Page 1

(1 Front Cover)

(2 Warranty)

(3 Introduction)

VEC-1016K 49-MHz Wireless-Band Monitor Receiver:

The 49-MHz consumer-wireless band is teaming with signals from baby monitors,

cordless phones, walkie-talkies, remote control boxes, wireless intercoms, and much

more. If you ever wanted to explore this especially-active portion of the radio spectrum,

this kit's for you. The VEC-1016K makes a great add-on baby monitor or test receiver,

and with the addition of an outdoor antenna, it pulls in weak wireless signals for miles

around--just like the best commercial scanner and monitor receivers! Building the VEC1016K provides excellent hands-on electronics experience. Detailed step-by-step

assembly instructions guide you through each stage of construction, and clearly-presented

alignment procedures ensure top performance without need for expensive test equipment.

Convenient electronic tuning covers just the 49-MHz band, with no need to enter long

strings of microprocessor commands to get the coverage you want. Once tuned to an

active channel, your radio's "tail-free" squelch mutes background noise between

transmissions. The VEC-1016K consumes minimal energy runs for many hours from its

self-contained 9-volt flat-pack alkaline battery. Plug in a 8-ohm speaker or use

headphones for loud-and-clear reception. All circuitry is self-contained on a rugged 3" x

3.2" pc board.

(4) Tools and Supplies:

Construction Area: Kit construction requires a clean, smooth, and well-lighted area

where you can easily organize and handle small parts without losing them. An

inexpensive sheet of white poster board makes an excellent construction surface, while

providing protection for the underlying table or desk. Well-diffused overhead lighting is

a plus, and a supplemental high-intensity desk lamp will prove especially helpful for

close-up work. Safety is an important consideration. Be sure to use a suitable hightemperature stand for your soldering iron, and keep the work area free of combustible

clutter.

Universal Kit-building Tools: Although your particular kit may require additional items

to complete, virtually all construction projects require a work area outfitted with the

following tools and supplies:

Page 2

[ ] Soldering Iron (grounded-tip and temperature-controlled preferred)

[ ] High-temperature Iron Holder with Cleaning Sponge

[ ] Rosin-core Solder (thin wire-size preferred)

[ ] Needle Nose Pliers or Surgical Hemostats

[ ] Diagonal Cutters or "Nippy Cutters"

[ ] Solder Sucker, Vacuum Pump, or Desoldering Braid

[ ] Bright Desk Lamp

[ ] Magnifying Glass

Special Tools for This Kit:

[ ] Insulated hex-head tuning wand

[ ] Small flat-blade screwdriver or tuning wand

[ ] Voltmeter, digital or analog

[ ] "Low-band" VHF antenna

(5) Before You Start Building:

Experience shows there are four common mistakes builders commonly make. Avoid

these, and your kit will probably work on the first try! Here's what they are:

Installing the Wrong Part: It always pays to double-check each step. A 1K and a 10K

resistor may look almost the same, but they typically act very differently in an electronic

circuit! Same for capacitors--a device marked 102 (or .001 uF) may have very different

operating characteristics from on marked 103 (or .01uF).

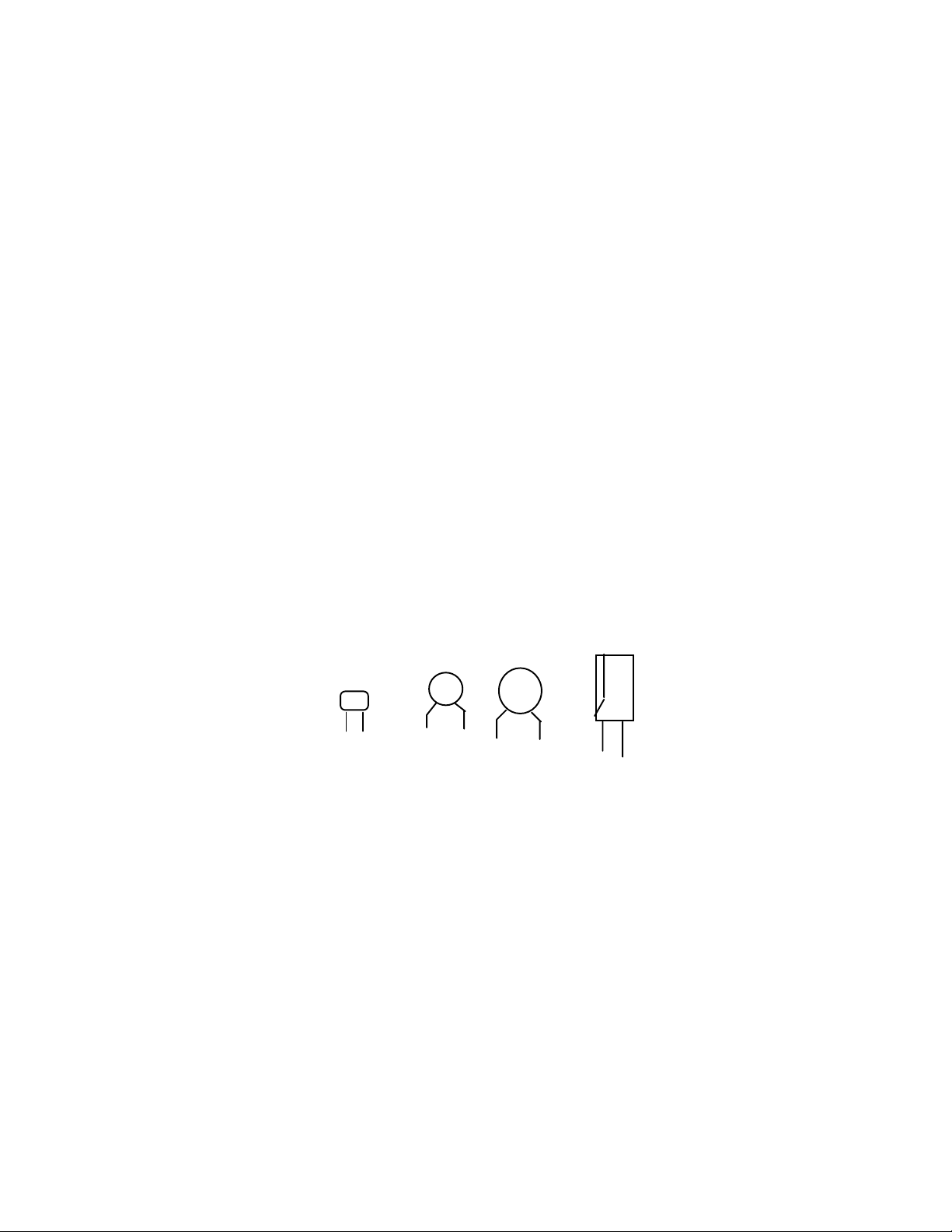

Installing Parts Backwards: Always check the polarity of electrolytic capacitors to

make sure the positive (+) lead goes in the (+) hole on the circuit board. Transistors have

a flat side or emitter tab to help you identify the correct mounting position. ICs have a

notch or dot at one end indicating the correct direction of insertion. Diodes have a

banded end indicating correct polarity. Always double-check--especially before applying

power to the circuit!

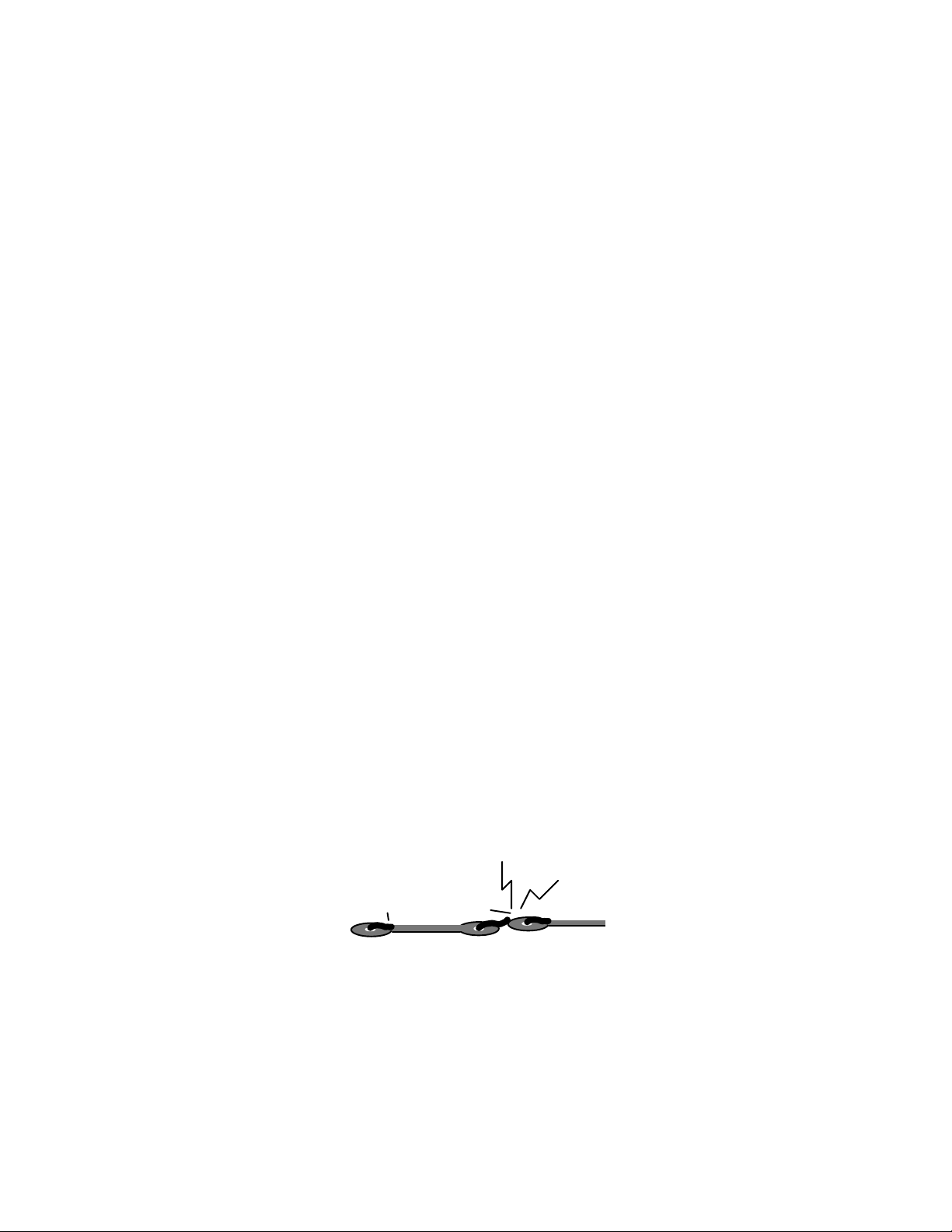

Faulty Solder Connections: Inspect for cold-solder joints and solder bridges. Cold

solder joints happen when you don't fully heat the connection--or when metallic corrosion

and oxide contaminate a component lead or pad. Solder bridges form when a trail of

excess solder shorts pads or tracks together (see solder tips below).

Page 3

Omitting or Misreading a Part: This is easier to do than you might think! Always

double-check to make sure you completed each step in an assembly sequence.

Soldering Tips: Cleanliness and good heat distribution are the two secrets of

professional soldering. Before you install and solder each part, inspect leads or pins for

oxidation. If the metal surface is dull, sand with fine emery paper until shiny. Allow the

tip of your iron to contact both the lead and pad for about one second (count "onethousand-one") before feeding solder to the connection. Surfaces must become hot

enough for solder to flow smoothly. Feed solder to the opposite side of the lead from your

iron tip--solder will wick around the lead toward the tip, wetting all exposed surfaces.

Apply solder sparingly, and do not touch solder directly to the hot iron tip to promote

rapid melting.

Desoldering Tips: If you make a mistake and need to remove a part, follow these

instructions carefully! First, grasp the component with hemostats, needle-nose pliers, or

your fingers. Heat the pad beneath the lead you intend to extract, and pull gently. The

lead should come out. Repeat for the other lead. Solder may fill in behind the lead as

you extract it--especially if you are working on a double-sided board with plate-through

holes. Should this happen, try heating the pad again and inserting a common pin into the

hole. Solder won't stick to the pin's chromium plating. When the pad cools, remove the

pin and insert the correct component. For ICs or multi-pin parts, use desoldering braid to

remove excess solder before attempting to extract the part. Alternatively, a low-cost

vacuum-bulb or spring-loaded solder sucker may be used. Parts damaged or severely

overheated during extraction should be replaced rather than re-installed.

Work Habits: Kit construction requires the ability to follow detailed instructions and, in

many cases, to perform new and unfamiliar tasks. To avoid making needless mistakes,

work for short periods when you're fresh and alert. Recreational construction project are

more informative and more fun when you take your time. Enjoy!

Sorting and Reading Resistors: The electrical value of resistors is indicated by a color

code (shown below). You don't have to memorize this code to work with resistors, but

you do need to understand how it works:

Resistor Color Code

1st Digit

2nd Digit

Multiplier

Tolerence

(gold or silver)

Black = 0 (tens)

Brown = 1 (hundreds)

Red = 2 (K)

Orange = 3 (10K)

Yellow = 4 (100K)

Green = 5 (1Meg)

Blue = 6

Violet = 7

Gray = 8

White = 9

Silver = 10%

Gold = 5%

Page 4

When you look at a resistor, check its multiplier code first. Any resistor with a black

multiplier band falls between 10 and 99 ohms in value. Brown designates a value

between 100 and 999 ohms. Red indicates a value from 1000 to 9999 ohms, which is

also expressed as 1.0K to 9.9K. An orange multiplier band designates 10K to 99K, etc.

To inventory resistors, first separate them into groups by multiplier band (make a pile of

10s, 100s, Ks, 10Ks, etc). Next, sort each group by specific value (1K, 2.2K, 4.7K, etc.).

This procedure makes the inventory easier, and also makes locating specific parts more

convenient later on during construction. Some builders find it especially helpful to

arrange resistors in ascending order of value along a strip of double-sided tape.

Some VEC kits may contain molded chokes which appear, at first glance, similar to

resistors in both shape and band marking. However, a closer look will enable you to

differentiate between the two. Chokes are generally larger in diameter and fatter at the

ends than resistors. When doing your inventory, separate out any chokes and consult the

parts list for specific color-code information.

Reading Capacitors: Unlike resistors, capacitors no longer use a color code for value

identification. Instead, the value, or a 3-number code, is printed on the body.

Value Code

10 pF = 100

100 pF = 101

1000 pF = 102

.001 uF = 102*

.01 uF = 103

.1 uF = 104

Multilayer

(270 pF)

271

Ceramic Discs

(.001 uF) (.1 uF)

102

104

Electrolytic

1uF

|

|

+

-

As with resistors, it's helpful to sort capacitors by type, and then to arrange them in

ascending order of value. Small-value capacitors are characterized in pF (or pico-Farads),

while larger values are labeled in uF (or micro-Farads). The transition from pF to uF

occurs at 1000 pF (or .001 uF)*. Today, most monolithic and disc-ceramic capacitors are

marked with a three-number code. The first two digits indicate a numerical value, while

the last digit indicates a multiplier (same as resistors).

Electrolytic capacitors are always marked in uF. Electrolytics are polarized devices and

must be oriented correctly during installation. If you become confused by markings on

the case, remember the uncut negative lead is slightly shorter than the positive lead.

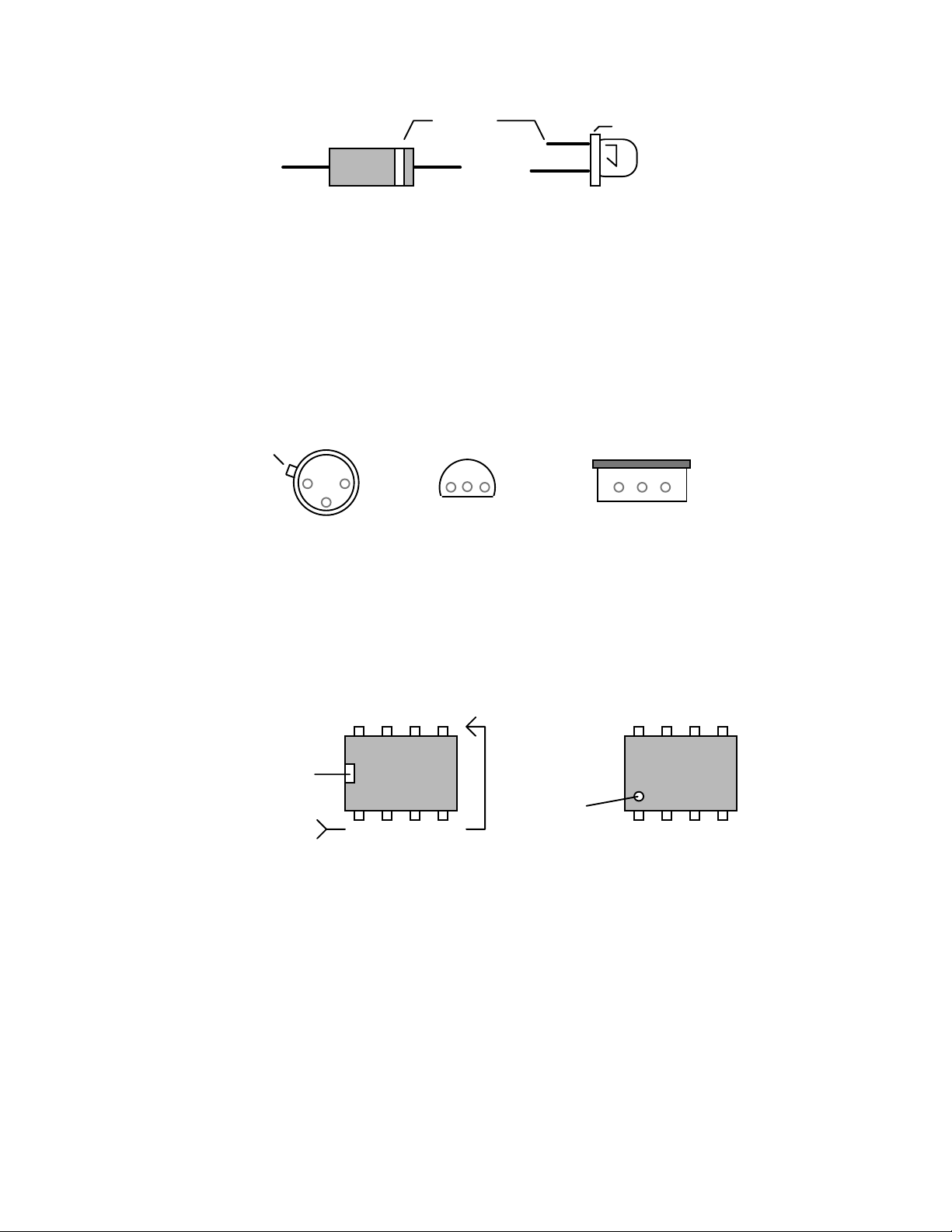

Diodes: Diodes are also polarized devices that must be installed correctly. Always look

for the banded--or cathode--end when installing, and follow instructions carefully.

Page 5

Cathode

Flat Side

(shorter Lead)

Diode

LED

Transistors: If transistors are installed incorrectly, damage may result when power is

applied. Transistors in metal cases have a small tab near the emitter lead to identify

correct positioning. Semiconductors housed in small plastic cases (TO-92) have an

easily-identified flat side to identify mounting orientation. Many specialized diodes and

low-current voltage regulators also use this type packaging. Larger plastic transistors and

voltage regulators use a case backed with a prominent metal tab to dissipate heat (T-220).

Here, orientation is indicated by the positioning of the cooling tab.

Metal Can Device Plastic Device Tab-cooled Device

Emitter

Flat Side

Metal Tab

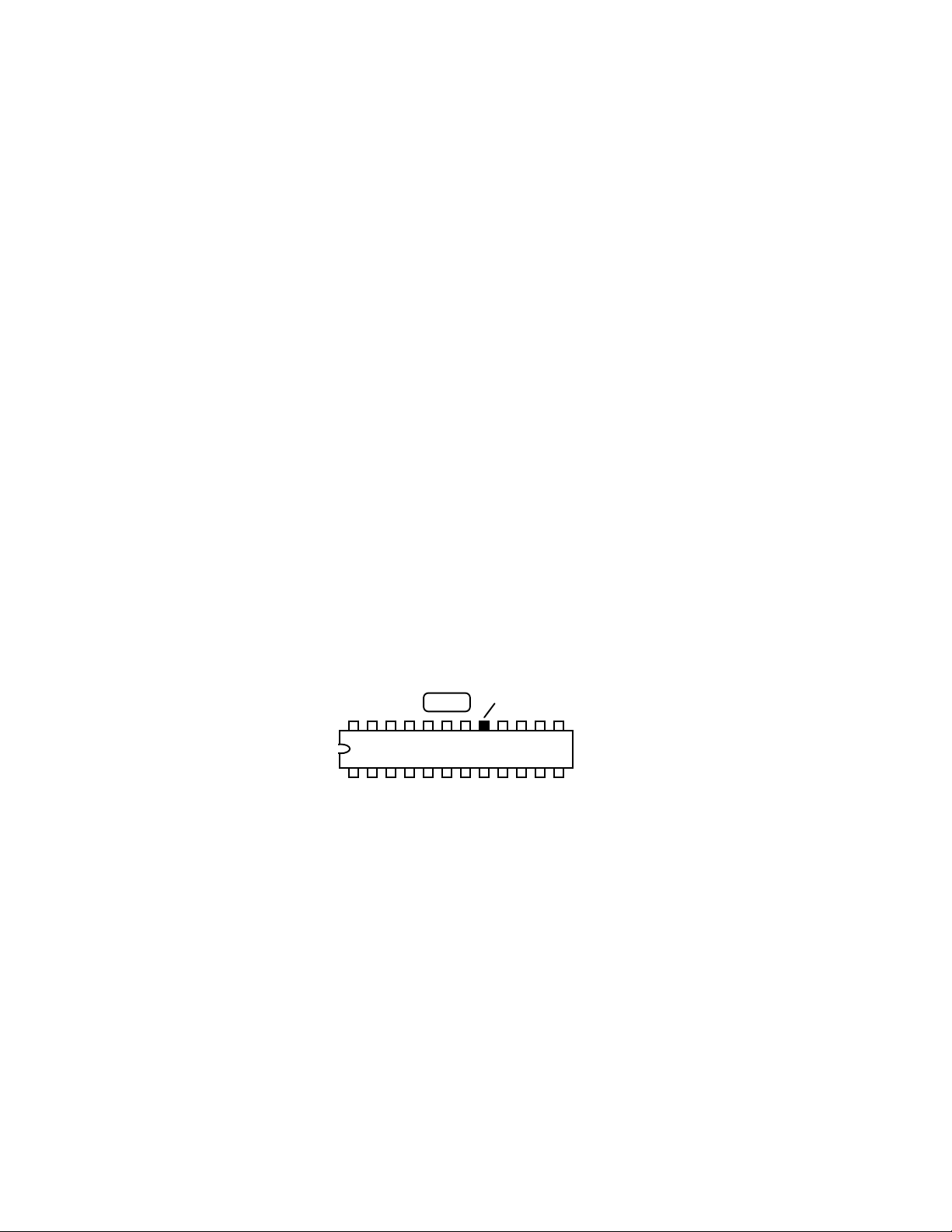

Integrated Circuits: Proper IC positioning is indicated by a dot or square marking

located on one end of the device. A corresponding mark will be silk-screened on the PC

board and printed on the kit's parts-placement diagram. To identify specific IC pin

numbers for testing purposes, see the diagram below. Pin numbers always start at the

keyed end of the case and progress counter-clock around the device, as shown:

8 7 6 5

Installation

Key

1 2 3 4

Pin Numbers

Installation

Key

(6) Parts List:

Your kit should contain all of the parts listed below. Please identify and inventory each

item on the checklist before you start building. If any parts are missing or damaged, refer

to the manual's warranty section for replacement instructions. If you can't positively

identify an unfamiliar item on the basis of the information given, set it aside until all

other items are checked off. You may then be able to identify it by process of

elimination. Finally, your kit will go together more smoothly if parts are organized by

Page 6

type and arranged by value ahead of time. Use this inventory as an opportunity to sort

and arrange parts so you can identify and find them quickly.

[ X] Quantity Description of Item Part Designation

Resistors:

[ ] 1 22 ohm (red, red, black) R3

[ ] 1 270 ohm (red, violet, brown) R4

[ ] 1 470 ohm (yellow, violet, brown) R2

[ ] 2 2.2K (red, red, red) R11, R14

[ ] 1 2.7K (red, violet ,red) R7

[ ] 1 4.7K (yellow, violet, red) R17

[ ] 1 6.8K (blue, gray, red) R5

[ ] 1 10K (brown, black, orange) R18

[ ] 2 39K (orange, white, orange) R12, R15

[ ] 1 47K (yellow, violet, orange) R8

[ ] 4 100K (brown, black, yellow) R1, R9, R13, R19

[ ] 2 10K potentiometer R6, R16

[ ] 1 100K potentiometer R10

Capacitors:

[ ] 1 3 pF disc ceramic (3 or 309) C3

[ ] 2 .001 uF disc ceramic (102) C14,C32

[ ] 3 .01 uF disc ceramic (103) C6,C13,C25

[ ] 1 .05 uF disc ceramic (503) C27

[ ] 8 .1 uF disc ceramic (104) C10,C11,C12,C21,C22,C24,

C26,C29

[ ] 1 10 pF multilayer (10 or 101) C1

[ ] 1 15 pF multilayer (15 or 150) C5

[ ] 1 18 pF multilayer (18 or 180) C19

[ ] 2 22 pF multilayer (22 or 220) C17, C18

[ ] 2 47 pF multilayer (47 or 470) C2,C4

[ ] 1 56 pF multilayer (56 or 560) C20

[ ] 1 220 pF multilayer (221) C7

[ ] 2 1000 pF multilayer (102) C15,C16

[ ] 2 1 uF electrolytic C23,C28

[ ] 2 10 uF electrolytic C30,C31

[ ] 2 100 uF electrolytic C8,C9

Semiconductors:

[ ] 1 5.1 volt zener diode, 1N751A D1

[ ] 1 2SC2498 transistor Q1

Page 7

[ ] 1 MC13135 IC (24 pin) U1

[ ] 1 MC34119 IC (8 pin) U2

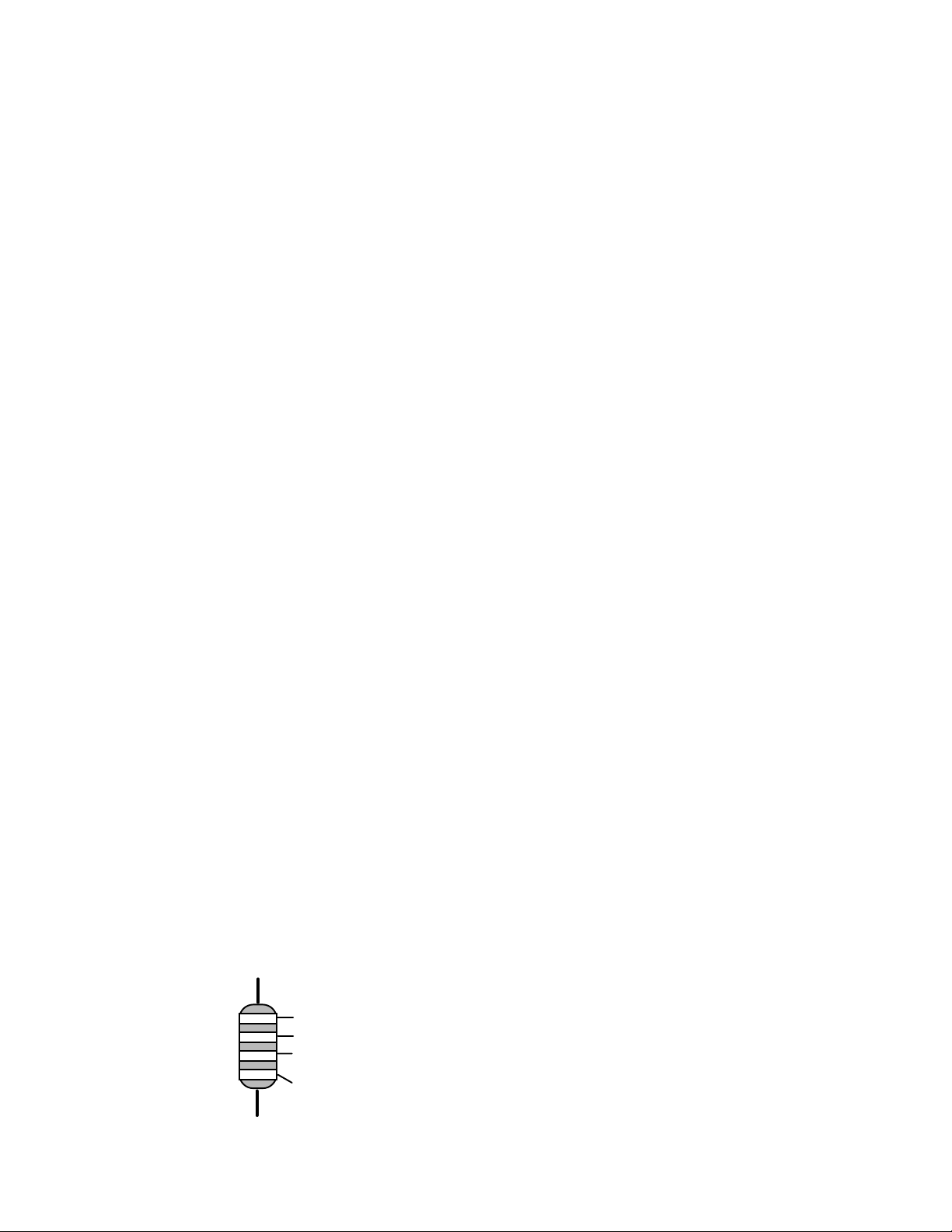

Inductors/Filters/Crystals

[ ] 1 24" length, #22 coil wire L1,L2

[ ] 1 .6 uH slug-tuned, shielded (yellow) L4

[ ] 1 660 uH adjustable, shielded (black) L5

[ ] 1 10.245 crystal Y1

[ ] 1 10.7 MHz ceramic filter (SFE10.7J) FL1

[ ] 1 455 kHz ceramic filter (55D or 55F) FL2

Switches/Jacks/Misc

[ ] 1 DPDT push-button power switch SW1

[ ] 1 RCA phono jack, pc-mounted J1

[ ] 1 3.5mm stereo jack (mini-jack) J2

[ ] 1 9-volt battery snap clip

[ ] 1 plastic cable tie

[ ] 1 PC board

[ ] 1 VEC-1016 Manual

(7 Parts Placement Diagram)

(8 Step-By-Step Construction)

In these instructions, when you see the term install, this means to locate, identify, and

insert the part into its mounting holes on the PC board. This includes pre-bending or

straightening leads as needed so force is not required to seat the part. Once a component

is mounted, bend each lead over to hold it in place. Use sharp side-cutters to clip off

excess lead length before soldering. Make sure trimmed leads don't touch other pads and

tracks, or a short circuit may result:

Good

Not Good

The term solder means to solder the part's leads in place, and to inspect both (or all)

solder connections for flaws or solder bridges. Nip off excess protruding leads with a

sharp pair of side cutters. Generally, it's easier to install small close-to-the-board parts

first, and then mount larger stand-up parts second. Delicate parts, such as air-wound,

coils go on the PC board last.

Page 8

Your kit has 16 fixed-value resistors. We'll mount these now, starting with the smallest

value and moving to the largest. Before mounting each one, carefully bend both leads

close to the resistor body to form right-angles, as shown below:

.4"

[ ] Find a 22 ohm resistor (red-red-black). Install at R3 and solder.

[ ] Find a 270 ohm resistor (red-violet-brown). Install at R4 and solder.

[ ] Find a 470 ohm resistor (yellow-violet-brown). Install at R2 and solder.

Locate two 2.2-K resistors (red-red-red).

[ ] Install 2.2 K at R11 and solder.

[ ] Install 2.2K at R14 and solder.

[ ] Find a 2.7-K resistor (red-violet-red). Install at R7 and solder.

[ ] Find a 4.7-K resistor (yellow-violet-red). Install at R17 and solder.

[ ] Find a 6.8-K resistor (blue-gray-red). Install at R5 and solder.

[ ] Find a 10-K resistor (brown-black-orange). Install at R18 and solder.

Locate two (2) 39-K resistors (orange-white-orange).

[ ] Install 39 K at R12 and solder.

[ ] Install 39 K at R15 and solder.

[ ] Find a 47-K resistor (yellow-violet-orange). Install at R8 and solder.

Locate four (4) 100-K resistors (brown-black-yellow).

[ ] Install 100 K at R1 and solder.

[ ] Install 100 K at R9 and solder.

[ ] Install 100 K at R13 and solder.

[ ] Install 100 K at R19 and solder.

This completes installation of the 16 fixed-value resistors (three variable resistors will be

installed later). Next, we'll install the kit's 15 disc-ceramic capacitors. All capacitors

should be seated as close to the board as possible.

[ ] Find a 2.7 pF disc-ceramic capacitor (2.2). Install at C3 and solder.

Page 9

Locate two (2) .001-uF disc-ceramic capacitors (102). Note that there are also two

multilayer type .001 uF (or 1000 pF) caps with your kit. Do not use those for C14 and

C32.

[ ] Install a .001-uF disc at C14 and solder.

[ ] Install a .001-uF disc at C32 and solder.

Locate three (3) .01-uF disc-ceramic capacitors (103).

[ ] Install .01 uF at C6 and solder.

[ ] Install .01 uF at C13 and solder.

[ ] Install .01 uF at C25 and solder.

Locate a .05 uF disc ceramic capacitor (503). Looking at the pc board, note that two (2)

installation holes are provided for the ground-side lead of C27. Choose the one that most

closely matches the lead spacing for the .05 uF capacitor provided in your kit.

[ ] Install .05 uF at C27 and solder.

Locate eight (8) .1-uF disc ceramic capacitors (104).

[ ] Install .1 uF at C10 and solder.

[ ] Install .1 uF at C11 and solder.

[ ] Install .1 uF at C12 and solder.

[ ] Install .1 uF at C21 and solder.

[ ] Install .1 uF at C22 and solder.

[ ] Install .1 uF at C24 and solder.

[ ] Install .1 uF at C26 and solder.

[ ] Install .1 uF at C29 and solder.

There are 11 multilayer capacitors provided with your kit. A multilayer cap is similar to a

surface-mount "chip" capacitor, except that it has a lead spot-welded onto each end of the

capacitor body. Multilayers have superior radio-frequency operating characteristics, but

the lead welds may fail if the device is over-heated and stressed during installation or

removal. For this reason, never use force to seat a multilayer cap into the PC board. If

the spacing isn't right, pre-form the leads to the correct spacing before installation.

[ ] Find a 10-pF multilayer capacitor (10 or 100). Install at C1 and solder.

[ ] Find a 15-pF multilayer capacitor (15 or 150). Install at C5 and solder.

[ ] Find a 18-pF multilayer capacitor (18 or 180). Install at C19 and solder.

Locate two (2) 22-pF multilayer capacitors (22 or 220).

[ ] Install 22 pF at C17 and solder.

[ ] Install 22 pF at C18 and solder.

Page 10

Locate two (2) 47-pF multilayer capacitors (47 or 470).

[ ] Install 47 pF at C2 and solder.

[ ] Install 47 pF at C4 and solder.

[ ] Find a 56-pF multilayer capacitor (56 or 560). Install at C20 and solder.

[ ] Find a 220-pF multilayer capacitor (221). Install at C7 and solder.

Locate two (2) 1000-pF multilayer capacitors (102).

[ ] Install 1000-pF at C15 and solder.

[ ] Install 1000-pF at C16 and solder.

This completes installation of the 11 multilayer caps. Remember to take frequent breaks

while building your kit to avoid fatigue.

The last six (6) capacitors in the kit are electrolytic. Electrolytic caps are polarized and

must be installed the correct way in order to work. Each capacitor's plus (+) mounting

holes are noted on both the circuit board and parts placement diagram. If the markings on

the capacitor body are unclear, the plus (+) lead is always the longer of the two.

Locate two (2) 1-uF electrolytic caps.

[ ] Install 1 uF at C23 and solder.

[ ] Install 1 uF at C28 and solder.

Locate two (2) 10-uF electrolytic caps.

[ ] Install 10 uF at C30 and solder.

[ ] Install 10 uF at C31 and solder.

Locate two (2) 100-uF electrolytic caps.

[ ] Install 100 uF at C8 and solder.

[ ] Install 100 uF at C9 and solder.

This completes installation of all capacitors. Before moving on to the next phase of

construction, check the polarity of each electrolytic one more time to confirm all six are

installed correctly.

Identify the 1N751 zener diode--the only diode supplied with the kit. Like electrolytic

capacitors, zener diodes are polarized and must be installed the right way. Diode polarity

is indicated by a black band located at one end of the glass body.

[ ] Install the 1N751 at D1 so the banded end corresponds with the band marked on the

PC board (toward U1). Solder.

Page 11

Locate the 2SC2498 plastic transistor and note its flat side. Position at Q1, as indicated

by the outline on the pc board. Gently pre-form the leads so the case is spaced

approximately .15" above the pc board surface when leads are fully inserted (see below).

2SC

2498

[ ] Install the 2SC2498 at Q1 and solder.

Your kit has six (6) jumper wires to install. Each should be pre-formed from a bare

length of discarded component lead, as shown below. The approximate distance between

mounting holes is given to help you pre-form each one. When installed, each jumper

should lay flat against the PC board.

span

discarded lead end

[ ] Make a jumper with a .2" span. Install at JMP1 and solder.

[ ] Make a jumper with a .25" span. Install at JMP2 and solder.

[ ] Make another jumper with a .25" span. Install at JMP3 and solder.

[ ] Make a jumper with a .3" span. Install at JMP4 and solder.

[ ] Make a second jumper with a .3" span. Install at JMP5 and solder.

[ ] Make a third jumper with a .3" span. Install at L3* and solder.

*Important Note: Inductor L3 is not used with the 49 MHz version of this kit. A jumper

is used in its place.

Locate the 10.7-MHz ceramic filter (looks like a square disc-ceramic capacitor with three

pins, marked 10.7J). This part is unpolarized and may be installed either way.

[ ] Install the 10.7-MHz filter at FL1 and solder.

Locate the 455-kHz ceramic filter (a small black cube with three pins marked 55D or

55F). This it will only fit one way on the PC board.

[ ] Install the 455-kHz filter at FL2 and solder.

[ ] Find the 3.5 mm stereo mini-headphone jack. Install and solder at J2.

[ ] Find the RCA phono jack. Install at J1 and solder all four taps.

[ ] Locate push-button power switch SW1. Install at SW1 and solder.

Page 12

[ ] Locate the 10.245 MHz crystal (frequency marked on can). Install at Y1 and solder.

The front-panel controls (tuning, squelch, volume) are mounted next. Before installing

these parts, inspect the type of potentiometer supplied with your kit. If the pins are

located on the front side of the pot, use the front set of mounting holes on the PC board

for installation. If the pins are on the rear, use the rear set of mounting holes (see below).

Also, using side cutters, remove the key tab from the side of each pot prior to installation.

Rear pins use rear holes.

Front pins use front holes.

Nip off tab.

Nip off tab.

Locate two (2) 10-K potentiometers (B103).

[ ] Install a 10-K pot at R6 (tuning) and solder.

[ ] Install a 10-K pot at R16 (volume) and solder.

[ ] Find the 100-K pot (B104). Install at R10 (squelch) and solder.

Locate the .6 uH shielded slug-tuned VFO coil (yellow form, 2 pins). Position at L4,

making sure the pins and shield-can tabs are straight and aligned with their mounting

holes.

[ ] Install the .6 uH coil at L4 and solder.

Locate the shielded quadrature-detector coil (five pins, black coil form). Position at L5,

making sure all pins and tabs are straight and aligned with their mounting holes.

[ ] Install the quad-coil at L5 and solder.

The last two coils are air-wound types made from the #22 wire supplied with your kit. In

addition to #22 wire, you'll also need a 1/4" screw or bolt at least 3/4" long to use as a

winding form (24 tpi). Carefully straighten the coil wire by drawing it over a plastic

rounded surface such as a screwdriver handle. Remove all bends and kinks. Cut into two

(2) equal lengths.

[ ] Take one length of wire and, while grasping both ends firmly, carefully wind seven

(7) full turns over the winding form--as shown below. The wire should conform into the

thread grooves.

Page 13

7-turns #22 enameled wire

1/4" screw thread

1/2" leads stripped

and tinned with solder

[ ] Remove the coil by unscrewing it from the 1/4" screw threads. Compress the turns of

the finished coil to make it as short as possible.

Each lead must be tinned prior to installation. The wire provided with your kit is coated

with enamel insulation formulated to melt at high temperatures. This quality should

allow you to strip, clean, and "tin" each coil lead in a single operation. To prepare each

lead, hold a hot soldering iron tip against it for several seconds while applying a small

amount of solder. Eventually, the enamel insulation should begin breaking down,

allowing solder to coat and adhere to the wire (it may be easier to perform this operation

with the coil threaded onto the screw). If your soldering iron doesn't generate enough

heat to start the enamel stripping process, scrape the enamel away with an Exacto knife

before tinning. Make sure both leads are clean and brightly tinned all the way around

before installing.

[ ] Dress, tin, and install a 7-turn coil at L1 and solder. Check coil shape and spacing

before moving on.

[ ] Repeat this operation, installing and soldering a second 7-turn coil at L2.

This completes coil installation. As noted above, no coil is required at L3 for the 49MHz version of your kit.

[ ] Install the 9-volt battery snap clip. The red lead is installed at (+ 9V), and the black

at GND. Solder in place.

[ ] Stress relief is provided to prevent battery leads from flexing and eventually breaking

at their connection point. Find a hole part-way back on the left edge of the PC board (not

to be confused with the board's mounting holes at the front and back). Use the plastic tiewrap provided in your kit to secure the battery leads in place, as shown below. Insert the

tie-wrap through the hole, close it over the wires, and pull tight. Nip off the excess end.

Page 14

Tie-wrap

Stress Relief

Finally, install receiver ICs U1 and U2. Before doing this, inspect both devices carefully

and straighten any bent or crooked pins. Use extreme care during insertion, and move

slowly. It's very easy to miss a pin opening and fold a IC pin underneath the body of the

device.

Locate U2, the MC34119 audio-amplifier IC (8 pins). Position its keyed (or notched) end

to correspond with the key marked on the pc board at U2. Carefully align the pins with

the U2 mounting holes before inserting.

[ ] Install the MC34119 IC at U2, checking carefully that all 8 pins enter their respective

mounting holes. Solder each pin in place.

Locate the MC13135 Receiver IC (24 pins). Position the keyed end to correspond with

the key marked on the pc board at U1. Carefully align the pins with the U1 mounting

holes before inserting.

[ ] Install the MC13135 IC at U1 and solder each pin in place.

Inspect the pads under both ICs carefully for solder bridges and cold-solder (use a

magnifying glass, if available). Correcting any problem before proceeding. This

concludes the construction phase of your receiver. You deserve a break! When you

come back, be ready to give your work a thorough "QC" quality control check before

moving on to the testing and alignment section.

(9 Testing and Alignment)

PC Board Inspection: Even the most experienced builders make mistakes! Before

applying power to your kit, give it a thorough QC (quality control) inspection. This will

help you find inadvertent assembly errors that might prevent the radio from working or

cause damage to sensitive parts. Follow this procedure:

Page 15

[ ] Compare parts locations against the parts-placement diagram. Was each part

installed where it is supposed to be? Was the correct value used? Start at one side of the

board and work your way across in an organized pattern.

[ ] Inspect the solder side of the board for cold-solder joins and solder bridges between

tracks or pads. Use a magnifying glass to obtain a clear view of the track area. If you

suspect a solder bridge, hold the board in front of a bright light for a better view. All

joints should be smooth and shiny, indicating good solder wetting and flow. Resolder

any beaded or dull-appearing connections.

[ ] Finally, check all electrolytic capacitors and diodes for correct polarity. Does the

plus (+) polarity symbol on the part agree with the pictorial and with the silk-screen

pattern on the PC board? Is the banded end of each diode positioned correctly? Also,

were your ICs installed so the dot or notch on the plastic case corresponds with the white

dot or marking on the PC board? Was Q1 installed correctly?

Be sure to correct all errors before moving on. If a careful inspection revealed that

everything is A-OK, you're now ready for the moment of truth!

Initial Checkout:

To check out your kit you'll need a 9-volt flat-pack type alkaline battery and a 8-ohm

extension speaker (or monaural headphones) outfitted with a 3.5-mm mini plug. Make

sure the radio's power switch is OFF (button out) before loading the battery. Plug in

speaker or phones and turn all potentiometer controls fully counter-clockwise.

[ ] Apply power (button in).

[ ] Turn up VOLUME (right-hand pot) clockwise. You should hear a rushing sound,

indicating the receiver and audio amplifier are functioning properly.

[ ] Slowly advance the SQUELCH (center pot) clockwise. The rushing sound should

stop abruptly around mid-range, indicating the squelch circuit is working.

If your radio passed its turn-on test, congratulations! You're well on your way to success,

and ready for pre-alignment.

If your radio didn't pass the turn-on test, don't despair. Odds are, you've overlooked

something minor that's easy to correct. Take a break, come back fresh, and carefully

repeat the QC inspection. If no undiscovered errors turn up during your second

inspection, proceed to the "In Case of Difficulty" section of this manual for

troubleshooting advice.

Page 16

Pre-Alignment:

You'll need the following items to adjust your receiver:

[ ] Insulated hex-head tuning wand to adjust L4.

[ ] Small flat-blade screwdriver or tuning wand to adjust L5.

[ ] Voltmeter, digital or analog, to adjust L5.

[ ] VHF "lowband" or six-meter ham antenna to receive off-air signals.

The instructions below describe how to pre-adjust each of the radio's coils for a ballpark

setting. This procedure will make final alignment easier.

[ ] Locate coils L1 and L2. Compress each coil so the turns are close together.

[ ] Make a small flag from a scrap of tape and install it on the hex-head tuning wand.

This will help you count revolutions as you adjust L4.

[ ] Locate tunable-oscillator coil L4. Insert the tuning wand and rotate the slug counterclockwise so the top surface is perfectly flush with the top of the metal shield can. Now,

watching the tape flag and counting revolutions, rotate the slug 4 turns clockwise down

into the body of the coil.

[ ] Set your voltmeter range to 10 Volts dc and connect the black (-) lead to a ground

point on the PC board. Locate pin # 17 on U1 (see below). This is the test point for

adjusting L5.

FL1

Test Point, 2.3 V

U1, MC13135

[ ] Set all front-panel controls on the radio counter clockwise, install a 9-volt battery on

the battery snap clip, and apply power via the OFF/ON switch. No antenna should be

connected during this test. With power applied, touch the red (+) voltmeter lead to pin

#17. Using a small screwdriver, adjust L5 for a reading of 2.3 volts. No further

adjustment will be required.

Final Alignment--Oscillator Coil L4:

Ideally, your kit should be mounted in the VEC-1016CK case for this procedure. If you

calibrate the radio out of its case, you may need to touch up L4 later--when the case is

added. There are several ways to calibrate your receiver. Choose the method most

compatible with the tools you have available:

Page 17

Option 1: Calibrating with a Signal Generator or FM-Service Monitor

Set the generator up as follows:

Frequency: 50.0 MHz

Output Level: 10 uV (-90 dBm)

Modulation: 1-kHz tone at 5-kHz FM deviation

Connect the generator output to your VEC-1016K antenna jack using a 50-ohm patch

cable. Plug in headphones or external speaker to monitor generator signal.

[ ] Set TUNE to 50 MHz (fully clockwise) and SQUELCH counter-clockwise (open).

[ ] Power the radio and set VOLUME for a comfortable level.

[ ] Slowly tune L4 back and forth with an insulated tuning wand to locate the 50-MHz

test signal.

Important Note: The receiver's 10.245-MHz local oscillator's generates a 5th harmonic

on 51.225 MHz. If you tune across this signal, it will be heard as a strong unmodulated

carrier. Don't mistake this signal for your signal generator's output signal!

Option 2: Calibrating with a Antenna Analyzer

Any MFJ or Autek antenna analyzer with VHF coverage may be used to generate an

alignment signal. Set the analyzer to 50.0 MHz and position a few feet from the VEC-

1016. Do not connect the analyzer directly to your VEC-1016, or damage may result.

Install a 47-ohm resistor on the VEC-1016K antenna jack and follow the test procedure

outlined above for using a signal generator.

Option 3: Calibrating with a Frequency Counter

Your VEC-1016K features a buffered test point for measuring oscillator frequency with a

digital counter. Locate this point on the diagram below:

FL1

U1, MC13135

3

Test Point

Connect Counter Here

FL2

[ ] Connect the frequency-counter ground lead to a ground point (case or PC board).

[ ] Set the TUNE to 50 MHz (fully clockwise) and apply power.

[ ] Touch counter probe to pin-3 and adjust L4 for a counter reading of 39.3 MHz.

Page 18

Important Note: The VFO signal will fall 10.7 MHz below the receiver's operating

frequency and may by too weak for some counters to sample (around -25 dBm). If you

don't obtain a stable counter reading, use a different method of calibration.

Option 4: Calibrating with a Scanner Receiver

You may use a synthesized scanner or extended-coverage HT to pick up the radio's

oscillator signal. Set the scanner to 39.3 MHz and position it near the kit.

[ ] Set TUNE to 50 MHz (fully clockwise if you have no cabinet), and apply power.

[ ] Slowly adjust L4 until the oscillator signal is heard on the scanner at 39.3 MHz.

Option 5: Calibrating with an off-air signal.

If no other option is available, you may calibrate L4 using the signal generated by a 49MHz consumer wireless product. To do this, you should know the product's operating

frequency (check the operating manual or look for a crystal with a frequency marked on

it). Your radio should be mounted in its case so the front-panel tuning-dial scale is

available. Begin by connecting a speaker (or phones) and an antenna.

[ ] Set the SQUELCH pot fully counter clockwise (open).

[ ] Apply power and set the VOLUME pot for a comfortable background-noise level.

[ ] Adjust the TUNE pot to correspond with the product's assigned operating frequency.

[ ] Slowly tune L4 until you receive the signal at the correct spot on the dial.

Aligning L1, L2 for maximum receiver sensitivity:

If coils L1 and L2 were formed and installed according to instructions, your radio should

operate with near-maximum sensitivity and require no further adjustment. However, if

you wish, you may "tweak" these two coils to optimize performance on weak low-power

signals. In order to make this adjustment, you'll need a weak signal source. This could be

a 1-uV 49.5-MHz signal produced by a signal generator, or a weak off-air signal with

audible background noise present. To adjust, use the blade of a non-metallic tuning wand

or your fingernail to expand or compress the spacing between turns. Note that adjusting

L1 and L2 may change the radio's operating frequency slightly. To compensate for this

interaction, readjust TUNE as you make each change to ensure the signal remains tuned

in.

Reduced background hiss and lower distortion indicates an improvement in signal

strength. As you find the best point for each coil, stretch or compress it permanently into

in that position. Don't attempt to adjust L1 and L2 while tuned to a strong local signal.

Use only a weak signal with clearly-audible background hiss. When peaked, the VEC1016 should render "solid copy" with good quieting on FM signals of .5 uV or less.

Page 19

(10 Operating Instructions)

Power

Tune Squelch Volume

1

48.8

23 4

50.0

VEC-1016K

1. POWER: Push-on/push-off switch turns unit on and off. The VEC-1016 runs on

internal battery power and shouldn't be left ON for extended period when not in use.

2. TUNE: Electrically tunes receiver. Tuning range is approximately 48.8 to 50.8 MHz

(the frequencies where most activity takes place).

3. SQUELCH: Adjusts threshold-point for cutting off receiver background noise.

4. VOLUME: Adjust audio amplifier gain a comfortable listening level.

Antennas: For local reception, a 56" length of wire may work reasonably well.

However, for long-range reception of weak 49 MHz signals, a roof-mounted six-meter

ham antenna or low-band VHF scanner antenna fed with coaxial cable will provide far

better performance. Alternatively, you can make your own "side-mount" vertical dipole

like the one illustrated below:

Page 20

Small Diameter

Aluminum Tubing or Rod

Threaded on One End

7-8 Turns RG-58

Mast Clamp

1-1/2" PVC Pipe

(Thick Wall)

108"

32"

TV Mast

Check battery condition: Operating your radio with a weak battery may lead to

unstable tuning (signals drifting off channel rapidly), weak or distorted audio, and motor

boating (a low-frequency "putt-putt-putt" noise in your speaker or headphones). Your

radio needs a minimum of 7-8 volts in order to work properly.

(11 In Case of Difficulty)

The VEC-1016K design has been thoroughly field tested, and is known to be both

reliable and "forgiving" of construction errors. If you have difficulty with your unit, the

cause may be something as simple as a broken cable or a dead battery. In most cases,

you will be able to find the cause with some organized troubleshooting. Begin your

search with this checklist of symptoms and cures:

[ ] Does not turn on: Check battery condition, snap clip, and power leads. Also, make

sure lead polarity is correct (red to +, black to GND). Make sure power switch is "on".

Also, squelch may be locked "on" (see below). Check operating voltages.

[ ] Turns on, does not receive signals: Check antenna, antenna lead, and plug for

shorted or open condition. Also, radio may not pick up signals in metal building without

an outdoor antenna.

[ ] Drifts off-frequency rapidly, "motorboats", weak audio: Symptoms of a weak

battery or insufficient operating voltage. Be sure to check battery voltage "under load"

(with the radio turned on).

Page 21

[ ] Squelch won't open when control is fully counter-clockwise: Check the value of

the squelch potentiometer. It must be 100K. If a 10K pot is installed at R10, the squelch

won't open.

[ ] Poor sensitivity: Look for antenna problems. Also, check condition of L1, L2. If

they are improperly shaped or if a lead is broken, sensitivity will be poor.

If these checks fail to uncover the problem, repeat the "QC" check one more time.

Service records show that, for most malfunctioning kits, outright component failure is

relatively rare. In most cases, the culprit is a misplaced part, reverse-polarized capacitor

or diode, or a faulty solder connection!

Voltage Analysis: One effective way to pin-point where a circuit problem might be is to

use voltage analysis. To do this, you'll need a voltmeter--preferably a high-impedance

DMM type. Set your meter to the 10-volt dc range and clip the black (-) test lead to a

ground point on the PC board (the frame of the antenna connector is a good point).

Make sure the radio's battery is fresh--the chart readings were made using a 9.0-volt

power source. Using the red (+) lead, check the voltage on each IC pin and compare it

against the voltage chart below. Readings should be within 10-15% of chart value:

U1, MC13135 U2, MC34119 Q1

Pin Voltage Pin Voltage Pin Voltage E B C

1 5.2 13 5.2 1 0.1* 0 .77 7.1

2 4.5 14 0.1* 2 4.0

3 4.3 15 0.1* 3 4.0

4 5.2 16 0 4 4.0

5 4.7 17 2.3 5 4.0

6 5.2 18 5.2 6 8.8

7 3.8 19 5.2 7 0

8 0 20 4.0 8 4.0

9 4.4 21 5.2

10 4.4 22 5.2

11 4.4 23 1.2-3.0

12 .2 (no sig) 24 0

*This represents the squelch-open or "logic-low" voltage. When squelch is closed

(receiver muted), voltage becomes 3.8 volts, or "logic-high").

If you find one or more pins that read radically different from the chart value, it may

indicate the device is bad--or it may mean a circuit problem exists in that portion of the

radio. If you have technical skills and can read a schematic diagram, this will help you.

For example, if you get an unreasonable reading on pin 23 of U1, the schematic shows

that the radio's voltage-tuning circuitry is connected here. You might look for defective

or misplaced components on that portion of the circuit board as a potential cause. If,

Page 22

despite your best effort, you cannot solve a problem with your radio, kit repair services

are available through Vectronics. See the warranty on the inside front cover for complete

instructions.

(12 Theory of Operation and Technical Specifications)

Technical Circuit Description:

The VEC-1016K is a sensitive voltage-tunable dual-conversion NBFM receiver that

includes an effective squelch circuit and gated AF-amplifier IC for speaker operation.

Incoming signals are filtered through a bandpass filter at L1/L2 to reduce out-of-band

interference, then boosted by low-noise preamplifier Q1. Q1 is series-matched to the

input of U1.

U1 is a Motorola device that perform nearly all receiver functions for the radio. The first

LO (local oscillator) is voltage-tuned by a temperature-compensated varactor diode built

into the receiver chip. Signals are converted in the receiver's DBM 1st-mixer stage down

to 10.7 MHz, the radio's 1st-IF. Here, they are fed through a roofing filter (FL1) to

reduce in-band interference. The second LO, crystal-controlled at 10.245 MHz, drives

the 2nd mixer for converting signals to 455 kHz. FL2 establishes the radio's messagechannel bandwidth prior to 100-dB of signal amplification and limiting in the 2nd IF.

Signals are demodulated by quardrature detection, and recovered audio signals are

preamplified to line level by U1's output stage. Audio is then sent to the receiver's

volume control and to AF amplifier U2.

In addition to processing FM signals, U1 also measures signal strength through log-amp

RSSI circuitry. RSSI output is sent to a built-in op-amp comparator, where signal

strength is compared to a reference level set by the radio's squelch control. The

comparitor then generates a logic signal to operate the "mute" pin of audio amplifier U2

for squelch action.

Audio is supplied to U2 via the radio's volume control. Here, audio signals are contoured

for frequency response and amplified to speaker-level. The output of U2 is fed to a

speaker/phone jack.

Technical Specifications:

Tuning Range 48.2-50.0 MHz (approximate)

Sensitivity .5 uV typical for 12-dB sinad

Selectivity 20-kHz message-channel bandwidth

AF Output 60 mW into 8-ohm load

Current Drain 15 mA squelched, 40 mA on voice peaks

Power Source 9-v flatpack battery

Page 23

(13 Schematic)

(14 Enclosure and Other Kits)

Loading...

Loading...