Page 1

IMPORTANT WARRANTY INFORMATION! PLEASE READ

Return Policy on Kits When Not Purchased Directly From Vectronics: Before continuing

any further with your VEC kit check with your Dealer about their return policy. If your Dealer

allows returns, your kit must be returned before you begin construction.

Return Policy on Kits When Purchased Directly From Vectronics: Your VEC kit may be

returned to the factory in its pre-assembled condition only. The reason for this stipulation is,

once you begin i nsta lli ng a nd sol deri ng pa rt s, you essenti al ly tak e over the rol e of the devic e's

manufacturer . From this point on, neither Vect ronics nor its dea lers can reas onably be held

accountab le for the qua lity or the outcome of your work. Because of this, Vectronics cannot

accept return of any kit-in-progress or completed work as a warranty item for any reason

whatsoever. If you are a new or inexperienced kit b uilder, we urge you to read the manual

carefully a nd determine whether or not you're r eady to tak e on the job. If you wish to c hange

your mind and return your ki t, you may--b ut you must do i t before you begin c ons tr uc ti on, a nd

within ten (10) working days of the time it arrives.

Vectronics Warrants: Your kit contains each item specified in the parts list.

Missing Parts: If you determine, during your pre-construction inventory, that any part is

missing, please contact Vectronics and we'll send the missing item to you free of charge.

However, before you contact Vect ronic s, please look carefully to c onf ir m you haven't misr ea d

the marking on one of the other items provided with the kit. Also, make certain an alternative

part hasn't been substituted for the item you're missing. If a specific part is no longer

available, or if Engineering has determined that an alternative component is more suitable,

Vectronics reserves the right to make substitutions at any time. In most cases, these changes

will be clearly noted in an addendum to the manual.

Defective Parts: Today's electronic parts are physically and electrically resilient, and

defective components a re r a re. However, if you disc over a n it em duri ng your pr e- c onst r uct i on

inventory that's obviously broken or unserviceable, we'll replace it. Just return the part to

Vectronics at the address below accompanied with an explanation. Upon receipt, we'll test it.

If it's defec tive and appear s unused, we'll ship you a new one right away at no charge.

Missing or Defective Parts After You Begin Assembly: Parts and materials lost or

damaged after construction begins are not covered under the terms of this warranty. However,

most parts supplied with VEC kits are relatively inexpensive and Vectronics can replace them

for a reasonable charge. Simply contact the factory with a complete description. We'll

process your order quickly and get you back on trac k.

Factory Repair After You Begin Assembly: Kits-in progress and completed kits are

specifically excluded from coverage by the Vectronics warranty. However, as a service to

customers, tec hnicia ns ar e availa ble t o evaluate a nd repai r malf unctioni ng kits for a minimum

service fee of $18.00 (½ hour rate) plus $7.00 shipping and handling (prices subject to

change). To qualify for repair service, your kit must be fully completed, unmodified, and the

printed circuit board assembled using rosin-core solder. In the event your repair will require

more than an hour to fi x (or $36.00, subject to change), our technicians will contact you in

advance by telephone b efore p erforming t he work. Def ective unit s should b e shipp ed prep aid

to:

Vectronics

1007 HWY 25 South

Starkville, MS 39759

Page 2

When shipping, pack your kit well and include the minimum payment plus shipping and

handling charges ($25.00 total). No work can be performed without pre-payment. Also,

provide a valid UPS return address a nd a day time phone number where you may be reac hed.

Page 3

VEC-121K Owner's Manual Crystal Radio Set Kit

INTRODUCTION

Relive those bygone days of radio--a time almost 90 years ago, when early radio

pioneers experimented with crystal radio receivers! Wind your own “inductor”

coil, wire up the earliest radio circuit; and, there’s no soldering needed!

Everything is assembled on a pine “breadboard”, just like great, great granddad

did when he was a youngster. Lear n ab o ut b a sic r a di o theo r y. Put up an antenna

(wire included), connect a ground, and experience the magic of a radio that

needs no power. A special high-sensitivity earphone allows you to hear AM

Broadcast signals from many miles away; this little baby really performs. The

VEC-121K is a fascinating project for youngsters of all ages!

The VEC-121K features a modern “fixed detector”, eliminating the need for

frequent and frustrating catwhisker adjustments. A large, Hi-Q antenna coil, and

a modern miniature Hi-Q tuning capacitor, are used for best sensitivity and

selectivity. The high-impedance parallel-resonant tuning circuit allows a short

receiving antenna to deliver maximum signal to the set.

TOOLS AND SUPPLIES

Having the right too l to do a job always makes things go be tter. There is no

soldering required, and only a few basic hand tools are needed to assemble your

VEC-121K crystal radio set.

This is a list of the tools you will need:

SAFETY EYEGLASSES or GOGGLES!

parts is a lot of fun, but please, safety first! Your local hardware store carries

inexpensive safe ty goggles. Befo re you are go ing to be cutting or wor king with

wires, hammering, handling any chemicals, or using any tools, put on your

safety eye wear first!

1.

Phillips screwdriver.

kit, and we will use this tool when it is time to mount parts on the wood

board. Try to find a screwdriver with a shaft (the distance between the tip

and start of the handle) that is at least 3” long.

2.

Long-nose pliers.

by electricians. The long slender nose makes it easy to hold or bend a wire

that is being worked on.

3.

Wire cutters.

long-nose pliers styles feature built-in wire cutters. Wire cutters are

sometimes called “nippy cutters” or “diagonal wire cutters”—depending on

how they’re made.

These special pliers have sharp cutters to cut wires. Some

There are eight Phillips head screws included in the

These pliers have a long and tapered nose and are used

Working with wires, tools and radio

1

Page 4

VEC-121K Owner's Manual Crystal Radio Set Kit

4.

Ruler or tape measure.

5.

Small penknife.

A penknife, or small E xacto

A small 12” ruler or flexible tape measure will do.

TM

knife, is needed to scrape

off wire insulati o n. If you a r en’t o l d e no ugh to use a knife , a small se ct io n o f

sandpaper will do.

6.

Small Hammer.

It will be used with a finishing nail to mark where the

screw holes are placed on the pine board.

7.

Small-Screwdriver or Hex-Tool

. Size to fit the set screw in the tuning

knob--depending on which type of knob is supplied with your kit.

Radio Shack carries many inexpensive small hand tools for electronics work.

Here are some items that will come handy:

1.

Masking tape.

2.

Cyanoacrylate adhesive.

is sold as “Super Glue

This is the fancy name for contact cement, which

TM

” or “Crazy GlueTM ”. You’ll use the contact cement

to hold the coil windings in place. These adhesives are very strong, and can

instantly glue your fingers t ogether i f you are not c areful! If you ar e not old

enough to work with co ntact cements, have someone who is o lder help you

when gluing is directed in the instructions. The glues used to assemble

plastic model airplanes are safer to work with and may also be used instead

of super glue. However, they will require a longer time to dry. Always have

an adult advise and supervise your use of any chemicals!

WOODWORKING AND FINISHING (OPTIONAL)

Perhaps this is your first kit building experience, or your first homemade

receiver project. If so, your VEC-121K crystal receiver will be a source of pride

for many years to come. Before assembling this kit, you might wish to consider

sanding and staining the pine board—this will bring out the beauty of the wood,

and make your project look as if it was done by an “old pro”. Many early radios

were built in what was called “breadboard” fashion. The radio parts were laid

out on a small section of wood board.

Early radio parts were very expensive, even a simple crystal radio set could cost

a week’s pay! Most experimenters had to improvise. Often an old breadboard

(used to roll out bread dough) was used as a base to mount radio parts. If you

were well-to-do, your “breadboard” was probably a fine piece of mahogany or

walnut board!

Sanding:

Before applying a stain finish, carefully sand the pine board using 200

grit sandpaper. When sanding the surfaces, always sand in the direction of the

grain to avoid scratching the wood. The two board edges that expose the end

2

Page 5

VEC-121K Owner's Manual Crystal Radio Set Kit

grains of the wood will be rather rough to the touch, and will require some extra

sanding to produce a smooth even surface. You may have to use a 150 grit in

the beginning on the end grains. Sanding is best done outdoors. Wear a

disposable paper dust mask while sanding.

Finishing:

Your local hardware store stocks small cans of woodworker stains.

Either a walnut or mahogany wood stain finish is a good choice. Both oil-based

and water-based stains are availab le. We suggest using a water-ba sed stain for

this project—it is easier to work with and easier to clean up afterwards. You

will need a clean cloth, or staining cloth, to apply the stain. Follow the

manufacturer’s directions very carefully, and read the safety information on the

label. Use dispo sable la tex gloves when hand ling stain. If you’re too young to

safely work with wood stains, ask an adult for assistance with this portion of the

project. Always handle any chemicals with great care!

Important Note:

begin. Before attaching the tuning capacitor with the double-sided adhesive

tape, the board should be allowed to dry for a few days. This will allow the stain

to fully cure, or dry, so it does not interfere with the tape adhesive.

Once the stain is dry to the touch, the assembly work may

BEFORE YOU START BUILDING

Your work area:

what you are doing. At times we will need to set items aside to allow glue to

dry; or you will need to stop working on your project for other activities. Your

work area should be in a place where your project does not interfere with others.

Keep your work area clean and free of clutter. Kit parts should be kept in the

box until you need to use them. When you are finished for the day, return the

tools to their proper place. Put unused kit parts back in the box so you will not

lose them. I f you are old eno ugh to use glues and wood stains, you may have

younger brothers and sisters who aren’t! Keep chemicals out of the reach of

younger children.

Use a good workbench with good lighting so you can see

Following directions:

Kits are built in “steps”. These steps follow a logical

order, that means following the instructions will make your kit building

experience easier and ensures that your project will work first time when

finished.

You will notice a check box ! as each instruction gives you a simple task, or

direction, to follow. When the task is finished, make a small check mark in the

box to show that part has been completed. This will allow you to keep track of

where you left off when returning from a break.

For example, a direction may read:

3

Page 6

VEC-121K Owner's Manual Crystal Radio Set Kit

!

Tighten the screw until snug, this will make a good electrical connection

between the Fahnstock clip and wire.

When finished following the directions, “check off” that the step has been done.

"

Tighten the screw until snug, this will make a good electrical connection

between the Fahnstock clip and wire.

Don’t rush!

Have you ever notic ed that when you try to rush do ing something, it never turns

out right? Don’t try to build the crystal set receiver in one day! The time spent

building a kit is most of the fun. We will be “breaking down” the kit assembly

into several phases. For example, the first phase is preparing the “breadboard”.

The next kit phase involves winding the c oil.

Working with wire:

Unspooling:

Your kit includes a 100-foot roll of 18 AWG enamel-coated wire.

This wire is used to wind the tuning coil, for your receiver’s antenna, and is also

to be used for making connections between the radio components. Do not

remove the wire tie from the roll of wire until you are ready to use it. There is a

right and wrong way to remove wire from the spool! Never allow the wire to

uncoil, like a Slinky

TM

toy! Doing so will cause the wire to twist and make kinks

when you try to use it. Instead, hold the spool of wire in both hands, and

carefully unroll the wire from the spool. Re-tape the unused portion when

finished.

Removing insulation:

Electrical connections are made by removing the

insulation from the enamel wire. When you need to make an electrical

connection, you will be instructed to remove the wire insulation. We will tell

you where the insulation should be removed, and how much to remove. This can

be done by using a small piece of 150 grit sandpaper. Fold the sandpaper in half

so the “sandy” sides face together. Place the wire into the sandpaper fold, and

slide the sandpaper back-and-forth over the wire while applying a gentle

pressure. Turn the sandpaper every so often to fully remove all of the insulation.

Gently scraping the insulation with a small penknife will also work. Lay the wire

on a piece of scrap board, and draw the knife blade over the insulation to scrape

it away. Always scrape in a direction away from your body!

All of the insulation must be removed to make a good electrical connection. The

bare area of the copper wire should be bright and shiny when you are finished.

Making connections:

The directions will tell you to make one of two types of connections: “End”

connections or “through” connections.

4

Page 7

VEC-121K Owner's Manual Crystal Radio Set Kit

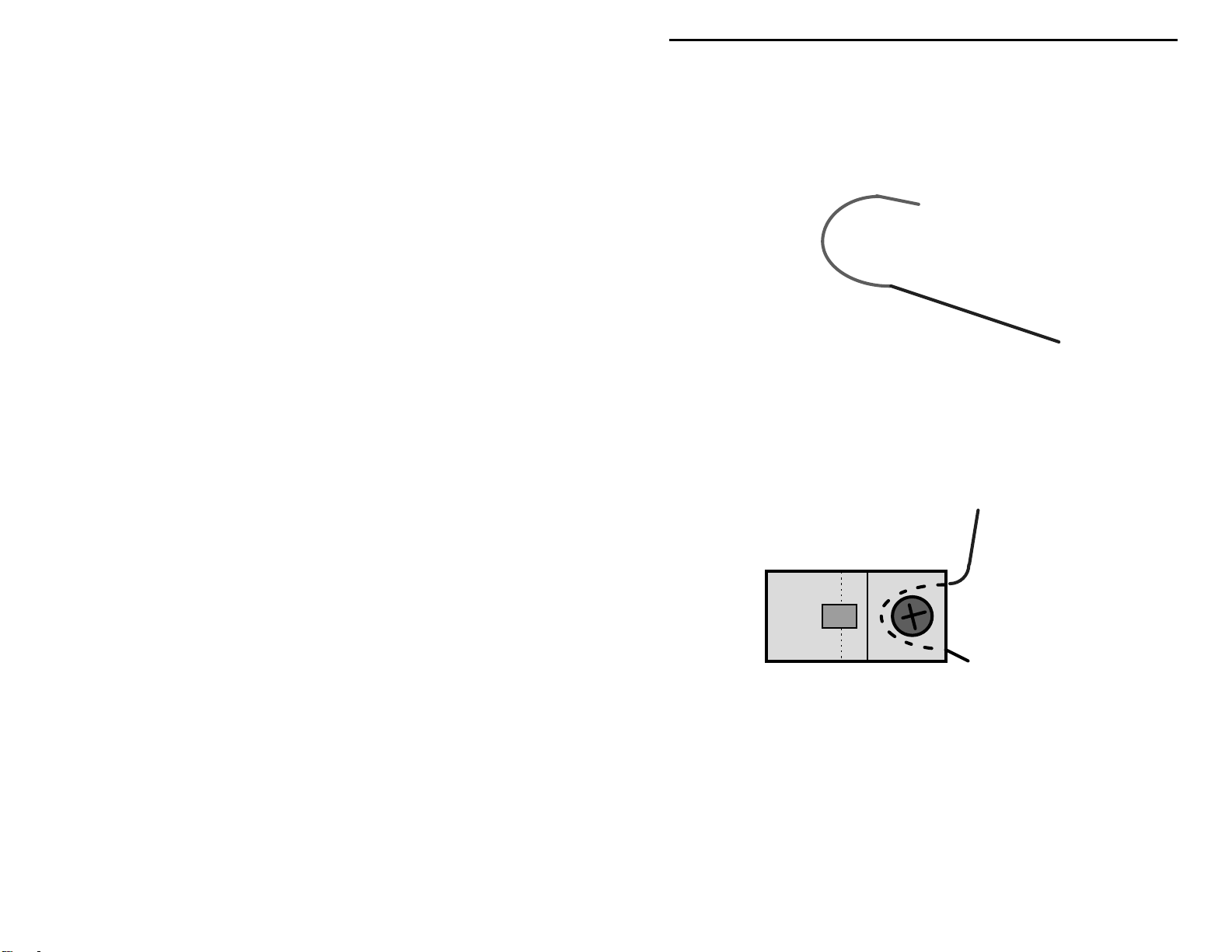

End Connections:

connected. To make an end connection, you will have to remove about 1” of

insulation from the wire and form the end into a “fishhook” shape, as shown

below.

In the following drawing, a wire end connection is used to make an electrical

connection to one of the Fahnstock clips mounted on the pine board. Note we

show the wire as a “dotted line” where it passes under the Fahnstock clip. When

the Phillips screw is tightened, a good electrical connection is made. The

drawing shows how the wire hook is placed between the Fahnstock clip and

board.

End connections are made when the end of a wire is

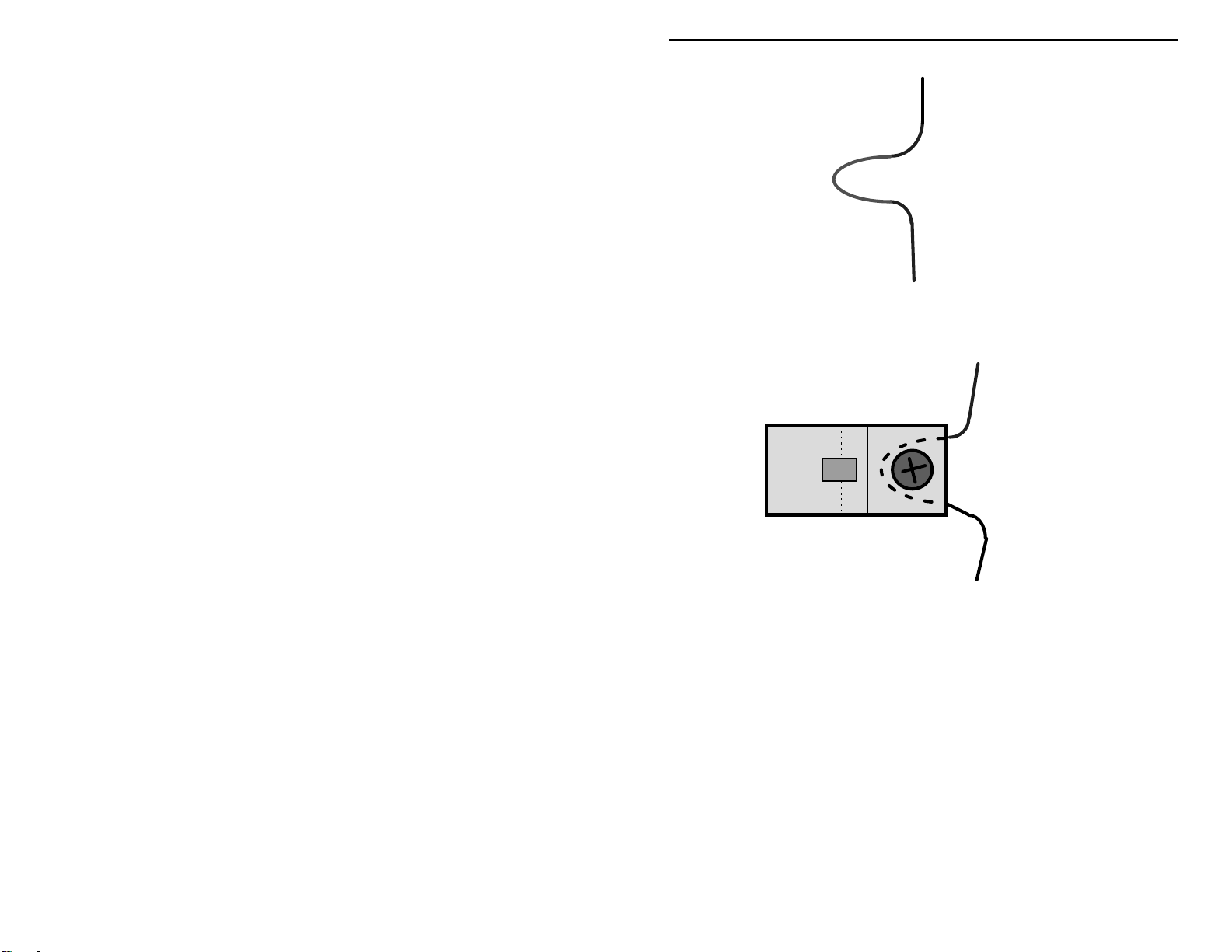

Through conne ctions are used when the wire goes to a electric al connecti on at a

Fahnstock clip, and then continues on to make one or more connections to other

points. T he directions will tell where to make a through connec tion on a wire,

and how much insulation needs to be removed.

5

Page 8

VEC-121K Owner's Manual Crystal Radio Set Kit

The wire insulation is removed where shown in the directions, and made into a

half loop as shown above.

The above d rawing shows a through c onnectio n being made to a Fahnsto ck clip.

The dotted line shows where the wire runs under the clip body.

6

Page 9

VEC-121K Owner's Manual Crystal Radio Set Kit

PARTS LIST

You are just about ready to begin your kit building adventure! But first, let’s

take a few minutes to make sure everything needed is present and accounted for.

If any parts a re missing or damaged , you’ll need to refer to the directio ns given

in the Vectronics kit warranty section of the manual.

Qty Part Description

"

!

8 Phillips head screws

!

1 5 inch length of white 2-1/2” diameter PVC plastic pipe

!

1 100 foot spool of 18 AWG enamel coated wire.

!

6 Fahnstock clips.

!

1 Tuning capacitor shaft extension

!

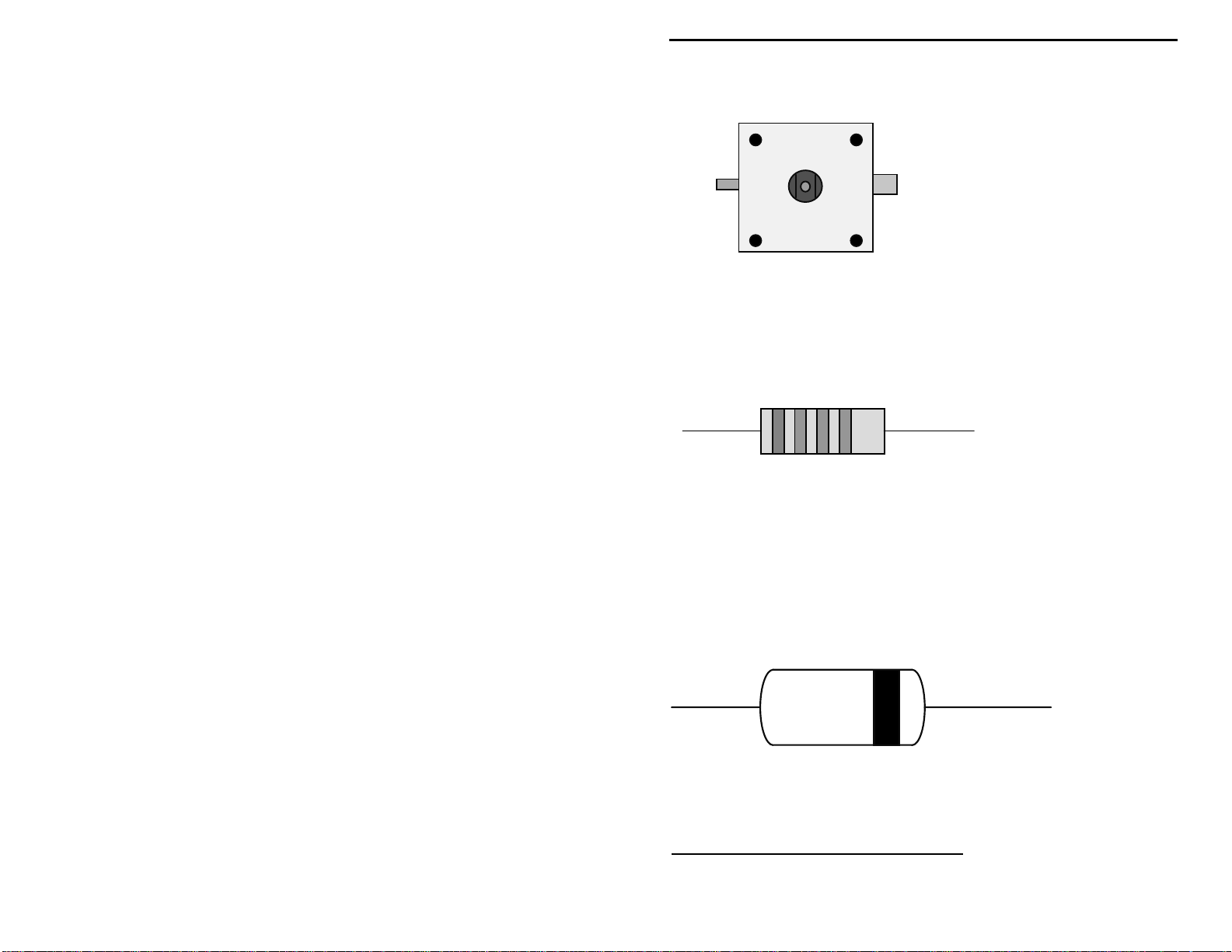

1 Tuning capacitor

!

1 Tuning knob

!

1 Double-sided foam tape

!

1 Earphone

!

1 Pine board , 3/4” high by 5-1/4” deep by 6” wide

!

1 Insulated stranded wire, 7 feet long

!

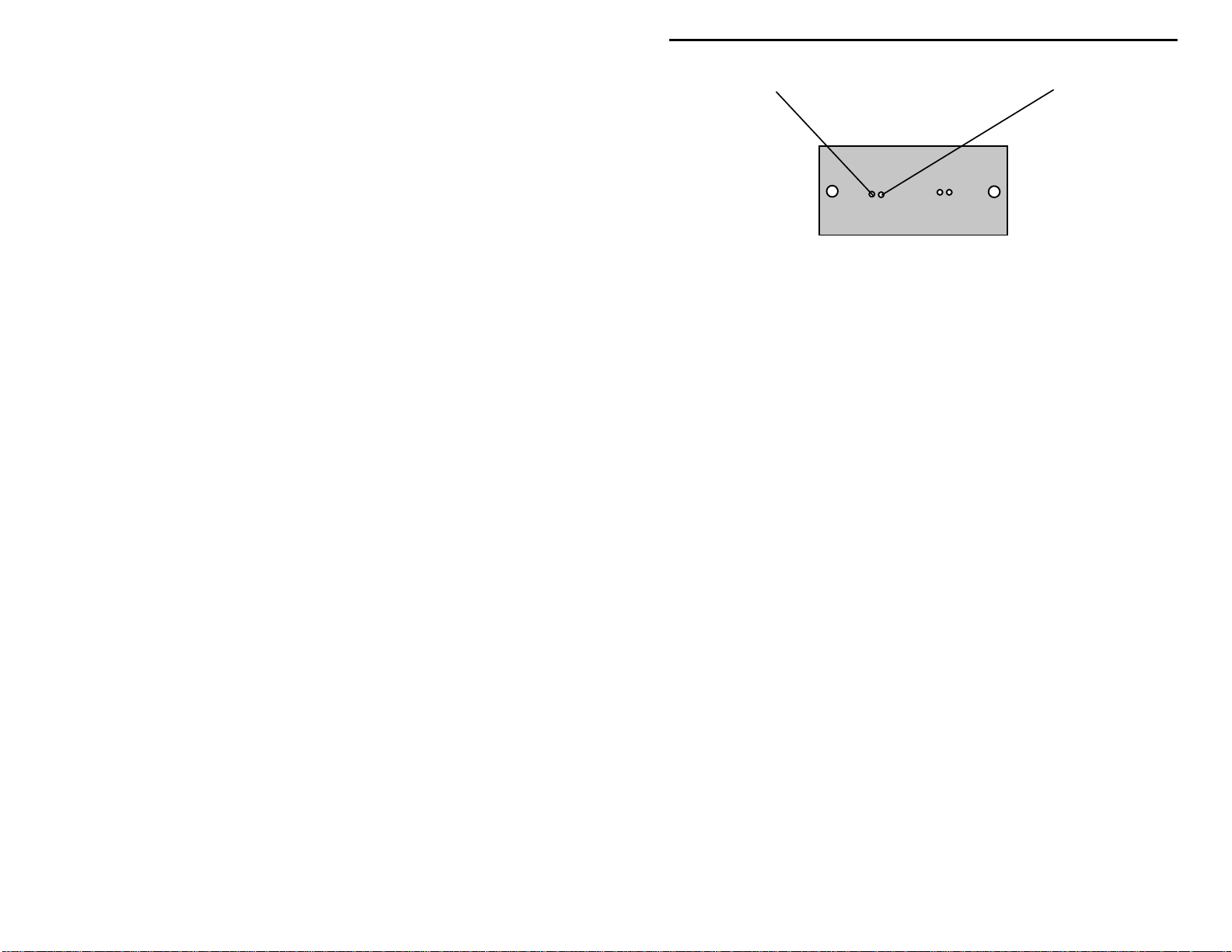

1 27K resistor (red-violet-orange-gold)

!

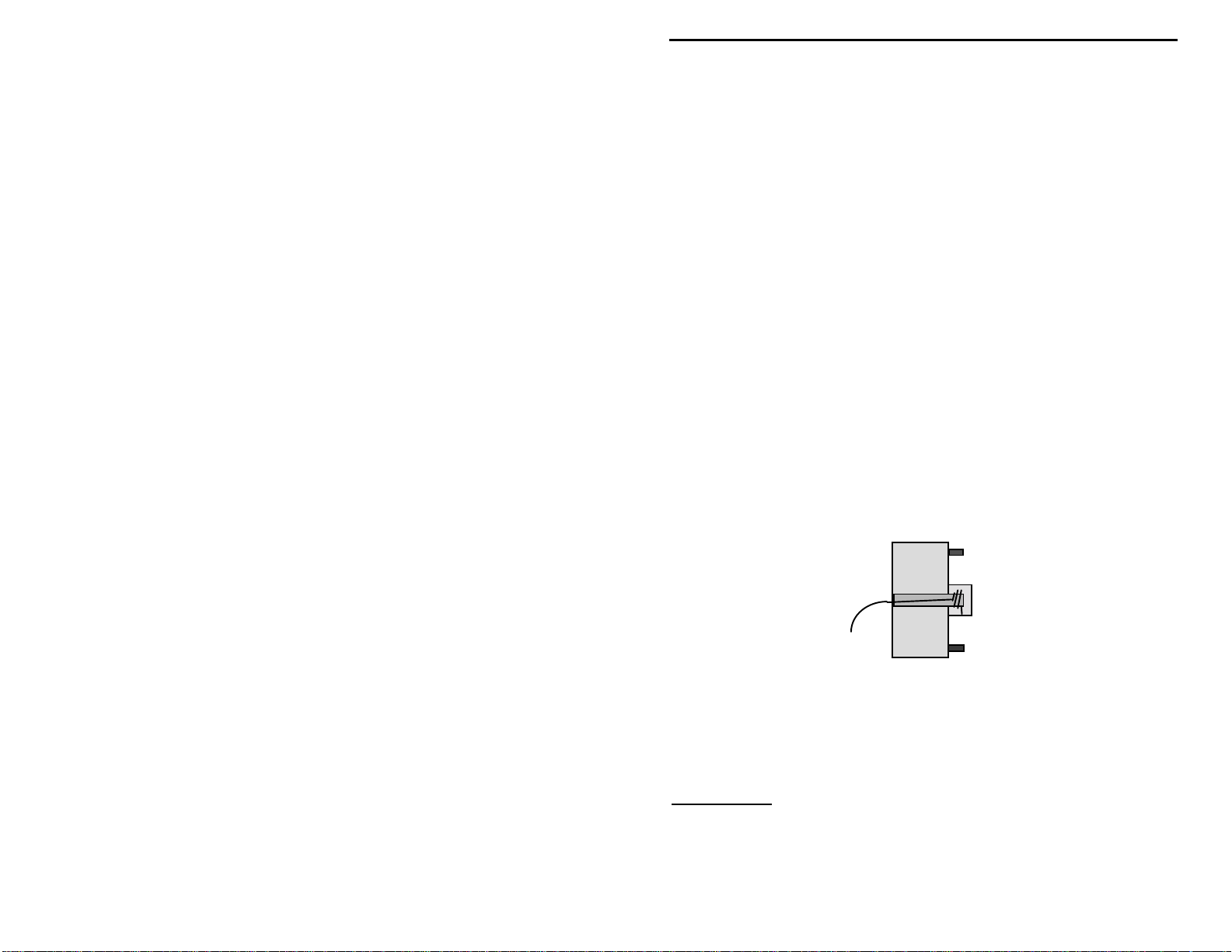

1 1N34A germanium diode

Fahnstock clips

Tuning capacitor.

7

Page 10

VEC-121K Owner's Manual Crystal Radio Set Kit

Resistor:

Germanium diode:

1N34A

STEP-BY-STEP CONSTRUCTION

8

Page 11

VEC-121K Owner's Manual Crystal Radio Set Kit

Before starting any construction, please read the Vectronics warranty. Kits that

have been started cannot be returned for credit. Make sure this kit is within your

skill level before starting assembly!

Phase 1: Breadboard preparation

!

Find the pine board. Look it over carefully, and select which side you wish

to use for mounting the parts. Chose the side that has the fewest

imperfections, and has the nicest looking grain pattern.

!

Locate the drawing that shows the screw hole pattern for the pine board.

!

Place the screw hole pattern guide over the board, be sure the board edges

line up with the outline on the drawing. Use masking tape to hold the

pattern to the board.

!

Using a finishing nail and small hammer, make a small punch mark at each

of the eight screw hole locations. These marks will show you where the

screw holes are located on the board. Don’t drive the nail into wood! We

need only make small indentations, about 1/8”, to mark the screw locations,

and to provide pilot holes for the wood screws.

!

Remove the paper pattern guide.

!

Find one of the eight Phillips head screws and a Phillips head screwdriver.

!

At each of the eight screw hole locations marked by the finishing nail, screw

the Phillips head screw fully into the board, stopping when its head reaches

the board surface. Make sure the screw remains perfectly straight, and not

tilted, when doing each of the eight holes.

!

Return the screw to the parts bag.

!

Find the 5-inch length of PVC pipe. The tuning coil will be wound on this

section of plastic pipe. It is called a coil form.

!

There are six holes drilled through the pipe, look for the two outer, and

larger sized, mounting holes.

9

Page 12

VEC-121K Owner's Manual Crystal Radio Set Kit

Mounting hole

Mounting hole

!

Now, make sure that the two screw pilot holes on the pine board for

mounting the coil form are correct. Refer to the drawings in the manual that

show the placement for the Fahnstock clips and coil form. Temporarily

mount the coil in its proper location using two Phillips head screws. You do

not need to fully tighten the screws, we are just checking to see that things

fit properly.

Important Note:

three inches) for these two screws because of the large diameter of the coil

form.

!

If the coil form mounting holes align properly with the breadboard’s

You will need to use a screwdriver with a long shaft (about

mounting holes, you may remove the coil and return the screws to the parts

bag. If things don’t match up just right, you will have to mark the correct

position for the breadboard pilot hole with a pencil, and remove the coil.

Make a new pilot ho le by using the hammer and finishing nail to make a

small indentation to start the screw. Run a screw into the pilot hole until the

head reaches the board surface. Remove the screw and return it to the parts

bag.

This completes Phase 1. There should be eight screw holes in the pine

breadboard at this point. If so, the mounting holes have been properly located,

marked, and the screw holes are ready for parts installation!

If you haven’t already done so, this is an excellent time to stain the board (if you

are planning to do so).

We are ready to begin Phase 2.

10

Page 13

VEC-121K Owner's Manual Crystal Radio Set Kit

Phase 2: Winding the tuning coil

This portion of the assembly involves winding about 66 turns of 18 AWG

enamel coated copper wire over a 2½” area of the PVC plastic coil form. This

will take time, patience, planning and prac tice! Here are a few suggestions to

help you along.

You will be directed to unwind a length of wire from the 100-foot coil of enamel

wire in several of the following steps. Always unspool the wire, never allow it to

uncoil in Slinky

TM

toy fashion. The unspooled length of wire should be laid out

in a straight line—do not allow it to simply pile onto the floor, or you will end

up with a hopeless tangl e of wire. After unwinding a length of wire, use two

strips of masking tape to secure the remaining wire on the coil.

The winding on the co il should be smoo th and even—with no gap s or kinks. If

the copper wire kinks during handling, smooth it out as best you can before

trying to wind it. We are going to wind a single-layer coil, this is called a

solenoid winding. The winding is done in several steps. You will be instructed

to stop winding a fter a certain amount of wire is wound. If you have a friend

who is willing to help, ask him to give you a hand winding the coil. Four hands

can be very helpful!

!

Remove several 5-inch lengths of masking tape from the roll of tape. Keep

them within arm’s reach while winding the coil.

!

Find the PVC coil form and the 100-foot hank of coil wire.

!

Unspool about 15’ of wire from the 100-foot coil of wire. Leave wire

attached to the spool—do not cut it! Tape the remaining wire so it will not

unwind and become tangled.

!

First, secure the wire at the starting point of the winding. Insert about 16”

of wire into the starting hole, and loop it back out of the adjacent wire hole

and pull tightly. Either end of the form may be used as the starting point.

This will secure the wire. The illustration below shows how to do this:

11

Page 14

VEC-121K Owner's Manual Crystal Radio Set Kit

16” wire tail

!

Tuck the 16” wire tail back inside of the coil form, so it will be out of the

way during winding.

!

Hold the coil form in your left hand. The wire coming from the 100-foot

coil should be between you and the form. Insert the middle and index finger

of your left hand into the coil form. Place your left thumb over the wire at

the starting hole.

!

Use your right hand to help turn the PVC coil form while winding the coil.

This takes a little practice, but you will quickly master the technique once

you st art.

!

Wind several tur ns of wire by tur ning the form. Use your left hand thumb to

guide the wire, a nd keep enough pressure o n the wire with your thumb so

that the windings are tight, even, and spaced together.

!

After several turns are completed, examine your work. (Keep your thumb in

place so the wire doesn’t loosen on the coil form!) The wire windings

should be even and spaced so the wire of each turn is firmly pressed against

the next. The windings sho uld be tight. T here should b e no gaps between

the wire turns. You can squeeze the windings together to remove small

gaps.

!

The first several turns of the winding form the foundation for the rest of the

windings. If you didn’t quite get it right the first time, unwind the coil and

try again.

!

Once you are satisfied with your work, grab a piece of masking tape with

your right hand, and tape acro ss the windings to hold them securely. Note:

Tape across and over the windings—the tape should follow the 5” width of

the coil.

!

Using its dispenser tip, put a small drop of contact adhesive on the winding

at its beginning and end point. Smear any excess back over adjacent

12

Page 15

VEC-121K Owner's Manual Crystal Radio Set Kit

windings using the di spenser ti p. Dr aw a very light b ead of adhe sive ac ross

the full width of the winding. Very little adhesive is needed for these tasks!

Let the coil sit until the contact cement has fully cured! (You may use the

glue sold for assembling plastic models for these tasks. Remember, it will

take several ho urs for the glue to harden.)

!

Now, finish winding the tuning co il. It takes ab out 3 fe et of wire to do four

full turns. It takes about 66 turns of wire to fully wind the coil over the 2.5”

coil span; so you will use about 52 feet of wire for the entire winding. Don’t

bother trying to count turns as you go. A few extra or missing turns will not

affect the performance of the crystal set. What is important is to have the

winding cover the full 2.5” inch span, without gaps.

!

Unspool another 20 feet of 18 AWG enamel coated wire. Remove the

masking tape from the coil form. Continue winding until the 20 feet of wire

is used. Tape the new windings to hold them in place.

!

Again, inspect the new windings you have just c ompleted. Are they tightly

wound, and free of gaps between adjacent windings? Squeeze the newer

windings towards the st arting windings to clo se up any gaps. W hen you’re

satisfied, use masking tape to secure the turns, and then fix the windings in

place using contact cement or model glue.

Important Note:

your left hand fingers will no longer reach inside of the PVC coil form. At this

point, you will need both hands on the form as you work, and you will be using

both thumbs to guide the wire and keep the proper tension.

!

Continue by unspooling 20 foot lengths of wire at time, winding the coil

As you continue adding windings, you will reach a point where

until you reach the "finish" point on the coil form. Securely tape the coil

windings, and glue the new windings in place.

!

At the end of the winding, mark off an additional 16” of wire, and cut the

wire at this point.

!

Insert the 16” inch wire tail into the “finish” wire hole in the PVC coil form.

Bring the wire back out through the adjacent hole and pull with enough

force so the wire i s snug. Secure the end p oint of the winding with a very

small drop of contact cement.

!

Fish the wire end for the starting point of the winding out of the form. Your

coil should now resemble the illustration below:

13

Page 16

VEC-121K Owner's Manual Crystal Radio Set Kit

16” wire tails

!

Rewind any excess wire back onto the supply spool.

Congratulations! You have just wound an inductor that has about 217-uH of

inductance! Put the coil aside for now, you’ll be mounting it on the breadboard

soon.

Phase 3: Mounting the parts

!

Locate the six Fahnstock clips, and six of the eight Phillips screws supplied

with the kit.

!

Refer to the positioning guide below for the following steps.

DET1 DET2

ANT

GND

EAR1

EAR2

In the following several steps, we will mount the six Fahnstock clips.

!

Place a Fahnstock clip at the point shown as GND in the drawing. Align the

clip so its rounded over edge faces the board edge.

!

Secure the clip to the board using one of the Phillips head screws. Tighten

the screw until snug, so it holds the clip firmly. Do not over tighten.

14

Page 17

VEC-121K Owner's Manual Crystal Radio Set Kit

For the remaining steps, align the Fashnstock clips as shown in the drawing.

!

Mount a second clip at the ANT position on the breadboard using a Phillips

screw.

!

Mount a clip using a Phillips screw at the DET1 position on the breadboard.

!

Mount a clip using a Phillips screw at the DET2 position on the breadboard.

!

Mount a clip using a Phillips screw at the EAR2 position on the breadboard.

!

Mount a clip using a Phillips screw at the EAR1 position on the breadboard.

The six Fahnstock clips should all be mounted at this point.

!

Find the coil and the remaining two Phillips head screws.

!

Mount the coil to the board using the two Phillips head mounting screws.

Before tightening the screws, make sure the two 16” coil lead wires are

oriented towards the front of the breadboard. You may now tighten the

screws so the coil is mounted snugly against the board. NOTE: Over-

tightening the screws may damage the coil form, or cause the screws to

strip the pine board.

Your crystal receiver should resemble the following drawing:

You have finished Phase 3 of your crystal set receiver project. In Phase 4, we'll

be doing the wiring between the crystal set’s components.

Phase 4: Wiring the crystal set

In phase 4, most of the wiring will involve using the two 16” coil wires. For

clarity, we are only showing the components we are going to be working with.

15

Page 18

VEC-121K Owner's Manual Crystal Radio Set Kit

You need to know where the wire leads need to be sanded to make connections.

Route the coil wire, as shown in the following diagram, by loosening the Phillips

screws mounting the two Fahnstock clips labeled ANT and DET1 (as shown):

3.5”

2.5”

!

Measure and mark the coil wire lead at the left-hand side of the crystal set at

3.5 inches. The measurement is taken from the point where the wire exits

the form.

!

Remove about 1” of insulation at the 3.5” mark.

!

Form the wire so the area stripped of insulation forms a through connection.

!

Loosen the Phillips head screw for the ANT Fahnstock clip.

!

Route the through-connection loop so it passes between the ANT Fahnstock

clip and breadboard.

!

Tighten the ANT clip mounting screw so it is snug.

!

Measure and mark the wire lead emerging from the antenna clip at 2.5”.

!

At the 2.5” point, remove 1” of wire insulation, and form a second through-

connection half loop.

!

Loosen the Phillips screw mounting the DET1 Fahnstock clip.

!

Route the second through connection so it passes under the DET1

Fahnstock, loops around the screw shank, and exits as shown in the

drawings.

!

Tighten the Phillips screw for the DET1 clip so it is snug.

!

Several inches of wire should remain from the DET1 clip connection, this

will be used later.

In the next few steps you will be working with the right-hand coil wire. Refer to

the drawing below for the following steps:

16

Do not cut the wire until told to do so!

Page 19

VEC-121K Owner's Manual Crystal Radio Set Kit

5”

5.5”

GND EAR2

Important Note:

!

Mark the left-hand coil wire at 5” from where it exits the coil.

!

At the 5” point, remove 1” of insulation from the wire.

!

Form the area stripped of insulation into a through-connection half loop.

!

Loosen the Fahnstock clip mounting screw for the EAR2 clip.

!

Pass the through-connection between the EAR2 clip and breadboard, with

The “dotted” lines show wiring done in previous steps.

loop going around the Phillips screw shank, as shown above.

!

Tight en the mounting screw for the EAR2 c lip until snug.

!

Measure the wire exiting from the EAR2 connection, and at the 5.5” point

remove 1” of insulation from the wire.

!

Form the area of wire stripped of insulation into a second through-

connection half loop.

!

Loosen the Phillips screw that mounts the Fahnstock clip used for the GND

connection.

!

Pass the through-connection between the GND clip and breadboard, with

the loop going around the Phillips screw shank, as shown above.

!

Tighten the GND P hillips mounting screw until snug.

!

Several inches of wire should remain from the GND connection.

Do not cut

this wire until instructed to do so!

This completes Phase 4. You’ve come a long way since first opening the kit.

Your little crystal receiving set is really starting to look like something.

Phase 5: Final wiring

17

Page 20

VEC-121K Owner's Manual Crystal Radio Set Kit

Only a few more steps remain, and the set will be finished.

Refer to the drawing below for the last wiring steps.

EAR1

DET2

!

Cut a 4½” length of 18 AWG enamel wire from the wire spool in the kit.

!

Remove 1” of insulation from each end.

!

Form each end of the wire into an end connection.

!

Loosen the screws mounting the Fahnstock clips DET2 and EAR1.

!

Take one of the wire end connections and place between the DET2 clip and

breadboard.

!

Tighten the mounting sc rew for the DET2 clip until snug.

!

The remaining end connection is placed between the EAR1 clip and

breadboard.

!

Tighten the mounting sc rew for clip EAR1 until snug.

18

Page 21

VEC-121K Owner's Manual Crystal Radio Set Kit

!

The wire should be routed so it crosses over the wire from the right end of

the coil without the wires touching each other.

!

Find the 27K ohm resistor (it has the Red-Violet-Orange-Gold colored

bands) and form the leads as shown below:

Important Note:

connection.

It makes no difference which lead is used for either

!

The ends of the resistor leads are formed into little half loop hooks.

!

Loosen the two Phillips screws for EAR1 and EAR2 clips.

!

Put one of the half loop connections between the top of the clip body, and

the bottom of the screw head for the EAR1 clip. Adjust the size of the loop

so it fits snugly around t he shank of the screw.

!

Tighten the mounting screw for clip EAR1 until snug. The resistor lead

should remain firmly attached.

!

Place the remaining loop between the screw head and body of the clip

EAR2. Re-form the loop so it fits snugly around the screw body.

!

Tighten the screw for clip EAR2 until snug. The resistor lead should remain

firmly attached.

!

Find the germanium detector diode. Form the leads as shown below.

19

Page 22

VEC-121K Owner's Manual Crystal Radio Set Kit

!

A 3/8” length of each of the diode’s lead ends is sharply folded back on

itself. This is done because the diode will be mounted in the DET1 and

DET2 Fahnstock clips. The diode lead wires are a very small diameter, and

may not be held tightly enough b y the clip unless the leads ar e made a bit

thicker.

!

Follow the diagram below, and clip the diode's anode lead into the DET1

Fahnstock clip, and the cathode lead (the lead with the band close to it) into

the DET2 Fahnstock clip. Gently pressing down on the clip opens the jaw,

permitting the wire lead to be inserted.

Find the tuning capacitor. Refer to the drawing below for the following steps.

20

Page 23

VEC-121K Owner's Manual Crystal Radio Set Kit

Stator

stud

Rotor lug

(narrow)

This is the correct orientation for installing the capacitor. Note that the

narrower rotor lug must be at the left hand side!

Variable capacitors have two sets of plates. One set of plates remain stationary,

and are called the “stator” plates. The tuning shaft is attached to another set of

plates that rotate as the shaft is turned. They are called the “rotor” plates. As

the shaft is turned, the plates are either meshed or unmeshed, changing the

capacitance value. This is how the tuning capacitor works.

The tuning capacitor will be mounted at the front center of the breadboard using

the double-sided foam tape. The remaining enamel wire lead coming from the

GND Fahnstock clip will be connected to the narrow rotor lug terminal on the

tuning capacitor. The remaining enamel wire lead from the DET1 Fahnstock

clip will be connected to the round stator stud on the front of the capacitor.

The above drawing shows how the wires will be routed to the tuning capacitor

connections.

Connecting the stator lead

21

Page 24

VEC-121K Owner's Manual Crystal Radio Set Kit

!

Temporarily place the tuning capacitor as shown in the drawing.

Be sure the

narrowest stator lug is at the left hand side!

!

Cut the free enamel wire lead from the GND clip to a length of five inches.

!

At the end of the wire, remove 2” of insulation.

!

Route the enamel wire from the GND clip so it reaches to the capacitor

body. At that point, the wire goes up to the middle of the capacitor, and

then makes another sharp bend towards the front of the board.

Study how the capacit or i s made. I f you loo k into the cap acito r thr ough it s clea r

plastic housing, you ca n see ho w the nar r ow ro to r l ug co nti nues t o t he r ea r o f the

capacitor. At that point, there is a tiny opening in the plastic capacitor housing.

!

Take the wire from the GND clip and insert it into this capacitor opening.

Carefully feed the wire so it passes through the ca pacitor body (it will be

between the plastic housing and narrow metal strap) and finally emerges at

the front end of the capacitor.

!

Continue feeding the wire until 1” of bare enamel wire clears the front

opening in the capacitor.

!

Using your long nose pliers, carefully wrap the enamel wire around the

narrow rotor lug until two or three full turns are made. Trim off the excess

wire.

!

Gently, but firmly, squeeze the turns wrapped around the rotor lug, using the

long nose pliers, until they are compressed tightly--making a good, tight

electrical connection.

Important Note:

to attach the lead, use the wider rotor lug as an alternate connection point.

If for some reason the narrow rotor lug is damaged while trying

Making the stator connection

22

Page 25

VEC-121K Owner's Manual Crystal Radio Set Kit

!

Temporarily place the capacitor at its mounting location.

!

Route the free enamel wire coming from the DET1 Fahnstock clip so it

follows the breadboard, and comes up and over the top of the capacitor until

it reaches the stator stud. (Refer to the drawings to identify the proper stud.)

!

Trim the wire coming from the DET1 clip to a length of 4½”.

!

Remove 1½” of insulation from the wire end.

!

Wind the wire over the stud to form three tightly wound turns. See the

following drawing. Use e nough wire so when finished you have a small ½”

pigtail remaining.

!

You need a good, tight electrical connection. Slide the turns off of the

stud—note how they make a little coil. Gently tighten the coil by twisting

the coil so it is smaller.

!

The coil should slide back on with some difficulty—otherwise the turns are

to loose.

!

To make an even tighter connection, take the pigtail, and wrap it back over

the wire in a half-loop.

23

Page 26

VEC-121K Owner's Manual Crystal Radio Set Kit

!

Using the long nose pliers, gently twist the half loop to take up wire slack

and tighten the wire wraps made over the stud.

Important Note:

directly beneath it may be used as a backup. The two right hand studs may not

be used.

!

Place the capacitor at its mounting location at the center front of the board.

If the stator stud is damaged beyond use, the stud located

The body of the capacitor should sit about 1/8” back from the board edge.

Use a ruler to center the capacitor body at 3” from either outside board

edge.

!

Mark the capacitor body outline by tracing its outline onto the breadboard

with a pencil.

!

Find the double-sided foam tape.

!

Remove one of the protective covers from one side of the tape. Place the

sticky side over the capacitor outline on the breadboard. Firmly press the

tape to set the adhesive.

!

Remove the protective cover over the top of the tape.

!

While being careful to keep the capacitor centered on the board, and parallel

to the front edge of the board, pr ess it to the foam tape. Apply gentle, but

firm, pressure to set the adhesive.

!

Find the ¼” diameter aluminum tuning shaft extension. Align the threaded

screw end with the opening in the capacitor tuning shaft. Screw the

extension into the tuning capacitor.

!

Unscrew the tuning shaft about 1 or 2 turns, to open a gap between the two

shafts.

24

Page 27

VEC-121K Owner's Manual Crystal Radio Set Kit

!

Using the dispenser, allow a small drop of contact adhesive to flow into the

gap and onto the threaded portion of the extension. Quickly screw the

extension back into the tuning capacitor to close the gap. If you are using

model airplane cement, unscrew the shaft extension, and lightly smear a

small amount of glue over the threads. Quickly screw the extension back

into the capacitor shaft.

!

Allow time for the glue to harden.

!

Using a small screwdriver or hex tool , install the tuning knob on the shaft

extension.

This completes the construction of the VEC-121K crystal set receiver.

TESTING AND ALIGNMENT

1. Turn the capacitor shaft in a counter clockwise direction until the stop is

reached.

2. Loosen the tuning knob set screw, and a lign the tuning indicato r on the knob

so it corresponds to the 9 o’clock position.

3. Tighten the set screw.

4. Verify that the knob indicator properly corresponds to the capacitor stops at

the 9 and 3 o’clock positions.

OPERATING INSTRUCTIONS

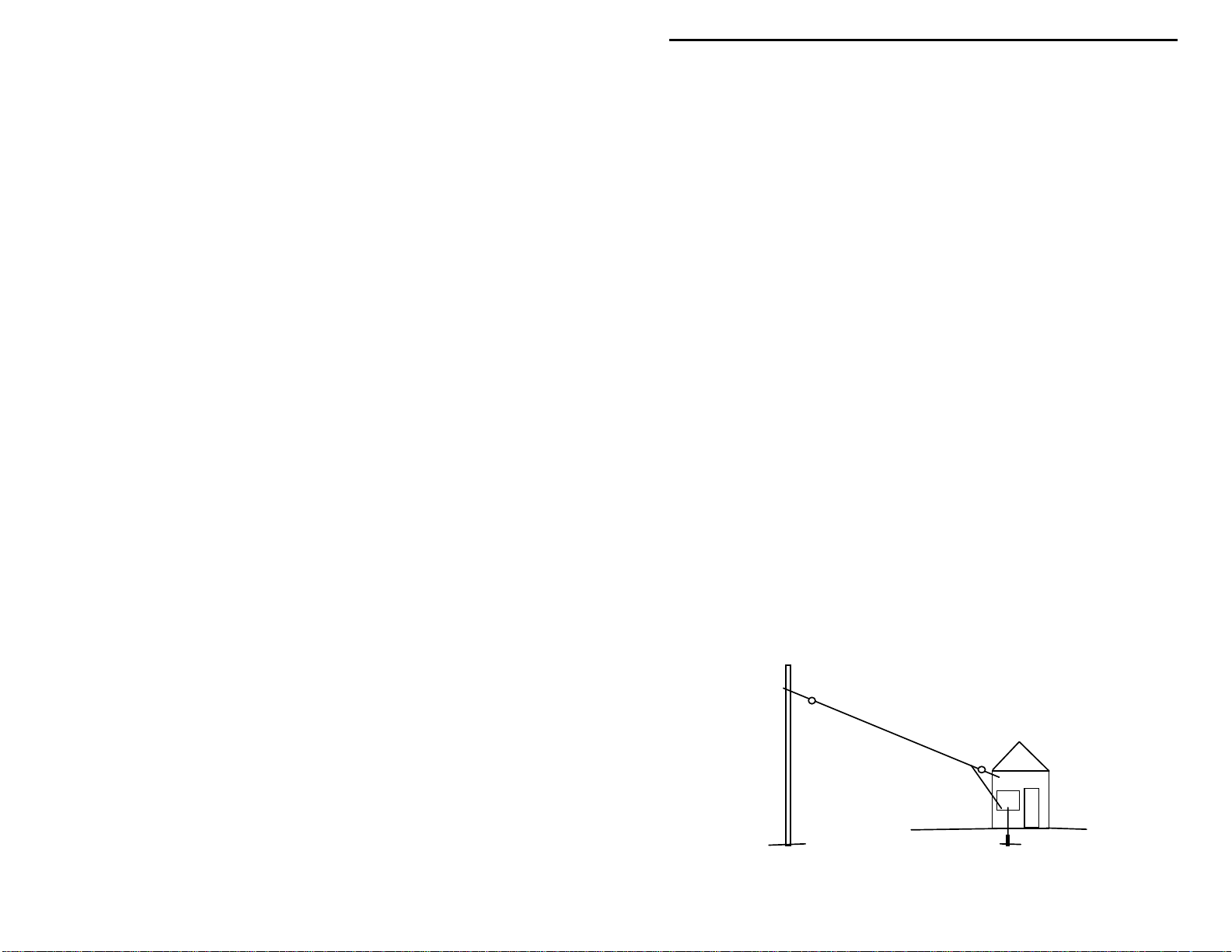

1. Use the hookup shown in the following diagram to make the antenna (aerial),

ground, and earphone connections.

aerial

earphone

Tuning k n ob

ground

2. Connect the earphone wires to the Fahnstock clips at the right hand side of

the radio.

25

Page 28

VEC-121K Owner's Manual Crystal Radio Set Kit

3. Connect a good ground connection to the crystal receiver. Use the 7 foot

length of stranded hookup wire supplied with the kit to make the ground

connection between a good earth ground and the Fahnstock clip on the

receiver.

4. Connect a long wire antenna to the Fahnstock clip on the receiver.

5. Carefully tune the tuning knob while listening for signals in the earphone.

You should be able to copy at least one, and maybe several, stations without

difficulty.

What can I hear?

difficulty. The crystal set tunes the entire broadcast band from 530 kHz to 1700

kHz. The antenna and ground system are the keys to success when using crystal

sets. Where you live affects how well you receive signals. If you live in a salt

marsh, or along the shore, you may experience exceptional reception. The

fellow living in an arid area with poor soil moisture may have much poorer

reception.

When to listen?

radio signals propagate over greater distances. Listening just before the sun goes

down may yield some pleasant surprises! Also, as the seasons change, you may

find you can hear different distant stations at sundown. Keep a simple log of

new stations when you receive them. Note the time, call letters and frequency.

It’s always fun to add a “new one” to the list.

Erecting a good antenna

Your radio will work only as good as the antenna and ground it is connected to

do. The best antenna for a crystal set is located outdoors, it is between 100 and

30 feet long, and is mounted high and in the clear. Your kit inc ludes enough

wire to make an outdoor 40 foot wire antenna and short lead-in wire to the

crystal set receiver.

You should be able to hear local stations without much

You should hear local stations at any time of the day. At dusk,

26

Page 29

VEC-121K Owner's Manual Crystal Radio Set Kit

This diagram shows an aerial going between a pole (or tall tree trunk) and

location where the receiver is located. A small length of lead-wire connects the

antenna to the crystal set inside of the house. (Make sure the lead-in wire makes

good electrical connection to the antenna wire!) Note the insulators between the

antenna wire and the supporting structures. A good earth ground is provided by

a short ground rod driven into the earth outside of the window where the crystal

set is located. You may make your own insulators from scraps of 1” plastic pipe,

or small sections of 1” by 6” Lexan

TM

or PlexiglasTM . Drill holes at the ends of

the insulators for tie-points for the antenna wire and support rope. Clothesline is

a good way to tie the insulator to the supporting structures.

The antenna wire should not be allowed to touch leaves or rub against branches.

Doing so will affect your reception. Keep your antenna wire away from power

lines.

Finding the elusive ground

Several feet of insulated stranded hookup wire is included in your kit. This is

provided to connect a ground to the crystal set. But, what is a good ground and

how can you make or find o ne?

Ground rods

. Many times a crystal set will work quite well without a ground

connection, especially if a very good antenna is being used. The most effective

ground is a 10 foot ground rod dr iven into the ea rth. If you have a TV antenna

on your home, it should be connected to a gro und rod for li ghtning protecti on. If

it is near your operating position, you may be able to tie a wire between your

crystal set a nd the TV a ntenna ground rod. Even four or five fe et length of ol d

copper pipe driven into the earth will do in a pinch! But, be sure you use some

sandpaper to remove any corrosion on the pipe that would prevent making a

good electrical connection to your ground wire lead in.

Water pipe grounds.

If you live in an older home that uses metal instead of

plastic plumbing, you have a good ground point at the nearest water pipe or

radiator. Connect a short wire between the crystal set ground and the water pipe.

Remember that the pipe must be free of corrosion or paint to make a good

electrical connection.

Counterpoise grounds.

The reason the crystal set needs a ground is because a

single wire antenna is really only one-half of a complete antenna! The ground

makes up for the missing half of the antenna, and gives the wire antenna

something to “work against”. If you have 50 or 60 feet of scrap wire laying

about, you can make what is called a “counterpoise” to serve as a ground for the

crystal set. Simply run the wire out on the ground in a straight line. The wire

needn’t be buried, it will “couple” to the earth due to “stray capacitance”.

Connect one end of the counterpoise wire to the ground Fahnstock on the crystal

set, and you’re in business!

27

Page 30

VEC-121K Owner's Manual Crystal Radio Set Kit

IN CASE OF DIFFICULTY

This crystal set almost has to work, if it was built according to the directions. If

you can not hear any stations at all, go back over the assembly instructions and

try to find any erro rs that you might have made during constructi on. Perhaps

you missed removing the insulation from the wire at a connection. Or, a wire is

in the wrong place. Have a friend check your work. It’s very easy to look over a

mistake, and a fresh pair of eyes will often quickly find mistakes that elude your

detection. Factory repair is available for assembled kits that do not work.

Consult the warranty for information regarding factory service.

Here’s a quick check list of common problems.

The set receives several signals at once.

don’t have the ability to separate signals that very are strong or close in

frequency.

The tuning control has no effect.

capacitor are tight, and that the proper connection points to the tuning capacitor

were used.

Signals are very weak, or I can only hear one station.

normal, if there are no strong signals in your area. Check your ground and

antenna connect ions. A longer antenna or better ground may improve things.

Set works intermittently

Fahnstock clips are making good connections to the antenna, ground and

earphone wires. If a clip won’t grip the wire properly, remove the wire and bend

the clip upwards slightly. This should restore the clasping action of the clip’s

jaw.

There is a local station at the high or low end of the dial that I can’t hear.

The VEC-121K is designed to tune the entire broadcast band. However, there

will be certain antenna lengths that will behave in unexpected manners at certain

frequencies. Also, because of the way the antenna and ground are coupled to the

receiver tuned circuits, they will also have some effect on the tuning range limits.

. This sounds like a poor connection. Check that the

This is normal for crystal sets. They

Check that the connections to the tuning

Again, this may be

THEORY OF OPERATION AND SPECIFICATIONS

The tuning capacitor and coil form a parallel resonant circuit that tunes from

about 530-kHz to over 1.6 MHz. The antenna and ground are directly applied

across the resonant circuit. Thus, the set is optimized for use with short, high-

28

Page 31

Loading...

Loading...