Varec 4532 User Manual

4532 Average Temperature Sensor and

Converter

Installation and

Operations Manual

For software version V1.45

IOM019NVAE0208

www.varec.com

5834 Peachtree Corners East, Norcross (Atlanta), GA 30092 USA

Tel: +1 (770) 447-9202 Fax: +1 (770) 662-8939

Varec, Inc.

4532

Copyright

All rights reserved. Printed in the United States of America. Except as permitted under

the United States Copyright Act of 1976, no part of this publication may be reproduced,

stored in a retrieval system or transmitted in any form or by any means- electronic,

mechanical, photocopying, recording or otherwise- without the prior written permission

of the Publisher:

Varec, Inc.

5834 Peachtree Corners East

Norcross (Atlanta) GA 30096

USA

Trademarks acknowledged

Varec, Inc. recognizes all other trademarks. Trademarks of other products mentioned in

this document are held by the companies producing them.

Varec® is a registered trademark of Varec, Inc., a wholly-owned subsidiary of

Science Applications International Corporation

Varec, Inc. 1

Average Temperature/Water Bottom Sensor and Converter

Disclaimer of Warranties

The contract between the Seller and the Buyer states the entire obligation of the Seller.

The contents of this document shall not become part of or modify any prior or existing

agreement, commitment or relationship between the Seller and Buyer. There are no

express or implied warranties set out in this document. The only warranties that apply

are those in the existing contract between the Seller and Buyer.

Varec, Inc. products have not been tested by Varec, Inc. under all possible operational

conditions, and Varec, Inc. may not have all the data relative to your application. The

information in this document is not all inclusive and does not and cannot take into

account all unique situations. Consequently, the user should review this product

literature in view of his/her application. If you have any further questions, please contact

Varec, Inc. for assistance.

Limitations of Seller's Liability

In the event that a court holds that this document created some new warranties, Seller's

liability shall be limited to repair or replacement under the standard warranty clause. In

no case shall the Seller's liability exceed that stated as Limitations of Remedy in the

contract between the Seller and Buyer.

Terms of Use

The information provided in this document is provided “as is” without warranty of any

kind. Varec, Inc. disclaim all warranties, either express or implied, including the

warranties of merchantability and fitness for a particular purpose. In no event shall

Varec, Inc. or its suppliers be liable for any damages whatsoever including direct,

indirect, incidental, consequential, loss of business profits or special damages, even if

Varec, Inc. or its suppliers have been advised of the possibility of such damages.

Use of parts that are not manufactured or supplied by Varec, Inc. voids any Varec, Inc.

warranty and relieves Varec, Inc. of any obligation to service the product under warranty.

Varec, Inc. recommends the use of only Varec, Inc. manufactured or supplied parts to

maintain or service Varec, Inc. products.

Use of parts that are not manufactured or supplied by Varec, Inc. invalidates the agency

approval for this product.

2 Installation and Operations Manual

4532

Safety Precaution Definitions

Caution! Damage to equipment may result if this precaution is disregarded.

Warning! Direct injury to personnel or damage to equipment which can cause injury to

personnel may result if this precaution is not followed.

Safety Precautions

Read and understand this instruction manual before installing, operating or performing

maintenance on the Varec 4532 Average Temperature Sensor and Converter. Follow all

precautions and warning noted herein when installing, operating or performing

maintenance on this equipment.

Varec, Inc. 3

Average Temperature/Water Bottom Sensor and Converter

4 Installation and Operations Manual

4532 Contents

Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Installation and operation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Software history. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 System functional diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Installation, commissioning and operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Product Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.1 Power source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.2 Use in hazardous areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.3 External connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.1 Hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.3 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6 Notes on safety conventions and symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Device designation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.1 Nameplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 CE marks, declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Flexible tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Special conditions for safe use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Mounting instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Mounting on a fixed roof tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.1 Top anchor method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.2 Thermo well method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Varec, Inc. 1

Contents Average Temperature/Water Bottom Sensor and Converter

5.2.3 Anchor weight method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Mounting on a floating roof tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3.1 Top anchor method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3.2 Thermo well method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.3 Guide ring and anchor weight method . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Terminal Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1.1 4532 ATC terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1.2 6000 Series Servo Tank Gauge terminal . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.3 4590 TSM i.s. terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Local HART connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.1 As a Varec tank gauging instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.2 As a standalone generic HART instrument . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 Device set up: 4590 TSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2.1 HART scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2.2 The 4532 ATC specific parameter set up on the 4590 TSM . . . . . . . . . . . 28

7.3 Device set up: 6000 Series Servo Tank Gauge . . . . . . . . . . . . . . . . . . . . . 28

7.3.1 Preparation of 6000 Series Servo Tank Gauge . . . . . . . . . . . . . . . . . . . . 28

7.3.2 4532 ATC configuration on 6000 Series Servo Tank Gauge . . . . . . . . . . . 28

8 Operation and Description of Instrument Function . . . . . . . 31

8.0.1 HART Device designation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.0.2 Device Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1 Temperature measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1.1 Primary values: VH00 ~ VH09. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1.2 Element Temperature 1: VH10 ~ VH15 . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1.3 Element Temperature 2: VH20 ~ VH29 . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1.4 Element Position 1: VH30 ~ VH35

(VH36~VH39 is used only in 4539 ATC)

8.1.5 Element Position 2: VH40 ~ VH45 are not available in 4532 ATC . . . . . . . 35

8.1.6 WB primary and Advanced temp: VH50 ~ VH59 . . . . . . . . . . . . . . . . . . . 37

8.1.7 WB Adjustment and Operation Power: VH60 ~ VH69 . . . . . . . . . . . . . . . 38

8.1.8 Temperature Adjustment: VH70 ~ VH79. . . . . . . . . . . . . . . . . . . . . . . . . 38

8.1.9 Device setting 2: VH90~VH99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

35

9 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Repairs to Ex-approved devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.4 Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2 Installation and Operations Manual

4532 Contents

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.1 System error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.1 Anchor weight (Tall profile) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.2 Anchor weight (Low profile) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.3 Wire hook, Top anchor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

12 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

A Order Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B Declaration of Contamination Form . . . . . . . . . . . . . . . . . . . . . . . 55

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Varec, Inc. 3

Contents Average Temperature/Water Bottom Sensor and Converter

4 Installation and Operations Manual

4532 Introduction

1 Introduction

1.1 Introduction

The 4532 Average Temperature Sensor and Converter (ATC) is a multi-element (Pt100)

resistance device designed to measure the average product temperature in bulk liquid

storage tanks. The measured value is converted into a HART® compatible output for use

in temperature compensated volumetric calculations. The 4532 ATC contains up to 6

temperature elements, spaced at 2 or 3 meter intervals along the length of the probe.

Power and local HART communications are provided over a 2-wire, intrinsically safe (i.s.)

connection from compatible instruments, such as the Varec 6000 Series Servo Tank

Gauge (STG), 7500 Series Radar Tank Gauges (RTG) and the 4590 Tank Side Monitor

(TSM).

1.2 Installation and operation ov erview

Step 1. Installing on tank top

• The actual installation may require an installer to work in a hazardous area. Safety

must be taken into account in order to avoid any harmful conditions.

• The installation method depends on the type of 4532 ATC. Refer to

Chapter 4, Installation.

Step 2. Wiring to the host instruments (4590 TSM)

• Wiring material and conditions must be in accordance with intrinsically safe

standards.

• One end (normally on the host instrument side) of the shield twisted pair of cables

must be grounded at the terminal connection.

• Refer to Chapter 4, Installation.

Step 3. 4532 ATC initial setup

• Set up device settings for the 4532 ATC and the local HART setting to the host

instrument.

Step 4. Data flow from the 4532 ATC to the host instruments

• Individual element temperature data: Individual row element temperature can be

accessed regardless of liquid level information on the 4532 ATC's data matrix.

Average temperature data: The host instrument sends liquid level data on the HART line

to the 4532 ATC. The 4532 ATC calculates both Gas / Liquid phase average temperature

based on this given liquid level.

1.3 Software history

Software version /

Date

V1.45/04.2006 Original software

Software changes Documentation

changes

Varec, Inc. 1

Introduction Average Temperature/Water Bottom Sensor and Converter

Pressure

Power AC

FuelsManager

Software

8130 RTU

or

8300 TGI

+24V

+5V

+15V

-15V

CPU

COMM

I/O

ERROR

Level

Temperature

To F T ool FieldT ool

Package

Commubox

FXA191/195

HAR T

2-wire

2-wire Power

(DC, Ex i)

Ex i

Ex i

Ex d

4590 TSM

Level

Interface

Density

Bottom

Temperature

HAR T

2-wire

Power AC/DC

HAR T

2-wire

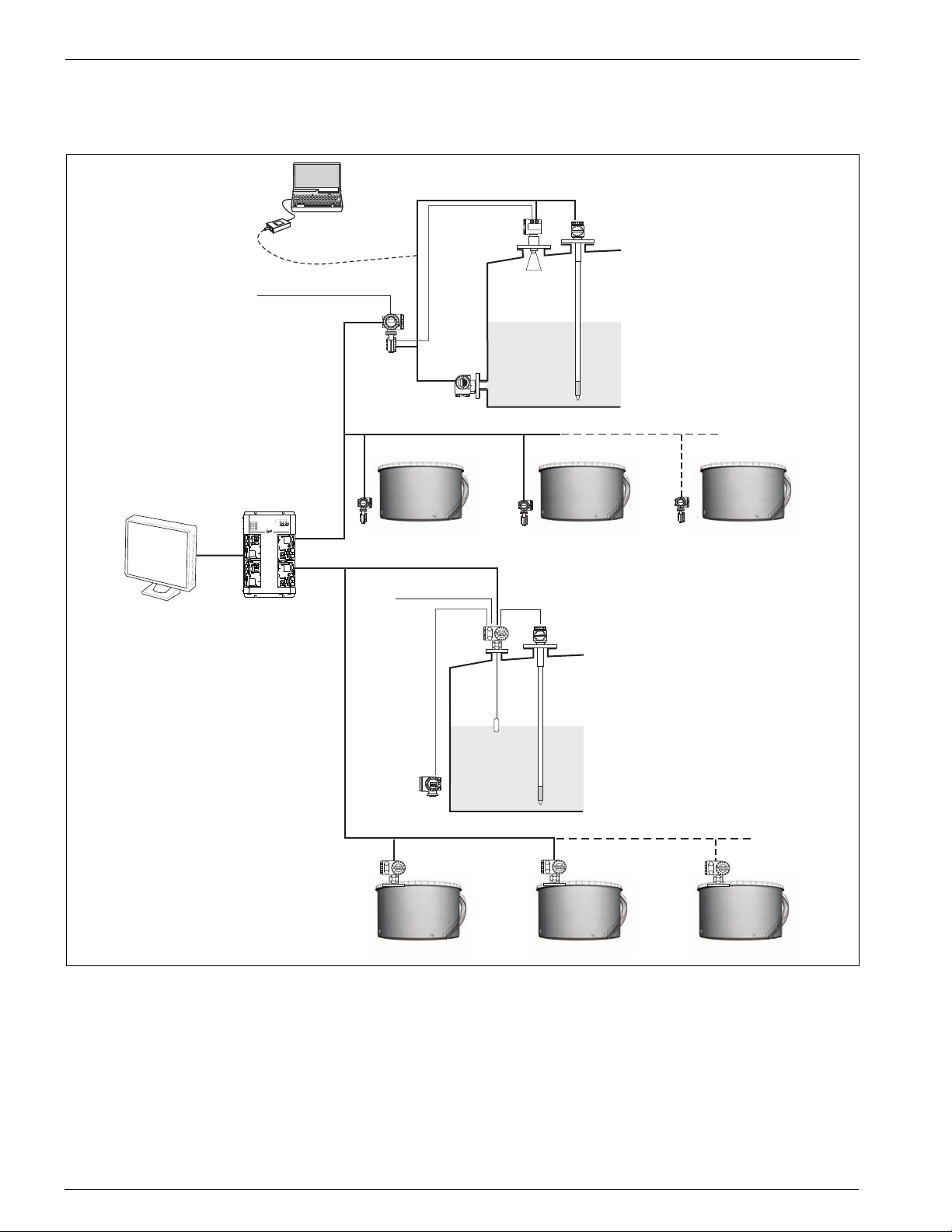

1.4 System functional diagram

Figure 1-1: Connection with 7500 Series Radar Tank Gauge and 6000 Series Servo Tank

Gauge

2 Installation and Operations Manual

4532 Safety instructions

2 Safety instructions

2.1 Installation, commissioning and operation

• Mounting, electrical installation, start-up and maintenance of the instrument may

only be carried out by trained personnel authorized by the operator of the facility.

• Personnel must absolutely and without fail read and understand this manual before

carrying out its instructions.

• The instrument may only be operated by personnel who are authorized and trained

by the operator of the facility. All instructions in this manual are to be observed

without fail.

• The installer must make sure that the measuring system is correctly wired

according to the wiring diagrams. The measuring system is to be grounded.

• Please observe all provisions valid for your country and pertaining to the opening

and repairing of electrical devices.

2.2 Product Requirements

2.2.1 Power source

Check the voltage of the power supply before connecting it to the product. It should be

the exact voltage required for proper operation of the product.

2.2.2 Use in hazardous areas

When using the product in the first or second-class hazard location (Zone 1 or Zone 2)

be sure to use an intrinsically safe or pressure and explosion-proof apparatus. Take the

utmost care during the installation, wiring, and piping of such apparatus to ensure the

safety of the system. For safety reasons, maintenance or repairs on the product while it

is being used with such apparatus should only be performed by qualified personnel.

2.2.3 External connection

When an external connection is required, the product should be protectively grounded

before it is connected to a measurement object or an external control circuit.

2.3 Operational safety

2.3.1 Hazardous area

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an

installation instructions and ratings as stated in this supplementary documentation is

mandatory.

integral part

of this manual. Strict compliance with the

• Please use the explosion-proof type for measurement in explosion-hazardous

areas.

• Instruments used in explosion hazardous areas should be mounted and wired

according to the explosion-proof regulations.

Varec, Inc. 3

Safety instructions Average Temperature/Water Bottom Sensor and Converter

• Instruments mounted in explosion hazardous areas must not be opened when the

power is on. Tighten the cable gland firmly.

• The maintenance and repair of the instrument is limited to fulfill the explosion

proof regulations.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local regulations.

2.3.2 Power supply

Check that voltage and frequency of the local power supply are in the range of the

technical data of the instrument before turning on the power, in Chapter 12, Technical

data.

2.3.3 Grounding

Do not remove the grounding of the instrument when the power supply is turned on.

This may set the instrument in a dangerous condition.

2.3.4 Wiring

2.4 Return

Make sure of the grounding of the instrument before connecting input and output to

another system.

Caution! Changes or modifications not expressly approved by the party responsible for com-

pliance could void the user’s authority to operate the equipment.

The following procedures must be carried out before the instruments is sent to Varec

for repair:

• Always enclose a duly completed "Declaration of Contamination" form. Only then

can Varec transport, examine and repair a returned device.

• Enclose special handling instructions if necessary, for example, safety data sheet as

per EN 91/155/EEC.

• Remove all residue which may be present. Pay special attention to the gasket

grooves and crevices where fluid may be present. This is especially important if the

fluid is dangerous to health, e.g. corrosive, poisonous, carcinogenic, radioactive,

etc.

A copy of the “Declaration of Contamination” is included at the end of this operating

manual in Appendix B.

Caution! No instrument should be sent back for repair without all dangerous material being

completely removed first, e.g. in scratches or diffused through plastic.

• Incomplete cleaning of the instrument may result in waste disposal or cause harm

to personnel (burns, etc.). Any costs arising from this will be charged to the

operator of the instrument.

2.5 Disposal

In case of disposal, please separate the different components according to their material

consistency.

4 Installation and Operations Manual

4532 Safety instructions

EX

EX

2.6 Notes on safety conventions and symbols

In order to highlight safety-relevant or alternative operating procedures in the manual,

the following conventions have been used, each indicated by a corresponding symbol in

the margin.

Safety conventions

Warning!

Caution!

Note!

Explosion protection

Warning!

A warning highlights actions or procedures which, if not performed

correctly, will lead to personal injury, a safety hazard or destruction of

the instrument

Caution!

Caution highlights actions or procedures which, if not performed

correctly, may lead to personal injury or incorrect functioning of the

instrument

Note!

A note highlights actions or procedures which, if not performed

correctly, may indirectly affect operation or may lead to an instrument

response which is not planned

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate, it can be

installed in an explosion hazardous area

Explosion hazardous areas

Symbol used in drawings to indicate explosion hazardous areas.

• Devices located in and wiring entering areas with the designation

“explosion hazardous areas” must conform to the stated type of

protection

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion

hazardous areas.

• Devices located in safe areas still require a certificate if their

outputs run into explosion hazardous areas

Explosion protection

Direct voltage

A terminal to which or from which a direct current or voltage may be

applied or supplied

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or

voltage may be applied or supplied

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is

already grounded by means of an earth grounding system

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making

any other connection to the equipment

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type

e.g. neutral star or equipotential line according to national or company

practice

Varec, Inc. 5

Safety instructions Average Temperature/Water Bottom Sensor and Converter

6 Installation and Operations Manual

4532 Identification

3 Identification

3.1 Device designation

3.1.1 Nameplate

4532 Series

Temperature Device

Ex ia IIB T

ATEX II 1/2 G

KEMA 08 ATEX 0012 X

Ambient Temperature -40 °C to °C

Ui<30V Ii<120mA Pi<1W

Ci=7.9nF Li=48µH

Do not modify parts and circuits of this instrument.

5834 Peachtree Corners East Norcross (Atlanta)

Made in Japan

WARNING

Varec, Inc.

Georgia 30092 USA

16-04532AT Rev B

Figure 3-1: 4532 ATC labels

N453

Order Code

Mfg. Date

Serial No.

Span °C to °C

0820

APPROVED

Ambient Temperature -40 °C to °C

Ui<30V Ii<120mA Pi<1W

Ci=6.6nF Li=48μH

Do not modify parts and circuits of this instrument.

5834 Peachtree Corners East Norcross (Atlanta)

Made in Japan

453x Series

Temperature Device

Length mm

5834 Peachtree Corners East Norcross (Atlanta)

Varec, Inc.

Georgia 30092 USA

4532 Series

Temperature Device

IS Cl. I, Div. 1, Gp. C,D

Cl. I, Zone0, AEx ia IIBT

NI Cl. I, Div. 2, Gp. C,D

WARNING

Install per control drawing Ex461-869

Varec, Inc.

Georgia 30092 USA

16-0453x Rev EMade in Japan

16-04532 Rev C

NEMA 4X

Figure 3-2: Product label for 453x average temperature devices

3.2 Scope of delivery

• Instrument according to the version ordered

• ToF Tool (CD-ROM)

• Accessories (as ordered)

Varec, Inc. 7

Identification Average Temperature/Water Bottom Sensor and Converter

3.3 CE marks, declaration of conformity

The instrument is designed to meet state-of-the-art safety requirements, has been

tested and left the factory in a condition in which it is safe to operate. The instrument

complies with the applicable standards and regulations in accordance with EN 50014

"Electrical apparatus for potentially explosive atmospheres-General requirements". The

instrument described in this manual thus complies with the statutory requirements of

the EG directives. Varec confirms the successful testing of the instrument by affixing to

it the CE mark.

8 Installation and Operations Manual

4532 Installation

4 Installation

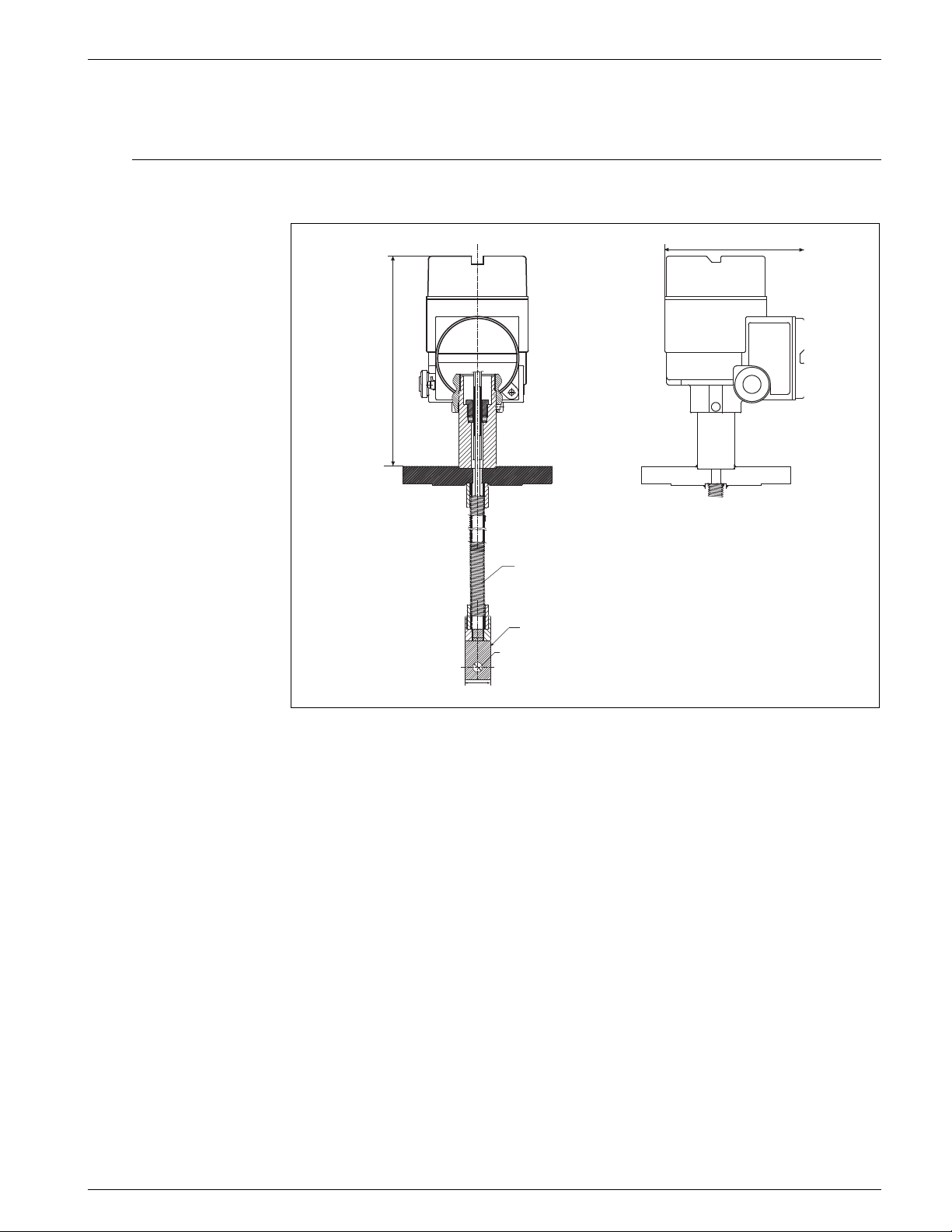

4.1 Design, dimensions

142.5 mm

215 mm

Ф10

Ф26

Figure 4-1: 4532 ATC dimensions

Flexible tube

depends on the

tank height

Bottom hook

Varec, Inc. 9

Installation Average Temperature/Water Bottom Sensor and Converter

Recommended procedure

Incorrect procedure

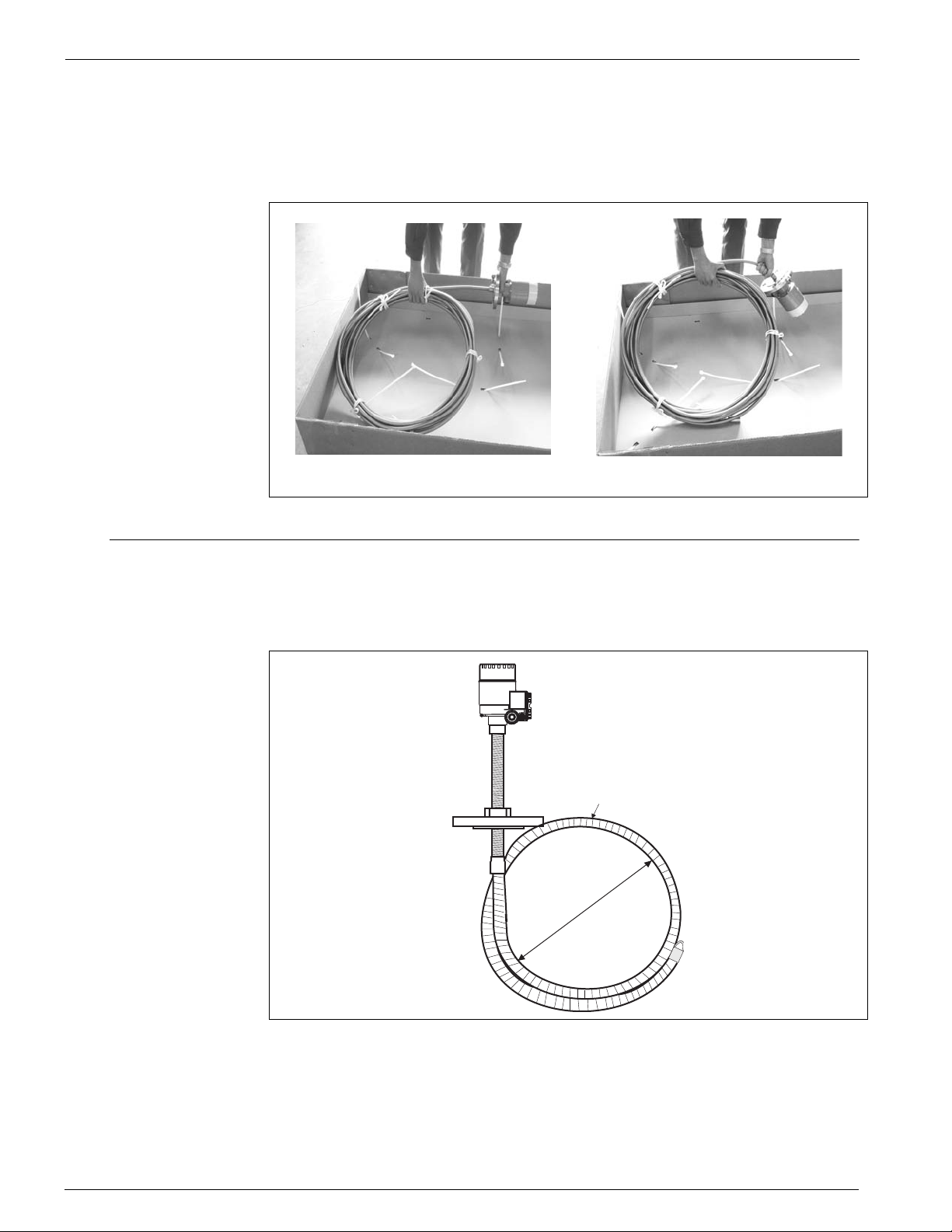

4.2 Unpacking

When unpacking, be careful not to bend, fold or twist the flexible tube. Please refer to

the recommended procedure below.

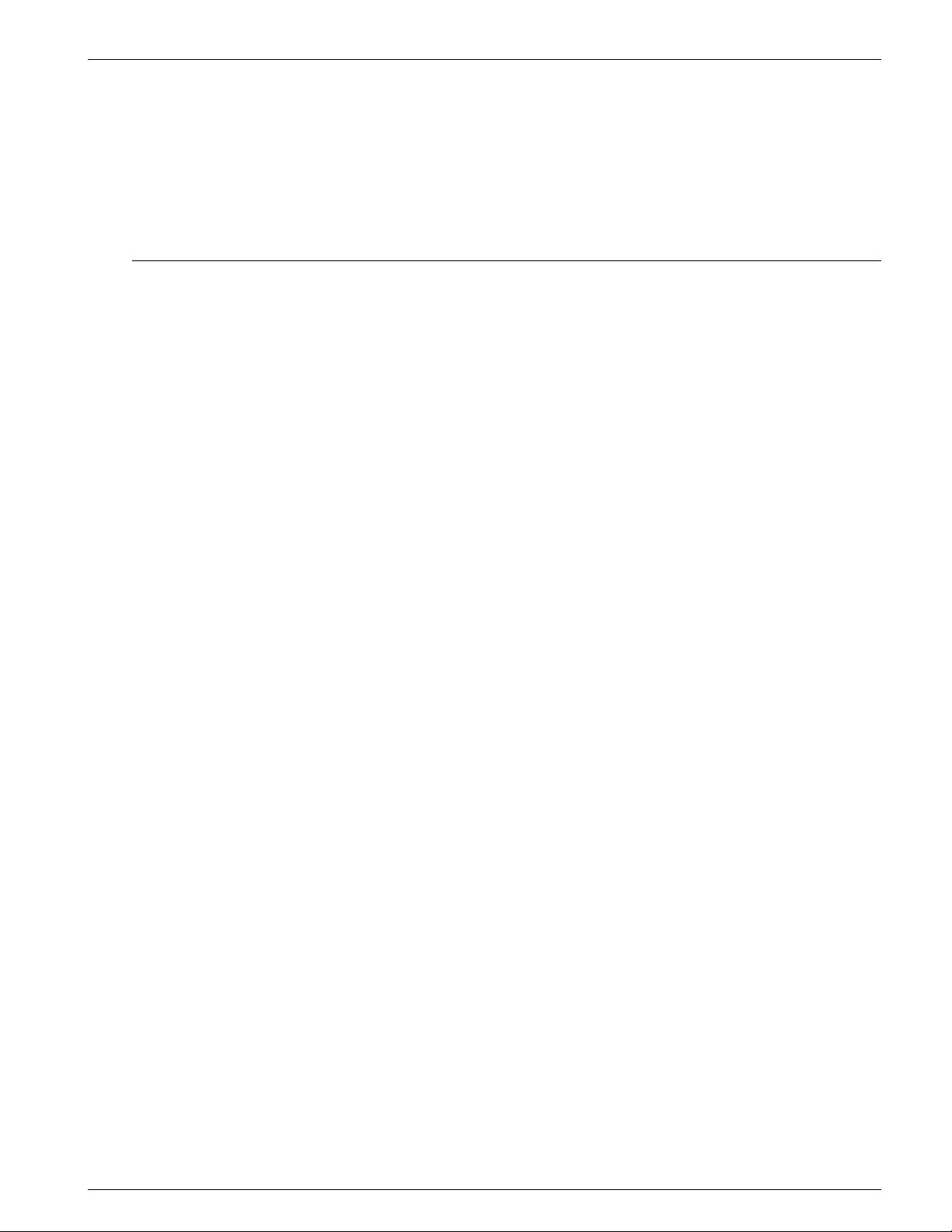

4.3 Flexible tube

When attaching and bending the flexible tube, the radius of curvature must be at least

300 mm (11.8") at any bend portion.

Flexible tube

Min.1m (39.37")

Figure 4-2: Flexible tube

Note! If a flexible tube is bent with a radius of curvature less than 300 mm (11.8"), the flex-

ible tube or the measuring element may be seriously damaged or broken.

10 Installation and Operations Manual

4532 Installation

4.4 Installation Instructions

Note! The level sensor circuit is connected to ground and is infallibly galvanically isolated

from the supply and output circuit and from the temperature measurement circuit.

All metal parts of the sensor and the transmitter shall be electrically conductive and

securely be connected to the potential equalization system within the hazardous area.

4.5 Special conditions for safe use

To exclude ignition sources due to sparks caused by impact or friction, even in the event

of rare incidents, do not subject the temperature sensor tube to environmental stress,

such as impact from moving parts. Also, make sure the bottom part is secured.

Varec, Inc. 11

Loading...

Loading...