Page 1

VEC-1680K Owner’s Manual Vacuum Tube Preamp

INTRODUCTION

General Infor mation: If names like Eric Clapton, Jimi Hend rix, and B.B. King

have personal meaning for you, you're gonna love this ki t! Today's solid-state

amps can't match the booming sound of the legendary tube-driven powerhouses

built by Fender and Marshall. The key to that magic lies with the electron tube-or "valve"--which has much softer saturation characteristics than the sharply

clipped response of transistor amplifiers.

With the VEC-1680K in line, your guitar's magnetic pick-ups are terminated

with the true ultra-high impedance load they were designed to feed, which

unleashes your instrument's natural full-bodied frequency response. And, when

you crank up the gain, each note expands in richness with warm even-order

harmonics, unlike the more jolting odd-order harmonics generated by transistors.

Virtually every great tube guitar amp ever built used a 12AX7 in its preamplifier

stage. When you fire up your VEC-1680K, you'll understand why!

Circuitry: The VEC-1680K uses a 12AX7 twin-triode, which is really two

individual tubes packaged in one glass envelope. The first stage runs "wide

open", with no manual gain control or negative feedback circuitry to load it

down. A Gain (or drive) control then regulates how hard you push the preamp's

second stage. Drive it lightly, and you get bell-like clarity. Drive it harder, and

you'll introduce progressively more fullness and grit! Most of the preamp's

distortion and coloring occurs in the second stage. At the preamp's output, the

signal is attenuated back down to "guitar" level. The Output control provides

added variable attenuation to set the optimum drive level for your power amp. A

built-in relay connected to the audio jacks lets you bypass the preamp, or--with

the click of a foot switch bring it on-line.

TOOLS AND SUPPLIES

Construction Area: Kit construction requires a clean, smooth, and well-lighted

area where you can easily organize and handle small parts without losing them.

An inexpensive sheet of white poster board makes an excellent construction

surface, while providing protection for the underlying table or desk. Diffused

overhead lighting is a plus, and a supplemental high-intensity desk lamp is

especially helpful for close-up work. Safety is always important! Use a suitable

high-temperature stand for your soldering iron, and keep the work area free of

clutter.

Universal Kit-building Tools: No sp ecial tools are required to complete this kit

beyond common items normall y used for bench constructio n. We recommend

the following:

! Soldering Iron (grounded-tip and temperature-controlled preferred)

1

Page 2

VEC-1680K Owner’s Manual Vacuum Tube Preamp

! High-temperature Iron Holde r with Cleaning Sponge

! Solder, 60/40 or 37/63 with rosin or "no-clean" flux (.031" dia. is good

size).

! Needle Nose Pliers or Surgical Hemostats

! Diagonal Cutters or "Nippy Cutters"

! Solder Sucker (squeeze or vacuum pump type), or Desoldering Braid

! Bright Desk Lamp

! Magnifying Glass

BEFORE YOU START BUILDING

Experience shows there are four common mistakes builders make. Avoid these,

and your kit will probably work on the first try! Here's what they are:

1. Installing the Wrong Part: It always pays to double-check each step. A 1K

and a 10K resistor may look almost the same, but they may act very

differently in an electronic circuit! Same for capacitors--a device marked

102 (or .001 uF) may have very different operating characteristics from one

marked 103 (or .01uF).

2. Installing Parts Backwards: Always check the polarity of electrolytic

capacitors to make sure the positive (+) lead goes in the (+) hole on the

circuit board. ICs have a notch or dot at one end indicating the correct

direction of insertion. Always double-check--especially before applying

power to the circuit!

3. Faulty Solder Connections: Inspect for cold-solder joints and solder

bridges. Cold solder joints happen when you don't fully heat the connection-or when metallic corrosion and oxide contaminate a component lead or pad.

Solder bridges form when a trail of excess solder shorts pads or tracks

together (see solder tips below).

4. Omitting or Misreading a Part: T his is easier to do than you might think!

Always double-check to make sure you completed each step in an assembly

sequence.

Soldering Tips: Cleanliness and good heat distribution are the two secrets of

professional soldering. Before you install and solder each part, inspect leads or

pins for oxidation. If the metal surface is dull, sand with fine emery paper until

shiny. Allow the tip of your iron to contact both the lead and pad for about one

second (count "one-thousand-one") before feeding solder to the connection.

Surfaces must become hot enough for solder to flow smoothly. Feed solder to

2

Page 3

VEC-1680K Owner’s Manual Vacuum Tube Preamp

the opposite side of the lead from your iron tip--solder will wick around the lead

toward the tip, wetting all exposed surfaces. Apply solder sparingly, and do not

touch solder directly to the hot iron tip to promote rapid melting. Keep a damp

sponge handy to wipe your so ldering tip on. This removes excess solde r, and

keeps the tip properly tinned. If the iron is going to sit idling for long periods,

wipe the tip, add some fresh solder, and unplug the iron.

Desoldering Tips: If you make a mistake and need to remove a part, follow

these instructions carefully! First, grasp the component with hemostats, needlenose pliers, or your fingers. Heat the pad beneath the lead you intend to extract,

and pull gently. The lead should come out. Repeat for the other lead. Solder

may fill in behind the lead as you extract it--especially if you are working on a

double-sided b o ar d with plat e-thr o ugh hol es. Sho uld this ha pp e n, tr y heat ing the

pad again and inserting a common pin into the hole. Solder won't stick to the

pin's chromium plating. When the pad cools, remove the pin and insert the

correct component. For ICs or multiple-pin parts, use desoldering braid to

remove excess solder before attempting to extract the part. Alternatively, a lowcost vacuum-bulb or spring-loaded solder sucker may be used. Parts damaged or

severely overheated during extraction should be replaced rather than reinstalled.

Work Habits: Kit construction requires the ability to follow detailed

instructions and, in many cases, to perform new and unfamiliar tasks. To avoid

making needless mistakes, work for short periods when you're fresh and alert.

Recreational construction projects are more informative and more fun when you

take your time. Enjoy!

Sorting and Reading Resistors: The electrical value of resistors is indicated by

a color code (shown below). You don't have to memorize this code to work with

resistors, but you do need to understand how it works:

Resistor Color Code

1st Digit

2nd Digit

Multiplier

Tolerence

(gold or silver)

Black = 0 (tens)

Brown = 1 (hundreds)

Red = 2 (K)

Orange = 3 (10K)

Yellow = 4 (100K)

Green = 5 (1Meg)

Blue = 6

Violet = 7

Gray = 8

White = 9

Silver = 10%

Gold = 5%

When you look at a resistor, check its multiplier code first. Any resistor with a

black multiplier band falls between 10 and 99 ohms in value. Brown designates

a value between 100 and 999 ohms. Red indicates a value from 1000 to 9999

ohms, which is also expressed as 1.0K to 9.9K. An orange multiplier band

designates 10K to 99K, etc. To inventory resistors, first separate them into

3

Page 4

VEC-1680K Owner’s Manual Vacuum Tube Preamp

groups by multiplier band (make a pile of 10s, 100s, Ks, 10Ks, etc.). Next, sort

each group by specific value (1K, 2.2K, 4.7K, etc). This procedure makes the

inventory easier, and also makes locating specific parts more convenient later on

during construction. Some builders find it especially helpful to arrange resistors

in ascending order along a strip of double-sided tape.

Reading Capacitors: Unlike resistors, capacitors no longer use a color code for

value identification. Instead, the value, or a 3-number code, is printed on the

body.

Value Code

10 pF = 100

100 pF = 101

1000 pF = 102

.001 uF = 102*

.01 uF = 103

.1 uF = 104

Multilayer

(270 pF)

271

Ceramic Discs

(.001 uF) (.1 uF)

102

104

Electrolytic

1 uF

|

1uF

|

35V

+

-

As with resistors, it's helpful to sort capacitors by type, and then to arrange them

in ascending order of value. Small-value capacitors are characterized in pF (or

pico-Farads), while larger values are labeled in uF (or micro-Farads). The

transition from pF to uF occurs at 1000 pF (or .001 uF)*. Today, most

monolithic and disc-ceramic capacitors are marked with a three-number code.

The first two digits indicate a numerical value, while the last digit indicates a

multiplier (same as resistors).

Electrolytic capacitors are always marked in uF. Electrolytics are polarized

devices and must be oriented correctly during installation. If you become

confused by markings on the case, remember the uncut negative lead is slightly

shorter than the positive lead.

Danger---High Voltage Warning:

volt wall adapter, a second internal trans former boosts voltages back up to

lethal levels to supply plate voltage to the 12AX7 tube! This voltage can

painfully shock, injure, or even cause death if you touch it!

tube-type equipment without first turning off and un-plugging the power

source from the AC mains!

capacitors before working on tube amplifier circuitry. This added safety

procedure will be described in the

manual.

Although your pre-amp runs from a 12-

Never work on

Also, you should discharge power supply filter

Testing and Alignment

section of the

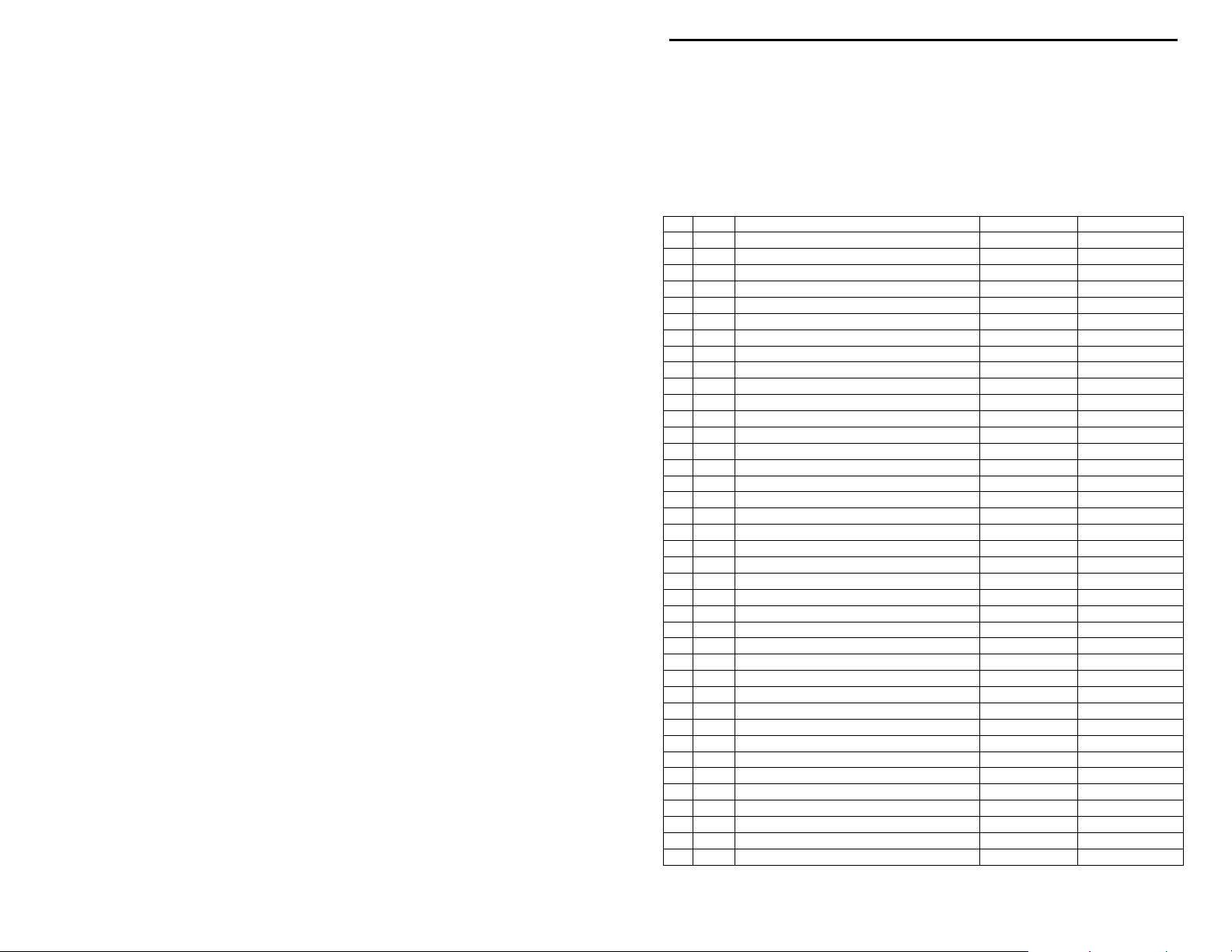

PARTS LIST

Your kit should contain all of the parts listed below. Please identify and

inventory each item on the checklist before you start building. If any parts are

missing or damaged, refer to the manual's warranty section for replacement

4

Page 5

VEC-1680K Owner’s Manual Vacuum Tube Preamp

instructions. If you can't positively identify an unfamiliar item on the basis of the

information given, set it aside until all other items are checked off. You may

then be able to identify it by process of elimination. Finally, your kit will go

together more smoothly if parts are organized by type and arranged by value

ahead of time. Use this inventory as an opportunity to sort and arrange parts so

you can identify and find them quickly.

"

Qty Part Description Designation VEC P/N

2 100 ohm 2 watt resist or (brn-blk-br n) R12, R13 104-2100

!

2 3.3K ohm ½ watt resistor (org-org-r ed) R1, R11 101-3330

!

2 10K ohm ¼ watt resistor (brn-blk-org) R5, R7 100-4100

!

1 22K ohm ¼ watt resistor (red-red-org) R8 100-4220

!

2 390K ohm ¼ watt resistor (org-wht-yel) R3, R4 100-5390

!

2 1M ohm ¼ watt resistor (brn-blk-grn) R2, R6 100-6100

!

2 500K chassis mounted potentiometer R9, R10 153-5500-1

!

1 .01 uF disc cerami c capacitor (103) C7 200-2100

!

2 .1 uF disc cerami c capacitor (104) C10, C11 200-3100-1

!

2 .22 uF multilayer capacitor (224) C3, C9 220-3220

!

3 10 uF 350 volt electrolytic capacitor C1, C2, C6 270-5100x-6

!

3 100 uF 25 volt electrolytic capacitor C4, C5, C8 270-6100-1

!

1 1N4148 diode D6 300-4148

!

5 1N4007 diode D1-D5 300-4007

!

1 12AX7 tube V1 380-12AX7A

!

1 12.6 volt 1 amp power transformer T1 406-1114

!

1 Power switch, SPST SW1 507-1028

!

1 Relay, 2P2T RLY1 408-2042

!

3 ¼” phone jack J1, J2, J4 601-1005

!

1 2.1mm power jack J3 601-6121

!

1 Power Adapter, 12 VAC @ 1 amp 407-1072

!

1 Tube socket, 9 pin 625-12AX7A

!

2 Screw, 2-56 652-0375

!

6 Nut, 2-56 705-0256

!

6 Screw, self-tapping, type B 654S-0250B-B

!

6 Screw, 6-32 x ¼” 656-0250

!

2 Kep Nut, 6-32 705-0632-K

!

3 Nut, metric 9mm 706-7075

!

3 Flat washer 710-2550

!

2 Spacer, ¾” threaded 6- 32 716C-0750

!

2 Knob 760-0033

!

1 Shielded wire, RG316 (12”) 878-0316

!

1 Orange and white twist ed pair (4”) 871-2239

!

"

Qty Part Description Designation VEC P/N

2 Hook-up wire (12”) 871-24xx-1200

!

1 PC board, 2 sided 862-VEC1680

!

1 Chassis, punched 800-VEC1680

!

1 Chassis plate 804-VEC1680

!

4 Stick-on rubber feet 770-1162

!

5

Page 6

Page 7

Page 8

VEC-1680K Owner’s Manual Vacuum Tube Preamp

Good

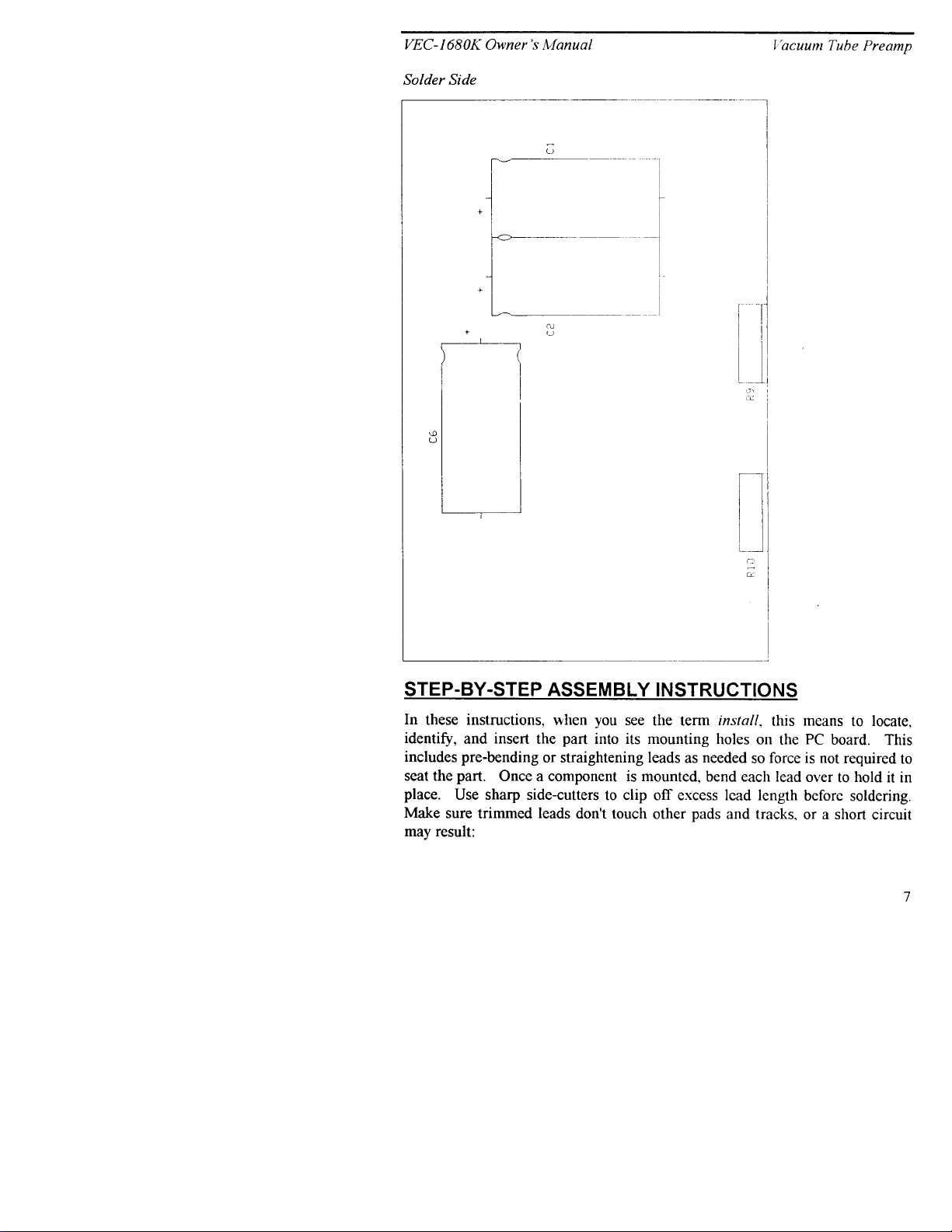

The term solder means to solder the part's leads in place, and to inspect both (or

all) solder connections for flaws or solder bridges. Nip off excess protruding

leads with a sharp pair of side cutters.

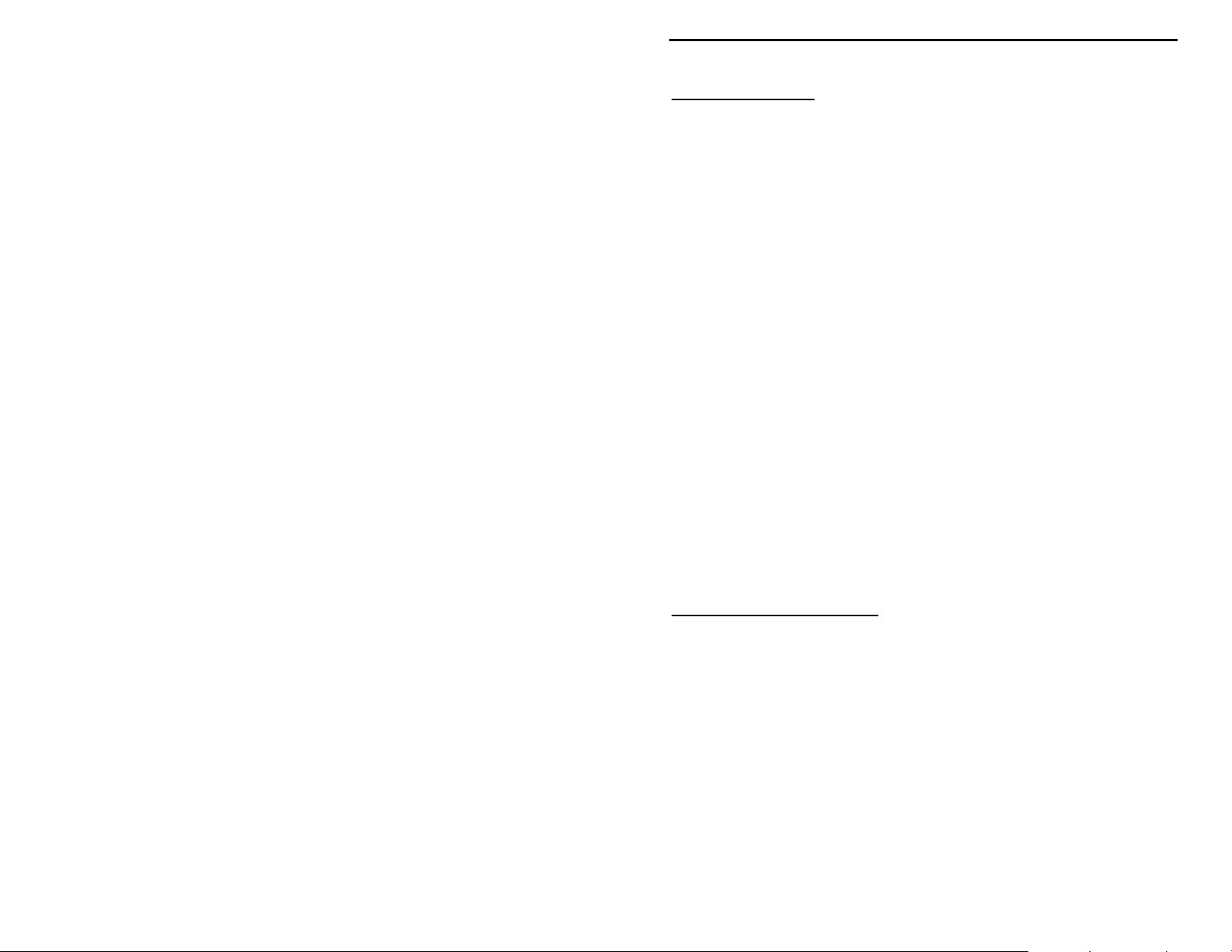

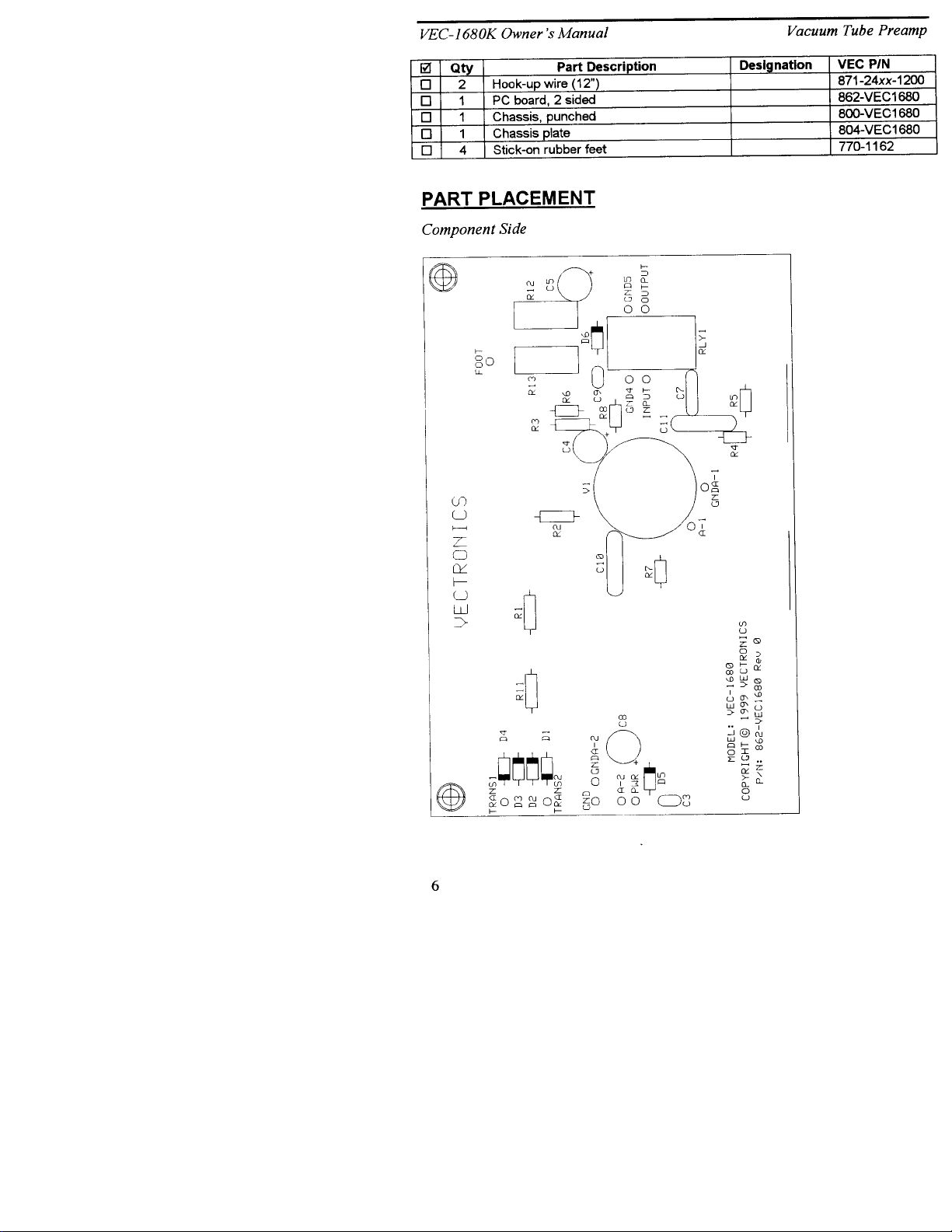

Begin construction by locating the 2-sided PC board. Find the side of the board

with long horizontal tracks on it. This will be called the solder-side during

construction. Flip it over to the side with no tracks. This will be called the

component side. Unless otherwise indicated, parts will be mounted on the

component side (exceptions are three large electrolytic capacitors and two gain

controls to be mounted on the other side).

Orient the PC board component-side up.

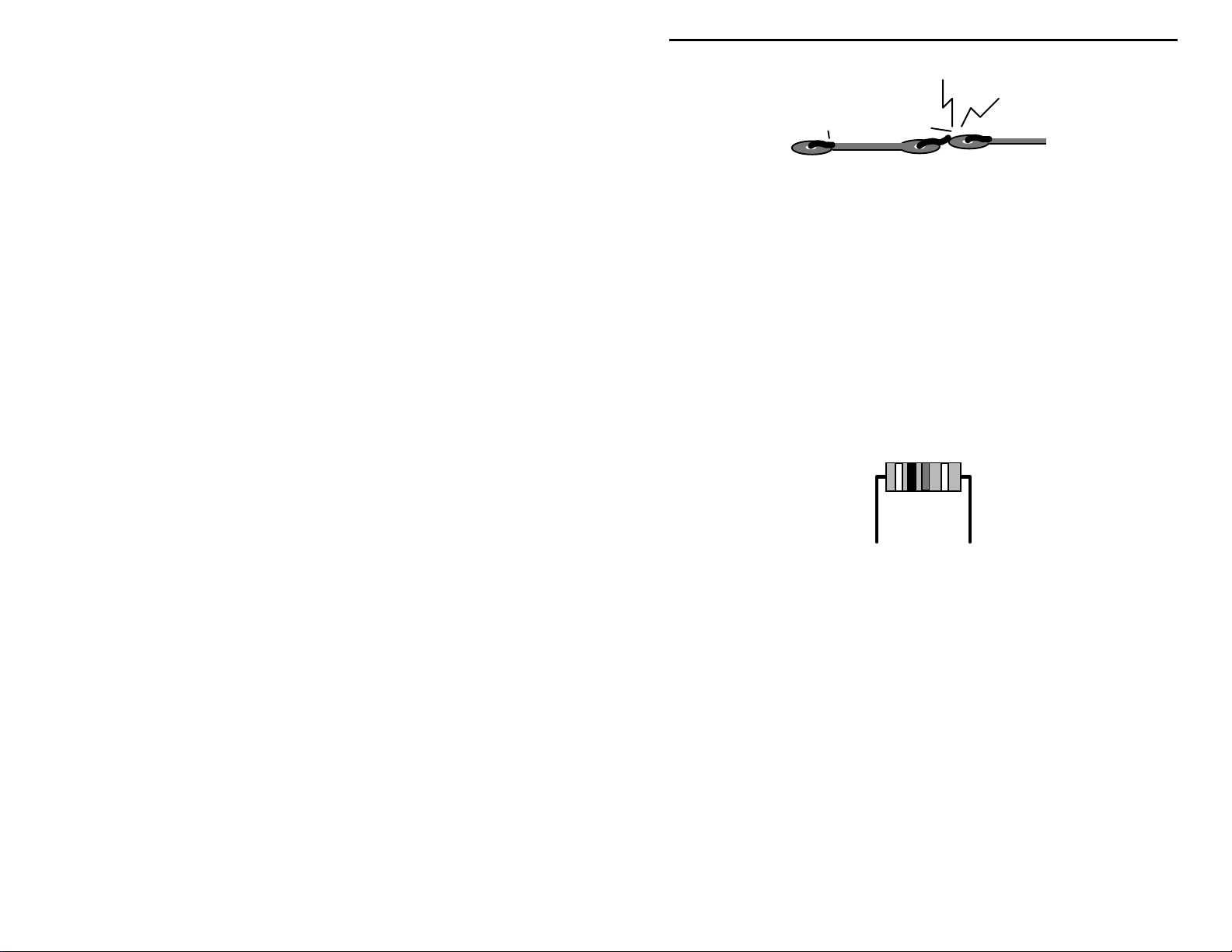

This kit has 11 fixed-value resistors. Mount these now, starting with the smallest

value and moving to the largest. Before mounting each one, carefully bend both

leads close to the resistor body to form right-angles, as shown below:

Not Good

Locate two (2) 100 ohm 2 watt resistors (brown-black-brown).

! ! Install a 100 ohm at R12 and solder.

! ! Install a 100 ohm at R13 and solder.

Locate two (2) 3.3K ½ watt resistors (orange-orange-red).

! ! Install a 3.3K at R1 and solder.

! ! Install a 3.3K at R11 and solder.

Locate two (2) 10K ¼ watt resistors (brown-black-orange).

! ! Install a 10K at R5 and solder.

! ! Install a 10K at R7 and solder.

! ! Find a 22K ¼ watt resistor (red-red-orange). Install at R8 and solder.

Locate two (2) 390K ¼ watt resistors (orange-white-yellow).

8

Page 9

VEC-1680K Owner’s Manual Vacuum Tube Preamp

! ! Install a 390K at R3 and solder.

! ! Install a 390K at R4 and solder.

Locate two (2) 1 Megohm ¼ watts resistors (brown-black-green).

! ! Install a 1 Megohm at R2 and solder.

! ! Install a 1 Megohm at R6 and solder.

This concludes installation of the 1 1 fixed-value resistors provided in your kit.

Double-check for placement, making sure each value is installed where it

belongs. The two 500K variable resistors (potentiometers) will be installed later

on.

Next, install the kit's capacitors.

! ! Find the .01 uF, 100 volt, disc ceramic capacitor (.01 or 103). Install at

C7 and solder.

Locate two (2) .1 uF, 500 volt, disc ceramic capacitors (.1 or 104).

! ! Install a .1 uF at C10 and solder.

! ! Install a .1 uF at C11 and solder.

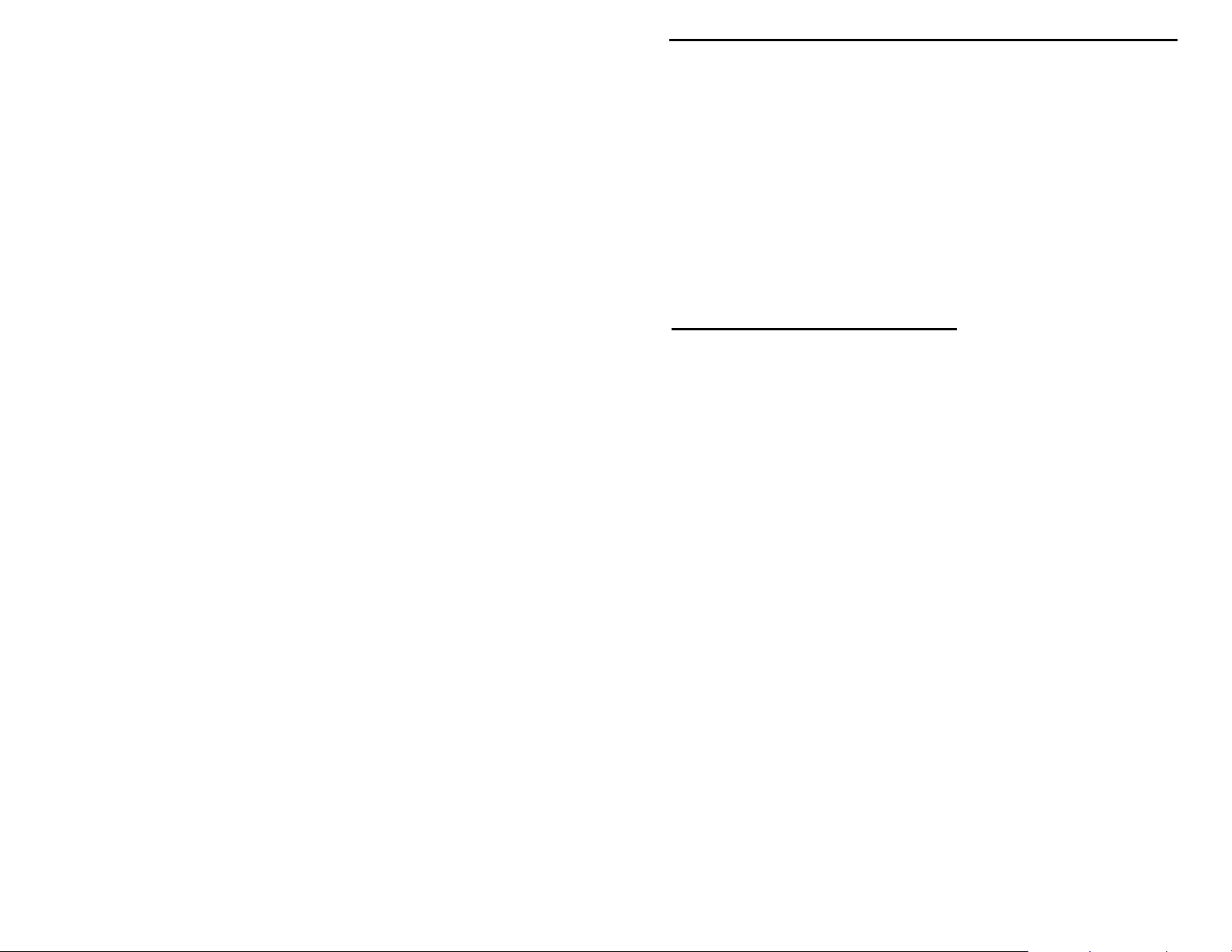

Locate the two (2) .22 uF multilayer capacitors. Avoid using force or excessive

heat when installing these. If the lead spacing isn't right, pre-form leads to the

correct spacing before inserting into the PC board.

Incorrect

Ooops!

Correct

! ! Install a .22 uF at C3 and solder.

! ! Install a .22 uF at C9 and solder.

The remaining capacitors in your kit are electrolytic. Electrolytic caps are

polarized and must be installed the correct way in order to work. Each

capacitor's plus (+) mounting hole is marked on both the circuit board and parts

placement diagram. If the markings on the capacitor body are unclear, the plus

(+) lead is always the longer of the two.

9

Page 10

VEC-1680K Owner’s Manual Vacuum Tube Preamp

+

Plus Lead

Locate the three (3) 100 uF electrolytic capacitors. Observing polarity:

! ! Install a 100 uF at C4 and solder.

! ! Install a 100 uF at C5 and solder.

! ! Install a 100 uF at C8 and solder.

The remaining three (3) 10 uF, 350 volt, electrolytic capacitors are mounted

laying down flat on the opposite side of the PC board (solder side). Double-

check capacitor polarity--high-voltage capacitors may literally explode with a

"bang" if they're installed backwards!

_

C6

+

++

C1

Solder Side

Flip the PC board over to its solder side and mount the 10 uF caps as shown:

! ! Install a 10 uF at C1 and solder.

C2

__

! ! Install a 10 uF at C2 and solder.

! ! Install a 10 uF at C6 and solder.

This completes capacitor installation. Before moving on, check each electrolytic

for correct polarity orientation.

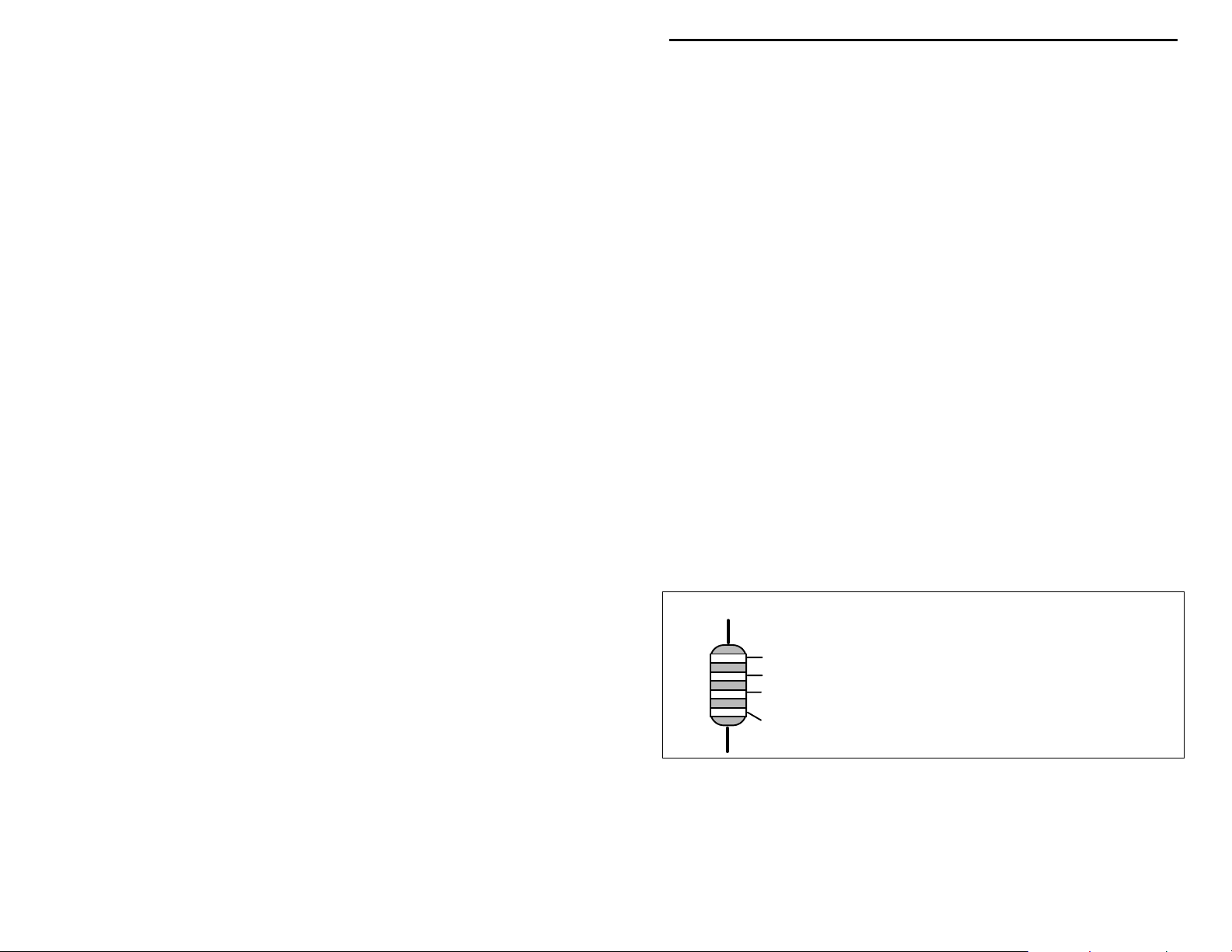

While we're working on the solder side, this is a good time to install the two (2)

500K gain-control potentiometers. Locate them now. Before installing, inspect

the type of potentiometer supplied with your kit. If the pins are located on the

front side of the pot, use the front set of mounting holes provided on the PC

board for installation. If the pins are on the rear, use the rear set of mounting

10

Page 11

VEC-1680K Owner’s Manual Vacuum Tube Preamp

holes (see below). Also, using side cutters, remove the key tab from the side of

each pot prior to installation.

Rear pins use rear holes.

Nip off tab.

! ! On the solder side of the PC board, mount a 500K pot at R9 and solder.

! ! Similarly, mount a 500K pot at R10 and solder.

Flip the PC board back to its component side to complete parts installation. The

next six items to install are diodes. Like electrolytic capacitors, diodes are

polarized devices that must be installed correctly. Always look for the banded

end when installing.

! ! Find the 1N4148 diode (small glass body with band at one end).

Observing polarity, install at D6 and solder.

Front pins use front holes.

Nip off tab.

Locate five (5) 1N4007 power diodes (black body, white band at one end).

Observing polarity, install these as follows:

! ! Install a 1N4007 at D1 and solder.

! ! Install a 1N4007 at D2 and solder.

! ! Install a 1N4007 at D3 and solder.

! ! Install a 1N4007 at D4 and solder.

! ! Install a 1N4007 at D5 and solder.

Locate the DPDT miniature relay and note the pin configuration on its base. The

pins are spaced so the relay fits only one way on the PC board. Be sure all pins

enter their mounting holes and the relay sits flush with the PC board surface

before soldering.

11

Page 12

VEC-1680K Owner’s Manual Vacuum Tube Preamp

! ! Align and install the DPDT relay at RLY1. Holding firmly in place,

solder all eight pins.

Now, install the preamp's 9-pin ceramic tube socket. As with the relay, these

mounting pins are keyed to ensure proper positioning. Make sure all pins are

firmly seated--and hold the socket in place when soldering.

! ! Align and install the ceramic tube socket at V1 and solder all 9 pins.

Next, install the twisted-pair filament leads to V1. Begin by locating the 4"

length of the orange-and-white twisted hook-up provided with your kit:

! ! Dress each wire at both ends, removing about ¼" of insulation.

! ! Install the white wire at one end at GNDA-1 and solder.

! ! Install the companion orange wire at A-1 and solder.

! ! Install the other end of the white wire at GNDA-2 and solder.

! ! Install the companion orange wire at A2 and solder.

! ! Cut and dress a 6" length of hook-up wire and install one end at FOOT

(this will be connected to the foot-switch jack later on). Solder.

Two shielded audio wires are used for the preamp's high-impedance INPUT and

OUTPUT leads. Shielding prevents these lines from picking up stray AC hum.

Note that only the circuit-board end of the lines are grounded. If both ends were

grounded, it could set up a "ground loop" inside the amplifier enclosure that

would introduce hum and noise. Prepare each cable as shown below:

1/2"

! ! Prep a 4" length of shielded cable, as shown.

! ! Connect the shield to GND5 and solder.

! ! Connect the inner conductor to OUTPUT and solder.

! ! Prep a 8" length of shielded cable, as shown.

! ! Connect the shield to GND4 and solder.

! ! Connect the inner conductor to INPUT and solder.

12

Trim off shield

Page 13

VEC-1680K Owner’s Manual Vacuum Tube Preamp

To J2

Input

Foot

To J4

Footswitch

GNDA-2

A-2

Filament

Line

A-1

V1

Input

GNDA-1

GND4 GND5

Output

RLY1

To J1

Output

This completes circuit-board wiring of your VEC- Kit. The remaining point-topoint wiring will be done with the preamp circuit board mounted in its cabinet.

Before moving on to that p hase, give the circuit board a thorough QC (quality

control) inspection. This will help you uncover assembly errors that might

prevent it from working properly. Follow this procedure:

1. Compare parts locations with the parts-placement diagram. Was each part

installed where it is supposed to be? Was the correct value used? Start at

one side of the board and work your way across in an organized pattern.

2. Inspect the solder side of the board for cold-solder joins and solder bridges

between tracks or pads. Use a magnifying glass to obtain a clear view of the

track area. If you suspect a solder bridge, hold the board in front of a bright

light for a better view. All joints should be smooth and shiny, indicating

good solder wetting and flow. Resolder any beaded or dull-appearing

connections.

3. Finally, check electrolytic capacitors and diodes for correct polarity. Does

the plus (+) polarity symbol on the part agree with the pictorial and with the

pattern on the PC board? Is the banded end of each diode positioned

correctly?

Be sure to correct all errors before moving on--once the board is mounted in its

cabinet, further inspections will require disassembly!

Begin final assembly by locating the chassis box and turning it upside down with

the jack and control holes facing you. Looking into the box near the rear wall,

find two mounting holes spaced approximately 4½” apart horizontally. Spacers

will be mounted here to support the PC board. Find two (2) ¾” threaded

aluminum spacers and two (2) 6-32 x ¼” screws.

13

Page 14

VEC-1680K Owner’s Manual Vacuum Tube Preamp

! ! Install a spacer in the left-hand mounting hole (do not tighten).

! ! Repeat, installing one in the r ight-hand mounting hole.

Now, locate the PC board and remove the mounting hardware from the

potentiometers.

Hold the PC board solder-side up with the gain control shafts facing toward you

(the capacitors will be on the right side). Tilting the board toward you, guide the

potentiometer shafts down into their mounting holes--allowing the rear of the PC

board to clear the back lip on the chassis. Drop the PC board into position on its

mounting spacers.

! ! Secure the PC board to its spacers with two 6-32 x ¼” screws.

! ! Tighten all hardware.

! ! Reinstall the potentiometer mounting hardware and tighten.

! ! Bring the ends of the audio and foot-switch leads out from under the

board.

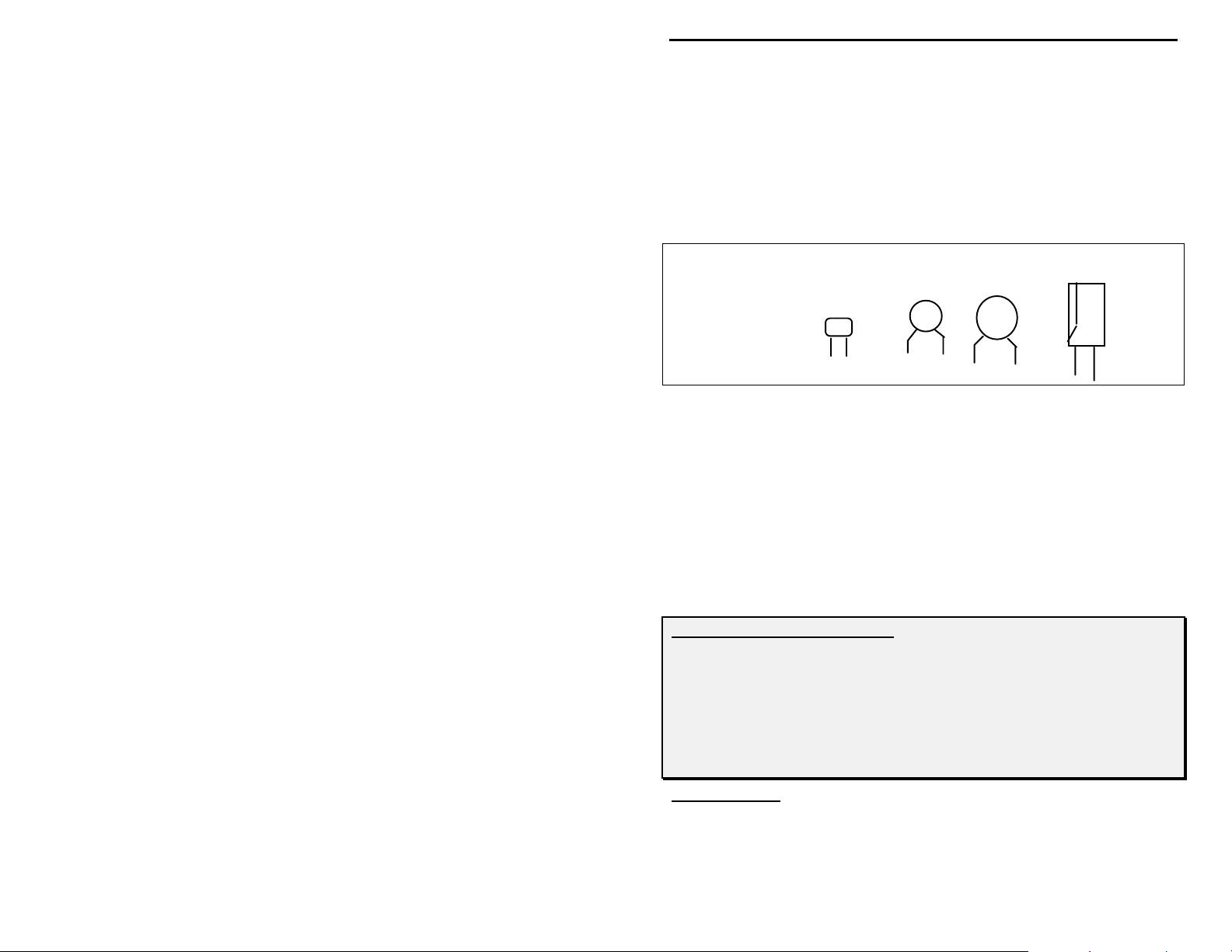

Each of these leads will be installed on the "tip" connection of a ¼” phone jack

and installed in the chassis. Locate all three (3) ¼” phone jacks and their

hardware--plus the three (3) 9mm spacer washers. Install as outlined below:

Tip

Connection

! ! Connect the center conductor of the 4" shielded line to the tip connection

on a ¼” jack and solder. Install the jack at Input on the chassis panel.

! ! Connect the center conductor of the 8" shielded line to the tip connection

on a ¼” jack and solder. Install the jack at Output on the chassis panel.

! ! Connect the hook-up wire leading from FOOT to the tip connection on a

¼” jack and solder. Install the jack at Foot Switch on the chassis panel.

Locate the 12.6 volt 1.5-amp power transformer. Also, locate the remaining two

(2) 6-32 x ¼” screws plus the two (2) kep nuts (thin squar e spring-like nuts).

! ! First cut the white lead off of the transformer. This lead is not needed.

14

N.C.

Spacer washer

Flat washer

Nut

Page 15

VEC-1680K Owner’s Manual Vacuum Tube Preamp

! ! Refer to the pictorial diagram below, and position the 12.6 volt

transformer so the black leads are toward the PC board and the red are

toward the side of the chassis. Align the mounting tabs with the punched

chassis holes.

! ! Using 6-32 hardware, secure the transformer in place--inserting each

screw up through the chassis and securing it inside with a kep nut.

Tighten both screws.

! ! Cut about half the lead length from both the black transformer leads.

Dress both lead ends. Solder the back lead to TRANS1 and the front lead

to TRANS2.

Black Transformer

Leads

Power Jack

Red Transformer

Leads

Input Output

Foot Switch

Power Switch

The preamp's power switch and power jack both mount from outside the chassis.

Since space is tight inside, you'll find it easier to wire these prior to installation.

This requires threading wires through the component mounting hole before

attaching. Begin by locating the power switch and positioning it as shown (note

the plastic partition between terminals #1 and #2). The switch tabs are raw

copper and should be cleaned with fine emery cloth or a pencil eraser prior to

attaching wires. Tab numbers are marked on the side of the switch.

! ! Thread the closest red transformer lead through the square switch

mounting hole in the chassis panel. Dress the lead end and connect it to

tab #1 without soldering.

! ! Cut a 4” length of hook-up wire and connect it to tab #1. Solder both

leads.

15

Page 16

VEC-1680K Owner’s Manual Vacuum Tube Preamp

! ! Cut a 6” length of hook-up wire and attach it to tab #2. Solder.

! ! Thread the 6” and 4” leads through the mount i ng hole.

! ! Holding the switch so tab #1 is up toward you, firmly press the switch into

its mounting hole (it may take some pressure to collapse the plastic

retainers on each end) . The switch should snap into place and hold

securely.

! ! Connect the 4" wire from tab #1 of the switch to PWR on the PC board.

Solder.

! ! Thread the 6" wire t hrough the power-jack mounting hole at the rear of

the chassis.

! ! Find the remaining red wire from the power transformer and thread that

through the power jack mounting hole.

Locate the 2.1mm power jack and position as shown in the pictorial diagram.

Note that there are three terminals. The terminal held in place by a rivet head is

attached to the center pin of the power connector. This is the (+) connection.

! ! Attach the 6" lead from the power switch to the (+) connection on the

power jack.

Find the terminal that exits the jack on the edge of the brown phenolic insulator.

This is the (-) connector, or ground.

! ! Cut a 4" length of hook-up wire and dress both ends.

! ! Connect one end to the (-) tab of the power jack without soldering.

! ! Connect the remaining red lead from the power transformer to the (-) tab

of the power jack and solder both leads in place.

Find the two (2) 2-5 6 screws and matching nuts.

! ! Install the power jack and secure it in place with 2-56 hardware.

! ! Connect the 4 " lead from the (-) side of the power jack to GND on the PC

board and solder.

Locate the 12AX7 tube and remove it from its box. Note that the tube's 9 pins

are keyed to insert into the socket only one way. Turn the chassis over, find the

socket at V1 ( thr ough t he ho le in the to p) , and ali gn the tub e p ins with the soc ket

holes.

! ! Carefully insert the 12AX7 tube into its socket (V1), taking care not to

bend or fold over any pins.

16

Page 17

VEC-1680K Owner’s Manual Vacuum Tube Preamp

Before installing the control knobs, set turn potentiometer shafts fully

counterclockwise.

! ! Find a knob and install it on one of the potentiometers. Set the knob

pointer to the 7-o'clock position and tighten the set screw.

! ! Repeat knob installation for the second potentiometer.

Locate the bottom cover for the chassis plus the six (6) self-tapping screws.

! ! Install the bottom chassis cover and secure.

! ! Find the sheet with four (4) rubber stick-on feet attached. Install a rubber

foot at each corner of the bottom panel.

This concludes assembly of your VEC-1680K preamp kit.

High Voltage Warning:

lethal voltages. Please read the

manual carefully before applying power or attempting to operate your

preamp!

Your preamp's 12AX7 tube operates at potentially

Testing and Alignment

section of this

TESTING AND ALIGNMENT

The VEC-1680K preamp has no internal adjustments and should work as

specified without additional set-up. However, there's always the remote

possibility that a construction error or defective component could prevent proper

operation. Before attempting to use your preamp, follow this initial test

procedure:

1. Turn both controls (Gain and Output) fully counter-clockwise.

2. Make sure the Power switch is Off.

Note

: Do not plug in an instrument or amplifier at this stage of the test.

3. Locate the 12-VAC wall adapter and plug its cord into the 2.1mm power

jack.

4. Plug the wall adapter into a 110 VAC mains.

5. Turn the Power switch On. The tube's filament should light.

If the filament fails to light, turn the preamp Off at once. First, check the 12AX7

filament for continuity. Remove the tube and hold it with pins facing you. The

first pin clockwise of the gap is pin 1. Count to pins 4 and 5, and check

resistance with an ohm meter. If the filament is good, you'll see a short. Pin 9 is

the filament's center tap.

17

Page 18

VEC-1680K Owner’s Manual Vacuum Tube Preamp

5

4

19

If the filament is okay, check the power adapter for 12 VAC output (this may be

significantly higher than 12 volts AC with no load attached).

Important Warning:

work inside with AC Power turned on--or with the AC adapter plugged into

110-VAC mains! Als o, before touching internal components, discharge the

unit's three filter capacitors.

To discharge the filter capacitors, rest a small screwdriver on the edge of the

chassis to make ground contact and touch the (+) lead of each capacitor with the

tip. This will bleed off any energy stored in the high-voltage circuit.

Never remove the bottom cover of your preamp and

_

C6

+

Filament Pins

+C2+

C1

If the tube's filaments heat properly, move on to a test of the foot-switch

function. If you have a st and ar d musical i nstr ument foot switch availab le, plug it

into the Foot Switch jack (these are available at most music stores). If you don't

have one, use a cliplead or short length of hook-up wire attached to a ¼” phone

plug (see following diagram).

When the foot switch is closed, it shorts the plug's center terminal to ground-energizing the by-pass relay. This routes audio signals through the preamp's

circuitry. When the foot switch is open, the Input and Output jacks are

connected together and signals bypass the preamp. This test will confirm that

the relay is activated when the foot switch is closed.

18

Page 19

VEC-1680K Owner’s Manual Vacuum Tube Preamp

6. Connect an instrument to the Input jack of the preamp.

7. Connect a patch cord between the Output jack and your guitar amp.

8. Turn the preamp's Gain and Output controls off (counter-clockwise).

9. Make sure the preamp's power switch is On.

With the foot switch open, your guitar should bypass the preamp and play

through the p ower amplifier normal ly--as if patched directl y in. With the foot

switch closed, the guitar signals should not reach the amp because both preamp

gain controls are fully down. If the relay fails to close, check the preamp's relay

circuit for errors.

If the relay circuit is working, check the operation of the preamp itself. With the

foot switch closed:

10. Set the preamp's Gain control at 12:00 (half open).

11. Slowly increase the Output control while plucking a note.

You should hear the guitar become progressively louder. Bring the Output

control up until the volume through the preamp roughly matches the volume

when in bypass mode setting. If strong hum or oscillation occurs, turn the

Output control down quickly and turn the preamp off. This indicates an

assembly problem in the preamp circuitry that needs correction. If the preamp is

operating correctly, you're done!

19

Page 20

VEC-1680K Owner’s Manual Vacuum Tube Preamp

OPERATING INSTRUCTIONS

Set-up of the VEC-1680K is pretty intuitive. Like most in-line instrument

accessories, the instrument connects to one end--and the power amp connects to

the other! The following diagram shows how to make these connections:

Power

Adapter

Foot Switch

Foot Switch

Power

Input

Gain Output

Output

VEC-1680K

Instrument

Power Amplifier

Foot Switch: To bring the preamp on-line, simply close the foot switch. The

internal relay re -routes the audio p ath through the preamp circ uitry. To bypass

the preamp, open the foot switch.

Gain Control: The first p re-amp stage runs wide open, with no manual gain

control or negative feedback. This boosts the audio signal, but introduces little

compression or d istortio n. The outp ut then passes through the Gain control and

into the second preamp stage. Unlike the first stage, the second stage can be

overdriven easily because the signal coming into it is much stronger. The Gain

knob regulate s how much stronger. Drive the stage lightly, and you'll get Mark

Knoffler bell-like clarity. Drive it harder, and you'll get increasing increments of

Stevie Ray Vaughan fullness and grit! Crank it way up, and you'll get a taste of

Jimi Hendrix!

Output: After the preamp's second stage, a fixed attenuator knocks the signal

back down to "guitar" level. The Output control then provides added gain

reduction to set the correct drive level for your particular power amp. For best

results, always set the Output control so that it approximates the "bypass"

volume level. This ensures that any tonal coloring of your instrument's sound

occurs in the second stage of the 12AX7 tube--and not because your preamp is

overdriving the transistors in your power amp!

IN CASE OF DIFFICULTY

Before seeking assistance, check below for a possible solution:

20

Page 21

VEC-1680K Owner’s Manual Vacuum Tube Preamp

Does not turn on: Is the power adapter plugged in? Does it have 12 VAC

output? Is the tube firmly seated in its socket?

Hum on Instrument: Are patch cables in good condition (no open grounds)?

Try flipping the polarity switch on the power amp.

Distorted Audio at all settings: Check condition of the tube. Is there a bluish

glow or does the tub e make a strong ringing sound when tapped with a pencil

eraser (is it microphonic)? Tubes deteriorate with age and require periodic

replacement.

If you have the necessary tools and technical skills to troubleshoot and repair

high-voltage equipment, voltage analysis is a good way to localize trouble. Here

are the normal voltage readings for the 12AX7. Any variation over 10% from

these values may indicate a problem area in the preamp's circuitry.

Important Warning:

Never

attempt to take "live" voltage readings on tube-type equipment unless you

are specially trained and qualified to do so!

Potentially lethal voltages are present in your preamplifier.

12AX7 Voltage Chart

V1a V1b

Pin-1 80 V

Pin-2 0.1 V

Pin-3 1.4 V

Pin-4 to Pin-5 13-VAC

Pin-4 to Pin-9 6.5-VAC

Pin-6 90 V

Pin-7 .1 V

Pin-8 1.0 V

If these checks fail to uncover the problem, repeat the "QC" check one more

time. Service records show that, for most malfunctioning kits, outright

component failure is relatively rare. In most cases, the culprit is a misplaced

part, reverse-polarized capacitor, or a faulty solder connection. If, despite your

best effort, you cannot solve the problem, kit repair services are available

through Vectronics. See the warranty on the inside front cover for complete

instructions.

THEORY OF OPERATION

The VEC-1680K preamp uses a 12AX7 high-mu dual triode at V1, a tube

designed especially for low-level audio preamplifier applications. The first stage

is optimized for linearity, with the grid-leak bias circuit (R6) chosen to present

minimal loading to magnetic instrument pickups. Output from this stage is AC-

21

Page 22

VEC-1680K Owner’s Manual Vacuum Tube Preamp

coupled into gain control R9, which establishes the drive level for the following

stage. The second stage is configured for high gain, but its plate supply is set

intentionally "soft". This allows the stage to be driven into saturation easily in

order to create a variety of special effects and tonal colorings. The output level

of the second sta ge, which is many orde r s of magnitud e str onge r t hat " inst rument

level", is attenuated back down to a useful drive level through a combination

fixed and variable attenuator network (R4, R5, and R10).

Foot-switch driven relay RLY1 controls signal routing by either connecting the

preamplifier circuitry on line, or bypassing it with a direct connection between

the Input and Output jacks.

The preamp is isolated from the AC line by a 12 volt AC adapter. This feeds

V1's filament circuit directly, and also energizes the preamp's two built-in DC

supplies. A simple low-voltage supply provides smoothed DC for the footswitch relay circuit (D5/C8). A second high-voltage supply develops plate

voltage for V1 by transforming 12-VAC back to AC line level through T1.

Diode bri dge D1-D4 convert s this energy to DC, where it is smoothed through

filter network C1, C2, C6 and R1, R11.

22

Page 23

Page 24

VEC-1680K Owner’s Manual Vacuum Tube Preamp

ENCLOSURE

Vectronics has designed a matching enclosure just for your VEC-1680K Vacuum

Tube Audio Preamplifier Kit. The matching enclosure is an all metal cover, with

mounting screws, to protect your tube . The Vectronics model number for the

matching enclosure is VEC-1680KC.

To install your VEC-1680KC matching enclosure follow these instructions:

1. Remove all debris and oil from the enclosure. You can do this with a piece

of cloth and alcohol.

2. Find the four (4) self-tapping (#4 x ¼”, type B) screws.

3. Align the enclosure with the four pilot holes.

4. With a philips head type screw drive, secure the enclosure using the selftapping screws. The screws should be snug—do not over ti ght en.

24

Page 25

Loading...

Loading...