Page 1

IMPORTANT WARRANTY INFORMATION! PLEASE READ

Return Policy on Kits When Not Purchased Directly From Vectronics: Before continuing

any further with your VEC kit check with your Dealer about their return policy. If your Dealer

allows returns, your kit must be returned before you begin construction.

Return Policy on Kits When Purchased Directly From Vectronics: Your VEC kit may be

returned to the factory in its pre-assembled condition only. The reason for this stipulation is,

once you begin i nsta lli ng a nd sol deri ng pa rt s, you essenti al ly tak e over the rol e of the devic e's

manufacturer . From this point on, neither Vect ronics nor its dea lers can reas onably be held

accountab le for the qua lity or the outcome of your work. Because of this, Vectronics cannot

accept return of any kit-in-progress or completed work as a warranty item for any reason

whatsoever. If you are a new or inexperienced kit b uilder, we urge you to read the manual

carefully a nd determine whether or not you're r eady to tak e on the job. If you wish to c hange

your mind and return your ki t, you may--b ut you must do i t before you begin c ons tr uc ti on, a nd

within ten (10) working days of the time it arrives.

Vectronics Warrants: Your kit contains each item specified in the parts list.

Missing Parts: If you determine, during your pre-construction inventory, that any part is

missing, please contact Vectronics and we'll send the missing item to you free of charge.

However, before you contact Vect ronic s, please look carefully to c onf ir m you haven't misr ea d

the marking on one of the other items provided with the kit. Also, make certain an alternative

part hasn't been substituted for the item you're missing. If a specific part is no longer

available, or if Engineering has determined that an alternative component is more suitable,

Vectronics reserves the right to make substitutions at any time. In most cases, these changes

will be clearly noted in an addendum to the manual.

Defective Parts: Today's electronic parts are physically and electrically resilient, and

defective components a re r a re. However, if you disc over a n it em duri ng your pr e- c onst r uct i on

inventory that's obviously broken or unserviceable, we'll replace it. Just return the part to

Vectronics at the address below accompanied with an explanation. Upon receipt, we'll test it.

If it's defec tive and appear s unused, we'll ship you a new one right away at no charge.

Missing or Defective Parts After You Begin Assembly: Parts and materials lost or

damaged after construction begins are not covered under the terms of this warranty. However,

most parts supplied with VEC kits are relatively inexpensive and Vectronics can replace them

for a reasonable charge. Simply contact the factory with a complete description. We'll

process your order quickly and get you back on trac k.

Factory Repair After You Begin Assembly: Kits-in progress and completed kits are

specifically excluded from coverage by the Vectronics warranty. However, as a service to

customers, tec hnicia ns ar e availa ble t o evaluate a nd repai r malf unctioni ng kits for a minimum

service fee of $18.00 (½ hour rate) plus $7.00 shipping and handling (prices subject to

change). To qualify for repair service, your kit must be fully completed, unmodified, and the

printed circuit board assembled using rosin-core solder. In the event your repair will require

more than an hour to fi x (or $36.00, subject to change), our technicians will contact you in

advance by telephone b efore p erforming t he work. Def ective unit s should b e shipp ed prep aid

to:

Vectronics

1007 HWY 25 South

Starkville, MS 39759

Page 2

When shipping, pack your kit well and include the minimum payment plus shipping and

handling charges ($25.00 total). No work can be performed without pre-payment. Also,

provide a valid UPS return address a nd a day time phone number where you may be reac hed.

Page 3

VEC-1220K/1230K/1240K/1280K Owner's Manual

INTRODUCTION

This kit provides a great introduction to QRP operation, one of the hottest and

fastest growing activities in amateur radio. With these little rigs, you'll discover

what thousands of QR P enthusiasts alread y know--the magic of communicating

world-wide using less energy than it takes to illuminate a pen-light bulb!

Your VEC QRP-CW Transmitter Kit is simple to build, yet it gives you many

sophisticated features to make QRP operating both easy and fun. For example, a

built-in diode antenna switch handles T/R transfer in milliseconds for full QSK

operation in between CW characters. In fact, if your receiver has a good AGC,

you can simply plug into the T/R jack and copy both sides of the conversation

simultaneously, without receiver muting. In addition to full QSK, you get

shaped keying--just like on the most expensive commercial transceivers.

For drift-free frequency stability, the transmitter is crystal-controlled. However,

that doesn't mean you're "stuck" in one spot. The wide-range VXO circuit uses a

high-Q variab le-c ap a ci to r fo r maximum frequenc y shift. Also , a se co nd o pt io nal

crystal frequency may be added and selected with the push of a switch. Best of

all, there's no need to order crystals to get started--each kit already includes one

cut for the internationally recognized QRP calling-frequency on that band.

Finally, when your kit is assembled and it's time to fire up, you won't need to

fiddle with tricky tuning--or to substitute output transistors for best results.

You'll get a solid 1-watt plus signal that's filtered through a high-Q toroid lowpass filter to ensure compliance with FCC rules. In short, your kit provides

everything you need to get on the air fast!

TOOLS AND SUPPLIES

Construction Area:

area where you can easily organize and handle small parts without losing them.

An inexpensive sheet of white poster board makes an excellent construction

surface, while providing protection for the underlying table or desk. Welldiffused overhead lighting is a plus, and a supplemental high-intensity desk lamp

will prove especially helpful for close-up work. Safety is an important

consideration. Be sure to use a suitable high-temperature stand for your

soldering iron, and keep the work area free of combustible clutter.

Universal Kit-building Tools:

additional items to complete, virtually all construction projects require a work

area outfitted with the following tools and supplies:

!

Soldering Iron

Kit construction requires a clean, smooth, and well-lighted

Although your particular kit may require

1

Page 4

VEC-1220K/1230K/1240K/1280K Owner's Manual

!

High-temperature Iron Holder with Cleaning Sponge

!

Rosin-core Solder (thin wire-size preferred)

!

Needle Nose Pliers or Surgical Hemostats

!

Diagonal Cutters or "Nippy Cutters"

!

Solder Sucker, Vacuum Pump, or Desoldering Braid

!

Bright Desk Lamp

!

Magnifying Glass

Special Tools for This Kit:

!

RF power meter or VSWR bridge

!

50-ohm dummy load or 1-watt 47 ohm carbon-film resistor

!

Telegraph key with a 3.5 mm "mini" phone plug.

!

LED (any color)

BEFORE YOU START BUILDING

Experience shows there are four common mistakes builders make. Avoid these,

and your kit will probably work on the first try! Here's what they are:

1. Installing the Wrong Part:

and a 10K resistor may look almost the same, but they may act very

differently in an electronic circuit! Same for capacitors--a device marked

102 (or .001 uF) may have very different operating characteristics from one

marked 103 (or .01uF).

2. Installing Parts Backwards:

capacitors to make sure the positive (+) lead goes in the (+) hole on the

circuit board. Transistors have a flat side or emitter tab to help you identify

the correct mounting position. ICs have a notch or dot at one end indicating

the correct direction of insertion. Diodes have a banded end indicating

correct polarity. Always double-check--especially before applying power to

the circuit!

3. Faulty Solder Connections:

bridges. Cold solder joints happen when you don't fully heat the connection-or when metallic corrosion and oxide contaminate a component lead or pad.

Solder bridges form when a trail of excess solder shorts pads or tracks

together (see Soldering Tips below).

2

It always pays to double-check each step. A 1K

Always check the polarity of electrolytic

Inspect for cold-solder joints and solder

Page 5

VEC-1220K/1230K/1240K/1280K Owner's Manual

4. Omitting or Misreading a Part:

Always double-check to make sure you completed each step in an assembly

sequence.

Soldering Tips:

Cleanliness and good heat distribution are the two secrets of professional

soldering. Before you install and solder each part, inspect leads or pins for

oxidation. If the metal surface is dull, sand with fine emery paper until shiny.

Also, clean the oxidation and excess solder from the soldering iron tip to ensure

maximum heat transfer. Allow the tip of your iron to contact both the lead and

pad for about one second (count "one-thousand-one") before feeding solder to

the connection. Surfaces must become hot enough for solder to flow smoothly.

Feed solder to the opposite side of the lead from your iron tip--solder will wick

around the lead toward the tip, wetting all exposed surfaces. Apply solder

sparingly, and do not touch solder directly to the hot iron tip to promote rapid

melting.

Desoldering Tips:

If you make a mistake and need to remove a part, follow these instructions

carefully! First, grasp the component with a pair of hemostats or needle-nose

pliers. Heat the pad beneath the lead you intend to extract, and pull gently. The

lead should come out. Repeat for the other lead. Solder may fill in behind the

lead as you extract it--especially if you are working on a double-sided board with

plate-through ho les. Should this happen, try heating the p ad again and inserting

a common pin into the hole. Solder won't stick to the pin's chromium plating.

When the pad cools, remove the pin and insert the correct component. For ICs

or multi-pin parts, use desoldering braid to remove excess solder before

attempting to extract the part. Alternatively, a low-cost vacuum-bulb or springloaded solder sucker may be used. Parts damaged or severely overheated during

extraction should be replaced rather than reinstalled.

This is easier to do than you might think!

Work Habits:

Kit construction requires the ability to follow detailed instructions and, in many

cases, to perform new and unfamiliar tasks. To avoid making needless mistakes,

work for short periods when you're fresh and alert. Recreational construction

projects are more informative and more fun when you take your time. Enjoy!

Sorting and Reading Resistors:

The electrical value of resistors is indicated by a color code (shown below). You

don't have to memorize this code to work with resistors, but you do need to

understand how it works:

3

Page 6

VEC-1220K/1230K/1240K/1280K Owner's Manual

Resistor Color Code

Black = 0 (tens)

1st Digit

2nd Digit

Multiplier

Tolerence

(gold or silver)

When you look at a resistor, check its multiplier code first. Any resistor with a

black multiplier band falls between 10 and 99 ohms in value. Brown designates

a value between 100 and 999 ohms. Red indicates a value from 1000 to 9999

ohms, which is also expressed as 1.0K to 9.9K. An orange multiplier band

designates 10K to 99K, etc. To sort and inventory resistors, first separate them

into groups by multiplier band (make a pile of 10s, 100s, Ks, 10Ks, etc.). Next,

sort each group by specific value (1K, 2.2K, 4.7K, etc.). This procedure makes

the inventory easier, and also makes locating specific parts more convenient later

on during construction. Some builders find it especially helpful to arrange

resistors in ascending order along a strip of double-sided tape.

Some VEC kits may contain molded chokes which appear, at first glance, similar

to resistors in both shape and band marking. However, a closer look will enable

you to differentiate between the two--chokes are generally larger in diameter and

fatter at the ends than resistors. When doing your inventory, separate out any

chokes and consult the parts list for specific color-code information.

Reading Capacitors:

Brown = 1 (hundreds)

Red = 2 (K)

Orange = 3 (10K)

Yellow = 4 (100K)

Green = 5 (1Meg)

Blue = 6

Violet = 7

Gray = 8

White = 9

Silver = 10%

Gold = 5%

Unlike resistors, capacitors no longer use a color code for value identification.

Instead, the value, or a 3-number code, is printed on the body.

Value Code

10 pF = 100

100 pF = 101

1000 pF = 102

.001 uF = 102*

.01 uF = 103

.1 uF = 104

As with resistors, it's helpful to sort capacitors by type, and then to arrange them

in ascending order of value. Small-value capacitors are characterized in pF (or

pico-Farads), while larger values are labeled in uF (or micro-Farads). The

transition from pF to uF occurs at 1000 pF (or .001 uF)*. Today, most

4

Multilayer

(270 pF)

271

Ceramic Discs

(.001 uF) (.1 uF)

102

104

Electrolytic

1 uF

1uF

|

35V

|

+

-

Page 7

VEC-1220K/1230K/1240K/1280K Owner's Manual

monolithic and disc-ceramic capacitors are marked with a three-number code.

The first two digits indicate a numerical value, while the last digit indicates a

multiplier (same as resistors).

Electrolytic capacitors are always marked in uF. Electrolytics are polarized

devices and must be oriented correctly during installation. If you become

confused by markings on the case, remember the uncut negative lead is slightly

shorter than the positive lead.

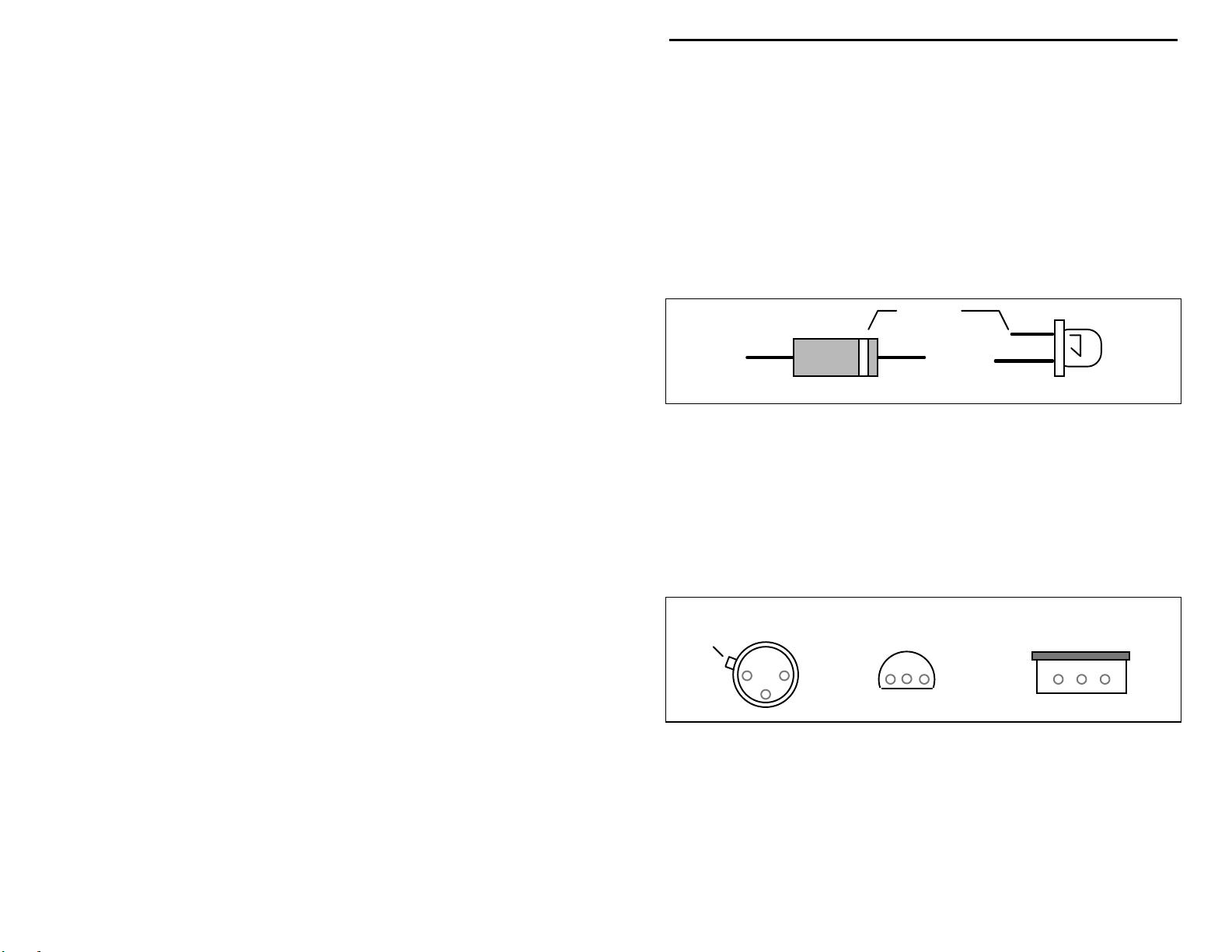

Diodes:

Diodes are also polarized devices that must be installed correctly. Always look

for the banded or cathode end when installing, and follow instructions carefully.

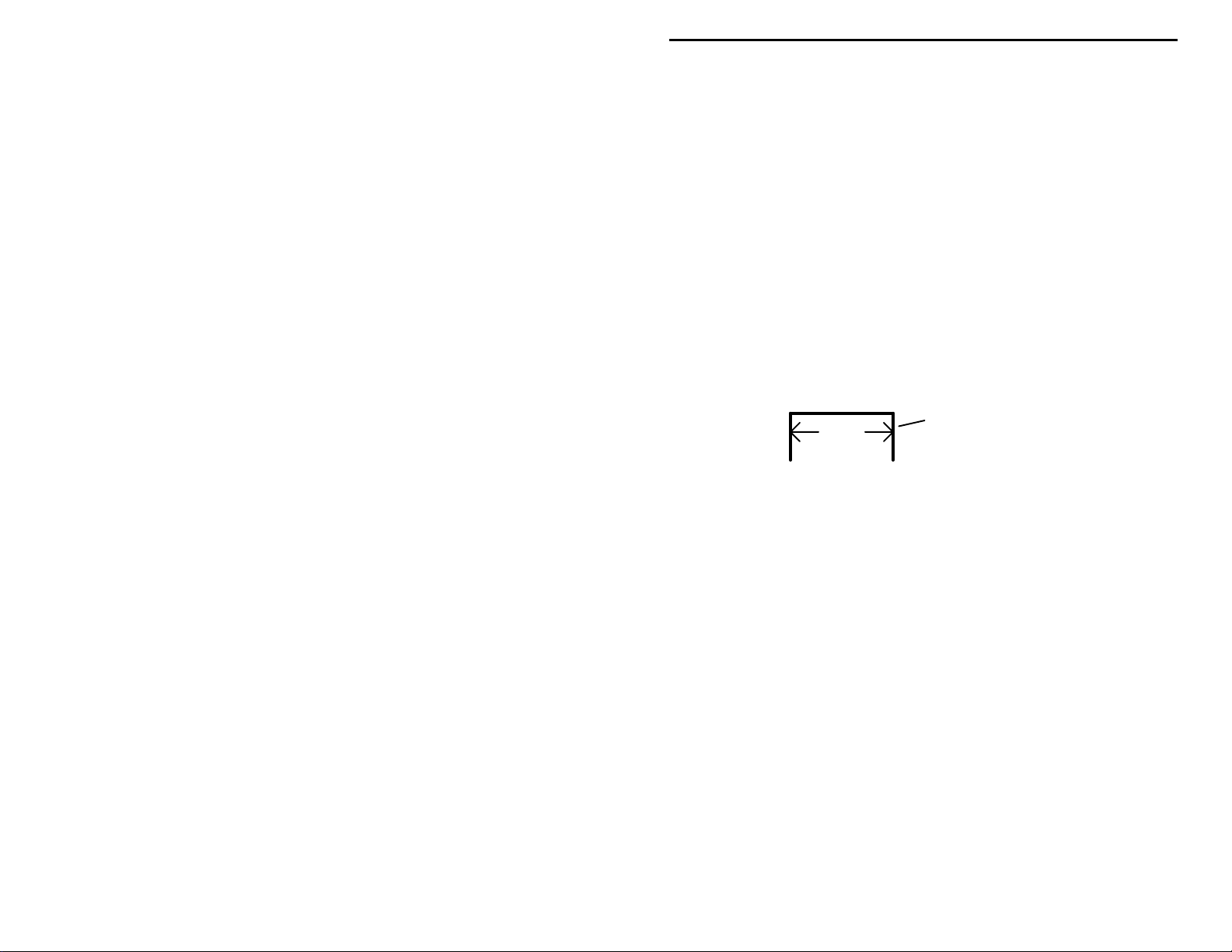

Transistors:

If transistors are installed incorrectly, damage may result when power is applied.

Transistors in metal cases have a small tab near the emitter lead to identify

correct positioning. Semiconductors housed in small plastic cases (TO-92) have

an easily-identified flat side to identify mounting orientation. Many specialized

diodes and low-current voltage regulators also use this type packaging. Larger

plastic transistors and voltage regulators use a case backed with a prominent

metal tab to dissipate heat (T-220). Here orientation is indicated by the

positioning of the cooling tab.

Cathode

(shorter Lead)

Diode

Metal Can Device Plastic Device Tab-cooled Device

Emitter

LED

Metal Tab

Flat Side

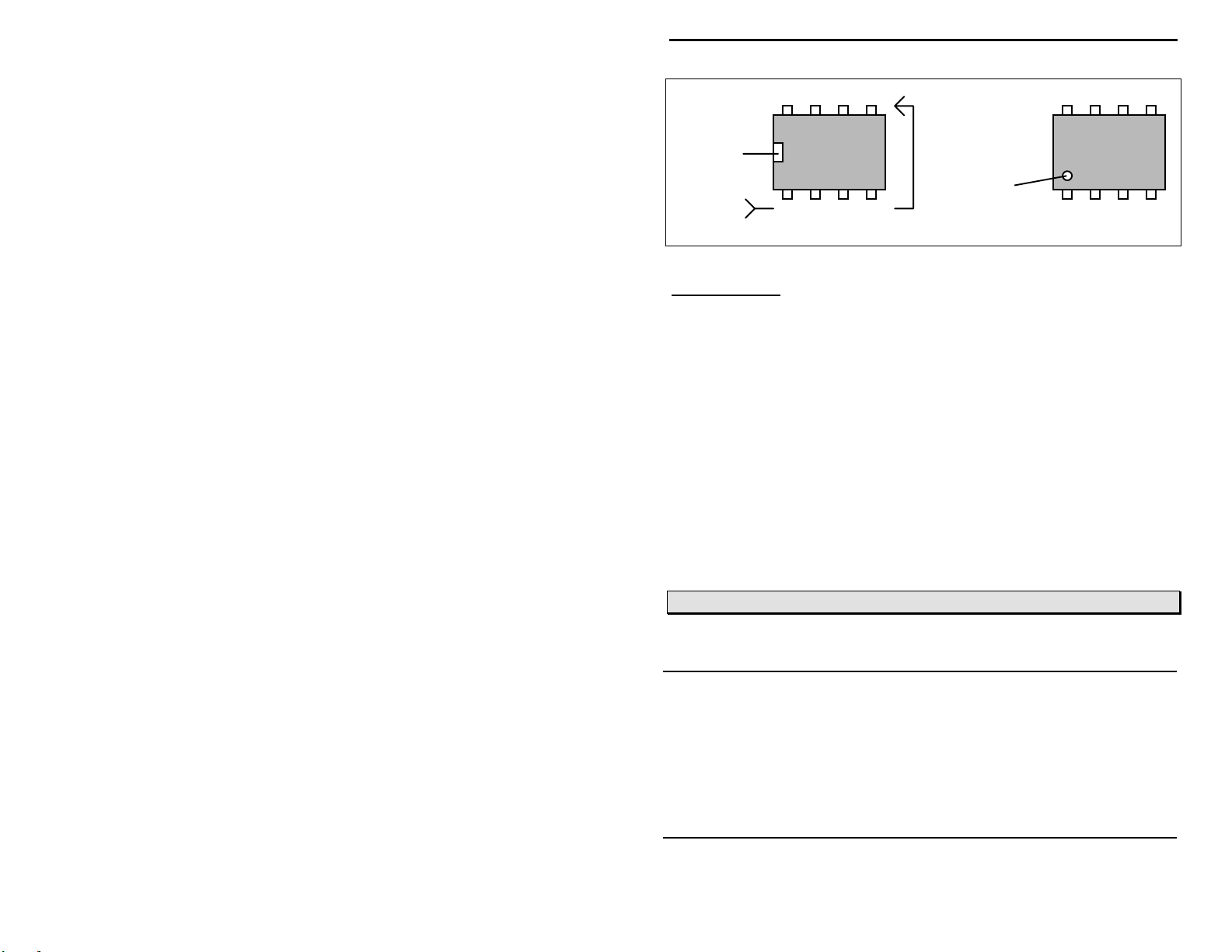

Integrated Circuits:

Proper IC positioning is indicated by a dot or square marking located on one end

of the device. A corresponding mark will be silk-screened on the PC board and

printed on the kit's parts-placement diagram. To identify specific IC pin

numbers for testing purposes, see the diagram below. Pin numbers always start

at the keyed end of the case and progress counter-clockwise around the device,

as shown:

5

Page 8

VEC-1220K/1230K/1240K/1280K Owner's Manual

8 7 6 5

Installation

Key

1 2 3 4

Pin Numbers

Installation

Key

PARTS LIST

The parts list for your kit is presented in two parts. First, you'll identify and

inventory the generic parts--those items common to all VEC QPR transmitter

kits regardless of band. Then, you'll inventory the parts specifically for your

particular VEC QPR transmitter, which contains frequency-critical parts that

determine the specific band of operation.

If any parts are missing or damaged, refer to the manual's warranty section for

replacement instructions. If you can't positively identify an unfamiliar item on

the basis of the information given, set it aside until all other items are checked

off. You may then be able to identify it by process of elimination. Finally, your

kit will go together more smoothly if parts are organized by type and arranged by

value ahead of time. Use this inventory as an opportunity to sort and arrange

parts so you can identify and find them quickly.

First, locate and identify the generic parts bags. These items are common to all

four models of the VEC QRP-CW Transmitter Kit:

Generic Parts

Resistors:

"

!

!

!

!

!

!

Capacitors:

"

6

(fourth gold color band indicates 5% tolerance)

Qty Part Description Designation

2 100 ohm (brown-black-brown) R4,R7

1 270 ohm (red-violet-brown) R8

3 470 ohm (yellow-violet-brown) R5,R9,R11

1 1K (brown-black-red) R10

3 10K (brown-black-orange) R1,R2,R3

1 47K (yellow-violet-orange) R6

Qty Part Description Designation

Page 9

VEC-1220K/1230K/1240K/1280K Owner's Manual

!

10 .1 uF disc ceramic (103 or 103Z) C1,C3,C9,C10,C11

C12,C15,C17,C18,C21

!

1 470 uF electrolytic C4

!

1 .1 uF disc ceramic (104 or 104Z) C2

!

1 multi-section variable capacitor C5

Chokes, Coils:

Qty Part Description Designation

"

!

2 100 uH (brown, black, brown, silver) RFC4, RFC5

!

1 T37-2 toroid form (round, red) L1

Semiconductors:

Qty Part Description Designation

"

!

1 2N3906 transistor Q1

!

1 2N3904 transistor Q2

!

1 PN2222 transistor Q3

!

1 2N3053 transistor Q4

!

2 1N4007 diode D1,D2

!

1 1N4148 diode D3

Jacks, Switches:

Qty Part Description Designation

"

!

1 3.5mm key jack J1

!

1 2.1mm coaxial power jack J2

!

2 RCA type phone jack J3,J4

!

2 DPDT push-button switch SW1,SW2

Miscellaneous Ite ms:

Qty Part Description

"

!

1 clip-on transistor heat sink

!

1 printed circuit board

!

1 instruction manual

!

1 length, double-sided tape

!

1 1/2" tuni ng shaft extension

(molded chokes are larger than resistors)

Now, to complete the inventory, select the correct list below for the specific

model of your kit--and check off those items:

VEC-1220K (20-Meter QRP-CW Transmitter Kit)

Capacitors:

Qty Part Description Designation

"

7

Page 10

VEC-1220K/1230K/1240K/1280K Owner's Manual

!

1 22 pF multilayer (22 or 220) C6

!

1 47 pF multilayer (47 or 470) C8

!

1 68 pF multilayer (68 or 680) C16

!

3 220 pF multilayer (221) C7,C19,C20

!

1 330 pF multilayer (331) C14

!

1 470 pF multilayer (471) C13

Inductors/Chokes:

Qty Part Description Designation

"

!

3 1.8 uH (brown, gray, gold, silver) RFC1,RFC2,RFC3

!

1 12" length of #22 enameled wire for L1

Crystal:

"

!

VEC-1230K (30-Meter QRP-CW Transmitter Kit)

Capacitors:

"

!

!

!

!

!

!

!

Inductors/Chokes:

"

!

!

Qty Part Description Designation

1 14.060 MHz crystal Y1

Qty Part Description Designation

1 33 pF multilayer C6

1 47 pF multilayer C8

1 100 pF multilayer C16

1 220 pF multilayer C7

2 330 pF multilayer C19,C20

1 470 pF multilayer C13

1 680 pF multilayer C14

Qty Part Description Designation

3 2.2 uH (red, red, gold, silver) RFC1,RFC2,RFC3

1 12" length of #22 enameled wire L1

Crystal:

"

!

VEC-1240K (40-Meter QRP-CW Transmitter Kit)

Capacitors:

"

!

!

8

Qty Part Description Designation

1 10.108 MHz crystal Y1

Qty Part Description Designation

1 47 pF multilayer C6

2 100 pF multilayer C8,C16

Page 11

VEC-1220K/1230K/1240K/1280K Owner's Manual

!

1 220 pF multilayer C7

!

3 470 pF multilayer C13,C19,C20

!

1 1000 pF multilayer C14

Inductors/Chokes:

Qty Part Description Designation

"

!

3 4.7 uH (yellow, violet, gold, silver) RFC1,RFC2,RFC3

!

1 12" length of #24 enameled wire L1

Crystal:

"

!

VEC-1280 (80-Meter QRP-CW Transmitter Kit)

Capacitors:

"

!

!

!

!

!

Inductors/Chokes:

Qty Part Description Designation

1 7.040 MHz crystal Y1

Qty Part Description Designation

1 68 pF multilayer C6

1 100 pF multilayer C8,C16

2 470 pF multilayer C13,C16

2 820 pF multilayer C19,C20

2 1000 pF multilayer C7,C14

Qty Part Description Designation

"

!

3 10 uH (brown, black, black, silver) RFC1,RFC2,RFC3

!

1 12" length of #24 enameled wire for L1

Crystal:

"

!

Once again, if any parts are missing, consult the warranty page on the inside

cover for specific replacement instructions. If your parts inventory is complete,

you're ready to star t buil ding. Re member, o nce c onstr uctio n begins, you may no

longer return your kit.

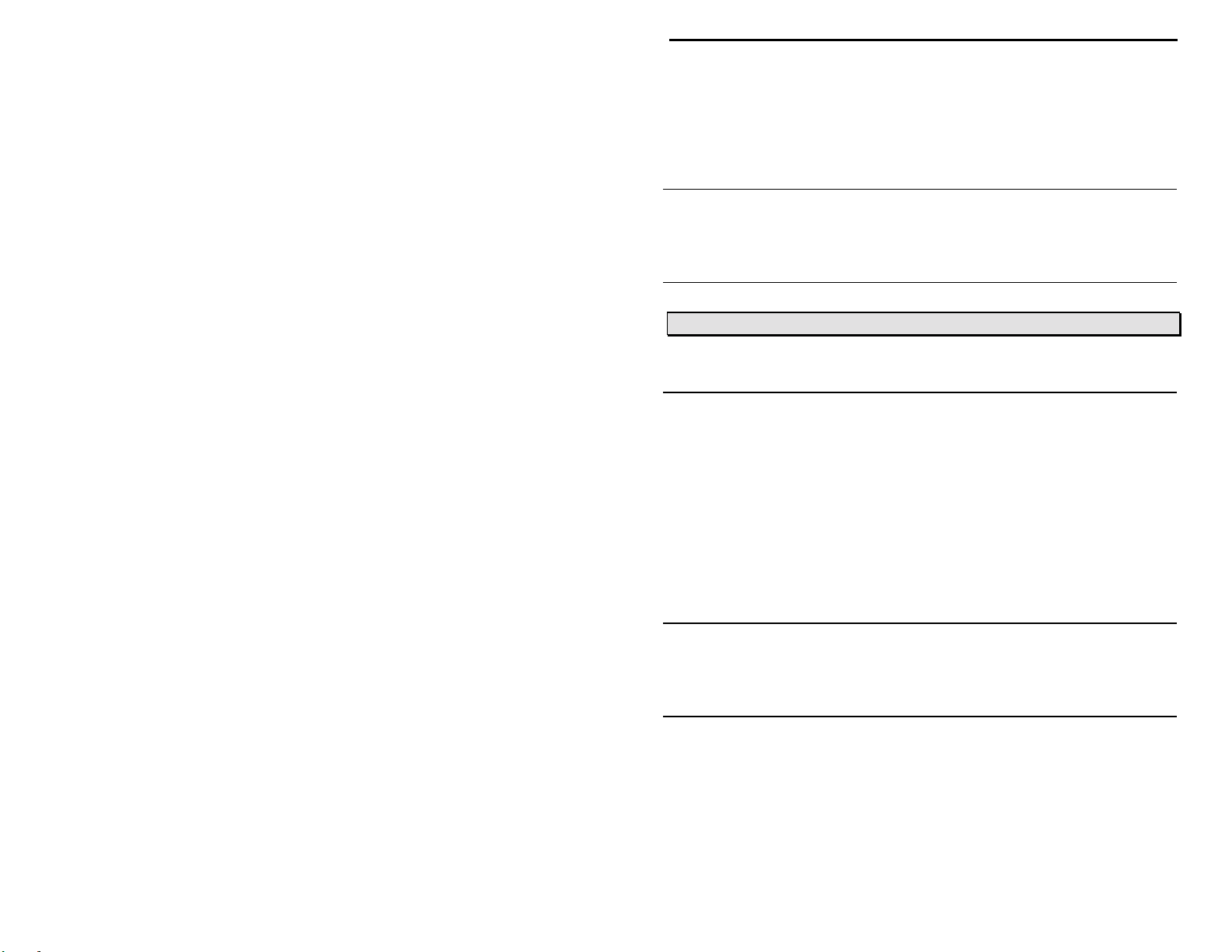

Many builders find it helpful to make a Xerox copy of the parts placement

diagram and the schematic diagram. These may then be posted in your work

Qty Part Description Designation

1 3.579 MHz crystal Y1

9

Page 12

Page 13

VEC-1220K/1230K/1240K/1280K Owner's Manual

STEP-BY-STEP ASSEMBLY

Your VEC QRP-CW Transmitter Kit will be constructed in three stages. First,

you'll install the smaller generic parts (resistors, capacitors, etc.) that are

common to all four models. Next, you'll mount frequency-determining

components--those parts that determine the specific band of operation for your

particular kit. Finally, you'll complete the project by installing larger generic

parts such as jacks and switches--things that might get in the way if installed

first.

In these instructions, when you see the term install, this means to locate, identify,

and insert the part into its mounting holes on the PC board. T his includes prebending or straightening leads as needed so force is not required to seat the part.

Once a component is mounted, bend each lead over to hold it in place. Use

sharp side-cutters to clip off excess lead length before soldering. Make sure

trimmed leads don't touch other pads and tracks, or a short circuit may result:

Good

The term solder means to solder the part's leads in place, and to inspect both (or

all) solder connections for flaws or solder bridges. Nip off excess protruding

leads with a sharp pair of side cutters.

This kit contains 11 fixed-value 1/4-watt resistors. Begin construction by

mounting these first, starting with the smallest value and moving to the largest.

Before installing each one, carefully bend both leads to form right-angles, as

shown below:

When installing resistor s, save some of the clip ped-off resistor lead ends--you'll

need these for pc-board jumpers later on.

Phase 1: Resistors

Find two (2) 100 ohm resistors (brown-black-brown).

! !

1. Install a 100 ohm resistor at R4 and solder.

! !

2. Install a 100 ohm resistor at R7 and solder.

! !

3. Find a 270 ohm resistor (red-violet-brown). Install this at R8 and

solder.

Not Good

.4"

11

Page 14

VEC-1220K/1230K/1240K/1280K Owner's Manual

Find three (3) 470 ohm resistors (yellow-violet-brown).

! !

4. Install a 470 ohm resistor at R5 and solder.

! !

5. Install a 470 ohm resistor at R9 and solder.

! !

6. Install a 470 ohm resistor at R11 and solder.

! !

7. Locate a 1K resistor (brown-black-red). Install at R10 and solder.

Find three (3) 10K resistors (brown-black-orange).

! !

8. Install a 10K resistor at R1 and solder.

! !

9. Install a 10K at R2 and solder.

! !

10. Install a 10K at R3 and solder.

! !

11. Find a 47K resistor (yellow-violet-orange). Install at R6 and solder.

This completes installation of the 11 fixed-value resistors supplied with the kit.

Take a moment to inspect your solder connections and to confirm each resistor

has been installed in the right PC board location. Next, you'll install the kit's 11

disc ceramic capacitors. Note that all but one has a value of .01 uF.

Phase 2: Ceramic and Electrolytic Capacitors

Locate ten (10) .01 uF disc ceramic capacitors (marked 103).

! !

1. Install a .01 uF disc ceramic at C1 and solder.

! !

2. Install a .01 uF disc ceramic at C3 and solder.

! !

3. Install a .01 uF disc ceramic at C9 and solder.

! !

4. Install a .01 uF disc ceramic at C10 and solder.

! !

5. Install a .01 uF disc ceramic at C11 and solder.

! !

6. Install a .01 uF disc ceramic at C12 and solder.

! !

7. Install a .01 uF disc ceramic at C15 and solder.

! !

8. Install a .01 uF disc ceramic at C17 and solder.

! !

9. Install a .01 uF disc ceramic at C18 and solder.

! !

10. Install a .01 uF disc ceramic at C21 and solder.

! !

11. Find the single .1 uF disc ceramic (104). Install this at C2 and solder.

Your kit also contains one electrolytic capacitor.

and must be installed the correct way in order to work.

mounting hole is noted on both the circuit board and parts placement diagram. If

12

Electrolytic caps are polarized

The capacitor's plus (+)

Page 15

VEC-1220K/1230K/1240K/1280K Owner's Manual

the markings on the capacitor body are unclear, the plus (+) lead is always the

longer of the two.

! !

12. Locate the 470 uF capacitor. Observing polarity, install this at C4 and

solder.

This completes capacitor installation for now. There are several multilayer

capacitors remaining, but these will be installed later as frequency-determining

components. Also, the VXO variable capacitor will be installed near the end of

construction because of its larger size. Before moving on, make a quick

inspection of your work to make sure each part is installed at the correct

location. Also, double-check the polarity of C4.

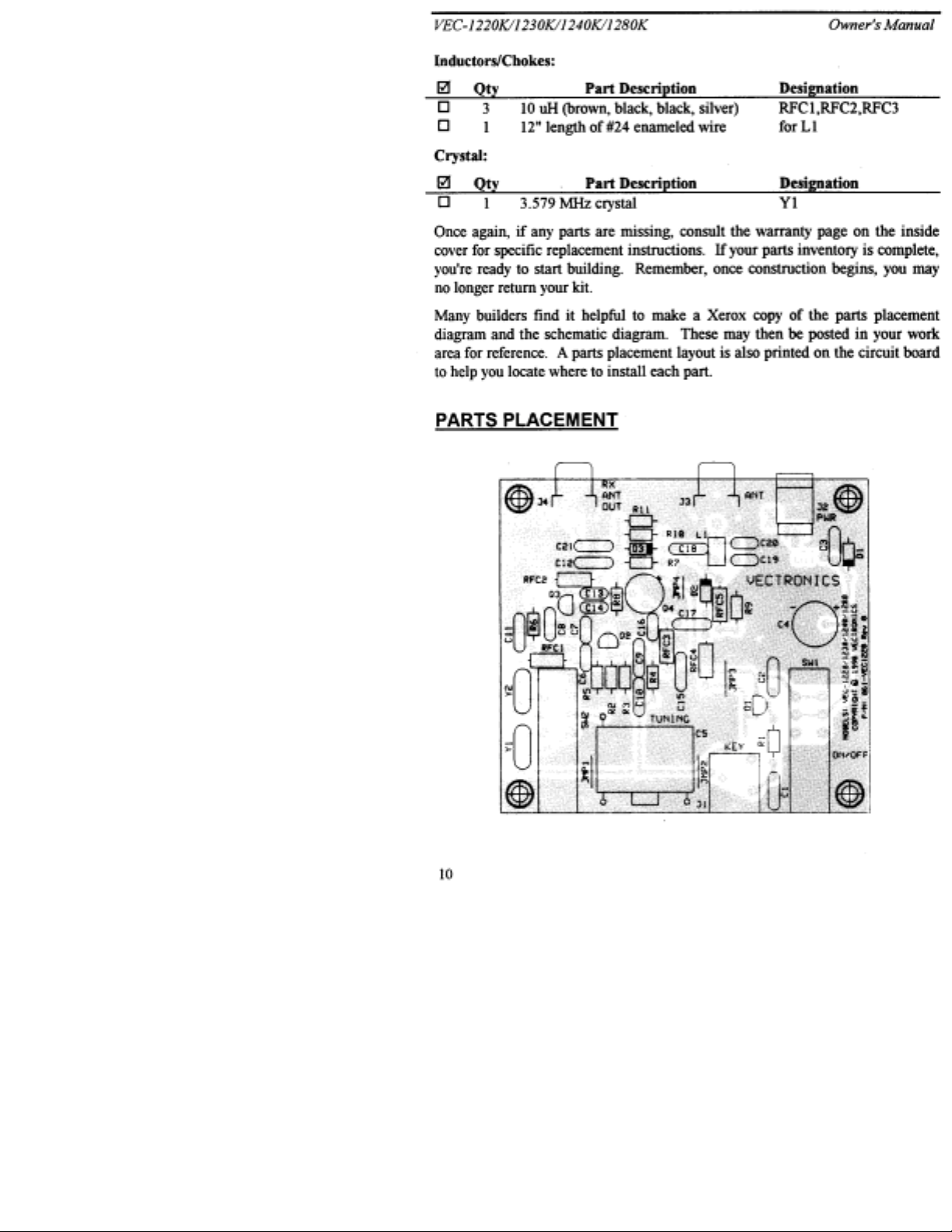

Now that you've accumulated good collection of nipped-off lead-ends, this is a

good time to install the board's four (4) jumper leads. These jumpers tie together

the ground areas surrounding the transmitter circuitry. Each should be preformed prior to installation, as shown below. An approximate distance between

mounting holes is given to help you pre-form each one. When installed, each

jumper should lay flat against the PC board.

span

Phase 3: Jumpers

! !

1. Form a 11/32" jumper and install at JMP1.

! !

2. Form a 11/32" jumper and install at JMP2.

! !

3. Form a 3/8" jumper and install at JMP3.

! !

4. Form a 1/4" jumper and install at JMP4.

Save one additional resistor lead for connecting variable capacitor C5 later on.

There are five (5) molded-epoxy radio-frequency chokes in your kit. The two

100-uH chokes are generic, and should be installed now. Note that the fourth

color-code band on a molded choke indicates tolerance. This may be either gold

(5%) or silver (10%).

Phase 4: Chokes

Find the two 100 uH molded chokes (brown-black-brown-silver or gold).

! !

1. Install 100 uH at RFC4

! !

2. Install 100 uH at RFC5

Next, you'll install the kit's transistors and diodes.

critical--they must be oriented correctly.

discarded lead end

Positioning of these parts is

13

Page 16

VEC-1220K/1230K/1240K/1280K Owner's Manual

Phase 5: Transistors and Diodes

! !

1. Locate the 2N3906 transistor (black plastic case), checking its

identification markings closely. Find its flat side, and make sure this is

aligned with the printed outline on the PC board before inserting the

leads. Install the 2N3906 at Q1 and solder.

2N3906

E B C

! !

2. Locate a 2N3904 transistor (black plastic case). Install at Q2 and

solder.

! !

3. Locate a PN2222 transistor (black plastic case). Install at Q3 and

solder.

! !

4. Find the 2N3053 transistor (metal case). Install at Q4, inserting leads

all the way so the metal case rests on the surface of the PC board. The

metal "emitter" tab should point toward R7. Solder.

Locate two (2) 1N4007 diodes. Note the white band at one end of the diode

case. When installing, position this band to correspond with the marking on the

PC board.

! !

5. Install a 1N4007 at D1, observing the position of the band. Solder.

! !

6. Install a 1N4007 at D2, observing the position of the band. Solder.

Save the clipped-off lead ends from the 1N4007s to use during installation of the

VXO tuning capacitor later on. This stiff "bus wire" will be used to support the

capacitor.

! !

7. Locate a 1N4148 diode (small glass case). Identify the banded end

and install at D3, matching the band to the PC board marking.

Solder.

14

Page 17

VEC-1220K/1230K/1240K/1280K Owner's Manual

This concludes the first phase of construction (small generic parts). Next, you'll

install frequency-determining components. However, before you start, this

might be a good time to take a well-deserved break! Be sure to check transistor

and diode positioning and polarity before moving on.

Phase 7: Frequency-Determining Parts

In this section, you'll select a specific set of instructions for your particular kit

(VEC-1220K, VEC-1230K, etc). However, before you do this, please review

these two important general construction tips that apply to all four models of the

kit.

Installing Multilayer Capacitors:

A multilayer cap is similar to a surface-mount "chip" capacitor, except that it has

a lead spot-welded onto each end of the capacitor body. Each cap is then

coated with an epoxy coating. Multilayers have superior radio-frequency

operating characteristics, but the lead welds may fail if the leads are placed

under stress while being heated during installation or removal. For this reason,

never use force to seat a multilayer cap into the PC board. If the spacing isn't

right, pre-form the leads to the correct spacing before installation!

Incorrect

There are 8 multilayer capacitors in your kit.

Ooops!

Correct

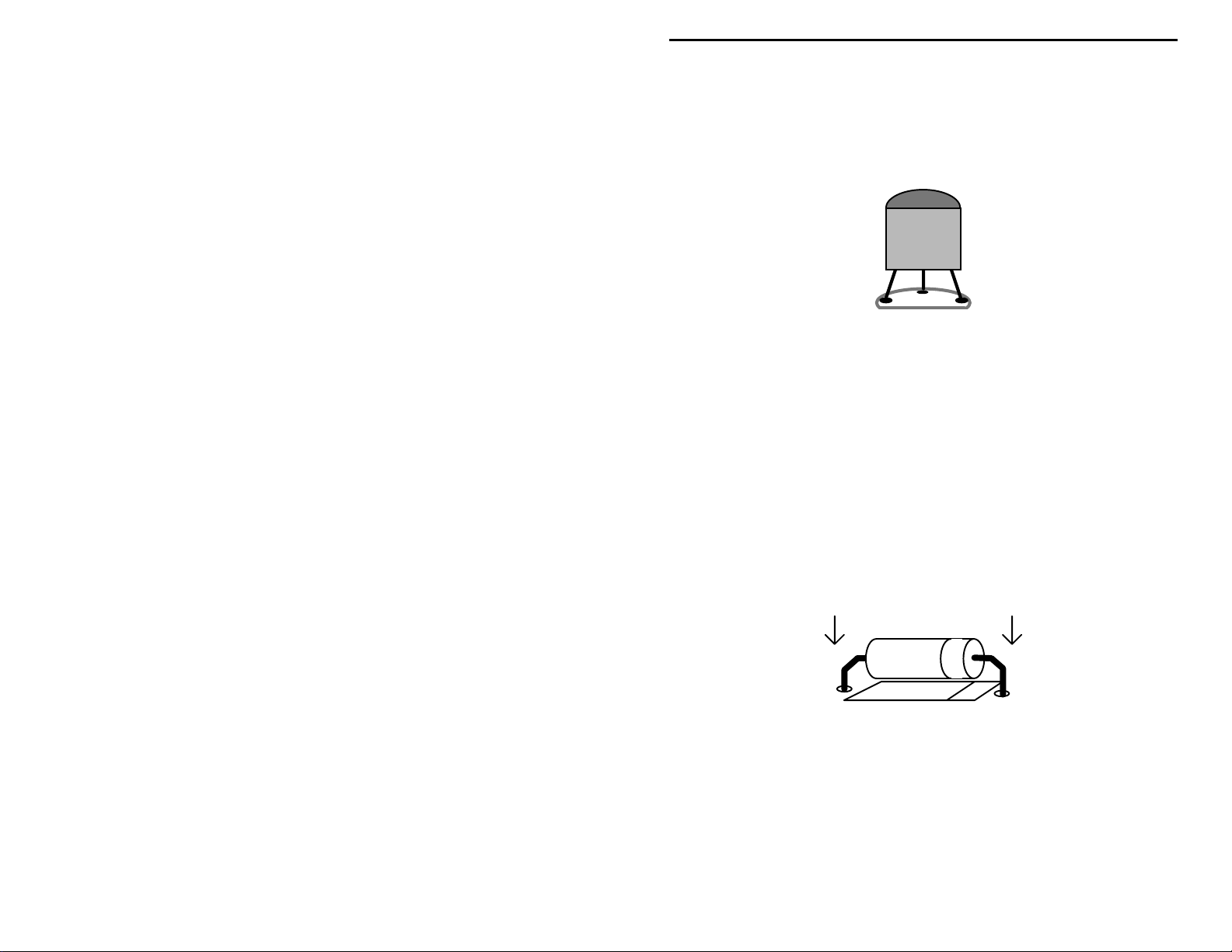

Winding and Installing Toroid Coil L1:

The transmitter's low-pass filter uses

a high-Q toroid inductor wound on a T37-2 form (T37 means the powdered-iron

form is .37-inches in diameter). When winding L1, the number of turns are

counted inside the form (not on the outside). This means, if the instructions call

for a 12-turn coil, you must pass the wire through the center of the core 12

times.

When winding this coil, be sure to pull each turn up tight before starting the

next. If the coil is wound loosely, its inductance increases--a condition that may

reduce transmitter output power.

Count turns on inside of form.

Pull each turn tight before winding the next.

Tin leads with solder before installing.

15

Page 18

VEC-1220K/1230K/1240K/1280K Owner's Manual

Finally, before installing L1 on the PC board, be sure to tin both leads with

solder. The coil wire provided with your kit is coated with heat-stripable enamel

insulation that breaks down at soldering-iron temperatures. If you touch the tip

of an iron to the end of the wire for several seconds, the insulation should start to

melt, allowing solder to adhere to the copper underneath. If your iron isn't hot

enough to start this process, carefully scrape the insulation off with a small

hobby knife and tin.

If necessary, refer back to these instructions at any time during assembly. You

may now move ahead to the section of the manual that corresponds with your

particular kit.

VEC-1220K 20-Meter QRP-CW Transmitter Kit

! !

1. Find a 22 pF multilayer cap (marked 22 or 220). Install at C6 and

solder.

! !

2. Find a 47 pF multilayer cap (47 or 470). Install at C8 and solder.

! !

3. Find a 68 pF multilayer cap (68 or 680). Install at C16 and solder.

Find three (3) 220 pF multilayer caps (marked 221).

! !

4. Install a 220 pF multilayer at C7 and solder.

! !

5. Install a 220 pF multilayer at C19 and solder.

! !

6. Install a 220 pF multilayer at C20 and solder.

! !

7. Find a 330 pF multilayer cap (marked 331). Install at C14 and solder.

! !

8. Find the remaining 470 pF multilayer cap (471). Install at C13 and

solder.

Locate three (3) 1.8 uH chokes (brown-gray-gold-silver or gold).

! !

9. Install 1.8 uH at RFC1 and solder.

! !

10. Install 1.8 uH at RFC2 and solder.

! !

11. Install 1.8 uH at RFC3 and solder.

Locate the T37-2 toroid coil form (a donut-shaped part about 3/8" in diameter

and color-coded red). Also, find the #22 enameled coil wire provided with your

kit.

! !

12. Wind twelve (12) turns of #22 wire onto the T37-2 form. Note that

turns are counted inside the form, and each turn is pulled tight before

winding the next. When do ne, spread the windings out, distrib uting

them over 80% of the form's circumference.

! !

13. Trim each coil lead to 1/2" in length and tin with solder.

16

Page 19

VEC-1220K/1230K/1240K/1280K Owner's Manual

! !

14. Install the coil at L1 and solder.

! !

15. Locate the 14.060 MHz crystal (metal can, two wire leads). Install at

Y1 and solder.

This completes stage 2 construction of the

checking for er rors, you may now move on to the fi nal stage of construction.

VEC-1230K 30-Meter QRP-CW Transmitter Kit

! !

1. Find a 33 pF multilayer capacitor (marked 33 or 330). Install at C6

and solder.

! !

2. Find a 47 pF multilayer cap (47 or 470). Install at C8 and solder.

! !

3. Find a 100 pF multilayer cap (101). Install at C16 and solder.

! !

4. Find a 220 pF multilayer cap (221). Install at C7 and solder.

Find two (2) 330 pF multilayer caps (331).

! !

5. Install 330 pF at C19 and solder.

! !

6. Install 330 pF at C20 and solder.

! !

7. Find a 470 pF multilayer cap (471). Install at C13 and solder.

! !

8. Find the remaining 680 pF multilayer cap (681). Install at C14 and

solder.

Locate three (3) 2.2 uH molded chokes (red-red-gold-silver or gold)

! !

9. Install a 2.2 uH choke at RFC1 and solder.

! !

10. Install a 2.2 uH choke at RFC2 and solder.

! !

11. Install a 2.2 uH choke at RFC3 and solder.

VEC-1220K 20-meter kit

After

.

Locate the T37-2 toroid form, a donut-shaped part about 3/8" in diameter and

color-coded red. Also, find the #22 enameled coil wire provided with your kit.

! !

12. Wind fifteen (15) turns of #22 wire onto the T37-2 form. Turns are

counted inside the form, and each one is pulled tight before winding

the next. When done, spread windings to distribute them over 80% of

the form's circumference.

! !

13. Trim coil leads to 1/2" and tin with solder.

! !

14. Install the coil at L1 and solder.

! !

15. Locate the 10.108 MHz crystal (metal can, two wire leads). Install at

Y1 and solder.

17

Page 20

VEC-1220K/1230K/1240K/1280K Owner's Manual

This completes stage 2 construction of the

checking for er rors, you may now move on to the fi nal stage of construction.

VEC-1240K 40-Meter CW Transmitter Kit

! !

1. Find a 47 pF multilayer capacitor (47 or 470). Install at C6 and

solder.

Find two (2) 100 pF multilayer caps (101).

! !

2. Install 100 pF at C8 and solder.

! !

3. Install 100 pF at C16 and solder.

! !

4. Find a 220 pF multilayer cap (221). Install at C7 and solder.

Find three (3) 470 pF multilayer caps (471).

! !

5. Install 470 pF at C13 and solder.

! !

6. Install 470 pF at C19 and solder.

! !

7. Install 470 pF at C20 and solder.

! !

8. Find a 1000 pF multilayer cap (102). Install at C14 and solder.

Find three (3) 4.7 uH molded chokes (yellow-violet-gold-gold or silver).

! !

9. Install a 4.7 uH choke at RFC1.

! !

10. Install a 4.7 uH choke at RFC2.

! !

11. Install a 4.7 uH choke at RFC3.

VEC-1230K 30-meter kit

After

.

Locate the T37-2 toroid form, a donut-shaped part about 3/8" in diameter and

color-coded red. Also, find the #24 enameled coil wire provided with your kit.

! !

12. Wind eighteen (18) turns of #24 wire onto the T37-2 form. Turns are

counted inside the form, and each one is pulled tight before winding

the next. When done, spread windings to distribute them over 80% of

the form's circumference.

! !

13. Trim each lead to 1/2" tin with solder.

! !

14. Install the coil at L1 and solder.

! !

15. Locate the 7.040 MHz crystal (metal can, two wire leads). Install at

Y1 and solder.

This completes stage 2 construction of the

checking for er rors, you may now move on to the fi nal stage of construction.

VEC-1280K 80-Meter CW Transmitter Kit

18

VEC-1240K 40-meter kit

After

.

Page 21

VEC-1220K/1230K/1240K/1280K Owner's Manual

! !

1. Find a 68 pF multilayer capacitor (marked 68 or 680). Install at C6

and solder.

! !

2. Find a 100 pF multilayer cap (101). Install at C8 and solder.

Find two (2) 470 pF multilayer caps (471).

! !

3. Install 470 pF at C13 and solder.

! !

4. Install 470 pF at C16 and solder.

Find two (2) 820 pF multilayer caps (821).

! !

5. Install 820 pF at C19 and solder.

! !

6. Install 820 pF at C20 and solder.

Find two (2) 1000 pF multilayer caps (102).

! !

7. Install 1000 pF at C7 and solder.

! !

8. Install 1000 pF at C14 and solder.

Locate three (3) 10 uH molded chokes (brown-black-black-gold or silver).

! !

9. Install a 10 uH choke at RFC1 and solder.

! !

10. Install a 10 uH choke at RFC2 and solder.

! !

11. Install a 10 uH choke at RFC3 and solder.

Locate the T37-2 toroid form, a donut-shaped part about 3/8" in diameter and

color-coded red. Also, find the #24 enameled coil wire provided with your kit.

! !

12. Wind twenty-two (22) turns of #24 wire onto the T37-2 form. Turns

are counted inside of the form, and each turn is pulled tight before

winding the next. Turns for the 80 meter coil should fill the entire

form.

! !

13. Trim coil leads to 1/2" and tin with solder.

! !

14. Install the coil at L1 and solder.

! !

15. Locate the 3.579 MHz crystal (metal can, two wire leads). Install at

Y1 and solder.

This completes stage 2 construction of the

checking for er rors, you may now move on to the fi nal stage of construction.

Phase 8: Completing your Kit

During this final stage of construction, you'll install the remaining larger

components. From now on, the finished product will take shape very quickly!

VEC-1280K 80-meter kit

. After

19

Page 22

VEC-1220K/1230K/1240K/1280K Owner's Manual

! !

1. Locate two (2) DPDT push-button switches (six pins). Install one of

these at SW1, making sure the switch pins are fully seated and the

switch body is level. Solder in place.

! !

2. Install the second DPDT push-button switch at SW2.

! !

3. Locate two (2) RCA PC mounted jacks. Install one of these at J3,

making sure the three metal tabs are seated all the way into the board.

Solder the tabs and center-pin.

! !

4. Install the second RCA jack at J4 and solder.

! !

5. Locate the 3.5 mm mini-phone jack. Install at J1, making sure the

plastic case is square to the edge of the PC board and flat against its

surface. Solder all pins.

! !

6. Locate the 2.1 mm DC power jack. Install at J2, seating the case flat

against the surface of the PC board. Twist each solder tab slightly to

secure the jack place, and solder all three.

Find the plastic-encased variable capacitor. T his is the transmitter's VXO tuning

control (C5).

Locate the small strip of double-sided tape. Also, find two of the heavy-gauge

leads removed from the 1N4007 diodes. These items will be used to secure C5

in place.

! !

7. Using scissors or a hobby knife, cut a 1/2" by 3/4" square of doublesided tape. Install this within the box printed at C5 on the PC board

(see diagram).

! !

8. To orient the variable capacitor for installation, use the following

diagram. There should be a ground tab to the left and right of the

shaft. At the rear of the cap, a solder tab will protrude from the case at

lower left. When the cap is positioned as shown, press it down onto

the tape to secure it in place.

C5 Connection

Tab

VXO

Capacitor

Ground Tab

SW2

VXO Capacitor

Heavy Leads

Shaft

Ground Tab

Double-sided Tape

SW2

20

Tape

Ground

Tabs

Page 23

VEC-1220K/1230K/1240K/1280K Owner's Manual

! !

9. Install two (2) heavy leads (from the 1N4007 diode) from the ground

tabs to the pads in front of the VXO capacitor on the PC board.

Solder each lead at both ends. The combined holding action of the

two-sided tape and the ground leads should anchor the cap firmly in

place. Rotate the cap thr ough its range--the capacitor should not shift

position.

! !

10. Find a resistor lead clip ping. Install this between the unused pad next

to SW2 and the nearest solder-tab on the rear of C5. Solder at both

ends.

! !

11. Find the TO-5-type clip-on heat sink for Q4. Slip this over the

2N3053 transistor.

! !

12. Find the 1/2" tuning shaft extension. Screw it into the main tuning

capacitor shaft. Back off about two turns to open a gap between the

two shafts. Allow a small drop of contact cement to flow into gap and

onto threads. Immediately screw shafts together until snug and allow

glue to set. (Do not over-tighten or threaded portion of the shaft

extension will break!)

Congratulations--this concludes construction your QRP transmitter, and you

deserve a well-earned break! When you come back, be prepared to give your

work a thorough "QC" quality-control check before moving on to the "T esting

and Alignment" section.

PC Board Inspection:

QC (quality control) inspection. This will help you find inadvertent assembly

errors that might prevent the radio from wo rking or cause damage to sensitive

parts. Follow this procedure:

!

Compare parts locations against the Parts Placement Diagram. Was each

part installed where it is supposed to be? Was the correct value used? Start

at one side of the board and work your way across in an organized pattern.

!

Inspect the solder side of the board for cold-solder joints and solder bridges

between tracks or pads. Use a magnifying glass to obtain a clear view of the

track area. If you suspect a solder bridge, hold the board in front of a bright

light for a better view. All joints should be smooth and shiny, indicating

good solder wetting and flow. Resolder any beaded or dull-appearing

connections.

!

Finally, check the electrolytic capacitor and diodes for correct polarity.

Does the plus (+) polarity symbol on the part agree with the pictorial and

with the pattern on the PC board? Is the banded end of each diode

positioned correctly? Were Q1-Q4 all installed correctly?

Before ap plying power to your kit, give it a thorough

21

Page 24

VEC-1220K/1230K/1240K/1280K Owner's Manual

Be sure to correct all errors before moving on. If a careful inspection revealed

that everything is A-OK, you're now ready for the moment of truth!

TESTING AND ALIGNIMENT

Tools And Materials Required For Testing:

Your VEC QRP-CW Transmitter is a "no-tune" design that has no adjustable

alignment trimmers or coils to set up prior to operatio n. If it's built correctly, it

will work. For initial testing, you'll need the following items:

1. 50-ohm dummy load:

handling up to two watts will provide a satisfactory transmitter load. If a

dummy load isn't available, you can make one using two (2) 100-ohm 1-watt

metal oxide resistors (Radio Shack 271-152). These should be connected in

parallel across a standard RF connector that will plug into your RF wattmeter

or VSWR bridge.

2. Power Meter:

power meter with a low-power range to measure the output of your

transmitter. This provides your best indication as to whether or not the

transmitter circuitry is working properly. If you don't have access to a

calibrated watt meter, an inexpensive CB-type VSWR meter will provide a

relative indication of transmitter output.

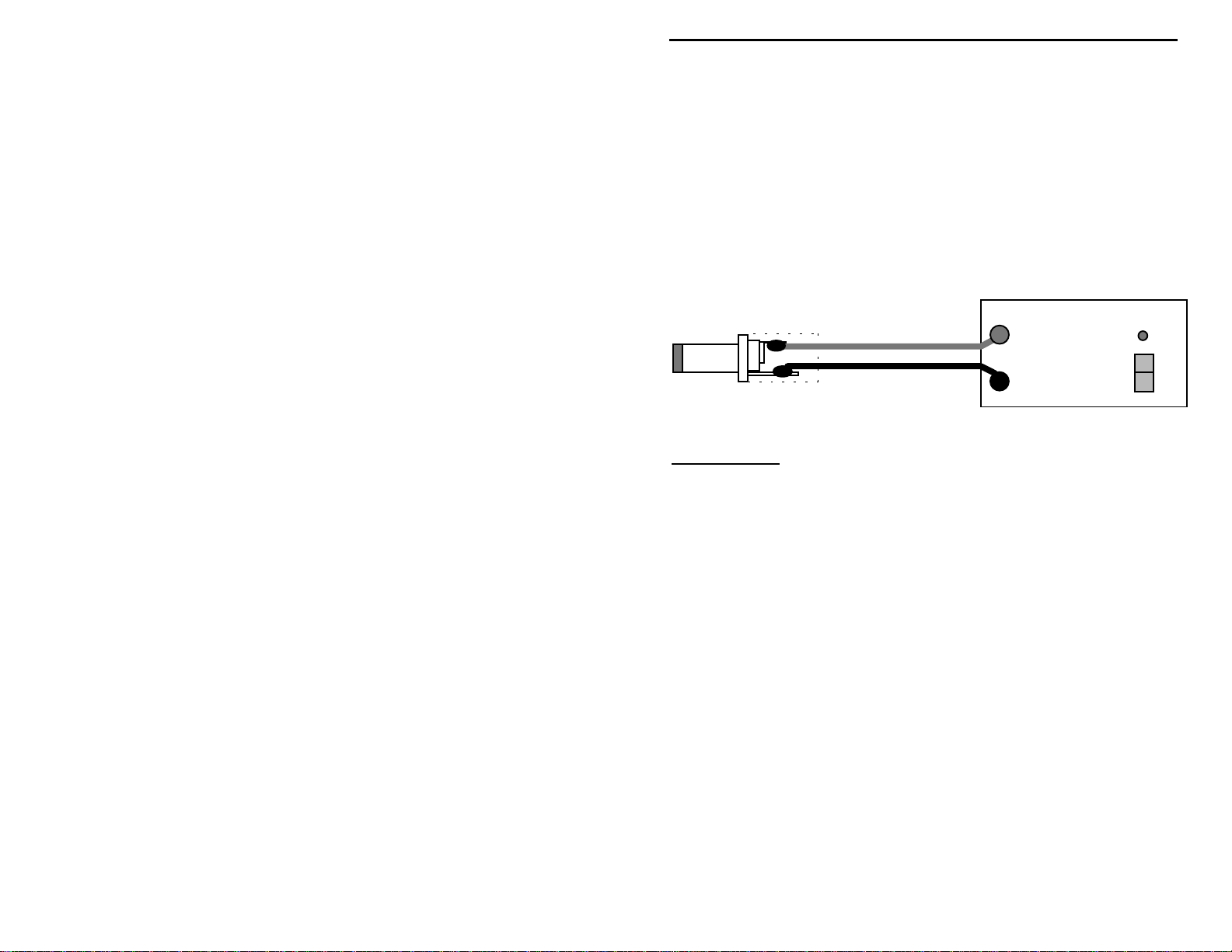

3. Telegraph Key:

or semi-automatic ke y, and with most el ec tr oni c ke yers. T o p lug i nto the ke y

jack, you'll need a standard 1/8" (3.5-mm) stereo phone plug (Radio Shack

274-284). Ground (or common) is connected to the plug's outer sleeve, and

the key line is connected to the plug's tip. A monaural type 1/8" plug will

also work.

Tip

In addition to a dummy load, you'll need a calibrated RF-

Your transmitter's keying circuit will work with any manual

3.5 mm Phone Plug

Sleeve

Any 50-ohm non-inductive resistor capable of

PL259

100 ohm

100 ohm

Key

Ring (not used)

4. Power Supply:

volt 500-mA DC (or 0.5 A) power source. Avoid using poorly-regulated or

22

Your transmitter will operate from any well-regulated 12-14

Page 25

VEC-1220K/1230K/1240K/1280K Owner's Manual

inadequately-filtered 12-volt wall-adapters. These can cause ripple on the

CW note, and may even damage your kit if the unloaded output exceeds 15

volts. A fully-charged 12-volt battery is a suitable power source, although

transmitter output may be reduced slightly (RF output is specified at 13.8

volts).

The power jack supplied with your kit is a common 2.1-mm DC connector. The

mating 5.0-mm OD x 2.1mm ID plugs are available at your local Radio Shack

store (274-1567). Take care not to reverse-connect the power leads.

(+) or red power supply lead connects to the center pin, and the minus (-) or

black lead connects to the outer sleeve.

confirm polarity with a voltmeter before installing the plug!

If your power wires aren't color-coded,

The plus

DC Power Supply

+

-

+

-

13.8V @ 0.5A

Important Note:

transmitter is protected against major damage by a "crowbar" diode (D1).

However, activation will blow a "trace fuse" etched onto the circuit board next to

the power connector. This must be replaced by a thin wire or a pig-tail type fuse

before your kit will operate again (see "In Case of Difficulty").

5. RF Cables:

wattmeter and receiver. You may make these up using RG-174 "mini-coax"

or RG-58. Install a RCA phono plug at the transmitter end, and the

appropriate connector at the opposite end.

If you already have patch cables, you may purchase 50-ohm coaxial transition

adapters that fit RCA jacks from your local Radio Shack store. For BNC patch

cables, use catalog number 278-250. For a direct PL-238 transition, use a

"scanner adapter" plug, catalog number 278-208. This is a UHF to "Motorolajack" type adapter that requires only minor modification to work with RCA

jacks. To modify, shorten the protruding center pin so that it extends about 1/8"

beyond the outer sleeve of the plug using a fine-toothed hack-saw or hobby saw.

De-burr and round off the end. The modified transition will now plug directly

into RCA jacks.

In case of accidental reverse-power connection, your

Patch cables are needed to interconnect the transmitter to your

23

Page 26

VEC-1220K/1230K/1240K/1280K Owner's Manual

Cut pin here and round off end.

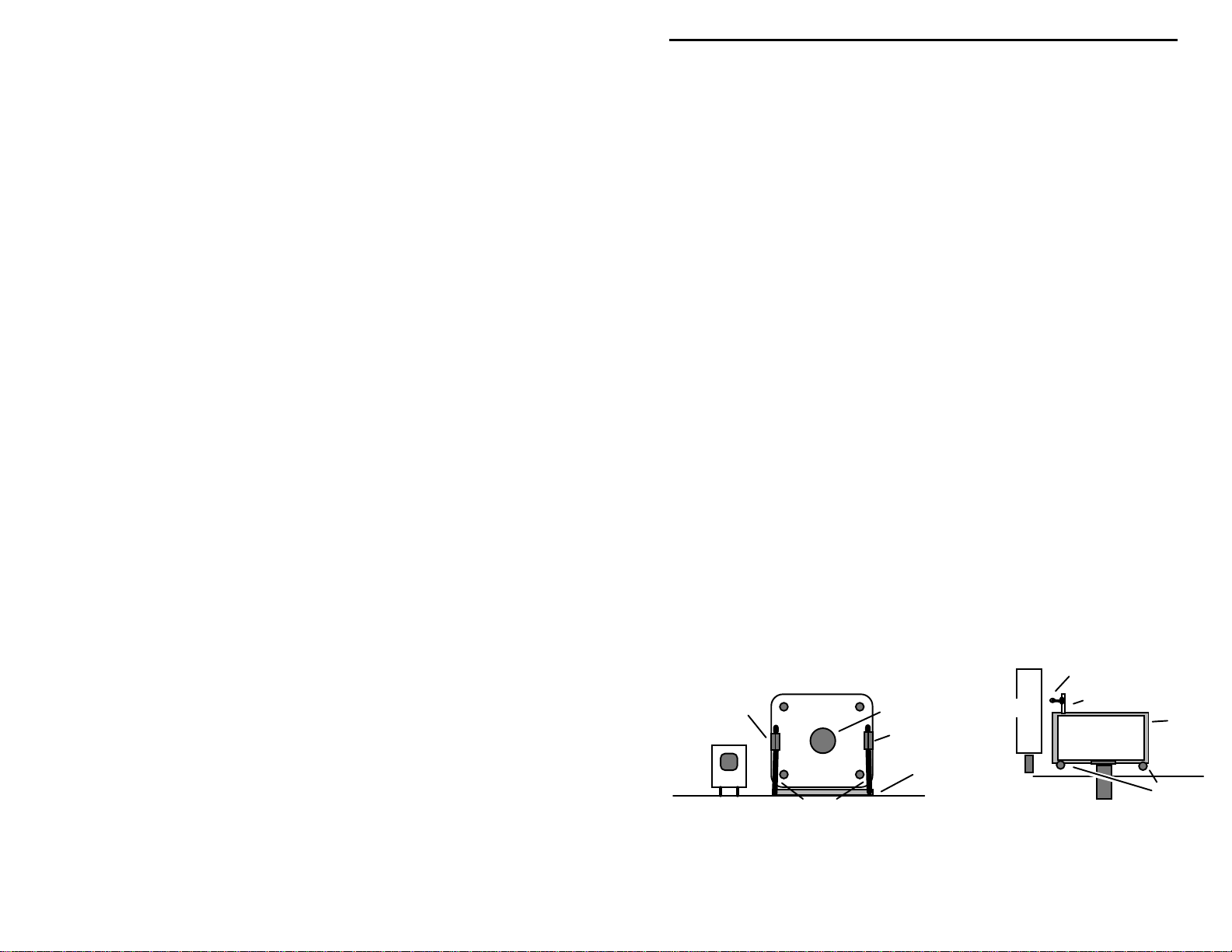

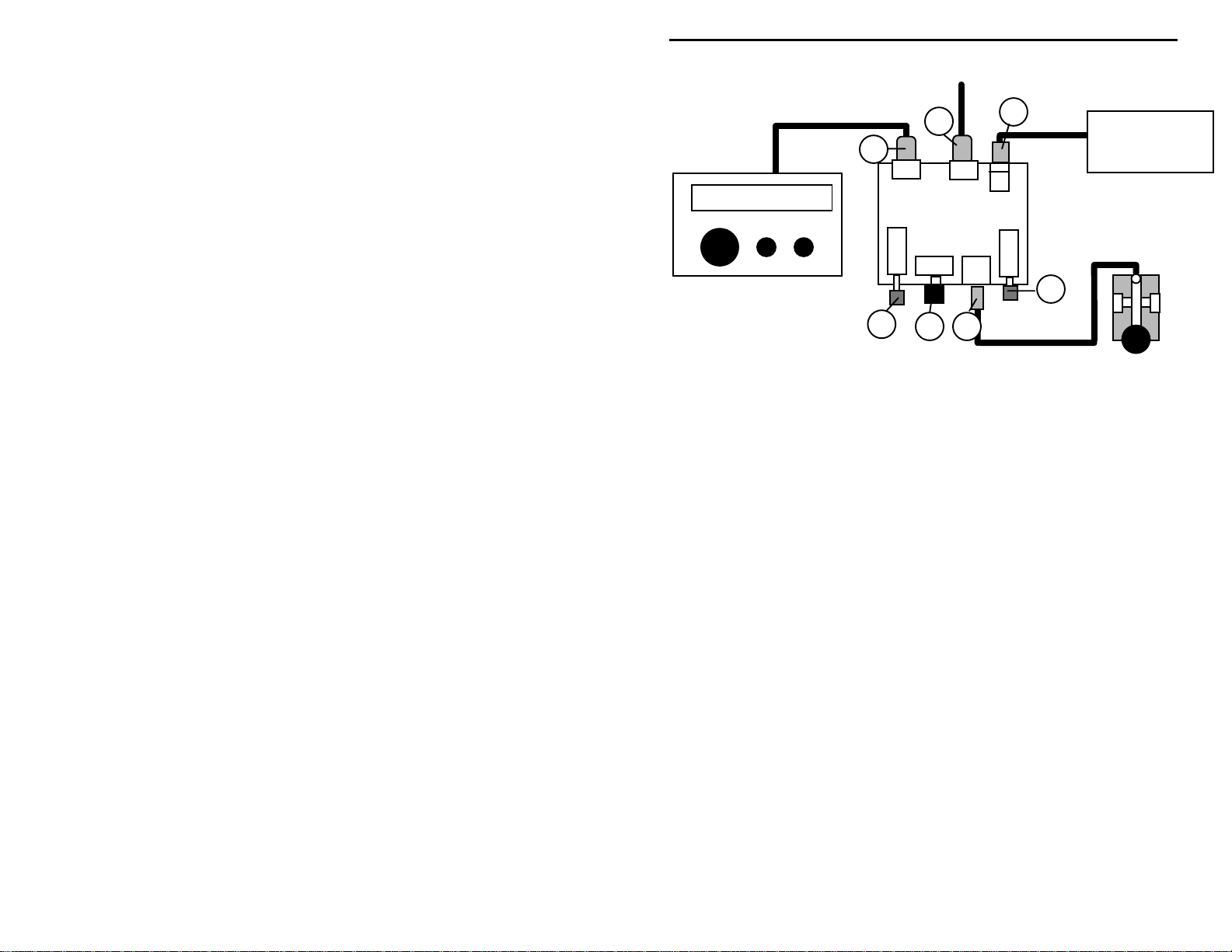

Test Set-up and Procedure:

To test your transmitter, set up as shown in the following diagram. Make sure

the PC board is on a clean non-metallic surface and that the test area is free of

lead-clipp ings, hardware, and other conductive debris that c ould get under the

board and cause a short circuit. Before connecting the power supply, make sure

the transmitter power switch (SW1) is turned OFF (out position). The crystal

selector switch (SW2) should be set for Y1 (out position). No direct connection

should be made to your receiver during the initial test. However, your statio n

receiver should be turned on, placed in the CW mode, and tuned in to the

transmitter's approximate frequency . If any of the steps outlined below fail,

refer to the "In Case of Difficulty" section of the manual.

Dummy Load

RF Wattmeter

Patch Cable

J4

REC

Crystal

Select

(out)

VXO

J3

ANT

KEY

J2

PWR

J1

Power

Switch

Power Supply

Key

Press power switch SW1 to ON. There should be no RF output indication.

1.

Confirm the crystal select switch is in the out position, selecting crystal Y1.

2.

Press the key. The power meter should indicate output of 1 watt or more.

3.

Release the key--the output power should drop to zero.

4.

Press the crystal select switch to the in position and key. There should be no

5.

output.

Return the crystal select switch to the out position.

6.

24

Page 27

VEC-1220K/1230K/1240K/1280K Owner's Manual

If you don't have access to a wattmeter, a standard 5 mm LED may be used to

give a rough indication of normal power output from the transmitter. When

using this test, however, the transmitter's antenna jack must be terminated with a

50-ohm dummy load. Connect the LED across the terminated antenna jack and

key the transmitter. The LED should illuminate brightly at normal power output

(do not attempt this test with higher power transmitters, or LED destruction may

result).

Key the transmitter and find its signal with your station receiver.

7.

Monitor the CW note for severe chirp, 60-Hz ripple, or key clicks.

8.

The presence of a "buzz" on the CW note may indicate poor power supply

filtering, or may simply mean there's a ground-loop in your test set-up that won't

affect your signal over the air. Obtain on-air reports to confirm hum or ripple

observations.

Key and tune the VXO capacitor. The transmit frequency should shift.

9.

The amount of frequency shift you obtain will depend upon the band of

operation. On 20 meters, a tuning range of 7-kHz or more is possible. On 80

meters, as little as 1.5-2 kHz shift is typical due to the lower frequency of the

transmit crystal.

T o test the receive side of the T/R switch, connect a 5-mm LED across J4

10.

and key. If the LED doesn't illuminate when the transmitter is keyed, the

T/R switch is working and it should be safe to connect receivers to the

receiver jack. The transmitted signal should appear approximately -25 dBc

at the receiver jack.

This concludes the testing phase of construction. If your VEC QRP-CW

Transmitter Kit made the grade, you're ready to connect a receiver and an

antenna for some serious QRP operating! If it didn't pass, please refer to the "In

Case of Diffic ulty" section for some suggestions that may help you isolat e and

cure the problem. If you purchased the VEC cabinet for your kit, now is a good

time to install your circuit board in it.

OPERATING INSTRUCTIONS

Connecting up the VEC QRP-CW Transmitter:

25

Page 28

VEC-1220K/1230K/1240K/1280K Owner's Manual

Antenna Lead

5

Power Supply

J2

PWR

Receiver

6

7

J4

REC

J3

ANT

KEY

VXO

Crystal

Select

1. Crystal Select:

provided).

2. VXO Tune:

3. Key Jack:

4. Power Switch:

5. Power Jack:

6. Antenna Jack:

7. Receiver Jack:

Receiver Hook-up:

QRP-CW Transmitter's receiver jack without risk of damage. Transmitter output

is typically around + 32 dBm and the energy reaching your receiver through the

T/R switch is normally 25 dB lower, or about +7 dBm. This is a very strong

signal, but a high-quality receiver with a wide AGC range can usually handle it

without blasting out the speaker! If you are able to leave the receiver on during

transmit, you'll enjoy the benefit of full QSK operation. This means you'll be

able to monitor incoming signals--and listen to your own outgoing signal-simultaneously. If your receiver has an attenuator switch, turning it on will help

reduce the effects of overload. By the same token, if your receiver has a preamplifier, you should turn it off. Receivers unable to limit speaker or headphone

volume over a wide range of signal inputs must be turned down or switched to

standby mode while you send.

Selects calling frequency (Y1) and optional crystal (not

Varies oscillator above and below crystal's "cut" frequency.

1/8" mini-jack, accepts manual keys and most electronic keyers.

Applies power to transmitter circuitry.

2.1x 5.0-mm, (+) to center (-) to sleeve, 12-14 V @ .5A

RCA, >1watt of RF into 50-ohms, 3:1 VSWR or less.

RCA, routes antenna to receiver via T/R switch.

You may patch most receivers directly into your VEC

1

J1

4

Power

3

Switch

2

Key

26

Page 29

VEC-1220K/1230K/1240K/1280K Owner's Manual

QRP Antennas:

stacked beams at 100' to get the job done! Most QRP operators use modest wire

antennas that have been carefully installed and tuned for minimum VSWR. It's

best to avoid compromised or severely shortened designs along with long lossy

feedlines and inefficient matching schemes. Like most of today's solid-state

radios, your VEC QRP-CW Transmitter uses a "no-tune" broadband output

network designed to match into 50-ohm loads. While it can tolerate a wide

range of mis-matches, you'll get more usable power and better harmonic filtering

with a low VSWR load.

Experience has shown that a full-sized 1/2-wave dipole or sloper installed as

high as possible is hard to beat. The fo llowing chart suggests dip ole wire lengths

for various CW sub-bands. These dimensions are sensitive to ground conditions

and near-by objects, so you may need to prune the length slightly to obtain

minimum VSWR at your location. Information is also provided for adding a

very low cost "choke" balun to your installation. A balun helps eliminate

unwanted feedline radiation on transmit and noise pick-up on receive. Heavyweight or premium cables are not required for QRP stations, and inexpensive

RG58 is usually sufficient to do the job. The lighter yo ur coax, the higher you

can pull the center of your antenna!

#14 stranded-copper wire

QRP operation requires a good antenna, but you don't need

Length

Balun

Band MHz. Length Per-side

80 3.6 130' 0" 65' 0"

40 7.1 66' 0" 33' 0"

30 10.1

20 14.05

Balun consists of RG58 coiled 10" in diameter and held with tape or plastic tie-wraps

For additional antenna information on a wide variety of HF antennas, consult the

ARRL Antenna Handbook, a publication of the American Radio Relay League

in Newington, Connecticut.

QRP Operating Tips:

works best. Rather than spending a lot of time calling CQ, look for other

stations calling CQ and answer them. Also, call stations that have just completed

a QSO and signed. When you do call CQ, you can usually expect more replies

around the QRP calling frequency where operators anticipate weaker signals.

Finally, never hesitate to call a weak station--he (or she) may also be operating

Most QRP DXe rs agree the "hunt-and-p ounce" method

46' 4" 23' 2"

33' 2' 16' 7"

Balun

20'

14'

10'

8'

27

Page 30

VEC-1220K/1230K/1240K/1280K Owner's Manual

QRP or may simply have a poor transmitting antenna! You'll soon discover

world-wide QRP cont acts are routi ne. A growing legion of CW operato rs have

QRP-DXCC certificates hanging on the wall to prove it!

IN CASE OF DIFFICULTY

Your VEC QRP-CW Transmitter has b een thoroughly field-tested a nd is known

to be r eliable and " forgiving" of const ruction e rrors. If you have diffi culty with

your unit, the cause may be something as simple as a broken cable or a defective

power source. In most cases, you will be able to find the problem with some

organized troubleshooting. Begin your search with this checklist of symptoms

and remedies:

Does not power up:

cable. Also, check supply polarity, direction of D1, and inspect the fuse trace

near J2.

Does not key:

Q2 for construction errors. Make sure Y1 is installed correctly and crystal-select

switch is out. Listen for the transmitter signal with a receiver to see if Q2 is

working.

Weak Signal, no measurable output:

Q3, Q4. Also, check position of diodes D2 and D3. Vcc should be present on

case of Q4.

Low Transmitter Output:

Q4, D2, RFC4, etc. (transmit side of T/R switch). Also, check values of C19,

C20, and count the number of turns on L1.

Severe chirp or key-clicks on signal:

Check values of C1, R1,C2.

Transmitter remains on when unkeyed:

or insufficient loading of Q1. Check all RFCs for correct value, location, and

continuity. Check circuitry around Q3, Q4 for errors. Also, is a load connected

to transmitter?

LED lights at J4 (receiver jack) when transmitter keyed:

for construction errors. Also, test D3 using " diode test" function on DVM.

VXO cap fails to shift frequency:

Check the condition of your power source and connecting

Check your key and plug. Also, check circuitry around Q1 and

Check for construction errors around

Check values of C13, C14. Inspect circuitry around

Check component values around Q2.

May be caused by parasitic oscillation

Check around D3

Check RFC1, connections to C5.

Blown Crowbar Fuse:

by a direct short circuit from Vcc to ground on the PC board. The etched copper

fuse may be replaced by a small 1-A pigtail fuse or by a short length of #32

enameled wire. Your kit will not power up until this is replaced.

28

This is usually caused by reverse power connection or

Page 31

VEC-1220K/1230K/1240K/1280K Owner's Manual

Voltage Analysis:

Voltage analysis is a great way to pinpoint circuit problems.

To do this, you'll need a voltmeter or DVM. Clip the black lead (-) to ground

and use the red (+) probe to check the DC voltage at each transistor lead. Before

you begin, disable oscillator Q2 by switching the crystal select switch "in". This

will remove the crystal from the oscillator circuit and prevent the transmitter

from generating RF while you're a ttempting to make DC vo ltage measurements.

Compare your readings against the chart below. They should agree to within 1015%. If you observe one or more "bad" readings, this may mean the device

you're checking is blown--or that an incorrectly-installed part is lurking near-by.

Try using the transmitter's schematic diagram to trace out the exact cause of the

problem.

2N3906-Q1

2N3904-Q2

PN2222-Q3

E B C

Front View

Important Note: Crystal Select Switch MUST be

pushed in to disable oscillator. Unit must not

generate RF during these checks!

(Emitter is grounded)

E

C

Top View

2N3053

Q4

B

(Collector is on Case)

Q1

Q2

Q3

Q4

D2

VOLTAGE CHART

Standby Key-Down

EBCEBC

13.2 0 13.8 13.0 13.6

13.8

0 0 0 5.7 6.3 12.6

0 0 13.8 0 .7 7.5

0 0 13.8 0 0 13.8

(banded end) 2.2 (banded end) 12.9

If these checks fail to uncover the problem, repeat the "QC" check one more

time. Service records show that, for most malfunctioning kits, outright

component failure is relatively rare. In most cases, the culprit is a misplaced

part, reverse-polarized capacitor or diode, improperly installed transistor, or a

faulty solder connection! If, despite your best effort, you cannot solve a problem

with your radio, kit repair services are available through Vectronics. See the

warranty on the inside front cover for complete instructions.

29

Page 32

VEC-1220K/1230K/1240K/1280K Owner's Manual

THEORY OF OPERATION AND SPECIFICATIONS

Technical Circuit Description:

The VEC QRP-CW Transmitter is a simple three-stage oscillator/amplifier with

no tune-up requirement. Q1 is keyed on by logic-low input from a mechanical

key or electronic keyer to power oscillator Q2. Q1 also supplies turn-on bias to

driver Q3 and T/R switching diode D2. Q2 is a crystal-controlled series-tuned

colpitts oscillator modified for VXO operation (RFC1, C5). SW2 selects an

optional second crystal. Q3 drives P A Q4 through cap acitive divider C13, C14 .

Q4 is a simple class-C amplifier that remains powered at all times, but only

draws current when RF excitation is present. In transmit mode, the antenna line

is routed to Q4 via diode switch D2. In receive mode, it is routed to the receiver

port via D3. A pi-section low-pass filter (which includes C16) provides

impedance matching and harmonic suppression between Q4 and the 50-ohm

antenna port. CW output averages +32 dBm with -25 dBc of antenna-port

isolation.

Specifications:

RF Power Output:............................1.25 watts at 14 MHz

Suppression:....................................35 dBc or better

Receiver Isolation:...........................-25 dBc

VXO tuning range:..........................8 kHz at 14 MHz (less at lower frequencies)

Stand-by-current:.............................10-15 mA

Transmit current:.............................250-350 mA at 13.8 Volts DC

30

Page 33

Page 34

VEC-1220K/1230K/1240K/1280K Owner's Manual

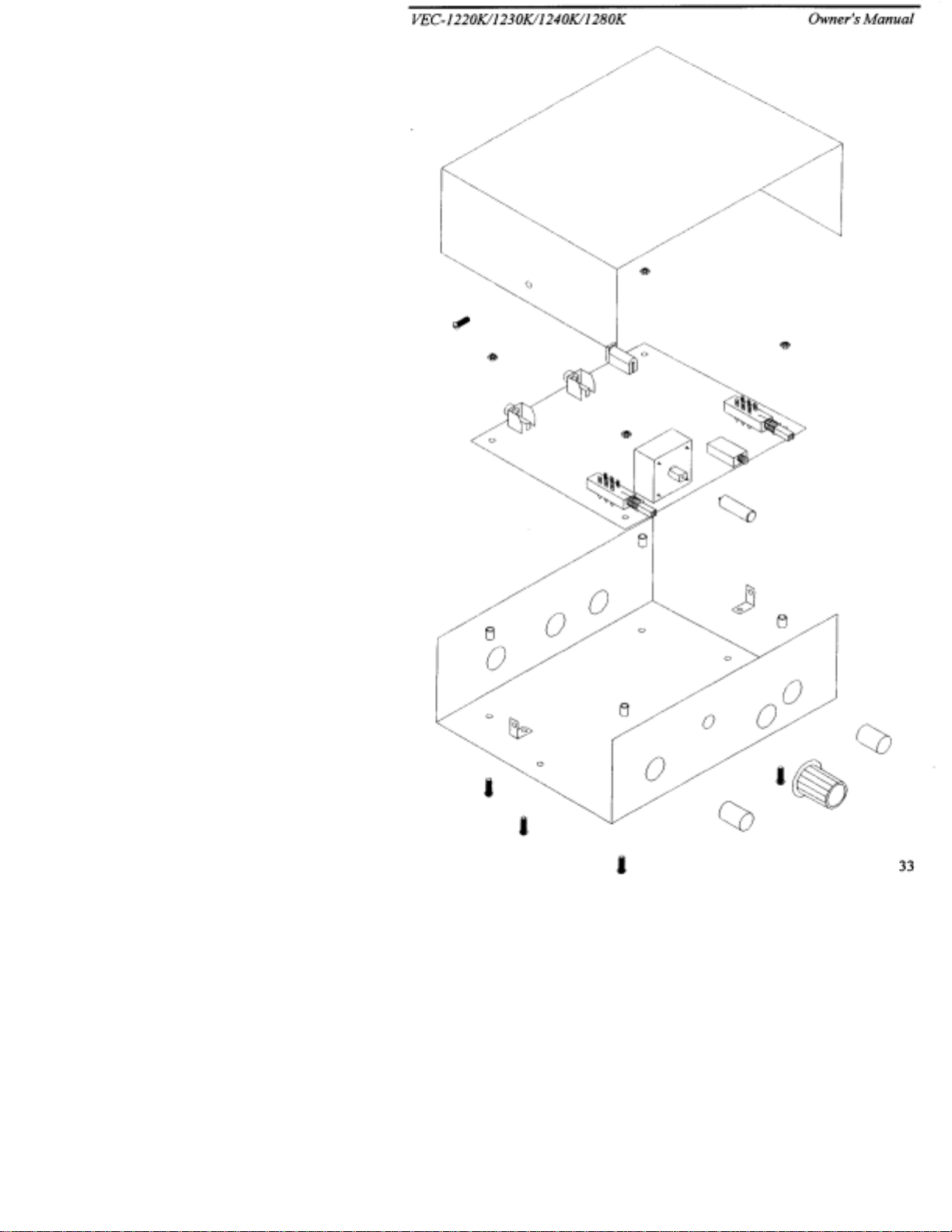

ENCLOSURE

Vectronics ha s designed a matching enclosur e just for your CW Transmitter Kit.

The matching enclosure is an all metal box which includes knobs, hardware,

decals, and rubber feet.

Enclosure model: VEC-1200KC.

To install your CW Transmitter in the VEC-1200KC matching enclosure follow

these instructions

1.

Find the front panel decal and rear panel decal; separate using scissors. Be sure to

leave excess decal material around the edges. Put the rear panel decal on first. This

is done by:

using a piece of cloth and alcohol.

adhesive.

Gently rub the alignment circles with your finger--if the circles are centered in the

enclosure holes (also check the corner alignment marks) secure the decal by rubbing

and removing all air bubbles.

decal accordingly, then secu re.

away the unused edges (cut from the adhesive side) and cut out the component holes

(cut from the description side).

2.

Next, install the two L-brackets on the chassis using two of the 3/16" screws. The

longer side of the L-bracket must be connected to the chassis using the two holes

centered on each ed ge of the enclosure. Refer to the diagram on the next page for

location and orientation.

3.

Install the four 1/2" mounting screws next. Insert the screws, from the bottom,

through the four holes at each corner of the chassis.

4.

Place the four 3/16" round spacers on the mounting screws.

5.

Now insert the PC board. This must be done by:

at an angle so the cont rols enter their resp ective holes.

the board. Make sure the mounting screws align with the mounting holes in the PC

board before pushing.

6.

Use the four hex nuts to secure the PC board. Be certain all appropriate components

are centered with the enclosure holes before tightening.

7.

Find the knob and switch caps. Align the red switch cap with SW1 and push it on. If

it is difficult to push on, then rotate it 90° and try again. Repeat procedure for SW2

using the black switch cap. Now place the knob on C5. You may need to loosen the

set screw. Align appropriately then tighten the set screw.

8.

Install the top now. Use the two remaining 3/16" screws for securing the top to the

L-brackets. Make sure the L-brackets are aligned properly.

9.

Finally, place the four rubber feet on the bottom of the enclosure at the corners.

(read all instructions before beginning ... take your time)

a.)

Remove all debris and oil from the chassis. This should be done

b.)

Remove the crack and peel to expose the

c.)

Place the decal on the rear panel without securing it completely.

e.)

If the alignment circles are not centered, adjust the

f.)

Use a penknife, or small Exacto

g.)

Repeat this procedure for the front panel.

a.)

Insert the front of the PC board

TM

knife, to cut

b.)

Push down on the rear of

:

d.)

32

Page 35

Loading...

Loading...