Varec 8620 User Manual

8620 Driver Entry Terminal

Field interface used for data entry and

process management at facility control

points

Installation and Operations Manual

Pending

IOM097GVAE0709

Software Version 1.0

Automation Solutions for oil & gas, defense and aviation applications

Copyright

All rights reserved. Printed in the United States of America.

Except as permitted under the United States Copyright Act of 1976, no part of this publication

may be reproduced, stored in a retrieval system or transmitted in any form or by any meanselectronic, mechanical, photocopying, recording or otherwise—without the prior written

permission of the Publisher:

Varec, Inc.

5834 Peachtree Corners East

Norcross (Atlanta), Georgia 30092

Phone: (770) 447-9202

Fax: (770) 662-8939

Trademarks Acknowledged

Varec, Inc. recognizes all other trademarks. Trademarks of other products mentioned in this

manual are held by the companies producing them.

FuelsManager®, TankView®, TacFuels®, and Varec® are registered trademarks of Varec,

Inc.

All other product and service names mentioned are the trademarks of their respective

companies.

Product Approvals

This document and the information provided within are controlled by the approvals agency(s)

listed below. All changes to this document must be submitted to and approved by the agency(s)

before public release.

FM Approvals (FM) — Pending

Varec, Inc. ii

Disclaimer of Warranties

The contract between the Seller and the Buyer states the entire obligation of the Seller. The

contents of this instruction manual shall not become part of or modify any prior or existing

agreement, commitment or relationship between the Seller and Buyer. There are no express or

implied warranties set out in this instruction manual. The only warranties that apply are those

in the existing contract between the Seller and Buyer.

The 8620 Driver Entry Terminal (DET) has not been tested by Varec under all possible

operational conditions, and Varec may not have all the data relative to your application. The

information in this instruction manual is not all inclusive and does not and cannot take into

account all unique situations. Consequently, the user should review this product literature in

view of his/her application. If you have any further questions, please contact Varec for

assistance.

Limitations of Seller's Liability

In the event that a court holds that this instruction manual created some new warranties, Seller's

liability shall be limited to repair or replacement under the standard warranty clause. In no case

shall the Seller's liability exceed that stated as Limitations of Remedy in the contract between

the Seller and Buyer.

Use of parts that are not manufactured or supplied by Varec voids any warranty and relieves

Varec of any obligation to service the product under warranty. Varec recommends the use of

only Varec manufactured or supplied parts to maintain or service Varec 8620 Driver Entry

Terminals (DET).

Terms of Use

The information provided in this document is provided "as is" without warranty of any kind.

Varec, Inc. disclaim all warranties, either express or implied, including the warranties of

merchantability and fitness for a particular purpose. In no event shall Varec, Inc. or its suppliers

be liable for any damages whatsoever including direct, indirect, incidental, consequential, loss

of business profits or special damages, even if Varec, Inc. or its suppliers have been advised of

the possibility of such damages.

This manual is solely intended to describe product installation and functions and should not be

used for any other purpose. It is subject to change without prior notice. This manual was

prepared with the highest degree of care. However, should you find any errors or have any

questions, contact one of our service offices or your local sales agent.

iii Installation and Operations Manual

Safety Precautions

Read this manual carefully and make sure you understand its contents before using this product.

Follow all instructions and safety guidelines presented in this manual when using this product.

If the user does not follow these instructions properly, Varec cannot guarantee the safety of the

system.

Note Comply with all applicable regulations, codes, and standards. For safety precautions,

the user shall refer to the appropriate industry or military standards.

Caution Electrical Hazard! Read and understand static and lightning electrical protection

and grounding described in API 2003. Make certain that the 8620 Driver Entry Terminal

(DET) installation, operation, and maintenance conforms with the practice set forth therein.

Make sure the power is turned off at the main circuit breaker or switch. The power switch

should be in the OFF position, locked, and labeled to prevent other personnel from turning

the power on during installation.

Varec, Inc. iv

Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Functionality and System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Preparing for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Site Preparation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Communications Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuring the DET.Config File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Using Local Diagnostics (LED Indicators) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacing a Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Host Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mechanical Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Certifications and Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7 Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Order Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Varec, Inc. v

Contents

vi Installation and Operations Manual

1 Introduction

Overview

8620 Driver Entry Terminal

This manual provides the information needed to install, maintain, and troubleshoot the Varec

8620 Driver Entry Terminal (DET).

The 8620 DET is a field interface device designed for data entry and process management at

facility control points, such as entry and exit gates, load racks, BOL request stations, weight

scale stations, and preload stations. It features multiple interface components, such as a display,

card reader, and fingerprint scanner that can be used to enter and record pertinent information

about the operator or operation.

The 8620 DET interfaces to FuelsManager® Oil and Gas Terminal Automation Edition software.

It captures data based on the desired configuration for the specific control point application,

process or operation. For example, it may capture driver ID for access control, truck ID for

equipment safety and loading or company ID for product allocations. Refer to the

Software User Guide(s)

and documentation for your specific implementation.

FuelsManager

Varec, Inc. 1

Introduction

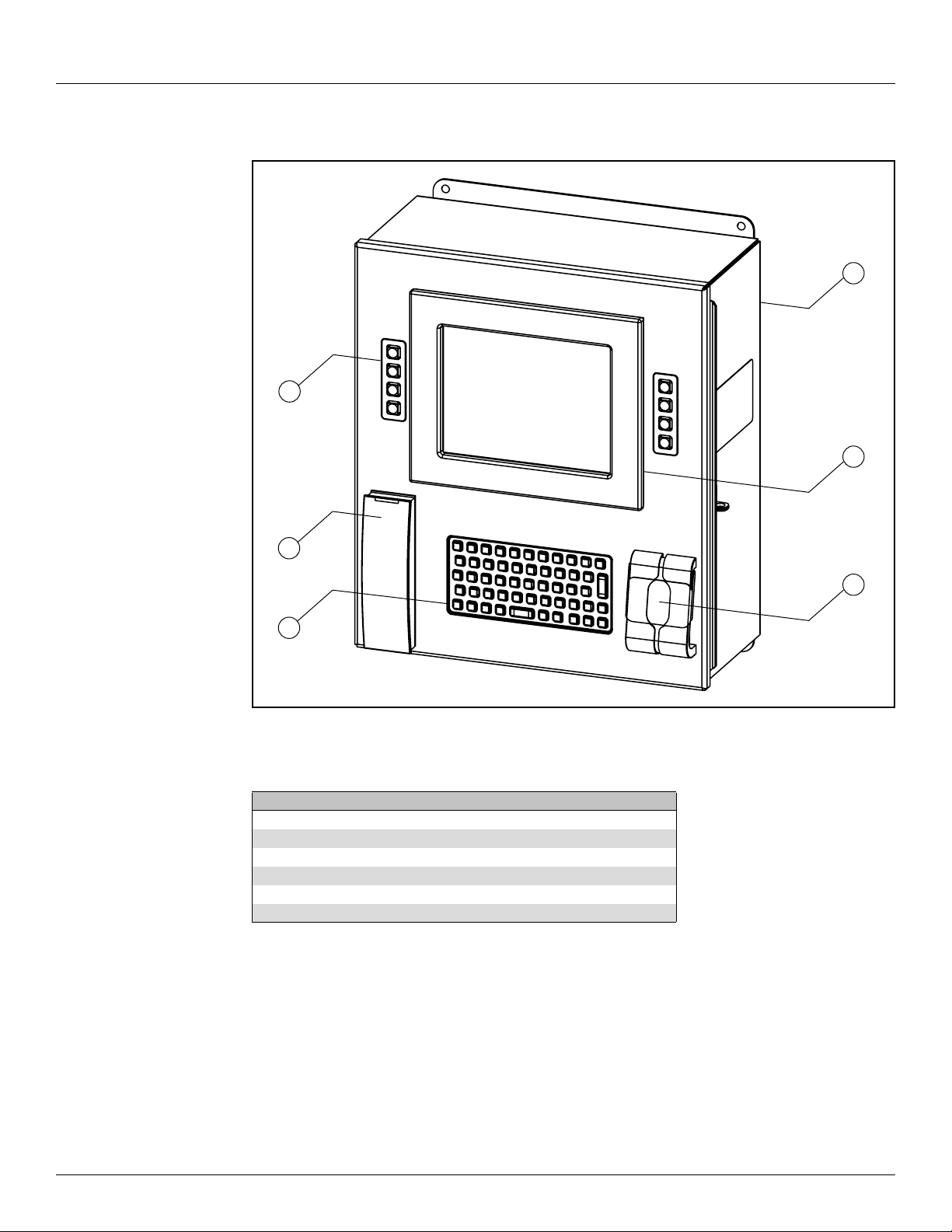

The 8620 DET is constructed with the following assemblies as shown in Figure 1-1:

1

4

2

5

6

Figure 1-1: 8620 DET System Components

Item Qty Description

1 1 17.50" x 14.92" Enclosure with Window Kit

2 1 8.4" LCD

3 1 Fingerprint Scanner

4 2 4 Key Keypad

5 1 Smart Card Reader

6 1 Keyboard

Table 1-1: 8620 DET System Components

3

2 Installation and Operations Manual

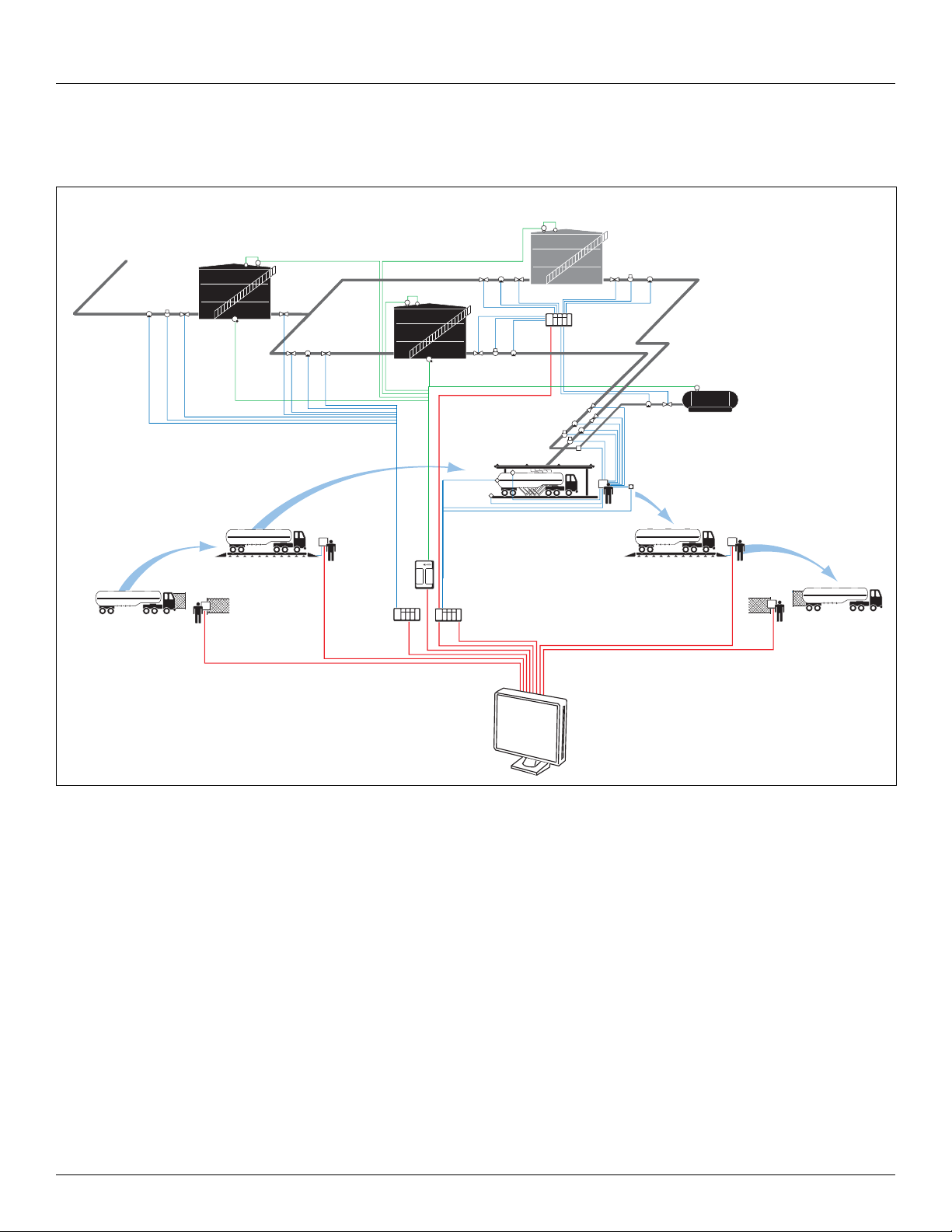

Functionality and System Design

Load Rack

• Preset Blending Control

• Preset Additive Injection Control

Entry Gate

• Access Control

• Truck Identity

• Truck Status

Weigh Scale

• Select Order to Load

• Configure Compartment Loads

• Capture Empty Weight

Exit Gate

• Exit Control

• Truck Identity

• Truck Status

Tank Storage

• Tank Gauging

• Inventory Management

• Alarms & Events

• Tank Trends

• Leak Detection

• Certificate of Analysis Records

Additives

• Tank Gauging

• Inventory Management

Pipeline, Truck, Rail or

Barge Receipts

Pump Meter Valve

Pump Valve

MeterValve Pump

Driver

Entry

Terminal

Driver

Entry

Terminal

Preset

Meter

Valve

Pump

Pump Valve

Valve

Tank Gauges

Tank Gauges

Leak

Detection

System

Injector

Tank Gauges

Valve

Valve

Overfill

Protection

Ground

Protection

Tank Gauges

Valve

Pump

PLC

RTU

Leak

Detection

System

MeterValve Pump

ESD

Driver

Entry

Terminal

Vapor

Recovery

PLC

PLC

SCADA

• Pump & Valve Control

• Emergency Shut Down

Weigh Scale & BOL Station

• Captured Load Weight

• Automatic BOL Printing

• Automatic COA Printing

• Truck Status

Driver Entry

Terminal & Printer

FuelsManager

System

8620 Driver Entry Terminal

Figure 1-2: 8620 DET System Diagram

Varec, Inc. 3

Introduction

4 Installation and Operations Manual

2 Preparing for Installation

This chapter provides a site preparation checklist, safety information, unpacking instructions,

and installation instructions.

Site Preparation Checklist

Before installing the 8620 DET, ensure the following items:

• Adequate space for installation

• The appropriate communication lines back to the FuelsManager Oil & Gas Terminal

Automation system

• Power (AC or DC)

• Grounding

• Enclosure protection, such as concrete barrier poles to prevent trucks from damaging

the unit

8620 Driver Entry Terminal

General Safety Guidelines

The 8620 DET is certified to be used in Class I, Div 2, hazardous locations.

The user shall follow safety guidelines provided by the Occupational Safety and Health

Administration (OSHA) for additional protection. Information may also be obtained from the

following sources:

• National Electrical Code (NEC)

• National Fire Protection Association (NFPA)

• Instrument Society of America (ISA)

• FM Approvals (FM)

• Underwriters’ Laboratories Incorporated (UL)

When in doubt about the safety of an area, check with the local safety authorities. Always

observe equipment labels and warning signs posted in the area.

Installation Safety Guidelines

This equipment should be installed only by qualified personnel familiar with the installation of

display and monitoring equipment.

Caution should be exercised when any area that is posted or otherwise assumed to contain

hazardous gases. Always follow OSHA guidelines.

To prevent shock hazards, the housing of all units should be properly grounded in accordance

with the National Electrical Code. A grounding conductor should be wired to the grounding

terminal provided on the 8620 DET.

! Warning Before attempting installation of the 8620 DET, review the "General Safety

Guidelines" above. Installation and maintenance personnel should become

familiar with any hazards present as well as any agency requirements before

working with any equipment.

Obtain a hot permit before opening the 8620 DET cover with power applied.

Varec, Inc. 5

Loading...

Loading...