamiliar item in the bag on the basis of the information given, set it aside until

all other items are checked off. You may then be able to identify it by process of

elimination. Finally, your kit will go together more smoothly if parts are

organized by type and arranged by value ahead of time. Use this inventory as an

opportunity to sort and arrange parts so you can identify and find them quickly.

Qty Part Description Designation

"

!

1 10 ohm (brown-black-black) R5

!

4 1.5K ohm (brown-green-red) R2,R3,R4,R7

!

1 10K ohm (brown-black-orange) R1

!

2 10K ohm potentiometer R6,R8

!

2 22 pF disc ceramic (22 or 220) C1,C2

!

7 0.01 uF disc ceramic (.01 or 103) C10,C11,C12,C13,C14,C15,C20

!

7 0.1 uF disc ceramic (.1 or 104) C3,C4,C5,C6,C7,C8,C9

!

1 0.47 uF electrolytic C16

!

2 10 uF electrolytic C17,C19

!

1 100 uF electrolytic C18

!

1 Red 5 mm round LED CR1

!

1 1N4007 rectifier diode D1

!

1 2N7000 field-effect transistor Q1

!

1 PIC16C72 microcontroller IC U1

!

1 24C04 serial EEPROM IC U2

!

1 LM386 audio amplifier IC U3

!

1 78L05 +5-volt regulator U4

!

1 1000 uH inductor (brown-black-red) L1

!

1 4 MHz crystal Y1

!

2 3.5 mm stereo jack J1,J3

!

1 RCA phono jack J2

!

1 12" length of #22 buss wire For JMP1 - JMP10

!

6 DPDT push-button switch SW1 - SW6

!

2 8-pin IC socket For U2,U3

!

1 28-pin IC socket For U1

!

1 9-volt battery snap clip

!

1 nylon tie wrap

!

1 PC board for VEC-221K

!

1 VEC-221K Owner's Manual

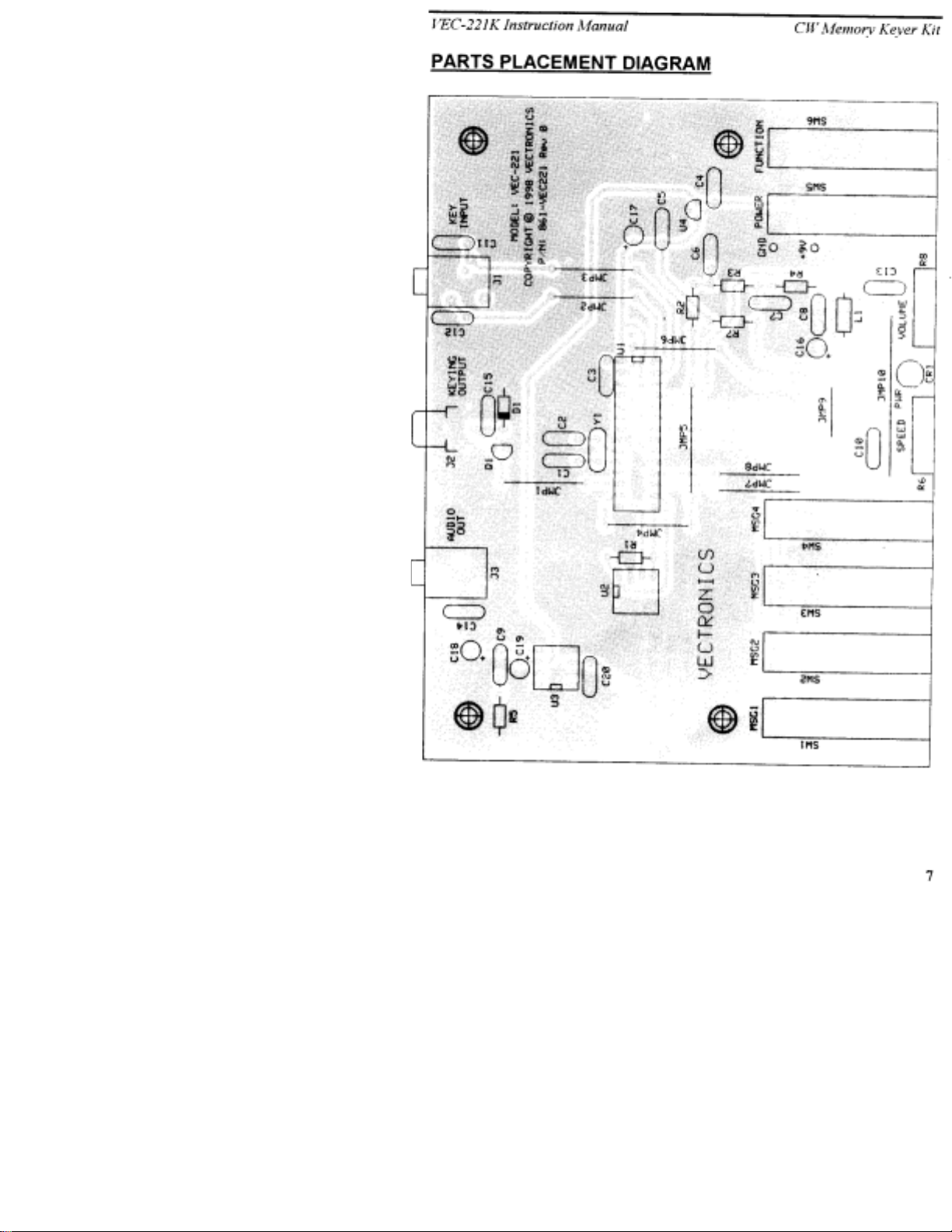

PARTS PLACEMENT DIAGRAM

6

Page 11

Page 12

VEC-221K Instruction Manual CW Memory Keyer Kit

STEP-BY-STEP CONSTRUCTION

Before assembling your kit, please take time to read and understand the VEC kit

warranty printed on the inside cover of this manual. Also, read through the

assembly instructions to make sure the kit does not exceed your skill level. Once

you begin construction, your kit will be non-returnable. Finally, if you haven't

already done so, please verify that all parts listed in the inventory are included.

If anything is missing or broken, refer to the warranty instructions for replacing

missing or damaged parts.

Observe correct polarity when mounting components such as the electrolytic

capacitors, diode, LED, transistor and voltage regulator. If you orient capacitors

so their values face the board edges, you'll be able to read them easily when the

kit is finished. Part designators for components such as R1, C3, etc., appear on

the silk-screened legend on the component-mounting side of the printed circuit

board. These correspond to the drawing shown in the section titled "Parts

Placement Diagram". The parts are inserted on the silk-screen side of the board.

All capacitors should be installed with their bodies as close to the PC board as

possible. This is very important in RF circuits.

If you have la st-minute questions about what you need to build your kit, p lease

refer back to the section titled "Tools and Supplies" . If you're ready to begin

now, let's get started!

“Install”

identify, and insert the part into its mounting holes on the PC board. This

includes pre-bending or straightening leads as needed so force is not required to

seat the part. Once a component is mounted, bend each lead over to hold it in

place. Make sure trimmed leads don’t touch other pads and tracks, or a short

circuit may result:

“Solder”

leads in place, and to inspect both (or all) solder connections for flaws or solder

bridges. If no soldering problems are noted, nip off the excess protruding leads

with a sharp pair of side cutters.

Notice the directions use two sets of check boxes. Check one when a step is

complete and use the other for double-checking your work before operation.

When you are directed to install a part, this means to locate,

Good

When you are directed to solder, this means to solder the part’s

Not Good

7

Page 13

VEC-221K Instruction Manual CW Memory Keyer Kit

! !

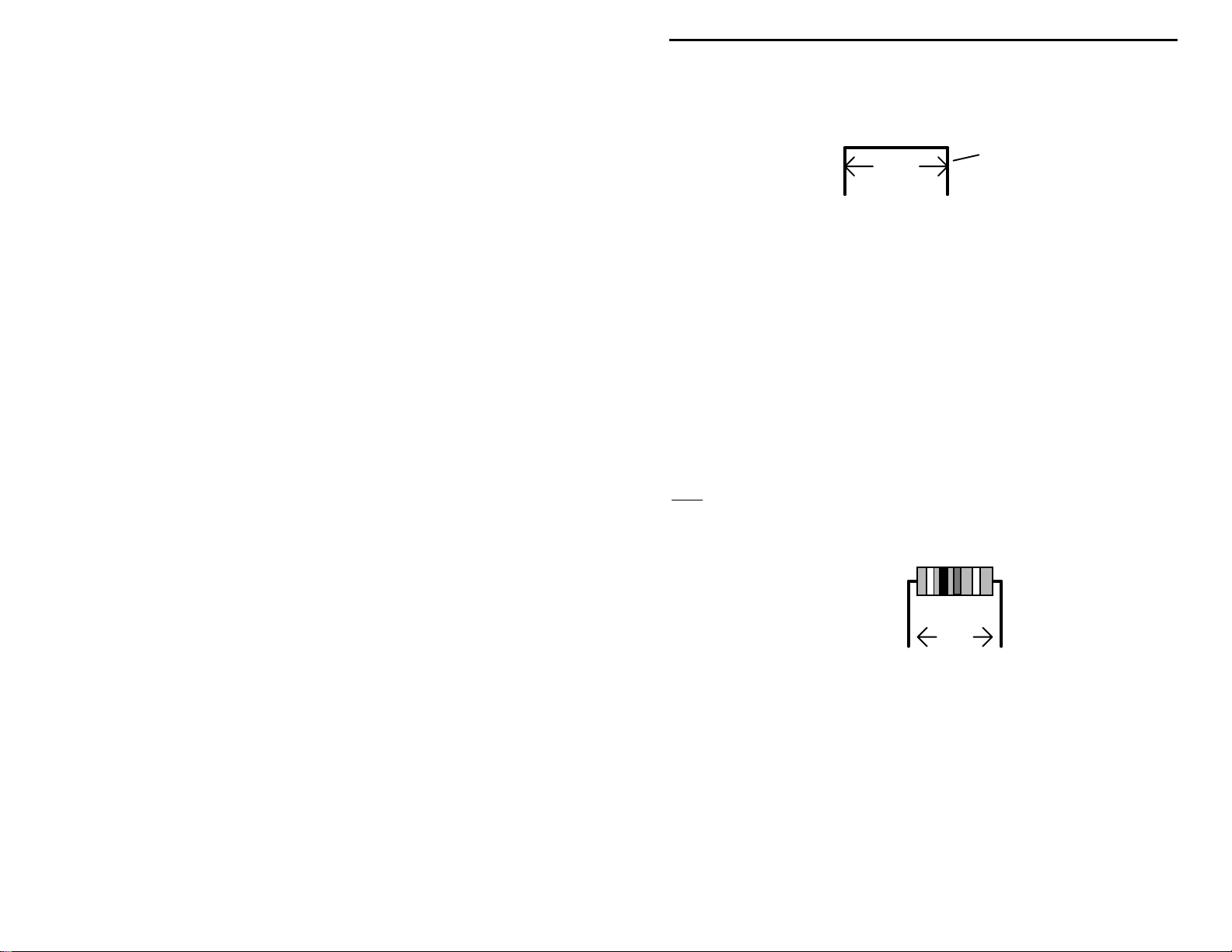

1. Cut the 12 inches wire into ten pieces of appropriate lengths for use as

jumper wires. Use needle-nose pliers to form each one, as shown

below, making sure each rests flat on the PC board when installed:

span

! !

Prepare, install, and solder a jumper wire at JMP1.

! !

Prepare, install, and solder another jumper wire at JMP2.

! !

Prepare, install, and solder another jumper wire at JMP3.

! !

Prepare, install, and solder another jumper wire at JMP4.

! !

Prepare, install, and solder another jumper wire at JMP5.

! !

Prepare, install, and solder another jumper wire at JMP6.

! !

Prepare, install, and solder another jumper wire at JMP7.

! !

Prepare, install, and solder another jumper wire at JMP8.

! !

Prepare, install, and solder another jumper wire at JMP9.

! !

Prepare, install, and solder another jumper wire at JMP10.

Resistor installation: The resistors packaged in this kit are all 5-percent

Note

:

tolerance ending with a fourth gold color band, only the first three bands

of the color code are needed for the following steps. All resistor leads

should be formed as shown below.

jumper wire

.4"

! !

2. Find the 10 ohm resistor (brown-black-black). Install and solder at

location R5.

! !

3. Find the four 1.5K ohm resistors (brown-green-red). Install and solder

at the following locations:

! !

R2 1.5K ohm resistor (brown-green-red)

! !

R3 1.5K ohm resistor (brown-green-red)

! !

R4 1.5K ohm resistor (brown-green-red)

! !

R7 1.5K ohm resistor (brown-green-red)

8

Page 14

VEC-221K Instruction Manual CW Memory Keyer Kit

! !

4. Find the 10K ohm resistor (brown-black-orange). Install and solder at

location R1.

! !

5. Locate the 1000 uH inductor or choke (brown-black-red). Pre-form

the leads in a similar manner as done for the resistors. Install and

solder at location L1.

! !

6. Locate the 1N4007 rectifier diode. Note that the band indicates the

cathode lead end of the device. Pre-form the leads in a similar manner

as done for the resistors. Install and solder at location D1, be sure to

observe the silk-screened marking for the cathode lead orientation!

Cathode

1N4007

! !

7. Locate the two 22 pF ceramic disc capacitors (marked 22 or 220).

Install and solder at the following locations:

! !

C1 22 pF ceramic disc capacitor (22 or 220)

! !

C2 22 pF ceramic disc capacitor (22 or 220)

! !

8. Locate the seven 0.01 uF ceramic disc capacitors (.01 or 103

marking). Install and solder at the following locations:

! !

C10 0.01 uF ceramic disc capacitor (.01 or 103)

! !

C11 0.01 uF ceramic disc capacitor (.01 or 103)

! !

C12 0.01 uF ceramic disc capacitor (.01 or 103)

! !

C13 0.01 uF ceramic disc capacitor (.01 or 103)

! !

C14 0.01 uF ceramic disc capacitor (.01 or 103)

! !

C15 0.01 uF ceramic disc capacitor (.01 or 103)

! !

C20 0.01 uF ceramic disc capacitor (.01 or 103)

! !

9. Locate the seven 0.1 uF ceramic disc capacitors (.1 or 104 marking).

Install and solder at the following locations:

! !

C3 0.1 uF ceramic disc capacitor (.1 or 104)

! !

C4 0.1 uF ceramic disc capacitor (.1 or 104)

! !

C5 0.1 uF ceramic disc capacitor (.1 or 104)

! !

C6 0.1 uF ceramic disc capacitor (.1 or 104)

9

Page 15

VEC-221K Instruction Manual CW Memory Keyer Kit

! !

C7 0.1 uF ceramic disc capacitor (.1 or 104)

! !

C8 0.1 uF ceramic disc capacitor (.1 or 104)

! !

C9 0.1 uF ceramic disc capacitor (.1 or 104)

! !

10. Locate the 0.47 uF electrolytic capacitor. Install and solder at location

C16 (observe polarity).

! !

11. Locate the two 10 uF electrolytic capacitors. Install and solder at the

following locations (observe polarity):

! !

C17 10 uF (observe polarity)

! !

C19 10 uF (observe polarity)

! !

12. Locate the 100 uF electrolytic capacitor. Install and solder at location

C18 (observe polarity).

! !

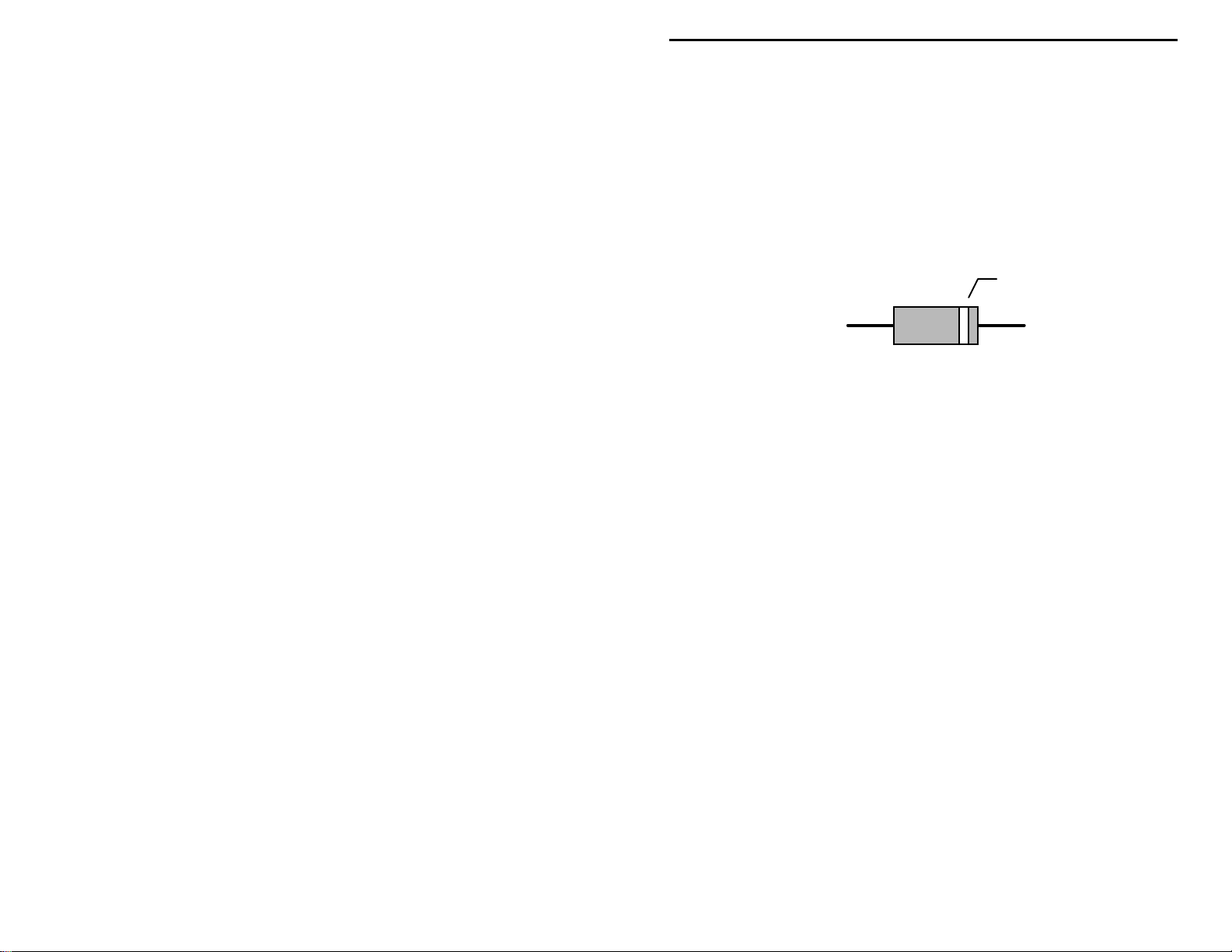

13. Locate the 78L05 +5-Vdc voltage regulator IC. Form the leads as

shown below to allow the device to fit at location U4. Make sure the

regulator is properly keyed to the silk-screened outline; if installed

incorrectly, damage to the PIC processor is certain when power is

applied. Install and solder.

78L05

! !

14. Find the 2N7000 field-effect transistor. Position the body outline to

correspond the silk-screened legend at Q1. Install and solder.

! !

15. Find the red LED. Note that the LED has a flat edge corresponding to

the shorter lead. Make sure that the LED is properly keyed to the silkscreened outline at CR1. Install the LED leads until the shouldered

stops on the leads are flush to the PC board Bend the leads so the

LED is flush with the edge of the PC board. Solder.

! !

16. Find the 4 MHz crystal. Install and solder at location Y1.

! !

17. Locate the two 8-pin IC sockets. Note that the socket is “keyed”, and

should be installed with its key aligned to the silk-screened outline on

10

Page 16

VEC-221K Instruction Manual CW Memory Keyer Kit

the PC board. Install and solder the sockets at the following locations.

Make sure key is orientated with board legend.

! !

U2 8-pin IC socket (observe key or i entation)

! !

U3 8-pin IC socket (observe key or i entation)

8 7 6 5

Installation

Key

1 2 3 4

Pin Numbers

! !

18. Install and solder the 28-pin IC socket at location U1. Make sure key

is orientated with board legend.

! !

19. Locate the two 3.5 mm stereo jacks. Install and solder at the following

locations:

! !

J1 3.5 mm stereo jack

! !

J3 3.5 mm stereo jack

! !

20. Find the RCA phono jack. Install and solder at location J2.

! !

21. Locate the six push-button switches. The leads should be fully seated,

and the switch body level to the board. Install and solder at the

following locations:

! !

SW1 push-button switch

! !

SW2 push-button switch

! !

SW3 push-button switch

! !

SW4 push-button switch

Top view of socket

! !

SW5 push-button switch

! !

SW6 push-button switch

! !

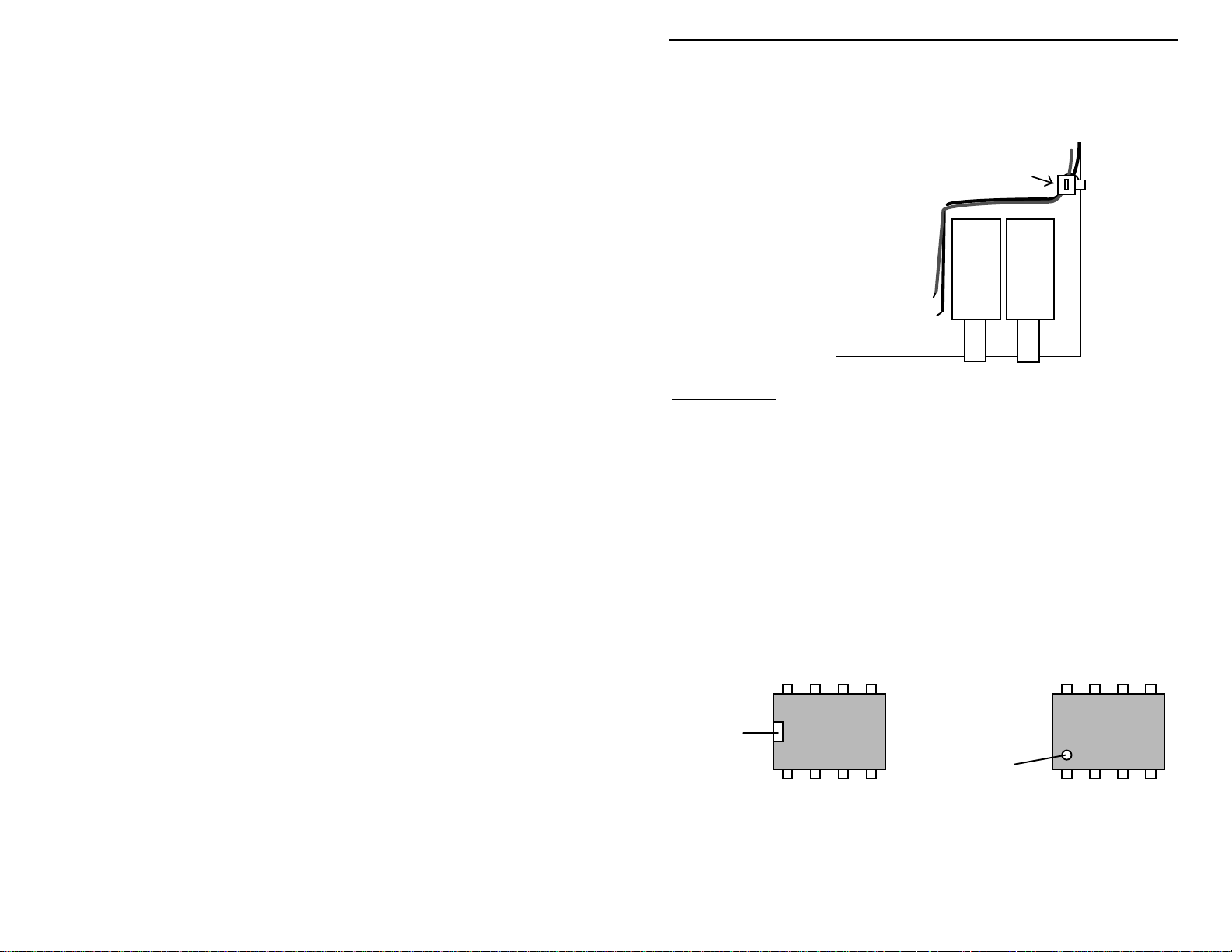

22. Switches SW1, SW2, SW3, SW4 and SW6 must be changed from

latching to momentary operation. Follow these directions carefully to

avoid damaging these switches! Set switch so shaft is latched in the

fully extended position. Using a pair of long-nose pliers, carefully lift

the latching clip's end near the switch body (away from the shaft) out

11

Page 17

VEC-221K Instruction Manual CW Memory Keyer Kit

of the switch assembly, and set it to the side of the switch body as

shown below. Be careful not to remove the end under the spring.

! !

23. The front-panel controls are mounted next. Before installing these

parts, inspect the potentiometer supplied with your kit. If the pins are

located on the front side of the pot, use the front set of mounting holes

on the PC board for installation. If the pins are on the rear, use the

rear set of mounting holes (see below). Also, using side cutters,

remove the key tab from the side of each pot prior to installation.

Rear pins use rear holes.

Nip off tab.

! !

24. Install a 10K ohm potentiometer at R6. Insert the potentiometer leads

until the shouldered stops on all three leads are flush to the PC board.

Solder the three leads.

! !

25. Install the other 10K ohm potentiometer at R8, following the

procedures used for R6. Solder.

! !

26. Locate the 9-volt battery clip. Install and solder the free end of the

black lead to the negative (GND) termination point on the PC board.

! !

27. The remaining red battery clip lead should be installed and soldered to

the positive (+9V) termination point on the PC board.

12

Front pins use front holes.

Nip off tab.

Page 18

VEC-221K Instruction Manual CW Memory Keyer Kit

y

! !

28. The nylon tie wrap should be used to firmly attach the battery clip

wires to the support hole on the PC board. Use the hole located

closest to the e dge of the PC board. Pull the ti e snug and trim excess.

Nylon tie-wrap

SW2

red

black

+

9V

GND

SW1

Important Note:

However, if you are working in a carpeted area, it's always a good idea to touch

a metal ground before handling semiconductors.

! !

29. Locate the PIC16C72. Align its key (see below) with the socket key

U1, U2 and U3 have good immunity to static discharge.

for U1. Be sure that all 28 pins are freely entering the socket holes,

and apply firm pressure to fully seat the IC.

! !

30. Locate the 24C04 EEPROM. Align its key (see below) with the

socket key for U2. Be sure that all 8 pins are freely entering the socket

holes, and apply firm pressure to fully seat the IC.

! !

31. Locate the LM386 audio amplifier. Align its key (see below) with the

socket key for U3. Be sure that all 8 pins are freely entering the socket

holes, and apply firm pressure to fully seat the IC.

8 7 6

Installation

Key

Installation

Ke

1 2 3 4

Pin Numbers

13

Page 19

VEC-221K Instruction Manual CW Memory Keyer Kit

The IC body has a small notch, or key, molded at one end, indicating pin

Note

:

1. A small dimple-like body-molding is often found adjacent to pin 1.

Some IC packages may include both key indicators.

At this point, your kit is finished and it's time to take a well-earned break! When

you come back, be prepared to give your work a close "quality control"

inspection before moving on to the testing and alignment section.

PC Board Inspection:

Before applying power to your kit, give it a thorough QC (quality control)

inspection. This will help you find inadvertent assembly errors that might

prevent the keyer from working or cause damage to sensitive parts. Follow this

procedure:

!

Compare parts locations against the parts-placement diagram. Was each

part installed where it is supposed to be? Was the correct value used? Start

at one side of the board and work your way across in an organized pattern.

!

Inspect the solder side of the board for cold-solder joints and solder bridges

between tracks or pads. Use a magnifying glass to obtain a clear view of the

track area. If you suspect a solder bridge, hold the board in front of a bright

light for a better view. All joints should be smooth and shiny, indicating

good solder wetting and flow. Resolder any beaded or dull-appearing

connections.

Important Note:

two, it will be easier if you have the right tools. One very convenient item for

freeing soldered-in parts is a "solder sucker". This consists of a suction bulb or

a spring loaded vacuum pump that draws molten solder away from the pad and

lead. Alternatively, you may use "solder wick". If you suspect you've damaged a

component during removal, it's better to replace the part than risk reusing it!

If you find a construction error and need to remove a part or

Now that assembly and inspection is completed, you're ready to begin the testing

and alignment phase of construction.

TESTING AND ALIGNMENT

The following items will be needed for testing:

!

9-volt alkaline transistor battery.

!

Keyer paddles (iambic preferred), terminated with 3.5 mm stereo plug.

Wired dot-to-tip and dash-to-ring.

!

4- to 32-ohm headphones or monitor speaker, terminated with 3.5 mm stereo

or mono plug.

14

Page 20

VEC-221K Instruction Manual CW Memory Keyer Kit

Actuate push-button switches SW1 to SW6 a few times and note the latching

action. The switches will toggle from off to on; the on condition exists when the

shaft remains partially recessed; off when the shaft is fully extended.

!

Set Power switch SW5 to off.

!

Attach the paddle plug to jack J1 (Key Input) on the PC board.

!

Attach a monitor speaker or headphones to jack J3 (Audio Out.)

!

Connect a fresh 9-volt battery to the battery clip.

!

Perform the self-test described below.

Self Test

A self-test routine is used to check the functions of the unit. This routine checks

the paddles, the push-button switches, the knob, the non-volatile memory and the

audio circuitry. During the self-test, you may stop the test by turning off the

unit; however, this should NOT be done during the memory test or the memory

could be corrupted. This self-test can be completed in approximately one

minute.

Performing the self-test will reset the unit to its factory default settings.

Note

:

Here is the self-test procedure:

1. Turn off the unit.

2. Turn the Speed control R6 to full clockwise position.

3. Set the Volume control R8 to a comfortable listening level (midrange).

4. Squeeze the paddle while turning the power on by pressing the Power switch

SW5. The test begins by sending a copyright message

VECTRONICS VX.XX"

. This is the test of the audio circuitry. Release the

"(c) 199X

paddles before this message completes.

5. The LED should be off after the copyright message is finished. For the

entire test, the LED should blink once after each operation. If the LED

blinks continuously, the unit fails the test and a Morse code message is sent

to indicate the nature of the failure.

6. Press and release the dot level (connected to the tip of the plug).

7. Press and release the dash level (connected to the ring of the plug).

8. Press and release the Message 1 switch SW1.

9. Press and release the Message 2 switch SW2.

10. Press and release the Message 3 switch SW3.

15

Page 21

VEC-221K Instruction Manual CW Memory Keyer Kit

11. Press and release the Message 4 switch SW4.

12. Press and release the Function switch SW6.

13. Turn the Speed control R6 to full counter-clockwise position.

14. Turn the Speed control R6 to full clockwise position.

15. The unit then tests its non-volatile memory. This step will reset the unit to

its factory default values.

16. If the unit is okay,

"PASS"

is repetitively sent to the speaker. If there is a

problem, a failure message is sent, indicating that you did not follow the

correct order or the unit failed the test. These messages are shown below.

17. Once you have confirmed that the audio is okay, turn the unit off.

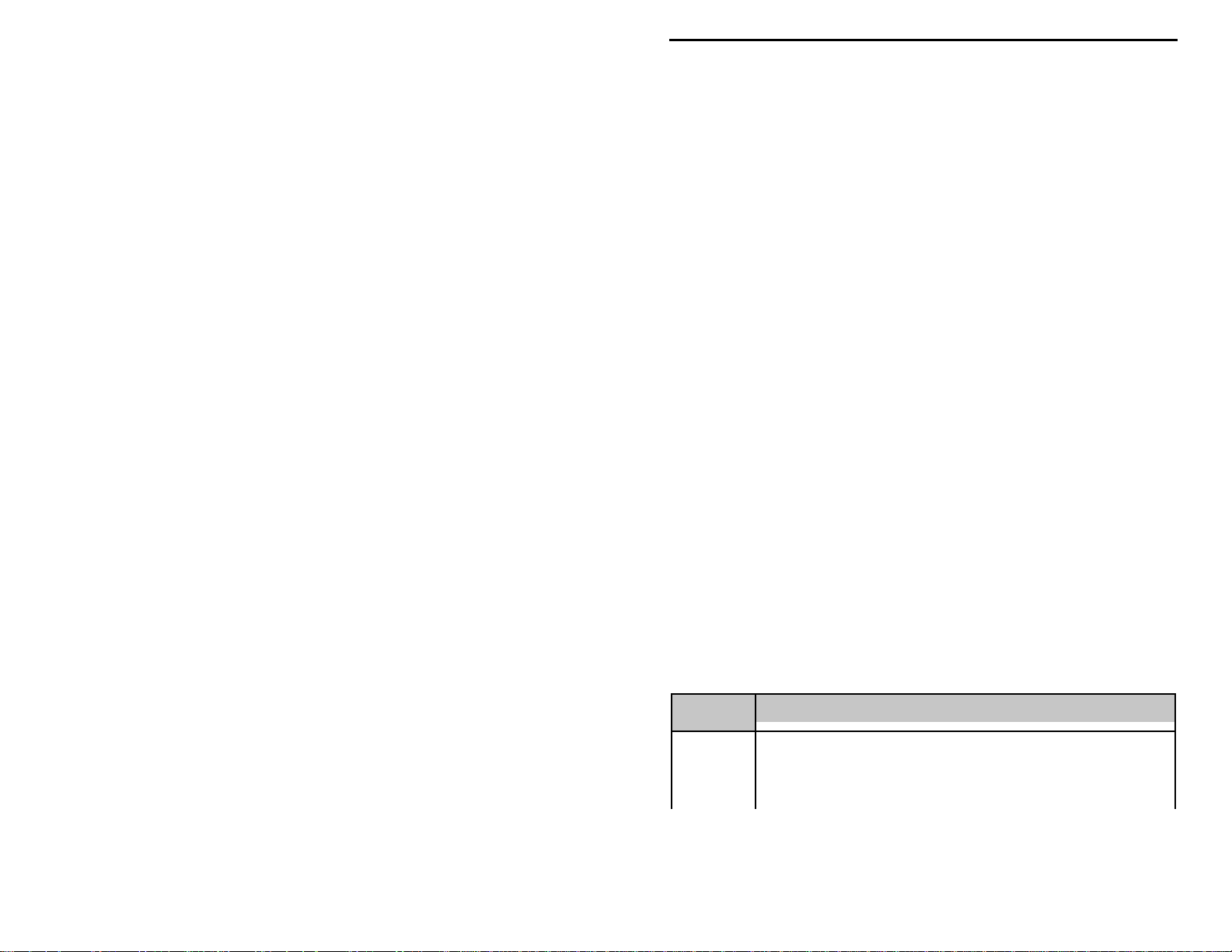

Failure

Message

DH FAIL

DT FAIL

EE FAIL

FN FAIL

M1 FAIL

M2 FAIL

M3 FAIL

M4 FAIL

SP FAIL

Dash level is shorted or improperly connected.

Dot level is shorted or improperly connected.

Non-volatile memory circuitry is improperly connected.

Function switch is shorted or improperly connected.

Message 1 switch is shorted or improperly connected.

Message 2 switch is shorted or improperly connected.

Message 3 switch is shorted or improperly connected.

Message 4 switch is shorted or improperly connected.

Speed control is faulty.

Meanings

Now that the self-test is completed, you're ready to continue the testing and

alignment phase of construction.

!

Preset Volume control R8 to midrange.

!

Preset Speed control R6 about 30% clockwise from the full counter-

clockwise stop.

!

Turn the keyer on using Power switch SW5.

!

Press and hold the dot paddle—you should hear a stream of “dits” from the

monitor speaker.

!

Press and hold the dash paddle—you should hear a stream of “dahs” from

the monitor speaker.

!

While generating a continuous stream of “dits” or “dahs”, verify that

adjusting Volume control R8 varies the monitor sidetone level.

!

While generating a continuous stream of “dits” or “dahs”, verify that

adjusting Speed control R6 va ries the sending rate.

16

Page 22

VEC-221K Instruction Manual CW Memory Keyer Kit

!

If your paddle is iambic, squeeze both paddles—this should produce a

continuous strea m of a l ternating “dits” and “dahs”.

!

Activate Function switch SW6. The keyer should verify that the function

mode has been entered by sending a Morse character “F” (di-di-dah-dit).

!

Enter the Morse character for the letter “S” (di-di-dit) via the paddles. The

keyer should respond with two beeps, indicating an invalid command.

!

Activate Function switch SW6. The keyer should verify that the function

mode has been entered by sending a Morse character “F” (di-di-dah-dit).

!

Enter the Morse character for the letter “R” (di-dah-dit) via the paddles. The

keyer will respond with a single beep indicating a valid command entry.

(This command reverses the action of the dot and dash paddles.)

!

Try your dot and dash paddles—the paddle action should be reversed.

!

Turn the unit off. Note that the reversed paddle orientation will resume

when power is reapplied. This indicates the function command is saved into

the non-volatile memory and ready to be used the next time without having

to set it again.

This completes the testing phase of the VEC-221K keyer. No alignment is

needed.

OPERATING INSTRUCTIONS

Dits, dahs, dots and dashes?

composed of strings of dots and dashes, the visual image conveyed when

viewing Morse CW characters on the printed page. Experienced CW operators

tend to think of CW characters as a sound, and hear dahs instead of dashes, and

dits instead of dots when listening to CW characters. Both terms will be used

interchangeably in the following text.

Determining keyer speed:

generated in a five-second p eriod. The number o f dashes roughly equals your

CW sending speed .

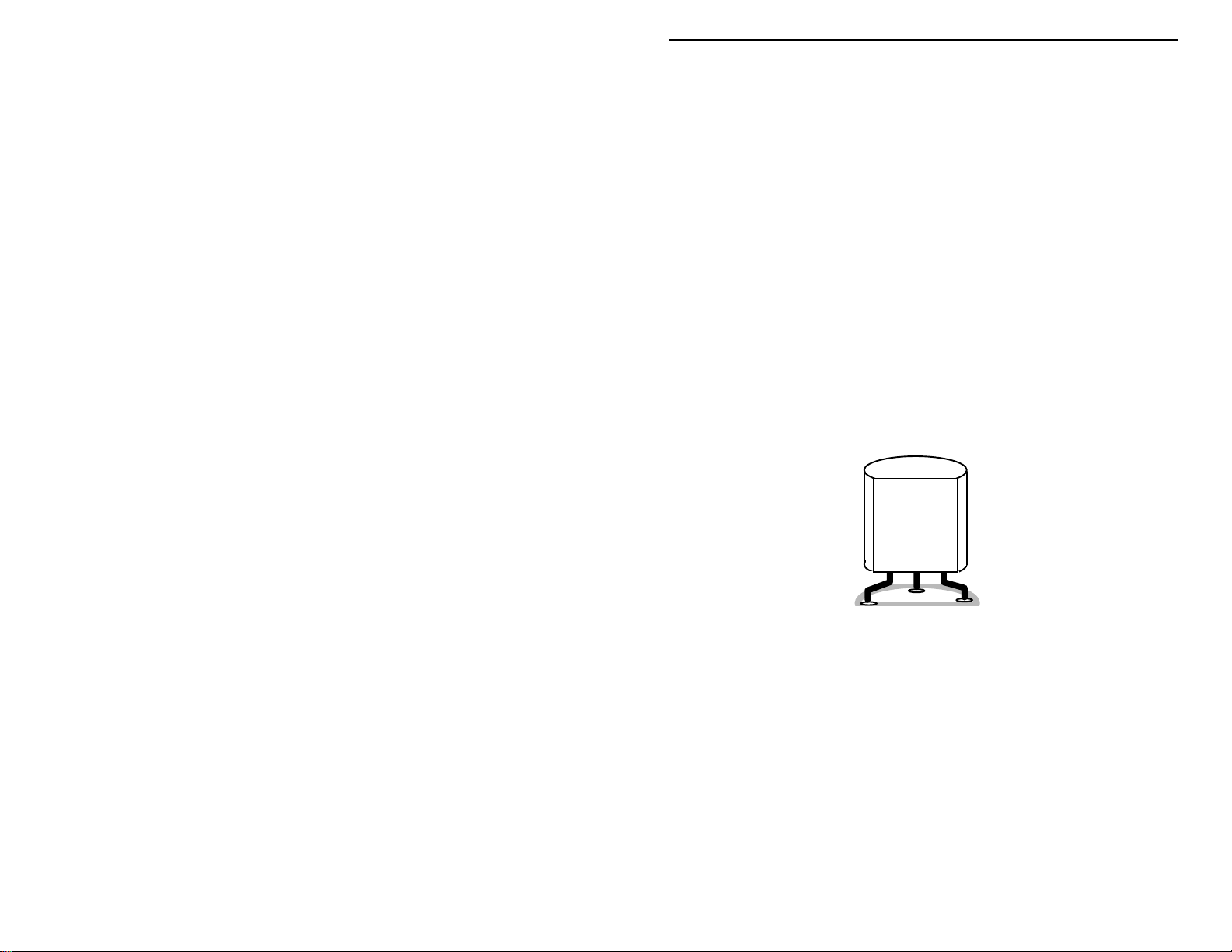

Enclosure:

to provide your own enclosure, allow room for the battery, and perhaps the

sidetone monitor speaker. The optional Vectronics VEC-221KC enclosure is

custom made for the VEC-221K keyer, and includes knobs, push-buttons, feet

and decals.

Power requireme nts:

source. An alkaline battery will give long service, but always remember to turn

the keyer power switch off when the keyer is not being used.

An enclosure will protect the keyer from damage. If you are going

Beginners often t hink of CW character s as being

Hold the dash lever and count the number of dashes

The keyer is designed to operate from a 9-volt DC battery

17

Page 23

VEC-221K Instruction Manual CW Memory Keyer Kit

Experienced builders may opt to power the VEC-221K from an external power

source. The absolute maximum DC supply voltage is limited to 12 Vdc by the

LM386 specifications. Keyers damaged by over-voltage conditions will not be

honored under the terms of the

Warranty

.

Keyer paddles:

Most popular paddles will work well with the VEC-221K. Full

enjoyment of the VEC-221K’s features requires paddles that are capable of

iambic operation. We recommend the Vectronics iambic paddles as being a

good value. Iambic paddles can be recognized by the totally independent

operation of the Dit (or “Dot”) and Dah (or “Dash”) paddles. Some CW

operators refer to iambic paddles as “squeeze paddles”.

The paddles should be equipped with a three-wire interconnecting cable

terminated in a 3.5 mm stereo jack. Miniature shielded and balanced

microphone cable is ideal for this. The common return is connected to the

longest “ring” (shaft) of the stereo jack. The Dah paddle connection is made to

the jack terminal for the smaller insulated ring. The Dit paddle is connected to

the jack tip connection. If your paddles are equipped with a ¼” stereo jack, a

suitable stereo adapter is available at most electronic or hi-fi shops. Reversed

paddle wiring can be corrected by a function entry, more on this later. The

paddles are connected to J1 on the VEC-221K.

Tip (dit)

Common

Ring (dah)

3.5mm stereo jack. Refer to the connector

packaging for wiring terminal details.

Linear controls:

There are two linear controls. Potentiometer R8 sets the

sidetone monitoring level. The second control, potentiometer R6, sets the CW

speed over a range of 3 wpm (words-per-minute) to 65 wpm. This is for good

reason, these are the controls that are most frequently adjusted.

Sidetone operation:

The sidetone is tone keyed by the CW keyer. This permits

you to monitor your keying and provides the aural “feedback” to assist in

sending good CW. Many transceivers already provide for internal CW sidetone

monitoring. If your transmitter does not have built-in sidetone monitoring

provisions, the VEC-221K will generate a sidetone for you. Either a monitor

speaker (4 to 32 ohms) or headphones equipped with a 3.5 mm stereo or mono

18

Page 24

VEC-221K Instruction Manual CW Memory Keyer Kit

jack should be attached to J3 to monitor the CW sidetone. Adjust potentiometer

R8 (sidetone level) to a comfortable listening level.

Factory defaults status:

turned on by depressing Power switch SW5, the unit is ready for operation. A

microprocessor program “subroutine” loads several operating parameters into

the keyer at power up. These parameters are the same as the last time you turn

the unit off, many of them may be changed to suit your preferences—more on

this later. Commands entered via the Function switch are stored in non-volatile

memory.

At factory default settings, the keyer assumes standard paddle wiring, that is dit

key to tip and dah key to the ring of the 3.5 mm jack. Iambic operation is set to

mode “A”. The sidetone frequency is set to 701 Hz. The CW weight is set to

50%, the standard 1:3 dit to dah ratio. The keyer is in the automatic mode.

If CW opera tion is a new experience fo r you, consider runni ng the keyer in its

basic default configuration until you become comfortable with its feel and

operation. Feel free to learn the more advanced features at your own pace.

Factory default settings after the self-test:

1. 701 Hz sidetone

2. Standard weight (50%, dot-dash-space ratio of 1:3:1)

3. Iambic A

4. Automatic

5. Standard paddle wiring (dot = tip, dash = ring)

6. Serial number = 0001

7. Leading zeros sent as "O" (dah-dah-dah)

8. Other zeros sent as "0" (dah-dah-dah-dah-dah)

9. Nines sent as "9" (dah-dah-dah-dah-dit)

As soon as power is supplied and the VEC-221K

Transmitter keying:

need a cable to connect between the keyer and the CW keying jack of your radio.

The operation instructions for your set should show what sort of connector is

needed and its location on your radio. Many modern transceivers use RCA

phono jacks for connecting accessories, in those cases ready-made cables for

home entertainment devices may be used between the VEC-221K and radio.

Keyer output specs:

modern solid-state transceivers and QRP transmitters meet this requirement.

Always check the owner’s manual before attaching the keyer to a radio. The

VEC-221K will key positive voltages to 50 Vdc maximum. Keying current is

limited to 100 mA maximum. Exceeding these limits may damage keying

transistor Q1.

The keyer output is through RCA phono jac k J2. You will

The keyer is de signed for

positive keying output

. Most

19

Page 25

VEC-221K Instruction Manual CW Memory Keyer Kit

Use with vintage sets:

be compatible with the VEC-221K. If the transmitter uses grid-block keying (a

negative key voltage), it can not be used with the VEC-221K. An example of a

grid-block keyed transmitter is the Heathkit DX60. Check the ARRL handbooks

for circuit s for adapti ng keyers to grid-b lock keying.

Vintage novice transmitters commonly used cathode keying, a combination of

high current and high voltage. The Heathkit DX40 used cathode keying, for

example. In general, most cathode-keyed transmitters should be compatible with

the VEC-221K keying circuit, so long as the 50 Vdc and 100 mA limits are not

exceeded.

Dot-and-dash memories and iambic keying:

making sending CW easi er. T he memor y allows the user to ke y a dot b efo re the

completion of a dash, and vice-versa. This feature maybe checked by setting the

keyer to the lowest speed and tapping first the dash lever and then the dot lever

before the completion of the dash. The keyer will generate both the dash and the

dot with perfect spacing. Test the dash memory in a similar manner. First tap

the dot lever and quickly tap the dash lever. The keyer will send the dot

followed by the dash, again with perfect character spacing.

Iambic paddles allow both paddles (or levers) to be depressed at the same.

Pressing (squeezing) both paddles simultaneously will generate a continuous

stream of alternating dots and dashes. The first paddle contacted determines

whether a dot or dash occurs first. CW characters such as "C", "K", "Q" and

"R" are very easily generated with iambic paddles.

Early tube transmitters and hybrid transceivers may not

The dot and dash memories

Non-volatile memory:

number, the keyer settings, and the four message memories. Because it is nonvolatile, it does not require battery backup to preserve the memory.

Special Functions

All programmable special functions are saved in non-volatile memory.

Note

:

These settings are restored at power on.

Automatic mode :

send high-speed code. T he bug would automatic ally send a string of dits when

the dot paddle was depressed and held. Bugs did not generate strings of dashes,

the dash had to be depressed once to generate each individual “dah”. The VEC221K normally operates in the fully automatic mode. However, it may be set for

“semi-automatic” operation, to emulate the sound and feel of a mechanical bug.

Weight:

operators prefer slightly different ratios; and the VEC-221K weight is adjustable

from 25 to 75% of a dot to suit those preferences. The factory default is 50%, or

3:1 dash-to-dot ratio.

20

A 3:1 ratio between dit’s and dah’s is considered to be optimum. Some

The non-volatile memory is used to store the serial

Early telegraphers used a mechanical device called a bug to

Page 26

VEC-221K Instruction Manual CW Memory Keyer Kit

Sidetone frequency:

sidetone may be programmed from approximately 300 to 1000 Hz to suit

individual tastes. There are two ways of setting the sidetone frequency.

Reverse:

paddle is shared by both left and right handed operators.

Iambic modes A and B:

iambic "A" mode.

Serial number:

Only three digits are sent for numbers less than 1000--use leading zeros when

appropriate. The serial number is automatically post-incremented each time it is

sent (9999 will increment to 0001, skipping 0000 since it is not used) and is

updated in the non-volatile memory when the message is finished. The factory

default is 0001.

Zeros and nines:

ways. The factory defaults are leading zeros as "O" (dah-dah-dah), other zeros

as "0" (dah-dah-dah-dah-dah), and nines as "9" (dah-dah-dah-dah-dit).

Using the Function switch:

preferences. To set or change a setting, depress the Function switch. The keyer

acknowledges by sending the Morse character for the letter "F" (di-di-dah-dit).

Keyer functions are entered via the keyer paddles. If an invalid character is

entered, the keyer responds with two beeps. Multiple functions may not be

entered at one time. That is, each function must be individually entered and

preceded by pressing the Function switch. A valid entry is acknowledged by a

single beep. The transmitter key line is disabled during programming. The

function mode maybe exited at any time by pressing the Function switch. The

keyer confirms the exit with two beeps.

Reverses the sense of the left and right paddles. Useful when the

The factory default sidetone is about 701 Hz. The

Either mode may be selected. Factory default is

A four digits serial number can be embedded within a message.

Zeros and nines in t he serial number can b e sent in differe nt

The Function switch customizes the keyer to your

Command

Character

A

I#

Function

utomatic−toggles between automatic and semi-automatic (bug)

A

mode.

ambic−sets iambic mode A or B, where # represents A or B.

I

21

Page 27

VEC-221K Instruction Manual CW Memory Keyer Kit

####

N

umber−sets the seri al number. You must enter four numbe rs,

N

most significant digit first. All numbers must be in the proper

Morse code format. For example, the number "1" must be "didah-dah-dah-dah" and the number "0" must be "dah-dah-dahdah-dah". The serial number can be set from 0000 to 9999

(0000 will be converted to 0001).

P##

R

T

W##

X

###

Z

itch−sets the sidetone frequency to approximately ##0 Hz,

P

where ## represents two digits in the range of 30 to 99.

everse−reverses the sense of the dot and dash paddles.

R

one−sets the sidetone frequency in the range of approximately

T

300 to 1000 Hz. Press the dash paddle to raise the sidetone

frequency; press the dot paddle lowers. Squeeze both paddles

exits. Notice an alternating series of dots and dashes are sent to

the sidetone monitor to assist in the setting of the desired

sidetone fre quency.

eight−sets the code weighting to ## percent, where ##

W

represents two digits in the range of 25 to 75. Weighting is

independent of the speed.

mit (tune)−gives continuous key-down for adjusting transmitter

X

or antenna tuner. Tapping either paddle exits tune mode and

releases the key line.

eros and nines−sets the way zeros and nines in the serial

Z

number are sent. The first # sets whether to send the leading

zeros as "0", "O", "T" or not at all by setting # to the double

dash character "=" (dah-di-di-di-dah). The second # sets

whether the other zeros are sent as "0", "O" or "T". The last #

sets whether the nines are sent as "9" or "N". For example,

"ZO09" will send the leading zeros as "O" (dah-dah-dah), the

other zeros as "0" (dah-dah-dah-dah-dah), and the nines as "9"

(dah-dah-dah-dah-dit).

Message Memory

The Message buttons are used to record and play your message. To record a

message, press and hold the corresponding Message button until the keyer plays

"GO" (dah-dah-dit dah-dah-dah) in Morse code and the LED flashes. You may

now key in the message of your choice. As you pause after every word, the

keyer will play a "W" (di-dah-dah) over the sidetone speaker to show that it is

22

Page 28

VEC-221K Instruction Manual CW Memory Keyer Kit

inserting a word break (uses one unit of memory). If you make a mistake

entering a word, you can back up over it by briefly pressing and releasing the

same Message button. The keyer will erase the last word, then play the word

before it (if any) to let you know where you stopped. If deleting the first word of

the message, the keyer will play "GO" instead. At the end of your message,

press and hold the same Message button until the keyer sends an end of message

character "+" (di-dah-di-dah-dit) and the LED stops flashing. If you try to save

more characters than you have memory, the keyer will automatically end your

message and send you an end of message character. To play a message,

momentarily press the cor r esp ond ing M essa ge b utt on. On-go ing message ca n be

stopped by tapping either paddle or pressing a Message button to send another

message. The speed cannot be changed during message sending and message

recording. Also, the output keying circuit is disabl ed during recording.

The messages are stored in non-volatile memory: message 1 has 120 units of

memory and the other three messages have 128 units of memory each. Each

normal character uses one unit of memory; only the rarely used 7-, 8- and 9element (dots and dashes) characters require two units of memory. Characters

with more than nine elements are ignored. When there are ten or less units of

memory in the message remaining, the LED will flash faster to let you know the

memory is running low.

Note

A straight key cannot be used to record the message.

:

Embedded Commands:

While in the message recording mode you may use embedded commands for

special features. To use an embedded command simply store the multi-character

embedded command code within your message.

Embedded

Command

/D

ecrement−decrements the serial number. Serial number 0001

D

Represents

will decrement to 9999, skipping 0000 since it is not used. This

feature allows a serial number to be sent twice in a message.

Example:

UR RST 559 559 SN /N /D SN /N

23

Page 29

VEC-221K Instruction Manual CW Memory Keyer Kit

/G#

/L

/N

mmss

/P

ap−inserts a gap of # standard intra-character spaces into the

G

message, where # is a digit in the range of 1 to 9 (0 can be used

but not practical). Invalid numeral code will automatically

default to zero. This command is used to exaggerate intercharacter and word spacing.

oop−creates a message loop (message repeat). Note that any

L

character recorded after

Example:

umber−inserts a contest serial number, in the range of 001 to

N

BEACON AA5CS 5 W /L

"/L"

will not be sent.

9999, into the message. Only three digits are sent for numbers

less than 1000--use leading zeros when appropriate. The serial

number is automatically post-incremented each time it is sent

(9999 will increment to 0001, skipping 0000 since it is not used)

and is updated in the non-volatile memory when the message is

finished. The serial number is set to the same one as before

when power on. If a different serial number is desired, it must

be set using the paddle-entered Number function.

Example:

ause−inserts a timed pause of mm minutes and ss seconds into

P

YOU ARE CONTACT NR /N

the message. Four numbers must fol low "/P". Invalid numeral

code will automatically default to zero.

Example:

TIMEOUT 1 HR 40 MIN 39 SEC /P9999

TIMEOUT 1 HOUR /P6000 TIMEOUT 1.5 MIN /P0090

/S

pace−inserts an extra standard word space into the message.

S

This command yields the same result as "/G7" but uses one less

unit of memo ry.

//

/#

Slash character−stores the slash character "/" into the message.

Message call−inserts message number # into the current

message, where # is a digit from 1 to 4.

Morse Code Character Set 1

A di-dah

B dah-di-di-dit

C dah-di-dah-dit

D dah-di-dit

E dit

F di-di-dah-dit

G dah-dah-dit

−

N dah-dit

•

−

•••

−•−

•

−

Q dah-dah-di-dah

••

R di-dah-dit

•

••−•

−−

T dah

•

24

−

O dah-dah-dah

P di-dah-dah-dit

S di-di-dit

−−−

•−−•

−−•−

•−•

•••

−

•

Page 30

VEC-221K Instruction Manual CW Memory Keyer Kit

H di-di-di-dit

I di-dit

J di-dah-dah-dah

K dah-di-dah

L di-dah-di-dit

M dah-dah

1 di-dah-dah-dah-dah

2 di-di-dah-dah-dah

3 di-di-di-dah-dah

4 di-di-di-di-dah

5 di-di-di-di-dit

Period [.] di-dah-di-dah-di-dah

Comma [,] dah-dah-di-di-dah-dah

Question Ma rk or

Request for Repetition [?] di-di-dah-dah-di-dit

Fraction Bar [/] dah-di-di-dah-dit

End of Message or Cross [+] di-dah-di-dah-dit

End of Work di-di-di-dah-di-dah

Double Dash, Pause or Break [=] dah-di-di-di-dah

Semicolon [;] dah-di-dah-di-dah-dit

Colon [:] dah-dah-dah-di-di-dit

Apostrophe ['] di-dah-dah-dah-dah-dit

Quotation Ma rk ["] di-dah-di-di-dah-dit

Hyphen or Dash [-] dah-di-di-di-di-dah

Underline [_] di-di-dah-dah-di-dah

Dollar Sign [$] di-di-di-dah-di-di-dah

Left Parenthesis [(] dah-di-dah-dah-dit

Right Parenthesis [)] dah-di-dah-dah-di-dah

Wait di-dah-di-di-dit

Understood di-di-di-dah-dit

Starting Signal dah-di-dah-di-dah

Error di-di-di-di-di-di-di-dit

Paragraph [¶] di-dah-di-dah-di-dit

Invitation to Transmit dah-di-dah

1.

FCC test requirement consists the 26 letters, the 10 numerals, the period, the comma, the question mark, AR, SK, BT and DN.

U di-di-dah

••••

V di-di-di-dah

••

−−−

W di-dah-dah

•

−•−

X dah-di-di-dah

Y dah-di-dah-dah

•−••

−−

Z dah-dah-di-dit

−−−−

6 dah-di-di-di-dit

•

−−−

7 dah-dah-di-di-dit

••

−−

8 dah-dah-dah-di-dit

•••

−

9 dah-dah-dah-dah-dit

••••

0 dah-dah-dah-dah-dah

•••••

−

••

−

•••

−−

•

−••−

−•−−

−−

••

−

••••

−−

•••

−−−

••

−−−−

•

−−−−−

−

•−•−•

−−••−−

••−−••

−••−

•

•−•−•

−

•••−•

−

−

•••

−•−•−

•

−−−

•••

−−−−

•

•

•−••−•

−

−

••••

−

••−−•

−

•••−••

−•−−

•

−•−−•−

•−•••

•••−•

−•−•−

••••••••

•−•−••

−•−

K

AAA

MIM

IMI

DN

AR

SK

BT

KR

OS

WG

AF

DU

IQ

SX

KN

KK

AS

SN

KA

HH

AL

IN CASE OF DIFFICULTY

Only high-quality components and proven circuit designs are used in Vectronics

kits. In very rare instances is a defective component the source of a problem.

Replacement of defective parts is covered in the

Warranty

section. Nine ty-five

percent of the kits returned for factory repair are due to soldering problems or

parts in the wrong locations. We advise repeating the assembly instructions

step-by-step, looking for mistakes or soldering problems. Be especially wary of

electrolytic capacitors and semiconductors. Kit builders often miss obvious

25

Page 31

VEC-221K Instruction Manual CW Memory Keyer Kit

mistakes. What is needed is a “fresh” set of eyes. Enlist a friend to go over your

work.

Always check the obvious! Is the battery dead or weak? Is the power switch on?

Check the keying cable and paddle cable for intermittent or broken wires. Note

that the solder connections for the various jacks may fail due to stress from

frequent insert ion and removal o f plugs.

Trouble shooting guide:

Performing the self-test will isolate the problems in most cases.

No sidetone, but keying line actuates:

from pin 13 of U1. Look for the sidetone signal at R2, R3, R4, C13, pin 3 of

U3, pin 5 of U3, and both sides of C18 to isolate problem stage. Set scope for

AC coupling, 100 mV (or higher, as needed) per-division. Pin 6 of U3 should

show 9 Vdc. Pin 5 of U3 should measure about 4.5 Vdc with no tone (use scope

or VOM).

Dot or Dash characters not being generated:

going logic leve l at pin 28 of U1. Dash l evel should produce low-going logic

level at pin 2 7 of U 1. Che ck pi n 12 o f U1 for high-going CW signal . Check for

5 Vdc on pins 1 and 20 of U1. Set scope for DC coupling, 1 volt-per-division.

Sidetone okay, but keyline remains low:

from pin 12 of U1 when paddles are actuated. Set scope for DC coupling, 1

volt-per-division. Presence of signal indicates possible failure of Q1 or D1.

Keyer dead:

U1. Loss of 5 volts may indicate failure of U4 voltage regulator.

Sidetone distorted, erratic operation:

keyer; use an enclosure and shielded leads.

Can’t enter function mode:

U1.

Can’t enter message mode:

logic low on pins 21, 22, 23 and 24 of U1, respectively.

LED not lit:

screened outline. Check for 5 volts at R7 and a logic low on pin 18 of U1.

Check for 9 volts at pin 6 of U3. Check for 5 volts at pin 20 of

Pressing SW6 should put a logic low on pin 25 of

Pressing SW1, SW2, SW3 and SW4 should put a

Check the LED to make sure it is properly keyed to the silk-

Use a scope to view the sidetone signal

Dot lever should produce low-

Check for high-goi ng logic signal

Weak battery. There is RF getting into

Keyer gives error beeps on function entry:

formed, with proper timing. Invalid command prefix or suffix.

Code characters must be perfectly

THEORY OF OPERATION AND SPECIFICATIONS

26

Page 32

VEC-221K Instruction Manual CW Memory Keyer Kit

Circuit Description:

The VEC-221K features the powerful PIC16C72 microcontroller. This

integrated circuit contains the programming and basic power of a microprocessor

chip. CW speed is set via R6, a 10K-ohm potentiometer, that controls the

voltage input to pin 2 of U1 (PIC chip). Pin 2 is an analog-to-digital input for

the PIC processor. Programming subroutines scan the digitized setting of R6,

and adjust the speed accordingly.

Keyer paddle activation is also sensed by the PIC chip. All dot-and-dash

memories, iambic operations, and sidetone generation and sidetone frequency

are under the control of the PIC16C72 device.

The message memories and parameter settings are stored in the 24C04

EEPROM, a non-volatile memory IC that does not require battery backup to

preserve the recorded messages and settings.

Power to the PIC controller is regulated at 5 volts by 78L05 (U4), a low-power

5-Vdc regulator IC. The sidetone signal from the processor is filtered by R2-C6,

R3-C7, R4-C8 and L1-C16 to form a sinewave signal, which is amplified by U3,

a linear audio amplifier IC. U3 is powered directly from the 9-volt battery.

Transistor Q1 is a silicon-gate TMOS switching FET, and is used to key the

transmitter. The maximum FET ratings are 50 Vdc at 100 mA.

Specifications:

Voltage requirement........................Internal 9-volt transistor battery

Keyer speed.....................................Typically 3 to 65 WPM

Sidetone level..................................50 mW max., adjustable

Sidetone frequency..........................701 Hz default, adjustable 300 to 1000 Hz.

Keying limit.....................................Positive keying. 50 volts at 100 mA max.

CW generation.................................Iambic A or B, Automatic or Semi-auto

Memory...........................................Dot-Dash memory

Weight.............................................50% default, adjustable 25 to 75 percent

Message memories ..........................4 messages, about 120 characters each

SCHEMATIC

27

Page 33

Page 34

VEC-221K Instruction Manual CW Memory Keyer Kit

ENCLOSURE

Vectronics has designed a matching enclosure just for your VEC-221K CW

Memory Keyer Kit. The matching enclosure is an all metal box which includes

knobs, hardware, decals, and rubber feet.

Enclosure Model: VEC-221KC.

To install your receiver in the VEC-221KC matching enclosure follow these

instructions (read

Find the front and rear panel decal; separate using scissors. Put the rear

1.

panel decal on first. This is done by:

chassis.

decal on the rear panel without securing it completely.

all

instructions before beginning ... take your time):

Remove all debris and oil from the

a.)

Remove the crack and peel to expose the adhesive.

b.)

c.)

Gently rub the

d.)

alignment circles with your finger--if the circles are centered in the enclosure

holes (also check the corner alignment marks) secure the decal by rubbing

and removing all air bubbles.

adjust the decal accordingly, then secure.

TM

Exacto

holes.

Next, install the two L-brackets on the chassis using two of the 3/16" screws.

2.

knife, to cut away the unused edges and cut out the component

Repeat procedure for the front panel.

g.)

If the alignment circles are not centered,

e.)

Use a penknife, or small

f.)

The longer side of the L-bracket must be connected to the chassis using the

two holes centered on each edge of the enclosure. Refer to the diagram on

the next page for location and orientation.

Install the four 1/2" mounting screws next. Insert the screws, from the

3.

bottom, through the two holes close to each rear corner of the chassis.

Place the four 3/16" round spacers on the mounting screws.

4.

Now insert the PC board. This must be done by:

5.

washers from R6 and R8.

Insert the front of the PC board at an angle,

b.)

Remove the nuts and

a.)

then push down on the rear of the board. Make sure the mounting screws

align with the mounting holes in the PC board before pushing.

Use the four hex nuts to secure the PC board. Be certain all appropriate

6.

components are centered with the enclosure holes before tightening. Put the

washers and nuts--removed from R6 and R8--back on and tighten.

Find the knobs and switch caps. Align the switch cap with SW1 and push it

7.

on. If it is difficult to push on, then rotate it 90° and try again. Repeat for

SW2 through SW6. Now put the kno bs on R6 and R8. You may need to

loosen the set screw. Align appropriately then tighten the set screw.

The top should now be installed. Use the two remaining 3/16" screws for

8.

securing the top to the L-brackets.

Place the four rubber feet on the bottom of the enclosure at the corners.

9.

Place the

c.)

28

Page 35

Loading...

Loading...